Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Improve hydrogen permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

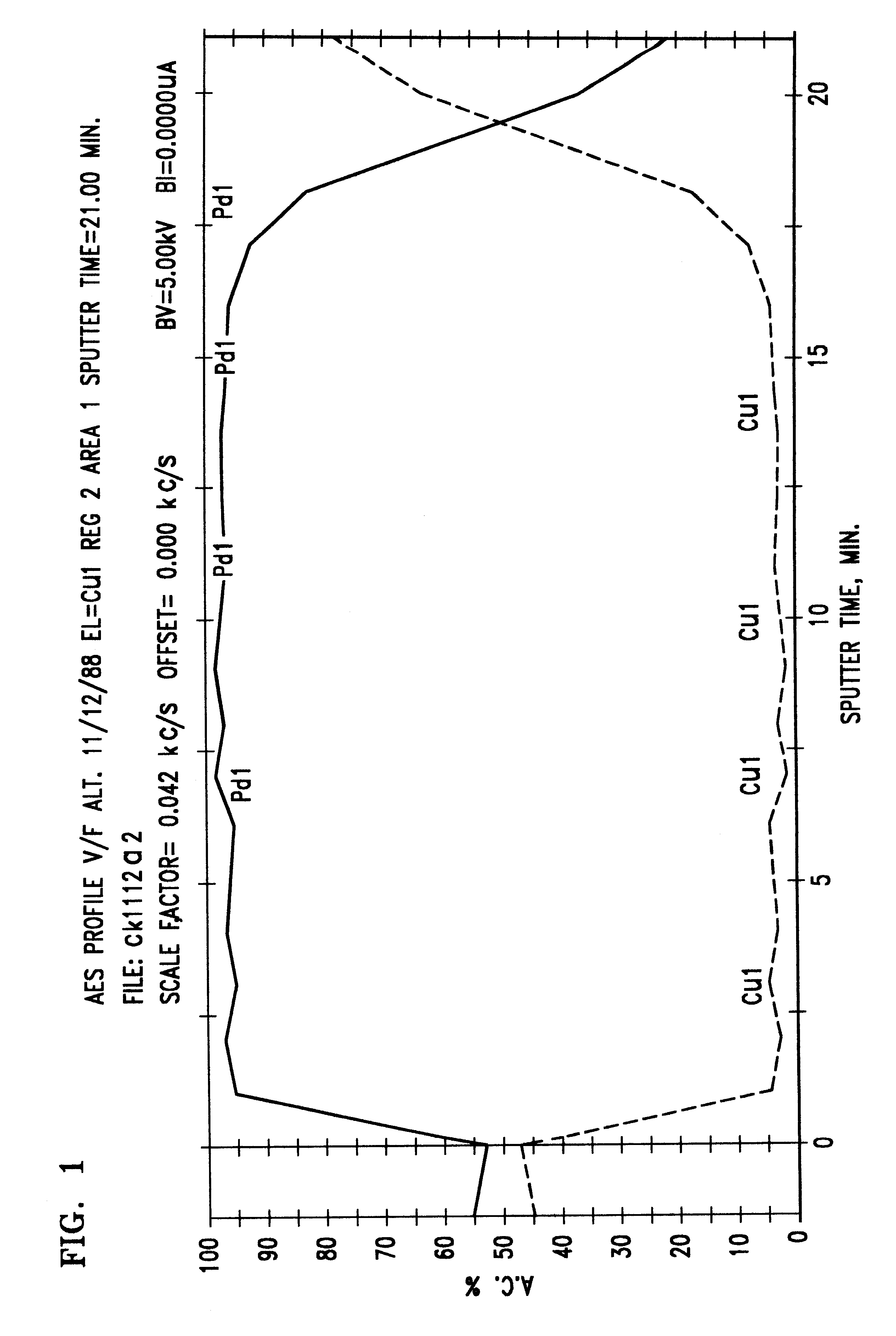

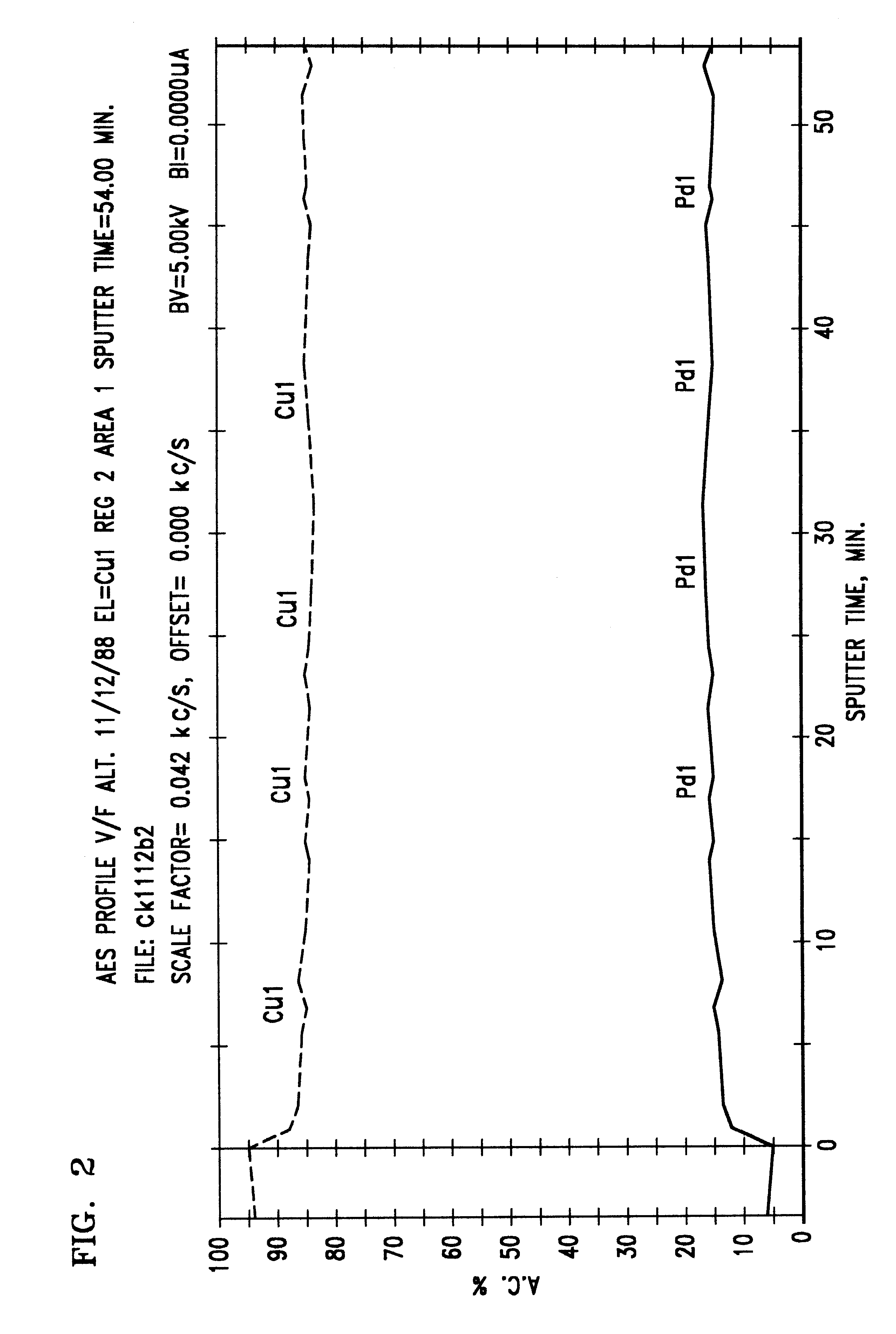

Method of producing thin palladium-copper and the like, palladium alloy membranes by solid-solid metallic interdiffusion, and improved membrane

InactiveUS6238465B1Improve facilitiesImprove performanceSemi-permeable membranesMembranesHydrogenSufficient time

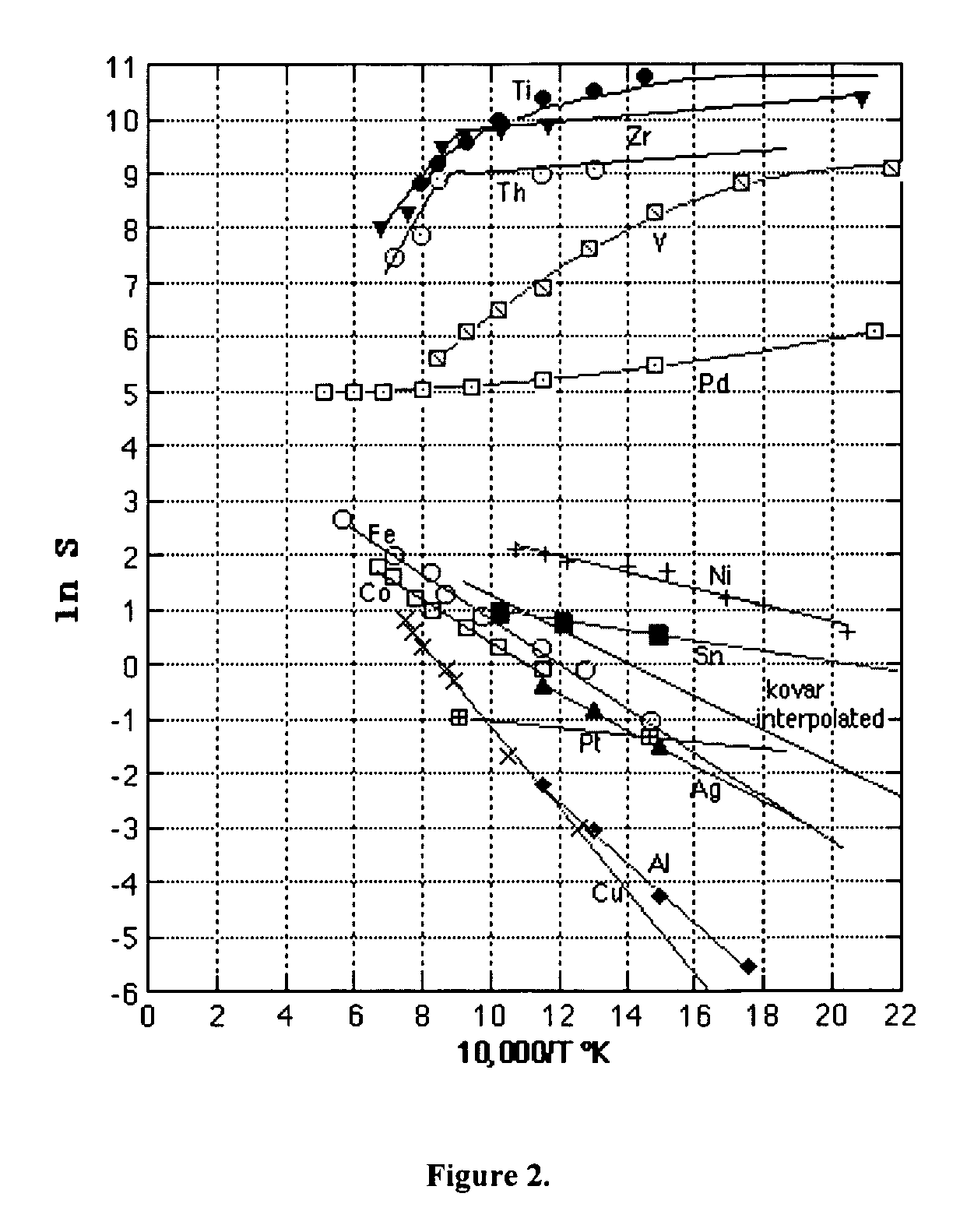

A novel method of producing an improved thin hydrogen-selective palladium-alloy membrane, through solid-solid interdiffusion of thin films or layers of palladium and a palladium-enhancing metal, such as copper, subjected in the presence of a reducing agent, such as hydrogen, to an elevated temperature below the melting point of both metals, for a sufficient time to effect substantially complete interdiffusion of the metals.

Owner:HYDRIP LLC

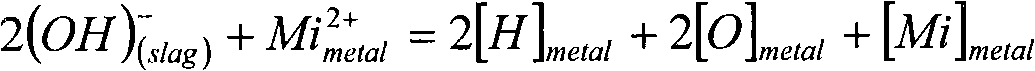

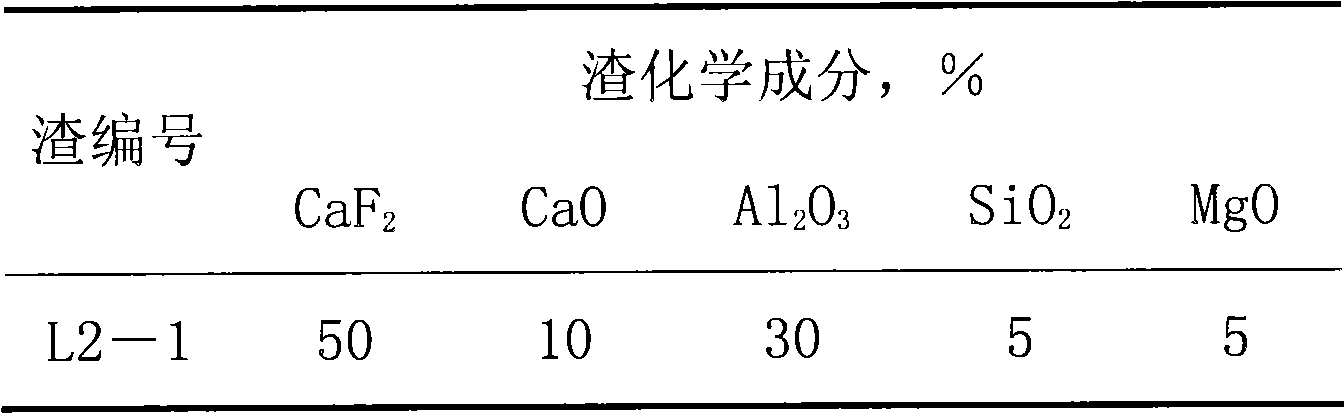

Electroslag remelting slag system with low hydrogen permeability, preparation method and using method thereof

The invention discloses an electroslag remelting slag system with low hydrogen permeability, and a preparation method and a using method thereof. The slag system is prepared from the following chemical compositions in percentage by weight: 45 to 50 percent of CaF2, 10 to 15 percent of CaO, 30 to 35 percent of Al2O3, 5 to 10 percent of SiO2, and 5 to 10 percent of MgO, wherein the MgO is adopted toreplace partial CaO. The preparation method is to crush the compositions into particles after melting, and bake the particles. The using method adopts pre-melting slag and argon protection to carry out electroslag remelting. Compared with the prior art, the slag system and the methods have the advantages that: the slag system has low hydrogen permeability, can effectively reduce the hydrogen content in steel in the remelting initial stage to ensure that the hydrogen content in the steel in the normal remelting stage is maintained at a lower level, and the hydrogen content in the remelted steel is less than 1.5ppm.

Owner:BAOSHAN IRON & STEEL CO LTD +1

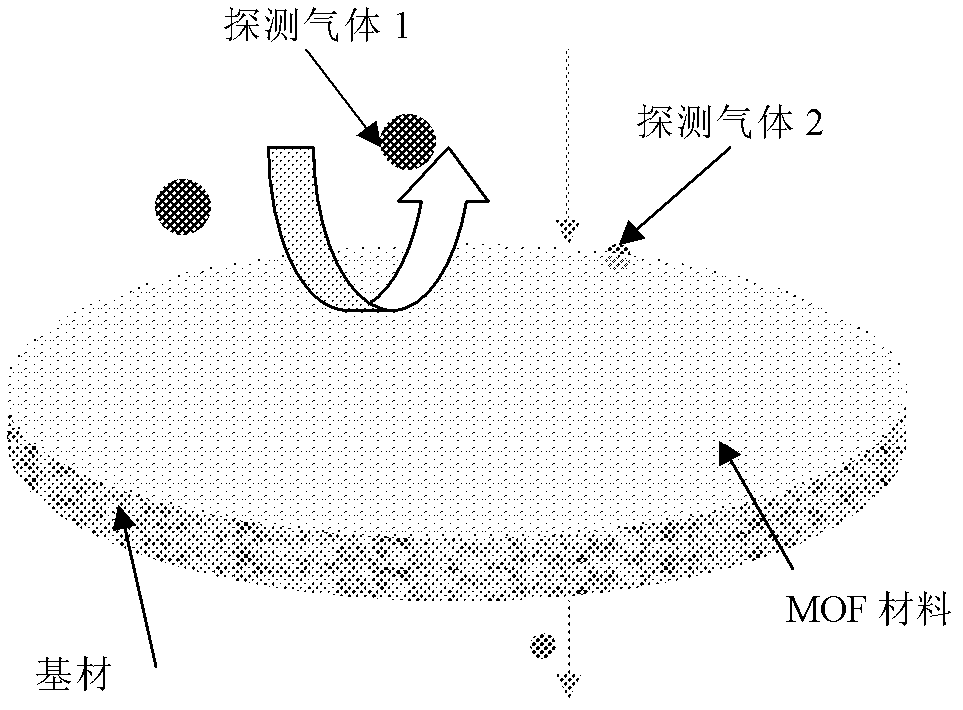

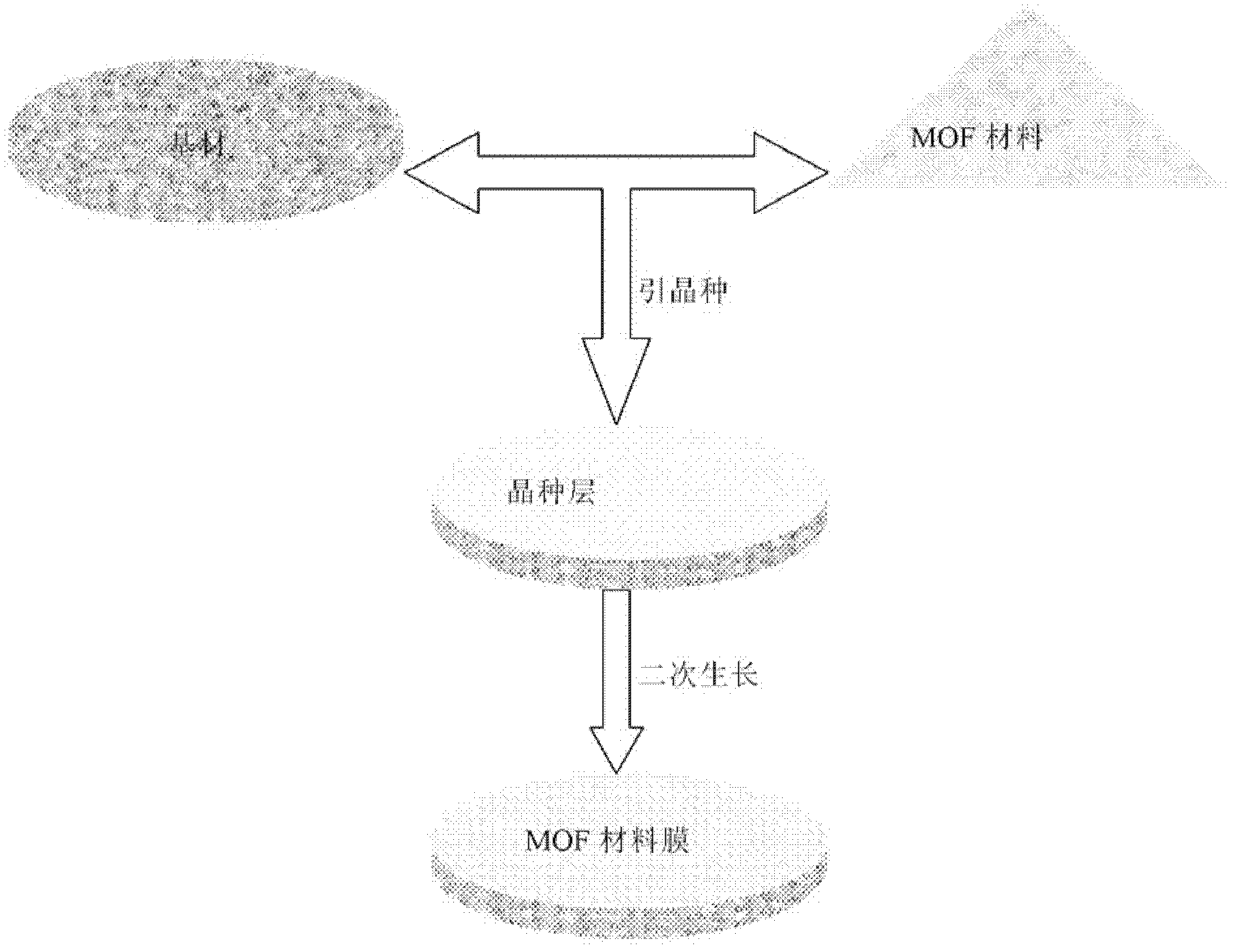

Metal-organic framework (MOF) material for permeating and separating gases and preparation method thereof

ActiveCN102489183AEasy to manufactureWell formedSemi-permeable membranesDispersed particle separationMetal-organic frameworkPermeation

The invention discloses a metal-organic framework (MOF) material for permeating and separating gases and a preparation method thereof. Specifically, an MOF film disclosed by the invention is provided with a functional group, which contributes to nucleating on a substrate, increase the nucleating density on the substrate and contributes to the growth of a dense film; and the functional group can coact with certain specific gases, so that selective permeation of gases is facilitated. Due to the adoption of a film preparation method disclosed by the invention, the growing process of the film is simplified, the structure and shape of the film are optimized simultaneously, and film permeating and separating performance is enhanced. The MOF film prepared with the method has the advantages of high permeation amount, high separating coefficient, low energy consumption and avoidance of secondary pollution, and is particularly suitable for permeating and separating gases such as H2, CO2, CH4 and the like.

Owner:宁波大膜科技有限公司

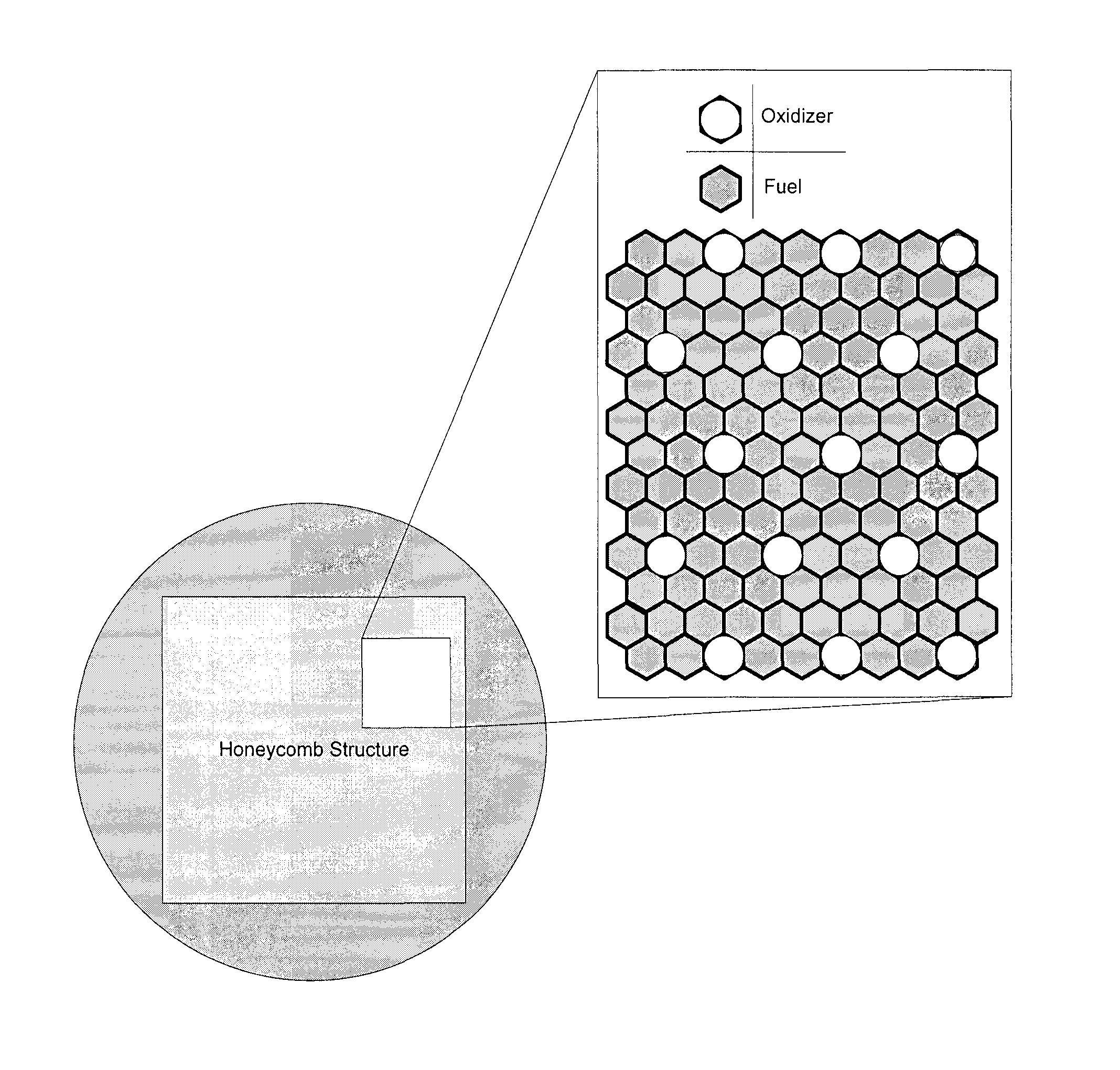

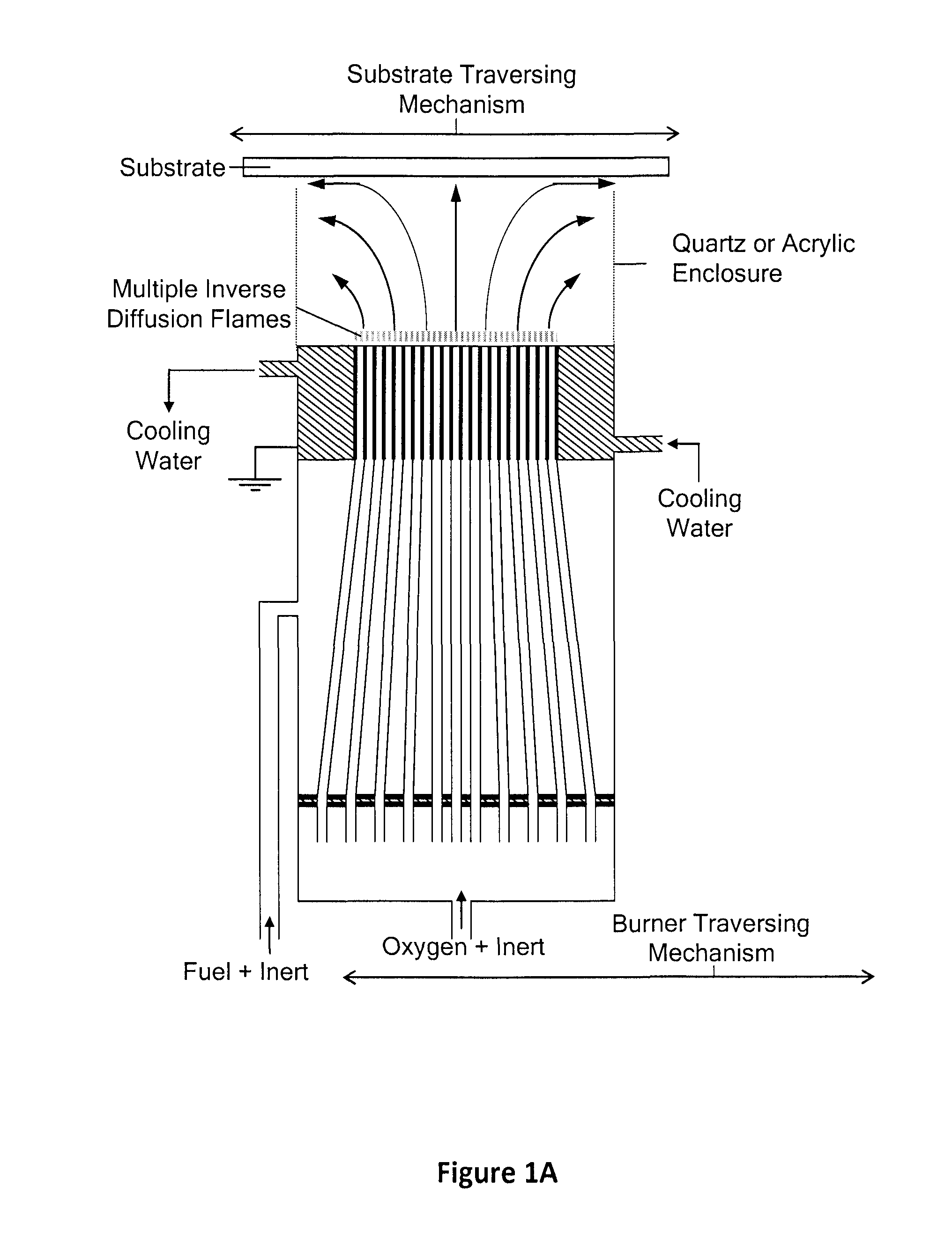

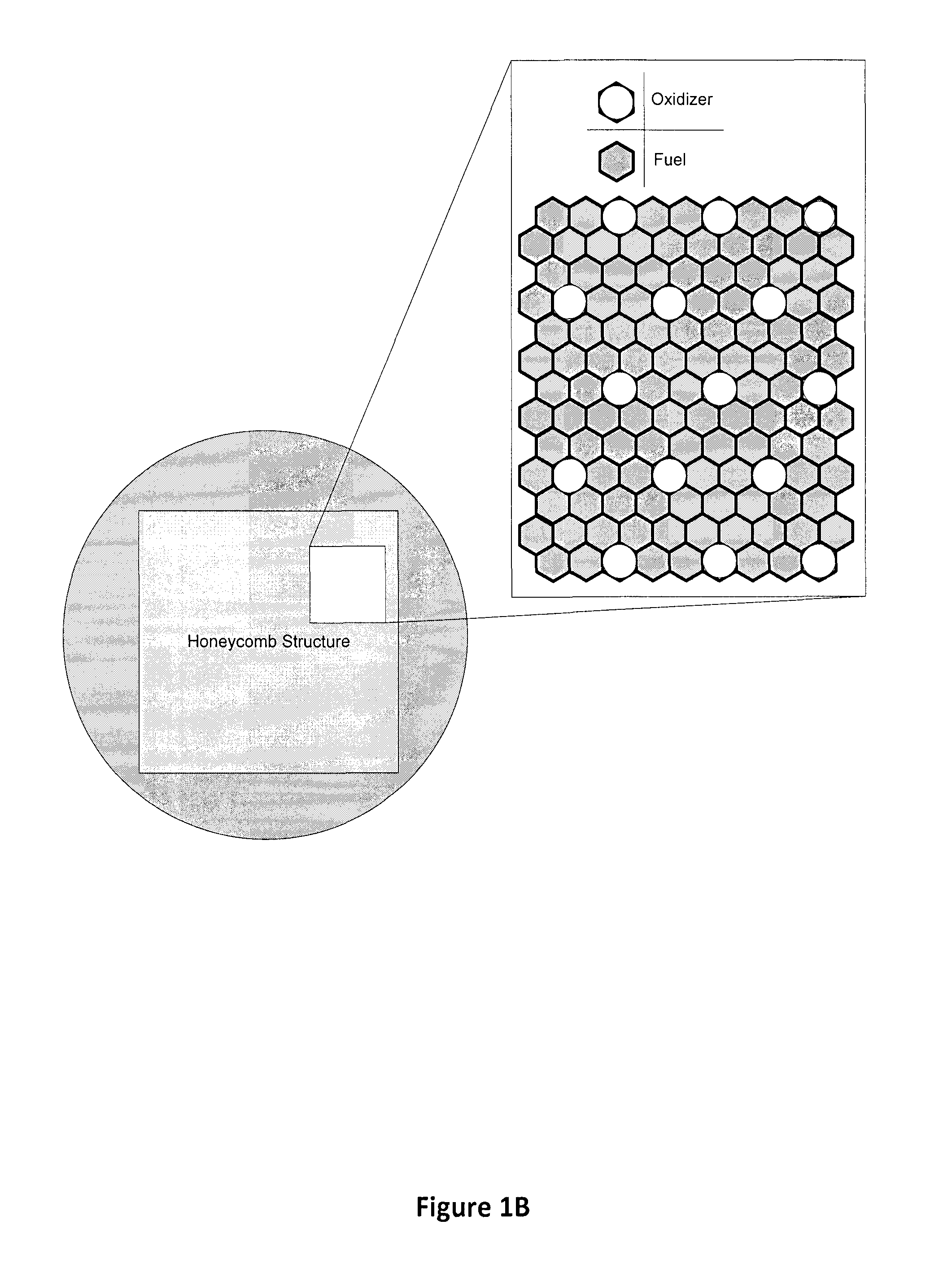

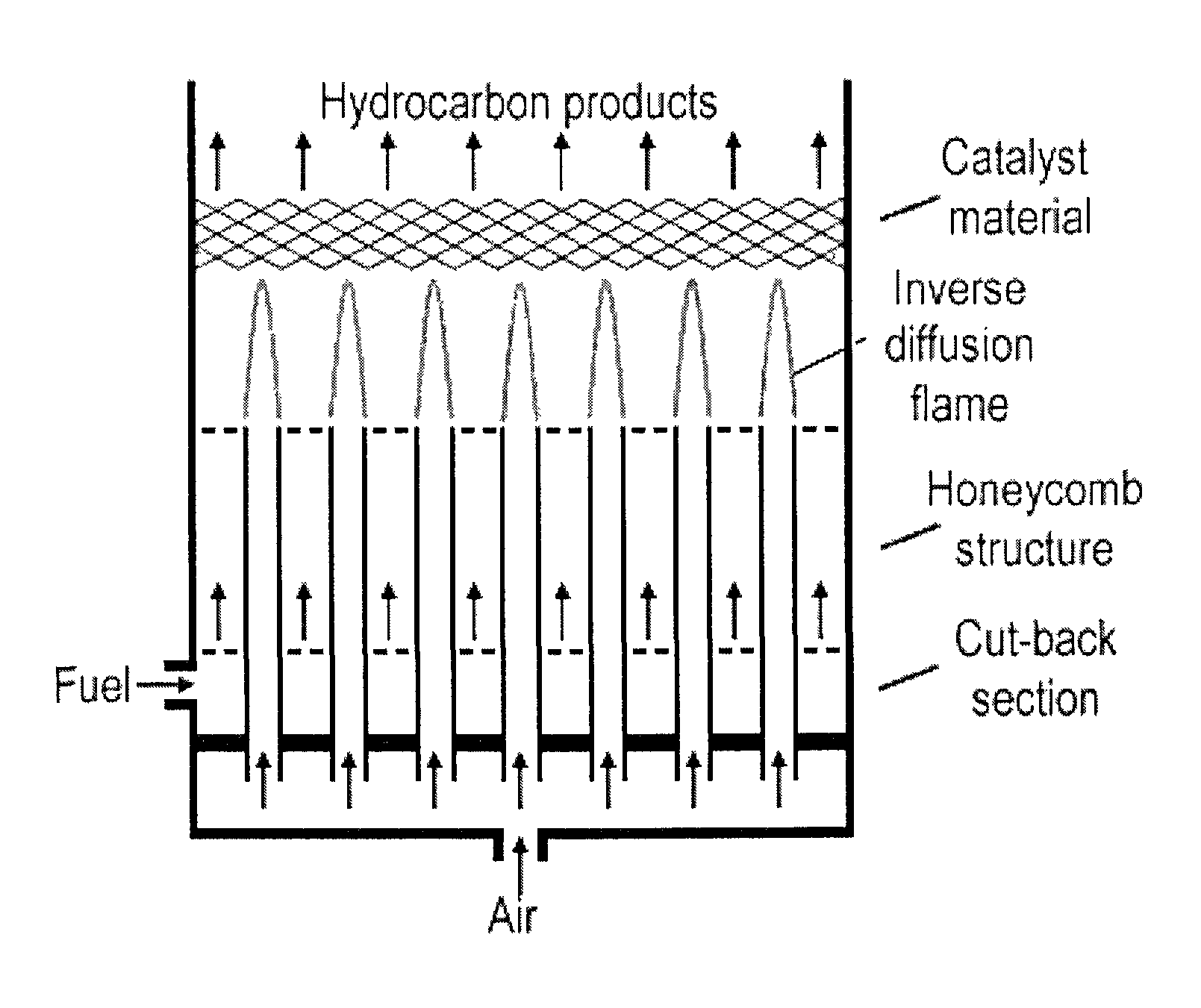

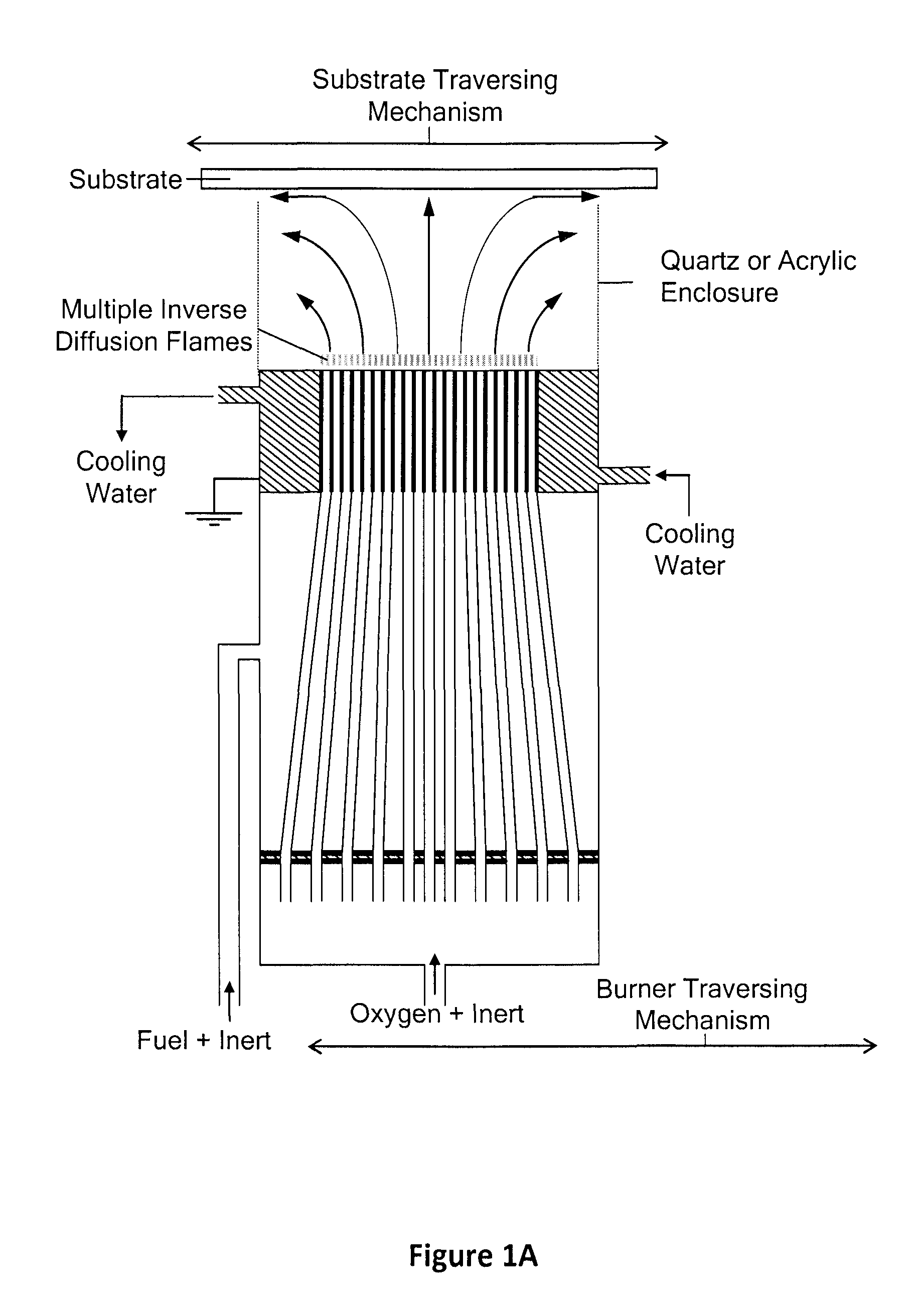

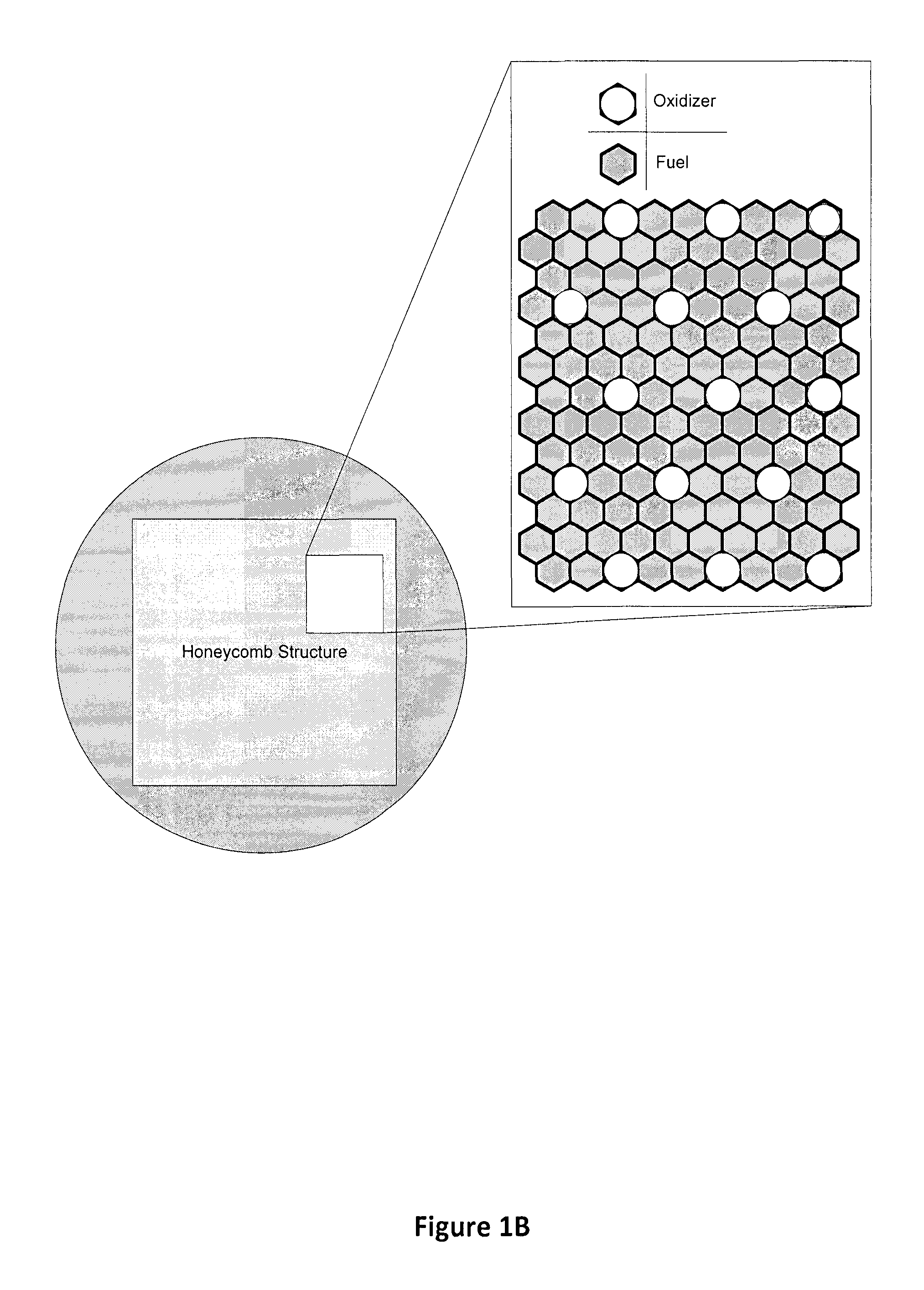

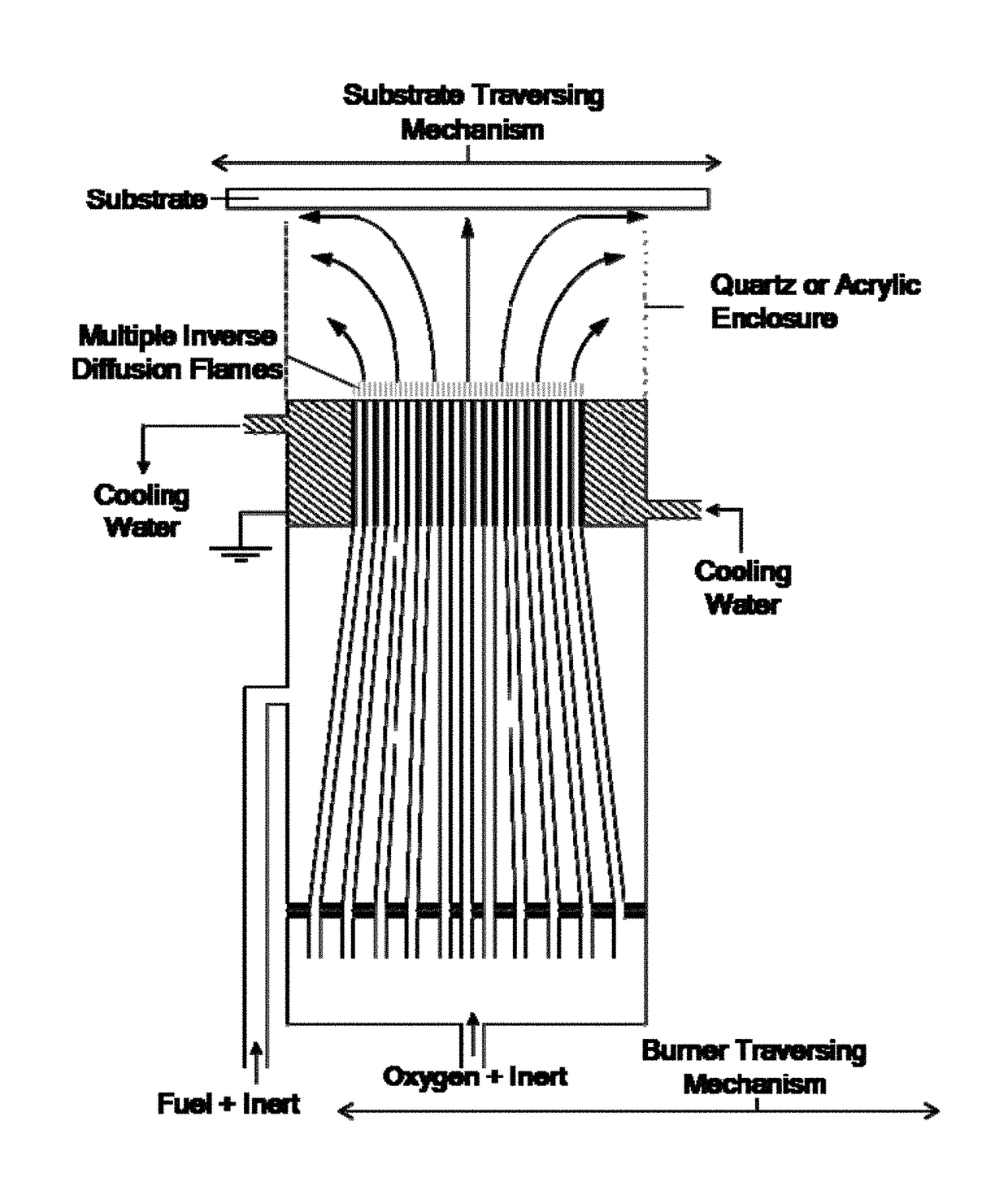

Scalable Multiple-Inverse Diffusion Flame Burner for Synthesis and Processing of Carbon-Based and Other Nanostructured Materials and Films and Fuels

ActiveUS20140054505A1Efficient hydrogen extractionImprove hydrogen permeabilityCyanogen compoundsThiosulfates/dithionites/polythionitesDiffusion flameNanostructured materials

Owner:RUTGERS THE STATE UNIV

Hydrogen-permeable membrane and process for production thereof

ActiveUS7393392B2Improve hydrogen permeabilityReduce deteriorationVacuum evaporation coatingSputtering coatingRare-earth elementHydrogen

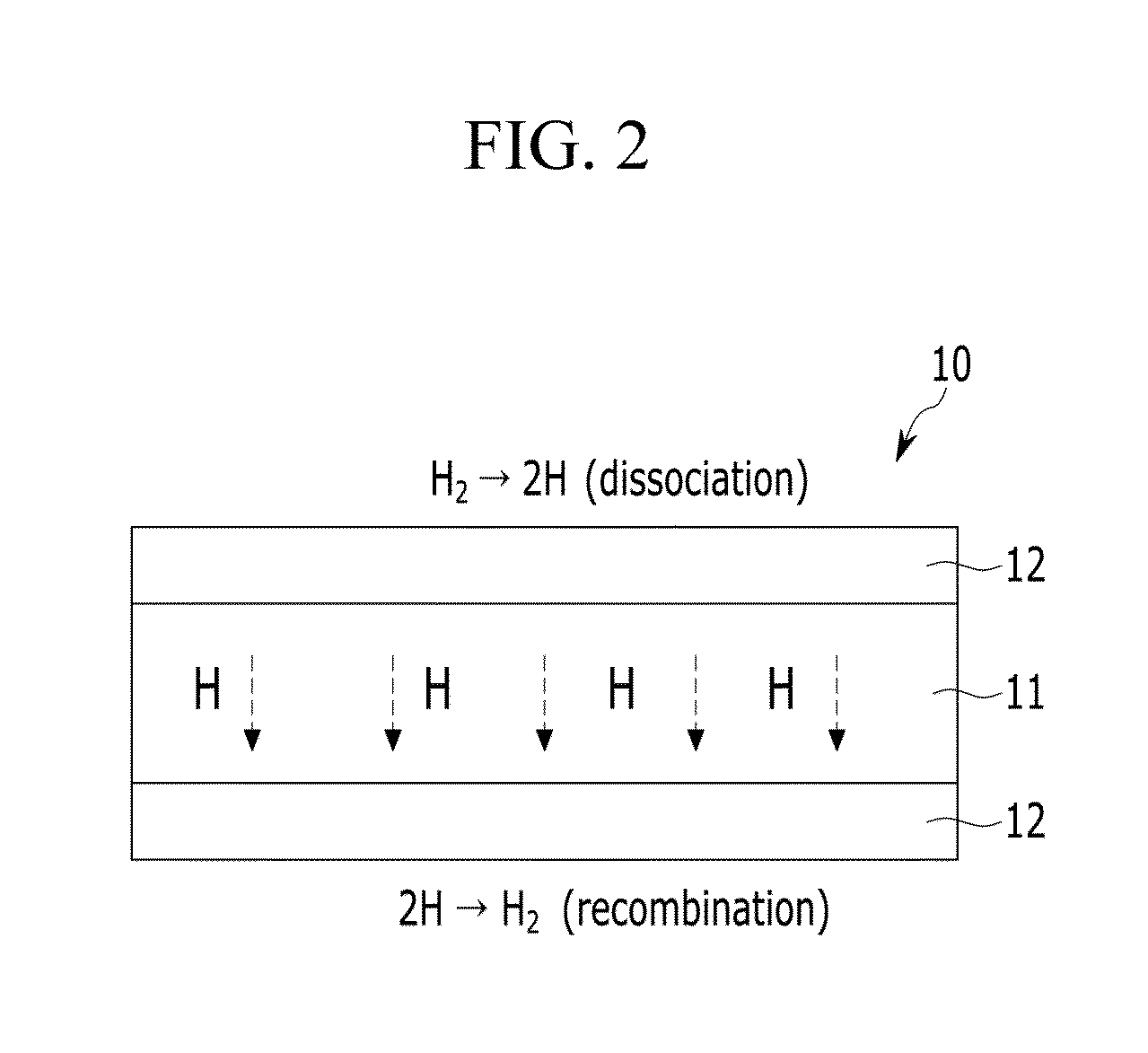

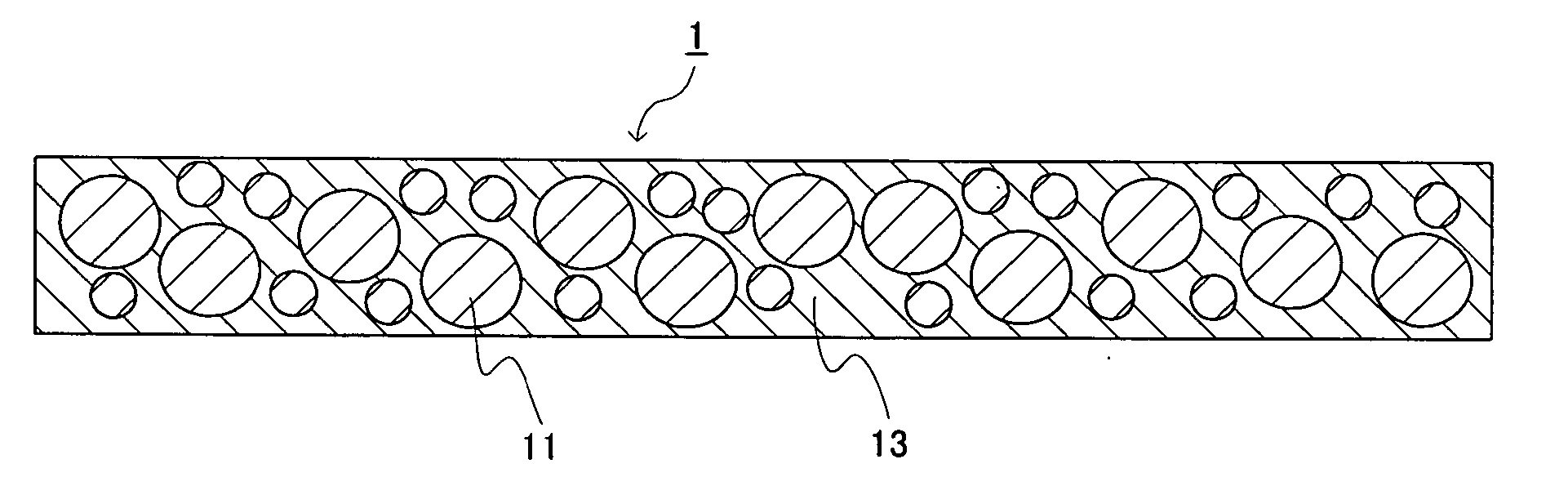

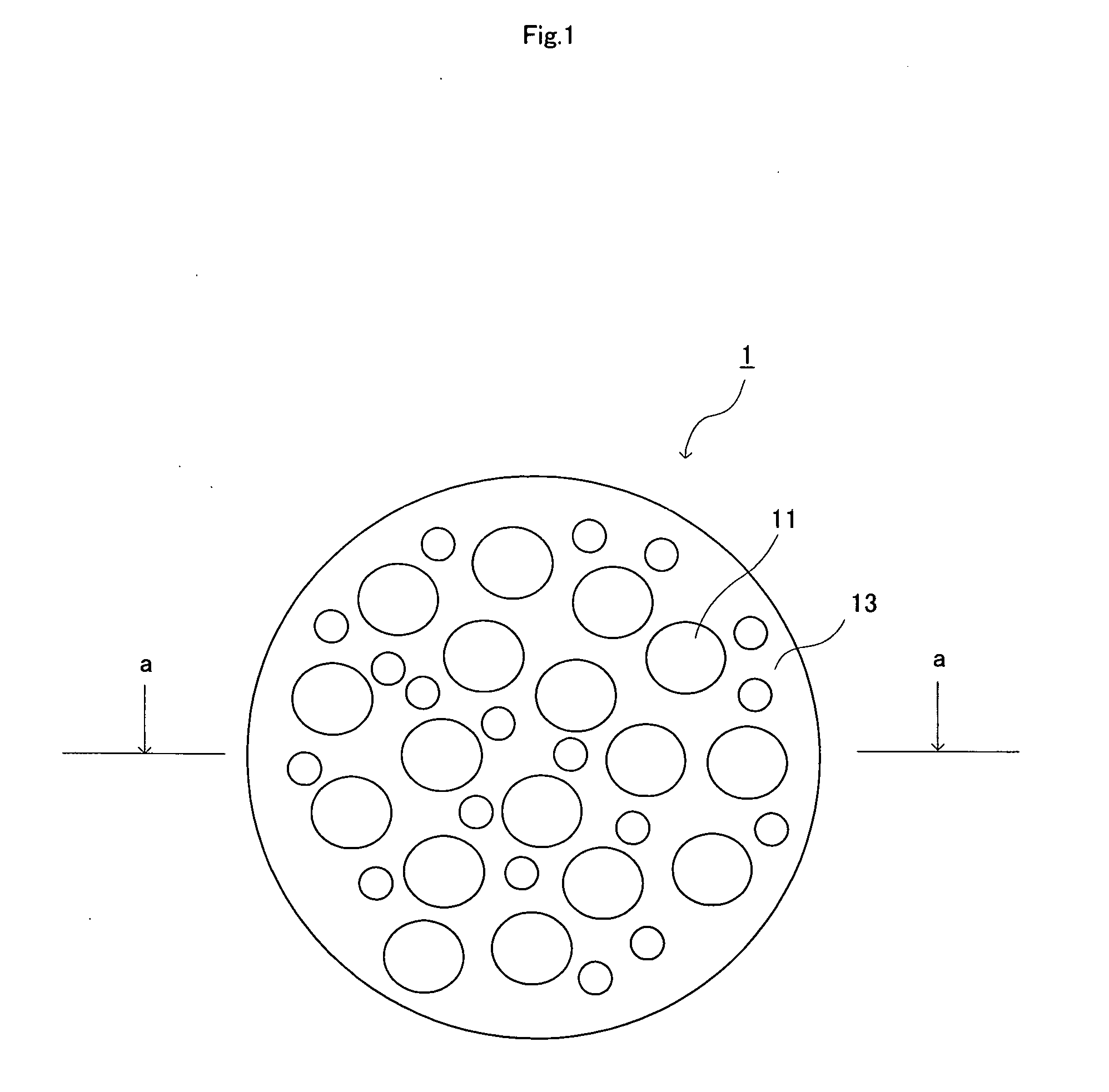

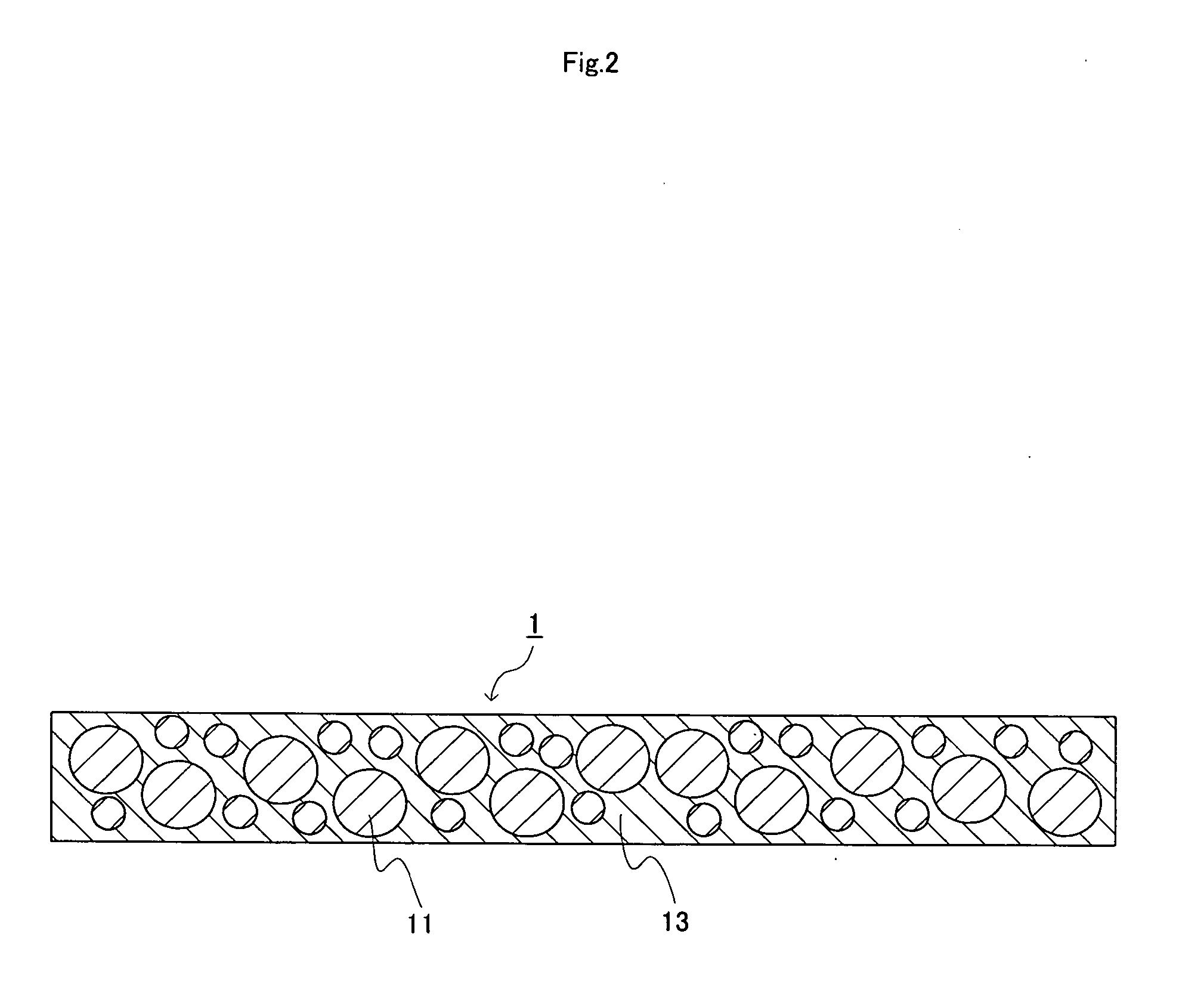

According to the present invention there is disclosed a hydrogen-permeable membrane which comprisesa ceramic material composed of a nitride of aluminum (Al) and / or silicon (Si), an oxide of aluminum (Al) and / or silicon (Si), or a silicide of a rare earth element, andparticles of at least one kind of hydrogen-permeable metal selected from palladium (Pd), niobium (Nb), vanadium (V), tantalum (Ta) and an alloy thereof, dispersed in the ceramic material,wherein a proportion of the hydrogen-permeable metal particles in the hydrogen-permeable membrane is 30 to 70% by mass and a thickness of the membrane is 5 to 1,000 nm.

Owner:MIKUNI CORP

Separation membrane, method of manufacture thereof, and apparatus including the separation membrane

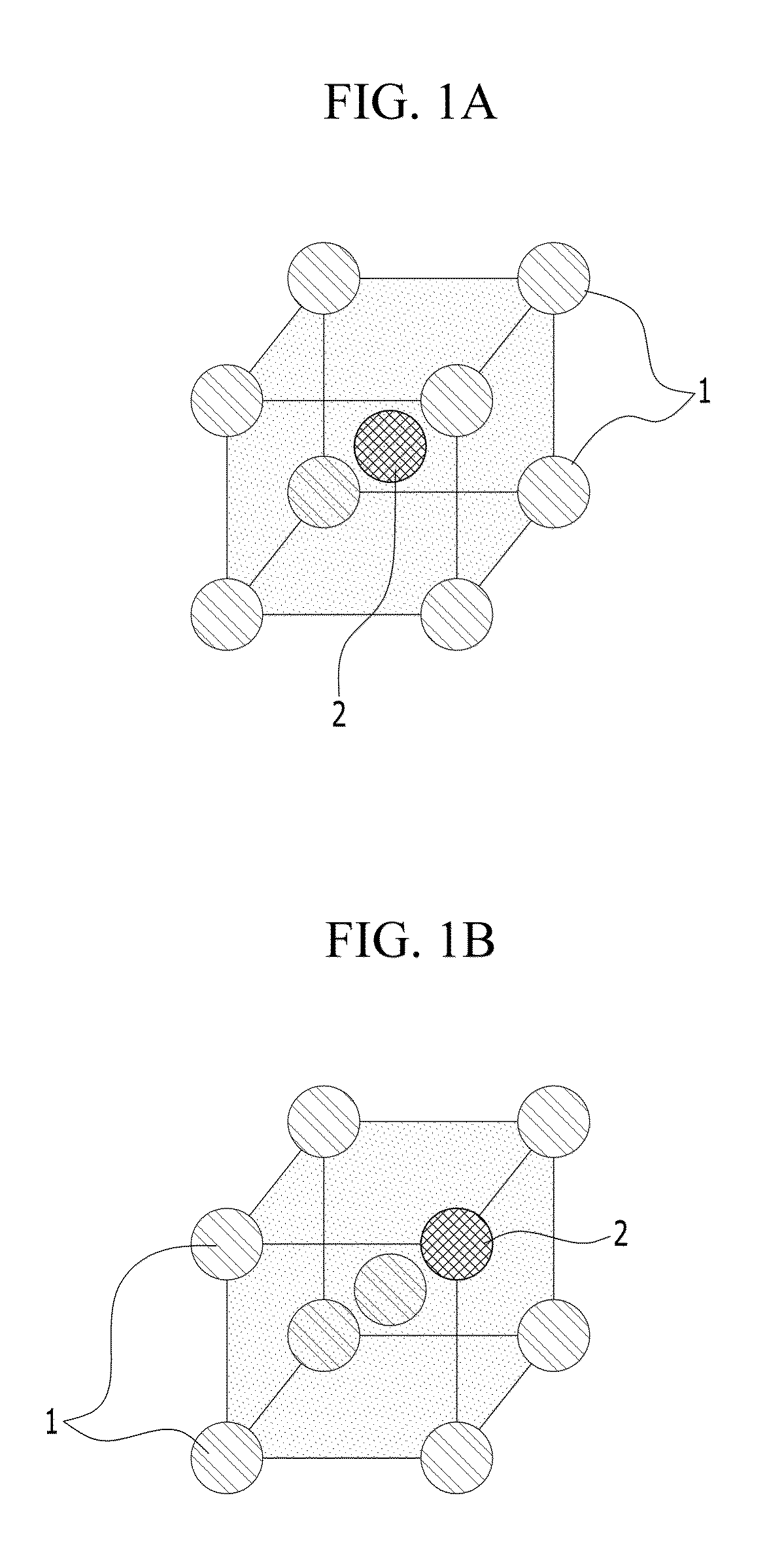

ActiveUS20130136666A1Improve hydrogen permeabilityReduced hydrogen embrittlementSemi-permeable membranesIsotope separationCrystal structureAlloy

Owner:SAMSUNG ELECTRONICS CO LTD

Hydrogen-permeable membrane and process for production thereof

ActiveUS20050188845A1Improve hydrogen permeabilityReduce deteriorationVacuum evaporation coatingSputtering coatingRare-earth elementHydrogen

According to the present invention there is disclosed a hydrogen-permeable membrane which comprises a ceramic material composed of a nitride of aluminum (Al) and / or silicon (Si), an oxide of aluminum (Al) and / or silicon (Si), or a silicide of a rare earth element, and particles of at least one kind of hydrogen-permeable metal selected from palladium (Pd), niobium (Nb), vanadium (V), tantalum (Ta) and an alloy thereof, dispersed in the ceramic material, wherein a proportion of the hydrogen-permeable metal particles in the hydrogen-permeable membrane is 30 to 70% by mass and a thickness of the membrane is 5 to 1,000 nm.

Owner:MIKUNI CORP

Composite thin film and preparing method thereof

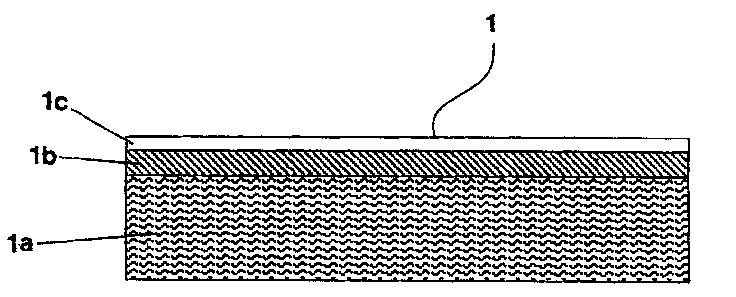

Composite membrane (1) comprises a layer system consisting of a rigid non-self supporting non-metallic inorganic diffusion barrier layer (1b) and hydrogen-permeable non-porous metallic membrane layers (1c) arranged on a flexible metallic substrate (1a). Preferred Features: The diffusion barrier layer is arranged between the substrate and one membrane layer and is formed as a single layer. The single layer is open-pored and / or has micro-tears. The substrate has an open porosity in the region of 15-60%. At least one of the membrane layers is galvanically deposited on the surface of the diffusion barrier layer facing away from the substrate. An Independent claim is also included for a process for the production of the composite membrane.

Owner:W C HERAEUS GMBH

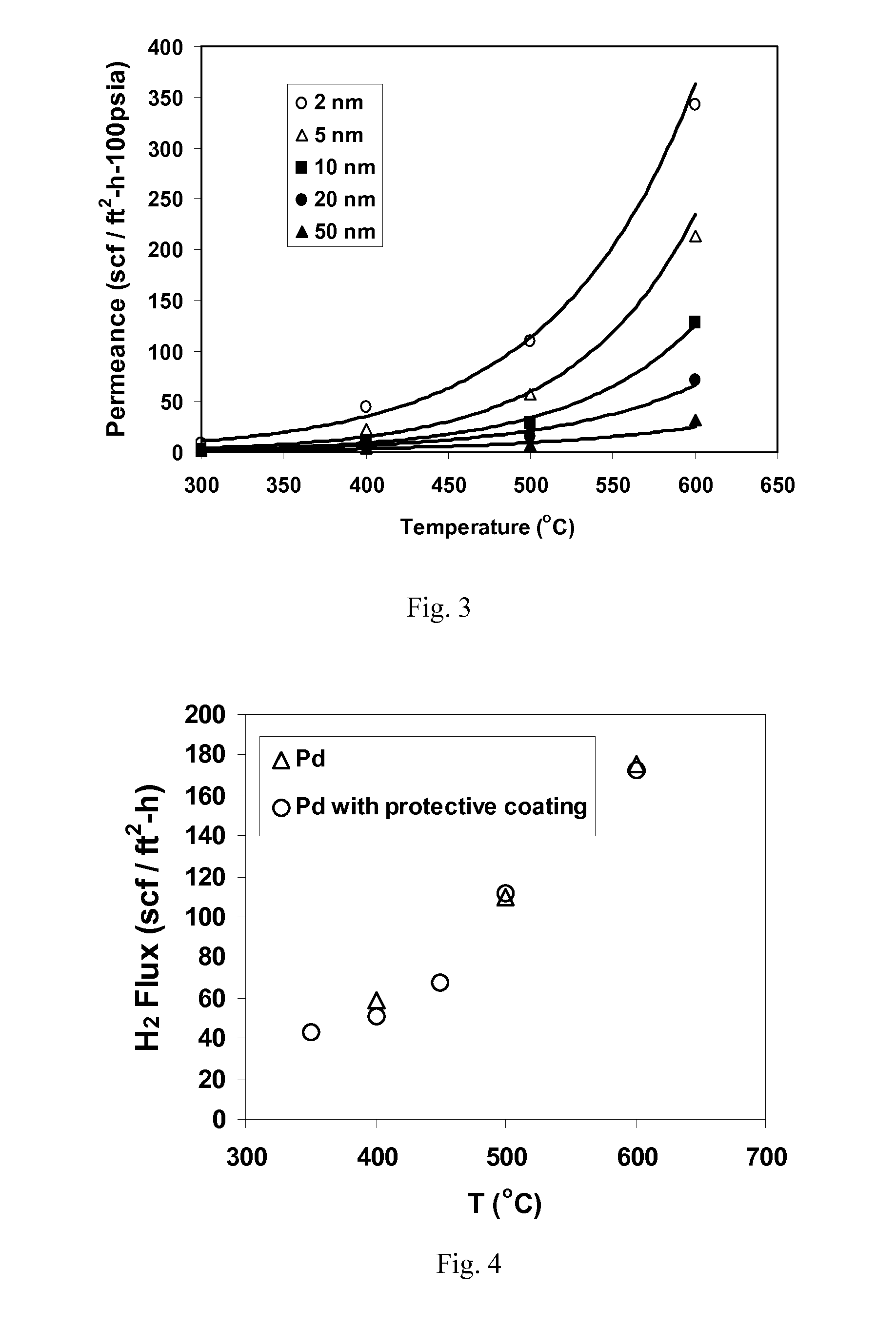

Hydrogen selective protective coating, coated article and method

ActiveUS20120325087A1Improve hydrogen permeabilitySemi-permeable membranesIsotope separationPollutantCermet

Hydrogen selective coatings, coated articles and methods for their formation and for hydrogen separation or purification. The coatings are formed by atomic layer deposition of suitable metal oxides with desirable hydrogen activation energy or hydrogen flux, e.g., silicon dioxide, and can be borne on a nonporous, thin-film metal or cermet substrate, e.g., a palladium sheet or layer. The coated substrate may include a porous support for the sheet or layer. The coated article may be used as a purification membrane and the coating can protect the metal layer from contaminants in the gas or process stream from which hydrogen is being purified. In some embodiments, the coated article can provide such protection at elevated temperatures in excess of 300° C.; and in other embodiments, can provide protection at temperatures in excess of 600° C. and even in excess of 800° C.

Owner:T3 SCI

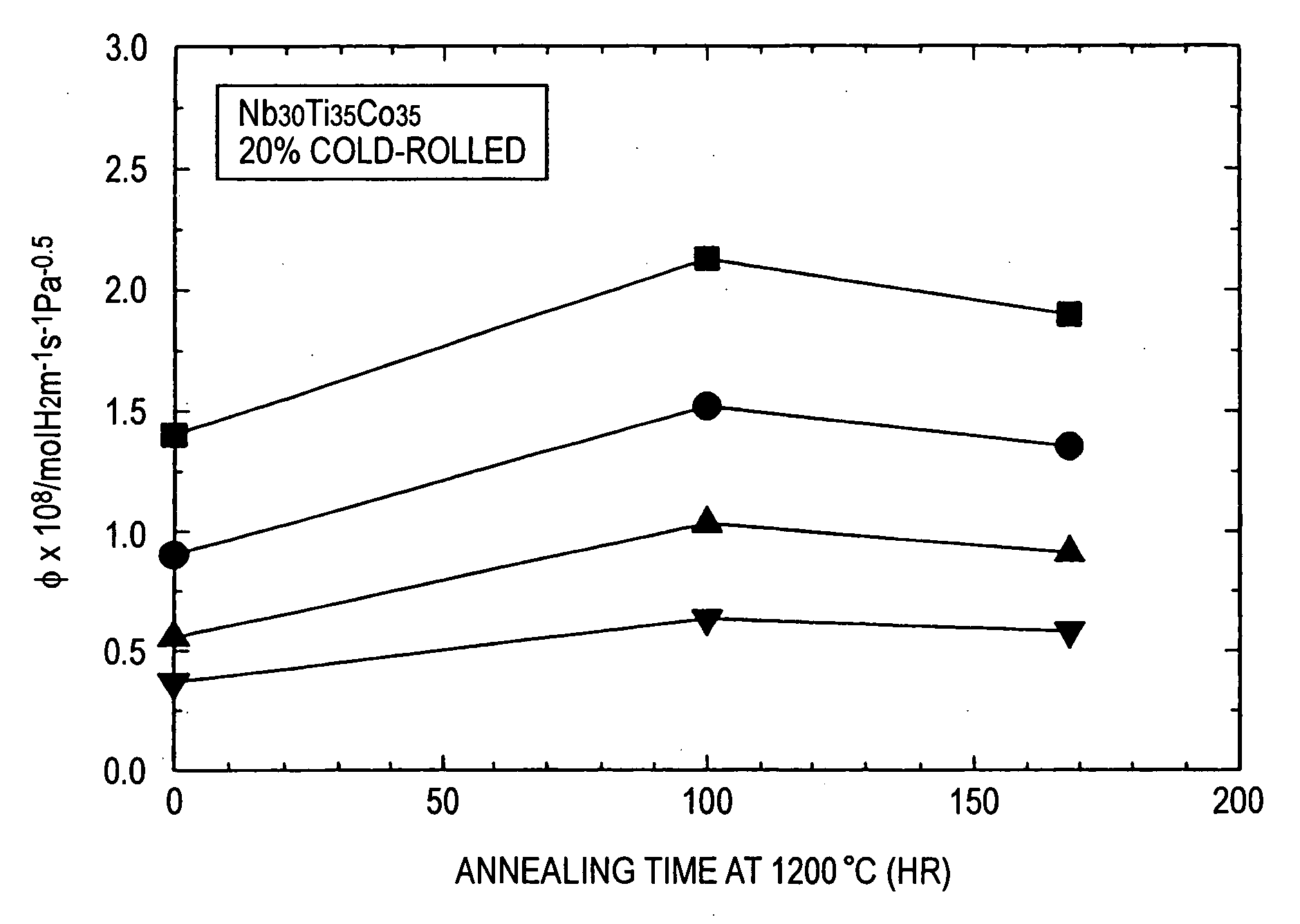

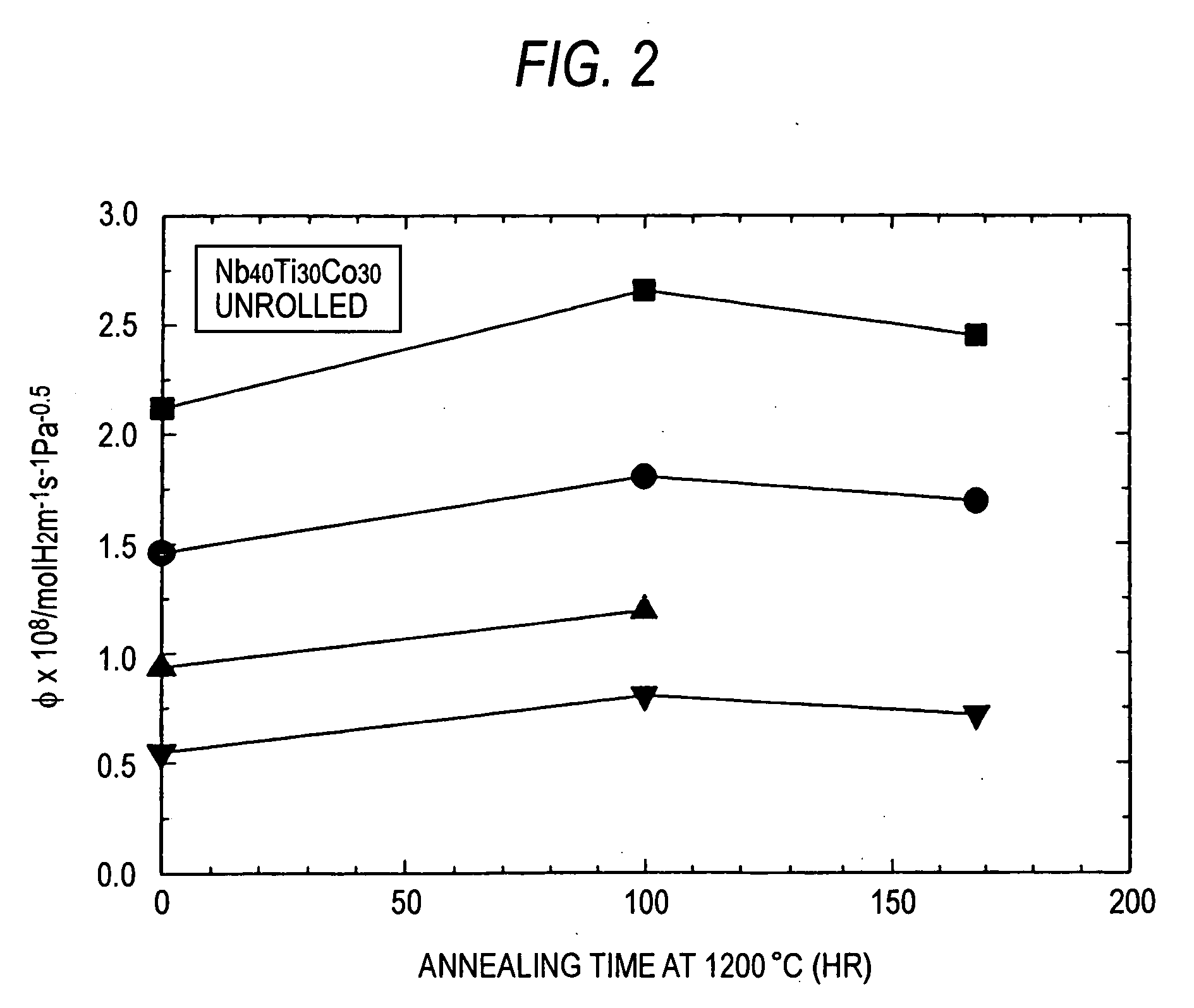

Hydrogen permeable alloy and method for producing the same

InactiveUS20070056660A1Improve permeabilityImprove hydrogen embrittlement resistanceSemi-permeable membranesReactant parameters controlAlloyTitanium

A (Nb, Ti) phase in an Nb—Ti—Co alloy is composed of a granular structure. The Nb—Ti—Co alloy is preferably subjected to heat treatment at 800° C. or more so that the eutectic structure in the casted state can be changed to a granular structure. The Nb—Ti—Co alloy used there is preferably NbxTi(100-x-y)Coy, (x≦70, 20≦y≦50 (mol %)). By properly predetermining the heating temperature and time, the resulting alloy exhibits improved hydrogen permeability in combination with a good hydrogen embrittlement resistance characteristic in the CoTi phase, making it possible to provide a practical hydrogen permeable membrane having an advantageously high performance.

Owner:JAPAN STEEL WORKS LTD +1

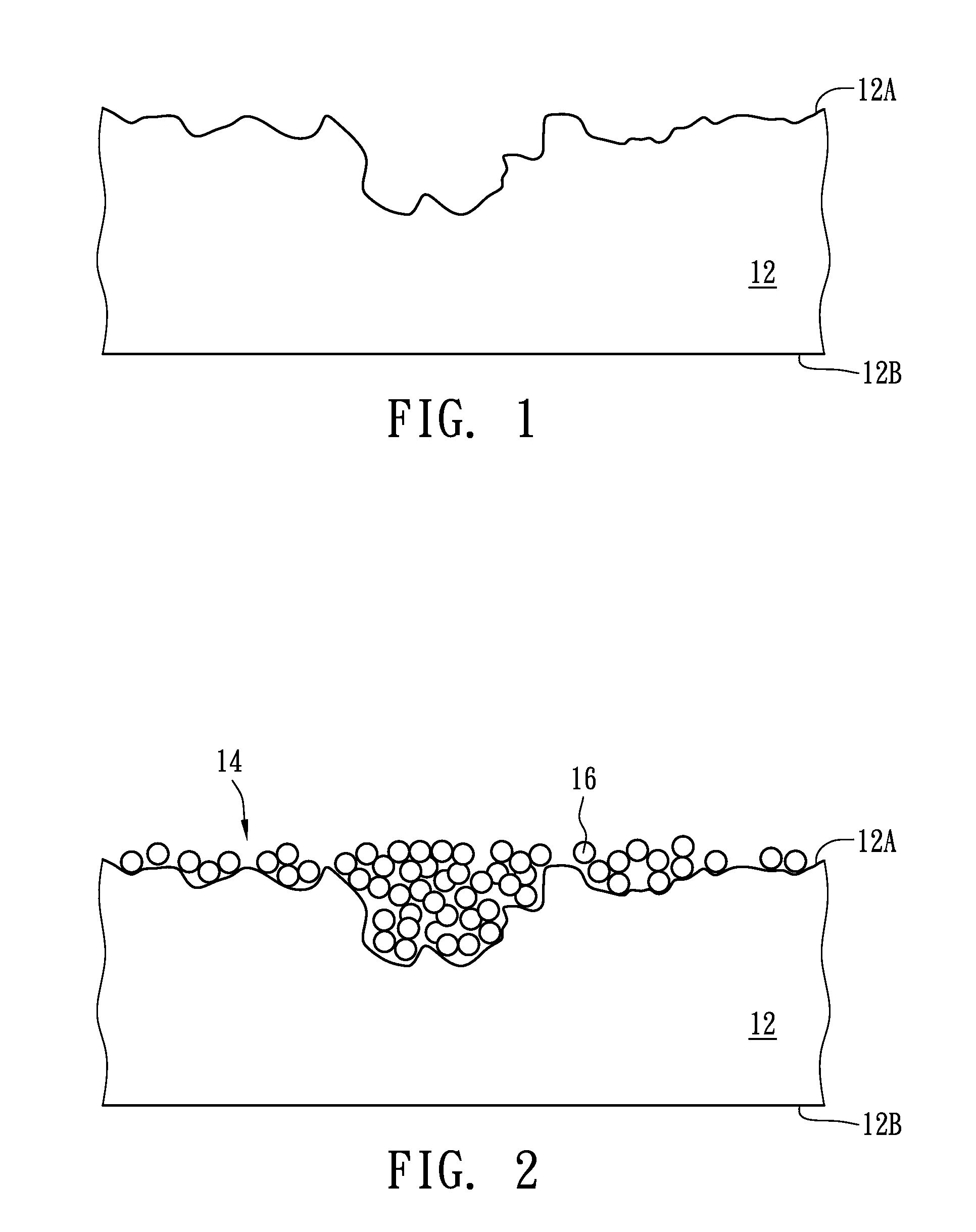

Method for Preparing a Palladium-Containing Layer

InactiveUS20080014355A1High selectivityImprove hydrogen permeabilitySemi-permeable membranesMembranesPorous substrateNanoparticle

A method for preparing a palladium-containing layer comprises the steps of cleaning a top surface of the porous substrate, modifying the top surface of the porous substrate to form a planar surface, performing a seeding process on the planar surface to adhere palladium nanoparticles on the planar surface and performing an electroless plating process to form the palladium-containing layer on the planar surface. The step of modifying the top surface of the porous substrate includes filling holes of the porous substrate with aluminum oxide particles, coating a sol-gel containing aluminum oxide or silicon oxide on the top surface of the porous substrate, The step of performing a seeding process on the planar surface includes exposing the planar surface of the porous substrate in a nanocolloidal solution having dispersed palladium nanoparticles derived from a palladium-containing species and a surfactant.

Owner:NATIONAL TSING HUA UNIVERSITY

Chemical plating method for preparing ultrathin palladium film with high specific surface area

InactiveCN102011108AImprove continuityImprove hydrogen permeabilityLiquid/solution decomposition chemical coatingChemical platingAlloy

The invention relates to a chemical plating method for preparing a palladium film or a palladium and silver alloy film, which comprises the following steps of: dividing plating solution of palladium salt complex or plating solution of palladium and silver amine salt complex into two parts by utilizing a porous carrier, adding a reducing agent to the plating solution at one side, making the reducing agent have self catalytic reaction with palladium salt complex or palladium and silver amine salt complex in the plating solution through holes and flaws, and forming a palladium film at one side of the porous carrier, which comes into contact with the palladium salt complex or the palladium and silver amine salt complex. High specific surface area can be obtained with the chemical plating method without any extra complicated processing, and the hydrogen permeation properties and the surface activity of the film can be enhanced. The palladium film prepared with the method is ultrathin, so resource waste can be reduced. Besides, the invention also has the advantages of simple technique, simple equipment and economic investment saving.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

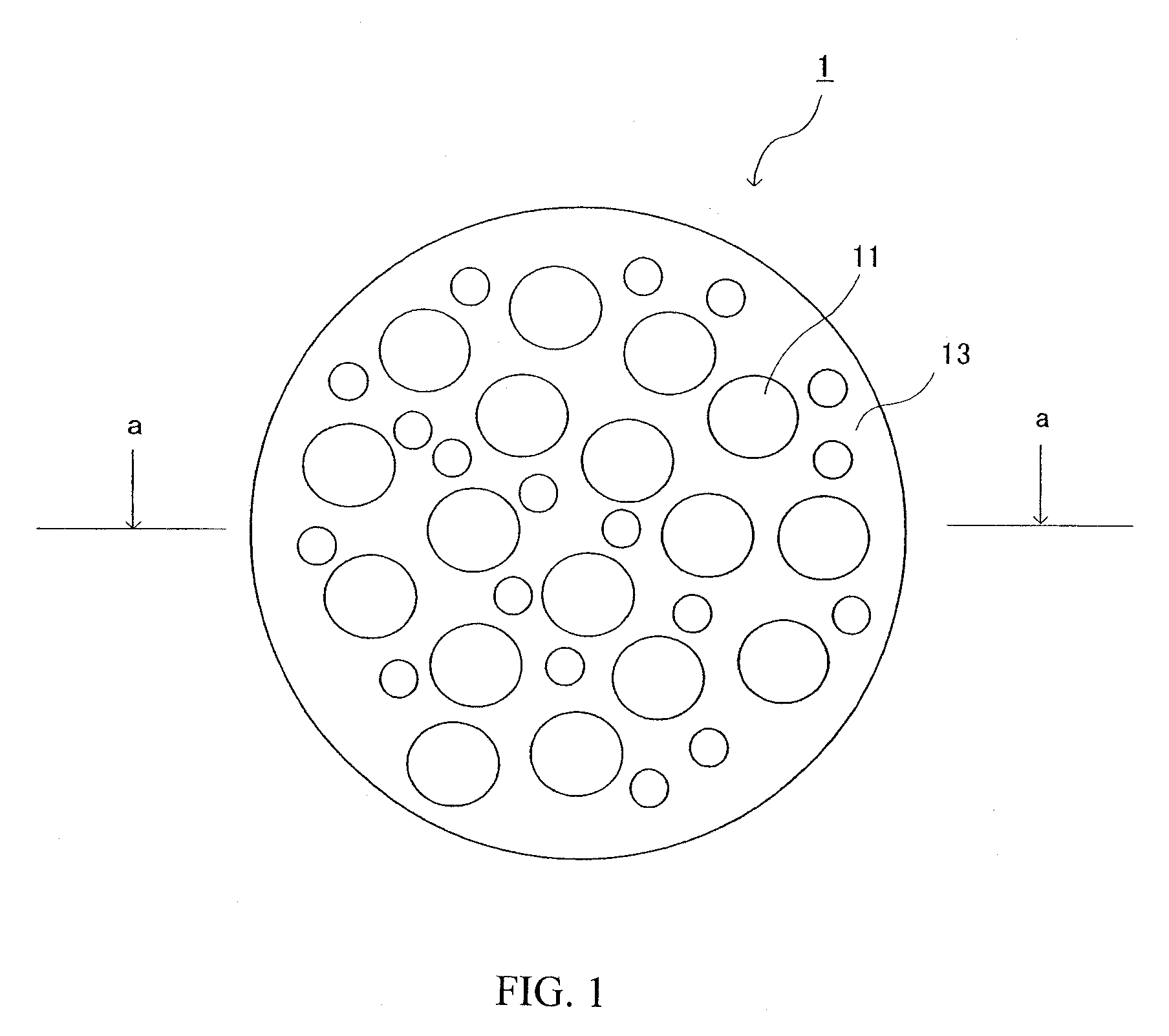

Hydrogen separation membrane, hydrogen separation unit, and manufacturing method for hydrogen separation membrane

InactiveUS7144444B2Reduce thicknessDefect in holeSemi-permeable membranesMembranesHydrogenPhysical chemistry

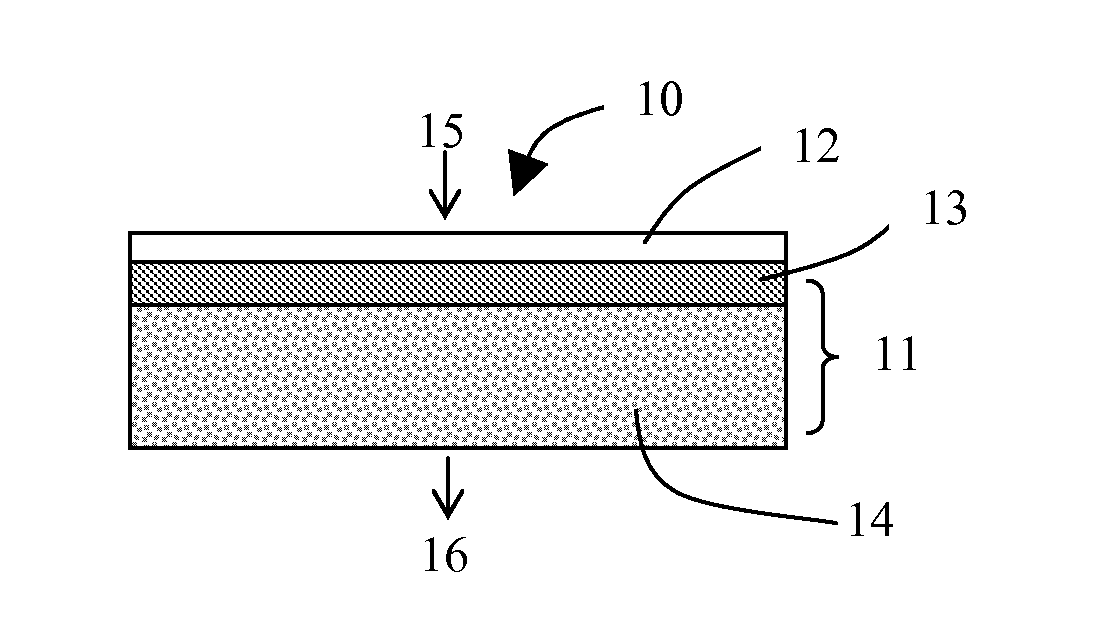

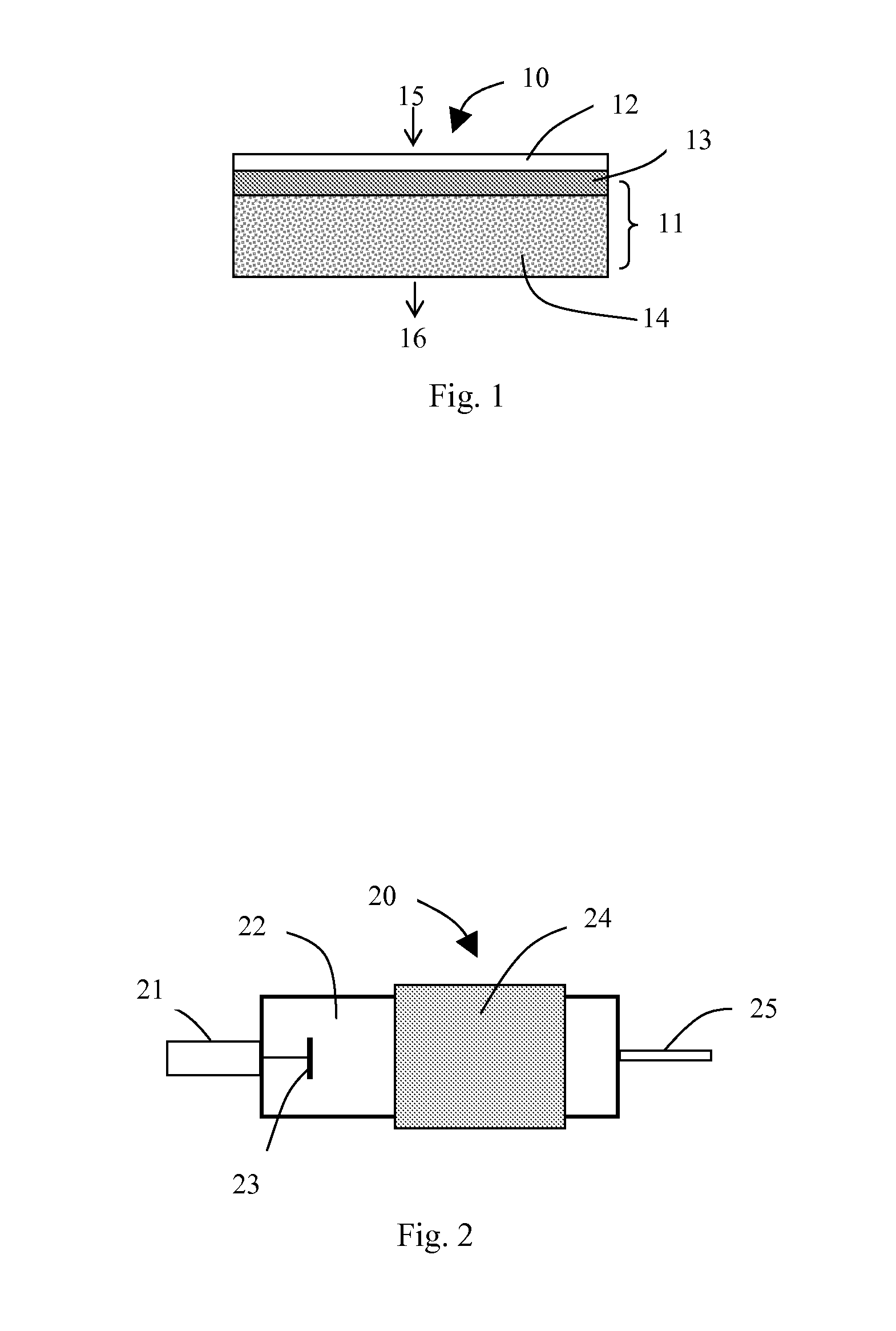

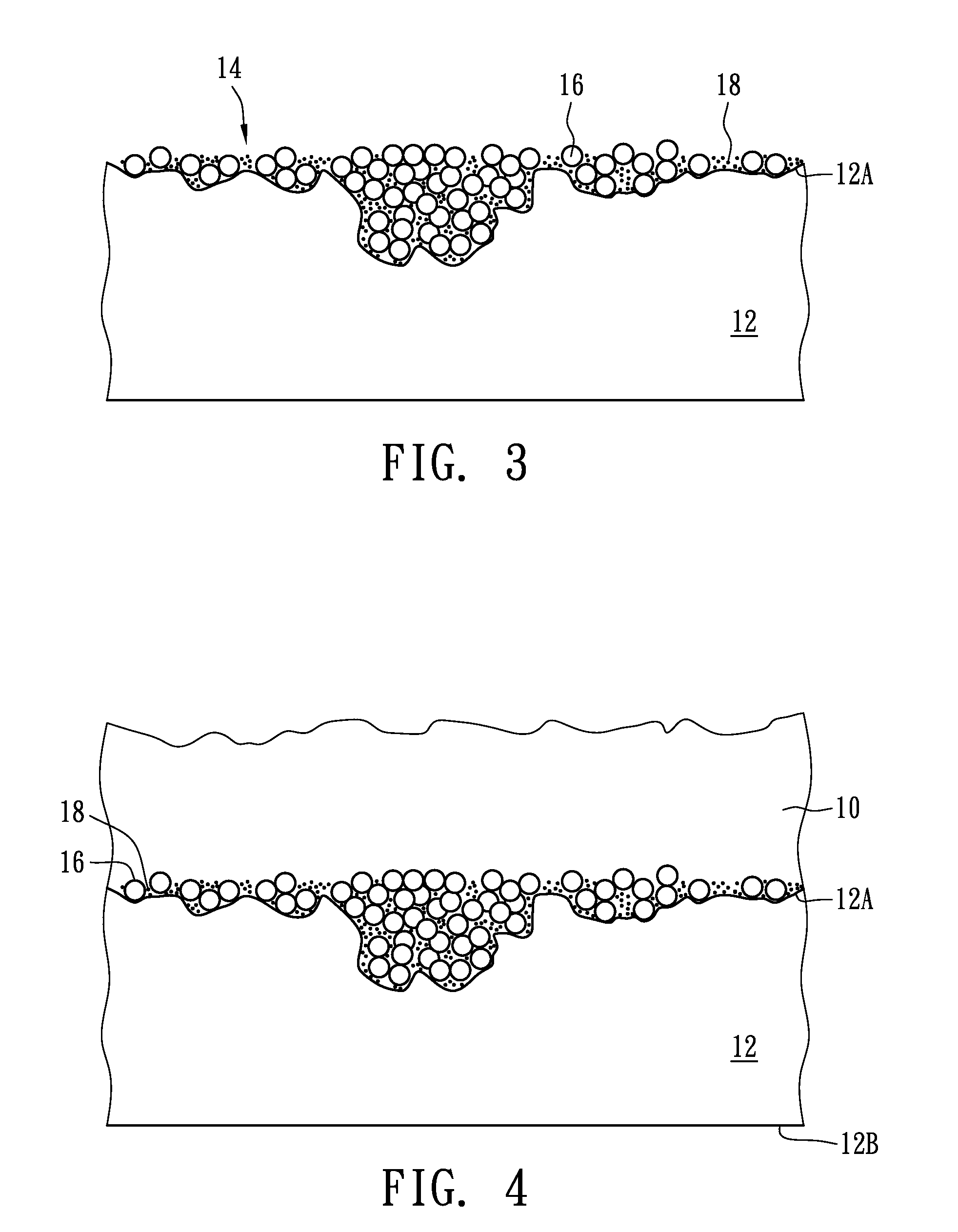

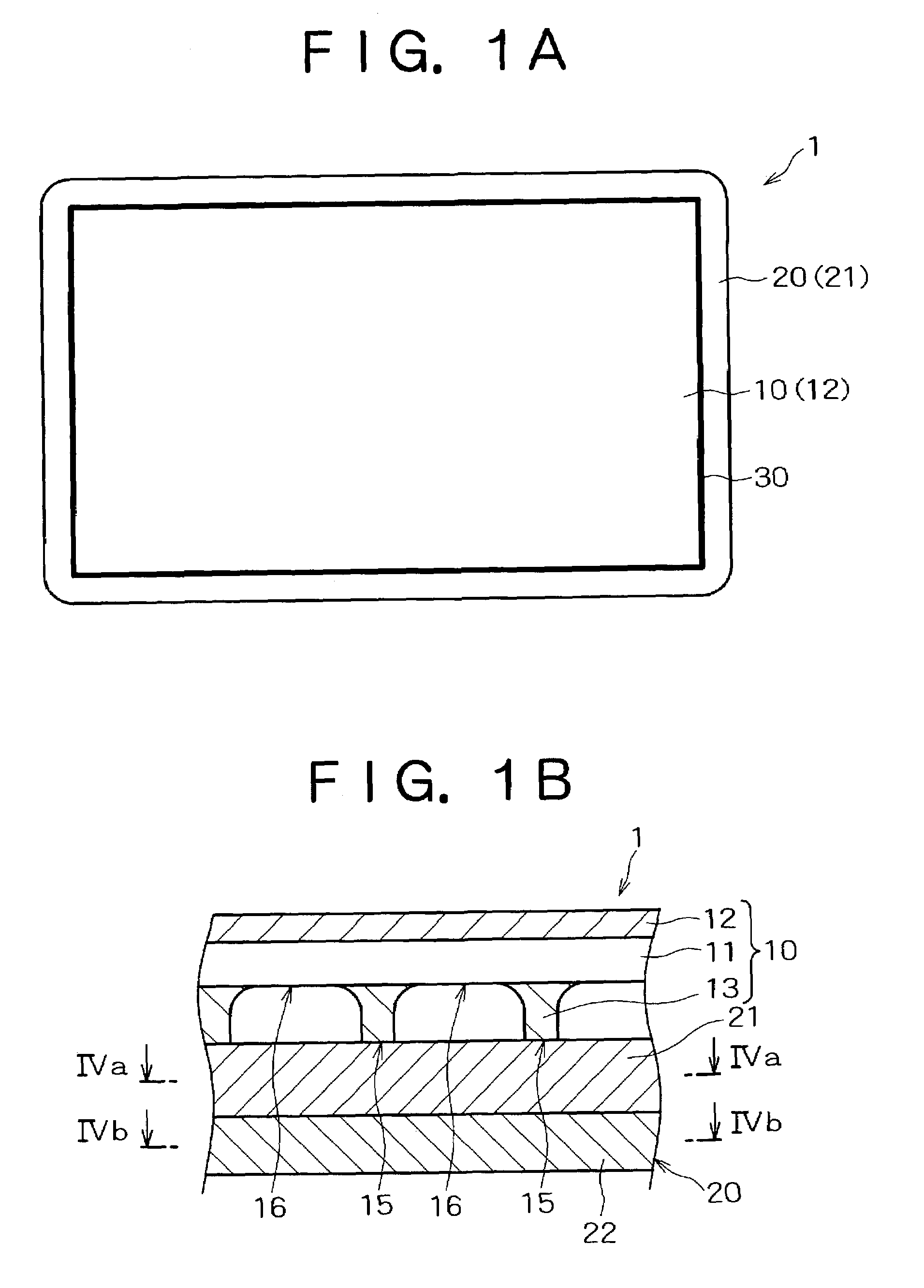

There is provided a hydrogen separation membrane capable of providing high hydrogen permeability and accommodating an increase in pressure difference, a hydrogen separation unit, and a manufacturing method for a hydrogen separation membrane. The hydrogen separation unit 1 has a hydrogen separation membrane 10 and a metallic porous support sheet 20 attached to the hydrogen separation membrane 10. By forming a plurality of pits in the surface of the hydrogen separation membrane 10, a thick-wall portion 15 having a large thickness and a thin-wall portion 16 having a small thickness are provided on the hydrogen separation membrane 10. Also, as a method for forming pits i.e. thin-wall portions 16, etching process is used.

Owner:MITSUBISHI HEAVY IND LTD

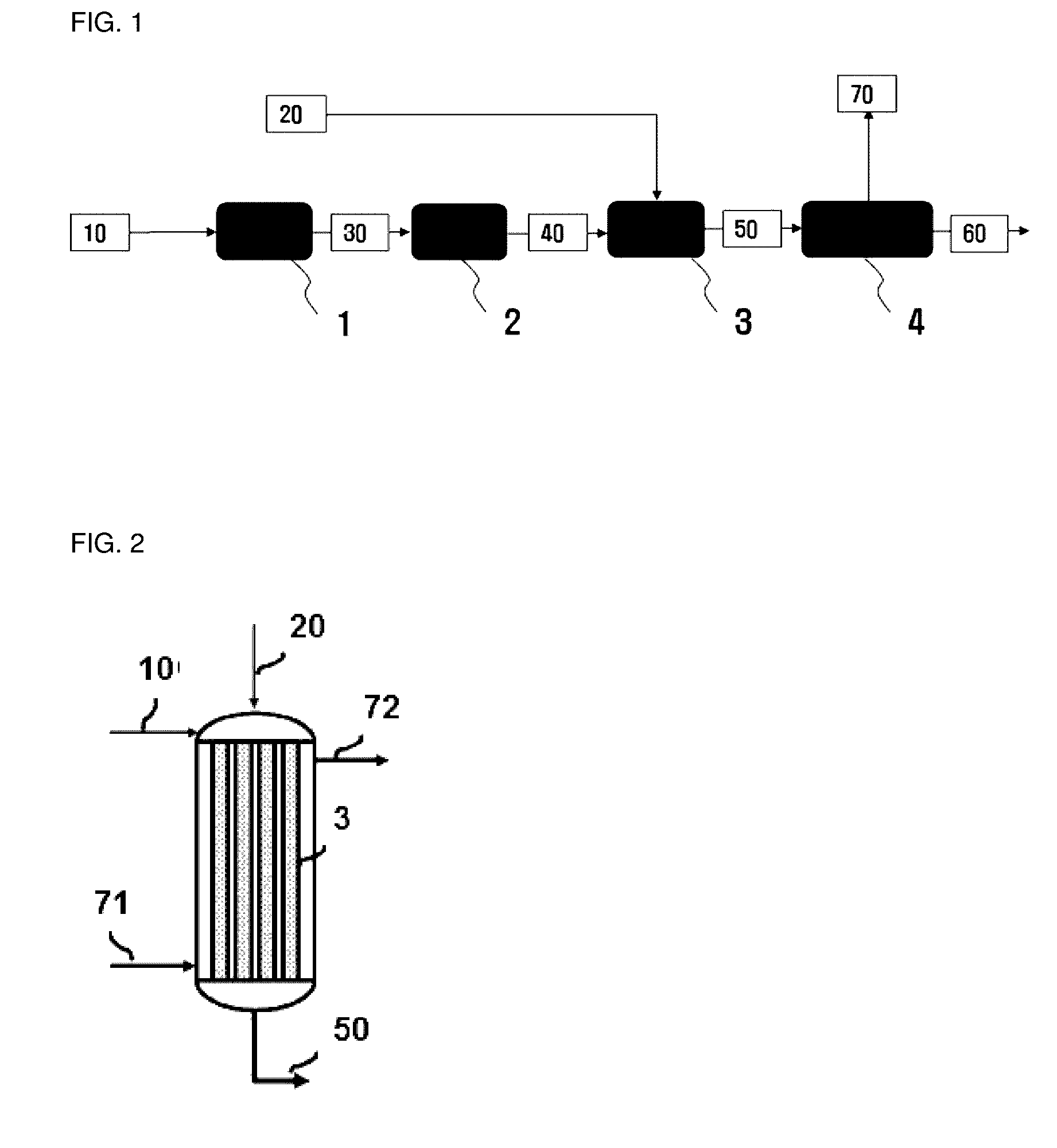

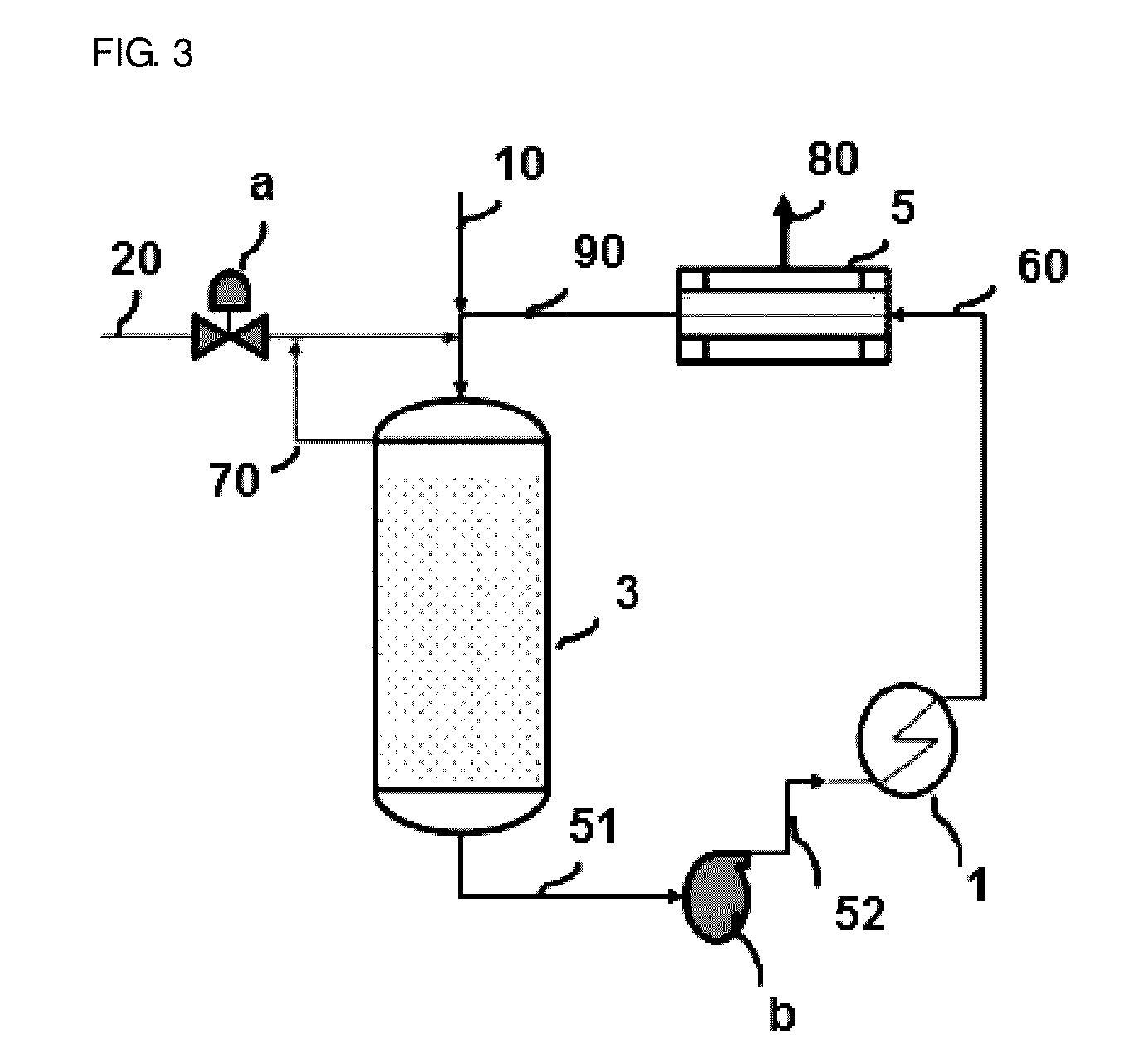

Online hydrogen production system and method

ActiveCN109399561AOverall light weightLow priceHydrogenHydrogen/synthetic gas productionCombustion chamberProcess engineering

The invention provides an online hydrogen production system and a method. The system comprises a reforming hydrogen production chamber and a combustion chamber, the reforming hydrogen production chamber is provided with a hydrogen filter element, and an air inlet, an unreacted raw material outlet and a hydrogen outlet are formed in the reforming hydrogen production chamber; the reforming hydrogenproduction chamber is disposed in the combustion chamber, and a heating unit is disposed between the combustion chamber. The method comprises the steps of (1) gasifying a reforming hydrogen productionmaterial to obtain a gasification material; (2) simultaneously heating the reforming hydrogen production chamber and the combustion chamber by using the same heat source, using the gasification material as a raw material in the reforming hydrogen production chamber to reform and produce hydrogen so as to obtain a hydrogen-containing mixture, and burning the unreacted gasification material in thecombustion chamber; (3) separating the the hydrogen in the hydrogen-containing mixture to obtain the hydrogen product. The system and method have high hydrogen production rate per unit volume / weight,good stability, fast response, complete fuel reaction, safety, reliability and low cost.

Owner:TIANJIN POLYTECHNIC UNIV +1

Scalable multiple-inverse diffusion flame burner for synthesis and processing of carbon-based and other nanostructured materials and films and fuels

ActiveUS9388042B2High strengthEfficient extractionSemi-permeable membranesHydrogenDiffusion flameNanostructured materials

Owner:RUTGERS THE STATE UNIV

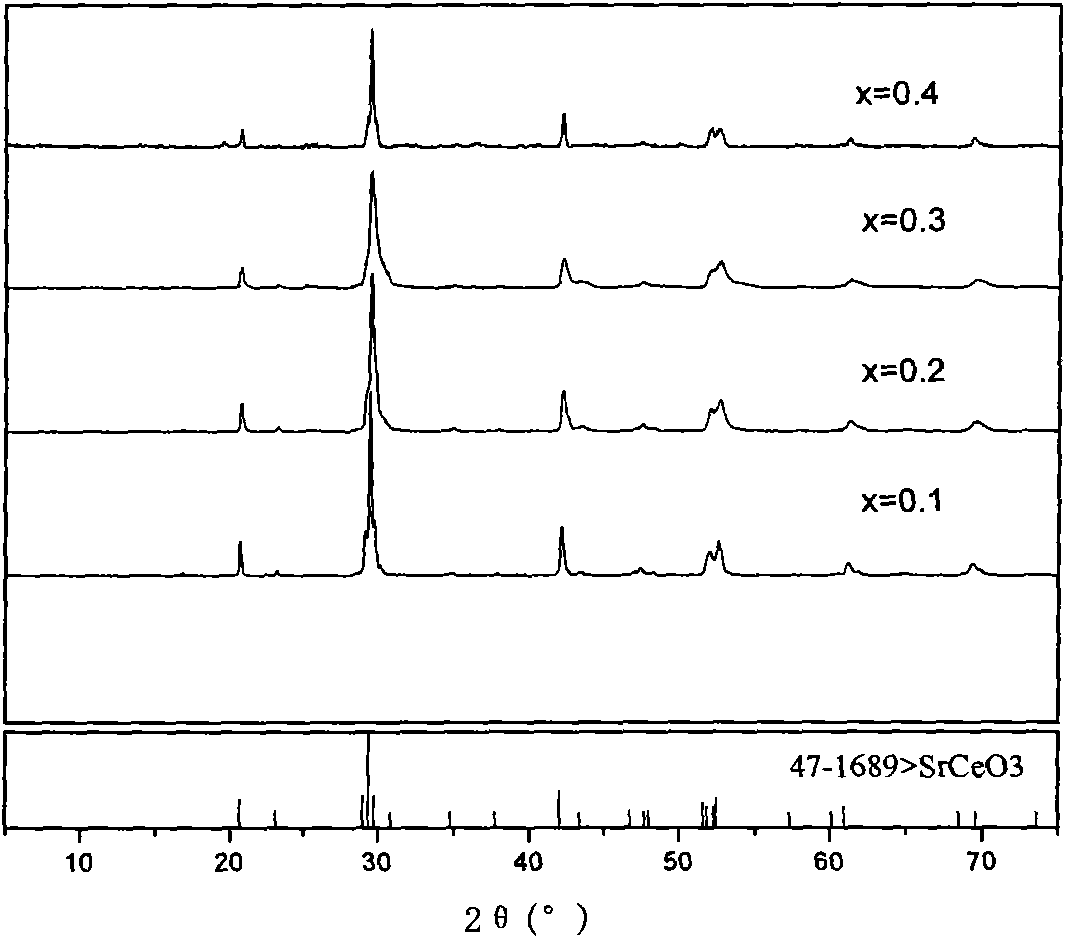

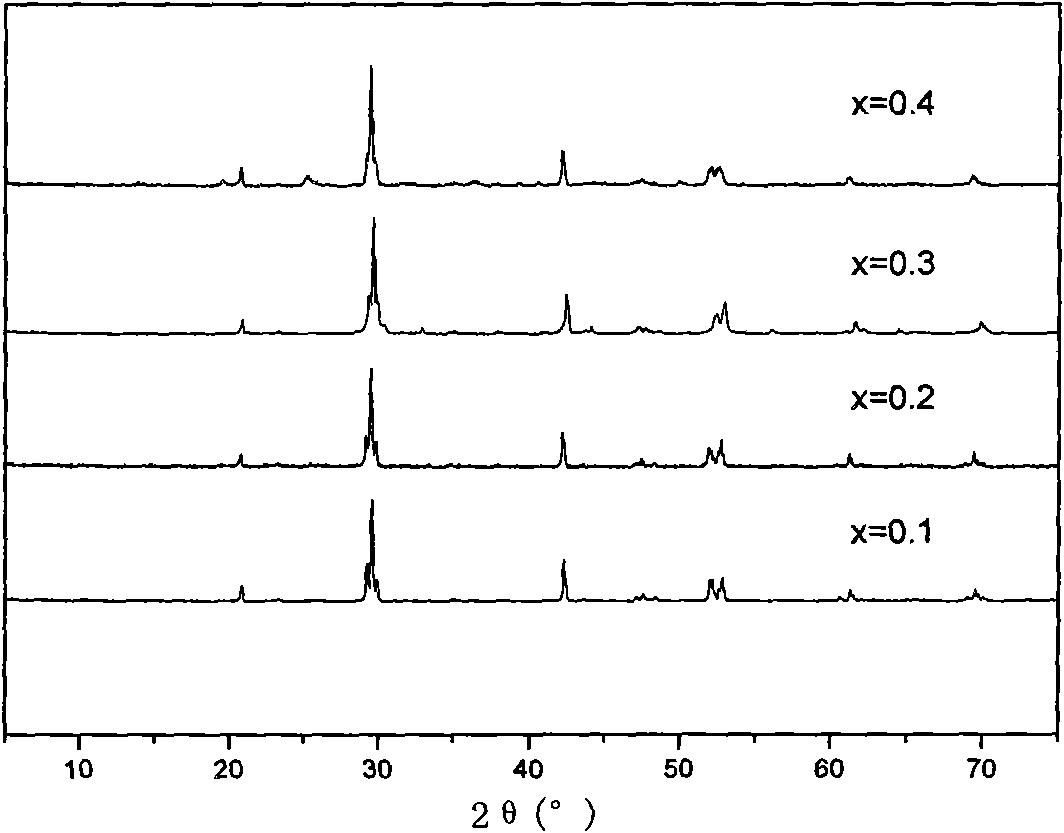

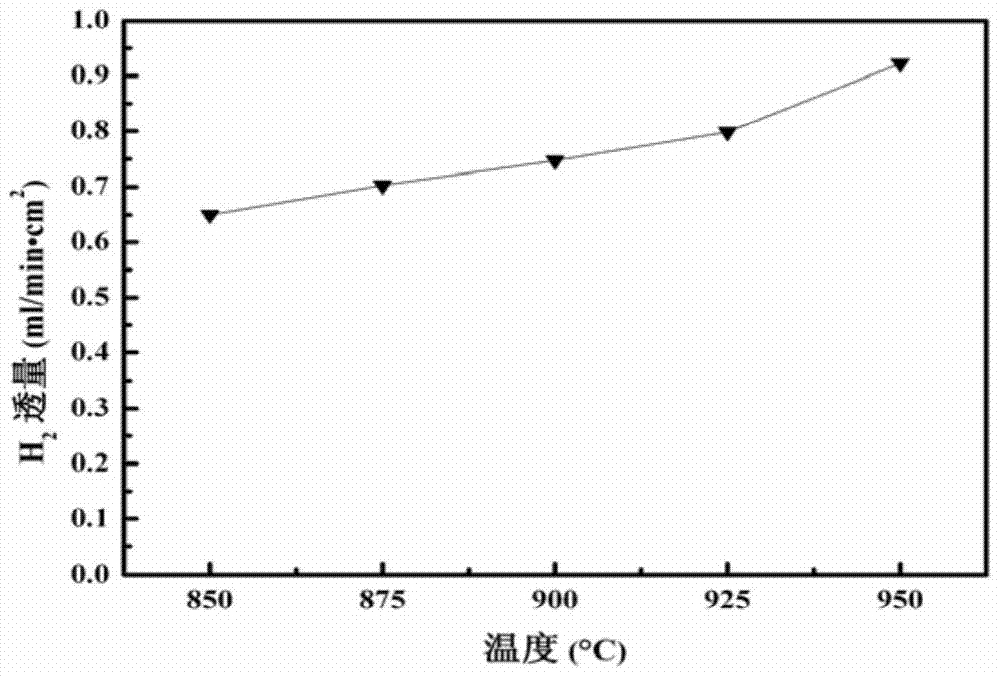

Mixed conductor hydrogen permeation membrane containing Zr system and Tm system perovskite and preparation method and application thereof

InactiveCN101612531AHigh proton conductivityImprove mechanical propertiesSemi-permeable membranesHydrogen separationHydrogenReducing atmosphere

The invention discloses a mixed conductor hydrogen permeation membrane containing Zr system and Tm system perovskite and a preparation method and an application thereof; the chemical formula of the hydrogen permeation membrane is SrCe0.95-xZrxTm0.05O3-delta; wherein, x is not less than 0.1 and not more than 0.40 and delta is not less than 0 and not more than 0.5. The preparation method comprises the following steps: preparing a precursor by EDTA-citric acid combination complexometry, sintering at 1000 DEG C for 7-10h to obtain powder, pressing the powder at 10-40MPa to obtain membranes by stationary method and finally roasting the membranes at 1100-1525 DEG C to obtain the mixed conductor hydrogen permeation membrane containing Zr system and Tm system perovskite. The hydrogen permeation membrane is perovskite oxide which is doped with Zr and Tm at the same time, has higher hydrogen permeability and high stability in reducing atmosphere and can be used for separating hydrogen from a mixed gas containing hydrogen.

Owner:SOUTH CHINA UNIV OF TECH

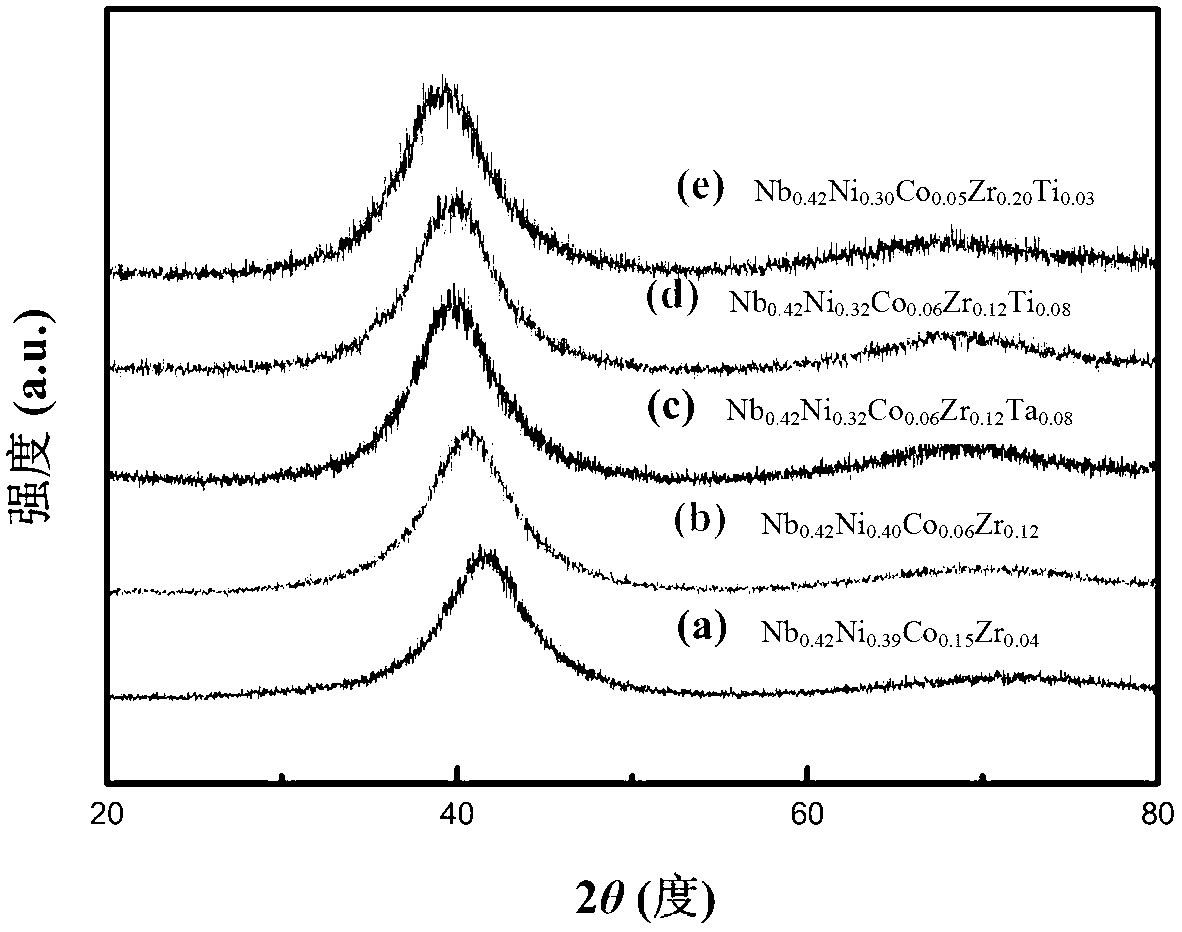

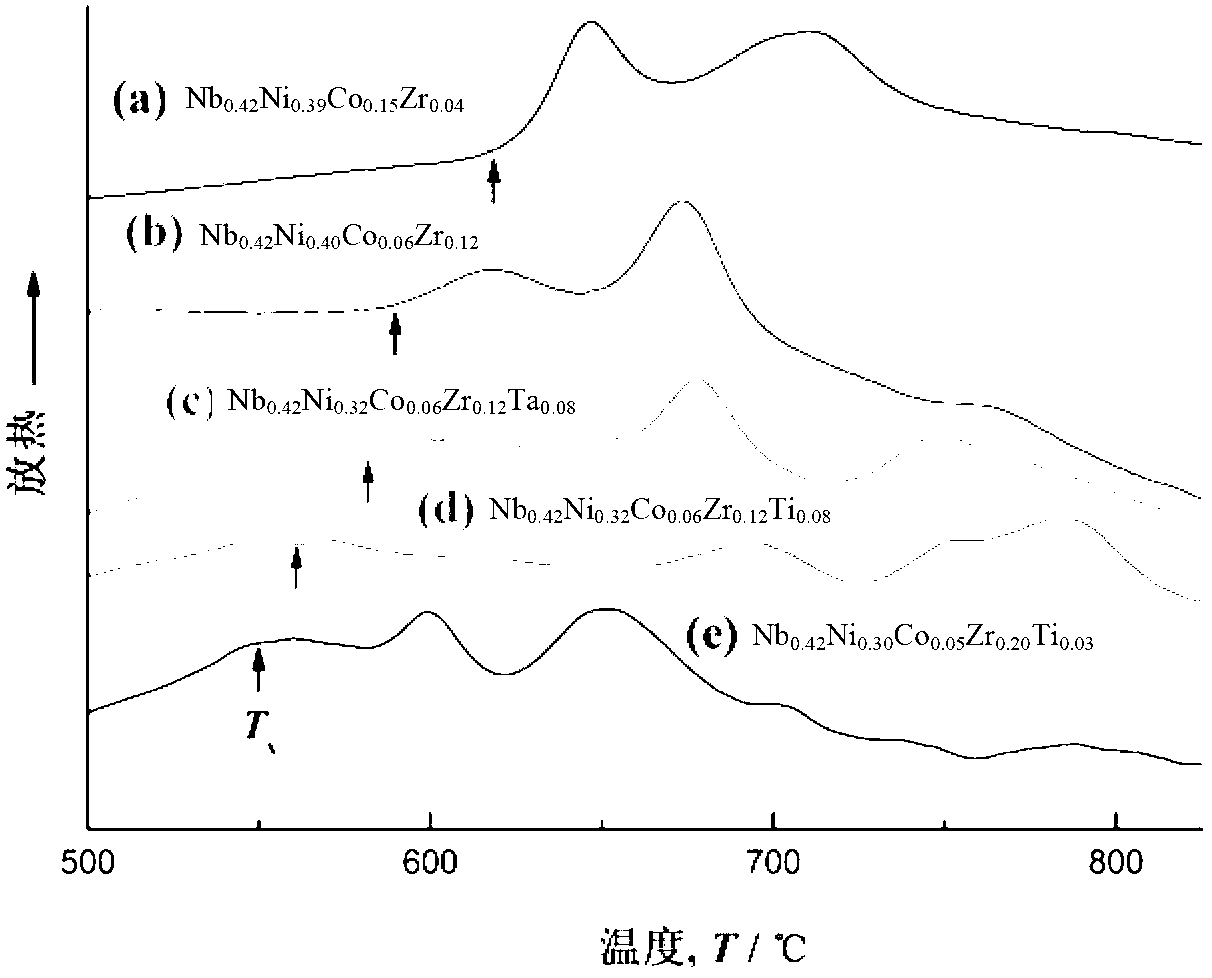

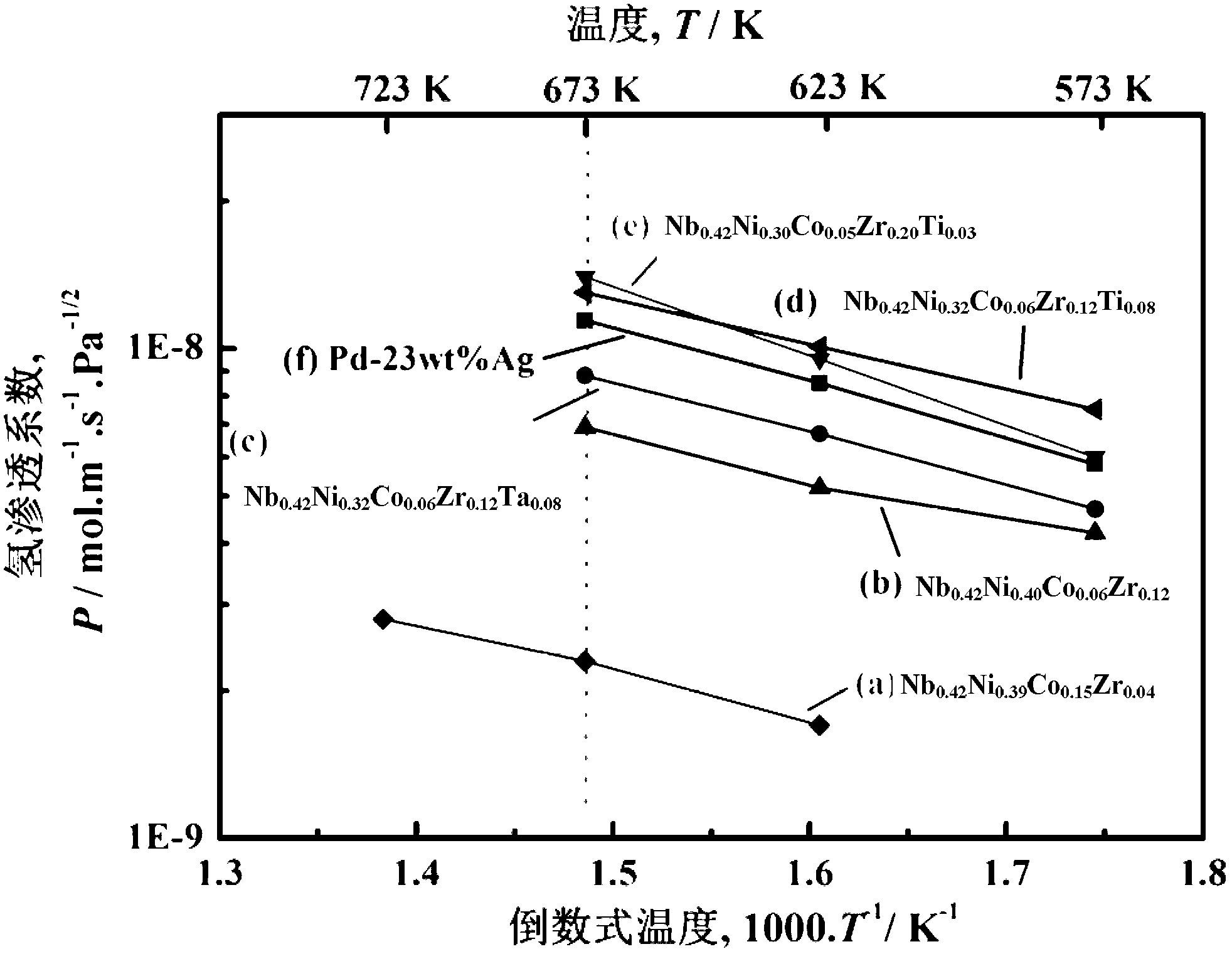

Preparation method of Nb-based amorphous alloy and stripe and hydrogen permeating metal film thereof

ActiveCN102851626AImproved hydrogen permeability and thermal stabilityImprovement ingredientsMetal layered productsAmorphous metalMetal

The invention provides a preparation method of an Nb-based amorphous alloy and a stripe and a hydrogen permeating metal film of the Nb-based amorphous alloy, According to the preparation method, the Nb-based amorphous alloy has the chemical formula as Nb0.42NiaCobZrcMd, wherein M=Ta, or Ti; a, b, c and d are respectively the atomic percentage of each component, wherein a is more than or equal to 0.30 and less than or equal to 0.40, b is more than or equal to 0.05 and less than or equal to 0.15, c is more than or equal to 0.04 and less than or equal to 0.02, d is more than or equal to 0 and less than or equal to 0.08, and the sum of a, b, c and d is equal to 0.58. With the adoption of the preparation method provided by the invention, the alloy components are further improved; the hydrogen permeating performance and thermal stability of the Nb-based amorphous alloy stripe and the hydrogen permeating metal film are improved; the Nb-based amorphous alloy capable of separating hydrogen and purifying is prepared, and the Nb-based amorphous alloy stripe and the hydrogen permeating metal film which have high performance of hydrogen permeating and are capable of separating and hydrogen and purifying can be obtained.

Owner:TSINGHUA UNIV

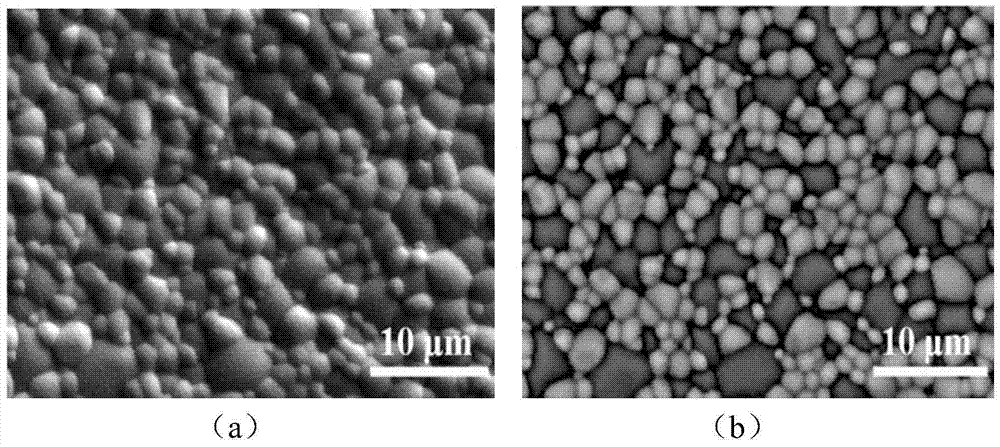

Preparation method of palladium membrane

ActiveCN103721576AHigh densityImprove compactnessSemi-permeable membranesLiquid/solution decomposition chemical coatingMicro nanoHydrogen

The invention relates to a preparation method of a palladium membrane. The preparation method of the palladium membrane is characterized in that a layer of palladium or palladium alloy membrane is deposited on the surface of a porous matrix by adopting a chemical plating method; the prepared palladium membrane is sintered in an inert atmosphere with certain positive pressure; rearrangement of micro-nano scale palladium grains is facilitated; a closed hole at the grain boundary intersection and isolated micro-pores in the grains are compact, and then the residual defects are filled in a chemical repairing manner. By adopting the method, the palladium membrane which is compact and uniform in film, long in service life and high in hydrogen permeability can be prepared.

Owner:RISON HI TECH MATERIALS CO LTD

Hydrogen permeation alloy material and preparation thereof

The invention discloses a hydrogen permeating alloy material and a method for preparing the same, and the alloy comprises the following components by molar percentage: titanium of 23mol%-54mol%, cobalt of 21mol%-39mol% and tantalum, titanium, cobalt and tantalum of which the total content is of 98-100mol%.The manufacturing of the alloy material comprises steps of putting titanium, cobalt and tantalum with a purity of more than 99% into a non-consumable vacuum arc furnace, vacuumizing to a pressure below 3*10 3 Pa, filling in argon of high purity to a pressure of 4*10 Pa, and then smelting. The alloy material of the invention has the hydrogen permeability and excellent hydrogen brittleness resistance ability higher than pure palladium under 573-673K, while the cost of the alloy material is only about 1 / 100 of that of the pure palladium, thus, the alloy material can be used for hydrogen gas isolation and purification, and can also be used for a catalytic-reformed compact membrane reactor and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Low temperature electrolyte membrane of H-SOFC (high temperature solid oxide fuel cell) and preparation method

InactiveCN108306032ALower working temperatureWill not diluteFinal product manufactureFuel cellsWorking temperatureNormal electrolytes

The invention relates to the field of fuel cells and discloses a low temperature electrolyte membrane of an H-SOFC (high temperature solid oxide fuel cell) and a preparation method. The method comprises the following steps of: (1) mixing a raw material A and a raw material B, adding a doping oxide to prepare a doped compound in an A2B2O7 solid solution fluorite structure, (2) adding the doped compound into concentrated nitric acid, di-ethyl alcohol and citric acid to prepare doped nano gel, and (3) performing drying, pressing, sintering, annealing and cold treatment on the doped nano gel to form a doped nano ceramic membrane material. Compared with the common electrolyte, since a reaction occurs at a cathode, the electrolyte membrane of the fuel cell is good in structural stability and durability and high in mechanical strength; output power of a cell is stable for a long time; the cell is low in working temperature and high in electrical efficiency; and the fuel cell electrolyte membrane is simple in preparation process and low in production cost and has better economic advantages and application prospects.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Aa alkaline battery

InactiveUS20090181299A1High mechanical strengthPrevents the gasket from being brokenCell electrodesSmall-sized cells cases/jacketsHydrogenZinc

In an AA alkaline battery according to the present invention, the opening of a battery case is sealed with a gasket. In the battery case, a positive electrode, a negative electrode, a separator, and an alkaline electrolyte are provided. The negative electrode contains 4.0 g or more of zinc. The gasket has a hydrogen gas permeability coefficient, per one gasket, in the range from 1.2×110−10 (cm3H2(STP) / sec·cmHg) to 9.9×10−10 (cm3H2(STP) / sec·cmHg), both inclusive.

Owner:PANASONIC CORP

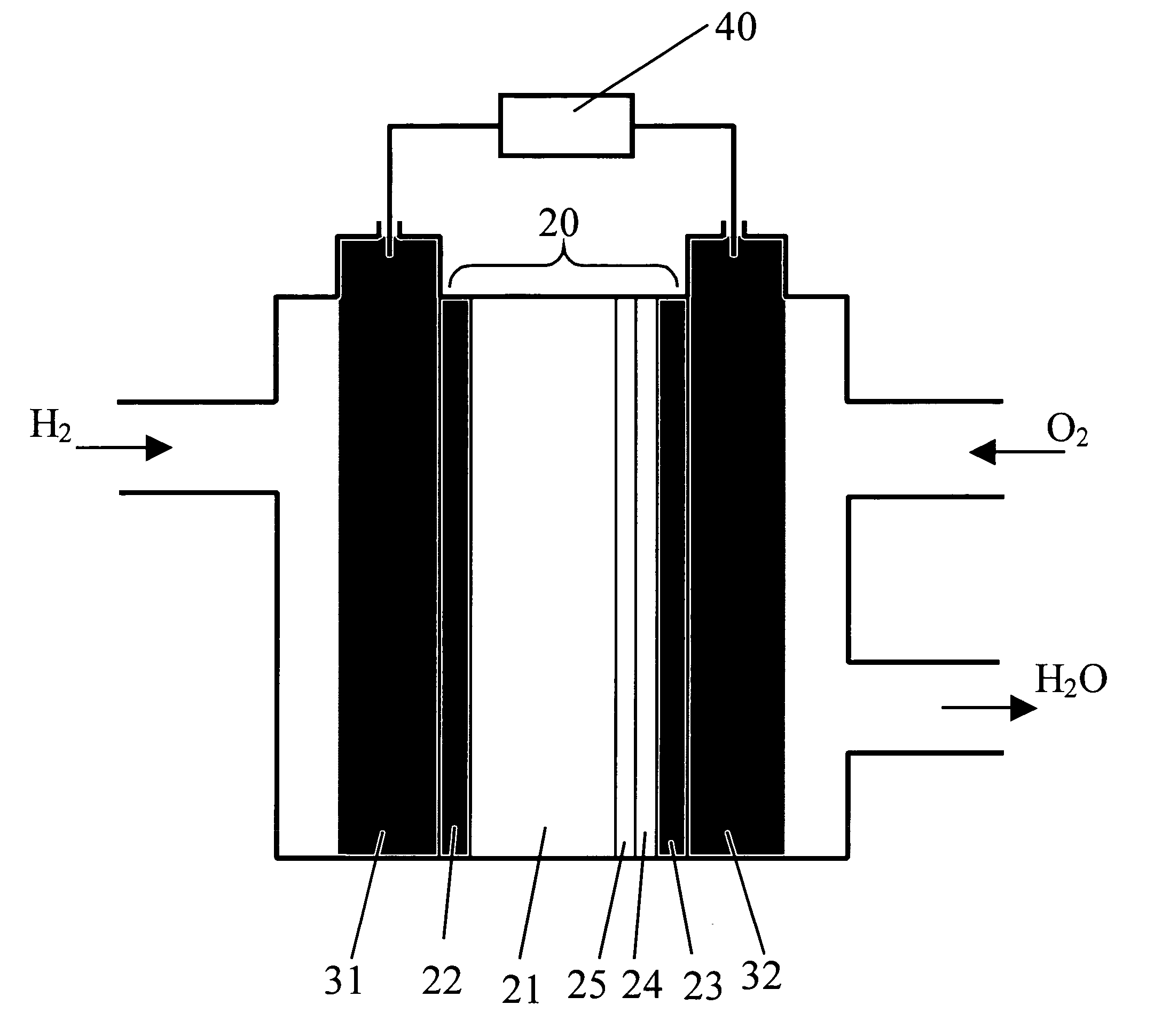

Solid state, thin film proton exchange membrane for fuel cells

InactiveUS20070042252A1Lower operating temperatureImprove power densityCell electrodesElectrolytesElectrolysisNiobium

A fuel cell according to the invention comprises a multilayer proton exchange membrane having high proton conductivity in the temperature range of 300-500° C. This is achieved by the use of very thin (<1 μm) metal oxide polymer films on a metal substrate by electrolytic anodizing of a metal alloy. An exemplary proton exchange membrane according to the invention comprises a Ta2-xHfxO5 film fabricated on a niobium foil. The invention allows for a significant increase in power density and, therefore, a significant reduction in fuel cell cost per unit power.

Owner:KAZARINOV RUDOLF FEODOR

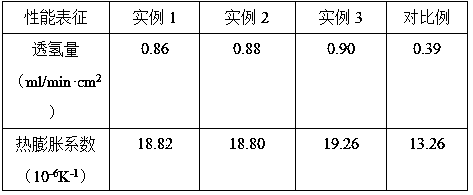

A dual-phase ceramic material of homologous double perovskite and its preparation method and application

The invention belongs to the technical field of application of hydrogen separation materials, and discloses a dual-phase ceramic material of homologous double perovskite, a preparation method and application thereof. The material is prepared from a proton-conducting phase and an electron-conducting phase, and both the proton-conducting phase and the electron-conducting phase are perovskite ceramic materials. The method is (1) weighing the raw materials of the proton-conducting phase and the raw materials of the electron-conducting phase according to the stoichiometric ratio, respectively adding organic solvents, ball milling, pretreatment, and roasting to obtain the proton-conducting phase and the electron-conducting phase; (2) Mix the proton conductive phase and the electronic conductive phase, add an organic solvent, ball mill, and then place it in a mold to form a green embryo; put the green embryo in a furnace, raise the temperature to 1300℃~1500℃, keep it warm for 10~20h, and cool down , to obtain a dual-phase ceramic material of homologous double perovskite. The prepared dual-phase ceramic material has good chemical stability and thermal stability, high hydrogen permeability, and is suitable for long-term industrial practical operation reactions.

Owner:SOUTH CHINA UNIV OF TECH

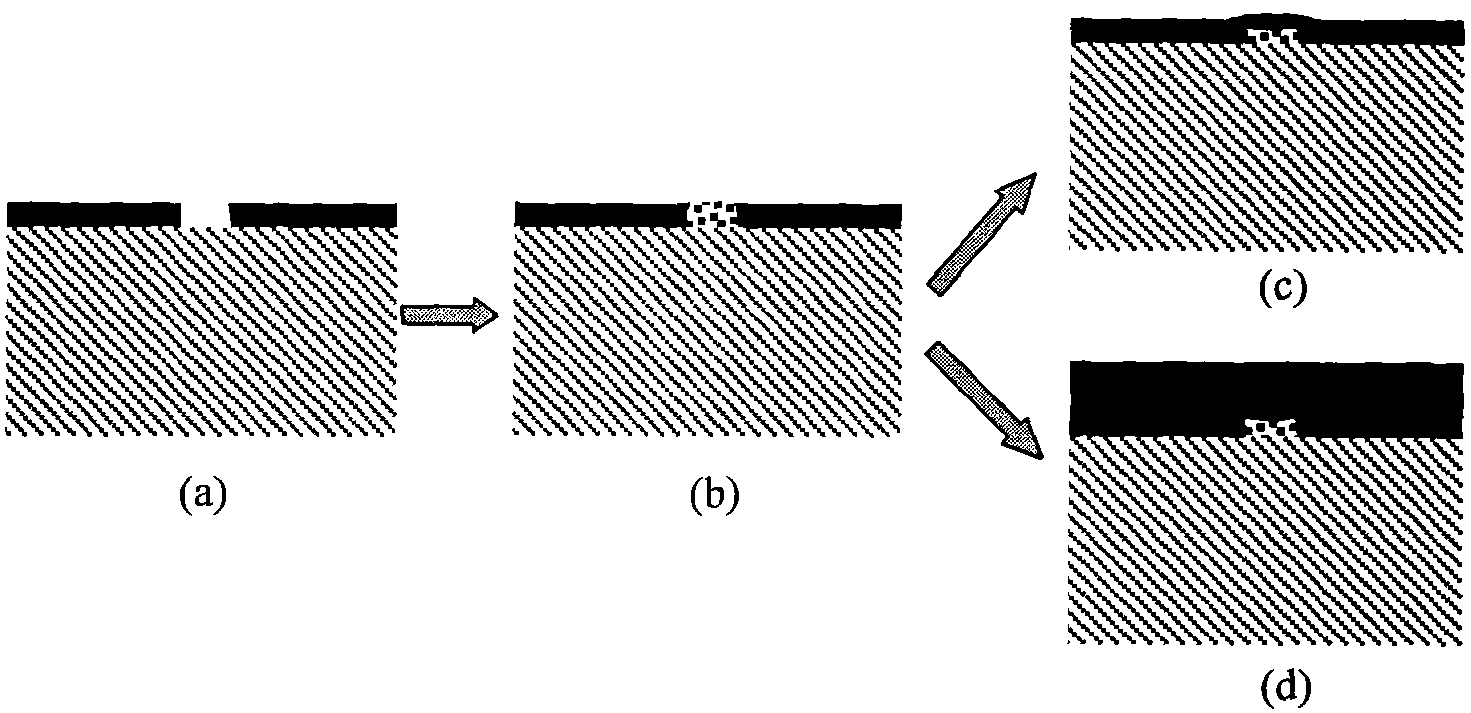

Hydrogenation method of phthalate compound

InactiveUS20160280629A1Improve hydrogenation reaction performanceHigh reaction yieldOrganic compound preparationCarboxylic acid esters preparationHydrogenation reactionHydrogenation process

There are provided a method for hydrogenation of a phthalate compound. According to the method for hydrogenation of the present invention, a hydrogenation reaction is performed in a multi-pipe type reactor in a state in which a viscosity of only a liquid-phase phthalate based raw material is lowered, such that a yield of a hydrogenation reaction process may be improved, and operation stability and economical efficiency on a commercial scale may be improved by hot spot control. According to another method of the present invention, long-term activity of a catalyst used in a reaction is maintained, and performance of the catalyst may be improved, such that stability and economical efficiency of a hydrogenation process may be improved. Therefore, a total amount of the catalyst required in the reaction may be decreased, and a replacement cycle may be extended, thereby making it possible to improving operation stability of the process and economical efficiency at the time of performing the process on a commercial scale.

Owner:HANWHA CHEMICAL CORPORATION

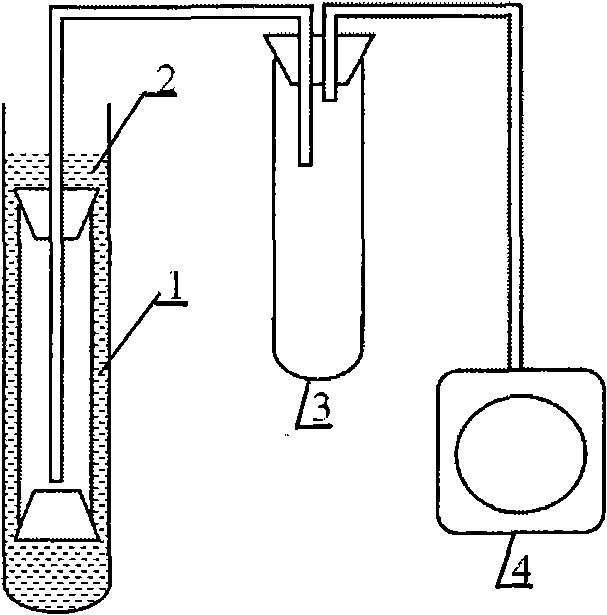

Chemical plating repairing method for palladium or palladium alloy composite film

ActiveCN101781760ASpeed up palladium platingHeal fastSemi-permeable membranesLiquid/solution decomposition chemical coatingHydrogen purityChemical plating

The invention relates to a chemical plating repairing method for a palladium or palladium alloy composite film. A solution or colloid of a metallic compound is used as a repairing liquid which is dipped into a film defect through capillary force and suction force and reduced to form metal particles that are filled into the defect, then a metal eliminating film is deposited by using a chemical plating method, wherein the metal particles play a role of a catalyst to the chemical plating. The method can be used for repairing the film, and can be alternated with the preparation process of the film, thereby realizing higher film compactness under the condition of same film thickness, or enabling the film to be thinner under the condition of film compactness, greatly improving the hydrogen penetrating property of the film and realizing higher hydrogen purity.

Owner:RISON HI TECH MATERIALS CO LTD

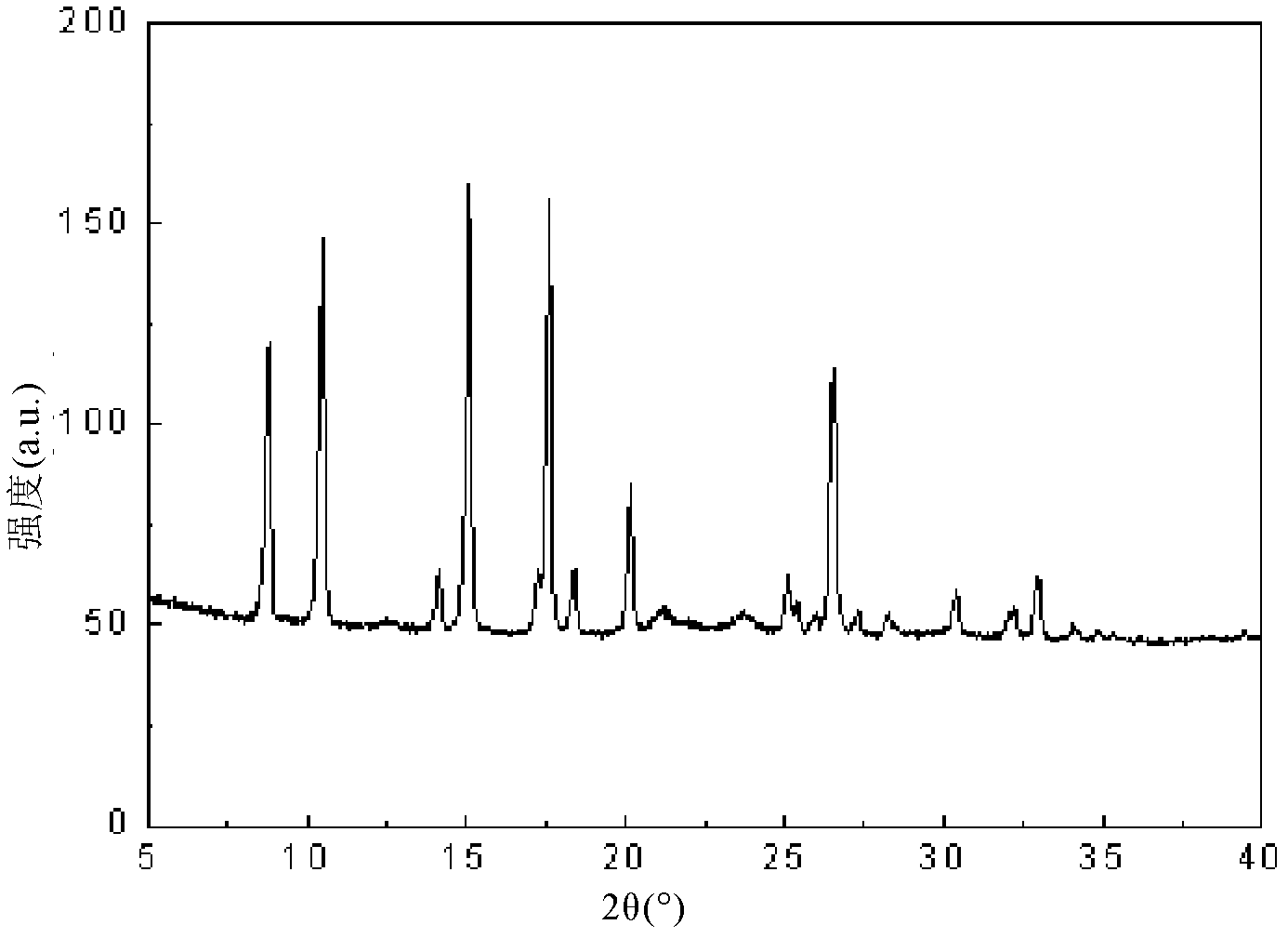

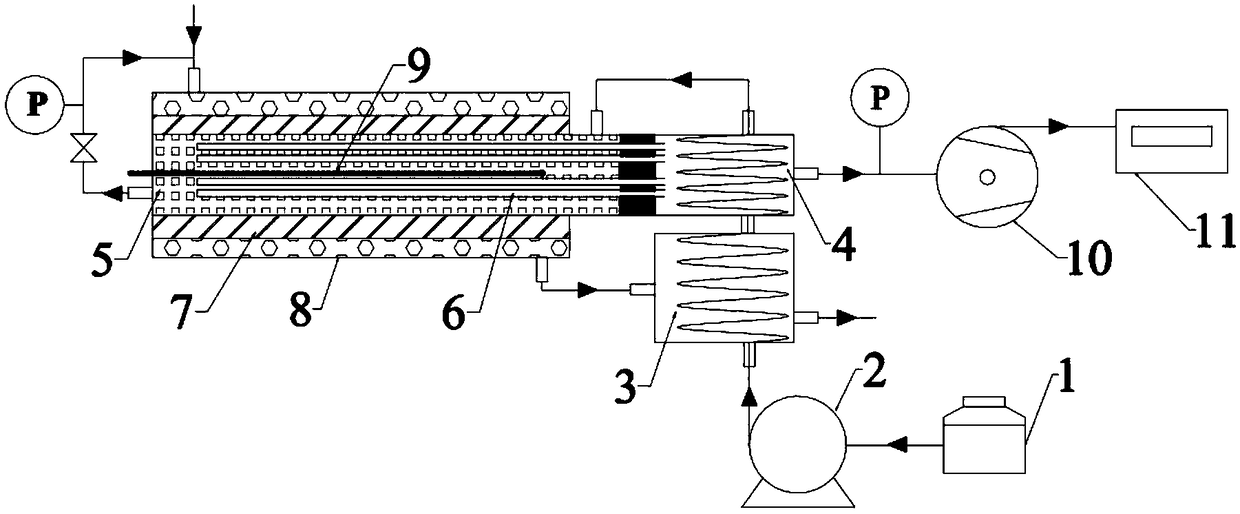

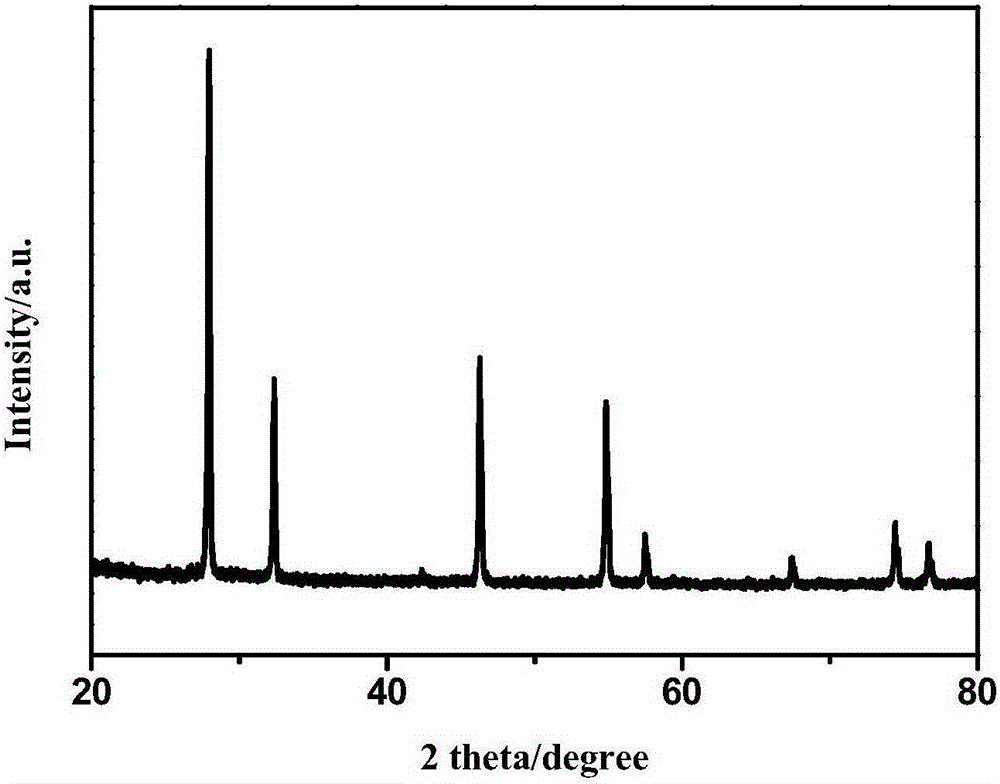

Preparation and measuring method of mixed conductor ceramic membrane used for H2S decomposition

InactiveCN105330290ALow costSimple processMaterial analysis using radiation diffractionElectrical conductorMixed conductor

The invention discloses a preparation and measuring method of a mixed conductor ceramic membrane used for H2S decomposition. The preparation and measuring method comprises following steps: a precursor of the mixed conductor ceramic membrane is prepared via a certain method; the precursor is subjected to calcining in a furnace for a certain period of time so as to obtain a phase-formed powder; shaping is realized via a certain method, and sintering is carried out so as to obtain the finished product material with special shapes. The finished product material is delivered into a testing device, and H2S decomposition testing is carried out at certain operation conditions. The preparation method is simple and feasible; production efficiency is high; cost is low; material operation stability is excellent; and the preparation method is convenient for industrialized large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of unsymmetrical composite ceramic hydrogen permeation membrane

InactiveCN109133919AIncreased bulk diffusion rateImprove hydrogen permeabilityElectrochemical responseComposite ceramic

The invention relates to a preparation method of an unsymmetrical composite ceramic hydrogen permeation membrane, and belongs to the technical field of environment-friendly materials. According to themethod, a tungsten acid rare earth compound with good chemical stability is selected as a membrane material, electronic conductive phase metal Ni is led into the membrane, nickel in an ion form is led into the tungsten acid rare earth compound by a citric acid-nitrate combustion method, simple-substance Ni is reduced, an electron conduction channel is formed, the bulk phase diffusion rate of themembrane is increased, hydrogen permeation amount of a diaphragm is increased, two phases of the a prepared two-phase membrane are more uniformly mixed, and the membrane has higher hydrogen permeationamount and chemical stability. According to the method, rare earth nano-particles with high catalytic activity are deposited on the inner wall of a green diaphragm of the hydrogen permeation membraneand serve as supporting frameworks, the rare earth nano-particles and conductive-phase metal Ni form continuous conductive grids, electrochemical reaction active sites are increased, the hydrogen permeation membrane has good catalytic activity, and poor stability and hydrogen permeation rate of the hydrogen permeation membrane are effectively improved.

Owner:FOSHAN WANHE NEW ENERGY TECH CO LTD

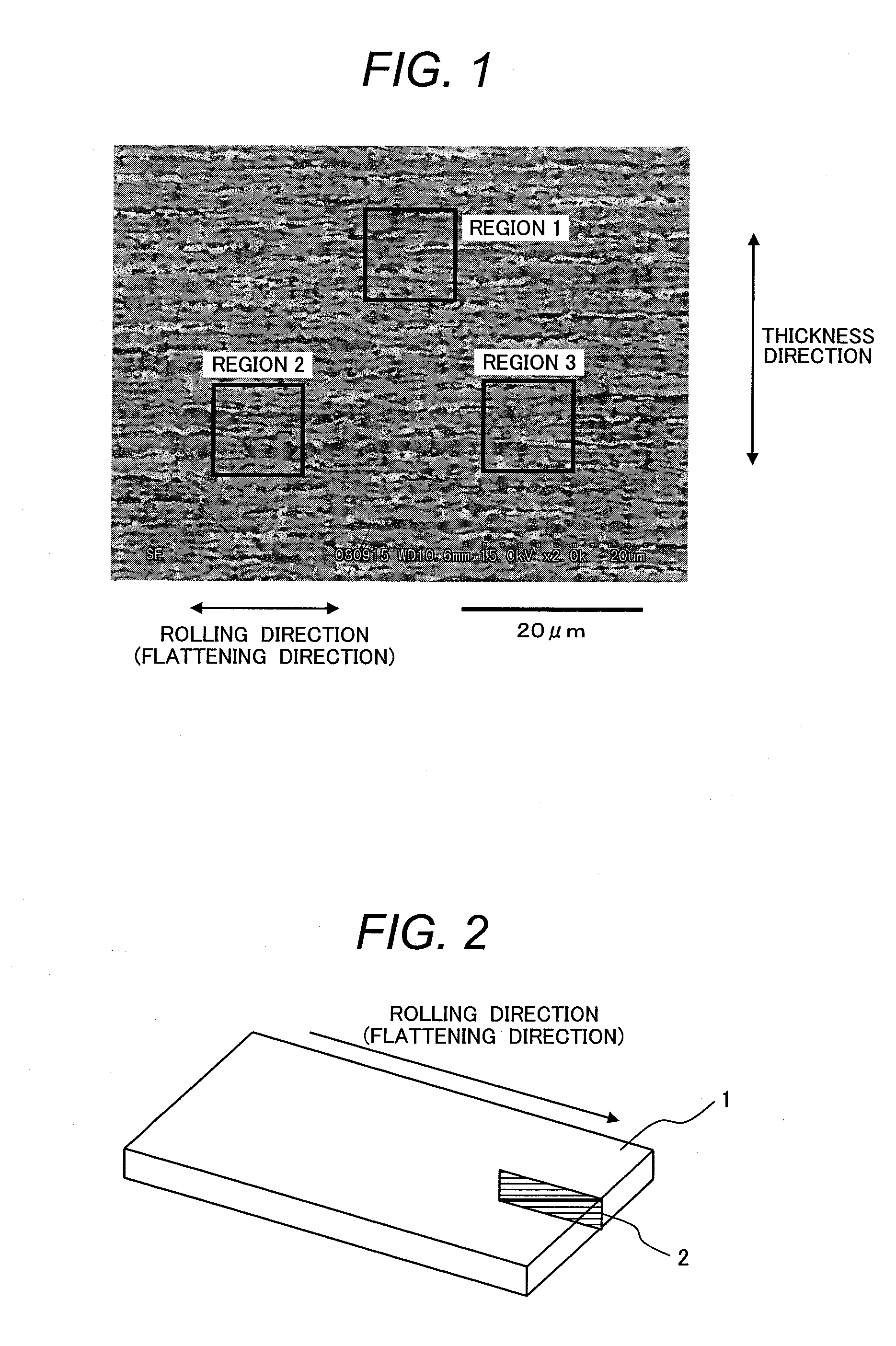

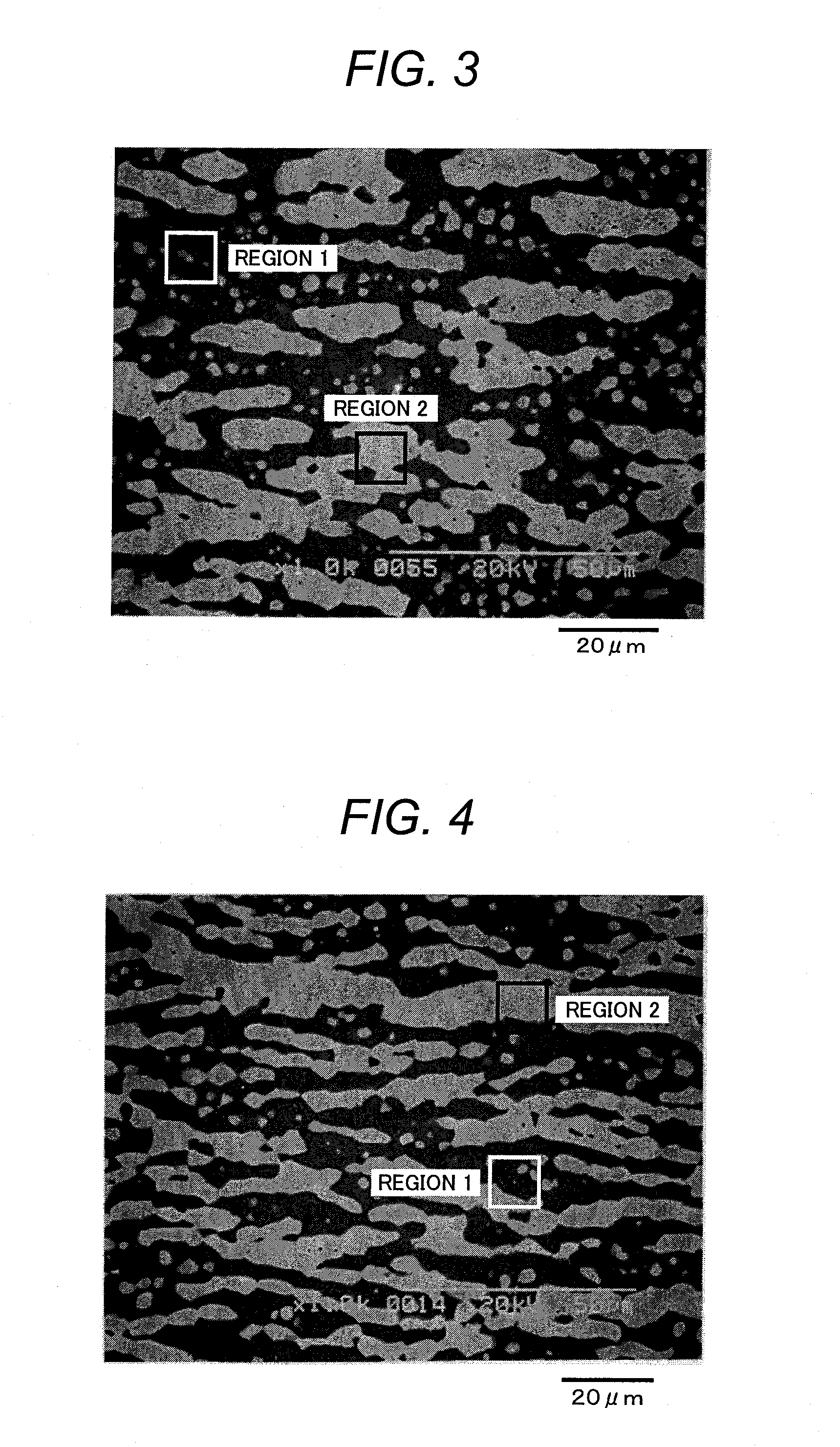

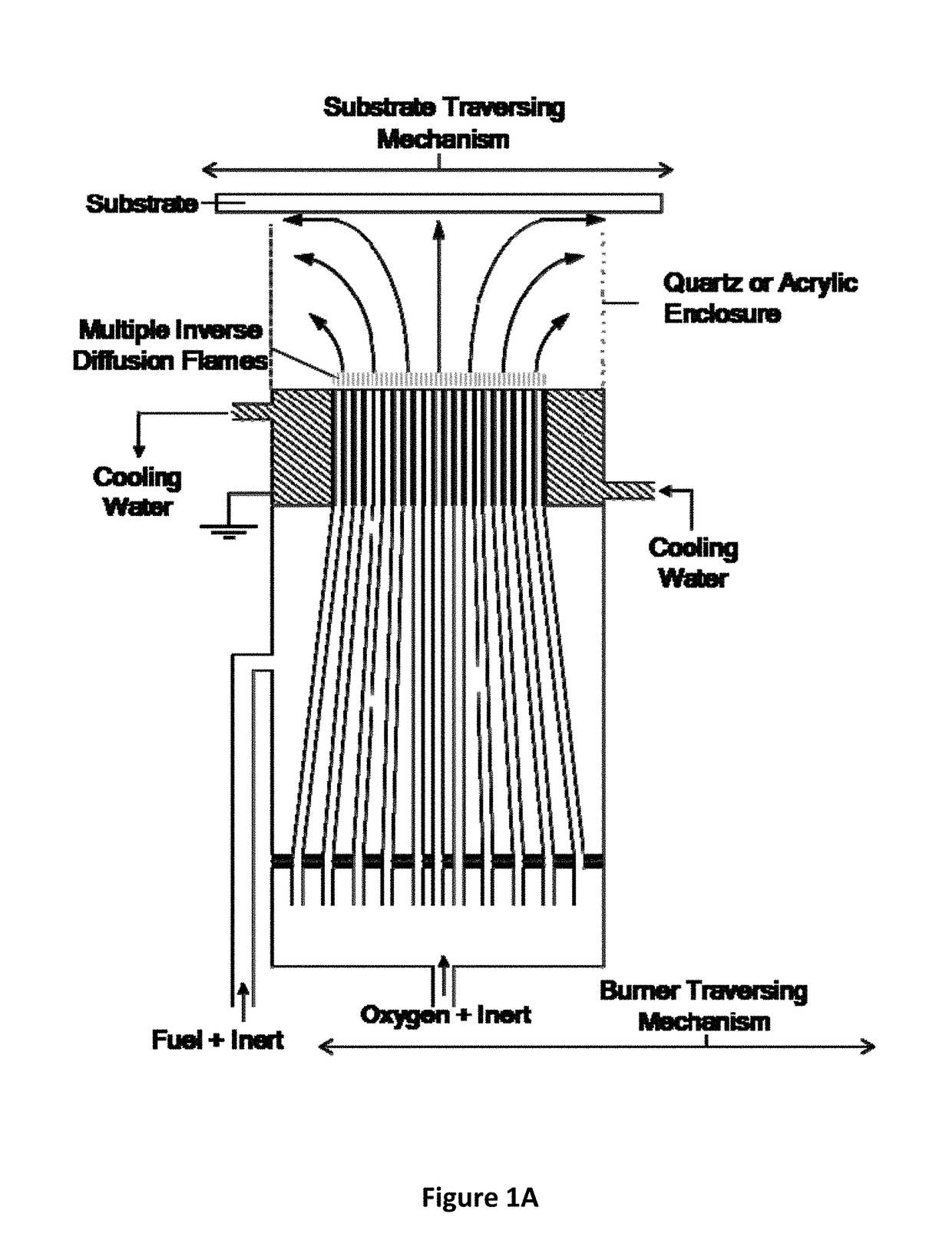

Hydrogen separation alloy and method for producing same

InactiveUS20120138196A1Improve the immunityImprove hydrogen permeabilitySemi-permeable membranesMembranesAlloyElectron microscopic

Disclosed is a hydrogen separation alloy which is adoptable to a product having a large surface area of a side where hydrogen permeates and which has such a metallographic structure as to improve hydrogen permeability and to improve hydrogen-embrittlement resistance. The hydrogen separation alloy used herein is represented by the compositional formula: Nb100−(α+β)M1αM2β where M1 is at least one element selected from the group consisting of Ti, Zr and Hf; M2 is at least one element selected from the group consisting of Ni, Co, Cr, Fe, Cu and Zn; 10≦α≦60, 10≦β≦50, and α+β≦80. The alloy contains inevitable impurities. And the alloy includes two phases, i.e., an Nb-M1 phase serving as a hydrogen-permeable phase, and a M2-M1 phase serving as a hydrogen-embrittlement-resistant phase. The hydrogen-permeable phase and the hydrogen-embrittlement-resistant phase have an elongated structure resulting from rolling. The hydrogen-permeable phase occupies 35% to 70% of an arbitrary 10 μm×10 μm region in a 50 μm×50 μm observation plane of a cross section of the alloy under an electron microscopic observation, the cross section is taken in a direction of thickness reduced by the rolling and in a direction of rolling and flattening.

Owner:HITACHI METALS LTD

Scalable Multiple-Inverse Diffusion Flame Burner for Synthesis and Processing of Carbon-Based and Other Nanostructured Materials and Films and Fuels

ActiveUS20170210628A1High strengthEfficient extractionSemi-permeable membranesHydrogenDiffusion flamePhysical chemistry

Owner:RUTGERS THE STATE UNIV

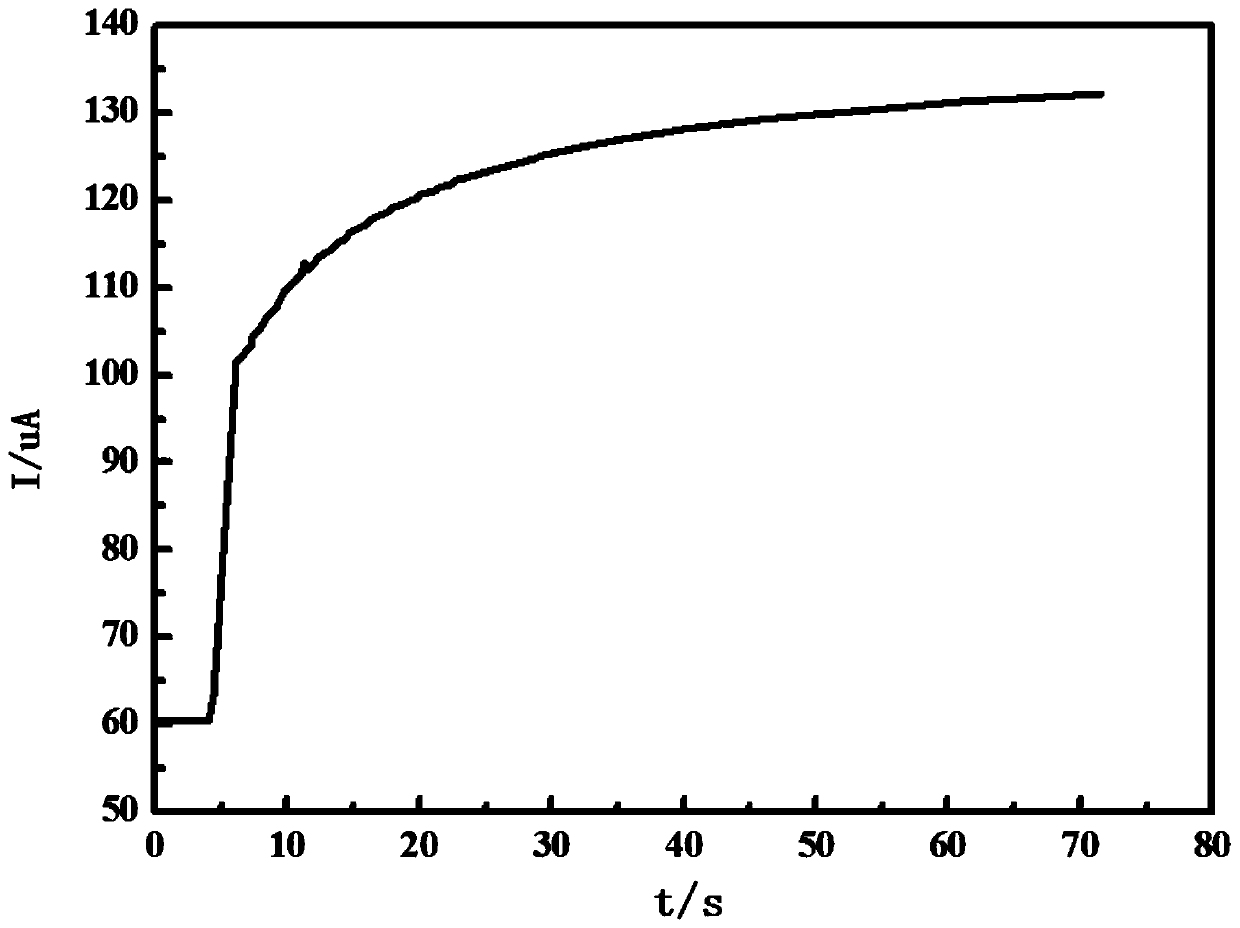

Nickel/titanium/vanadium nanowire alloy hydrogen permeability membrane and preparing method and application

InactiveCN110306096AImprove hydrogen permeabilityImprove plastic toughnessSemi-permeable membranesNanowireIngot casting

The invention discloses a nickel / titanium / vanadium nanowire alloy hydrogen permeability membrane and a preparing method and application. The method comprises the following steps that nickel, titaniumand vanadium particles are taken and evenly mixed to obtain mixed metal powder; the mixed metal powder is put into a smelting device to be smelted, and a nickel / titanium / vanadium alloy ingot casting is obtained; the nickel / titanium / vanadium alloy ingot casting is subjected to heat preservation for 30 min at the temperature of 900 DEG C, furnace cooling to the room temperature is carried out, and annealing is finished; the annealed nickel / titanium / vanadium alloy ingot casting is forged, the forging temperature is 750 to 850 DEG C, forging starting temperature is 780 DEG C, and rod-like nickel / titanium / vanadium alloy is obtained; the nickel / titanium / vanadium alloy is subjected to drawing at the temperature of 450 to 550 DEG C, and the filamentous nickel / titanium / vanadium nanowire alloy hydrogen permeability membrane is obtained. The prepared nickel / titanium / vanadium nanowire alloy hydrogen permeability membrane has the higher hydrogen permeability rate, higher plasticity and toughness and lower hydrogen embrittlement susceptibility.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com