Mixed conductor hydrogen permeation membrane containing Zr system and Tm system perovskite and preparation method and application thereof

A technology of mixed conductors and hydrogen permeable membranes, applied in separation methods, semipermeable membrane separations, chemical instruments and methods, etc., can solve problems such as poor mechanical stability, achieve high mechanical properties, high proton conductivity and mechanical stability, The effect of high proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

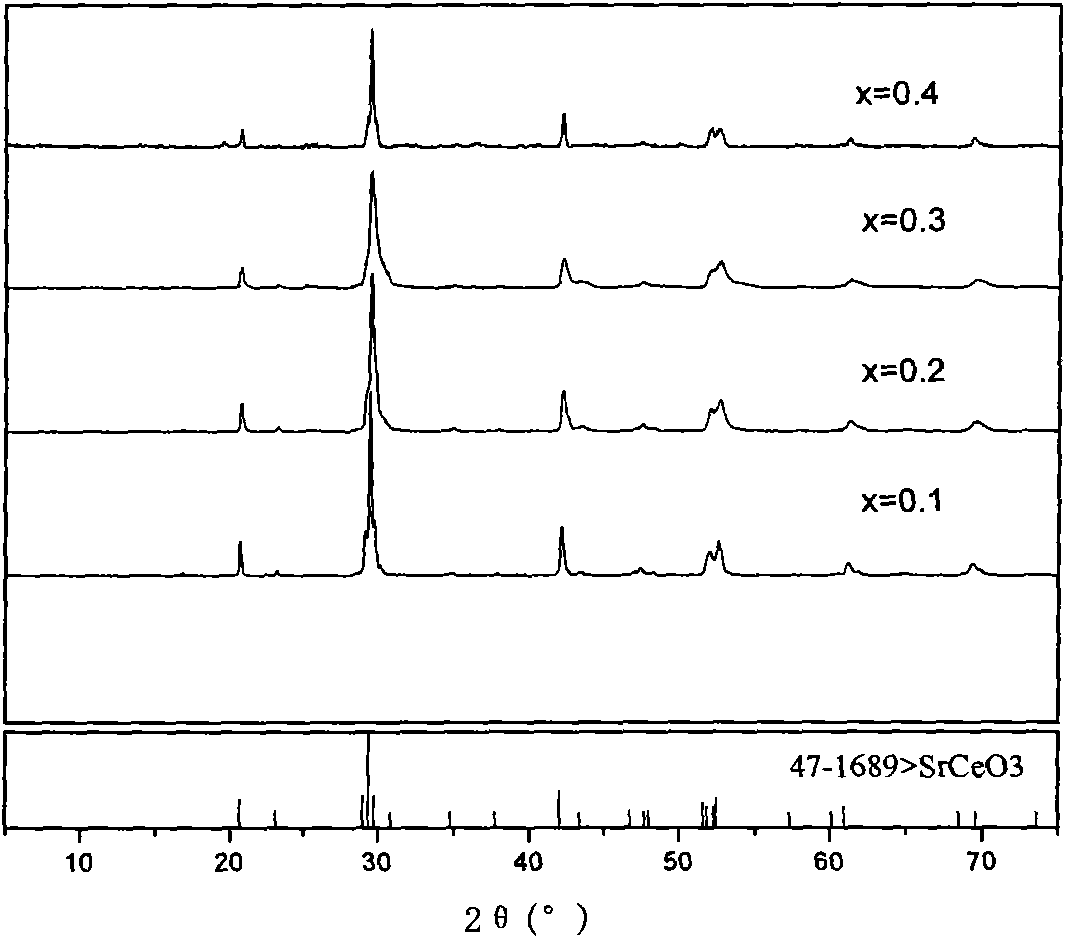

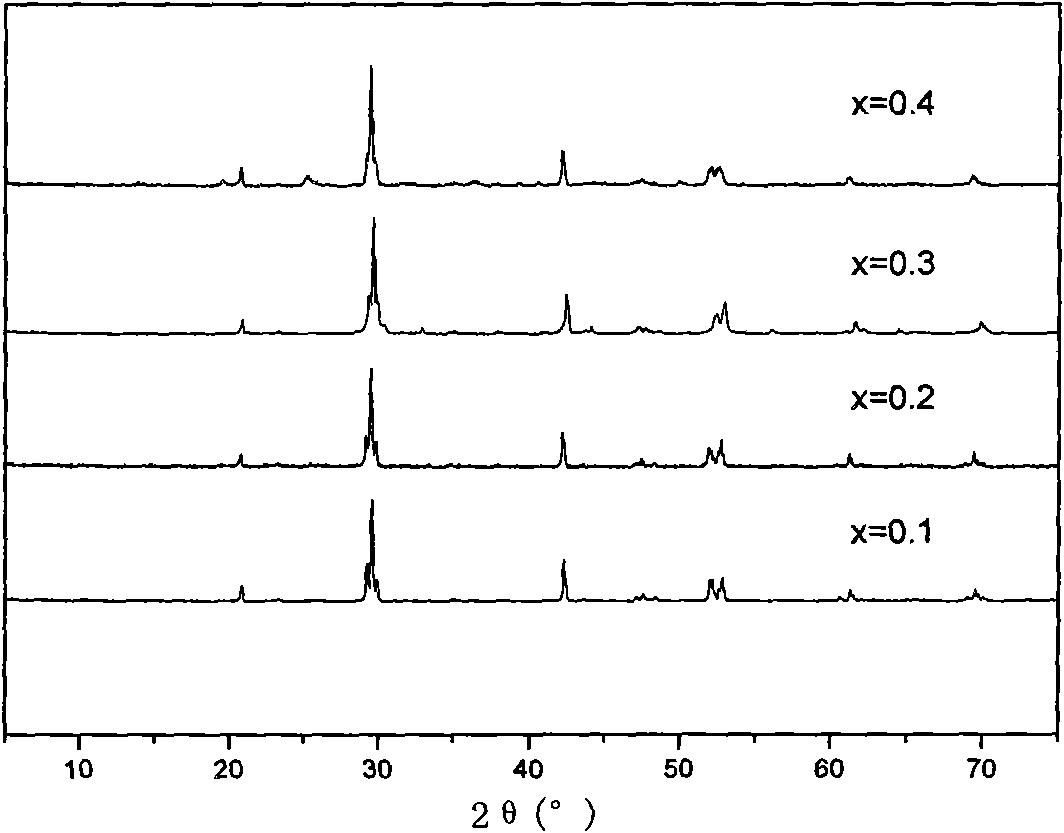

[0032] Preparation of 0.1mol SrCe by EDTA-citric acid joint complexation 0.85 Zr 0.10 T m 0.05 o 3-δ Powder: weigh 0.05molSr(NO 3 ) 2 , 0.0425mol Ce(NO 3 ) 4 , 0.005mol Zr(NO 3 ) 3 2H 2 O, 0.0025mol Tm (NO 3 ) 3 ·6H 2 Dissolve the four raw materials in 250ml of distilled water, put them into a heat-resistant beaker and stir for 30min, then add 0.1mol EDTA and stir for 30min, then add 0.15mol of citric acid, stir for 30min, add analytical reagent NH 3 ·H 2 O adjust the pH of the mixed solution to 8, heat and evaporate the mixed solution at 100°C to form a gel, and finally sinter the gel at 1000°C for 8 hours to obtain SrCe 0.85 Zr 0.1 T m 0.05 o 3-δ Powder, the obtained powder was subjected to phase analysis, the results are as attached figure 1shown. The diaphragm was prepared by static tableting method, 0.44g of perovskite oxide powder was placed in a stainless steel mold with an inner diameter of 1.6mm, kept at 20MPa for 10min, the diaphragm was obtained un...

Embodiment 2

[0034] Preparation of 0.1mol SrCe by EDTA-citric acid joint complexation 0.75 Zr 0.20 T m 0.05 o 3-δ Powder: weigh 0.05molSr(NO 3 ) 2 , 0.0375mol Ce(NO 3 ) 4 , 0.01mol Zr(NO 3 ) 3 2H 2 O, 0.0025mol Tm (NO 3 ) 3 ·6H 2 Dissolve the four raw materials in 250ml distilled water, put them into a heat-resistant beaker and stir for 30min, then add 0.1mol EDTA and stir for 30min, then add 0.15mol citric acid and stir for 30min, add analytical reagent NH 3 ·H 2 O adjust the pH of the mixed solution to 8, heat and evaporate the mixed solution at 100°C to form a gel, and finally sinter the gel at 1000°C for 8 hours to obtain SrCe 0.75 Zr 0.2 T m 0.05 o 3-δ Powder, the obtained powder was subjected to phase analysis, the results are as attached figure 1 shown. The diaphragm was prepared by static tableting method, 0.44g of perovskite oxide powder was placed in a stainless steel mold with an inner diameter of 1.6mm, kept at 20MPa for 10min, the diaphragm was obtained under...

Embodiment 3

[0036] Preparation of 0.1mol SrCe by EDTA-citric acid joint complexation 0.65 Zr 0.30 T m 0.05 o 3-δ Powder: weigh 0.05molSr(NO 3 ) 2 , 0.0325mol Ce(NO 3 ) 4 , 0.015mol Zr(NO 3 ) 3 2H 2 O, 0.0025mol Tm (NO 3 ) 3 ·6H 2 Dissolve the four raw materials in 250ml distilled water, put them into a heat-resistant beaker and stir for 30min, then add 0.1mol EDTA and stir for 30min, then add 0.15mol citric acid and stir for 30min, add analytical reagent NH 3 ·H 2 O adjust the pH of the mixed solution to 8, heat and evaporate the mixed solution at 100°C to form a gel, and finally sinter the gel at 1000°C for 8 hours to obtain SrCe 0.65 Zr 0.3 T m 0.05 o 3-δ Powder, the obtained powder was subjected to phase analysis, the results are as attached figure 1 shown. The diaphragm was prepared by static tableting method, 0.44g of perovskite oxide powder was placed in a stainless steel mold with an inner diameter of 1.6mm, kept at 20MPa for 10min, the diaphragm was obtained unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com