Online hydrogen production system and method

A technology of hydrogen production system and hydrogen production chamber, which is applied in the field of hydrogen production, can solve the problems of large space occupation and low heating efficiency, and achieve the effects of saving space, compact structure design and speeding up the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

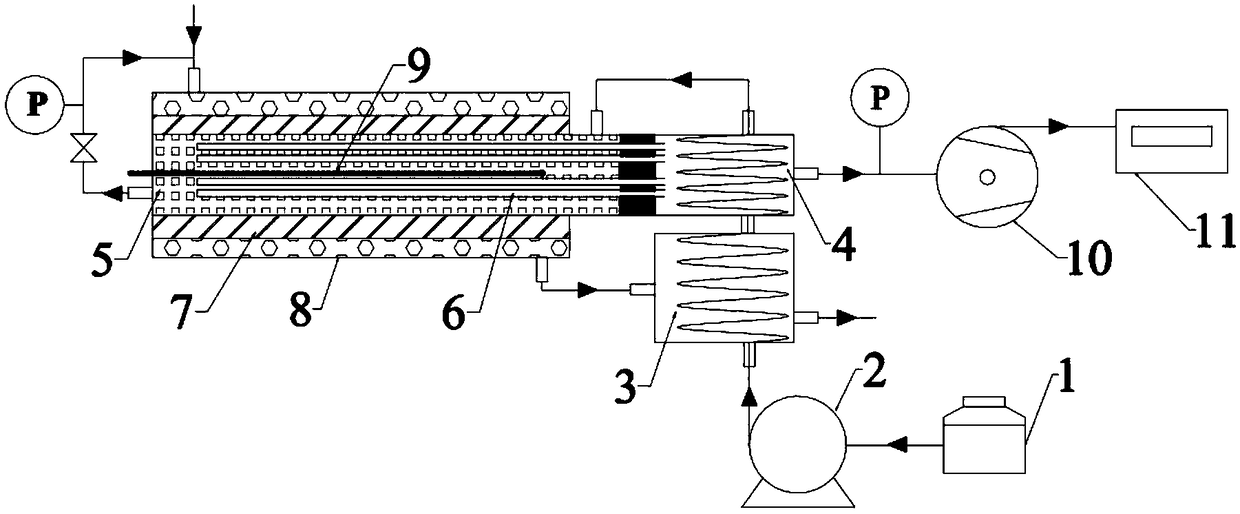

[0082] An online hydrogen production system for fuel cells, including a raw material supply unit, a gasification unit, a reforming hydrogen production unit, a heating unit, and a hydrogen detection and collection unit, the online hydrogen production system also includes a combustion unit, and the combustion unit includes combustion chamber;

[0083] The reforming hydrogen production unit includes a reforming hydrogen production chamber. The reforming hydrogen production chamber includes an upper shell, a hydrogen filter and a lower shell that are detachably connected in sequence. The upper shell is provided with an air inlet and an unreacted raw material outlet. , the lower casing is provided with a hydrogen outlet; the hydrogen filter includes a plurality of hollow fiber membranes and a fixing member for fixing the hollow fiber membranes;

[0084] The reforming hydrogen production chamber is arranged in the combustion chamber, and a heating unit is arranged between the combus...

Embodiment 2

[0107] An online hydrogen production system for fuel cells, such as figure 1 and figure 2 As shown, it includes a raw material supply unit, a gasification unit, a reforming hydrogen production unit, a heating unit, and a hydrogen detection and collection unit. The online hydrogen production system also includes a combustion unit, and the combustion unit includes a combustion chamber;

[0108] The reforming hydrogen production unit includes a reforming hydrogen production chamber. The reforming hydrogen production chamber includes an upper shell, a hydrogen filter and a lower shell that are detachably connected in sequence. The upper shell is provided with an air inlet and an unreacted raw material outlet. , the lower casing is provided with a hydrogen outlet; the hydrogen filter includes a plurality of hollow fiber membranes and a fixing member for fixing the hollow fiber membranes;

[0109] The reforming hydrogen production chamber is arranged in the combustion chamber, and...

Embodiment 3

[0127] The process of hydrogen production using the online hydrogen production system described in Example 2 is as follows:

[0128] Mix water and ethanol evenly at a ratio of 1:3, and then use the material liquid pump to inject into the first heat exchanger through the second heat exchanger. After gasification, the raw material is passed into the reforming hydrogen production chamber to reform and produce hydrogen. The 10 metal nickels are hollow The fiber membrane uses the vacuum pump connected to the permeate gas collection side to separate hydrogen from the mixed product, maintain a vacuum degree of 0.08MPa, and pump out the permeate gas to become hydrogen; among them, the tube lumen of the reforming hydrogen production chamber is filled with CuO-La 2 o 3 / CeO 2 -ZrO 2 Catalyst, the filler volume ratio is 0.75, the combustion chamber tube cavity is filled with Cu-Mn catalyst, the filler ratio is 0.8;

[0129] Open the control valve at the outlet of the reforming hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com