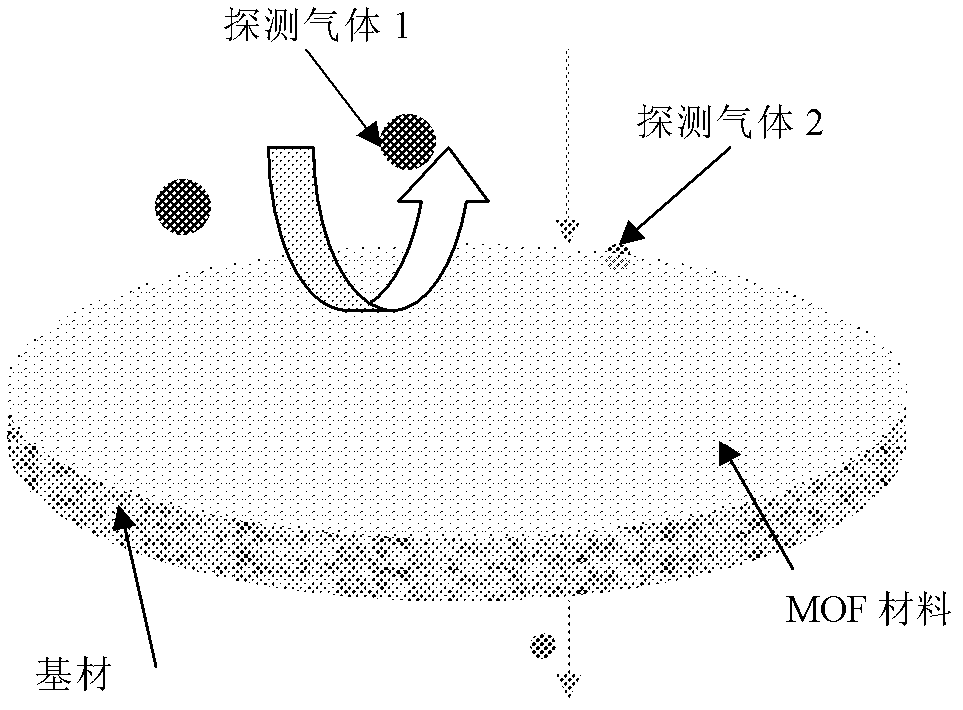

Metal-organic framework (MOF) material for permeating and separating gases and preparation method thereof

An organic framework and gas separation technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problem of poor formation of membrane materials and substrates, low permeability and separation coefficient of MOF membranes, and high permeability. Quantity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

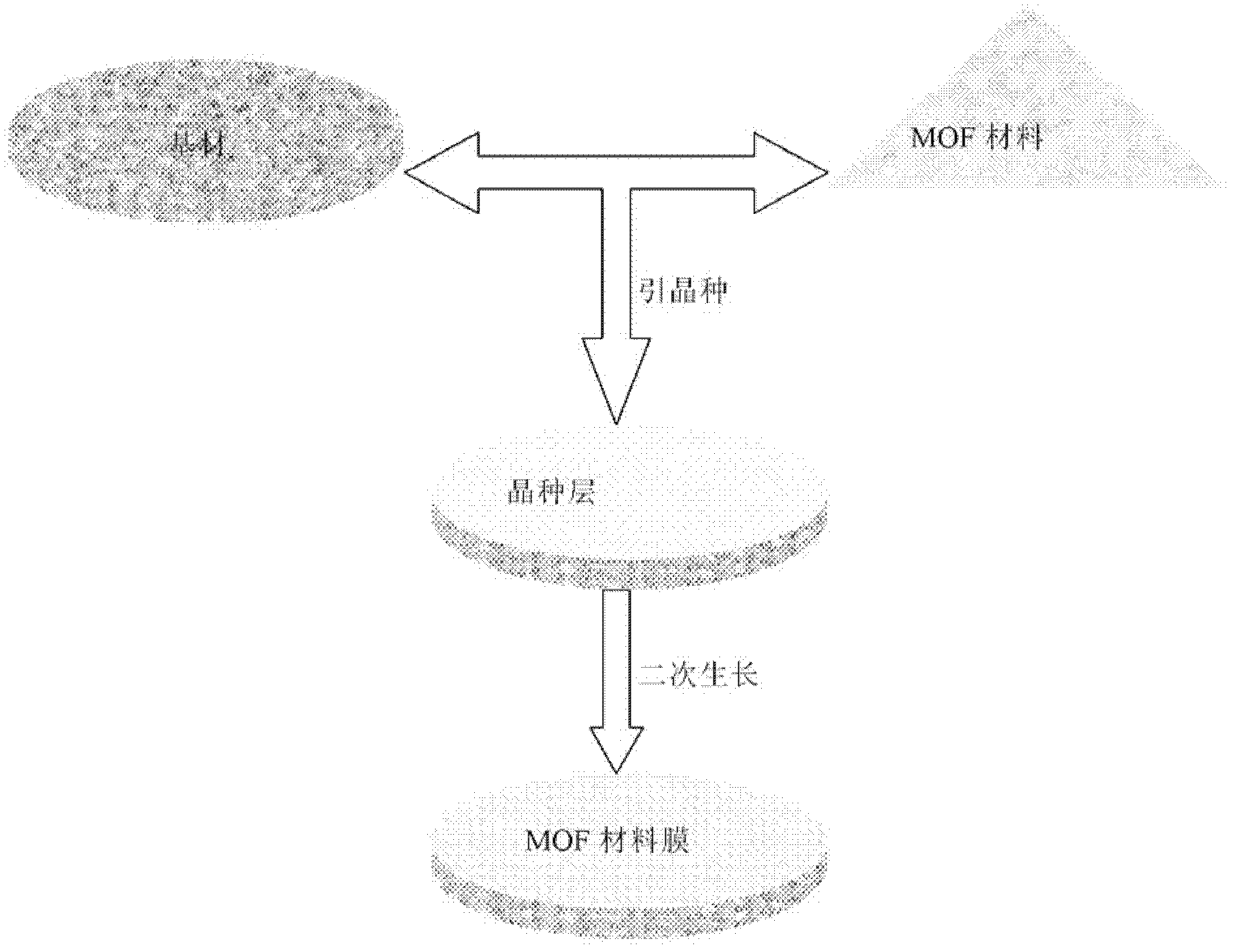

[0068] The preparation method of the metal-organic framework material film of the present invention comprises steps:

[0069] (i) introducing a metal-organic framework material seed crystal with a functional group on the substrate, thereby forming a substrate having a metal-organic framework material seed crystal with a functional group attached to the surface; and,

[0070] (ii) Place the substrate obtained in step (i) with the seed crystals of metal-organic framework materials with functional groups attached to its surface in the reaction system to perform a secondary film-forming reaction, thereby forming the metal organic framework material described in the present invention. - Membranes of organic framework materials.

[0071] Preferably, the steps include:

[0072] (i-1) providing a metal-organic framework material with functional groups;

[0073] Wherein, the preparation method of the metal-organic framework material with functional groups is a method commonly used by...

Embodiment 1

[0102] Embodiment 1MOF material film (NH 2 -MIL-53 film No.1)

[0103] (1.1) MOF materials (NH 2 - Synthesis of MIL-53 material):

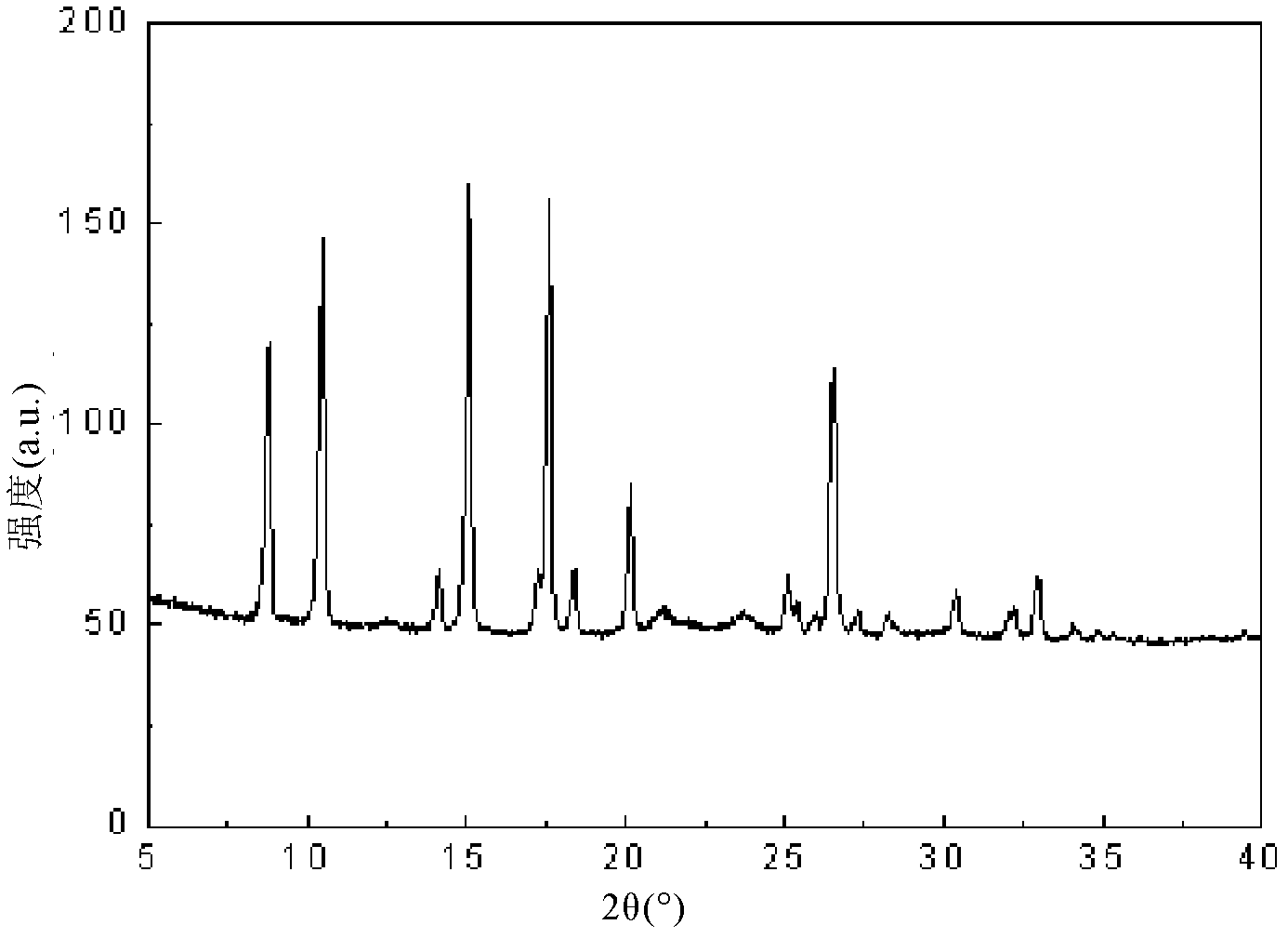

[0104] Aluminum nitrate, aminoterephthalic acid (NH 2 -BDC), deionized water according to the molar ratio: Al 3+ : NH 2 -BDC:H 2 O=1:1:139 mixed, stirred, ultrasonically oscillated, impregnated or a combination of the three methods, prepared into a uniform solution, and synthesized at 150 ° C for 5 hours, then filtered and centrifuged, dried and dried to form NH 2 - MIL-53 material powder, as seed crystal.

[0105] NH 2 -X-ray diffraction pattern and scanning electron microscope picture of MIL-53 material image 3 and Figure 4 Shown: The relative peak intensities in the X-ray diffraction pattern show that NH 2 -The crystallinity of MIL-53 grains is good, and there are no other impurity phases, and the prepared NH 2 - The scanning electron microscope image of the MIL-53 crystal grains shows that the morphology of the grains is relativel...

Embodiment 2-6

[0135] Embodiment 2-6MOF material film (NH 2 -MIL-53 film) No.2-6

[0136] Repeat Example 1, the difference is that the conditions or parameters described in Table 2 are used to replace the corresponding conditions or parameters in Example 1.

[0137] Table 2

[0138]

[0139] The test results show that within the error range, the prepared MOF material film (NH 2 -MIL-53 membrane) No.2-6 has similar gas permeation separation performance, and the hydrogen permeability of the membrane is 1.3×10 -5 to 2.0×10 -5 molm -2 Pa -1 the s -1 within range.

[0140] discuss:

[0141] The test results of embodiment 1 and comparative examples 1, 2, 3 are as shown in table 1, and it can be seen that: the film prepared by the method of the present invention has excellent performance, especially, its H 2 The penetration is significantly better than the existing technology (the penetration is about an order of magnitude improved), and its H 2 / CO 2 and H 2 / CH 4 The ideal separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com