Polymer based temperature-sensitive resistance material with negative temperature coefficient (NTC) effect and preparation method thereof

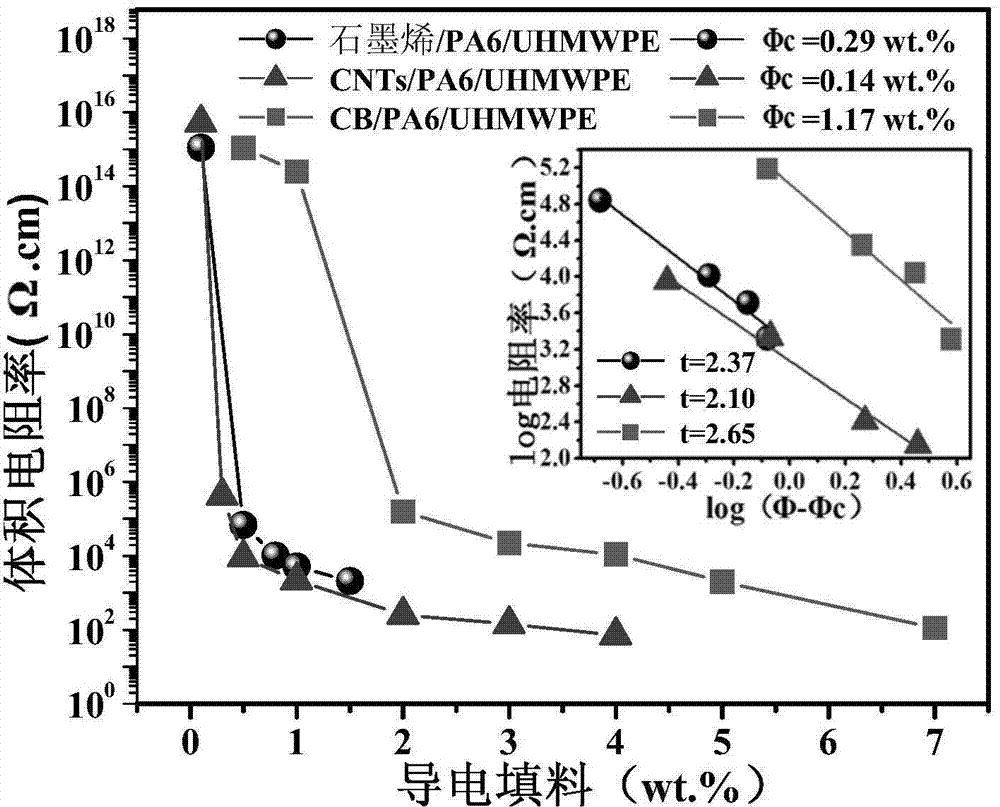

A technology of negative temperature coefficient and temperature sensitive resistance, which is applied in the field of preparation of conductive polymer composite materials, can solve the problems of high conductive phase filler, high room temperature resistivity, low sensitivity, etc., and achieve low processing temperature, stable electrical performance, Effect of low percolation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Preparation of polymer-based temperature-sensitive resistor material with negative temperature coefficient effect

[0050] Raw materials: the proportioning relationship of the amount of each raw material is shown in Table 1.

[0051] Preparation method: the specific preparation steps are as follows:

[0052] (1) Drying of raw materials: Dry PA6 and MAH-g-PE pellets in a vacuum oven for 8 hours at 80°C;

[0053] (2) Preparation of MAH-g-PE powder: Mix 25g MAH-g-PE pellets with 250ml xylene in a 500ml round bottom flask, and mechanically Stir for about 1 hour; then take out the MAH-g-PE solution completely dissolved in xylene and pour it into a petri dish, and place it in a ventilated place for 100 hours until it is completely dry; finally, break the dried block with a crusher To powder form, obtain MAH-g-PE powder;

[0054] (3) Composite material preparation: According to the ratio in Table 1, first dissolve PA6 in a formic acid solution with a temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com