Method for preparing sodium hexafluoroantimonate

A technology of sodium hexafluoroantimonate and sodium antimonate, applied in antimonate/antimonite and other directions, can solve problems such as long process, and achieve the effects of low comprehensive cost and easy control of stoichiometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

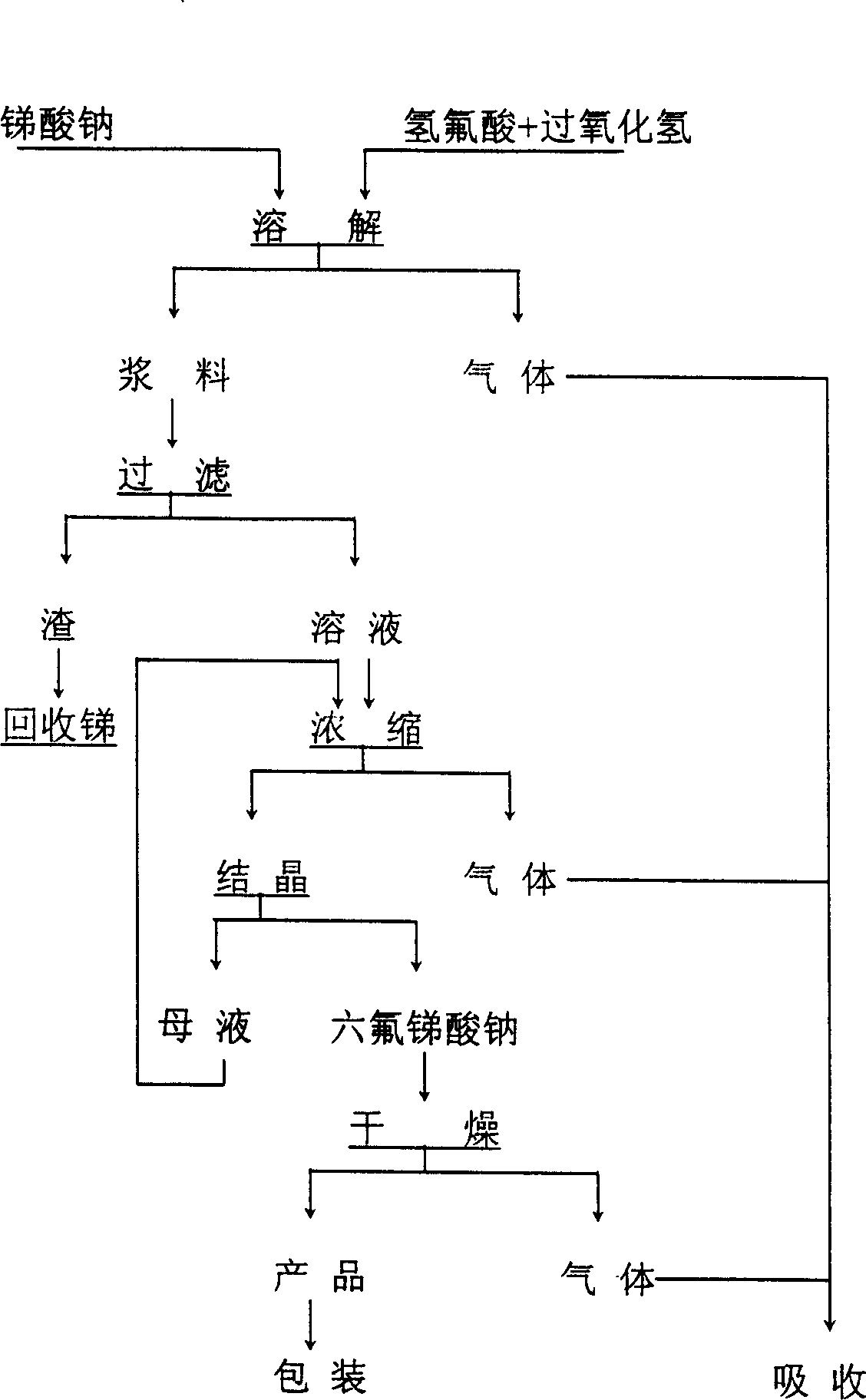

Image

Examples

Embodiment

[0028] Embodiment: industrial secondary sodium antimonate, its main component (%) is: Sb 48.39%, Sb 3+ 0.18, Fe 0.0126, Na 2 O 12.48, crystal water 21.49. Industrial grade hydrofluoric acid, its main components (%) are: HF≥55%, H 2 SiF 6 ≤0.4, non-volatile acid (as H 2 SO 4 Count) ≤ 0.05, Fe ≤ 0.01.

[0029] Put 50kg of industrial sodium antimonate of the above ingredients into a reaction kettle lined with polytetrafluoroethylene, then add 65kg of industrial hydrofluoric acid of the above ingredients, add 300ml of hydrogen peroxide, start stirring, and heat the reaction kettle until the reaction temperature is 95°C , keep warm for 0.5 hours, stop stirring, and cool. Put the reacted material into a plastic storage tank for clarification, and put the supernatant into a plastic filter barrel for natural filtration. The filtrate was put into a concentration kettle, and was indirectly heated to 125°C for concentration. When concentrated to a specific gravity of 1.8, discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com