Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

278results about How to "Realize closed loop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing titanium white

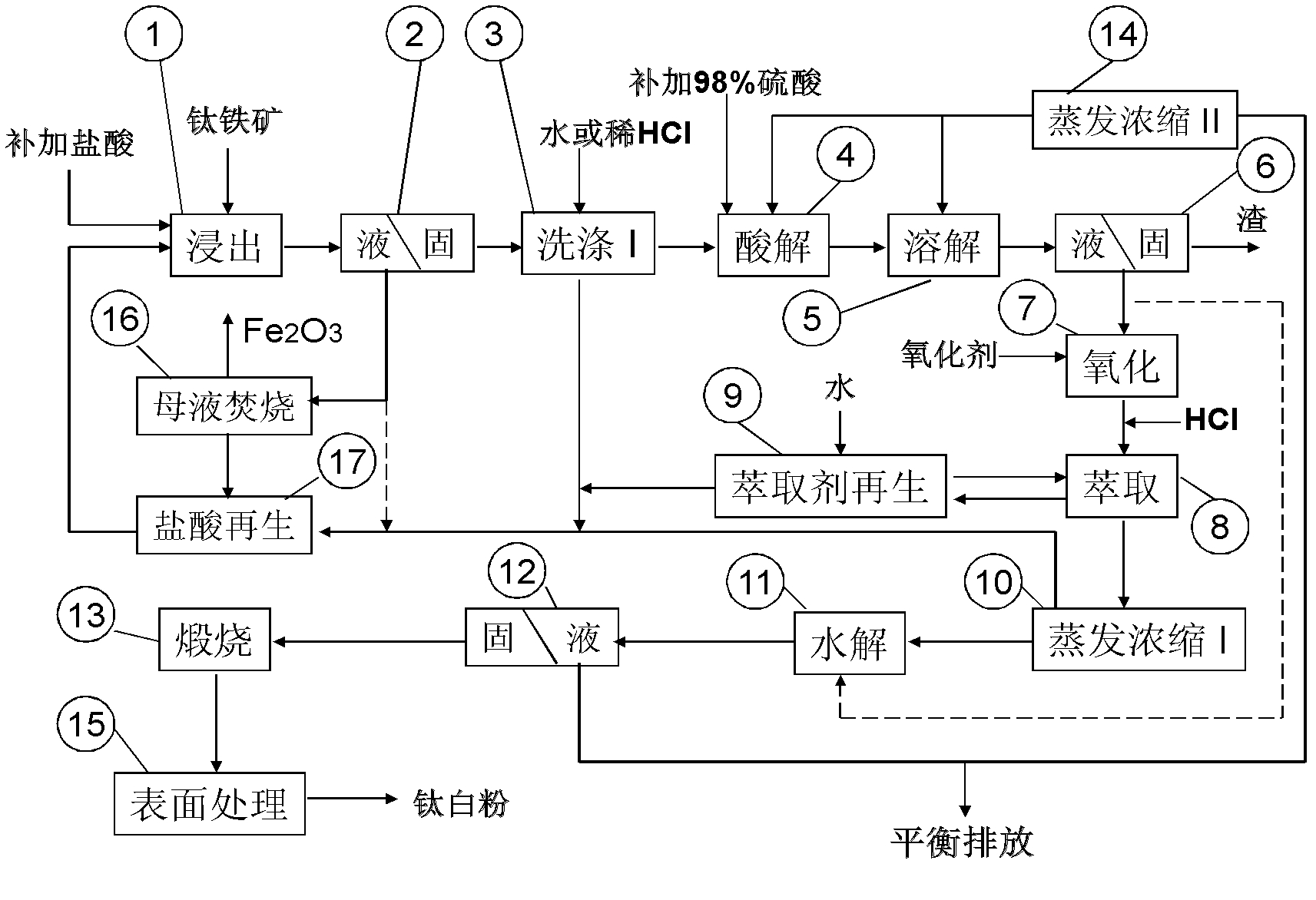

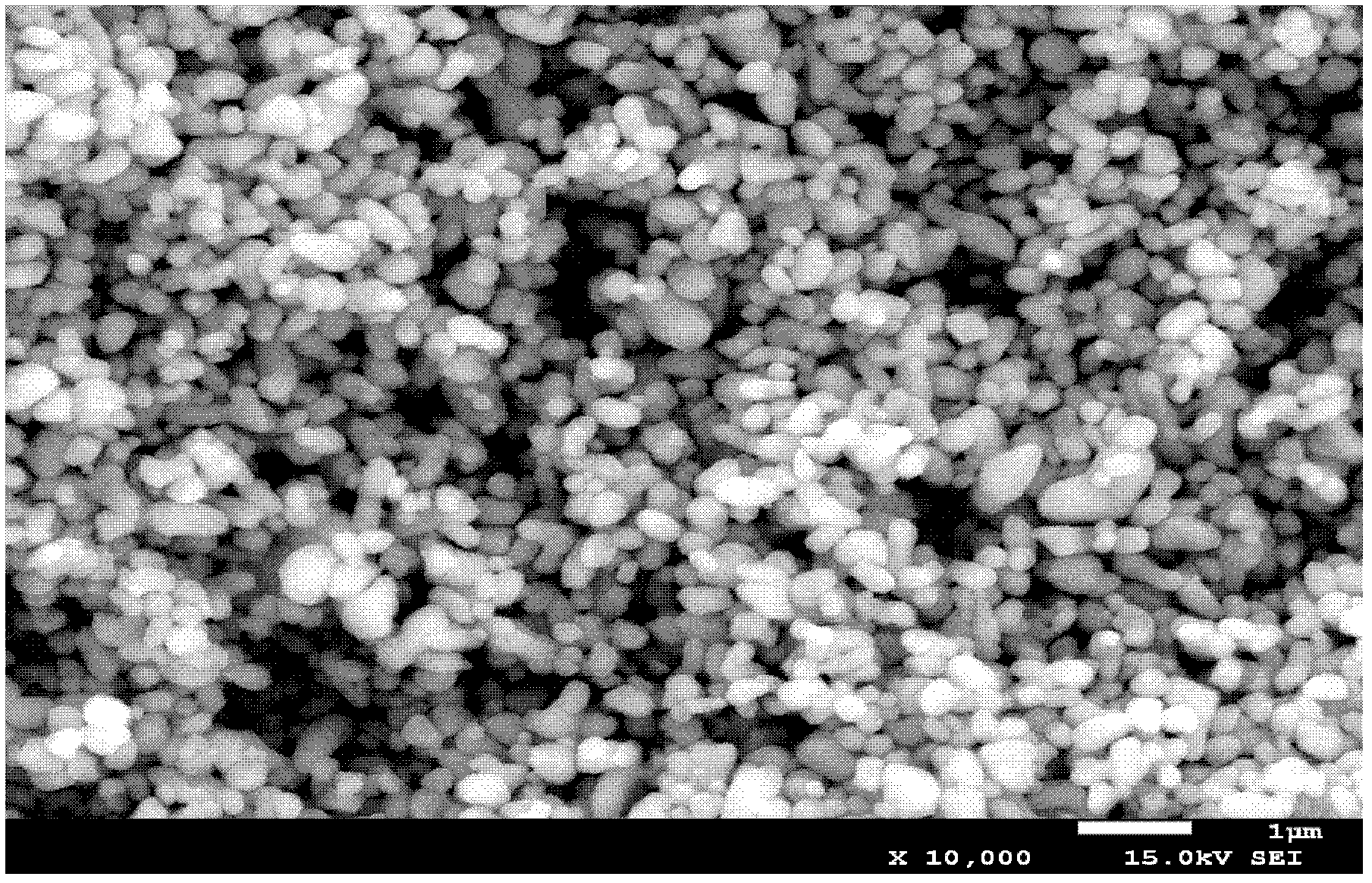

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

Comprehensive utilization method for bittern

InactiveCN101691239ARealize closed loopSimple process controlCalcium/strontium/barium carbonatesIodineSimple componentChemistry

The invention relates to a comprehensive utilization method for bittern, which belongs to the technical field of salt chemical engineering. The bittern is a liquid mineral product, and is rich in multiple elements such as potassium, sodium, lithium, boron, bromine, iodine and the like; and at present, in the prior domestic bittern development and utilization, some simple components or components with high additional value in the elements are extracted, and the un-extracted components are discharged along with old bittern to be abandoned so as to cause serious waste of resources and pollute the environment. Through reasonable combination of processes of removing H2S from the bittern, settling magnesium, settling calcium and preparing calcium carbonate, preparing potassium-sodium mixed saltthrough primary salt preparation and secondary salt preparation, extracting potassium chloride through flotation, extracting boron, iodine, bromine, rubidium and cesium through acidification, preparing rubidium chloride and cesium chloride, extracting lithium and the like, the method implements step-by-step ordered extraction of main components; the toil yield of several main components reaches over 95 percent; and the method has the advantages of mutually exclusive loss in component extraction, implementation of closed cycle of processes, no mother liquor discharge, simple process control, low cost, high yield, environmental protection and the like.

Owner:DAZHOU HENGCHENG ENERGY GROUP

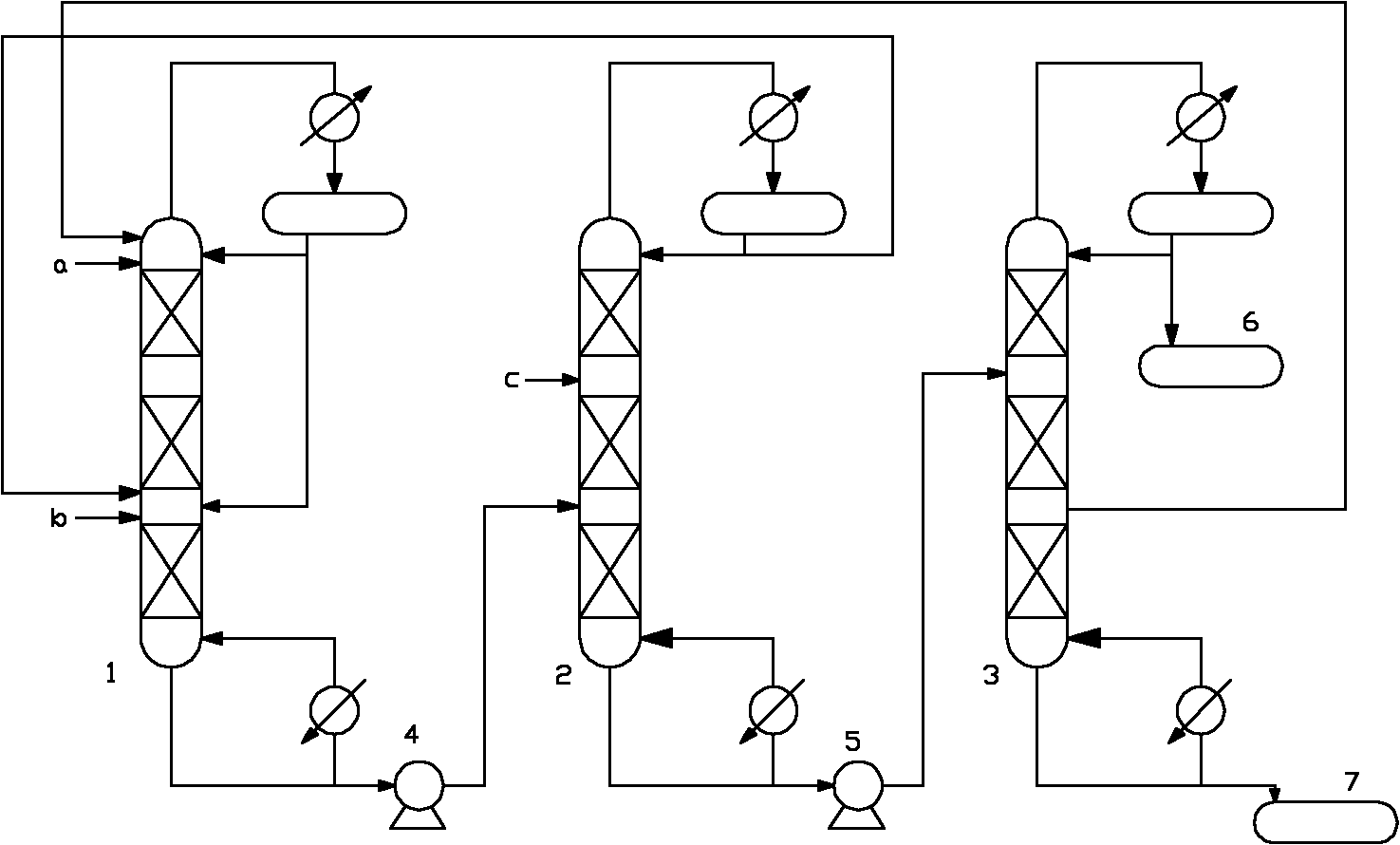

Method and apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction

ActiveCN101955187AResolve enrichmentIncrease profitChemical industryHalogenated silanesDichlorosilaneTower

The invention relates to a method and an apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction. The method comprises the following steps of: reacting dichlorosilane with silicon tetrachloride in the upper middle part of a reaction rectification tower, obtaining incompletely reacted dichlorosilane at the top of the reaction rectification tower; reflowing at the top of the tower and in the middle of the tower, obtaining a mixture of dichlorosilane, trichlorosilane and silicon tetrachloride at the bottom of the tower, entering a light-end removal tower to remove a light component, obtaining the dichlorosilane at the top of the light-end removal tower; reflowing to the reaction rectification tower for recycling, obtaining a mixture of trichlorosilane and silicon tetrachloride at the bottom of the tower, entering a heavy-end removal tower to separate the trichlorosilane from the silicon tetrachloride, wherein the trichlorosilane at the top of the heavy-end removal tower is a product; and taking out the silicon tetrachloride at the side line of the lower part of the tower, entering the reaction rectification tower for recycling, and obtaining excessive silicon tetrachloride at the bottom of the tower. In the invention, by utilizing the proportionate reaction, the utilization ratio of the raw materials is enhanced; the problem of dichlorosilane and silicon tetrachloride enrichment is solved; and the final conversion ratio of the dichlorosilane is ensured to reach 100 percent theoretically.

Owner:TIANJIN UNIV

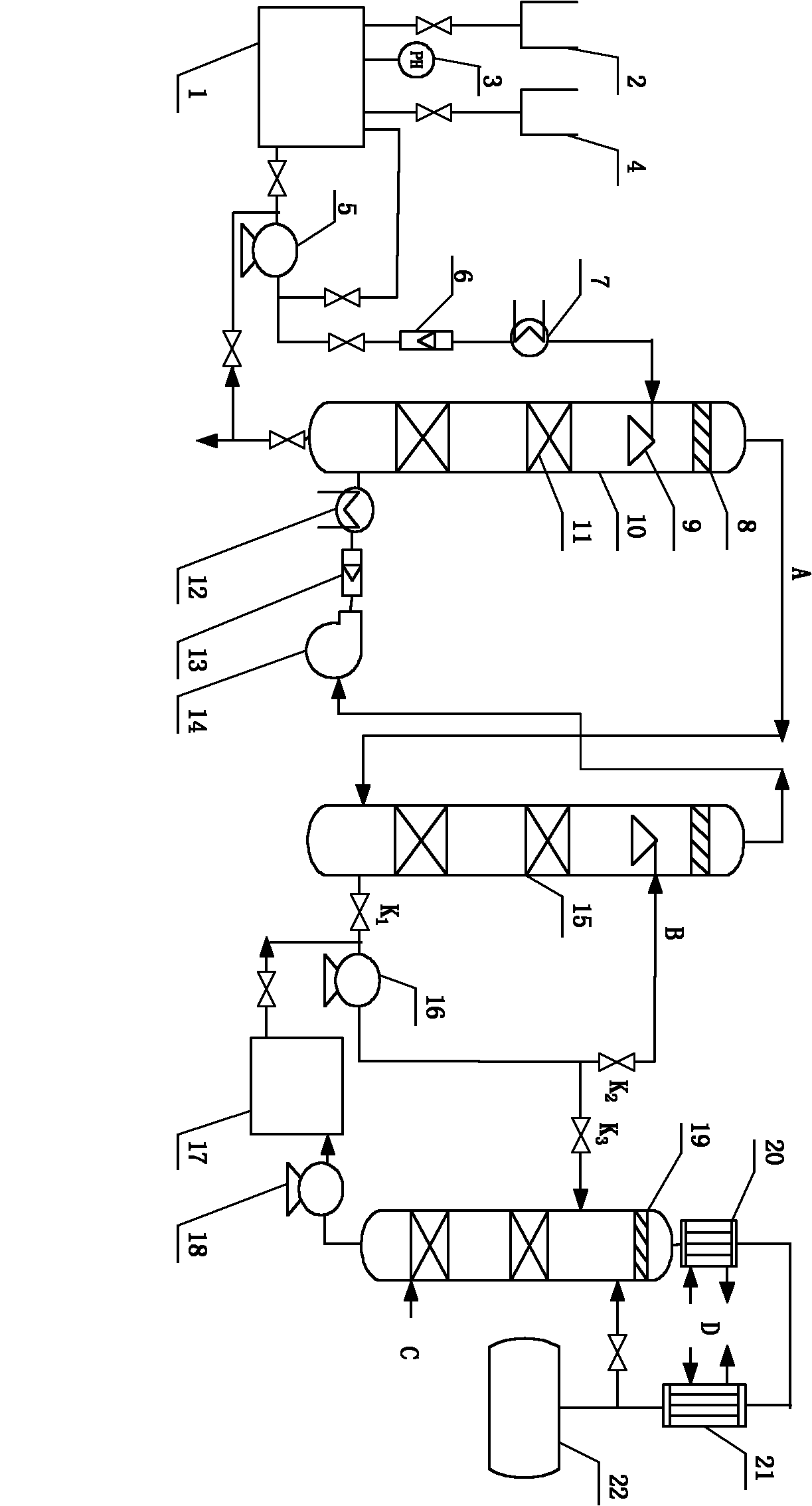

Closed-loop processing integrated process for high-efficiency air stripping and tail-gas ammonia recycling of ammonia-nitrogen wastewater

ActiveCN102060406AImprove ammonia removal efficiencyReduce the gas-liquid volume ratioChemical industryMultistage water/sewage treatmentExhaust gasProcess engineering

The invention relates to a closed-loop processing integrated process for the high-efficiency air stripping and the tail-gas ammonia recycling of ammonia-nitrogen wastewater, which is characterized in that: by selecting the types of fillers, tower internals and the like of an ammonia-nitrogen air-stripping tower and strengthening a gas-liquid mass transferring process, the ammonia removing efficiency is improved, and meanwhile, the gas-liquid volume ratio is reduced, thereby the energy consumption is markedly reduced; the invention provides a renewable ammonia-absorbing solution which can be used for efficiently absorbing the ammonia in air-stripping gas, and the ammonia is regenerated and desorbed to obtain strong ammonia water with the concentration of 10-25wt%, therefore, the high-efficiency recovery and the recycling of the ammonia in the air-stripping gas is realized, and the absorbing solution is recycled after being regenerated; the purified gas after absorption is used as the air-stripping gas for closed-loop circulating by adopting a closed-loop circulating technology, thereby the reaction heat in the absorbing process is effectively recovered, the energy consumption is further reduced, and meanwhile, the secondary pollution is eliminated; and the ammonia-removing and recycling processes of the wastewater are developed into a set of modularized process technologies by applying an integrated technology, thereby the technical requirements of industrial enterprises on processing the ammonia-nitrogen wastewater with different concentrations are satisfied.

Owner:NANJING UNIV OF TECH

Method for extracting vanadium from stone coal pickle liquor

InactiveCN103789560AShort processLess reagent consumptionProcess efficiency improvementSolventAluminium

The invention discloses a method for extracting vanadium from stone coal pickle liquor. The technical process mainly comprises the steps of extracting the stone coal pickle liquor subjected to aluminum removal through an acidic phosphate ester extracting agent solvent to remove ferric iron, enriching the vanadium through the acidic phosphate ester extracting agent solvent after the iron is removed and the pH of the liquor is adjusted, neutralizing precipitates with the vanadium-enriched liquor to obtain vanadium dioxide hydrate, refining the vanadium dioxide hydrate, calcining the refined vanadium dioxide hydrate to obtain a vanadium oxide product and the like. The method for extracting the vanadium from stone coal pickle liquor has the advantages of short technical flow, low consumption of reagents, low production cost, high product quality, environment friendliness and the like.

Owner:CENT SOUTH UNIV

Powder coal gasification powder processing and water recovery integrated system for high-moisture coal and method of system

ActiveCN103234214AReduce water dischargeTake advantage ofDrying solid materials with heatIndirect carbon-dioxide mitigationMoistureVacuum pump

The invention relates to a powder coal gasification powder processing and water recovery integrated system for high-moisture coal. The system comprises a steam indirect heat transfer drying machine, an absorption tower, a flash tower, a vacuum pump / Venturi injection pump and a raw coal bunker. The steam indirect heat transfer drying machine is connected with the raw coal bunker, a bag-type dust collector I and a surge bunker; the surge bunker is connected with a coal mill; the coal mill is connected with a hot blast heater, and a bag-type dust collector II and a delivery pipe II are arranged at the top of the coal mill respectively; the top of the absorption tower is connected with a carrier gas initial heater, a circulating pump is arranged at the bottom, and the side of the absorption tower is connected with the flash tower; the circulating pump is connected with an air heater and connected with the carrier gas initial heater; the air heater is connected with the flash tower and the hot blast heater respectively; the flash tower is connected with a condenser which is connected with the vacuum pump / Venturi injection pump; and the flash tower is connected with the carrier gas initial heater. The invention further discloses an application method of the system. According to the system and the method, the investment is small, and energy consumption can be reduced effectively.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

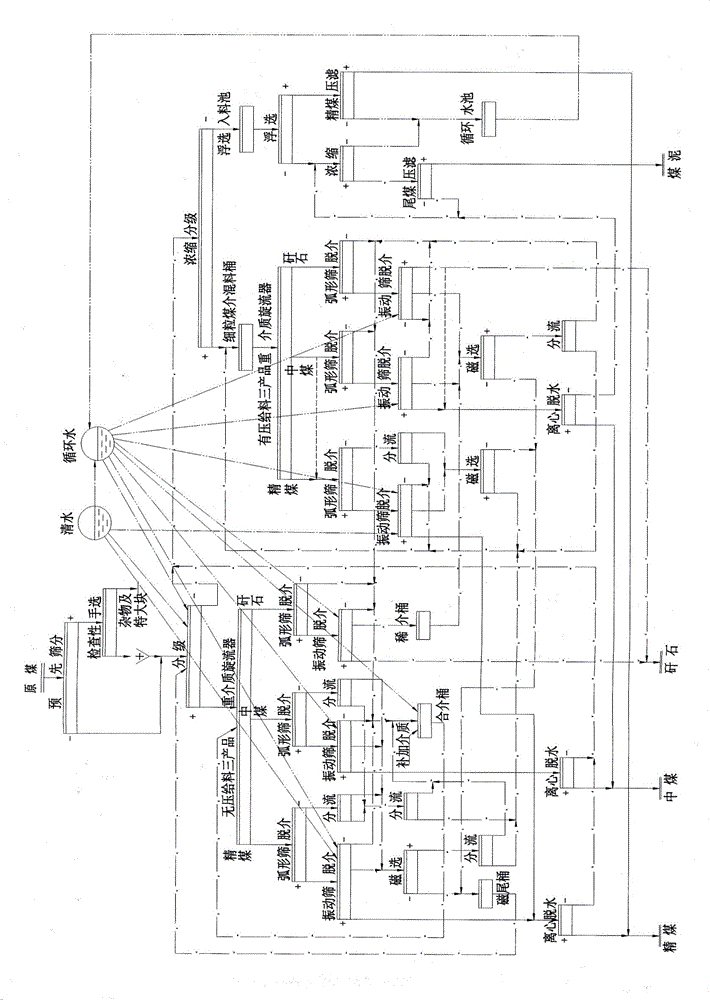

Wide-grain-grade double-dense-medium process for separating all coarse coal slime

The invention discloses a wide-grain-grade double-dense-medium process for separating all coarse coal slime. The wide-grain-grade double-dense-medium process includes that raw coal is preliminarily sieved, manually picked and graded, then oversize products can be used as coarse grain coal, the coarse grain coal is fed into a non-pressure tri-product dense-medium cyclone to be separated, undersize products are concentrated and graded and then are dehydrated in an underflow manner to be used as fine grain coal, the fine grain coal is fed into a pressure tri-product dense-medium cyclone to be separated, and excess flow is fed into a flotation filter-press system, so that the coal slime can be separated; qualified suspension liquid of a fine grain coal dense-medium separating system is provided by coarse grain clean coal of a coarse grain coal separating system, lower branches of coarse grain middling coal primary-section medium removing equipment and branches of coarse grain clean coal and coarse grain middling coal magnetic separation concentration; dilute suspension liquid of coarse grain gangue products and dilute suspension liquid of middling coal and gangue products of a fine grain coal system are treated together; magnetic separation tailings are used as wetting water or primary spray water for grading screens. The wide-grain-grade double-dense-medium process has the advantages that the fine grain coal dense-medium system has a medium automatic generating function, all the coarse coal slime can be efficiently separated by dense media, the suspension liquid is circulated in a closed-loop manner, the separation efficiency is high, the products are flexible in structure, and the production and operation costs are low.

Owner:TANGSHAN BRANCH COAL SCI ACAD

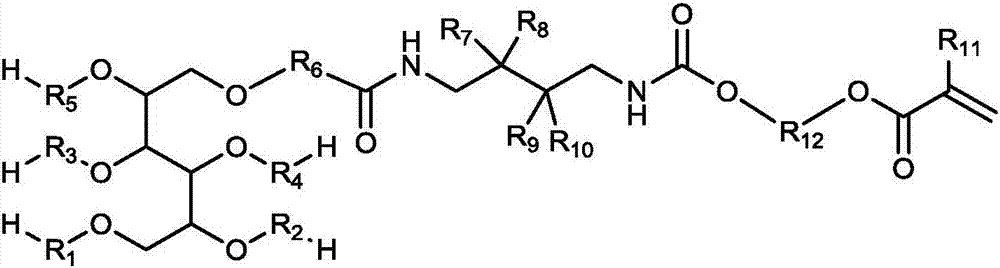

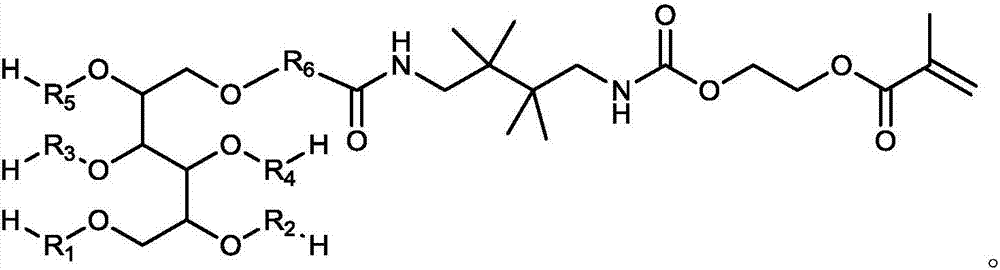

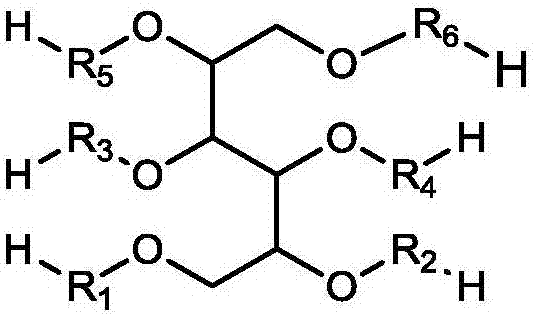

Macromonomer with multi-alkyl structure, preparation method and method for preparing polymer polyhydric alcohols by using macromonomer

The invention discloses a macromonomer with a multi-alkyl structure, a preparation method and a method for preparing polymer polyhydric alcohols by using the macromonomer. The basic polyether glycol is taken as a continuous phase and the macromonomer with the multi-alkyl structure is prepared into the polymer polyhydric alcohols under the effects of a chain transfer agent and a radical initiator. The initiator decomposition product can be used as the raw material for preparing the macromonomer with the multi-alkyl structure, so that the recycling of the chemical substances is realized, the use ratio of the atoms is increased, the generation of toxic and harmful waste residue is reduced and the three-waste treatment is reduced.

Owner:WANHUA CHEM GRP CO LTD

Method for preparing cryolite by alkaline leachate of cathode carbon block of aluminum electrolytic cell

The invention relates to a method for preparing cryolite by alkaline leachate of a cathode carbon block of an aluminum electrolytic cell, and belongs to a leachate preparation method. The method comprises the steps of grinding the cathode carbon block of the aluminum electrolytic cell to a certain particle size, mixing the ground cathode carbon block with alkaline liquid, carrying out size mixing, carrying out stirring leaching at a heating temperature of 20-90 DEG C, filtering to obtain first filtrate and a first filter residue, adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate, controlling the introducing velocity of CO2-rich gas to generate precipitates while heating and stirring, after the reaction is finished, filtering to obtain second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C, so as to obtain a cryolite product. According to the method, acidy leaching is replaced with alkaline leaching, so that the equipment requirements in the production process are reduced, processing processes such as flotation are omitted, an absorption process of hydrogen fluoride is omitted, and the processing process is simplified; a high-temperature processing process is saved, so that the energy consumption is reduced; and by adding crystal seeds, high-quality cryolite with the uniform particle size is generated when airflow rate is controlled. The method has the beneficial effects that the process is simple, a closed loop is utilized, the resource utilization rate is high, and the secondary pollution is avoided.

Owner:CENT SOUTH UNIV

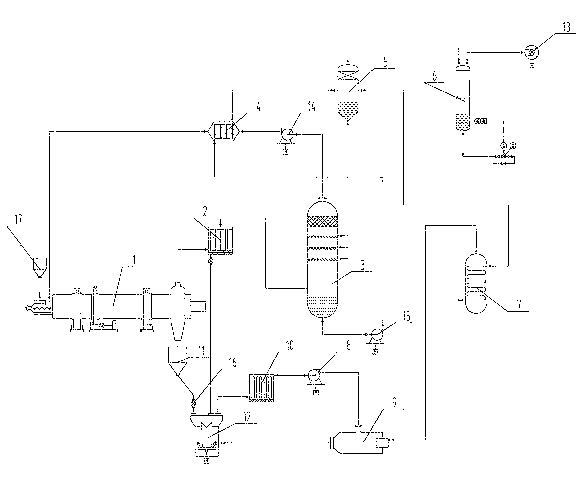

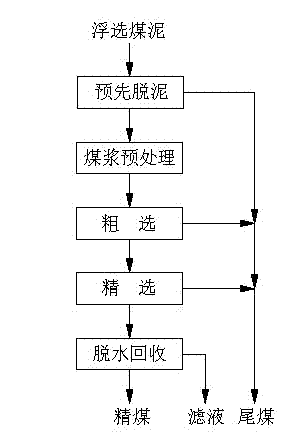

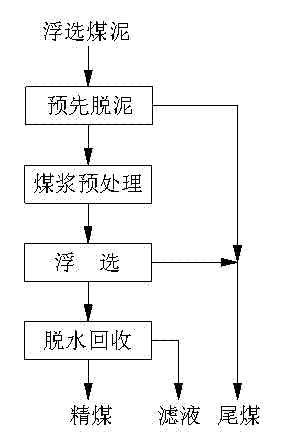

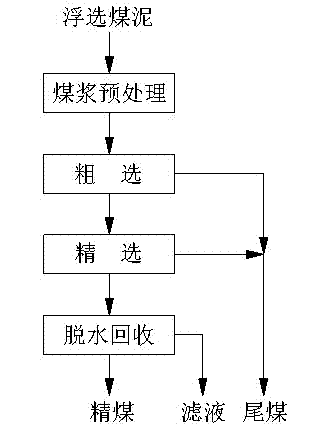

Flotation process method of high-ash-content fine coal slime

The invention relates to a flotation process method of high-ash-content fine coal slime. According to the method, pre-desliming is carried out by using a flotation coal slime flotation feeding desliming pond invented by Tangshan Guohua Technology International Engineering Co., Ltd., preprocessing is carried out by using a pulverization drop-type coal slurry preprocessor, and rough flotation and fine flotation are carried out by using an air jet flotation machine. The method comprises the following steps of: pre-desliming; preprocessing of the coal slurry; controlling of the feeding concentration of the flotation machine; and dehydration and recycling. According to the flotation process method of the high-ash-content fine coal slime, coking clean coal is sorted from inferior coal slime, the flotation process method is scientific and optimized, perfect indexes of sorting are substantially improved, the outward discharging of slime water is thoroughly avoided, the closed cycle of washing water of a coal cleaning plant is realized, and the method is scientific and environment-friendly.

Owner:唐山国华科技国际工程有限公司

Method for producing cryolites by using aluminum electrolytic cell cathode carbon block alkaline leaching solution

The invention relates to a method for preparing cryolites by using an aluminum electrolytic cell cathode carbon block alkaline leaching solution, and belongs to preparation methods of the cryolites. The method comprises the following steps: grinding aluminum electrolytic cell cathode carbon blocks finely to a certain particle size, performing slurry mixing with alkali liquor, and performing agitation leaching at a heating temperature of 20-90 DEG C; then performing filtration to obtain a first filtrate and a first filter residue; adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate; then controlling the speed of introducing NH3-rich gas or adding NH4F to generate a deposit under the action of heating agitation; and after reaction, performing filtration to obtain a second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C to obtain a cryolite product. According to the method provided by the invention, by replacing acid leaching with alkali leaching, the requirement of a production process on equipment is reduced, treatment processes including floatation are reduced, an absorption process of hydrogen fluoride is reduced, and the treatment process is simplified; a high-temperature treatment process is not used, so that the energy consumption is reduced; and by adding a crystal seed, high-quality cryolites with uniform particle sizes are generated under the condition that the airflow rate is controlled. The method provided by the invention is simple in process, achieves closed cycle, is high in resource utilization rate and avoids secondary pollution.

Owner:CENT SOUTH UNIV

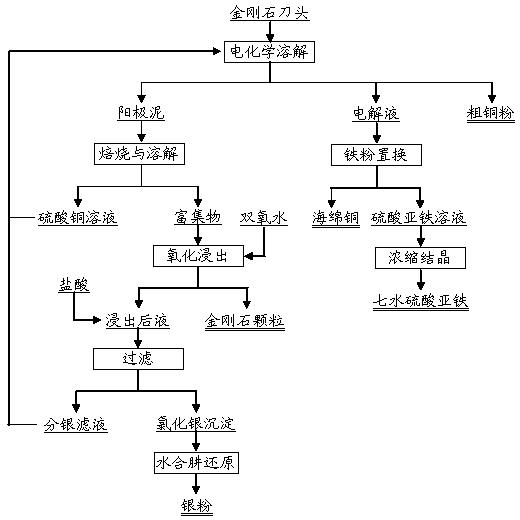

Method for processing waste copper/iron-based diamond tool bit

InactiveCN104046785AEfficient separationRealize closed loopProcess efficiency improvementIron sulfateClosed loop

The invention provides a method for processing waste copper / iron-based diamond tool bit. The method comprises the following steps: firstly, electrochemically dissolving the waste diamond tool bit in a sulfuric acid system so that most part of copper and iron are dissolved into the solution, while silver, diamond and the like are enriched into anode mud; secondly, roasting and oxidizing the anode mud and then adding the oxidized anode mud to the sulfuric acid so that the residual most part of copper is dissolved; next, adding the rest undissolved copper, silver and diamond particles to the sulfuric acid solution of hydrogen peroxide for further oxidizing leaching, recovering the diamond particles which are not dissolved, precipitating the silver in the solution by use of the hydrochloric acid and reducing the hydrazine hydrate to generate simple substance silver powder; finally, after displacing copper with iron powder, concentrating and crystalizing the electrolyte to directly prepare iron sulfate heptahydrate. The recovery rate of the copper is above 96%, while the recovery rate of the diamond particles and the silver is above 99%; the industrial-grade iron sulfate heptahydrate is directly produced, the recovery rate of iron is greater than 98%, closed-loop circulation can be realized, the production labor intensity is low and the method is environmental friendly.

Owner:CENT SOUTH UNIV

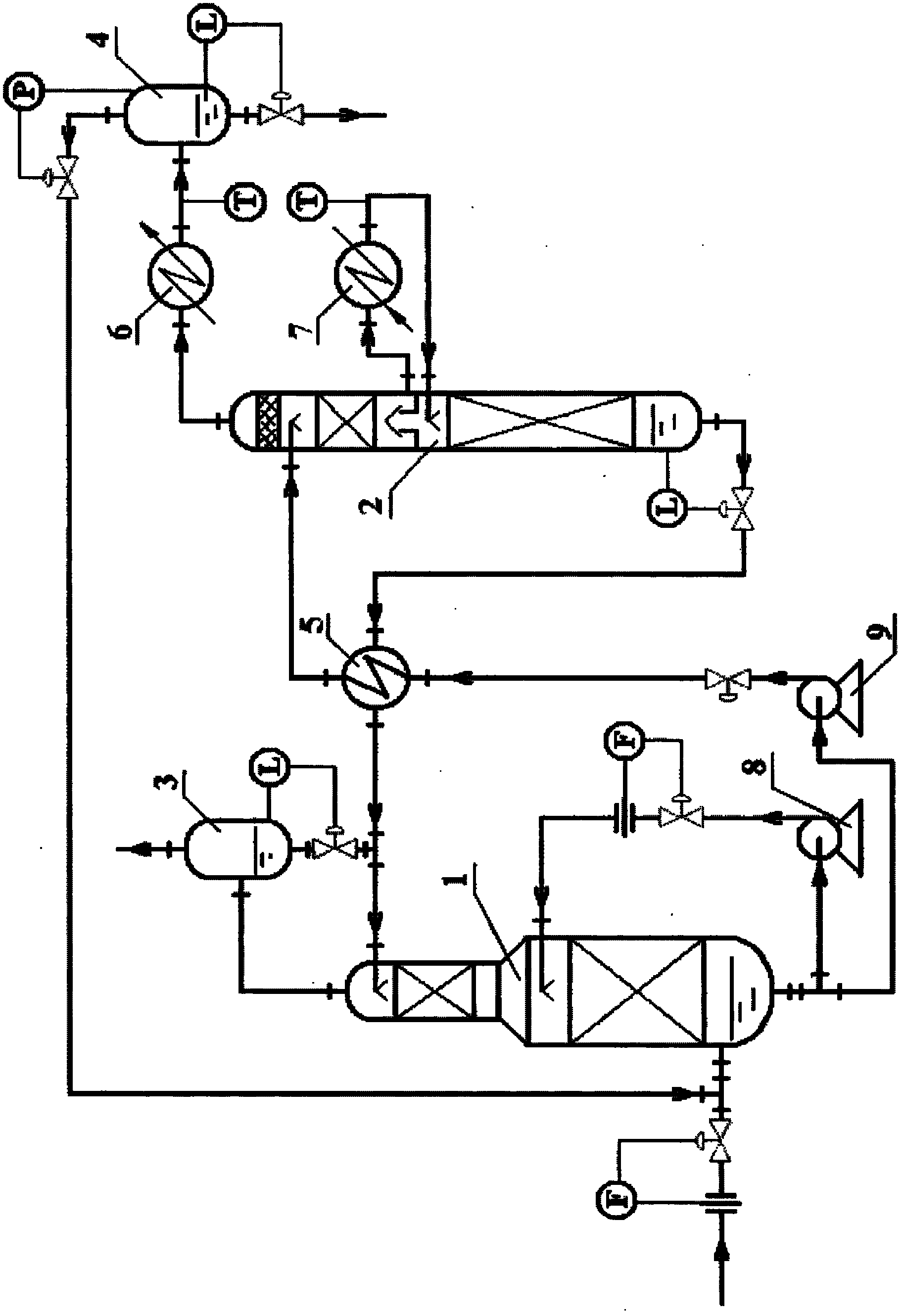

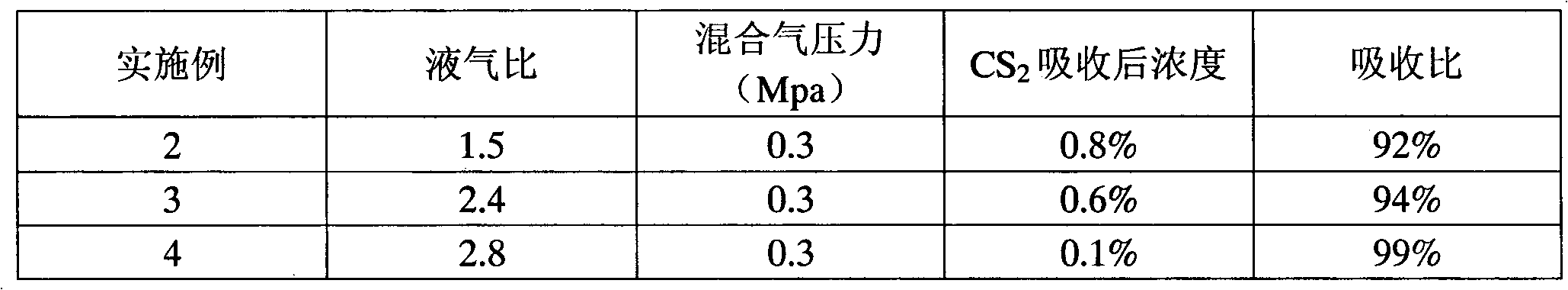

Device and method for absorbing carbon disulfide in hydrogen sulfide gas by using solvent

ActiveCN101912718AReduce the impactGood absorption and separation effectHydrogen sulfidesDispersed particle separationVapor–liquid separatorProduct gas

The invention discloses a device and a method for absorbing carbon disulfide in hydrogen sulfide gas by using solvent, which belong to the technical field of hydrogen sulfide gas and carbon disulfide preparation. The device of the invention mainly comprises an absorption tower, an analytical tower, a gas-liquid separator, a heat exchanger, a cooler, a heater, a pump, a valve and the like; and the method is to produce H2S and CS2 products by using the device and absorption and separation in a transfer mass dynamic control process and solvent. The device of the invention has a simple structure and low cost; and the method of the invention has the advantages of good absorption / separation effect, full utilization of resources, reduced energy consumption, low production cost and convenient popularization and application, wherein the absorption rate of CS2 is up to 99 percent. The device and the method of the invention can be widely applied to separation of H2S gases and CS2 in industrial production, particularly the separation of CS2 from H2S gases in the process of preparing CS2 by using natural gases.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Method for carbon dioxide suspension dealkalization of red mud for alumina plant

InactiveCN101927255ANo emissionsRealize sustainable comprehensive reuseSolid waste disposalCement productionChemical industryClosed loop

The invention relates to a dealkalization reutilization method of red mud which is a waste material produced by an alumina plant, which belongs to the technical field of chemical industry and environmental protection. The process comprises the following steps: (1) firstly baking the red mud in a muffle furnace, removing crystallization water in the red mud, and further smashing and grinding the red mud into powder; (2) placing the red mud powder after pretreatment in a dealkalization reactor, adding water, fully stirring and mixing into slurry; (3) introducing CO2 into the slurry-like red mud, and carrying out gas-liquid-solid three-phase dealkalization reaction; and (4) carrying out centrifugal separation on clarifying solution and solid residue after the reaction is finished and obtaining the red mud after the dealkalization. The method can realize the sustainable comprehensive reutilization of the waste; compared with the traditional quicklime dealkalization process, the CO2 suspension process has the advantages of simple operation, high dealkalization rate, high alkali purity of the obtained product, no emission of the wastes and the like; and the whole process can realize the closed loop circulation, and the reaction process does not produce the pollution of three wastes, thereby belonging to a green, environment-friendly and clean production process.

Owner:KUNMING UNIV OF SCI & TECH

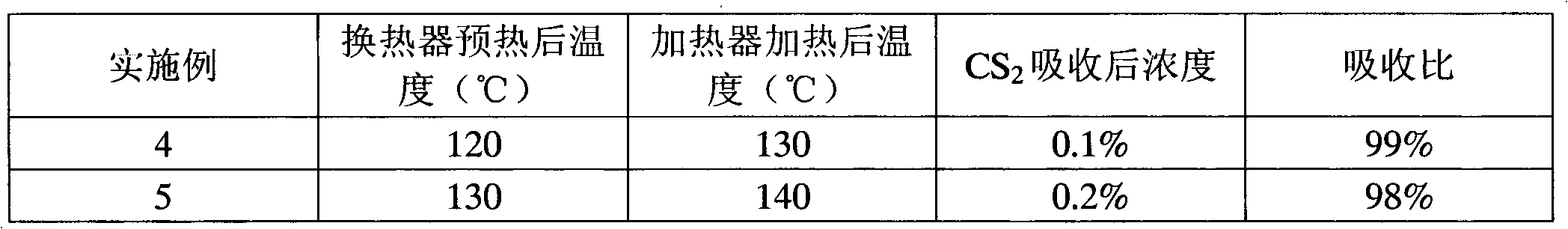

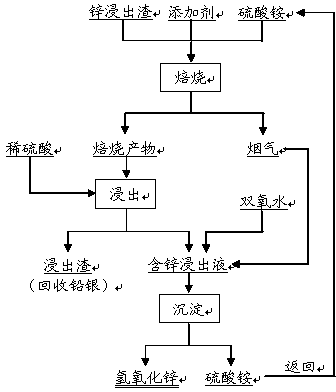

Method for separating zinc and iron from zinc leaching residues

InactiveCN104178642AAchieve regenerationIncrease incidenceProcess efficiency improvementZinc hydroxideSulfate zinc

The invention discloses a method for separating zinc and iron from zinc leaching residues. The method comprises the following steps: firstly, mixing the zinc leaching residues with ammonium sulfate and an additive, then performing roasting to ensure that zinc ferrite and the like in the zinc leaching residues are changed into soluble zinc sulfate and insoluble ferric oxide; secondly, directly leaching out a roasted product by using a dilute sulfuric acid solution; and finally, introducing fume which is produced during roasting and mainly contains ammonia gas into a zinc leaching solution to perform deposition so as to produce zinc hydroxide and an ammonium sulfate solution, and concentrating and crystallizing the ammonium sulfate solution to prepare ammonium sulfate which is returned to the ammonium sulfate roasting process. The ammonium sulfate roasting process in the method can ensure that a zinc ferrite phase in the zinc leaching residues is changed into soluble zinc sulfate, the leaching rate of zinc is more than 97%, and the leaching rate of iron is lower than 2%, so that the separation of zinc and iron is effectively realized; the ammonia gas produced in the ammonium sulfate roasting process is directly used for depositing zinc from the leaching solution, and the regeneration of ammonium sulfate can be realized while a zinc hydroxide product is generated; the comprehensive recovery rate of zinc is more than 96%; the method can realize closed-loop circulation and is relatively environment-friendly.

Owner:CENT SOUTH UNIV

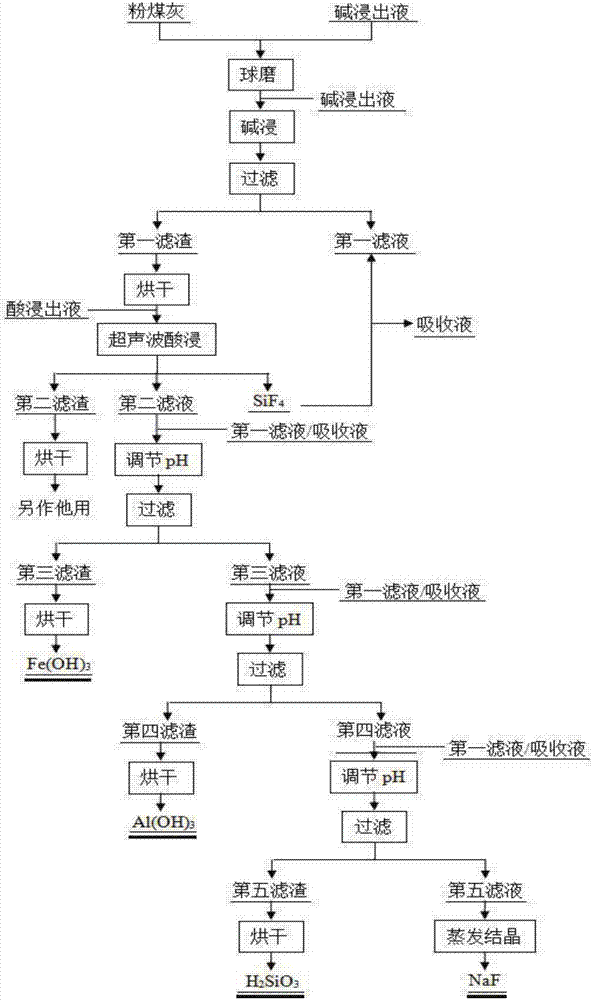

Combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of aluminum electrolysis cell waste cathode carbon block

InactiveCN107162061AEliminate hazardsLow costSilicaIron oxides/hydroxidesPregnant leach solutionElectrolysis

The invention discloses a combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of an aluminum electrolysis cell waste cathode carbon block. The pulverized fuel ash and the alkaline leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed and are subjected to ball milling; primary alkaline leaching is performed; then, the alkaline leaching liquid is replenished; secondary alkaline leaching is performed; solid and liquid separation of a secondary alkaline leaching system is separated to obtain first filter liquid and first filter slag; the first filter slag and the acid leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed; acid leaching is performed under the assistance of ultrasound; then, solid-liquid separation is performed to obtain second filter liquid; the pH of second filter liquid is increased in a gradient way; Fe(OH)3, Al(OH)3 and H2SiO3 are obtained from the second filter liquid through sequential separation; finally, the filter liquid subjected to H2SiO3 separation is concentrated to obtain NaF. The whole treatment method achieves the goals of treating wastes by wastes, reducing the energy consumption, reducing the consumption of industrial raw materials and reducing the equipment loss.

Owner:CENT SOUTH UNIV

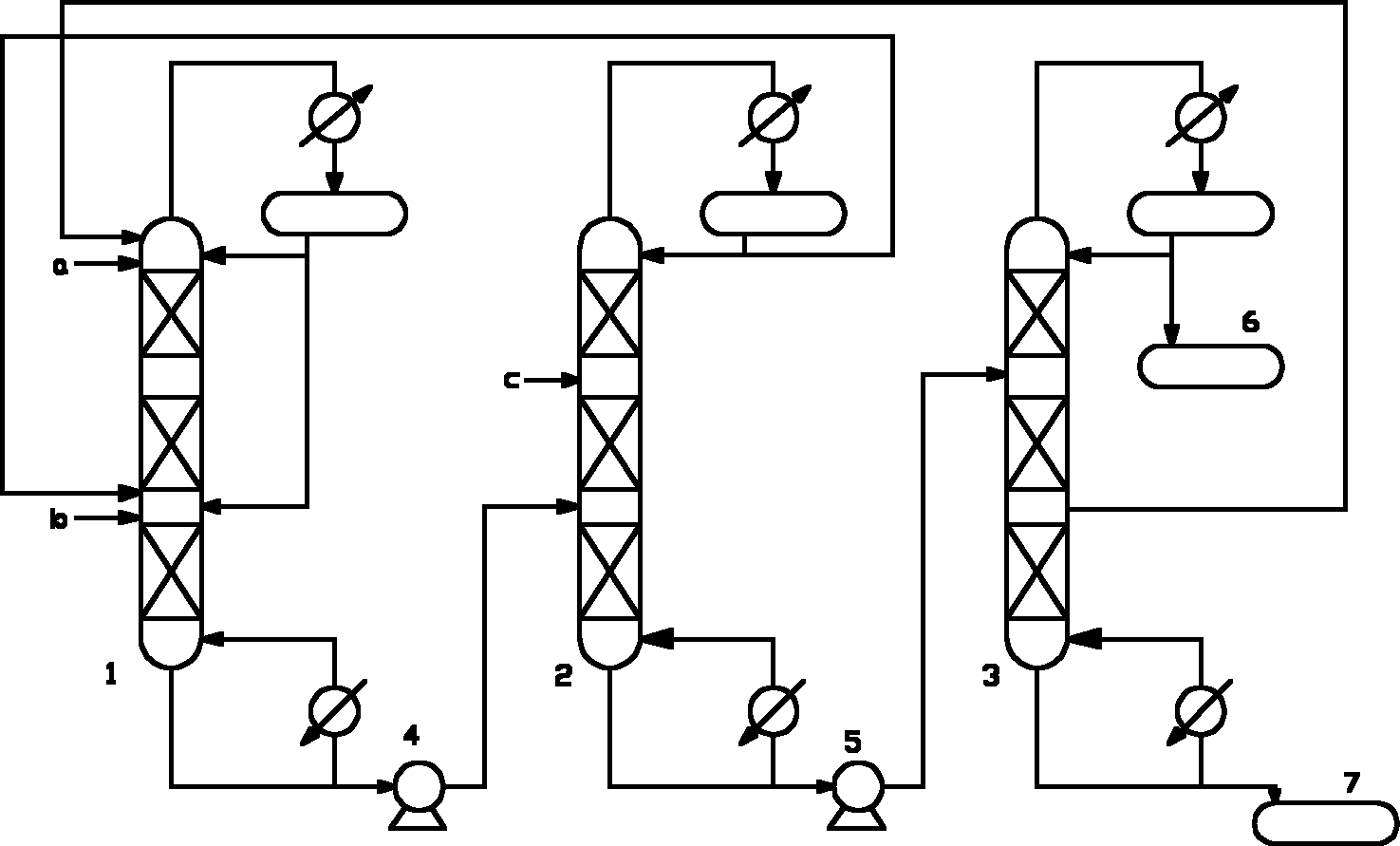

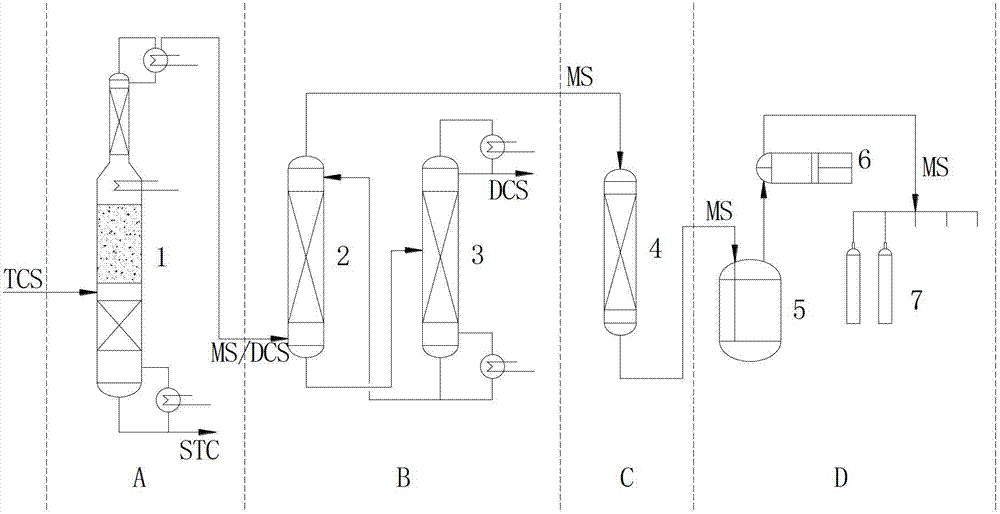

Device and method for preparing high-purity silane through disproportionation reactive distillation of trichlorosilane

ActiveCN103172071ASimple process equipmentRealization of multi-step disproportionation processChemical industrySilicon hydridesProcess equipmentGas phase

The invention relates to a device and a method for preparing high-purity silane through disproportionation reactive distillation of trichlorosilane. The method comprises a disproportionation reactive distillation process (A), a silicon tetrachloride absorption process (B), a fixed bed absorption process (C) and a product filling process (D). The method comprises the steps that: two-step disproportionation reaction is adopted, and the distillation separation action of a reactive distillation column is utilized to finally obtain a mixed gas of silane and dichlorosilane on a column top to be used as non-condensable gas of a condenser to be extracted, and a silicon tetrachloride product is obtained at a column bottom after reaction formation; a gaseous product which is recovered through a disproportionation reactive distillation column enters into a silicon tetrachloride absorption column, wherein the main ingredient of an absorbed gas is silane, an absorption liquid is filled into a silicon tetrachloride desorption column, the desorbed dichlorosilane is recovered on the column top, and the desorption liquid of the column reflows back to the silicon tetrachloride absorption tower; the absorbed gas is filled into a fixed bed to absorb so as to obtain a high-purity silane product; and the silane product is filled into a buffer tank under the pressurization condition. Technological equipment is simple, and the obtained silane product has high purity.

Owner:TIANJIN UNIV

Method and apparatus for atomizing, freezing and drying for powder production by using low-temperature low-dew point gas

InactiveCN101403561AReduce manufacturing costParticle rulesDrying solid materials with heatDrying solid materials without heatComing outFreeze-drying

The invention discloses a method for milling by low temperature low dew point gas spray freeze drying which uses an atomizer for nebulizing liquid to be dried into 1 to 250 micron droplets which are frozen into ice powder in the gas with the low temperature of -60 DEG C and the dew point of -70 to -80 DEG C, then air-intake temperature is adjusted to 2 to 4 DEG C lower than the eutectic temperature of materials, the gas passes through a pore plate of a fluidized bed to lead the ice powder which stays on the fluidized plate to be fluidized, and simultaneously the solvent in the ice powder is sublimated. The sublimation drying process is completed until the dew point of the gas at the gas vent returns to -55 to -60 DEG C. The ice powder is dried for 1 to 2 hours into powder products when the temperature is increased to 30 to 50 DEG C. The gas coming out of the gas vent returns to the place for low temperature low dew point gas preparation for recirculation. The method is characterized by easy operation, continuous duty, and the like, and is especially suitable for the drying of materials such as medicine, food, biochemical product, and the like, guarantees the quality of products and can directly obtain the dried powder products; simultaneously the drying time of the method is greatly shortened compared with the vacuum freeze drying.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Device for recovering waste heat and supplying steam through multistage dilatation flashing

ActiveCN103123107AIncrease the number of unitsTake advantage ofEnergy industrySteam generationEngineeringThermal water

The invention provides a device for recovering waste heat and supplying steam through multistage dilatation flashing. Hot water (or low-pressure steam or steam-water mixture two-phase flow) is used as a circulatory medium to absorb the high-temperature waste heat in the device; the high-temperature waste heat is changed into the steam with a pressure energy level, capable of being used by the device, through flashing, the dilatation flashing and steam jet type heat pump pressurization; and the steam is changed into condensate and returned to the system after being used, the steam and the low-temperature hot water after the dilatation flashing are delivered into the device to absorb high-temperature waste heat, and closed recirculation is formed. According to the device for recovering the waste heat and supplying the steam through the multistage dilatation flashing, energy can be fully absorbed and delivered in a long distance to heat using sites according to needs, the heat can be stably supplied, and the device can be suitable for waste heat recovery and steam supply of heat using units with used heat changed.

Owner:NINGBO JINHAI CHENGUANG CHEM +1

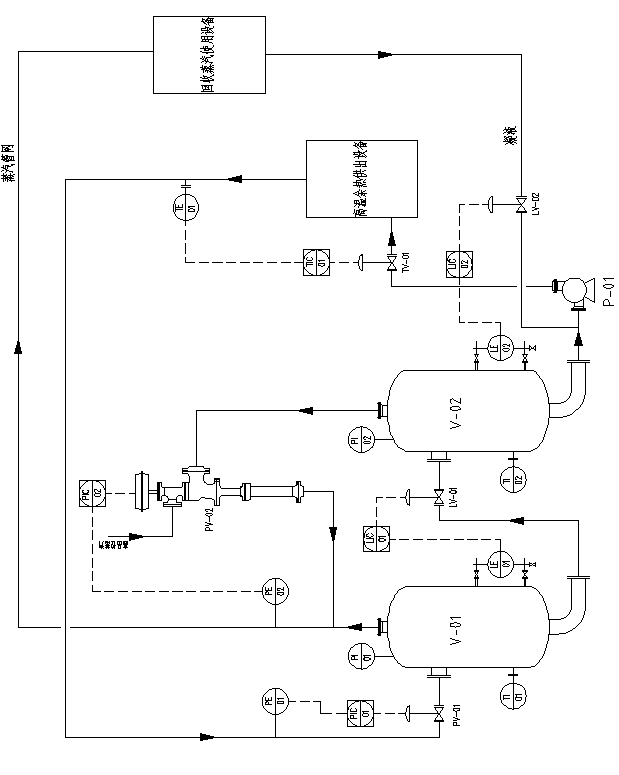

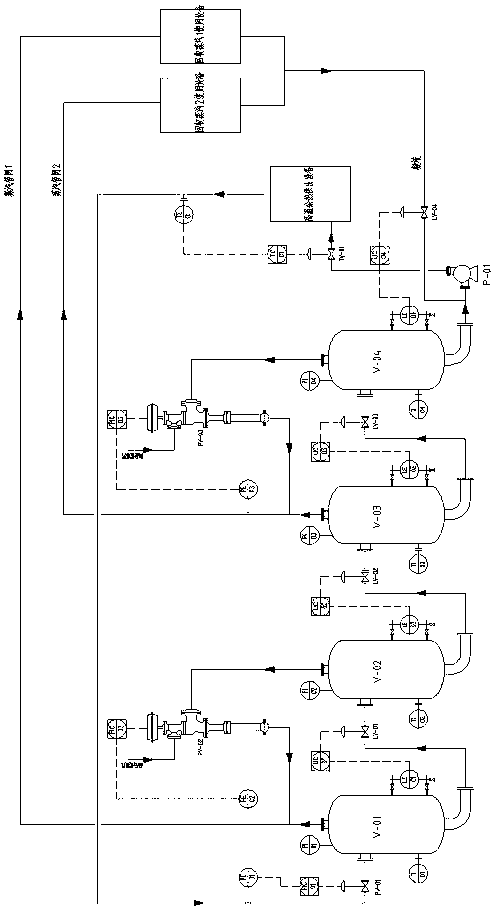

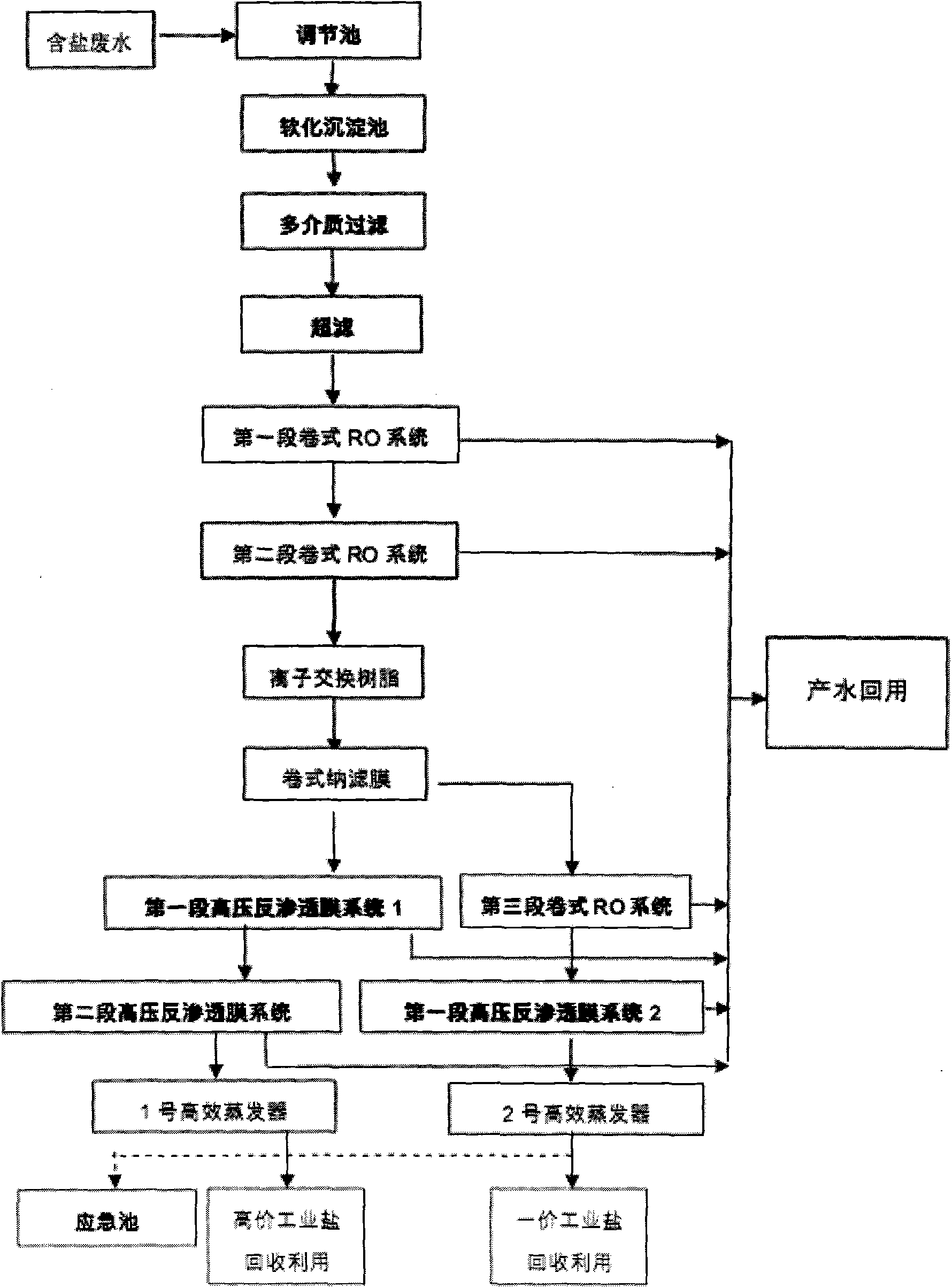

Salt-containing wastewater treatment method

ActiveCN103833172ASolve the problem of pollutionAvoid badWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisHigh concentrationIon exchange

The invention discloses a salt-containing wastewater treatment method. The wastewater goes through an adjusting tank, a softening sedimentation tank, a multi-medium filter, an ultrafiltration device, a first-section roll type reverse osmosis system, a second-section roll type reverse osmosis system, an ion exchange device, a roll type nanofiltration membrane device, a high-pressure reverse osmosis membrane system, a third-section roll type reverse osmosis system and an efficient evaporator. The treatment method disclosed by the invention has the advantages of strong anti-pollution capacity, solution of blocking problem, high concentration multiple, high recycling efficiency, high treatment efficiency, high automation degree, investment saving and low operation cost.

Owner:BEIJING NEWBIOLINK TECH DEV

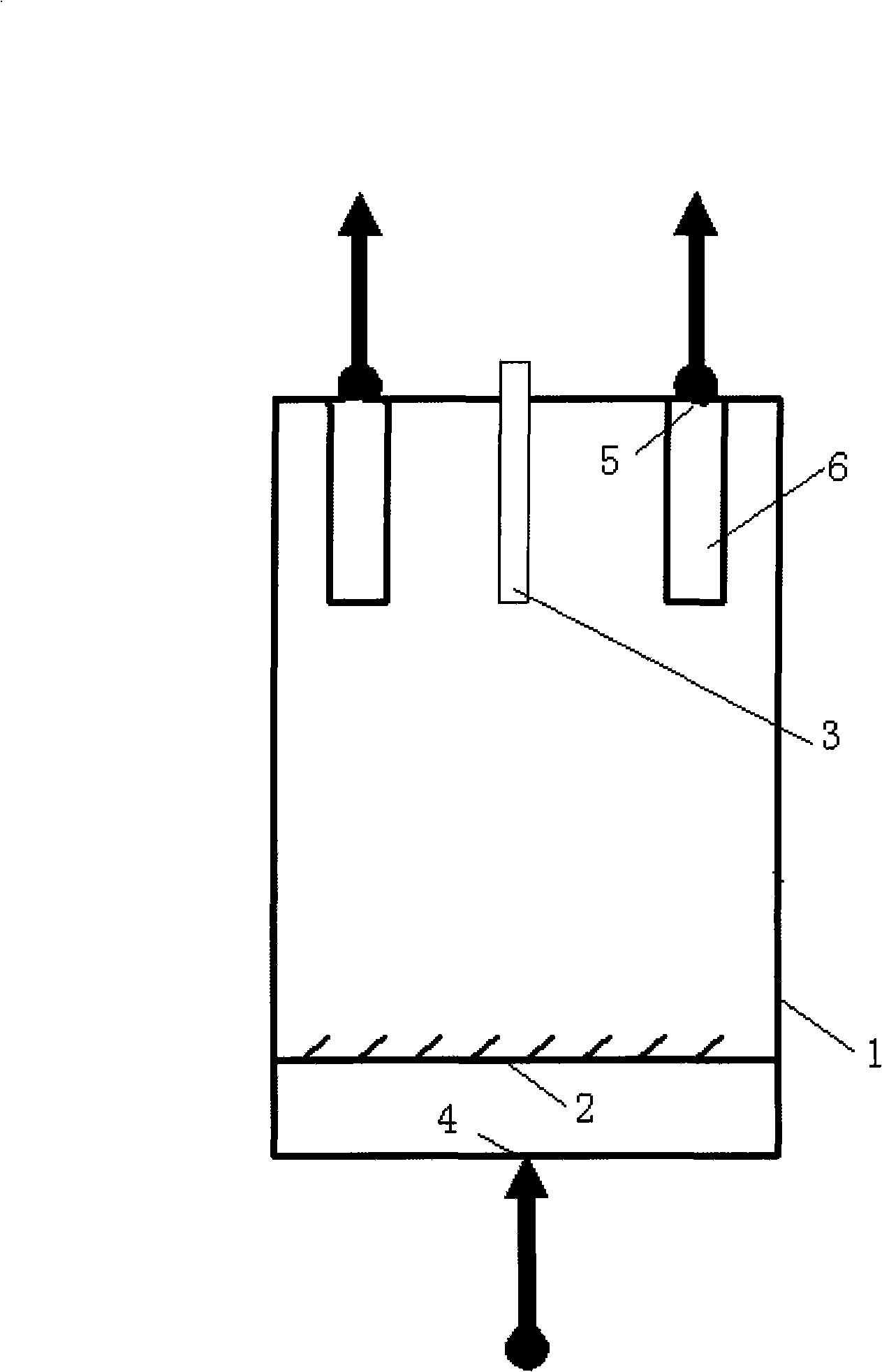

Device used for preparing Ni-SiC composite coating on inner surface of hollow workpiece

ActiveCN106283166AAvoid stirringReduce lossesElectrolysis componentsElectrolytic coatingsLiquid storage tankEngineering

The invention discloses a device for preparing a Ni-SiC composite coating on the inner surface of a hollow workpiece. A lower water outlet pipe and an upper water outlet pipe which are parallel and are arranged in an up-and-down manner are arranged in a liquid storage tank. After electroplating liquid flowing out of the upper water outlet pipe and electroplating liquid flowing out of the lower water outlet pipe are converged, the mixed electroplating liquid flows towards a sealed electroplating table under the drive force of an electroplating liquid circulation pump, and an electromagnetic flow meter is adjusted to control the volume flow rate of the electroplating liquid flowing towards the sealed electroplating table. After composite electroplating is completed in the sealed electroplating table, the electroplating liquid flows back into the liquid storage tank through a loop. One end of an air discharging pipe is connected with an outlet of a compressed air pump, and the other end of the air discharging pipe is connected in the liquid storage tank. The device is a the sealed and continuous-circulation electroplating device developed based on a traditional non-closed immersion type electroplating device and has the beneficial effects of being reasonable in structure, reliable in operation and convenient to use and operate, and the Ni-SiC composite coating with the good quality can be obtained on the inner surface of the hollow workpiece.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

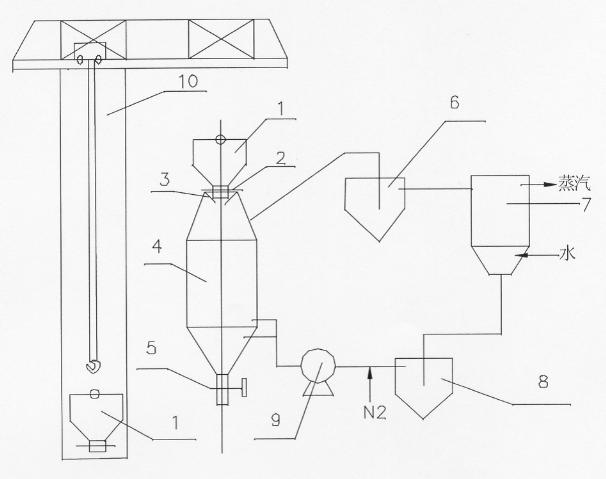

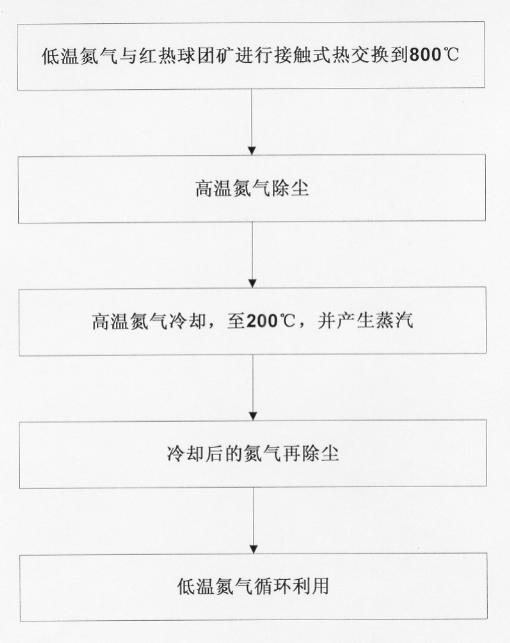

Device and method for recovering afterheat during red hot pellet cooling of rotary hearth furnace

ActiveCN102183154ARealize closed loopAchieve recyclingIncreasing energy efficiencyWaste heat treatmentBaghouseNitrogen

The invention relates to a device and a method for recovering afterheat during red hot pellet cooling of a rotary hearth furnace. A charging bucket is arranged on the top of a vertical contraflow cooler; an upper pipeline of the vertical contraflow cooler is connected with a first-stage dust pre-remover; the pipeline of the first-stage dust pre-remover is connected with the upper part of a boiler; the bottom of the boiler is connected with a second-stage bag-type dust remover; and the second-stage bag-type dust remover is connected with the lower part of the vertical contraflow cooler througha circulating fan. The method for recovering the afterheat comprises the following steps of: performing contact heat exchange between low-temperature nitrogen and red hot pellet until the temperatureof the low-temperature nitrogen is 800 DEG C; removing dusts from high-temperature nitrogen; cooling the high-temperature nitrogen until the temperature is 200 DEG C and producing steam; removing dusts from the cooled nitrogen; and recycling the low-temperature nitrogen. By adoption of the invention, closed cycle of the nitrogen can be realized so that recycling of energy mediums can be realized;meanwhile, separation between powder and the pellet is realized by controlling a flow speed of the pipeline nitrogen; moreover, due to the contact contraflow heat exchange, quick cooling is realized and the afterheat utilization efficiency is improved.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

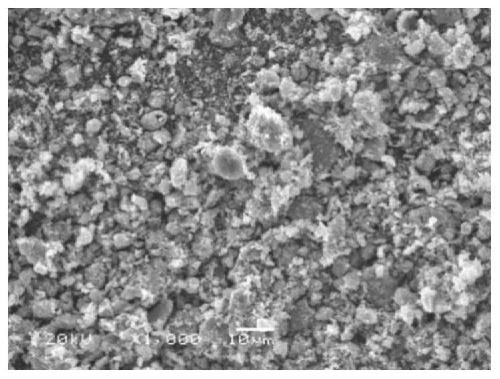

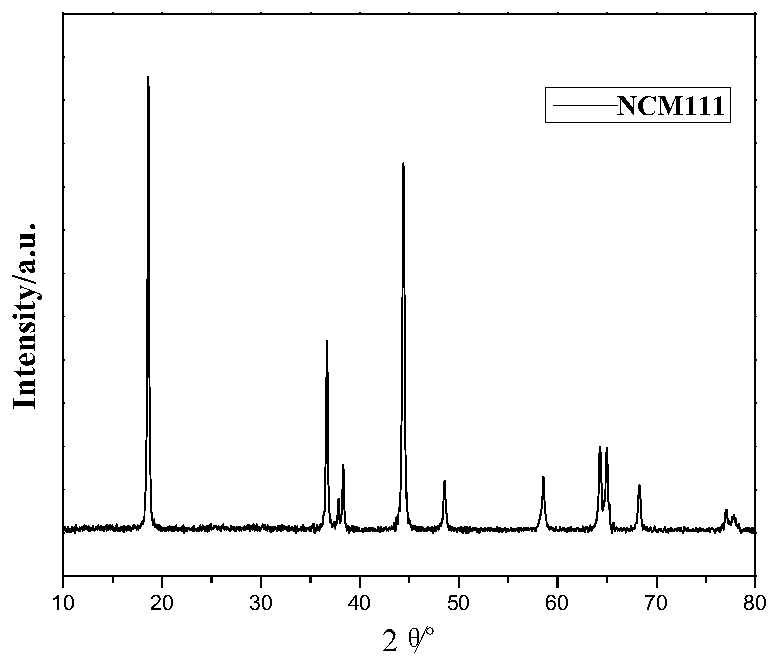

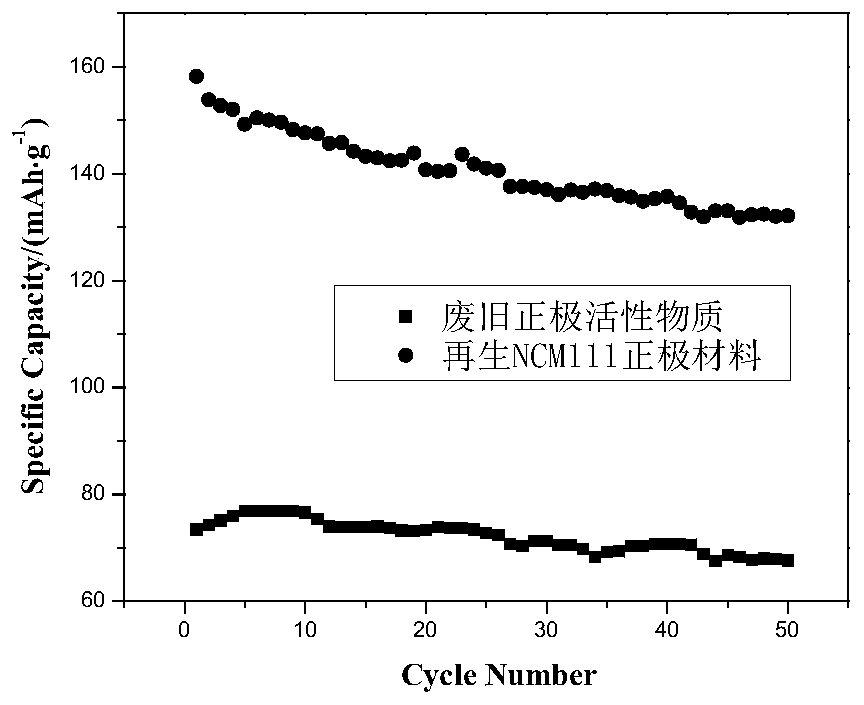

Method for recycling waste lithium battery positive electrode material under assistance of biomass waste

ActiveCN111430829AEasy to separateImprove crystal phasePositive electrodesWaste accumulators reclaimingSocial benefitsEnvironmental engineering

The invention discloses a method for recycling a waste lithium battery positive electrode material under the assistance of biomass waste, and belongs to the technical field of resource cyclic utilization. According to the method, the biomass waste is used as a reducing agent, and the recovery of a waste power lithium battery and the regeneration of a ternary positive electrode material are organically combined, so that the cyclic utilization of the waste power lithium battery is realized at low cost. The method is short in technological process and low in synthesis cost and is suitable for large-scale production, and the regenerated nickel-cobalt-manganese ternary positive electrode material is excellent in performance and has the very good economic benefits and social benefits.

Owner:湖南烯富环保科技有限公司

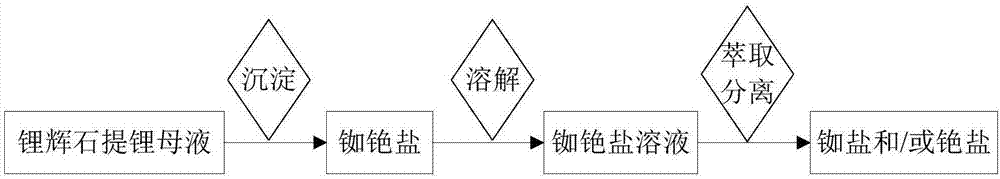

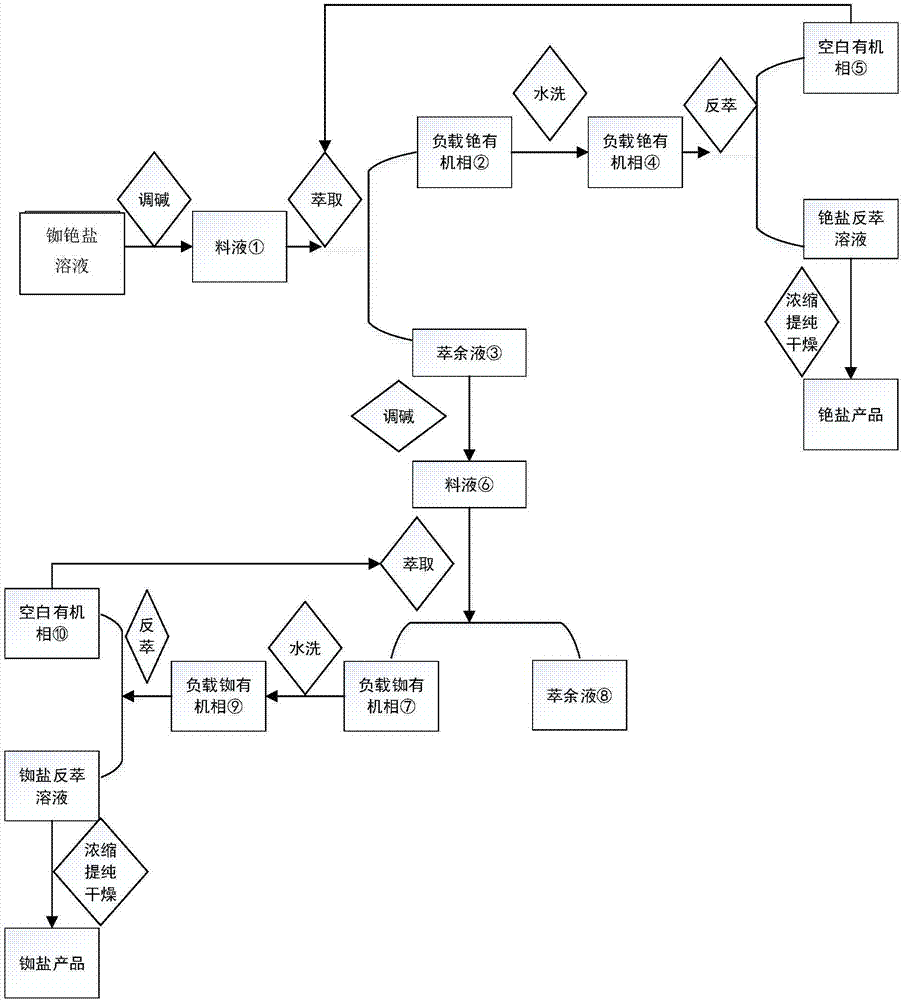

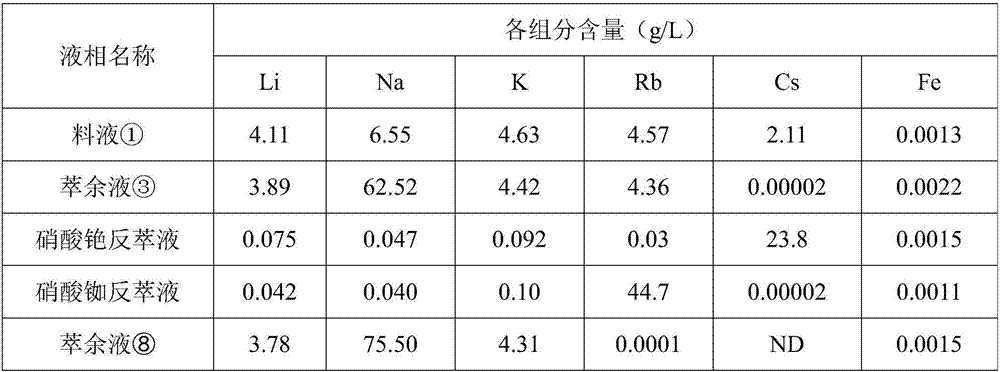

Method for extracting rubidium and cesium salts from mother liquor after extracting lithium from spodumene

The invention relates to a recovery method for a mother liquor for extracting lithium from spodumene, in particular to a method for extracting rubidium and cesium salts from the mother liquor for extracting lithium from spodumene. The technical problem solved by the invention is to provide a low-cost method for extracting rubidium and cesium salts from spodumene lithium extraction mother liquor. In this method, the lithium-extracting mother liquor of spodumene is used as the raw material, the rubidium and cesium in the lithium-extracting mother liquor are first precipitated, and then the solid is enriched and then dissolved, extracted and separated, and the rubidium and cesium valuable metals are comprehensively utilized, reducing the rubidium and cesium The cost of cesium extraction can produce considerable economic benefits. Moreover, the method of the present invention can extract rubidium and cesium at low temperature and normal pressure. The operation is simple, the energy consumption is low, the processing capacity is large, it is beneficial to continuous operation, the production cost is low, the waste water is returned to the lithium extraction workshop, and the closed circuit cycle is realized in the process, and the waste water is zero discharged. .

Owner:TIANQI LITHIUM CORP

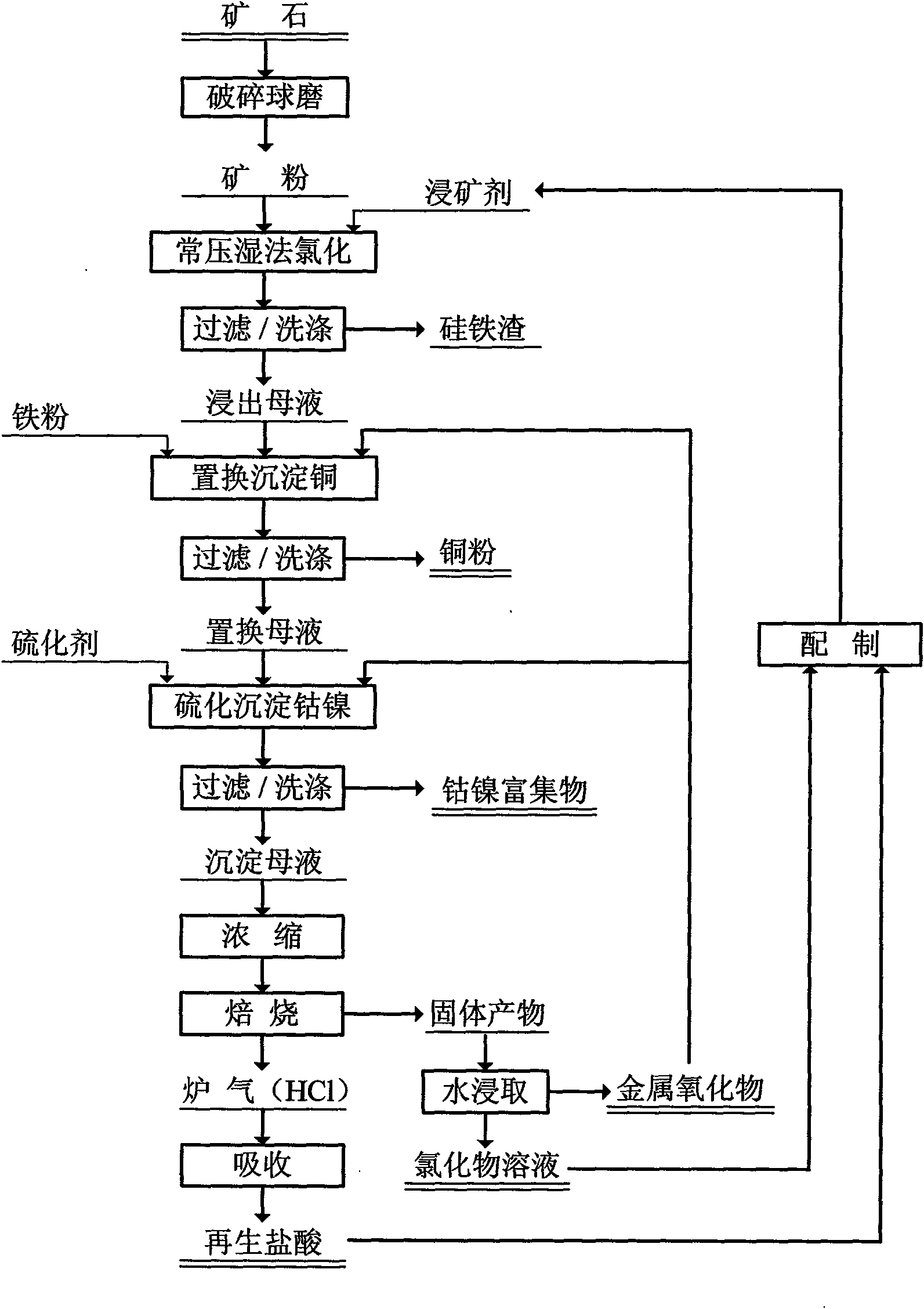

Method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore

ActiveCN101575673AImprove leaching ratePromote circulationProcess efficiency improvementSlurrySulfide

The invention provides a method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore, which uses low-grade complex mixed copper-cobalt ore (sulfide and oxide) as a raw material to extract an intermediate product of the copper and cobalt-nickel by adopting process flows of crushing and grinding ore into slurry, leaching the slurry with acidic villaumite by a wet method, extracting copper powder by reduction and replacement, vulcanizing and depositing nickel (cobalt), concentrating, drying, baking and hydrolyzing deposited mother solution at low temperature and the like. The method comprises main technical points that metallic elements in the mixed copper-cobalt ore are dissolved and leached by the acidic villaumite under normal pressure; copper in leaching liquor is reduced and deposited by a reducing agent; the cobalt and nickel are deposited by a vulcanizing agent to obtain the intermediate product; the mother solution is concentrated, dried, baked and hydrolyzed at low temperature after cobalt-nickel deposition to obtain metal oxide, metal oxychloride and hydrogen chloride containing iron, magnesium and the like; hydrogen chloride is reclaimed to obtain hydrochloric acid, and baked solid is leached into water to obtain chloride solution; and the hydrochloric acid and the chloride solution are used for leaching of ore slurry. The method comprehensively reclaims the copper, the cobalt-nickel and the like, and has the characteristics of high leaching rate of the copper and the cobalt-nickel, less energy consumption, low cost, closed circulation of chlorine (hydrochloric acid), less investment of project engineering and the like. The whole process is concise, clean and environment-friendly. The method is particularly applicable to large-scale industrial production.

Owner:福建常青新能源科技有限公司

Stainless steel pickling waste water resource recycling method

ActiveCN105060599AReduce dosageImprove recycling efficiencyWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodEvaporation

The invention discloses a stainless steel pickling waste water resource recycling method. The method includes the steps of firstly, conducting reduced pressure evaporation on mixed acid of hydrofluoric acid and nitric acid so that acid recycling can be achieved; secondly, separating out and recycling iron in the solution; thirdly, gathering diluted acid, nickel and chromium in a circulating mode; fourthly, recycling diluted acid through a film method; fifthly, conducting neutralization and iron recycling; sixthly, separating nickel and chromium and recycling nickel; seventhly recycling chromium. By means of the method, efficient recycling of valuable metal resources such as nitric acid, hydrofluoric acid, iron, chromium and nickel is achieved, purified water can stably reach the standard, and the method is remarkable in economic benefit.

Owner:CENT SOUTH UNIV

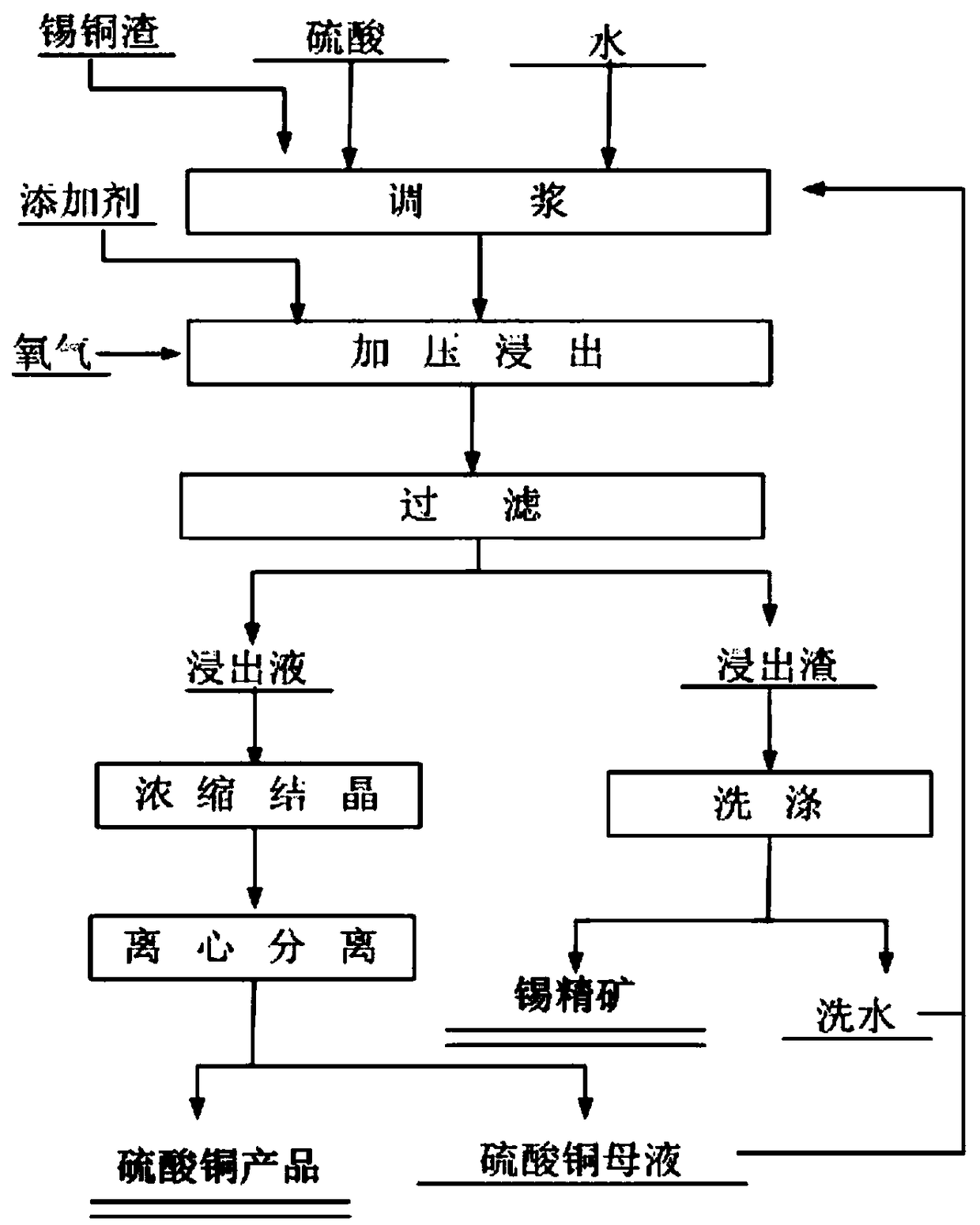

Wet processing method for tin-copper slag

InactiveCN108796237AEfficient separationAchieve open circuitProcess efficiency improvementCopper chlorideReaction temperature

The invention relates to a wet processing method for tin-copper slag. The method comprises the following steps that sulfuric acid and the tin-copper slag are put into a closed container according to aratio, and copper chloride is added according to 2-10 wt.% of the adding amount of the tin-copper slag; then oxygen is introduced into the closed container and pressurizing and heating are carried out, so that the tin-copper slag and the sulfuric acid are fully reacted under the action of an additive; a liquid-solid mass ratio of the sulfuric acid to the tin-copper slag is 4-8:1, and an initial acidity of a sulfuric acid solution is 100-200 g / l; the reaction pressure of the closed container is 0.8-2 Mpa, the reaction temperature is 120-200 DEG C, and the reaction time is 2-8 hours; and afterthe reaction is finished, solid-liquid separation is carried out, the leaching liquid is a copper sulfate solution, a copper sulfate product is obtained after concentrating and crystallizing, and theleaching residue is tin concentrate. According to the wet processing method for the tin-copper slag, the tin and the copper can be effectively separated, so that an open way of the copper is formed ina tin smelting system, and the processing cost of the tin-copper slag is reduced.

Owner:云南锡业研究院有限公司

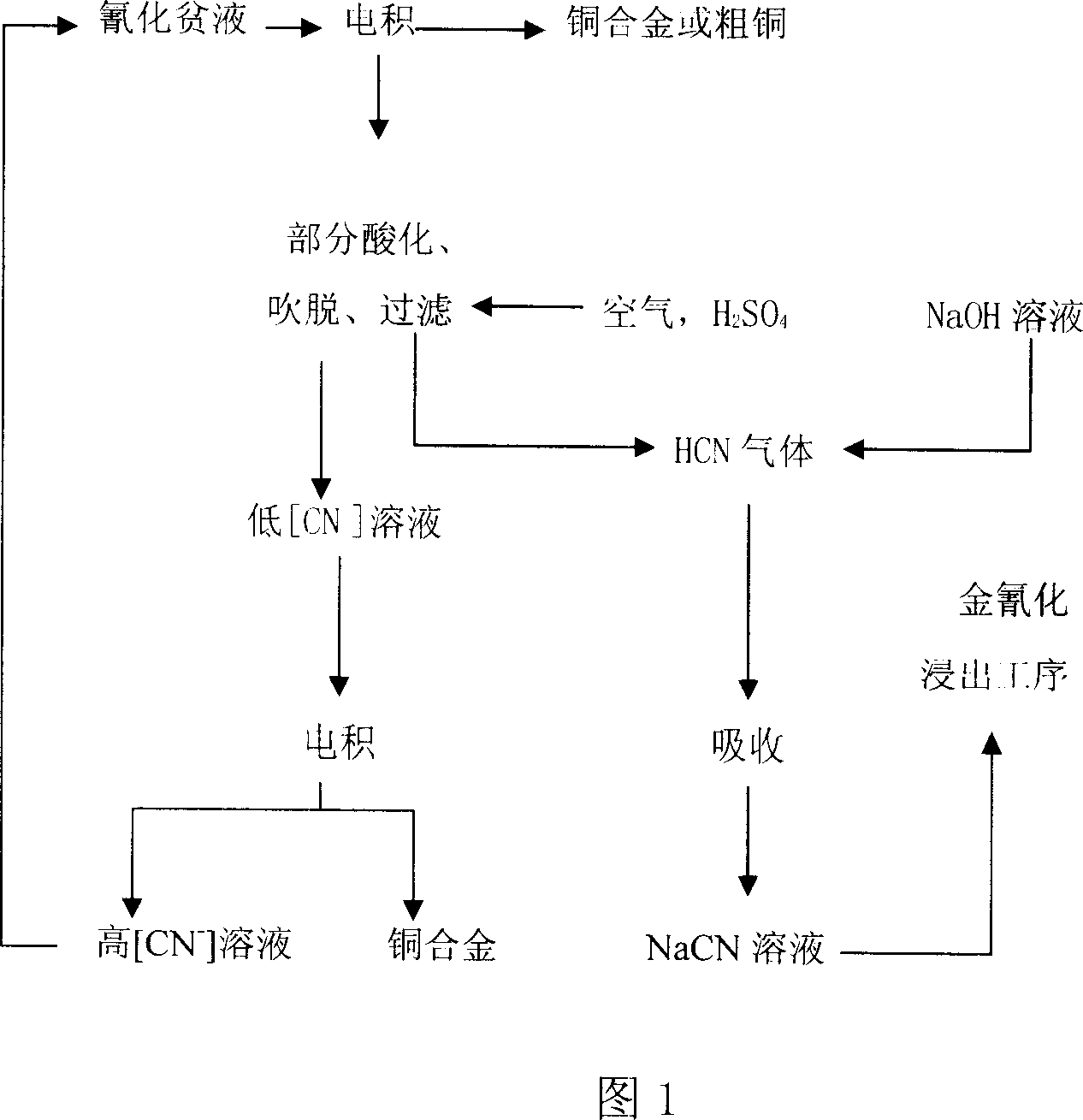

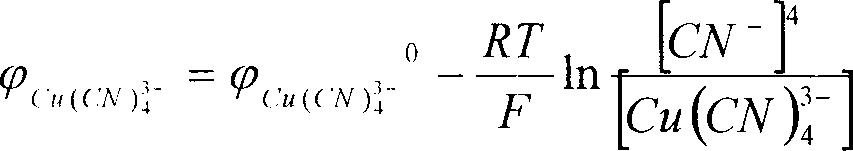

Method for recovering copper from cyanide-containing waste water and related waste water treatment method

InactiveCN101008090AHigh cathode current efficiencySolve the problem of low current efficiencyPhotography auxillary processesWater/sewage treatmentElectricityCyanide

The invention discloses a method for recovering copper from cyanic waste water and relative wastewater treatment method, belonging to non-ferrous metallurgy and environmental protection field. It is characterized in that it combines diaphragm electrodeposition with part of acidification, adds acid into electrodeposition liquid and aerates to blow off and recover free CN-, which greatly increases cathodic current efficiency; it employs diaphragm electrodeposition, that is to employ cationic exchange membrane to separate free cyanogen and metal- cyano complex from anode, to avoid cyanogen oxidation in anode; the waste electrodeposition liquid can be reused in cyanogen extraction process, or discharged after further treatment.

Owner:TSINGHUA UNIV

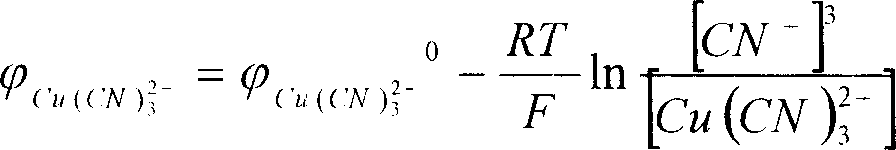

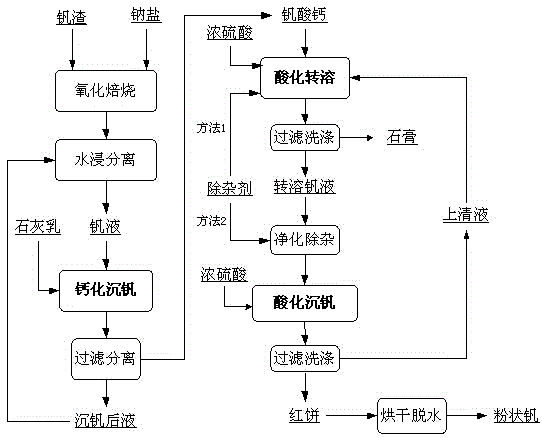

Method for extracting vanadium from vanadium solution through vanadium slag sodium salt roasting vanadium extraction process

InactiveCN104694761ARealize closed loopAchieving zero emissionsProcess efficiency improvementChemical industrySlag

The invention discloses a method for extracting vanadium from a vanadium solution through a vanadium slag sodium salt roasting vanadium extraction process. The method comprises the following steps: (1) adding calcium to deposit vanadium into the vanadium solution obtained by a vanadium slag sodium salt roasting-water leaching vanadium extraction process, thereby obtaining calcium vanadate; (2) performing solution conversion on the calcium vanadate by using a sulfuric acid solution; (3) removing impurities in the conversion solution, thereby obtaining a purified vanadium solution; and (4) regulating the pH value of the purified vanadium solution, precipitating under normal pressure to obtain a red cake, dehydrating, and drying, thereby obtaining a powdered vanadium product. According to the method for precipitating vanadium through calcification of a vanadium solution, acidifying for solution conversion and hydrolyzing to precipitate the vanadium, an ammonium salt is not added in the process, the solution subjected to calcification and vanadium precipitation and the solution subjected to hydrolysis and vanadium precipitation can be recycled, closed medium loop and zero wastewater emission can be realized, and a clean production method is realized. According to the method, the conventional vanadium chemical industry production process is simplified, the steps of ammonium salt vanadium precipitation and ammonium vanadate deamination are not needed, and the raw materials and energy consumption cost are greatly reduced; and moreover, the content of the vanadium product sigma(Na2O+K2O) obtained by the method is less than 0.1 percent.

Owner:HEBEI IRON AND STEEL

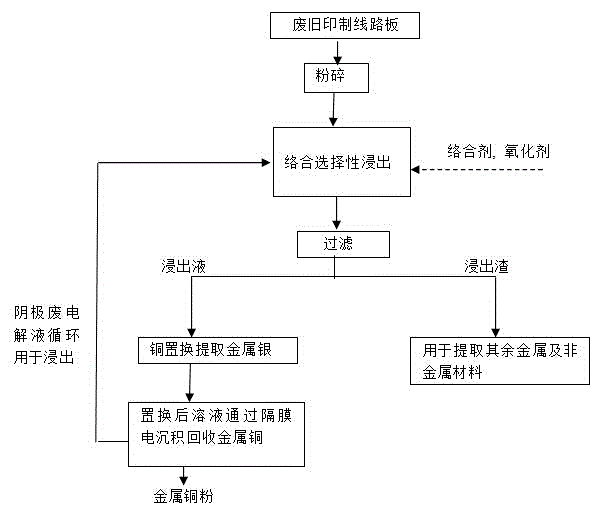

Method for extracting metallic silver from waste circuit board

InactiveCN104988317ASelect strong leachingAvoid emissionsPhotography auxillary processesProcess efficiency improvementEnvironmental geologyOxidizing agent

The invention discloses a method for extracting metallic silver from a waste circuit board. The method comprises the steps that after the waste circuit board is smashed into crushed materials, the crushed materials are placed into an extracting solution of a leaching reactor to be subjected to selective leaching reaction, wherein the extracting solution is formed by a complexing agent and an oxidizing agent; a copper sheet is added to an obtained leaching solution to be subjected to replacement reaction, and the metallic silver is prepared. The technology is simple, the cost is low, the metallic silver in the circuit board can be subjected to complexing leaching in a selective mode, it is avoided that strong acid is in use, and the environment-protected and resource-recovered processing on the metallic silver of the waste circuit board is achieved.

Owner:CHINA NAT ELECTRIC APP RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com