Wide-grain-grade double-dense-medium process for separating all coarse coal slime

A coarse coal slime and sorting technology, applied in the direction of solid separation, etc., can solve the problems of high production and operation cost, inconvenient management, large workshop volume, etc., and achieve the effect of improving the sorting effect, reducing the processing capacity and increasing the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

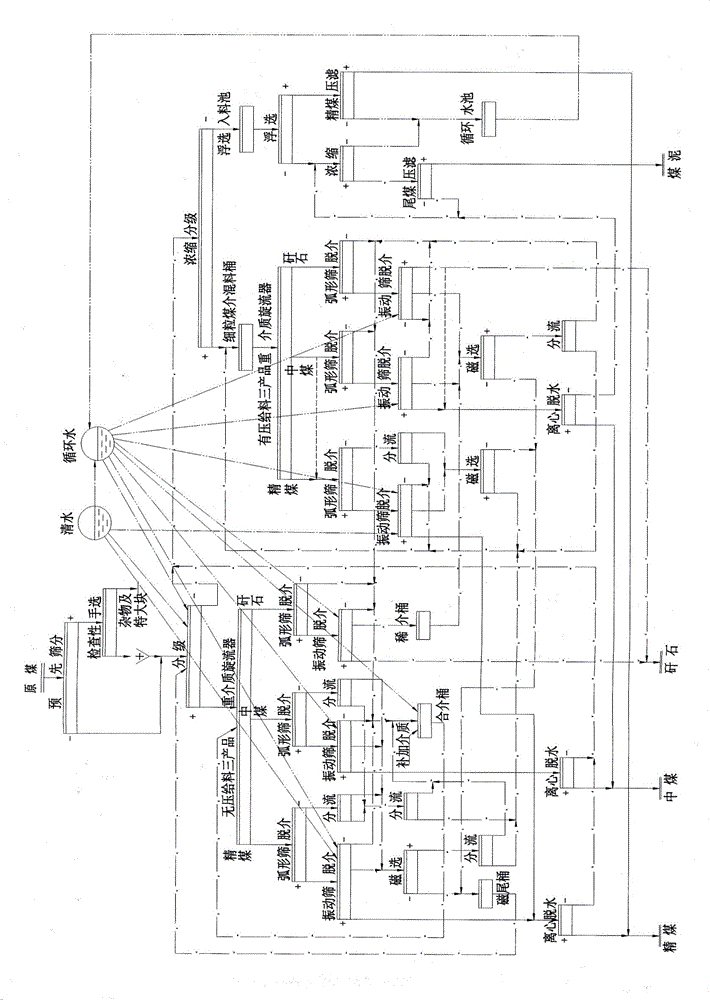

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039] This embodiment is a high-efficiency separation process that can realize wide-grained double mediation of all coarse coal slime. The equipment used in this process includes: pre-screening and grading sieves, crushers, grading sieves, thickening cyclones, and pressureless feeders. Material three-product dense medium cyclone, pressure-feeding three-product heavy medium cyclone, arc-shaped de-medium sieve, gangue de-medium sieve, medium coal de-medium sieve, clean coal de-medium sieve, magnetic separator, centrifugal dehydration machine, coal slime centrifuge, flotation machine, clean coal filter press, tailing coal filter press, tailing coal thickener, etc. The slime recycling system is located at the end of the whole sorting system. Between each system, the equipment is connected with chute and pipeline according to the functional sequence. The coarse-grained c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com