Method for recycling waste lithium battery positive electrode material under assistance of biomass waste

A technology for waste lithium batteries and cathode materials, applied in the field of ternary cathode materials, can solve the problems of high recycling production cost, complex procedures, secondary pollution, etc., and achieve the effects of low cost, shortened process flow, and full recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

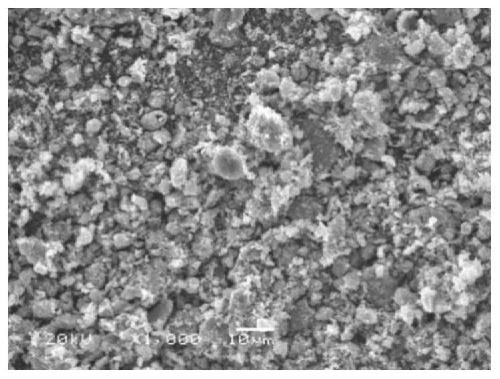

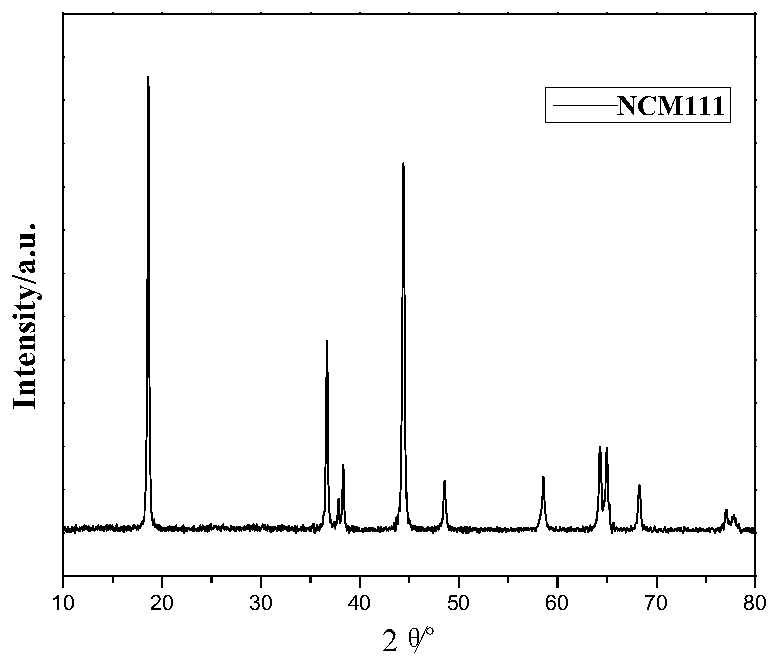

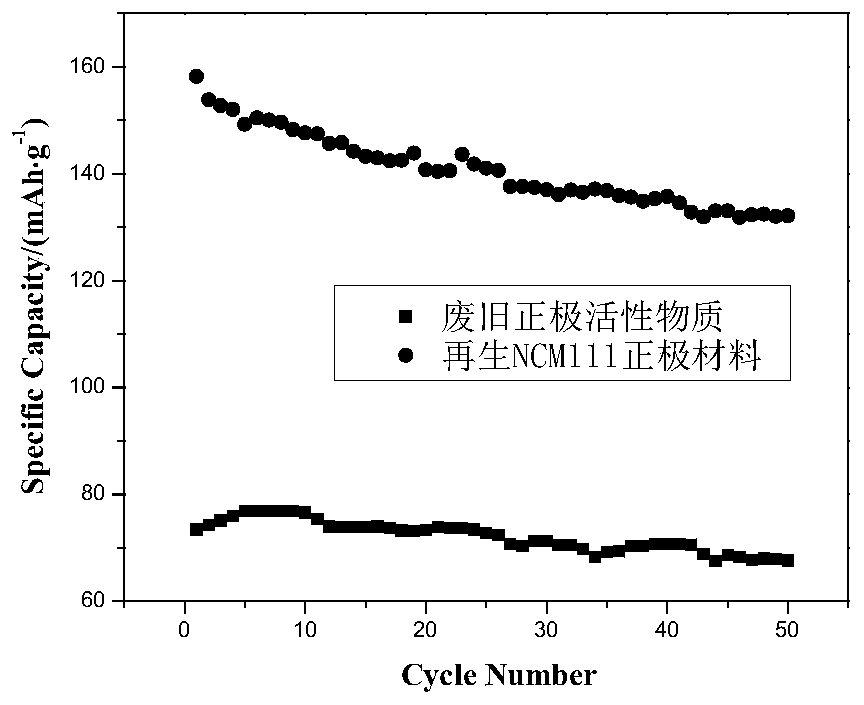

[0063] ①Pretreatment: the waste power lithium battery (the active material of the positive electrode is LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ) into 5mol / L salt water for 30min discharge treatment, dry the discharged battery at 80°C, disassemble and separate the positive electrode sheet, dissolve the positive electrode sheet in N-methylpyrrolidone, and remove the current collector in the positive electrode sheet , filtered, washed and dried to obtain the waste positive electrode active material;

[0064] ②Reduction roasting: Weigh 10g of waste positive electrode active material and appropriate amount of corn stalks, the doping amount of corn stalks is 30%, ball mill for 2h to mix evenly, put the mixed materials in a tube furnace, and sinter at 800℃ for 5h under Ar atmosphere to obtain reduction Roasting slag;

[0065] ③Water immersion: Take the above-mentioned reduced roasted slag, add it to 350mL of water according to the liquid-solid ratio (mL:g) of 30:1, and magnetically stir at 2...

Embodiment 2

[0072] ①Pretreatment: the waste power lithium battery (the active material of the positive electrode is LiNi 0.5 co 0.2 mn 0.3 o 2 ) into 5mol / L salt water for 30min discharge treatment, dry the discharged battery at 80°C, disassemble and separate the positive electrode sheet, dissolve the positive electrode sheet in N-methylpyrrolidone, and remove the current collector in the positive electrode sheet , filtered, washed and dried to obtain the waste positive electrode active material;

[0073] ②Reduction roasting: Weigh 10g of waste positive electrode active material and appropriate amount of chaff, the doping amount of chaff is 20%, ball mill for 2h until evenly mixed, the mixed material is placed in a tube furnace, and heated in N 2 Sintering at 750°C for 6 hours under atmosphere to obtain reduced roasted slag;

[0074] ③Water immersion: Take the above-mentioned reduced roasted slag, add it to 500mL of water according to the liquid-solid ratio (mL:g) of 50:1, and magneti...

Embodiment 3

[0082] ①Pretreatment: the waste power lithium battery (the active material of the positive electrode is LiNi 0.6 co 0.2 mn 0.2 o 2 ) into 5mol / L salt water for 30min discharge treatment, dry the discharged battery at 80°C, disassemble and separate the positive electrode sheet, dissolve the positive electrode sheet in N-methylpyrrolidone, and remove the current collector in the positive electrode sheet , filtered, washed and dried to obtain the waste positive electrode active material;

[0083] ②Reduction roasting: Weigh 10g of waste positive electrode active material and appropriate amount of rice straw, the doping amount of rice straw is 25%, ball mill for 2h to mix evenly, put the mixed material in a tube furnace, and sinter at 750°C for 5h under Ar atmosphere to obtain reduced roasting slag ;

[0084] ③Water immersion: Take the above-mentioned reduced roasted slag, add it to 550mL water according to the liquid-solid ratio (mL:g) of 60:1, and magnetically stir at 30°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com