Method for extracting metallic silver from waste circuit board

A technology for extracting metal from waste circuit boards, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of restrictions, secondary pollution, difficult recycling of leachate, etc., and achieve the effect of strong selective leaching and avoiding discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

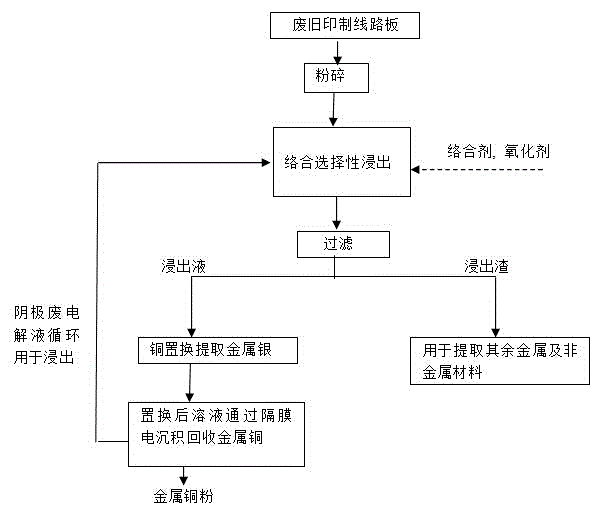

Image

Examples

Embodiment 1

[0018] Using waste computer printed circuit boards as raw materials, it contains 0.32% Ag and 17.9% Cu.

[0019] Crush 50g of the above-mentioned raw materials into 1-2mm fragments, add them into a mechanically stirred reactor, add 0.3 L of disodium edetate solution with a concentration of 15g / L and 30ml of oxidant hydrogen peroxide at the same time, and stir and leach for 1h. After leaching, filter and separate the leaching solution and leaching slag, add copper flakes to the leaching solution to replace to obtain coarse silver powder, the replaced solution is added to the cationic diaphragm electrolytic cell as the catholyte, and the stainless steel is used as the cathode plate for electrolysis to obtain copper powder, and the electrolysis conditions adopt the conventional process conditions. After electrolysis, the waste electrolyte is returned to the leaching process for recycling. Among them, the leaching rate of silver is 90.5%, and the leaching rate of other metals suc...

Embodiment 2

[0021] Using waste mobile phone printed circuit boards as raw materials, it contains 0.53% Ag and 23.5% Cu.

[0022] Crush 50g of the above-mentioned raw materials into 1-2mm fragments, add them into a mechanically stirred reactor, add 0.5 L of ethylenediamine solution with a concentration of 20g / L and 100ml of oxidant hydrogen peroxide, and stir and leach for 2 hours. After leaching, filter and separate the leaching solution and leaching slag, add copper flakes to the leaching solution to obtain coarse silver powder, add the replaced solution to the cationic membrane electrolytic cell as catholyte, and use stainless steel as the cathode plate for electrolysis to obtain copper powder, waste electrolyte after electrolysis Return to the leaching process for recycling. The leaching rate of silver is 93.7%, and the leaching rate of other metals such as copper is less than 5%. The resulting leaching slag is used to extract the remaining metal and non-metal materials.

Embodiment 3

[0024] The components after dismantling the printed circuit boards of waste mobile phones are used as raw materials, which contain 1.12% Ag and 41.7% Cu.

[0025] Crush 50g of the above-mentioned raw materials into 1-2mm fragments and add them to a mechanically stirred reactor. At the same time, add 0.5 L of ethylenediamine solution with a concentration of 20g / L and 150ml of oxidant sodium hypochlorite solution, and stir and leach for 3h. After leaching, filter and separate the leaching solution and leaching slag, add copper flakes to the leaching solution to obtain coarse silver powder, add the replaced solution to the cationic membrane electrolytic cell as catholyte, and use stainless steel as the cathode plate for electrolysis to obtain copper powder, waste electrolyte after electrolysis Return to the leaching process for recycling. The leaching rate of silver is 93.5%, and the leaching rate of other metals such as copper is less than 5%. The resulting leaching slag is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com