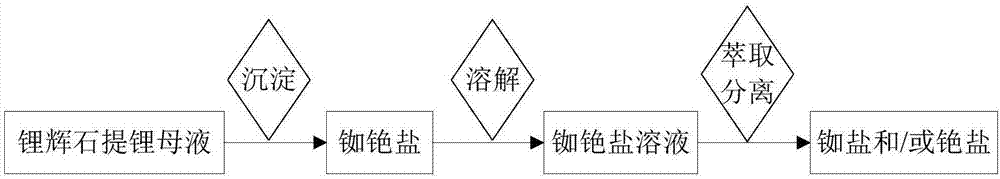

Method for extracting rubidium and cesium salts from mother liquor after extracting lithium from spodumene

A technology for extracting lithium mother liquor and spodumene, which is applied in the field of rubidium and cesium salt extraction, can solve the problems of large amount of mother liquor extraction, increased cost of rubidium and cesium extraction, and high toxicity of extractant, so as to achieve continuous operation, considerable economic benefits, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

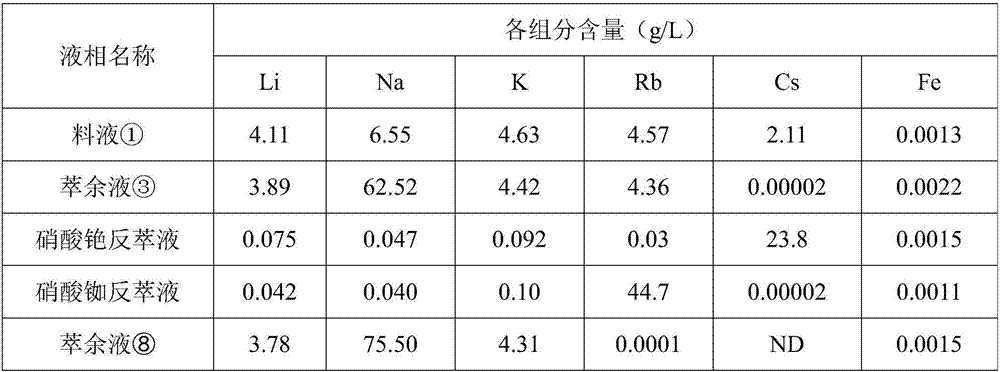

[0070] Step 1: Add sulfuric acid to neutralize the carbonate radical in the lithium mother liquor of spodumene (the components of the mother liquor are shown in Table 1), so that pH=2 in the mother liquor of lithium extraction. 15% ferric sulfate was added, kept at 90°C for 240min, and filtered to obtain the precipitate of rubidium and cesium salt. Then add the obtained rubidium and cesium salt precipitate into water according to the solid-liquid ratio of 1:5, then dissolve it with hydrochloric acid until clear, finally adjust the pH to 10 with NaOH, filter to separate the iron element from the rubidium and cesium, and obtain the rubidium and cesium salt solution at the solid-liquid ratio , the obtained rubidium and cesium salt solution can be used for extraction and separation in the subsequent section.

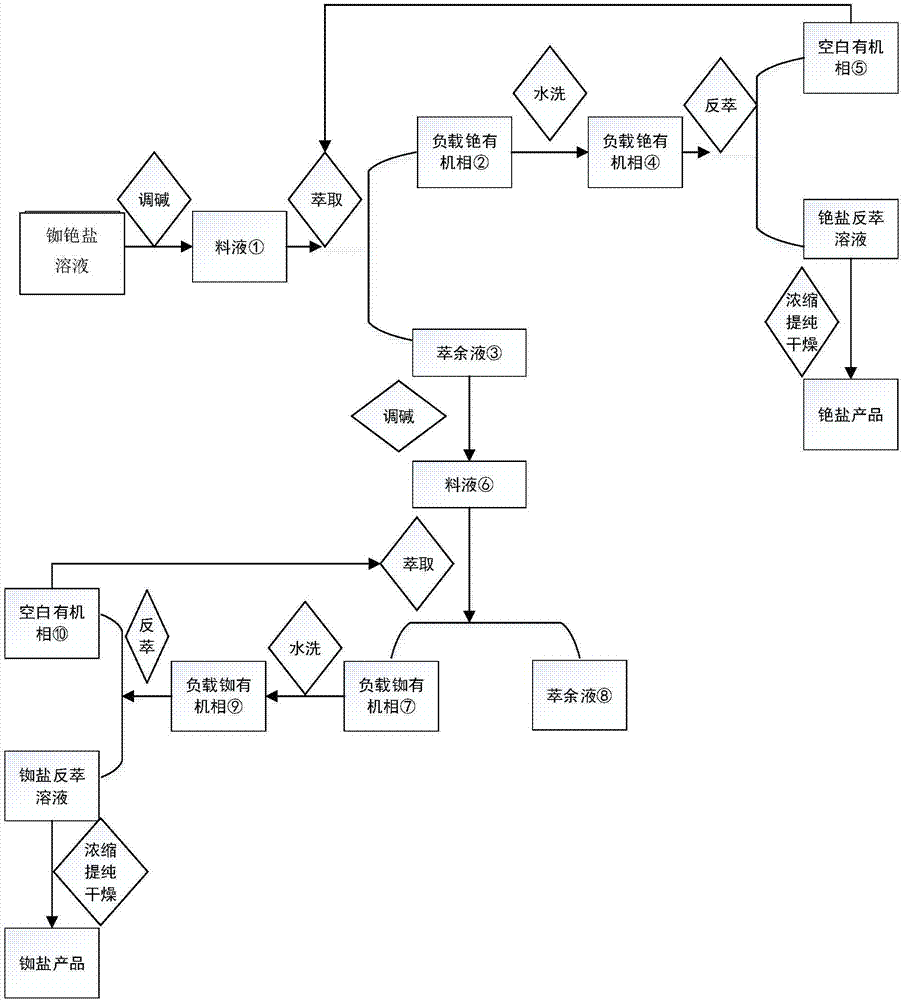

[0071] Step 2: Adjust the alkalinity of the rubidium and cesium salt solution obtained in the above step 1 to OH with sodium hydroxide - Concentration is 1.2mol / L, obtains ...

Embodiment 2

[0081] Step 1: Add hydrochloric acid to neutralize the carbonate radical in the mother liquor of spodumene for extracting lithium (the components of the mother liquor for extracting lithium are shown in Table 4), so that the pH of the solution is 3, and then the total amount of rubidium and cesium is calculated by an excess of 50%. Add tin tetrachloride, filter to obtain the precipitation of rubidium and cesium salt, then add the obtained rubidium and cesium salt precipitation into pure water at a solid-to-liquid ratio of 1:3, heat until the rubidium and cesium salt are completely dissolved, adjust the pH to 7 and filter to make the tin The element is separated from rubidium and cesium, and the obtained tin element can be purified and returned to the front for reuse. Obtain rubidium cesium salt solution.

[0082] Step 2: Adjust the alkalinity of the rubidium and cesium salt solution obtained in the above step 1 to OH with sodium hydroxide - Concentration is 1.5mol / L, obtains ...

Embodiment 3

[0092] Step 1: In the lithium mother liquor of spodumene (the components of the mother liquor are shown in Table 7), sulfuric acid is added to neutralize the carbonate radical, so that pH=1 in the mother liquor of lithium extraction, and then based on the total amount of rubidium and cesium, the excess Add 20% aluminum sulfate solution, stir well, then cool to 0°C to precipitate rubidium and cesium salt. Filtrate to obtain the precipitation of rubidium and cesium salt, then add the obtained rubidium and cesium salt precipitation into pure water according to the solid-liquid ratio of 1:5, heat until the rubidium and cesium salt are completely dissolved, adjust the pH to 5 with NaOH and filter to make the aluminum element and rubidium and cesium salt Separation to obtain rubidium cesium salt solution.

[0093] Step 2: Adjust the alkalinity of the rubidium and cesium salt solution obtained in the above step 1 to OH with sodium hydroxide - Concentration is 0.1mol / L, obtains feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com