Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

253 results about "Diphenylsilanediol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diphenylsilanediol, Ph₂Si(OH)₂, is a silanol. The tetrahedral molecule forms hydrogen-bonded columns in the solid state. It can be prepared by hydrolysis of diphenyldichlorosilane Ph₂SiCl₂. Diphenylsilanediol can act as an anticonvulsant, in a similar way to phenytoin. Although the compound is stable in normal conditions, the presence of basic impurities can accelerate the condensation of the silanol groups.

Valve sealing gasket sizing material and preparation method thereof

ActiveCN103012891AImprove performanceGood high and low temperature resistanceDiphenylsilanediolSolvent

The invention discloses a valve sealing gasket sizing material, which is prepared from the following raw materials in parts by weight: 20-30 parts of fluorosilicone rubber, 50-60 parts of hydrogenated nitrile-butadiene rubber, 15-25 parts of chlorosulfonated polyethylene rubber TS-320 (TOSOH, Japan), 2-3 parts of gamma-methacryloxypropyltrimethoxysilane, 1-2 parts of diphenyl silandiol, 14-16 parts of modified tree ash, 2-3 parts of ferrocene, 0.2-0.6 part of dicumyl peroxide (DCP), 20-30 parts of high-abrasion resistant carbon black N330, 20-25 parts of precipitated white carbon black, 5-7 parts of light calcium carbonate, 2-4 parts of zinc oxide, 1-3 parts of calcium stearate, 1-3 parts of aluminium oxide, 5-8 parts of dolomite, 13-15 parts of modified iron tailing powder, 0.1-0.3 part of accelerating agent MBTS, 1-2 parts of sulphur, 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent MB, 1-2 parts of benzimidazole-2-thiol, 1-3 parts of methyltrimethoxy silane, and 2-3 parts of paraffin. The sizing material of the rubber has excellent high and low temperature-resistant, oil-proof, solvent-resistant and chemical-resistant performance, and at the same time is good in mechanical property and low in cost.

Owner:平湖市博宏塑料制品厂

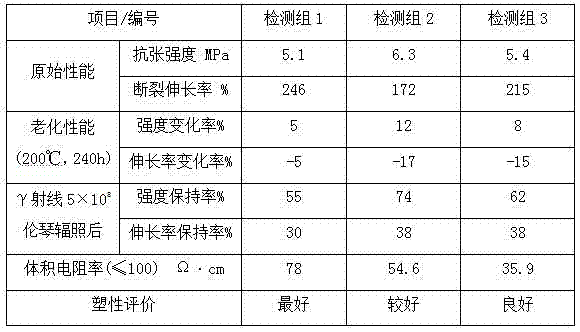

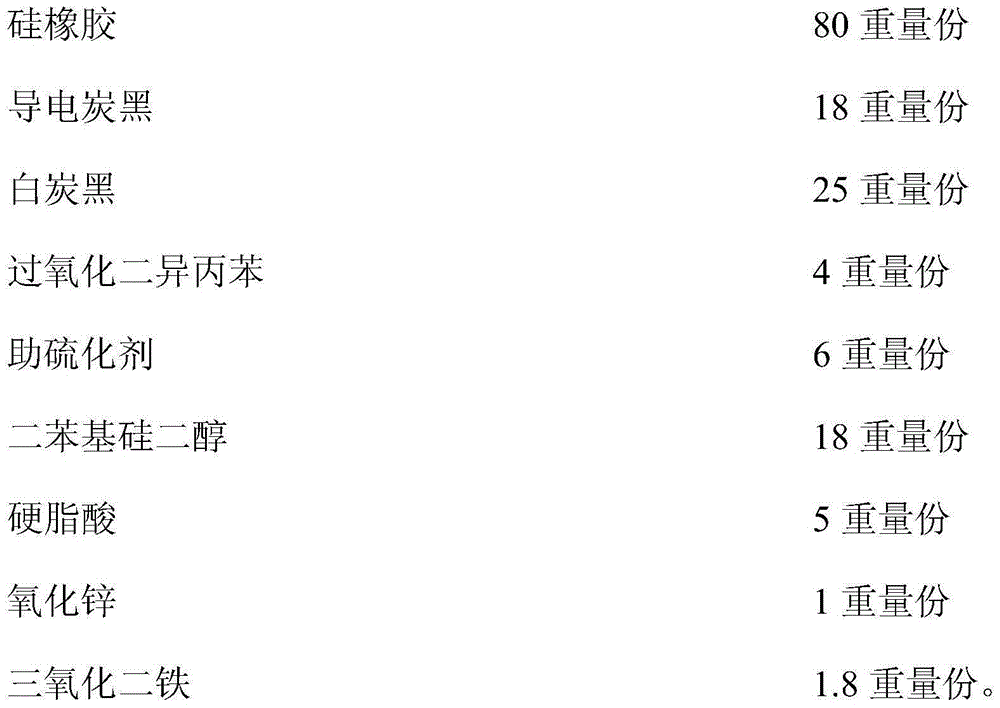

Semiconductive silicon rubber shielding material for radiation-resistant cable, and preparation method thereof

InactiveCN102964841AImprove radiation resistanceImprove plasticityInsulated cablesInsulated conductorsPolymer sciencePhenyl Ethers

The invention relates to a semiconductive silicon rubber shielding material for a radiation-resistant cable, and a preparation method of the material, belonging to the technical field of cable shielding material. The semiconductive silicon rubber shielding material comprises the raw material components in parts by weight: 100 parts of silicon rubber, 20-40 parts of conductive carbon black, 40-50 parts of white carbon black, 1.0-2.5 parts of dicumyl peroxide, 2.0-3.0 parts of auxiliary vulcanizing agent, 5-15 parts of diphenyl silanediol, 1.0-2.0 parts of stearic acid, 4-6 parts of zinc oxide and 2-5 parts of ferric oxide, wherein the silicon rubber is phenyl ether supporting silicone rubber or phenylene silicone rubber; and the auxiliary vulcanizing agent is triene propyl cyanurate. The silicon rubber shielding material is good in radiation-resistant performance, and can give play to the specified function for a long time on radiation occasion when being used as a shielding layer of an electric wire and the cable.

Owner:SICHUAN MINGXING CABLE

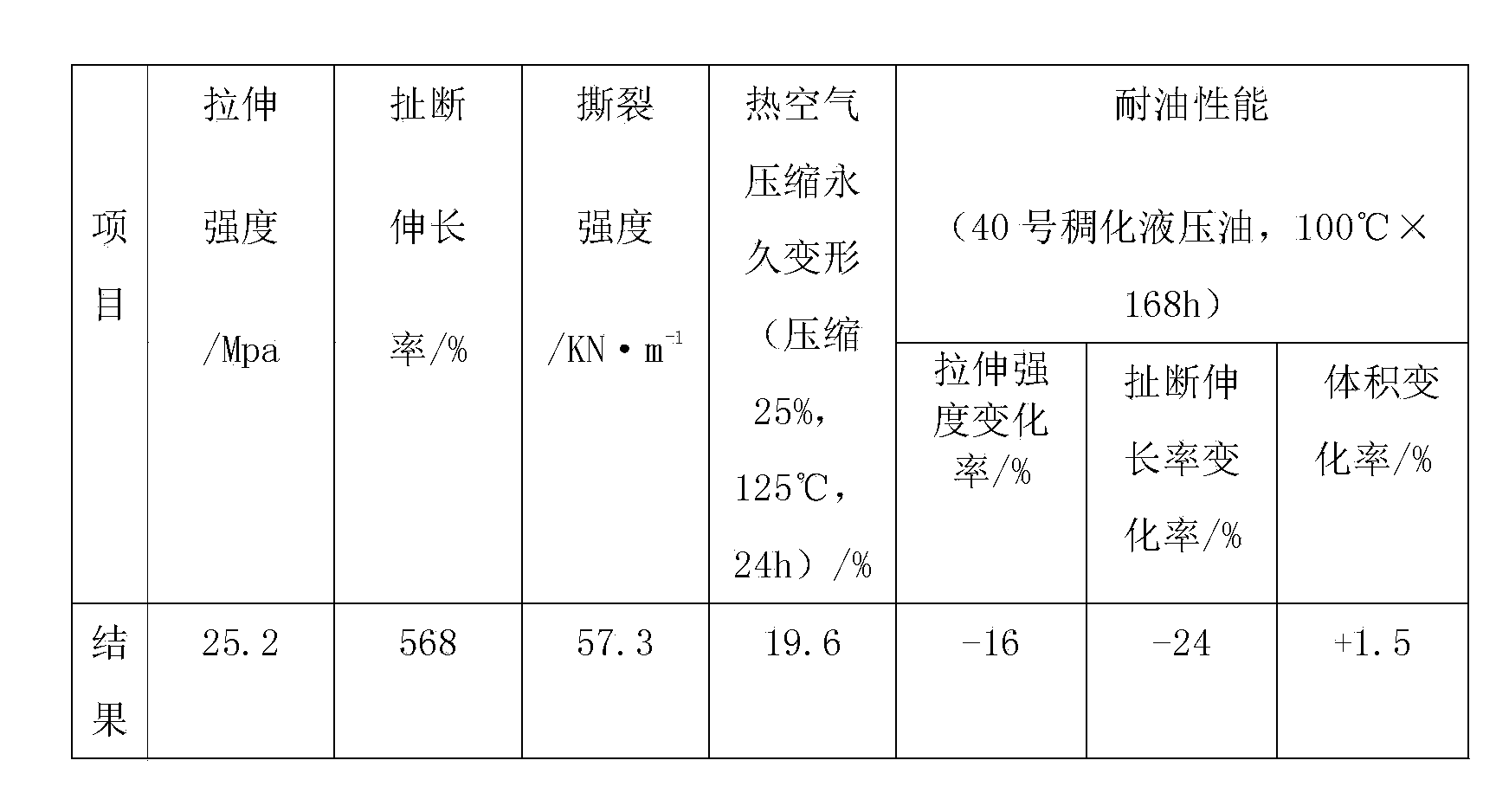

Silicon rubber/polyurethane rubber composite hydraulic sealing gasket and preparation method thereof

The invention relates to a silicon rubber / polyurethane rubber composite hydraulic sealing gasket and a preparation method thereof. The silicon rubber / polyurethane rubber composite hydraulic sealing gasket is prepared from methylvinylsiloxane rubber, polyether based polyurethane rubber, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, diphenyl silanediol, hexamethyldisilazane, gas-phase white carbon black, modified wollastonite and the like. The methylvinylsiloxane rubber, which has the advantages of excellent heat resistance, excellent freezing resistance, excellent ozone resistance, excellent atmospheric aging resistance and small permanent compression set, and the polyurethane rubber with favorable mechanical properties are compounded and blended, so that the respective advantages are displayed, thereby enhancing the sealing property of the sealing material; and in the blending process, the organically / inorganically modified wollastonite is added to obviously improve the dispersity of the wollastonite in the rubber, thereby enhancing the mechanical strength, oil resistance, wear resistance, high temperature resistance and other properties of the sealing material.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Fluorosilicone rubber cable material for coal mine cable and preparation method of cable material

The invention relates to a fluorosilicone rubber cable material for a coal mine cable and a preparation method of the cable material. The cable material comprises the following raw materials: fluorosilicone rubber, methyl vinyl silicone rubber, precipitation-method white carbon black, light calcium carbonate, zinc oxide, magnesium oxide, stearic acid, an accelerator N, N-tetramethylthiuram disulfide, an antiager-2-mercapto benzimidazole, a vulcanizer-2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, a flame retardant-ammonium polyphosphate, diphenyl silanediol, talcum powder and vaseline. According to the cable material, the advantages of the fluorosilicone rubber and the methyl vinyl silicone rubber as raw materials are combined, the performance of a conventional fluorosilicone rubber cable material is improved, the cable material has excellent performances such as friction and collision resistance, high and low temperature resistance, medium resistance, ageing resistance, flame retardance, waterproof and moistureproof properties, long service life and the like, the requirement of safety use in a coal mine in a special environment is met, and the preparation method of the cable material is simple in process and free of environmental pollution and three-waste emission.

Owner:WUXI HUAMEI CABLE

Building interior wall special-purpose antibacterial mildew-resistant emulsion paint

The invention discloses building interior wall special-purpose antibacterial mildew-resistant emulsion paint. The building interior wall special-purpose antibacterial mildew-resistant emulsion paint comprises acrylic acid emulsion, polyurethane emulsion, bisphenol A epoxy resin, diphenylsilanediol, nanometer titanium dioxide, nanometer silica sol, nanometer zinc oxide, active carbon, tourmaline nanometer powder, dodecafluoroheptyl methacrylate, a film forming assistant, sorbitan monopalmitate, lauric acid, phenolic resin, N-phenyl-N'-cyclohexyl-p-phenylenediamine, potassium citrate, propyl p-hydroxybenzoate, succinic acid, sodium alginate, imidazolidone, chitosan, water and an assistant. The building interior wall special-purpose antibacterial mildew-resistant emulsion paint can form a fine paint film, has good antibiosis and mildew resistance and excellent water resistance and workability, has a refreshing smell and has strong adhesion to a base material.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Preparation method of polyurethane rubber / silicone gross rubber

The invention discloses a preparation method of polyurethane rubber / silicone gross rubber. The method includes the following steps: 1, fully mixing 100 parts of white carbon black and 20 parts of hexamethyl-disilazane in a mixing mill, baking the mixture an oven at 80 DEG C to a neutral state, and placing for 24 h; 2, adding the mixture with 200 parts of methyl vinyl silicone rubber and 10 parts of diphenyl silanediol in a vacuum kneading machine, and kneading the mixture into gross rubber; and 3, respectively milling the silicone rubber gross rubber and polyurethane rubber in a double roller for 2 min, and then evenly mixing silicon rubber gross rubber and polyurethane rubber in a weight ratio of 3:2, adding a vulcanizing agent, conducting thin-filming and discharging. According to the preparation method of the polyurethane rubber / silicone gross rubber provided by the invention compound, white carbon black is added to methyl vinyl silicone rubber for mixing, and then subjected to co-mixing with polyurethane; without the addition of the compatibilizer, the curing agent can realize the vulcanization; and the prepared gross rubber has good mechanical properties.

Owner:青岛欧美亚橡胶工业有限公司

High-temperature resistant anti-corrosion pump valve sealing gasket and preparation method thereof

ActiveCN103436029AImprove high temperature resistanceHigh mechanical strengthPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSilanesDiphenylsilanediol

The invention discloses a high-temperature resistant anti-corrosion pump valve sealing gasket and a preparation method thereof. The sealing gasket comprises the following raw materials in parts by weight: 60-70 parts of methyl vinyl silicone rubber, 20-30 parts of ethylene-propylene-diene monomer, 10-15 parts of polyethylene, 1-2 parts of a corundum powder, 5-10 parts of hydroxyl silicone oil, 15-20 parts of fumed silica, 2-3 parts of dihydroxydiphenylsilane, 2-3 parts of zinc oxide, 1-2 parts of alkylated diphenylamine, 4-8 parts of polyethylene wax, 0.5-1 part of 2,4-dihydroxy benaophenonel, 8-12 parts of nano argil, 10-15 parts of modified nano-diamond, 1-2 parts of triallyl cyanurate, 1-3 parts of vinyl-tris(beta-methoxyethoxy)silane, 1-2 parts of an accelerant CZ, 2-3 parts of an anti-aging agent RD, and 1-2 parts of an anti-aging agent 4020. The sealing gasket can resist high temperature, has high mechanical strength, high oil resistance and good corrosion resistance, can work in acids, alkalis, oil and other media for a long time, and is durable in use.

Owner:ANHUI TIANMA PUMP VALVE GROUP

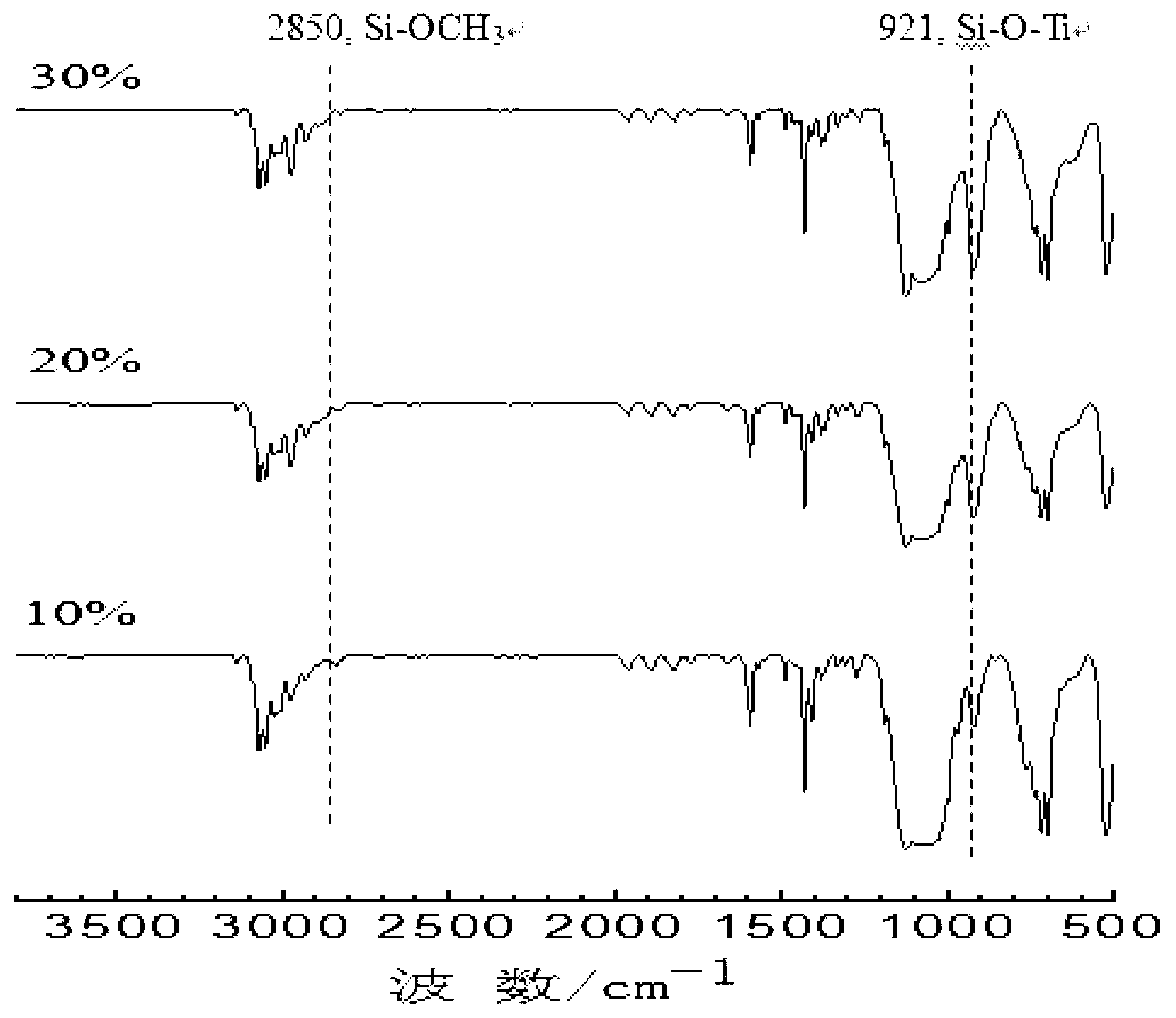

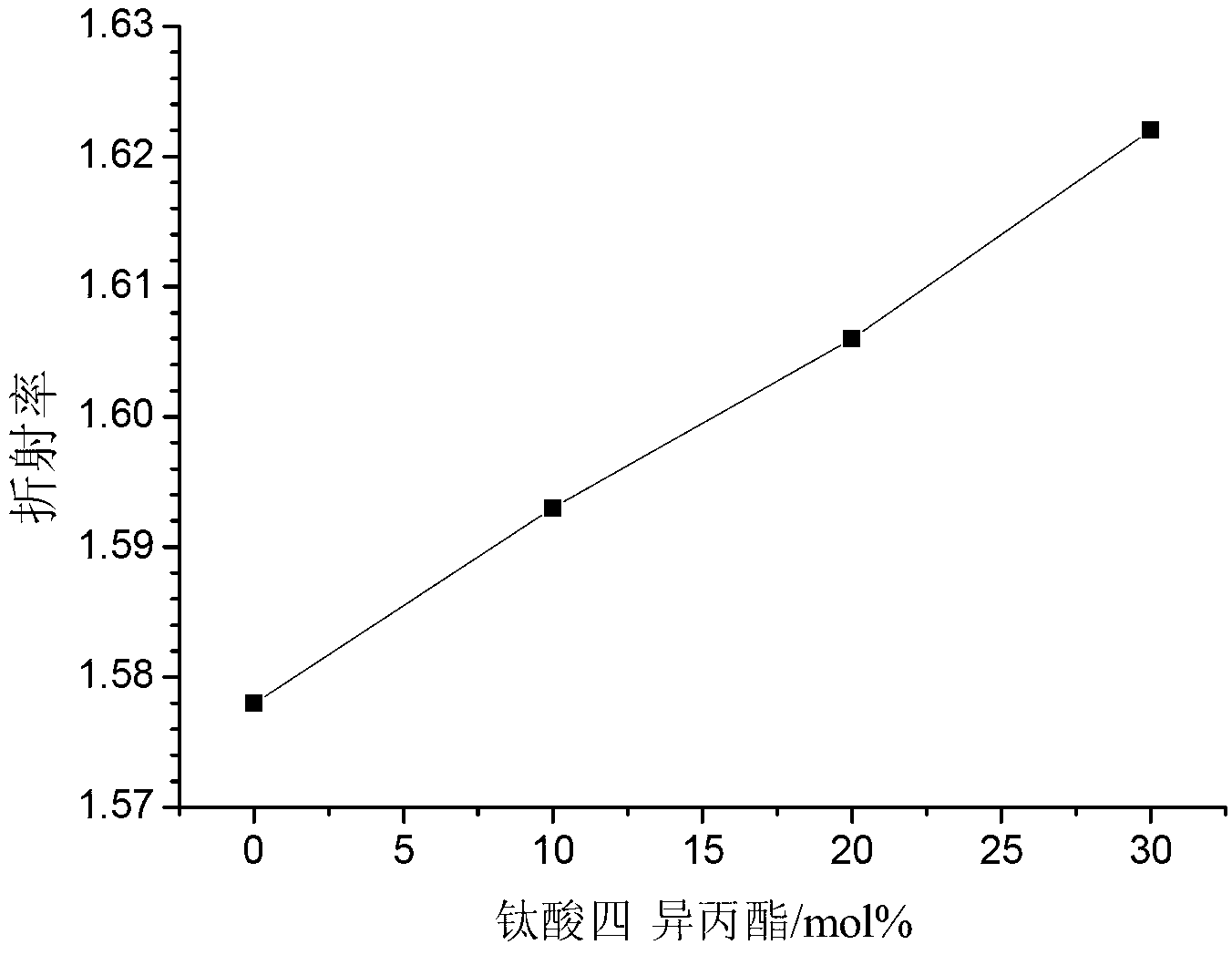

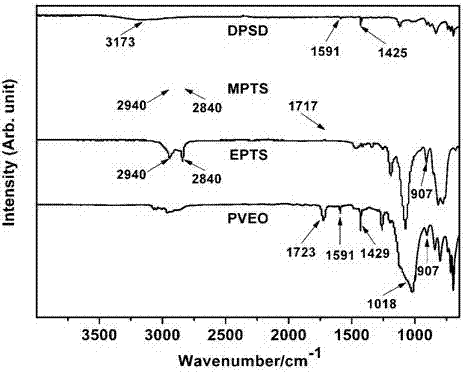

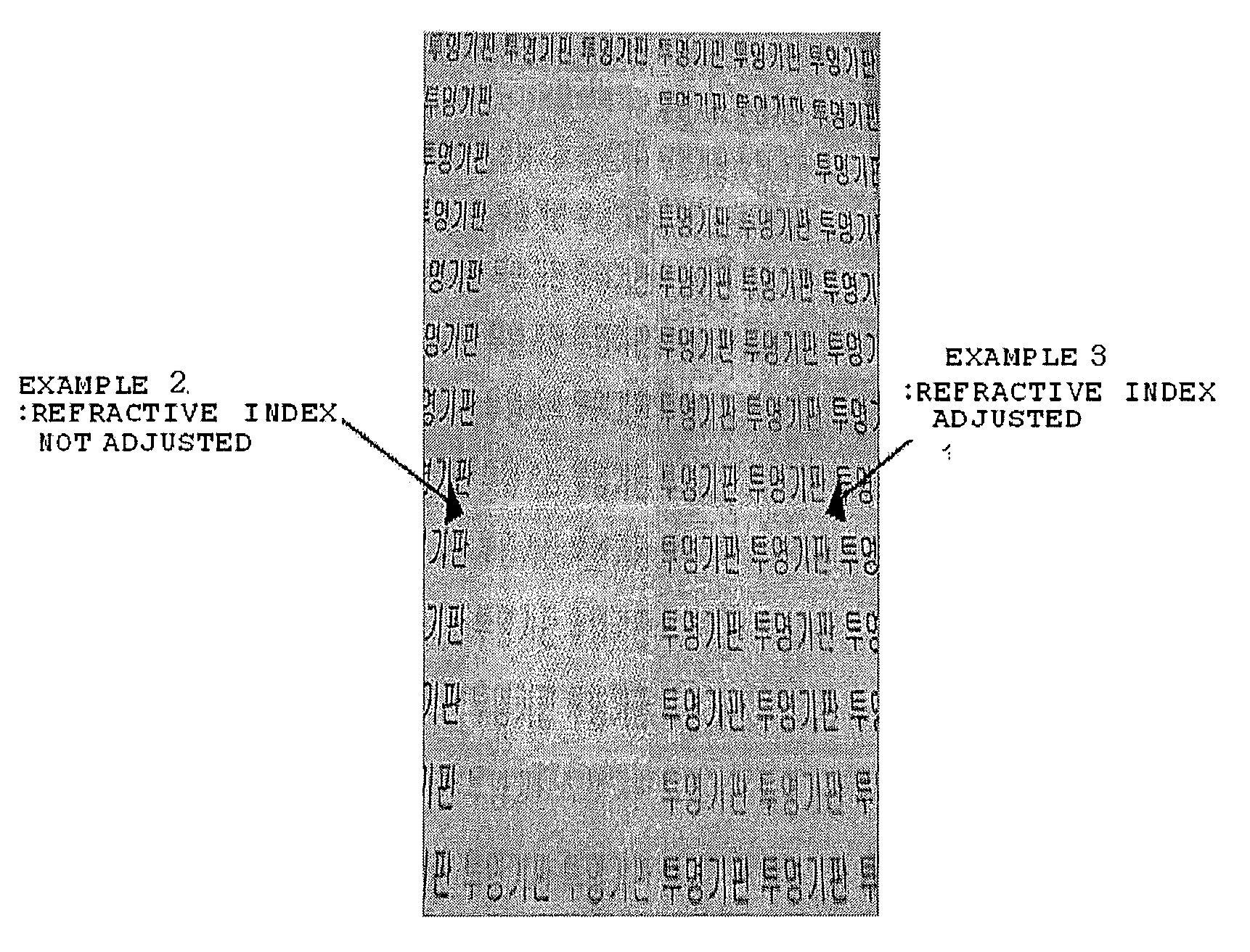

High refractive index titanium hybrid silicon resin and preparation method thereof

InactiveCN103265703AOvercoming high shrinkageOvercome the shortcomings of cured products with defectsPolymer scienceSilanes

The invention relates to a high refractive index titanium hybrid silicon resin and a preparation method thereof, and belongs to the technical field of organic-inorganic hybridization. The preparation method comprises: placing a titanate monomer, a trifunctional alkoxy silane monomer and a solvent into a reactor, then adding dihydroxydiphenylsilane in batch, and carrying out copolycondensation for 2-12 h at a temperature of 60-110 DEG C under an alkaline catalyst effect to prepare a series of transparent and highly-viscous hybrid silicon resins with an adjustable refractive index, wherein the resins concurrently contain a Si-O-Si structure unit and a Ti-O-Si structure unit. The preparation method has advantages of simple process, mild reaction conditions, good repeatability, good controllability and the like. The hybrid resin has characteristics of high refractive index, excellent weathering resistance, excellent high temperature resistance and excellent low temperature resistance, wherein the double bond in the resin can be subjected to addition curing, small molecule substances are not generated during the curing process, and defects of high condensation type curing shrinkage rate, sand holes in the cured material, and the like are improved.

Owner:BEIJING UNIV OF CHEM TECH

Mixed silicon rubber-based conductive nonlinear insulating material

InactiveCN103214850AGive full play to the synergistic effectPlastic/resin/waxes insulatorsGas phaseCarbon nanotube

The invention discloses a mixed silicon rubber-based conductive nonlinear insulating material, relates to a rubber-based nonlinear dielectric material, and mainly solves the problems that the existing silicon rubber-based nonlinear dielectric material is low in breakdown strength and poor in physical-mechanical properties because a large amount of nonlinear functional filler is added. The nonlinear insulating material is made of a mixed silicon rubber, a nonlinear functional filler, white carbon black by gas phase method, nano-ferric oxide, diphenyl silanediol and organic peroxide, wherein the nonlinear functional filler consists of nano-zinc oxide, nano-silicon dioxide, nano-silicon carbide, a carbon nano-tube, conductive carbon black and nano-graphite. The prepared nonlinear insulating material has the advantages that the alternating-current breakdown strength is not smaller than 30kV / mm, the direct-current breakdown strength is not smaller than 60kV / mm, the maximum nonlinear coefficient is 6-18, the tensile strength is not smaller than 9.0MPa, and the breaking elongation is not smaller than 200%. The invention is mainly applicable to high-voltage composite insulating materials.

Owner:HARBIN UNIV OF SCI & TECH

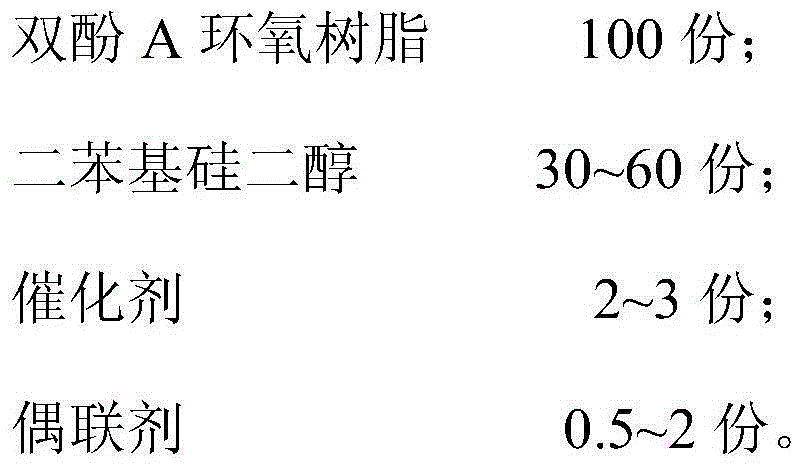

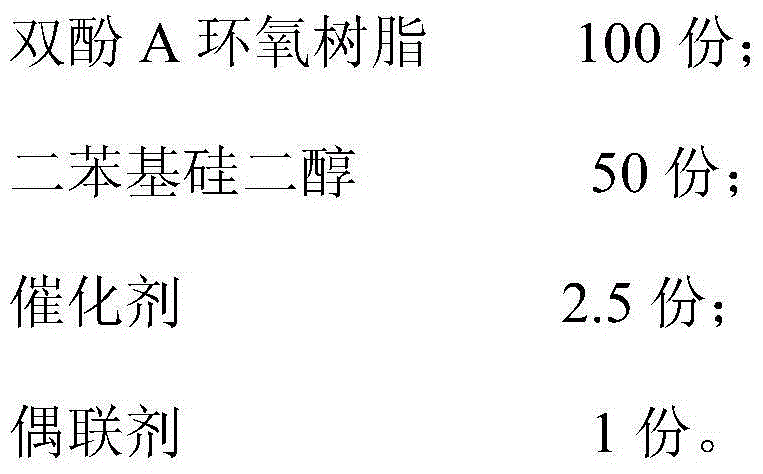

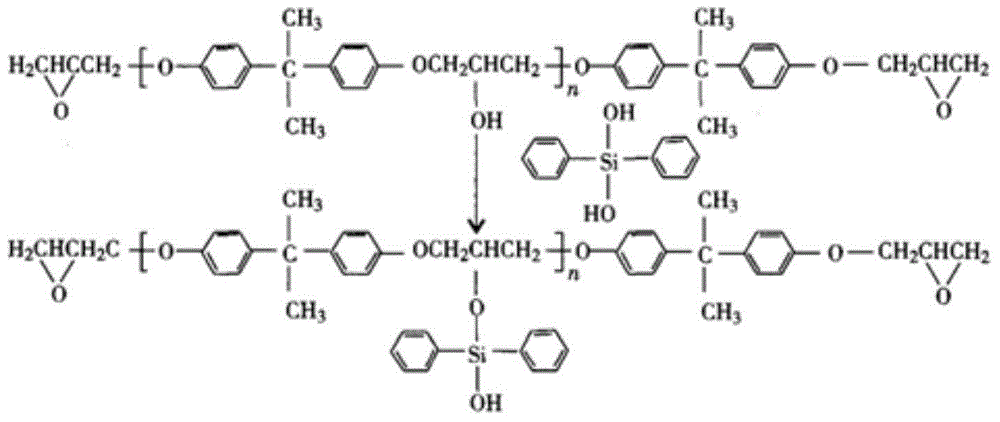

Organosilicone modified epoxy resin and preparation method thereof as well as mica capacitor

The invention provides organosilicone modified epoxy resin and a preparation method thereof as well as a mica capacitor of a spacecraft. The organosilicone modified epoxy resin comprises the following components in parts by mass: 100 parts of bisphenol A epoxy resin, 30-60 parts of diphenyl silanediol, 2-3 parts of a catalyst and 0.5-2 parts of a coupling agent. The reliable operating temperature of the mica capacitor of the spacecraft prepared from organosilicone modified epoxy resin as a mica paper impregnated material is improved to over 55 DEG C and can reach over 180 DEG C. The reliable operating height of the mica capacitor of the spacecraft can be improved by three times and reaches over 15000m; under 6000V D. C breakdown voltage, the percent of pass can reach over 97%.

Owner:卢儒

Synthesis method of phenyl hydrogen-containing silicone oil

The invention provides a synthesis method of phenyl hydrogen-containing silicone oil. The synthesis method comprises the following steps of: removing hydrogen chloride from diphenylsilanediol and methyl hydrogen dichlorosilane serving as raw materials under the action of an acid receiving agent; performing a balanced reaction under a strong-acid condition; and decoloring, filtering, and removing a solvent and a low-boiling-point substance so as to obtain the phenyl hydrogen-containing silicone oil. The synthesis method has the advantages of readily available raw materials, mild reaction condition and simple and practical process. The viscosity of the phenyl hydrogen-containing silicone oil obtained by the method of the invention is between 200 and 500 mm<2> / s, the refractive index is between 1.50 and 1.53 and the hydrogen content is between 0.2 and 0.6 percent. The phenyl hydrogen-containing silicone oil can be used in crosslinking curing reactions of a light-emitting diode (LED) potting compound and other addition polysiloxanes with high refractive indexes and has the characteristics of quick curing, attractive appearance and high refractive index.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

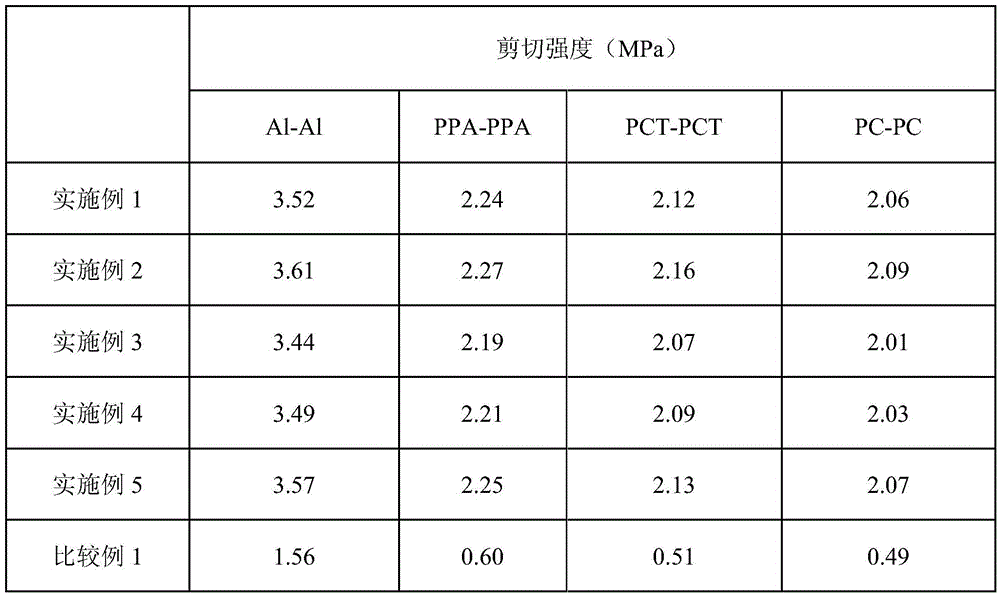

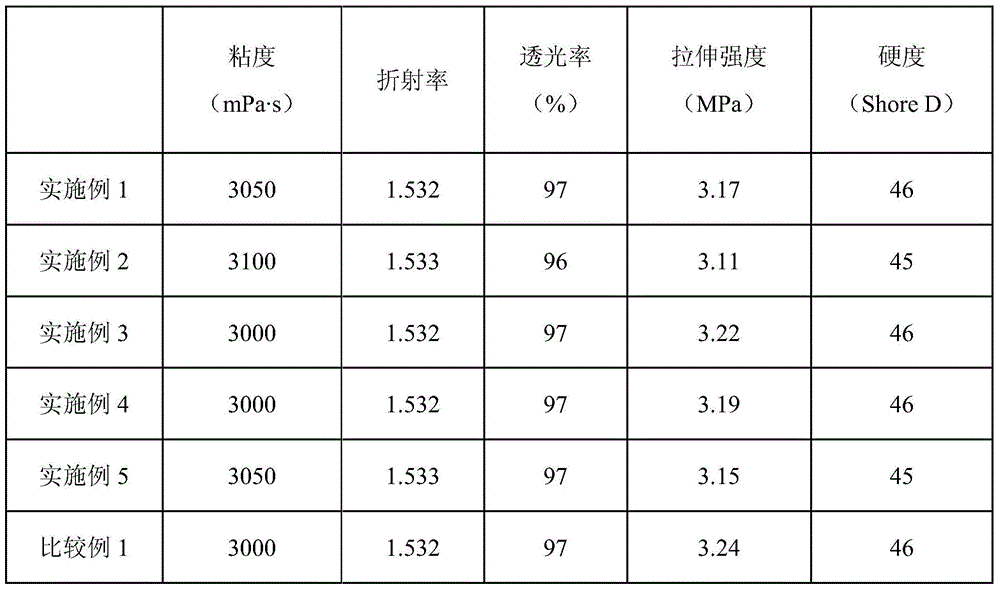

Organic boron silicon adhesion promoter with high refractive index as well as preparation method and application of organic boron silicon adhesion promoter

ActiveCN105524282AHigh refractive indexAvoid the disadvantage of easy to open loopMacromolecular adhesive additivesEpoxySilanes

The invention discloses an organic boron silicon adhesion promoter with a high refractive index as well as a preparation method and an application of the organic boron silicon adhesion promoter. The preparation method comprises steps as follows: diphenylsilanediol, epoxy silane, ester silane, borate and a solvent are uniformly stirred at the room temperature, a titanate catalyst is added, a mixture reacts for 4-14 h at the reaction temperature controlled in a range from 25 DEG C to 60 DEG C and continuously reacts for 2-6 h at the vacuum degree controlled in a range from 0.05 MPa to 0.098 MPa and at the temperature controlled in a range from 60 DEG C to 140 DEG C, and the organic boron silicon adhesion promoter with the high refractive index is prepared. The prepared adhesion promoter can not only remarkably improve the adhesion performance of high-refractive-index addition type silica gel for LED packaging, but also has the high refractive index and good compatibility with the silica gel, particularly has a remarkable function for improvement of the adhesion performance of plastic base materials such as polyphthalamide, polyethylene terephthalate, 1,4-cyclohexanedimethanol terephthalate, polycarbonate and the like and can be expected to be widely applied to the field of LED device packaging.

Owner:SOUTH CHINA UNIV OF TECH

Modified natural rubber composite material for tire treads

The invention discloses a modified natural rubber composite material for tire treads, relating to the technical field of natural rubber processing. The modified natural rubber composite material is prepared from the following raw materials in parts by quality: 80-100 parts of natural rubber, 10-15 parts of carbon nanotube, 5-10 parts of magnesium carbonate, 3-8 parts of calcium silicate, 2-6 parts of diphenyl silanediol, 3-8 parts of coumarone indene resin, 1-5 parts of rosin, 2-5 parts of trioctyl metabenzenetricarboxylate, 2-3.5 parts of kaolin, 0.5-3 parts of zinc dialkyl dithiophosphate, 1-2 parts of titanium white, 3-8 parts of benzoperoxide, 2-6 parts of superfine magnesium hydroxide and 1-5 parts of zinc borate. By using the carbon nanotube to modify the natural rubber, the prepared rubber composite material has the advantages of high temperature resistance, wear resistance, slip resistance, aging resistance and favorable mechanical properties.

Owner:ANHUI ZHONGMA RUBBER & PLASTIC PROD

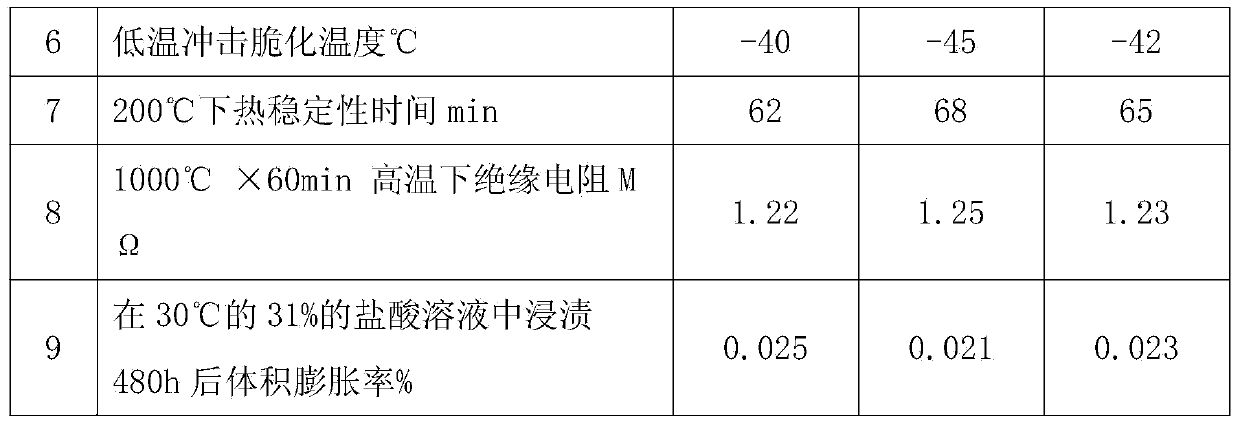

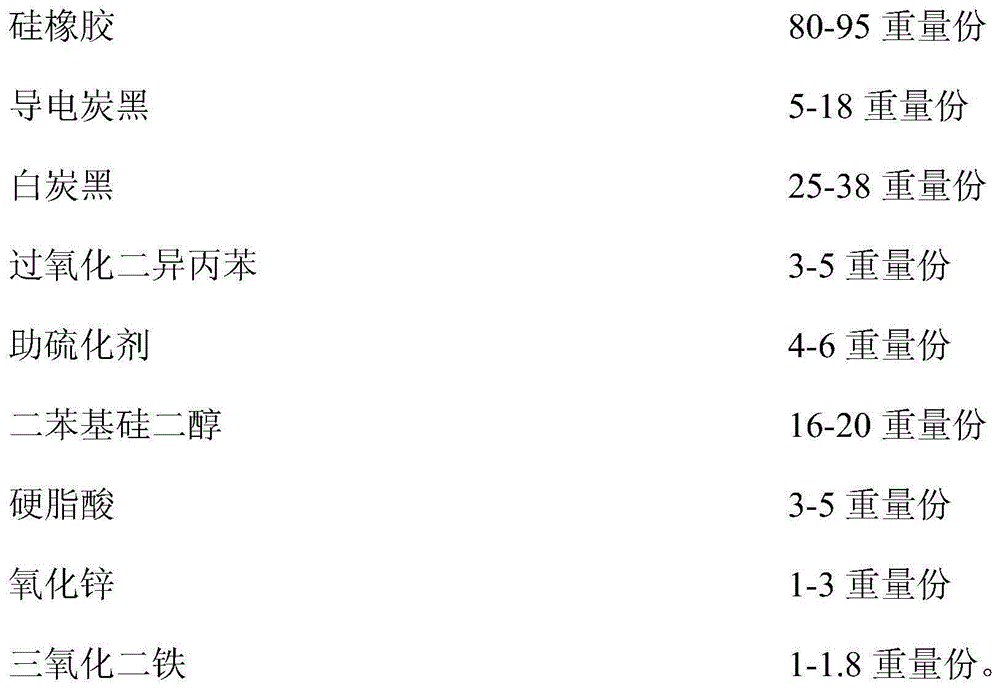

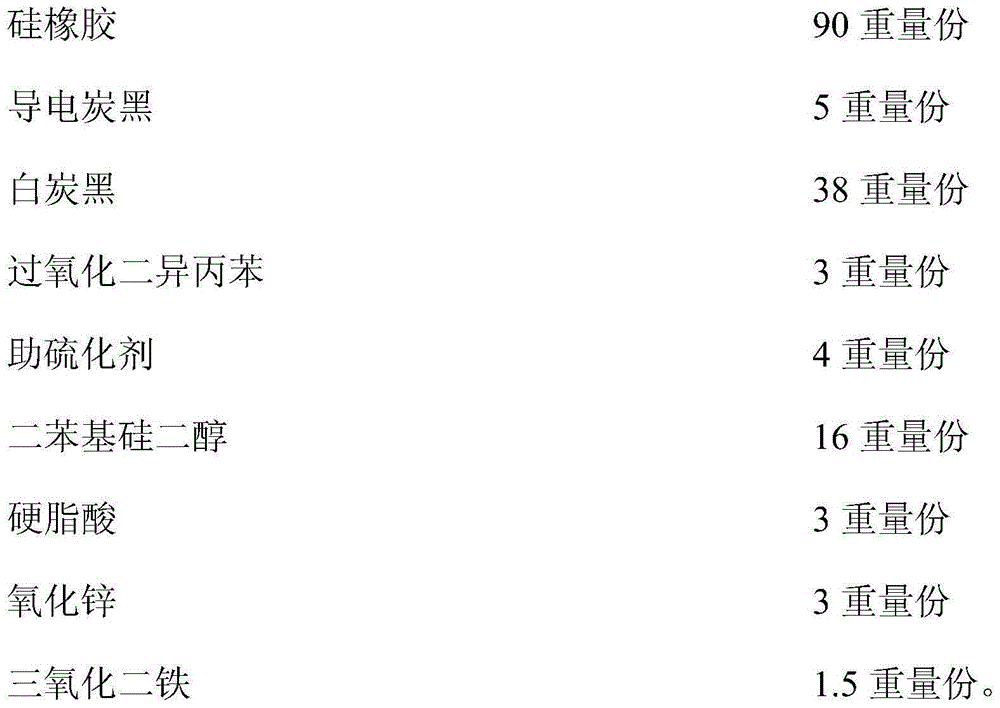

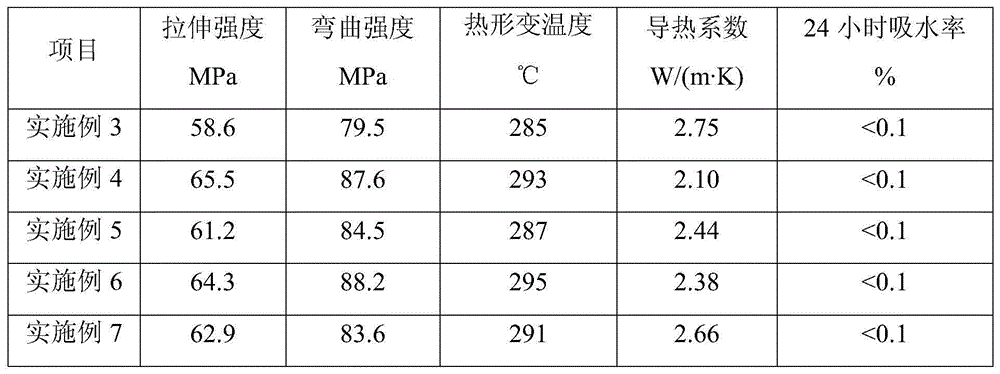

Semi-conducting silicon rubber shielding material for cables

InactiveCN105086458AImprove radiation resistanceExcellent ElectricalInsulated cablesInsulated conductorsDiphenylsilanediolStearic acid

The invention provides a semi-conducting silicon rubber shielding material for cables and a preparation method thereof. The semi-conducting silicon rubber shielding material for cables is mainly prepared from the following materials: 80 to 95 parts by weight of silicon rubber, 5 to 18 parts by weight of conductive carbon black, 25 to 38 parts by weight of white carbon black, 3 to 5 parts by weight of dicumyl peroxide, 4 to 6 parts by weight of assistant vulcanizing agent, 16 to 20 parts by weight of diphenyl silanediol, 3 to 5 parts by weight of stearic acid, 1 to 3 parts by weight of zinc oxide and 1 to 1.8 parts by weight of ferric oxide. The radiation resistance of the semi-conducting silicon rubber shielding material disclosed by the invention is good, and the semi-conducting silicon rubber shielding material has good electrical and mechanical properties; when the semi-conducting silicon rubber shielding material is used as a wire and cable shielding layer, in a radiation place, the strength retention rate of the wire and cable shielding layer can be more than 80 percent and the elongation retention rate is about 45 percent for a long time, and the wire and cable shielding layer has excellent plasticity.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Novel high-hardness plastic shell composition for capacitor

The invention discloses a novel high-hardness plastic shell composition for a capacitor. The novel high-hardness plastic shell composition is characterized by consisting of the following components in parts by weight: 35 parts of polypropylene, 15 parts of linear polyethylene, 10 parts of a high barrier film, 5 parts of polypropylene random copolymer, 5 parts of di-tert-butyl peroxide, 2 parts of cassava flour, 5 parts of modified wood plastic powder, 2 parts of tributyl citrate, 2 parts of silicone rubber, 2 parts of glycerol, 5 parts of carbon fiber, 2 parts of a rear-earth light converter, 2 parts of diphenyl silanediol, 2 parts of a plasticizer, 2 parts of silicon carbide micro powder, 2 parts of a lubricant, 2 parts of paraffin, 2 parts of vermiculite, 2 parts of sepiolite fabric, 2 parts of glass fibers, 2 parts of rear earth and 2 parts of talcum powder. The novel high-hardness plastic shell composition disclosed by the invention is simple in component and low in cost; the prepared finished product has good toughness, strong bearing capacity and high compactness, is easy to degrade and nonhazardous under a high temperature environment; meanwhile, the conventional preparation process is changed and a freezing process is increased, so that the safety of the product is improved and the product has relatively good stable performance at a relatively high temperature.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Wear-resisting and high-temperature-resisting silicone rubber cable sheath material

InactiveCN103804913AImprove cooling efficiencyImprove thermal conductivityInsulated cablesInsulated conductorsPolymer scienceAntioxidant

The invention discloses a wear-resisting and high-temperature-resisting silicone rubber cable sheath material. The wear-resisting and high-temperature-resisting silicone rubber cable sheath material comprises the following raw materials in parts by weight: 33-45 parts of polydimethyl methyl vinyl siloxane, 25-30 parts of silicon micro-powder, 0.3-0.5 part of hydroxyl silicone oil, 0.2-0.9 part of isobutyltriethoxysilane, 5-8 parts of a vulcanizing agent, 0.15-0.3 part of a platinum catalyst, 8-13 parts of acetylene carbon black, 20-25 parts of white carbon black, 3-6 parts of aluminum oxide, 0.15-0.45 part of magnesium oxide, 0.3-1.2 parts of an antioxidant, 3-7 parts of a de-molding agent and 1-3 parts of diphenyl silanediol. The wear-resisting and high-temperature-resisting silicone rubber cable sheath material disclosed by the invention has good cold-resisting, wear-resisting and conductive performances and an excellent heat conduction performance, is anti-aging and has long service time.

Owner:ANHUI HUAYUAN CABLE GROUP

High-temperature-resistant capacitor plastic shell and preparation method thereof

InactiveCN104311991AImprove performanceImprove securityBulk chemical productionCyclohexanoneSimple component

A high-temperature-resistant capacitor plastic shell consists of the following components in parts by weight: 35 parts of polypropylene, 15 parts of linear polyethylene, 10 parts of methyl silicone rubber, 5 parts of diphenyl silanediol, 5 parts of dimethyl siloxane, 5 parts of nano silica, 5 parts of a modified wood plastic powder, 2 parts of azadirachtin, 2 parts of an emulsifier, 2 parts of soybean oil, 5 parts of carbon fibers, 5 parts of metallocene polyethylene, 0.5 part of a catalyst, 2 parts of a plasticizer, 2 parts of oxidized polyethylene, 2 parts of cyclohexanone, 2 parts of paraffin, 2 parts of boron fibers, 2 parts of sepiolite velvet, 2 parts of glass fibers, 2 parts of butyl acetate, and 2 parts of a talc powder. The high-temperature-resistant capacitor plastic shell has the advantages of simple components, and low cost; the prepared finished product has the advantages of high temperature resistance, stable performance, and no toxicity under a high-temperature environment; and at the same time, due to change of a conventional preparation process, a freezing process is increased, the safety of the product is improved, and the product still has relatively good stable performance at higher temperatures.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Silicon seal ring

The invention discloses a silicon seal ring, relating to the technical field of a rubber composite material, which is prepared from the following raw materials in parts by weight: 80-100 parts of methyl vinyl silicone rubber, 25-35 parts of polyether polyurethane rubber, 2-6 parts of diphenylsilanediol, 0.5-3 parts of dihydroxy polydimethyl siloxane, 40-60 parts of fumed silica, 6-10 parts of hydroxyl silicone oil, 2-3 parts of anti-aging agent, 2-3 parts of zinc stearate, 1-2 parts of ferric oxide, 2-3 parts of copper oxide, and 2-3 parts of accelerator. Compared with the prior art, the silicon seal ring is good in chemical stability, high in mechanical strength, wear-resistant, high-temperature-resistant and anti-aging.

Owner:LIUZHOU JULONG TECH

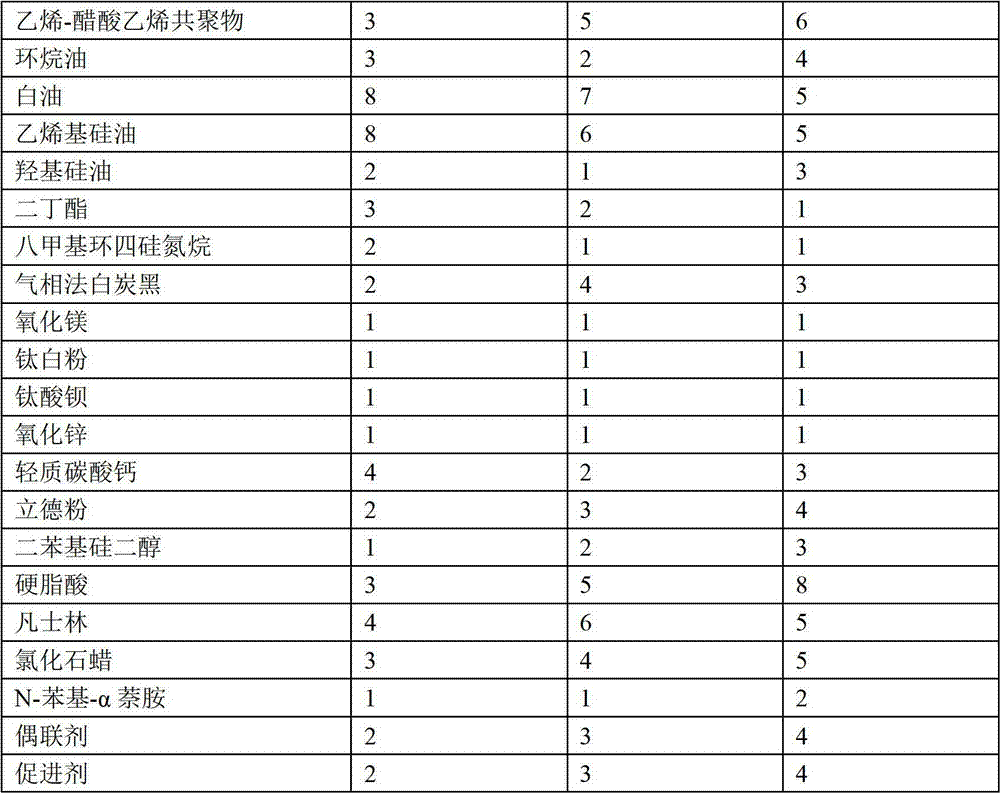

Tearing-resistant silicone rubber composition

The invention discloses a tearing-resistant silicone rubber composition, falling into the technical field of polymer material. The composition comprises the following materials by weight: 30-50 parts of vinyl silicone rubber, 5-10 parts of polyethylene, 5-10 parts of polyolefin resin, 3-6 parts of ethylene-vinyl acetate (EVA) copolymer, 2-4 parts of naphthene oil, 5-8 parts of white oil, 5-8 parts of vinyl silicone oil, 1-3 parts of hydroxyl silicone oil, 1-3 parts of dibutyl ester, 1-2 parts of octamethylcyclotetrasilazane, 2-4 parts of fumed silica, 1 part of magnesia, 1 part of titanium dioxide, 1 part of barium titanate, 1 part of zinc oxide, 2-4 parts of light calcium carbonate, 2-4 parts of lithopone powder, 1-3 parts of diphenylsilanediol, 3-8 parts of stearic acid, 4-6 parts of vaseline, 3-5 parts of chlorinated paraffin, 1-2 parts of N-phenyl-alpha-naphthylamine, 2-4 parts of a coupling agent, and 2-4 parts of accelerator. The silicone rubber composition has excellent mechanical properties, especially tearing-resistant property.

Owner:汕头市科源有机硅材料有限公司

Cold-resistant rubber seal ring

The invention discloses a cold-resistant rubber seal ring. The cold-resistant rubber seal ring is prepared from the following raw materials in parts by weight: 30-50 parts of ethylene propylene diene monomer, 50-80 parts of butadiene rubber, 2-3.5 parts of zinc stearate, 3-5 parts of diphenyl silandiol, 1-3 parts of dioctyl phthalate, 2.6-3.5 parts of microcrystalline wax, 6-8 parts of high wear-resistant carbon black, 10-15 parts of magnesium oxide, 12-15 parts of modified silica powder, 4-6 parts of rutile type titanium dioxide, 3-6 parts of alum powder, 5-8 parts of nanometer calcium carbonate, 5-8 parts of naphthenic rubber oil, 1-2 parts of sodium pyrophosphate, 2-3 parts of antiager, 3-5 parts of accelerant PZ, 0.15-0.3 part of sodium lignin sulfonate, 5-7 parts of solid coumarone, 1.2-1.4 parts of turpentine oil, 20-30 parts of cold-resistant agent and 2-2.5 parts of sulfur. The cold-resistant rubber seal ring disclosed by the invention has very good cold resistance and does not crack at a low temperature; in subzero 30 DEG C environments, the cold-resistant rubber seal ring does not become brittle, and the good performances of the cold-resistant rubber seal ring are maintained.

Owner:安徽金科橡塑制品有限公司

Heat-resistant flame-retardant powder coating

InactiveCN105062303AAccelerated corrosionImprove water resistancePowdery paintsPolyamide coatingsEpoxyBenzoyl peroxide

The invention discloses heat-resistant flame-retardant powder coating. The coating comprises the following raw materials: epoxy resin, carboxyl-terminated unsaturated polyester resin, nitrogen-containing phenolic resin, polyamide resin, thermoplastic styrene-butadiene rubber, ammonium polyphosphate, pentaerythritol, melamine, expansible graphite, nano-zirconia, titanium dioxide, talcum powder, diphenyl silanediol, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, octadecendioic acid, tetrahydro-1,3,4,6-tetrakis(methoxymethyl)imidazo[4,5-d]imidazole-2,5(1H,3H)-dione, benzoyl peroxide and auxiliaries. The heat-resistant flame-retardant powder coating has good heat resistance and excellent flame retardant performance, can be used for coating surfaces of kitchen ware, instrument shells, display stands, electromechanical equipment, automobile components and parts and the like, and has the advantages of good comprehensive performance and long service life.

Owner:安徽圣德建材科技有限公司

Salt-fog preventing coating for cable and preparation method thereof

ActiveCN101629052AFast curingEasy to useInsulated cablesAnti-corrosive paintsBenzoyl peroxideUltraviolet

The invention discloses a salt-fog preventing coating for a cable, comprising the following components based on portions by weight: 100 portions of silicon rubber, 20-40 portions of No.2 fumed silica, 2-6 portions of diphenyl silanediol, 0.5-1 portion of benzoyl peroxide, 15-35 portions of zinc oxide, 0.5-1 portion of ultraviolet radiation resistant agent, 4-8 portions of olefin, 3-6 portions of olefin oil and 4-6 portions of transformer oil. The invention also discloses a preparation method of the salt-fog preventing coating for the cable. The salt-fog preventing coating for the cable can well prevent strong ultraviolet radiation from irradiating the cable and prevent high salt dirty, brine dipping, acid, alkali, oil, salt, and the like from seriously eroding the cable. In a process of using the coating, the olefin and the transformer oil can be gradually separated out on the surface of the cable so that crystal salt caused by seawater can be effectively prevented from adhering on the surface of the cable, the cable can be well protected, and the service life of the cable can be greatly prolonged.

Owner:江苏东旭电缆有限公司

High-temperature-resistant high-thermal-conductivity boron-dopedorganosilicon epoxy pouring sealant as well as preparation method and application thereof

ActiveCN104479606AGood compatibilityExcellent moisture resistanceNon-macromolecular adhesive additivesOther chemical processesHeat conductingDiphenylsilanediol

The invention discloses a high-temperature-resistant high-thermal-conductivity boron-doped organosilicon epoxy pouring sealant as well as a preparation method and an application thereof. The pouring sealant comprises a component A and a component B, wherein the component A comprises 100 parts of diphenylsilanediol modified epoxy resin, 1-5 parts of anacetylacetone metal complex and 20-100 parts of boron-modified methyl MQ silicon resin; the component B comprises 100 parts of liquid anhydride and 50-100 parts of boron nitride heat-conducting ceramic powder. The prepared boron-doped organosilicon epoxy composite material has excellent moistureresistance and heat resistance, high mechanical strength and the high heat-conducting property and is suitable to be used as a high-temperature-resistant high-thermal-conductivity insulating moisture-resistant packaging protection material.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

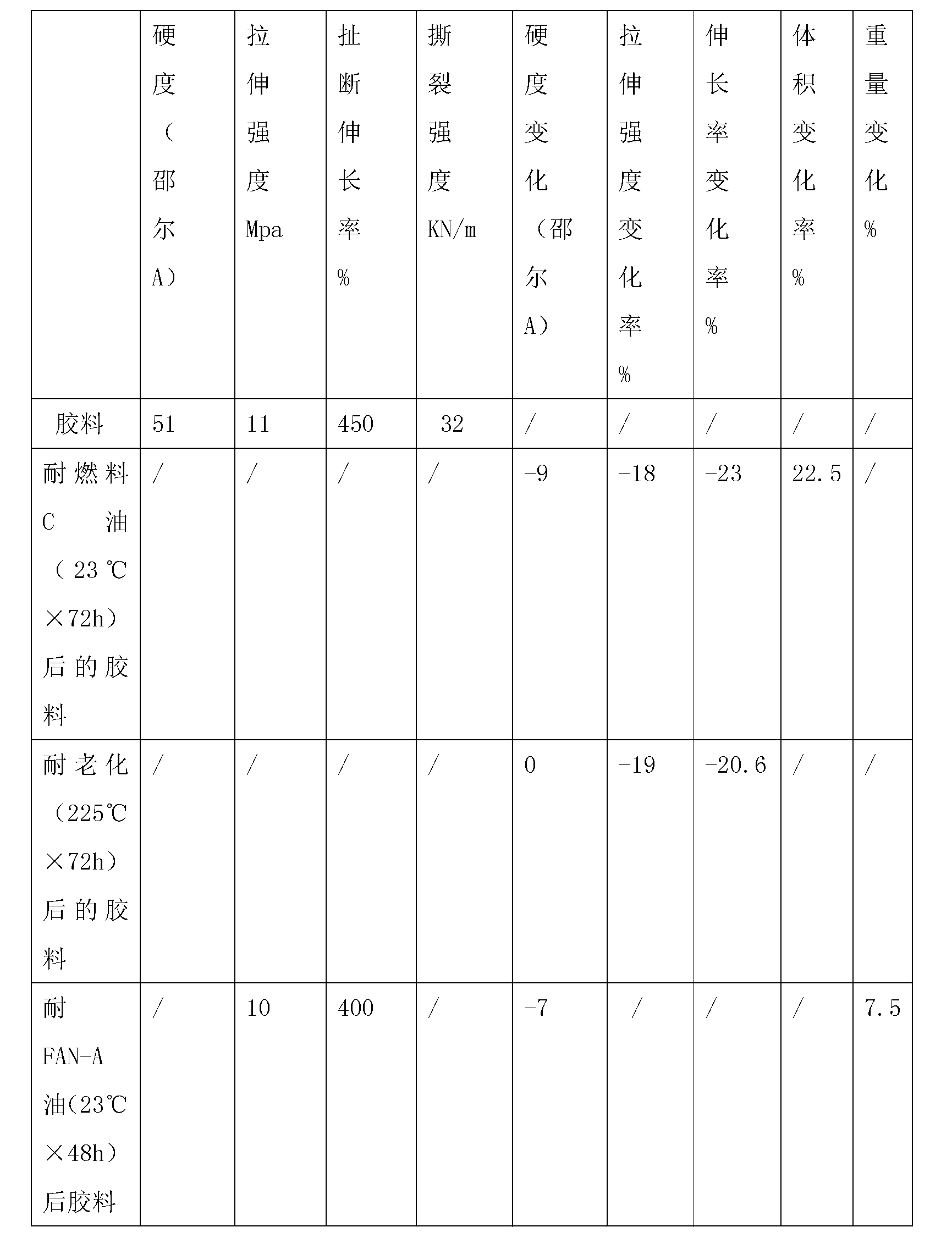

Piston rubber material for mud pumps and preparation method thereof

ActiveCN103044927AImprove performanceGood high and low temperature resistance2-mercaptobenzimidazoleDiphenylsilanediol

The invention discloses a piston rubber material for mud pumps. The piston rubber material is made from the following raw materials in parts by weight: 20-30 parts of fluorosilicone rubber, 50-60 parts of hydrogenated nitrile rubber, 15-25 parts of chlorosulfonated polyethylene rubber TS-320 (Tosoh), 2-3 parts of gamma-methacryloxypropyl trimethoxy silane, 1-2 parts of diphenyl silanediol, 14-16 parts of modified tree ashes, 2-3 parts of ferrocene, 0.2-0.6 part of dicumyl peroxide (DCP), 20-30 parts of high abrasion furnace (HAF) black N330, 20-25 parts of precipitated silica, 5-7 parts of light calcium carbonate, 2-4 parts of zinc oxide, 1-3 parts of calcium stearate, 1-3 parts of aluminum oxide, 5-8 parts of dolomite, 13-15 parts of modified iron ore tailing powder, 0.1-0.3 part of accelerant MBTS, 1-2 parts of sulfur, 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent MB, 1-2 parts of 2-mercaptobenzimidazole, 1-3 parts of methyl trimethoxysilane and 2-3 parts of paraffin wax. The rubber material disclosed by the invention has excellent resistance to high / low temperature, oil, solvents and chemicals; and meanwhile, the mechanical property is good, and the cost is low.

Owner:平湖市泓博科技有限公司

Intumescent flame-retardant fireproof and heatproof material

The invention discloses an intumescent flame-retardant fireproof and heatproof material. The intumescent flame-retardant fireproof and heatproof material is prepared from, by weight, 60-80 parts of methyl RTV silicone rubber, 20-35 parts of alkali free glass fiber cotton, 5-20 parts of silicate fiber, 3-10 parts of mullite fiber, 1-3 parts of benzoyl peroxide, 0.5-2 parts of dibutyltin dilaurate, 1-5 parts of diphenyl silanediol, 1-3 parts of henylethynyl polysiloxane,5-10 parts of nanometer TiO2, 3-10 parts of nano-MMT, 2-10 parts of silicon carbide, 2-8 parts of boron nitride, 2-5 parts of cerium oxide, 3-10 parts of ferric oxide, 5-10 parts of flame retardant and 5-20 parts of aerogel. The intumescent flame-retardant fireproof and heatproof material has the advantages of excellent fireproof and good heatproof performance, and long service life.

Owner:曾照韦

Preparation method of graphene modified slurry heat insulation material

The invention provides a preparation method of a graphene modified slurry heat insulation material. According to the method, firstly, expanded perlite, polystyrene particles, graphene, aluminum silicate fiber, lecithin and glycerol are added into a stirring machine; stirring and mixing are carried out; then, an obtained mixture A is added into a reaction kettle; heating is performed; phenolic resin and diphenyl silanediol are added; then, a mixture B is added into a backflow device; absolute ethyl alcohol is added; heating back flow, filtering and drying are carried out; finally, a mixture C is subjected to temperature rise under the vacuum condition; gelatin, dibutyltin dilaurate and n-butyl borate are added; stirring, temperature rise, stirring and cooling to room temperature are performed, and the graphene modified slurry heat insulation material is obtained. The folding-resistant intensity of the obtained heat insulation material can reach more than 10MPa; the absorption rate is lower than 25 percent; the heat conduction coefficient is higher than 0.08W*(mk)-1.

Owner:孟红琳

Sealing gasket material prepared by mixing three types of rubber and preparation method of sealing gasket material

The invention discloses a sealing gasket material prepared by mixing three types of rubber. The sealing gasket material is characterized by being prepared from the following raw materials in parts by weight: 20-25 parts of silicone rubber, 30-35 parts of epichlorohydrin rubber (H45), 20-24 parts of butadiene-acrylonitrile rubber, 24-28 parts of precipitated silica, 3-4 parts of diphenyl silanediol, 3-4 parts of ferric oxide, 2-3 parts of dicumyl peroxide, 1.5-2.5 parts of eleostearic acid, 2-5 parts of zinc oxide, 1-2 parts of butadiene, 10-15 parts of butyl rubber (BBK232), 3-5 parts of triethyl citrate, 3-5 parts of tung oil, 18-23 parts of N220 carbon black, 25-30 parts of N339 carbon black and 10-12 parts of modified attapulgite. By adding the modified attapulgite, the process performance of a rubber material is improved. By using an environment-friendly ingredient, the toxic and side effects and the environmental pollution are reduced. The sealing gasket material is high in temperature change resistance, high in oil resistance, high in corrosion resistance, high in ageing resistance and good in sealing performance.

Owner:WUHU WANRUN MACHINERY

Silicone rubber sealing gasket for fire-proof seam and preparation method of silicone rubber sealing gasket

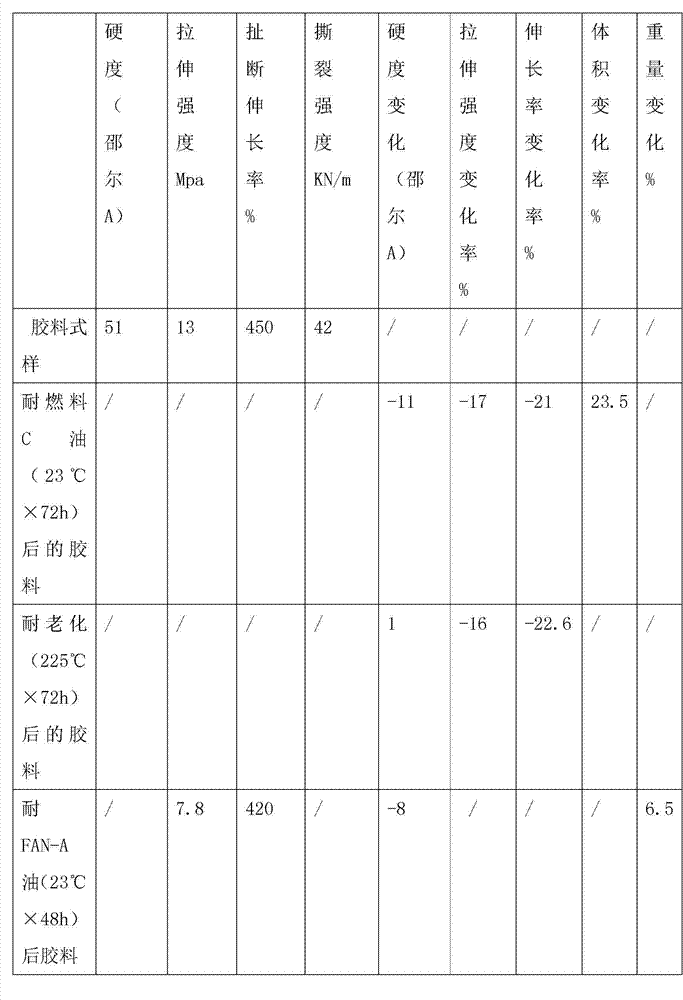

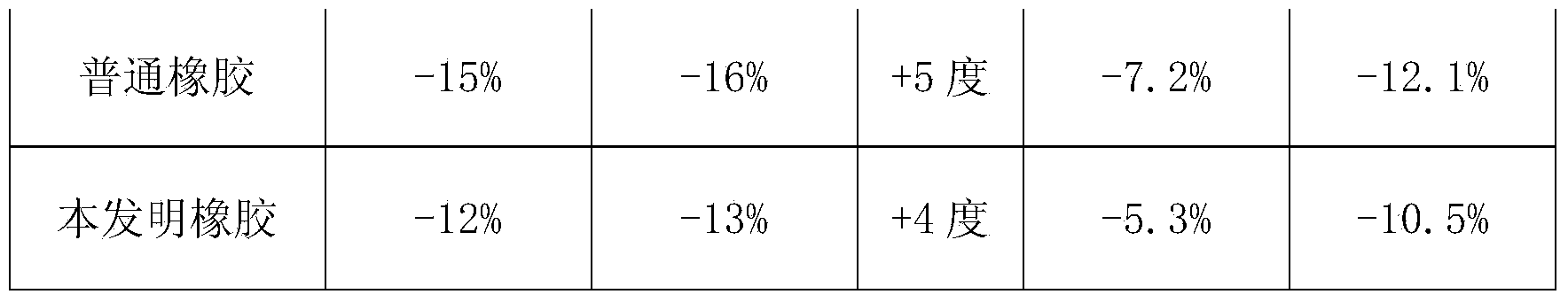

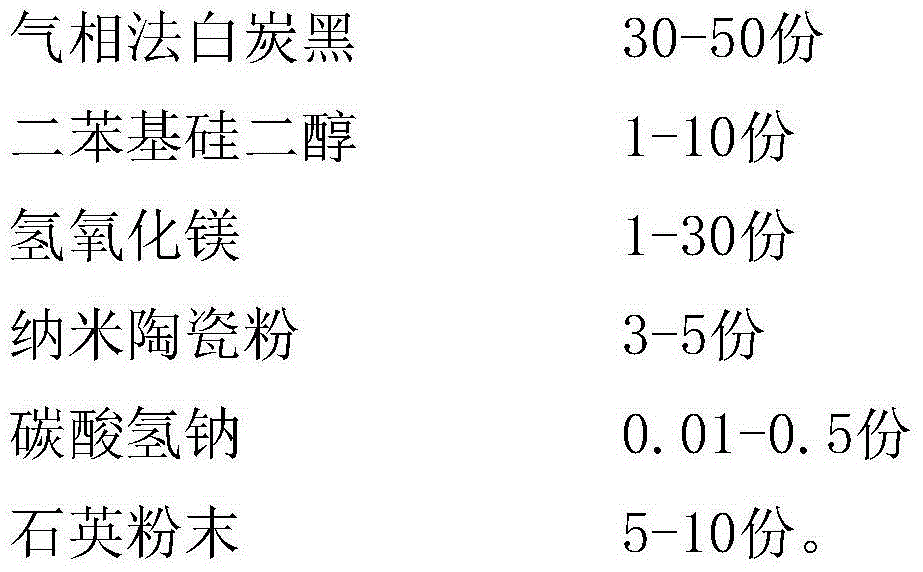

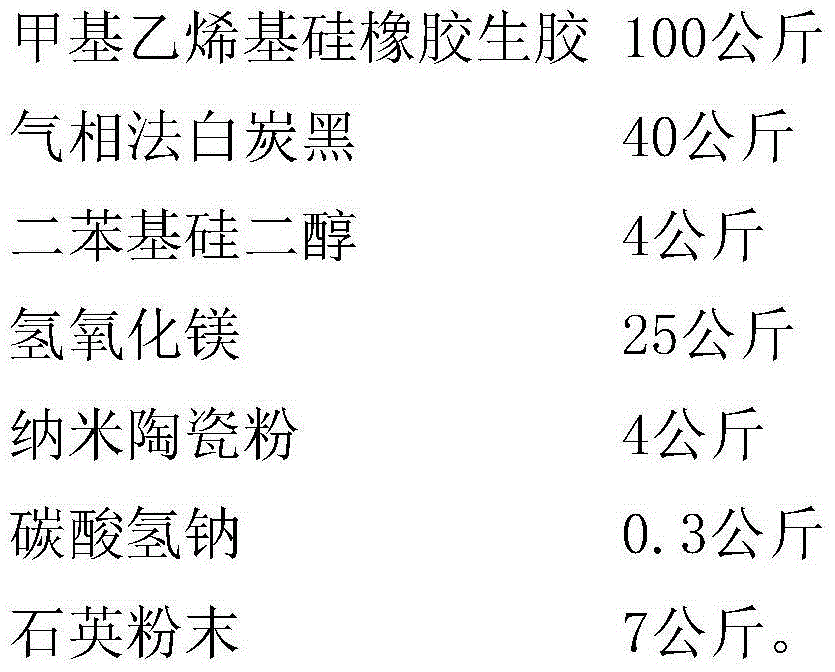

The invention discloses a silicone rubber sealing gasket for a fire-proof seam, and relates to the technical field of rubber products. The method comprises the following steps: mixing the methyl vinyl silicone raw rubber, white carbon black and diphenyl silanediol in a kneading machine, controlling the temperature at 150 DEG C, performing heat treatment for 4 hours, adding magnesium hydrate, nano ceramic powder, sodium bicarbonate and quartz powder, and plasticizing in a double-roller machine so as to be prepared into a sizing material. The product is not deformed and tendered in long time under high temperature of flame, is not easy to drop from the seam under the action of external stress, and can prevent smog, flame and hot gas from penetrating through the seam; the fire-proof mixed silicone rubber can be prepared by adding magnesium hydrate and platinum complex material in a formula, a hard ceramic protective layer can be formed on the surface of the silicone rubber when the silicone rubber is in contact with the flame, so that the silicone rubber cannot drop from the seam.

Owner:穆晓凤

Preparation and application of vinylphenyl polysiloxane resin containing epoxy groups in side groups

InactiveCN107236129AEasy to removeImprove insulation performanceSemiconductor devicesEnvironmental resistanceBoiling point

The invention discloses preparation and application of vinylphenyl polysiloxane resin containing epoxy groups in side groups. A trialkoxysilane compound containing epoxy groups, a trialkoxysilane compound containing alkenyl groups as well as diphenyl silanediol are subjected to a condensation reaction at 25-70 DEG C for 8-15 h innitrogen atmosphere under catalysis of anion exchange resin, then a product is subjected to reduced-pressure processing at 100 DEG C and 0.096 MPa, low-boiling-point substances are removed, the anion exchange resin is removed by filtering, and the vinylphenyl polysiloxane resin containing the epoxy groups in the side groups is obtained. The reaction process is easy to control, the preparation is economical, environment-friendly and more suitable for large-scale volume production, and the product contains no inorganic ions and has excellent insulating property. With adoption of the anion exchange resin as a catalyst, a postprocessing process is simple, the anion exchange resin can be recycled, so that the cost is reduced, benefits are provided for environmental protection, the combination property of the vinylphenyl polysiloxane resin is excellent, and the vinylphenyl polysiloxane resin can be applied to the field of high-power LED packaging, fills up the market gap and has huge market potential.

Owner:三友(天津)高分子技术有限公司

Composite materials, composite film manufactured by using the same and method for manufacturing composite film

ActiveUS20110052890A1Low viscosityShort curing timeSynthetic resin layered productsPretreated surfacesComposite filmDiphenylsilanediol

The present invention provides a composite material comprising a glass cloth; and an organic- inorganic hybrid composition comprising diphenylsilanediol and alkoxy si lane, a composite film manufactured by using the same, and a method for manufacturing the composite film.

Owner:LG CHEM LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com