High-temperature-resistant high-thermal-conductivity boron-dopedorganosilicon epoxy pouring sealant as well as preparation method and application thereof

A silicone epoxy, high thermal conductivity technology, applied in the direction of epoxy resin glue, adhesives, other chemical processes, etc., can solve the problems of poor compatibility, difficulty, and affecting the overall performance of packaging materials, and achieve excellent moisture resistance and high humidity resistance. Effect of thermal conductivity and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of diphenylsilanediol modified epoxy resin:

[0036] (1) Referring to the method in the document [1], the diphenylsilanediol modified epoxy resin SE0 was prepared using stannous octoate as a catalyst.

[0037] Document 1: Wu Wanyao, Yu Moufa, Lin Guoliang. Study on Heat Resistance of Diphenylsilanediol Modified Epoxy Resin[J]. Journal of Xiamen University (Natural Science Edition), 2009,48(2):251-254

[0038] (2) Add 600g of epoxy resin E-51 into a 1000mL three-necked flask, add 7.7g of catalyst aluminum acetylacetonate, heat up to 110°C, slowly add 162g of diphenylsilanediol three times within 1 hour under stirring, Continue to react for 4 hours, cool to obtain viscous liquid 769.7g, which is diphenylsilanediol modified epoxy resin SE1 containing aluminum acetylacetonate (the aluminum acetylacetonate content is 1.00wt% in SE1, diphenylsilanediol Alcohol-modified epoxy resin content is 99.00wt%), sealed preservation, standby.

[0039] (3) Add 504.6g of cyc...

Embodiment 2

[0041] Preparation of boron-modified methyl MQ silicone resin:

[0042] (1) In a 1000mL three-necked flask, add 60wt% xylene solution of methyl MQ silicone resin (product of Guangzhou Delta Organic Silicon Technology Development Co., Ltd., hydroxyl content 2.0wt%) 500g, add boric acid 21g and 79g of absolute ethanol was heated to 90°C for 8 hours to react, and cooled to obtain 600g of boron-modified methyl MQ silicone resin BMQ1 solution.

[0043] (2) In a 1000mL three-necked flask, add 500g of 60wt% xylene solution of methyl MQ silicone resin (product of Guangzhou Delta Organosilicon Technology Development Co., Ltd., hydroxyl content 2.0wt%), and add trimethyl borate under stirring 18g of ester was heated up to 70°C to react for 4 hours, then cooled to obtain 518g of boron-modified methyl MQ silicone resin BMQ2 solution.

[0044] (3) In a 1000mL three-necked flask, add 500g of 60wt% xylene solution of methyl MQ silicone resin (product of Guangzhou Delta Organic Silicon Techn...

Embodiment 3

[0047] A preparation method of high temperature resistant and high thermal conductivity bora silicone epoxy potting glue, comprising the following steps:

[0048] (1) Get 100g of the diphenylsilanediol-modified epoxy resin SE0 prepared in Example 1, heat up to 60°C, add 1g of aluminum acetylacetonate and 40g of boron-modified methyl MQ silicon prepared in Example 2 Resin BMQ1 solution, after stirring evenly, remove the organic solvent under reduced pressure to obtain component A;

[0049] (2) Add 60 g of 300-mesh boron nitride, 35 g of 1250-mesh boron nitride and 5 g of 9000-mesh boron nitride into 100 g of methyl hexahydrophthalic anhydride, and mix well to obtain component B;

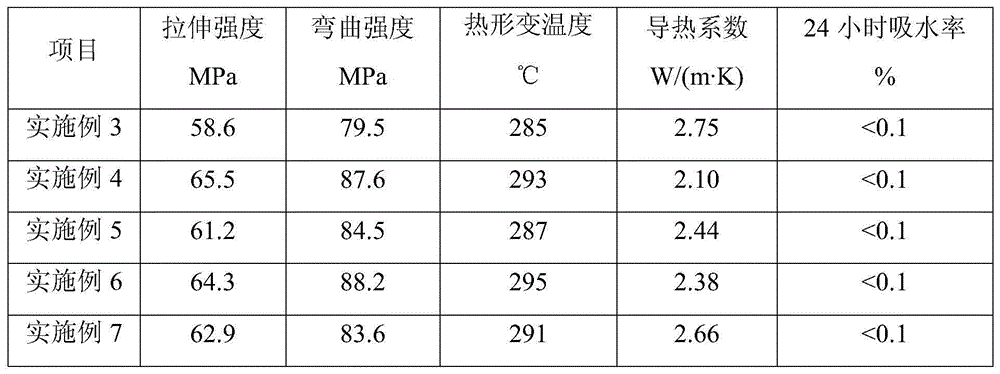

[0050] (3) Take 100g of components A and B and mix them evenly to obtain the potting glue, place them in an oven at 110°C for 4 hours to cure, and obtain a cured high-temperature-resistant and high-thermal-conductivity bora silicone epoxy potting glue. It was tested for performance, and the results a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com