Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92 results about "Aluminum acetylacetonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing aluminum oxide nanofiber by electrostatic spinning

InactiveCN101982581AGuaranteed fibrillationGuaranteed continuityInorganic material artificial filamentsFilament/thread formingFiberElectrospinning

The invention relates to a method for preparing an aluminum oxide nanofiber by electrostatic spinning, comprising the following steps: (1) dissolving a polymer in a solvent to obtain a polymer solution and then pouring the polymer solution into an aluminum acetylacetonate solution to obtain a precursor solution; (2) carrying out spinning on the precursor solution; and (3) exposing as-spun fibre to the air, then sintering the exposed as-spun fibre, and naturally cooling the as-spun fibre to obtain the aluminum oxide nanofiber. With the precursor solution, the smooth electrostatic spinning can be ensured, the content of aluminum in the system can be improved and the strength of the alumina fibre can be enhanced.

Owner:DONGHUA UNIV

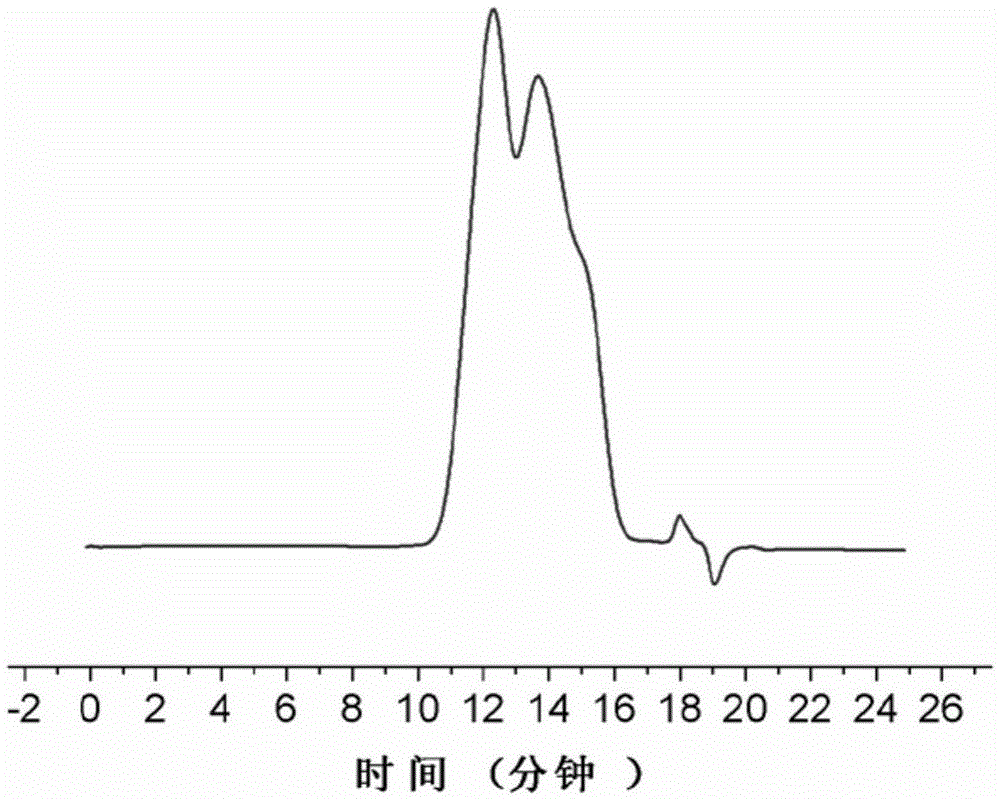

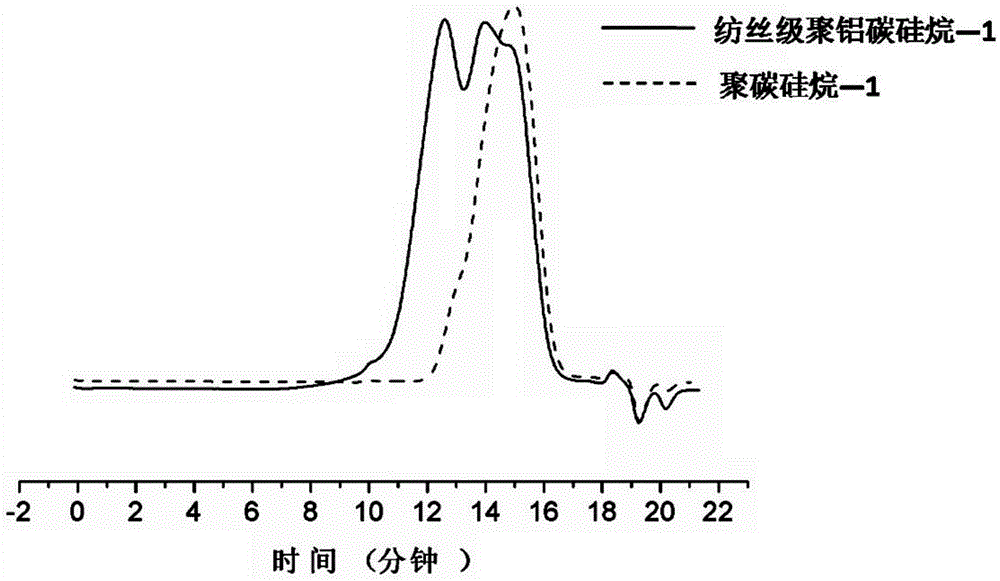

Synthetic method of spinning grade polyaluminocarbosilane precursor

ActiveCN105384940AIncrease the lengthImprove toughnessFibre chemical featuresWeight distributionRaw material

The invention provides a synthetic method of a spinning grade polyaluminocarbosilane precursor. The method is characterized in that polycarbosilane with suitable molecular weight and molecular weight distribution, adopted as a raw material, reacts with aluminum acetylacetonate to prepare the precursor with excellent spinnability.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of cardanol modified phenolic resin

The invention discloses a preparation method of cardanol modified phenolic resin. The method comprises steps that: 16 to 24 parts of phenol by weight, 5 to 9 parts of cardanol by weight and 10 to 14 parts of formaldehyde by weight are well-mixed in a reaction vessel; 2600 to 2700 parts of sulfuric acid by weight are added to the mixture, wherein the weight percentage concentration of sulfuric acid is 2%; the mixture is heated to a reflux state, and is subject to a reaction for 40 to 60min; the mixture is evacuated and the state is maintained for 40 to 50min, such that the mixture is dehydrated; the dehydrated mixture is cooled to a temperature of 65 DEG C; 4.6 to 8.6 parts of formaldehyde by weight is added to the mixture, and the mixture is heated to a reflux state; the temperature of the mixture is maintained for 2 hours, and the mixture is evacuated and dehydrated until transparent; the mixture is cooled to a temperature of 65 DEG C; 13 to 17 parts of toluene by weight, 13 to 17 parts of ethanol by weight and 20 to 25 parts of epoxy 6101# is added to the mixture, wherein the weight percentage concentration of ethanol is 95%; the mixture is stirred for 20 to 40min; aluminum acetylacetonate is added to the mixture for regulating a gel time to 90-120s / 180 DEG C; when the gel time reaches 90-120s / 180 DEG C, 3 to 7 parts of magnesium hydroxide by weight is added to the mixture; the mixture is well-mixed, and the obtained material is discharged. According to the invention, tung oil is completely replaced by cheap cardanol, and cardanol is subject to a reaction with formaldehyde, such that cardanol modified phenolic resin is synthesized. Therefore, cost is further reduced, and the heat resistance and cold punching performance of the material are improved.

Owner:HUNAN HENGYUAN NEW MATERIAL TECH CO LTD

Automobile exhaust PM2.5 pollutant treatment agent

InactiveCN102559336AIncrease oxygen contentBurn fullyLiquid carbonaceous fuelsFuel additivesSuccinic acidInternal combustion engine

The invention relates to an automobile exhaust PM2.5 pollutant treatment agent added in fuel oil. The formula of the treatment agent comprises the following components by weight percent: 10%-30% of methanol, 0.03%-0.07% of ferrocene, 13%-16% of butanol, 0.5%-0.8% of nanometer lanthanum oxide, 0.6-0.9% of nanometer cerium oxide, 0.05%-0.08% of potassium permanganate, 13%-15% of methyl isopropyl ether, 0.1%-0.5% of aluminum acetylacetonate, 12%-18% of dodecyl alkenyl succinic acid, 1%-3% of urea, 5%-10% of isopropanol, 1%-5% of multi-alkenyl succinimide, 0.02%-0.05% of manganese dioxide and 10%-30% of ethanol. The treatment agent is prepared through simple processes such as mixing, stirring, precipitating and filtering. The automobile exhaust PM2.5 pollutant treatment agent is non-toxic, has no bad smell, does not corrode the equipment and can be used to increase the power of the engine and greatly reduce the emission of PM2.5 in the exhaust; and after 10-20g of the automobile exhaust PM2.5 pollutant treatment agent added in fuel oil is added in 1L of oil and the engine runs for 10min, the effect can be realized and the PM2.5 concentration of the exhaust discharged by the kerosene internal combustion engine can be reduced from 330mg / m<3> to 60mg / m<3>.

Owner:洛阳万山高新技术应用工程有限公司

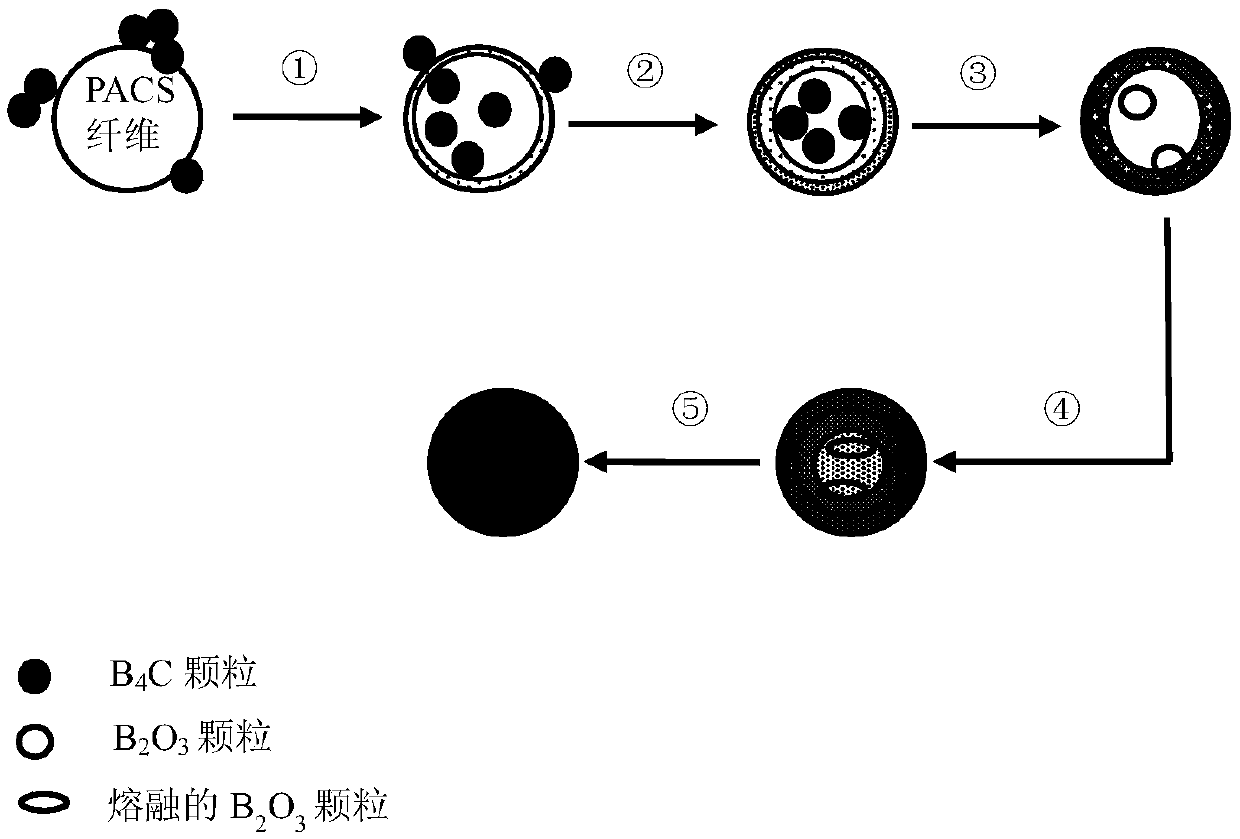

Silicon carbide fibers having a low oxygen content and a preparing method thereof

ActiveCN108035014AImprove mechanical propertiesImprove high temperature resistanceFibre chemical featuresAir atmosphereFiltration

The invention relates to silicon carbide fibers having a low oxygen content and a preparing method thereof. The method includes S101) reacting aluminum acetylacetonate with polysilacarbosilane to obtain a polyaluminocarbosilane crude material, dissolving the crude material with xylene, and performing filtration and vacuum distillation to obtain a refined polyaluminocarbosilane material; S102) subjecting the refined material to melting spinning treatment to obtain a polyaluminocarbosilane fiber bundle; S103) then performing curing treatment with air to obtain crosslinked fibers; and S104) sintering the crosslinked fibers at a high temperature in an inert atmosphere to obtain the silicon carbide fibers. The prepared silicon carbide fibers have excellent mechanical performance and high-temperature resistance. At room temperature, strength of the silicon carbide fibers can be 2.8 + / - 0.3 GPa, and elasticity modulus is 210 + / - 10 GPa. After the silicon carbide fibers are treated at 1000 DEGC in an air atmosphere for 100 h, the strength retention rate can be still 80% or above, and therefore the silicon carbide fibers have wide application value and a wide application prospect in the field of high-performance fibers.

Owner:江西信达航科新材料科技有限公司

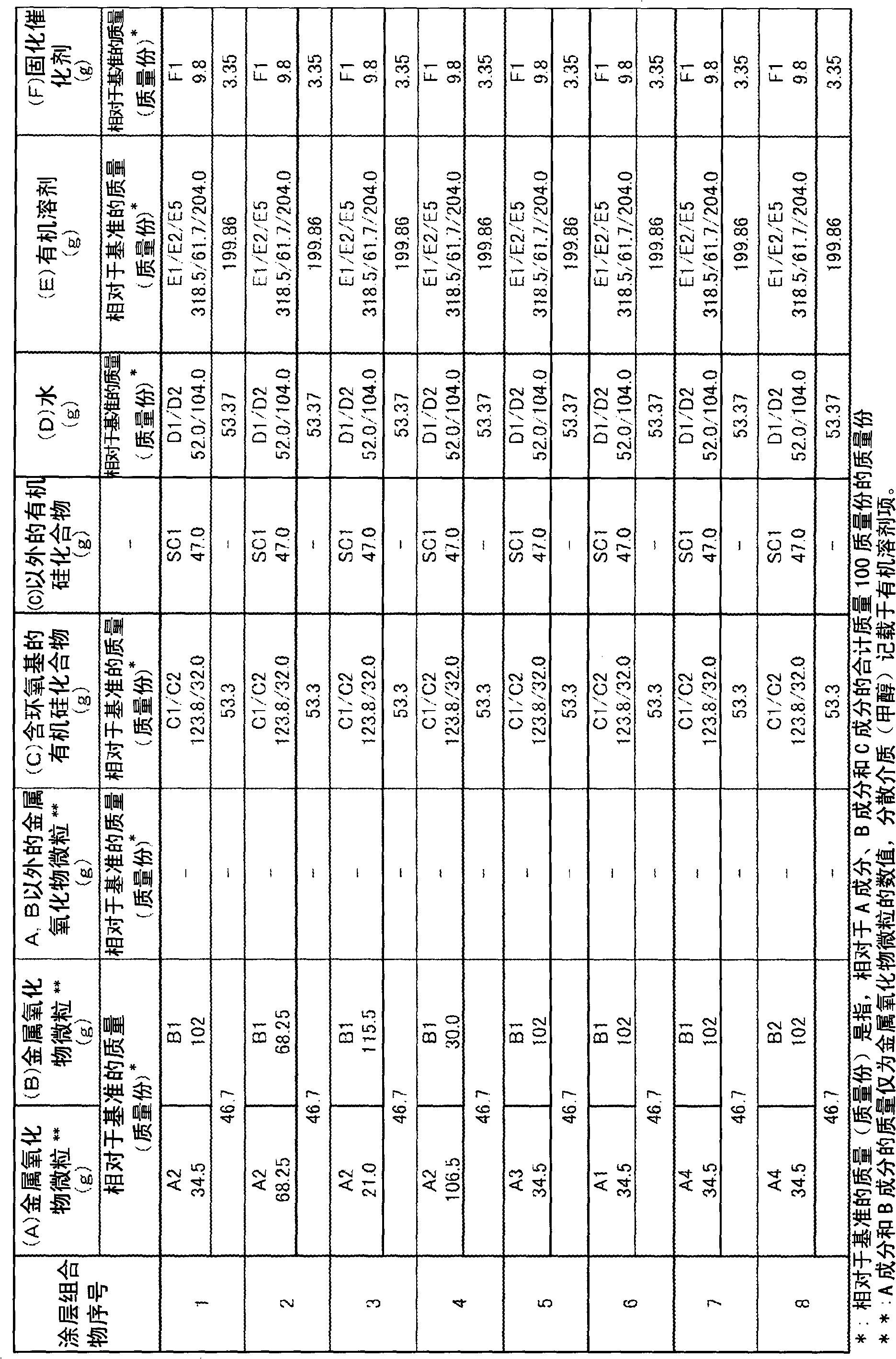

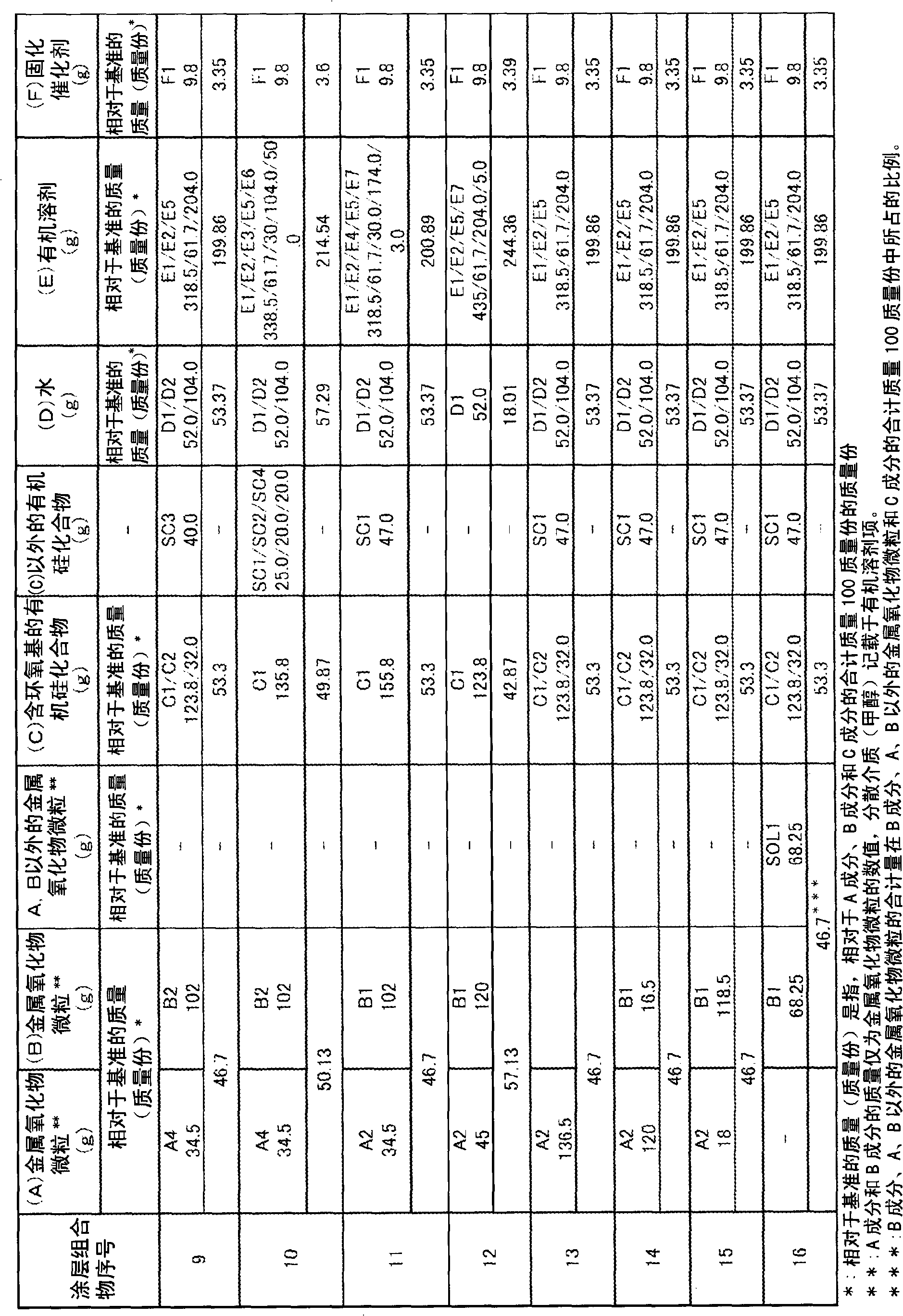

Coating composition and optical article

InactiveCN102421861AHigh refractive indexImprove scratch resistanceSynthetic resin layered productsOptical partsRefractive indexMicroparticle

Disclosed is a coating composition appropriately usable for forming a hard coat film that is obtained by applying the composition onto a light-permeable member, such as a plastic lens having a high refractive index or a photochromic plastic lens having a color-developing function and a high refractive index, and hardening. This coating composition exhibits an extremely improved weather resistance (prevention of discoloration) while sustaining a high refractive index, a good scratch resistance and an excellent adhesiveness to an optical base. Specifically disclosed is a coating composition, comprising: titanium oxide-containing metal oxide microparticles (A) together with titanium oxide-containing metal oxide microparticles (B), provided that the titanium oxide-containing metal oxide microparticles (A) and the titanium oxide-containing metal oxide microparticles (B) have been selected through a specific light irradiation test and show different properties; an epoxy group-containing organosilicon compound (C) such as ?-glycidoxypropyltrimethoxysilane; water (D); an organic solvent (E) such as methyl alcohol; and a hardening catalyst (F) such as aluminum acetylacetonate or magnesium perchlorate, each in a specific amount.

Owner:TOKUYAMA CORP

Novel powder nanometer catalytic sulfur fixation agent for dry cement raw material, and preparation method thereof

InactiveCN107164013ALower activation energyEmission reductionSolid fuelsTitanium oxideFixation agent

The invention discloses a novel powder nanometer catalytic sulfur fixation agent for a dry cement raw material, and a preparation method thereof, wherein the novel powder nanometer catalytic sulfur fixation agent comprises nanometer lanthanum oxide, nanometer thorium oxide, nanometer praseodymium oxide, nanometer titanium oxide, nanometer nickel oxide, nanometer magnesium oxide, nanometer calcium oxide, nanometer calcium carbonate, hydroxyl calcium, potassium permanganate, potassium bismuthate, fly ash, carbon black, and the balance of a dispersion carrier. According to the technical scheme, by adding europium oxide and aluminum acetylacetonate, the sulfur fixation efficiency can achieve more than 98%. According to the present invention, the product is mixed into the raw material through the air chute in front of the homogenizing bin, and at the high temperature, the surface activity of the raw material is improved and the activation energy of the reaction with sulfur dioxide is sufficiently reduced through catalysis, oxidation and metal ion exchange, such that SO2 generated during the combustion process generates the sulfate-like solid material, and sulfate-like solid material is subjected to solid solution into the cement clinker so as not to cause corrosion and other side effects on the cement pre-heater, the kiln and other equipment.

Owner:严生

Aluminum oxide/titanium oxide heterojunction nano fiber carrier in anti-sintering precious metal catalyst system as well as preparation method and application of carrier

InactiveCN103977779AHigh porosityRough fiber surfaceCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionFiber

The invention discloses an aluminum oxide / titanium oxide heterojunction nano fiber carrier in an anti-sintering precious metal catalyst system as well as a preparation method and application of the carrier. The preparation method comprises the following steps: dispersing PVP into ethyl alcohol, stirring and dissolving to obtain a PVP ethyl alcohol solution; taking glacial acetic acid to be added into the solution, and adding titanium isopropoxide; dispersing aluminum acetylacetonate into an organic solvent, mixing and stirring the two solutions to obtain a precursor solution, adopting an electrostatic spinning method, indrawing the precursor solution in an injector, inserting the injector into a trace injection pump, connecting with an electrode, adjusting the flow speed and the voltage of an electrostatic field, wherein the distance from a syringe needle to a receiver is 5-15cm, and controlling the indoor humidity to be 30-50%, thereby obtaining nano fibers; sintering the nano fibers obtained by the electrostatic spinning method in a muffle furnace, thereby obtaining the aluminum oxide / titanium oxide heterojunction nano fiber carrier. The catalyst carrier disclosed by the invention is short in preparation cycle, simple in process, low in energy consumption, high in productivity, and good in reproducibility.

Owner:SOUTHEAST UNIV

Preparation method of paint calcium carbonate with high activating rate and low oil absorption value

InactiveCN107446383AHigh activation rateLow oil absorptionCoatingsPigment treatment with macromolecular organic compoundsTrimethylolpropaneSOAP

The invention discloses a preparation method of paint calcium carbonate with high activating rate and low oil absorption value. The paint calcium carbonate is prepared from the following raw materials of broken calcium carbonate, a grinding aid, triethanolamine oleic soap, aluminum acetylacetonate, vanadium pentoxide, diethylene triamine sodium pentacarboxylate, a modifier, trimethylolpropane tris(3-aziridinylpropanoate), phthalandione bis(2-ethyl hexoate) ester, modified polyacrylate, hexenyl distearamide, 2-(2'-hydroxyl-3',5'-ditert phenyl)-5-benzotriazole chloride, polyacrylamide and a stabilizer. The paint calcium carbonate is prepared by the steps of stone cleaning, decontaminating, dewatering, breaking, grinding, surface modifying, performance adjusting, smashing, drying and the like. The paint calcium carbonate disclosed by the invention has the advantages of small agglomeration, good dispersion, high activating rate and low oil absorption value when being added into a high-molecular polymer.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Surface treated calcium carbonate powder and preparation method thereof

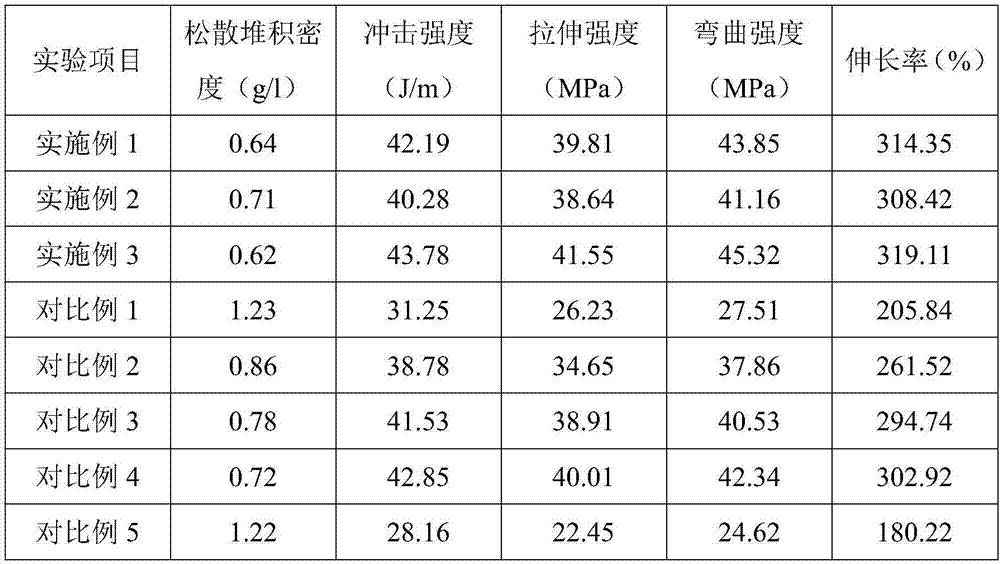

InactiveCN107446382ALoose packing densityImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityMechanical property

The invention discloses surface treated calcium carbonate powder and a preparation method thereof. The surface treated calcium carbonate powder is prepared from the following raw materials of broken calcium carbonate, a grinding aid, sodium dodecyl sulfate, aluminum acetylacetonate, magnesium oxide, diethylene triamine sodium pentacarboxylate, a modifier, 3-aminopropyltriethoxysilane, phthalandione bis(2-ethyl hexoate) ester, modified polyacrylate, hexenyl distearamide, 2-(2'-hydroxyl-3',5'-ditert phenyl)-5-benzotriazole chloride, polyacrylamide and a stabilizer. The surface treated calcium carbonate powder is prepared by the steps of stone cleaning, removing impurities, dewatering, breaking, grinding, surface modifying, performance adjusting, smashing, drying and the like. The surface treated calcium carbonate powder disclosed by the invention can be fully dispersed, has small agglomeration after being added into plastic and has good dispersity, and all items of mechanical property of modified calcium carbonate are all remarkably improved.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Application method of aluminum acetylacetonate

InactiveCN102234491AImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesAluminum acetylacetonatePre treatment

The invention discloses an application method of aluminum acetylacetonate, and the method comprises the following steps: 1) performing chemical pretreatment of a substrate to allow the treated substrate to generate active groups of -OH, -COOH, -NH2; 2) adding aluminum acetylacetonate into an acrylate pressure sensitive adhesive under stirring with an adding amount of aluminum acetylacetonate being 0.1-0.3% of the weight of the acrylate pressure sensitive adhesive; 3) coating the pressure sensitive adhesive added with aluminum acetylacetonate obtained in step 2) onto the substrate at 70-80 DEG C, and performing vacuum drying. The advantage of the invention is that the adhesion of the acrylate pressure sensitive adhesive on the substrate is increased.

Owner:郭春和

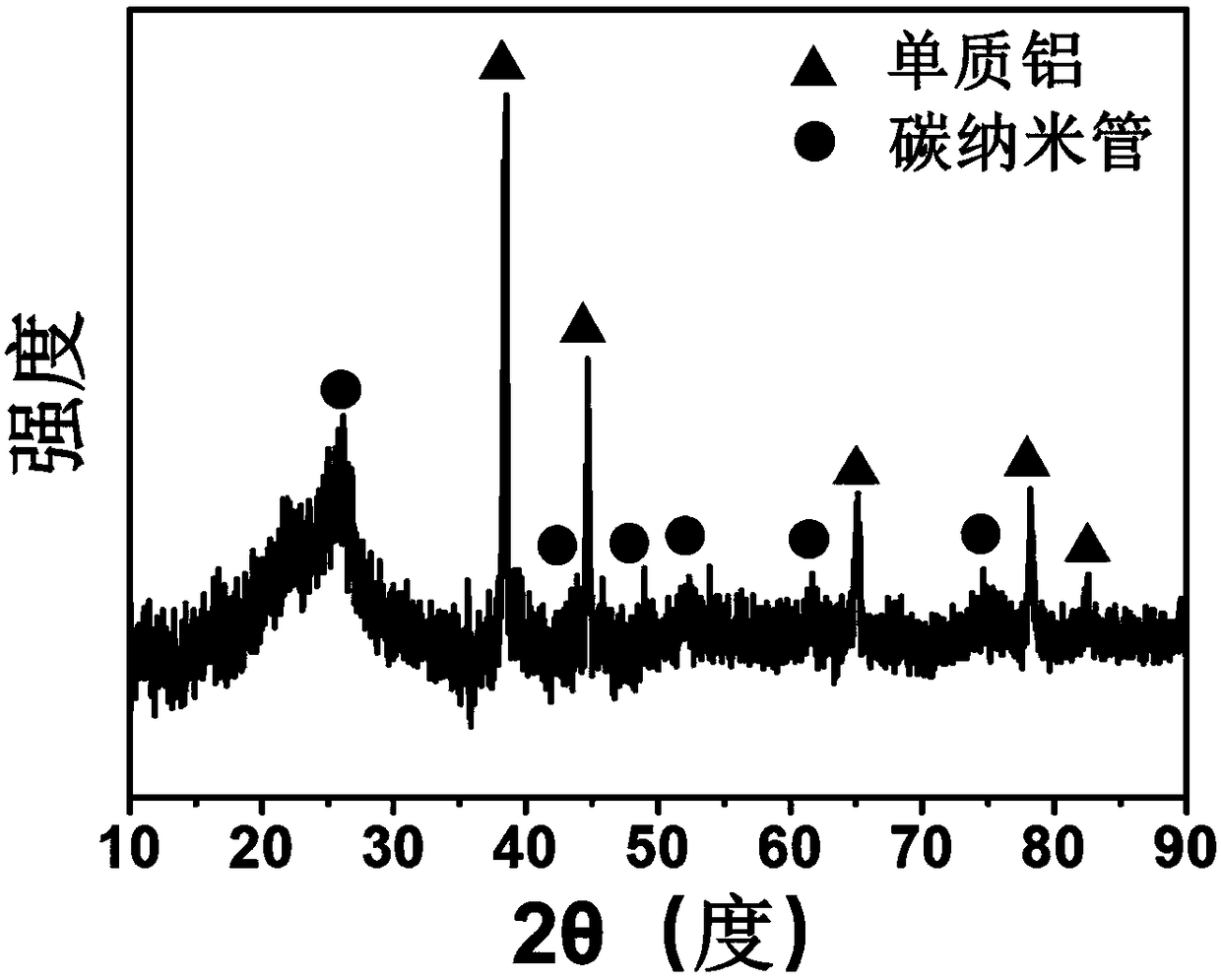

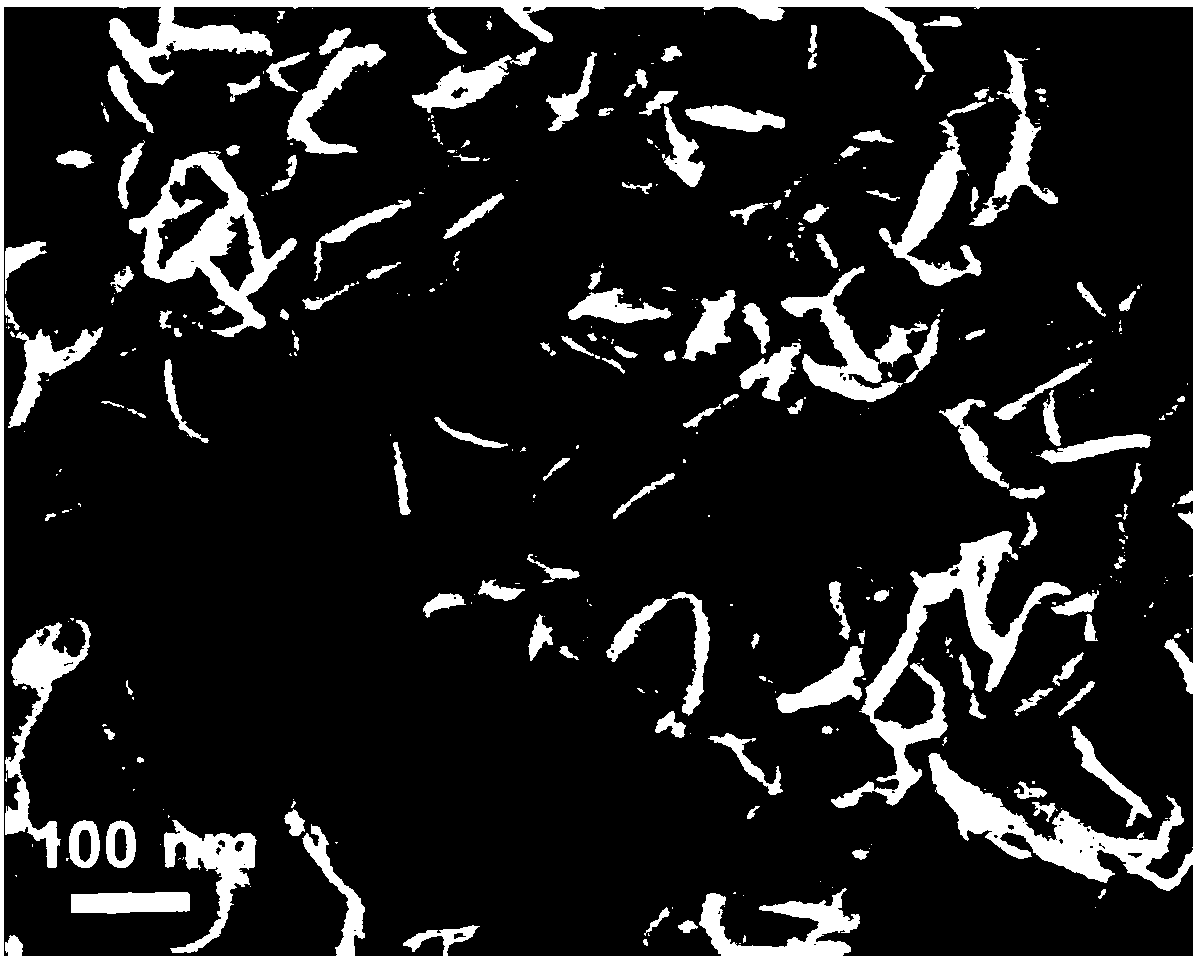

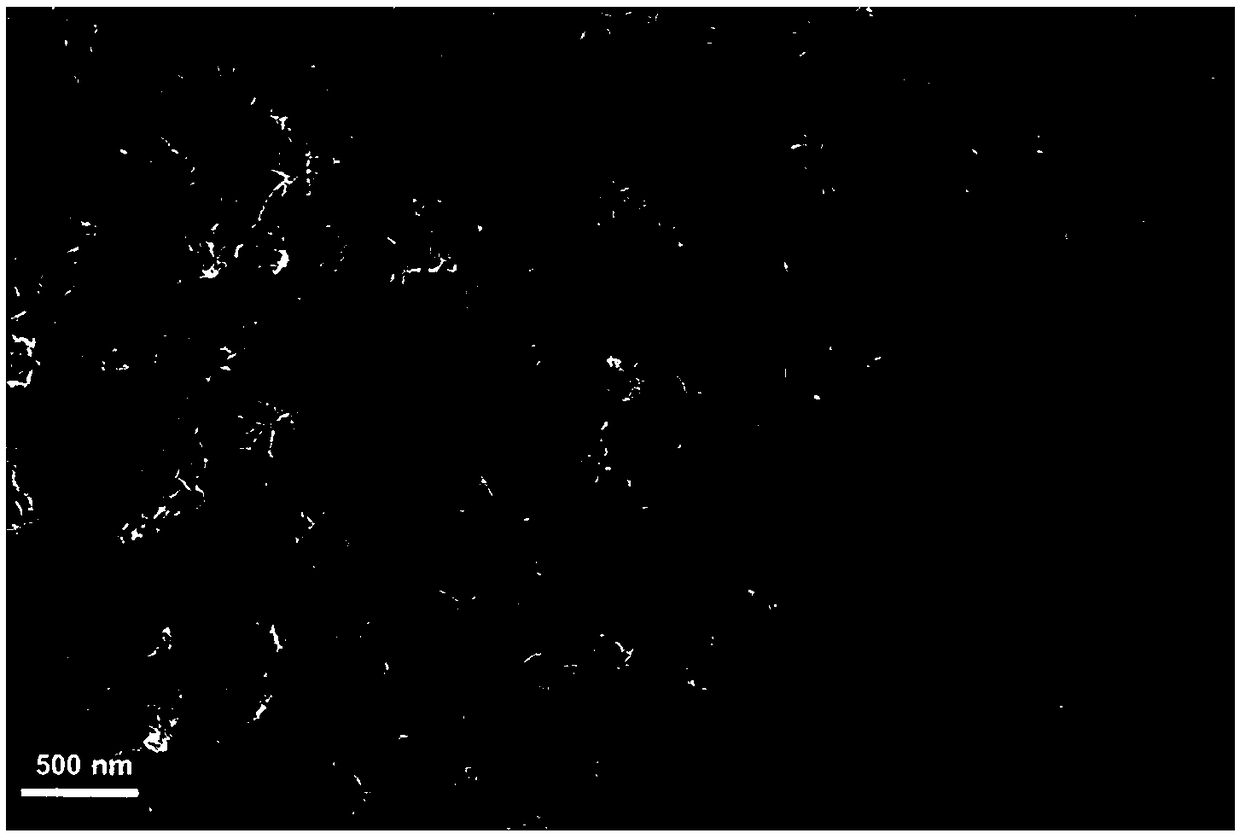

High-performance lithium ion battery aluminum-based negative electrode material and preparation method thereof

ActiveCN108550817AHigh purityMild preparation conditionsMaterial nanotechnologyCell electrodesCarbon nanotubeReaction temperature

The invention discloses a high-performance lithium ion battery aluminum-based negative electrode material and a preparation method thereof, and belongs to the technical field of inorganic advanced materials. The aluminum-based negative electrode material is a three-dimensional long-range ordered structure formed by compounding aluminum nanosheets and carbon nanotubes, has less oxide layer and a high bulk density, and has excellent cycle stability and excellent rate performances as an active substance for a lithium ion battery negative electrode. The preparation method comprises the following steps: a, preparing a reaction solution: adding the carbon nanotubes to a two-necked flask containing anhydrous trimethylbenzene, performing heating and stirring at 60 DEG C, and sequentially adding aluminum trichloride, aluminum acetylacetonate and a reducing agent lithium aluminum hydride to the above system; and b, performing a reduction reaction: raising the reaction temperature to 120-165 DEGC, and performing the reaction for 2-12 h to obtain a crude product of the above compound. The aluminum-based negative electrode material has the advantages of low cost, mild preparation conditions, large scale production, and good application prospect in the field of lithium ion batteries.

Owner:BEIJING UNIV OF CHEM TECH

Anti-aging binding agent for corrugated carton box

InactiveCN105820775AGood anti-aging performanceWill not degradeNon-macromolecular adhesive additivesStarch adhesivesPhenyl EthersPotato starch

An anti-aging adhesive for corrugated boxes, made of the following raw materials in parts by weight: 25-35 parts of potato starch, 15-30 parts of sweet potato starch, 5-10 parts of chlorosulfonated polyethylene rubber, 5-10 parts of nitrile rubber 10 parts, 8-9 parts of nano-graphene, 10-12 parts of talc, 7-14 parts of aluminum triacetylacetonate, 7-14 parts of propylene oxide phenyl ether, N-tert-butyl-2-benzothiazolium 7‑14 parts of sulfonamide, 0.5‑1.5 parts of cyclohexanone oxime, 6‑7 parts of linoleic acid, 45‑62 parts of water, 20‑26 parts of modified antioxidant. The adhesive of the present invention has very good anti-aging performance, will not degrade in an oxygen-enriched environment, will not open the glue under strong ultraviolet radiation, and has a service life 40-50% longer than that of ordinary adhesives, and the metal ions in the composition It forms strong ionic bonds with functional groups, making it more cohesive.

Owner:ANHUI FENGHUANGSONG PACKAGING

Multifunctional liquid efficient fuel-coal sulfur-fixing agent and preparation method thereof

InactiveCN107177387AEasy to useAccurate measurementSolid fuelsFuel additivesFatty alcoholVanadium oxide

The invention discloses a multifunctional liquid efficient fuel-coal sulfur-fixing agent and a preparation method thereof. The multifunctional liquid efficient fuel-coal sulfur-fixing agent comprises lanthanum oxide, cerium oxide, vanadium oxide, nano-titanium oxide, nano-zinc oxide, nano-nickel oxide, nano-calcium carbonate, nonylphenol polyoxyethylene ether, octylphenol polyoxyethylene ether, fatty alcohol-polyoxyethylene ether, oily penetrating agents, polydiethylene glycol monooleate, glycerol, polymeric glycol, propylene glycol polyoxyethylene polyoxypropylene ether, dimethyl polysiloxane polyether, dehydration sorbitol monooleate and the balance diethylene glycol. According to the technical scheme, yttrium oxide, aluminum acetylacetonate and polyoxyethylene ether are added. The sulfur-fixing efficiency of the multifunctional liquid efficient fuel-coal sulfur-fixing agent can reach 99% or more, the denitration efficiency of the sulfur-fixing agent can reach 50% or more, the combustion rate and the burn-off rate of coal can be sufficiently increased, the ignition point of the coal is remarkably reduced by 50 DEG C or more, the combustion efficiency of the coal is improved by 25% or more, so that combustion environments are reasonably improved, and boiler coking is prevented and removed.

Owner:NANJING RONGFENG ES&T CO LTD

Modified calcium carbonate for paint

The invention discloses modified calcium carbonate for paint. The modified calcium carbonate is prepared from the following raw materials in parts by weight: 182-205 parts of calcium carbonate broken parts, 4.5-6.4 parts of a grinding aid, 3.6-6 parts of triethanolamine oleic soap, 0.4-0.8 parts of aluminum acetylacetonate, 0.2-0.3 parts of vanadium pentoxide, 0.6-1 part of sodium diethylenetriaminepentacarboxylate, 0.2-0.4 parts of a regulator, 0.5-0.7 parts of a coupling agent, 1.5-2.8 parts of bis(2-ethylhexyl) phthalate, 0.4-0.7 parts of modified polyacrylate, 0.3-0.5 parts of N,N'-ethylenebis(stearaimde), 0.3-0.5 parts of 2-(2'-hydroxy-3', 5'-ditert-phenyl)-5-benzotriazole chloride, 0.2-0.4 parts of polyacrylamide and 0.4-0.8 parts of a stabilizer. The modified calcium carbonate for the paint has high activation rate, low oil absorption value and good compatibility with high polymer.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Polyving akohol chrome-free corrosion-resistant silane passive film

InactiveCN106756953AImprove corrosion resistanceGood self-lubricating performanceMetallic material coating processesMethacrylateSilanes

The invention discloses a polyving akohol chrome-free corrosion-resistant silane passive film. The polyving akohol chrome-free corrosion-resistant silane passive film is prepared from, by weight, dodecafluoroheptyl methacrylate, hexafluorobutyl methacrylate, a silane coupling agent KH560, azodiisobutyronitrile, a silane coupling agent KH570, a proper quantity of a silane coupling agent KH858, imvite, triethoxy methyl silane, aluminum acetylacetonate, polyether amine, ammonium metavanadate, hexafluorotitanic acid, sodium molybdate, trisodium phosphate, silica sol, polyving akohol, a proper amount of absolute ethyl alcohol, a proper amount of tetrahydrofuran, a proper amount of isopropanol, a proper amount of dilute hydrochloric acid, a proper amount of dilute nitric acid and a proper amount of deionized water. Prepared passivating liquid can form a film layer on the surfaces of various kinds of substrates, the adhesive force is high, the compactness is good, the film is high in abrasion resistance, oil resistance, salt mist resistance and alkali resistance, and the film is free of pollution to the environment, harmless to human bodies and worthy of popularization.

Owner:张庆

Low dielectric constant polyimide film and preparation method thereof

InactiveCN110358134ANo pollution in the processSimple processResin-Based CompositeAluminum acetylacetonate

The invention discloses a low dielectric constant polyimide film and a preparation method thereof. The preparation method comprises: taking a certain amount of aluminum acetylacetonate, uniformly dispersing in a synthesized polyamic acid solution, paving by using the obtained composite resin solution to form a film, and carrying out thermal imidization to prepare the low dielectric constant polyimide film. Compared with the prior art, the method of the present invention has the following characteristics that aluminum acetylacetonate is used as the pore-forming agent, and can be sublimated andvolatilized during the thermal imidization of polyimide, such that the holes are left in the polyimide matrix, and the hole forming process is simple, easy-performing, safe and environmentally friendly; and the prepared low dielectric constant polyimide film has characteristics of uniform air hole distribution, low dielectric constant and good mechanical property, and has good application prospects in the fields of electronics, microelectronics, and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

Synthesis method of high-performance phenyl block silicon resin

The invention relates to a synthesis method of high-performance phenyl block silicon resin. The method comprises the following steps: taking phenyl trichlorosilane, diphenyl dichlorosilane, methyl phenyl dichlorosilane, methyl trichlorosilane, a solvent and dihydroxy polytrifluoropropyl methyl siloxane as raw materials, and one or more of aluminum triisopropoxide, aluminum triacetylacetonate, isopropoxy distearoyloxy aluminate, triethyl propyl aluminate and tribenzyl aluminate as catalysts, and carrying out hydrolysis, prepolymerization, washing, dehydration, condensation and desolvation to obtain the phenyl block silicon resin. Fluorine groups are introduced, so that the phenyl silicone resin has lower surface energy and excellent oil resistance, antifouling property and anti-sticking property. The synthetic silicon resin can be cured into a transparent film at room temperature, and the prepared coating adhesive has the tensile strength of 5 Mpa or above and the shore hardness of 80 angstroms. The branched silicon resin and the straight-chain siloxane are combined, so that the silicon resin has better flexibility and flexibility, and the possibility of needing an application material with certain toughness in some high-temperature occasions is provided.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD +1

Environment-friendly carbon-silicon composite material

InactiveCN104201329APromote sustainable developmentComposite fullyCell electrodesSecondary cellsCarbon monofluorideChemical industry

The invention discloses an environment-friendly carbon-silicon composite material. The environment-friendly carbon-silicon composite material comprises the following substances in parts by weight: 55-64 parts of betelnut shell powder, 35-42 parts of nano-silicon powder, 10-12 parts of isobutyl methacrylate, 5-9 parts of nano-calcium sulfate, 11-14 parts of organic montmorillonite, 13-20 parts of stearic acid, 3-7 parts of polycarbodiimide, 5-9 parts of liquid paraffin, 10-14 parts of N-N'-diphenyl-p-phenylenediamine, 3.5-6.4 parts of aluminum acetylacetonate and 10-14 parts of carbon monofluoride. The environment-friendly carbon-silicon composite material has the beneficial effects that raw materials are low in cost, are wide in sources and meet the requirements of green chemical industry; a carbon material is composited with silicon by virtue of a mechanical ball-milling method, so that the preparation process is simple, and the materials are adequately composited together; the initial charge-discharge capacity of the carbon-silicon composite material disclosed by the invention is greatly increased, and the carbon-silicon composite material has good cycling stability.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

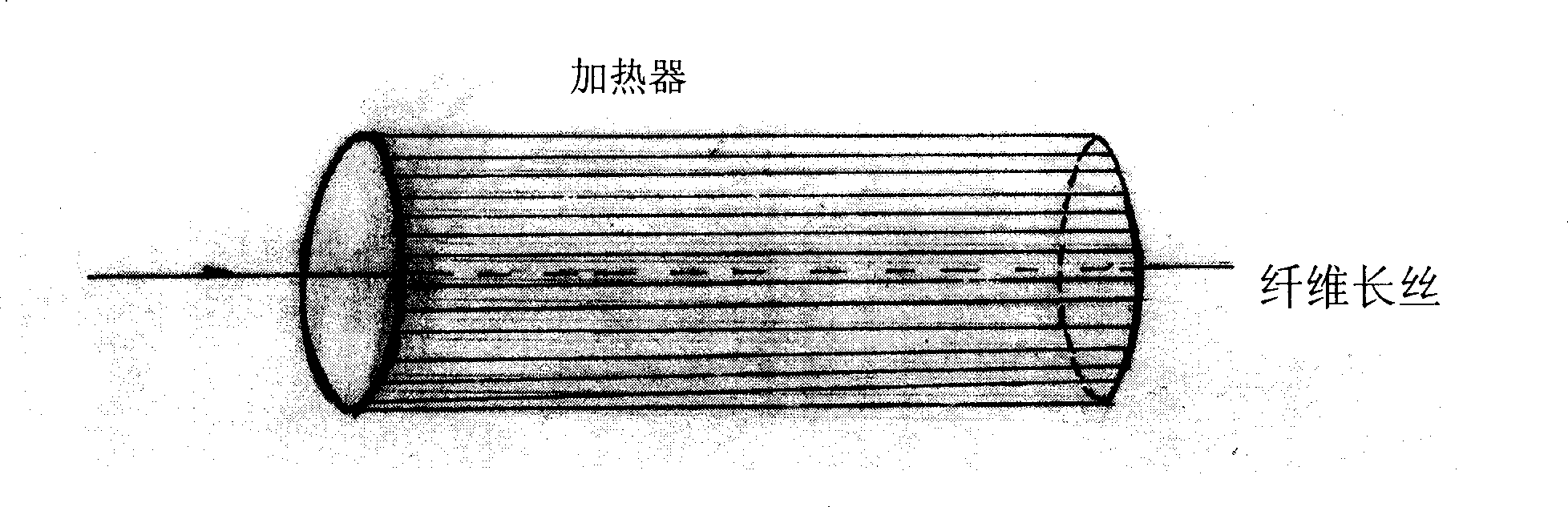

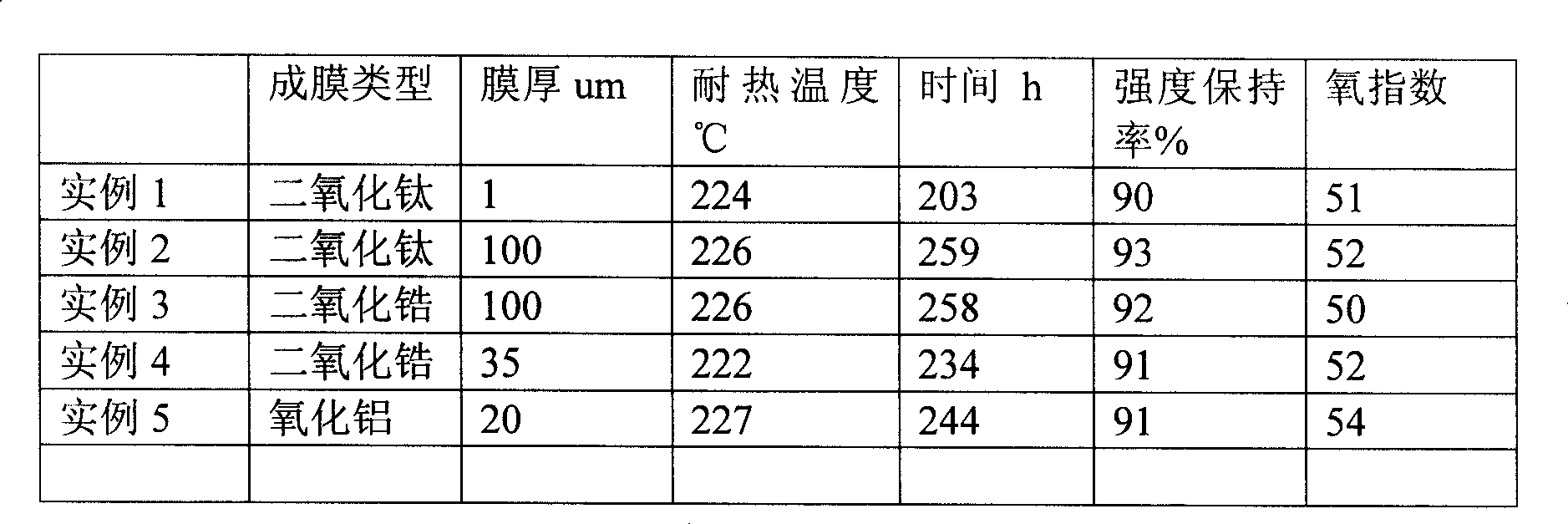

Technique for coating inorganic strengthening layer on polyphenyl thioether fabric surface

The invention discloses a technique method of coating an inorganic strengthening layer on the surface of polyphenylene sulfide fiber. Polyphenylene sulfide fiber precursor is synthesized from raw materials of sodium sulfide and p-dichlorobenzene and spinned by melt spinning. The hot stretching treatment is implemented on the fiber precursor to obtain finished fiber. Then, the finished fiber is impregnated and pre-coated. Isopropanol solution containing one of film forming matters of lactic acid titanium, triethanolamine titanium, aluminum acetylacetonate, Zirconium Butoxide and zirconium n-propoxide is used for impregnated material. After the air drying at 20 DEG C and the heat treatment at 600-760 DEG C and normal pressure, the inorganic strengthening layer which is 1-100 micrometers is obtained on the surface of the polyphenylene sulfide fiber. Then, polyphenylene sulfide composite fiber which is provided with the inorganic strengthening layer on the surface is obtained. The polyphenylene sulfide composite fiber obtained through the method of the invention is provided with high temperature strength retention and is especially applicable to professional filtering materials which are professionally used for thermal power generation, waste incinerators, chemical filtering, etc.

Owner:SICHUAN DEYANG CHEM

Water-soluble double-sided adhesive tape and double-sided adhesive tape cutting apparatus

PendingCN110591578AImprove initial tack performanceSolve the problem of low initial viscosityMonocarboxylic acid ester polymer adhesivesAmide/imide polymer adhesivesCross-linkSolubility

The invention discloses a water-soluble double-sided adhesive tape and a double-sided adhesive tape cutting apparatus, wherein the water-soluble double-sided adhesive tape has a four-layer structure,and sequentially comprises release paper, an acrylate polymer layer, water-soluble paper and an acrylate polymer layer, and the acrylate polymer layer mainly comprises: a viscous monomer, a cohesive monomer, a cross-linking monomer, methanol, ethyl acetate, an initiator, a surfactant and a curing agent aluminum acetylacetonate. According to the present invention, the double-sided adhesive tape prepared from the high-performance acrylate polymer has high initial adhesion and good water solubility, the connecting point does not easily slide and shift when the double-sided adhesive tape is used in the paper overlapping process in papermaking and printing industries, and the double-sided adhesive tape can be quickly dissolved in water after being used so as not to affect the recycling of products; and the double-sided adhesive tape cutting apparatus can cut to obtain multiple double-sided adhesive tape sections at a time so as to solve the problems of more steps, time consuming and labor consuming of the traditional multi-section cutting.

Owner:南京五人光学薄膜有限公司

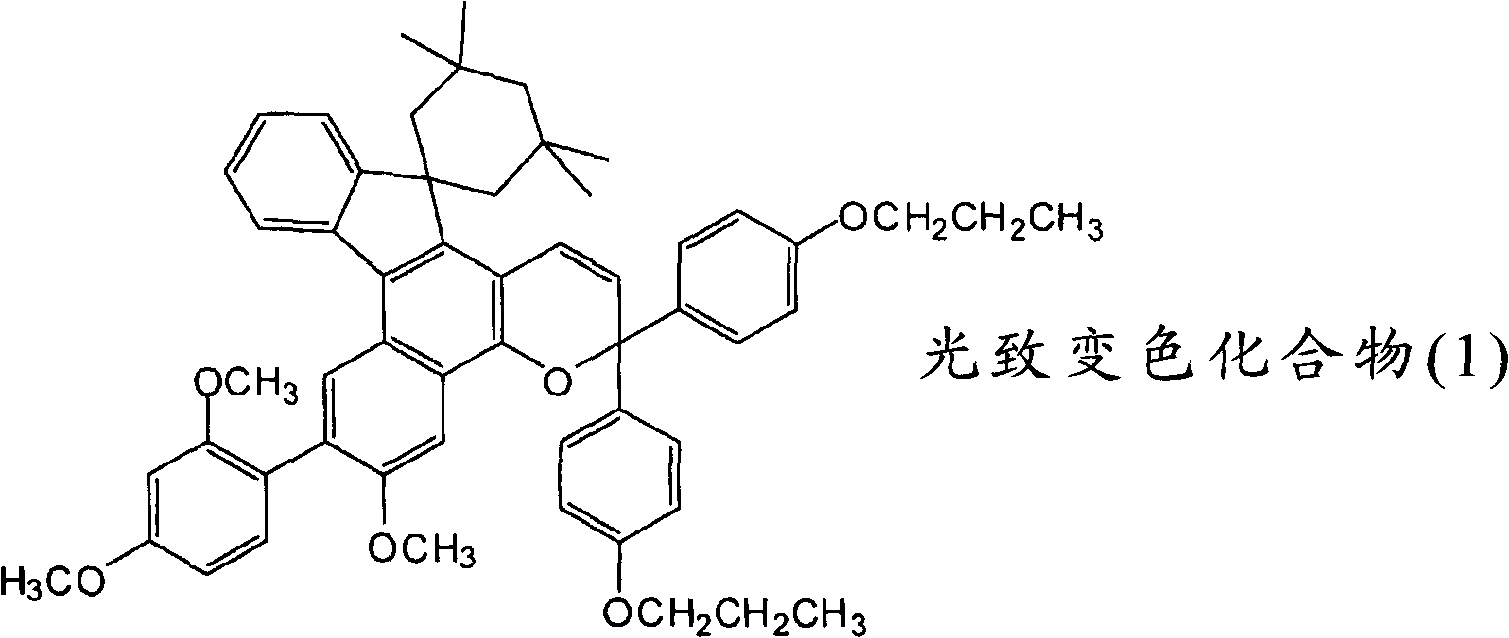

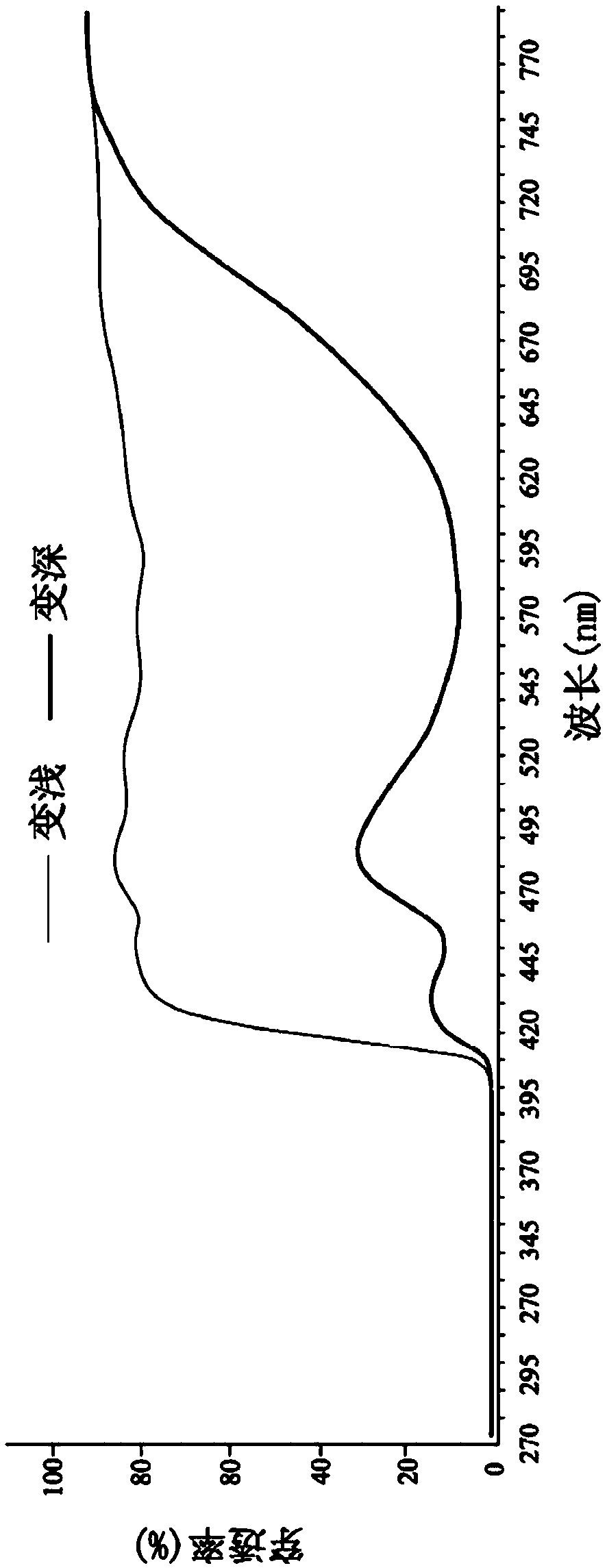

Photochromic lens

The invention discloses a photochromic lens. The photochromic lens comprises a lens base material and a photochromic film; the photochromic film is formed by spin-coating a photochromic fluid on the lens base material, infrared heating and curing, and cooling; the photochromic film has a thickness of 15 microns; the photochromic fluid is prepared from the following raw materials in part by mass: ablue toner 8410, a green toner 8409, a red toner 8405, toluene, polytetramethylene ether glycol, an acrylic polymer, 2-mercaptoethyl sulfide, poly(methylene phenyl isocyanate), an isocyanate compound, a 1358 curing agent, a 306 flow agent, dibutyltin dilaurate, a BASF light stabilizer 144,a 1010 antioxidant and aluminum acetylacetonate. The transmission rate of the photochromic lens disclosed bythe invention for a wave length of 420-790 nm is 15.63-81.79%; the time required for changing light color to dark color is 3-4 s; the time required for changing dark color to light color is 3-4 s; andthe usage effect is obviously improved.

Owner:厦门立扬光学科技有限公司

Microporous ceramic used for processing sewage

InactiveCN106467404AImprove filtering effectExtend the life cycleCeramicwareCeramic sinteringDimethylaniline N-oxide

The invention discloses a microporous ceramic used for processing sewage. The microporous ceramic comprises the following raw materials in parts by weight: 30-42 parts of dimethyl sulfoxide, 5-10 parts of magnesium oxide, 10-18 parts of trichloromethane, 5-10 parts of iron oxide, 11-15 parts of cerium acetylacetonate, 1-4 parts of antimony oxide, 10-22 parts of silicon nitride, 2-5 parts of barium carbonate, 3-10 parts of magnesite, 5-8 parts of dimethylaniline, 20-30 parts of porcelain stone, 1-8 parts of quartz powder, 2-5 parts of allophone, 5-10 parts of aluminum acetylacetonate, 1.5-2.5 parts of polycarbosilane, 2-5 parts of cresol, and 3-5 parts of wollastonite. The microporous ceramic selects a plurality of raw materials with reasonable ratio, the size of the aperture can be controlled in a small scope, the finally produced microporous ceramic has stable and efficient filtering capability. The raw material configuration can uniformly distribute heat during a ceramic sintering process, so that the aperture distribution on the ceramic is more uniform, and the filtering capability stability can be guaranteed.

Owner:郭琳

Method of preparing polyaluminocarbosilane

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

Method for preparing aluminum oxide nanofiber by electrostatic spinning

InactiveCN101982581BGuaranteed continuityIncrease contentInorganic material artificial filamentsFilament/thread formingFiberElectrospinning

The invention relates to a method for preparing an aluminum oxide nanofiber by electrostatic spinning, comprising the following steps: (1) dissolving a polymer in a solvent to obtain a polymer solution and then pouring the polymer solution into an aluminum acetylacetonate solution to obtain a precursor solution; (2) carrying out spinning on the precursor solution; and (3) exposing as-spun fibre to the air, then sintering the exposed as-spun fibre, and naturally cooling the as-spun fibre to obtain the aluminum oxide nanofiber. With the precursor solution, the smooth electrostatic spinning can be ensured, the content of aluminum in the system can be improved and the strength of the alumina fibre can be enhanced.

Owner:DONGHUA UNIV

Novel vacuum ultraviolet coating material

The invention discloses a novel vacuum ultraviolet coating material which is prepared from the following raw materials in parts by weight: 1.5-3 parts of toluene, 3.2-5.5 parts of organic sulfonic acid compound, 1.5-2 parts of aluminum acetylacetonate, 8.5-10 parts of tripropylene glycol diacrylate, 2.5-3.4 parts of thickener, 2.3-3.5 parts of epoxy resin, 4.5-7 parts of water, 3.4-5.6 parts of hexyl diisocyanate tripolymer and 0.07-0.12 part of preservative. The formula is relatively environment-friendly, optimizes the tripropylene glycol diacrylate and epoxy resin diluting monomer and enhances the adhesion property for the low-surface-tension substrate, so that the new developed product has higher heat resistance and favorable weather resistance and is applicable to multiple substrates. The ultraviolet resistance and stability of the paint are improved, the heat resistance, adhesive force and weather resistance are enhanced, the production cost is lowered, and the coating material is convenient for popularization.

Owner:QINGDAO DESHENGTAI CONSTR INSTALLATION ENG

Super-strength abrasion-resistant rubber

The invention discloses super abrasion-resistant rubber. The super abrasion-resistant rubber is prepared from the following substances in parts by weight: 50 parts of buna-n rubber, 30 parts of carbon black, 20 parts of zinc oxide, 2 parts of stearic acid, 1 part of sulfide, 2 parts of lead tetroxide, 2 parts of titanium dioxide, 3 parts of anti-aging agent, 0.5 part of accelerant, 0.6 part of scorch retarder and 1 part of zinc stearate; and the accelerant is any one or a combination of two of triethylene diamine, stannous octoate or aluminum acetylacetonate. Compared with the prior art, by adjusting the ratio of the formula, the abrasion resistant degree of the rubber can be achieved, and the high temperature resistance and the stretching resistance can be improved.

Owner:HEFEI ZHONGLAN NEW MATERIAL TECH CO LTD

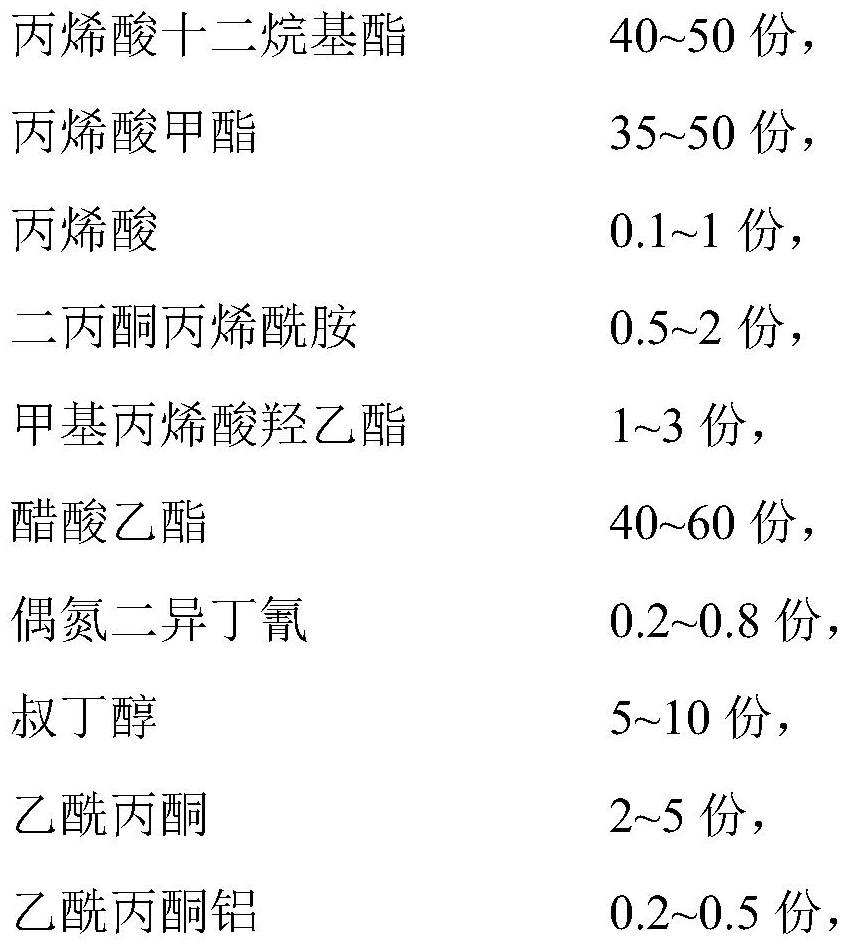

Removable pressure-sensitive adhesive composition

ActiveCN112226183AImprove aging resistanceGood weather resistanceEster polymer adhesivesCoatingsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a removable pressure-sensitive adhesive composition which comprises 40-50 parts of dodecyl acrylate, 35-50 parts of methyl acrylate, 0.1-1 part of acrylic acid, 0.5-2 parts ofdiacetone acrylamide, 1-3 parts of hydroxyethyl methacrylate, 40-60 parts of ethyl acetate, 0.2-0.8 part of azodiisobutyronitrile, 5-10 parts of tert-butyl alcohol, 2-5 parts of acetylacetone and 0.2-0.5 part of aluminum acetylacetonate. The preparation method comprises the following steps of Q1, adding dodecyl acrylate, methyl acrylate, acrylic acid, diacetone acrylamide, hydroxyethyl methacrylate, ethyl acetate and azodiisobutyronitrile into a container, and stirring to obtain a mixed solution A, Q2, putting the mixed solution A into a reaction kettle, and continuously introducing nitrogen for reaction, Q3, dropwise adding the mixed solution A into the reaction kettle, Q4, reducing the temperature to 40-45 DEG C, and Q5, adding tert-butyl alcohol, acetylacetone and aluminum acetylacetonate into the reaction kettle, stirring, and discharging. The adhesive composition provided by the invention has excellent aging resistance and weatherability, good application property and removability, and is not easy to remain adhesive.

Owner:浙江龙游道明光学有限公司

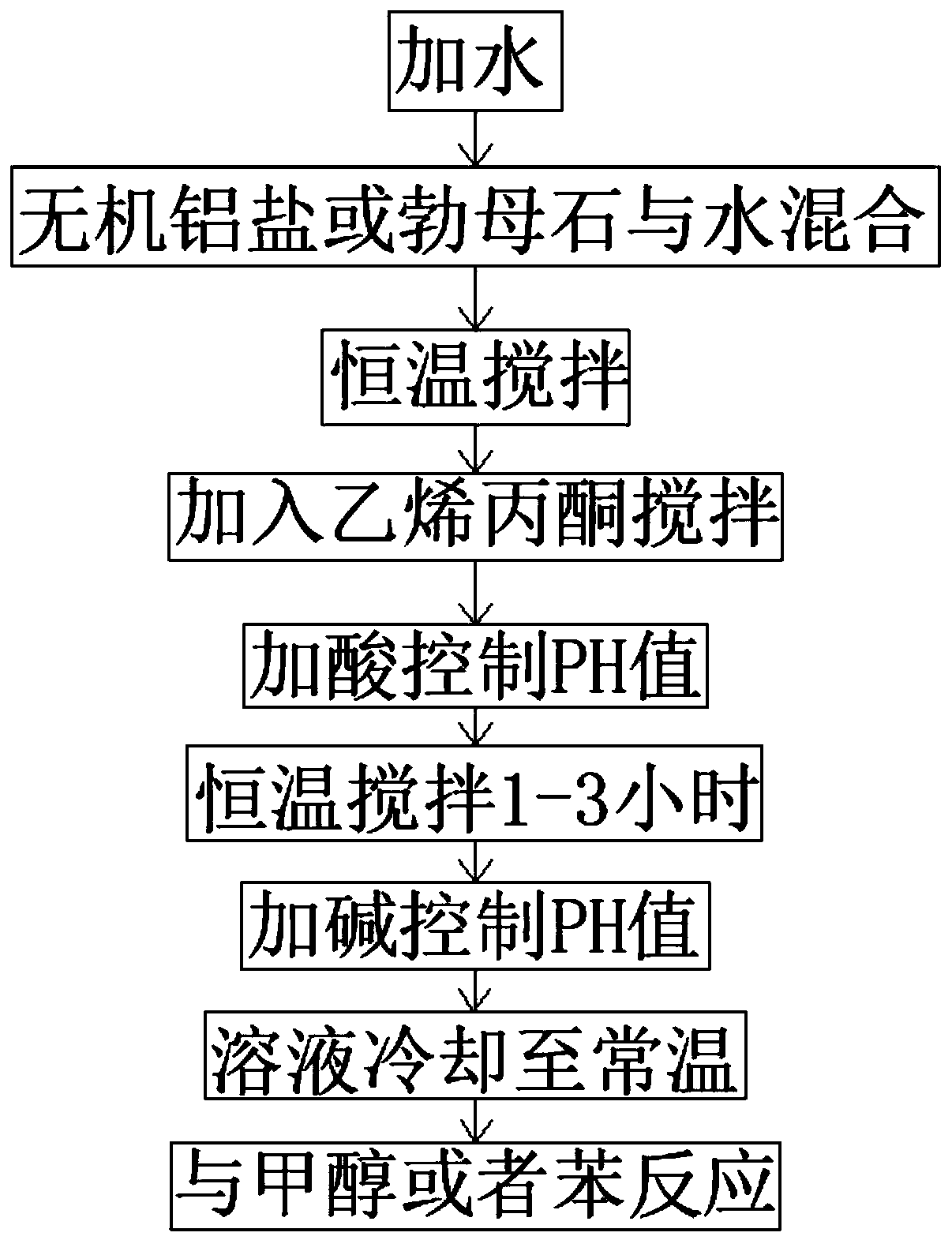

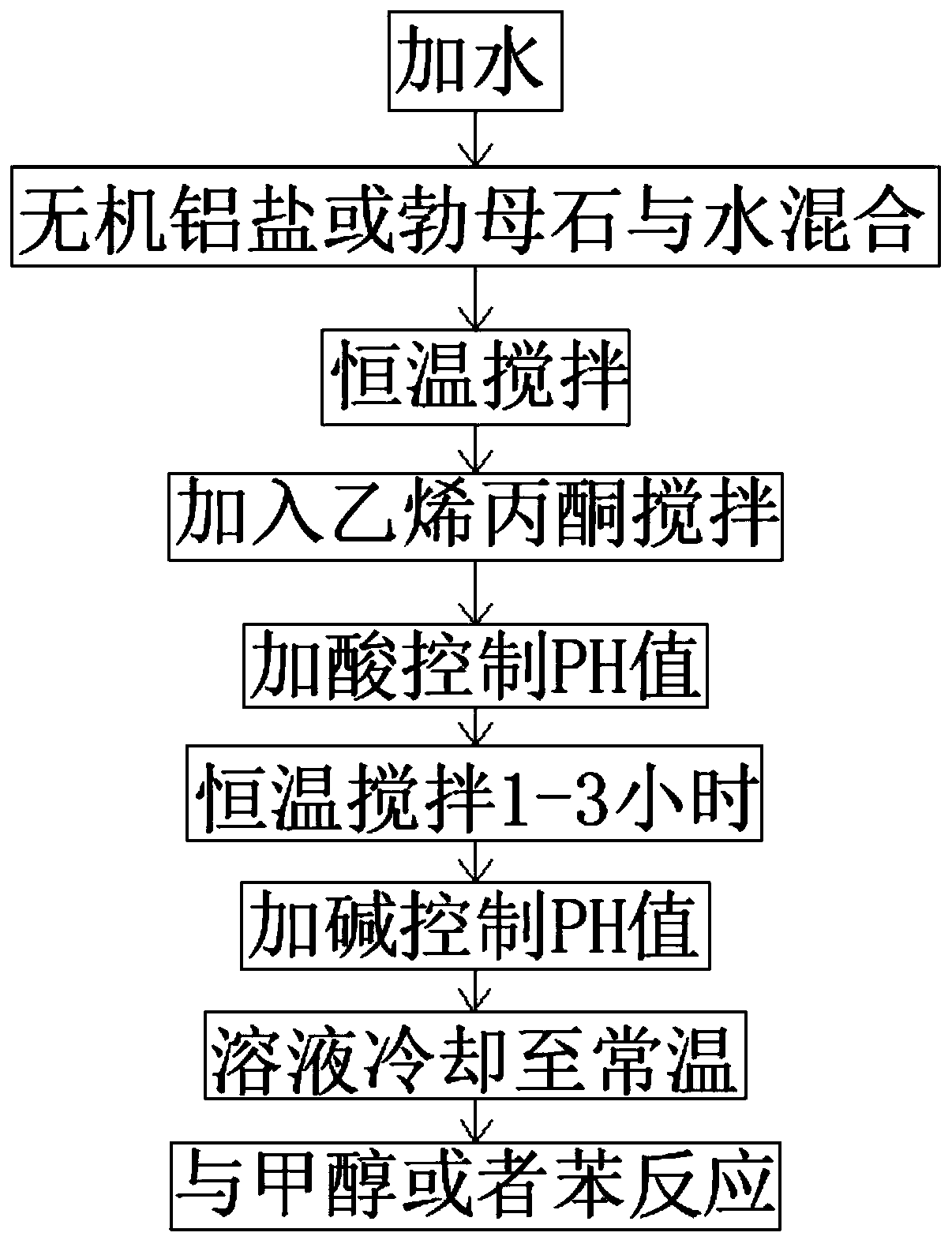

Green preparation method of aluminum acetylacetonate

InactiveCN109970539AReasonable structural designPrevent the problem of increasing environmental pollutionPreparation of aldehyde/ketone chelatesReaction rateAluminum acetylacetonate

The invention discloses a green preparation method of aluminum acetylacetonate in the technical field of fine chemical engineering. The green preparation method of the aluminum acetylacetonate comprises the following steps that step 1, a certain proportion of water is poured into a reaction kettle; step 2, a certain proportion of inorganic aluminum salt or boehmite is added while water is stirred,so that the inorganic aluminum salt or the boehmite is uniformly mixed with the water; step 3, a solution is heated to 60-90 DEG C while stirring; step 4, under a constant temperature state, a certain proportion of acetylacetone is added, and uniform stirring is carried out; step 5, during stirring, an acidic material is added into the solution, so that the PH value of the solution is 1.0-4.0; step 6, the solution in the reaction kettle is stirred for 1-3 hours at 60-90 DEG C. The green preparation method of the aluminum acetylacetonate has the advantages that the reaction rate between the inorganic aluminum salt or the boehmite and ethylene acetone is improved, the reaction between the inorganic aluminum salt or the boehmite and the ethylene acetone is relatively complete, residues are reduced, and the environmental protection property is improved.

Owner:扬州市立达树脂有限公司

Energy-saving glass coating capable of replacing LOW-E

The invention discloses an energy-saving glass coating capable of replacing LOW-E. The energy-saving glass coating comprises the following components in percentages by weight: 55 to 75% of organosilicon resin, 0.3 to 0.6% of poly butyl titanate, 0.4 to 0.6% of aluminum acetylacetonate, 5 to 10% of superfine hollow glass beads, 1 to 2.5% of nanometer titanium dioxide, 1 to 3% of polyethylene wax, 0.2 to 1.0% of nanometer silica particles, 0.5 to 1.5% of an infrared reflective pigment ALTIRIS-800, 15 to 25% of butyl acetate and 10 to 15% of mixed dibasic acid and dimethyl ester. The energy-saving glass coating capable of replacing LOW-E provided by the invention can reflect infrared ray and retard the rising of an indoor temperature in summer, reduces the uptime of an air conditioner, can reduce heat radiation to the outdoors in winter, and maintains indoor warmth.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com