Synthetic method of spinning grade polyaluminocarbosilane precursor

A technology of polyaluminocarbosilane and polycarbosilane, which is applied in the direction of textiles, papermaking, fiber chemical characteristics, etc., can solve the problems of poor spinning performance, increase the reaction rate, avoid easy breakage, and improve the effect of effective length and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

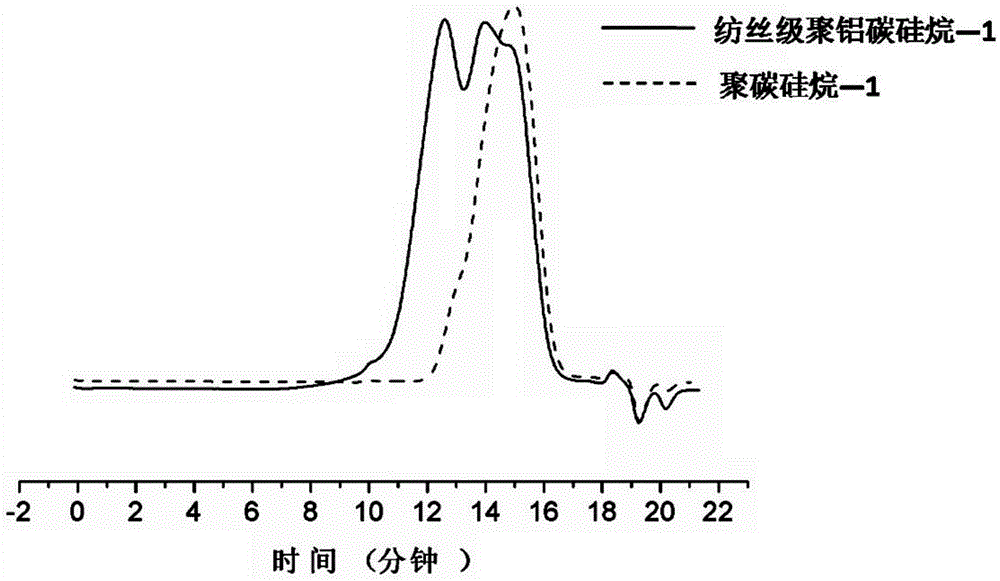

[0044] (1) Put 2.0kg of polydimethylsilane and 2.0L of xylene in a high-pressure reactor, evacuate, replace with nitrogen, repeat three times, then pre-fill 0.5MPa of nitrogen in the kettle, raise the temperature to 420°C, and keep warm After 8 hours, stop the reaction when the final pressure rises to 9MPa, cool to room temperature, filter and distill under reduced pressure after the reaction is completed, to obtain polycarbosilane-1.

[0045] (2) Dissolve 1320g of polycarbosilane in xylene, place the solution in an autoclave, and then add 79.2g of aluminum acetylacetonate. Vacuumize and replace nitrogen three times, then pre-fill nitrogen in the kettle to 1.0MPa, then heat to 300°C for reaction, keep warm for 2 hours, and the pressure at the end of keep warm is 4.3MPa. After the reaction, the mixture was filtered to remove insoluble matter.

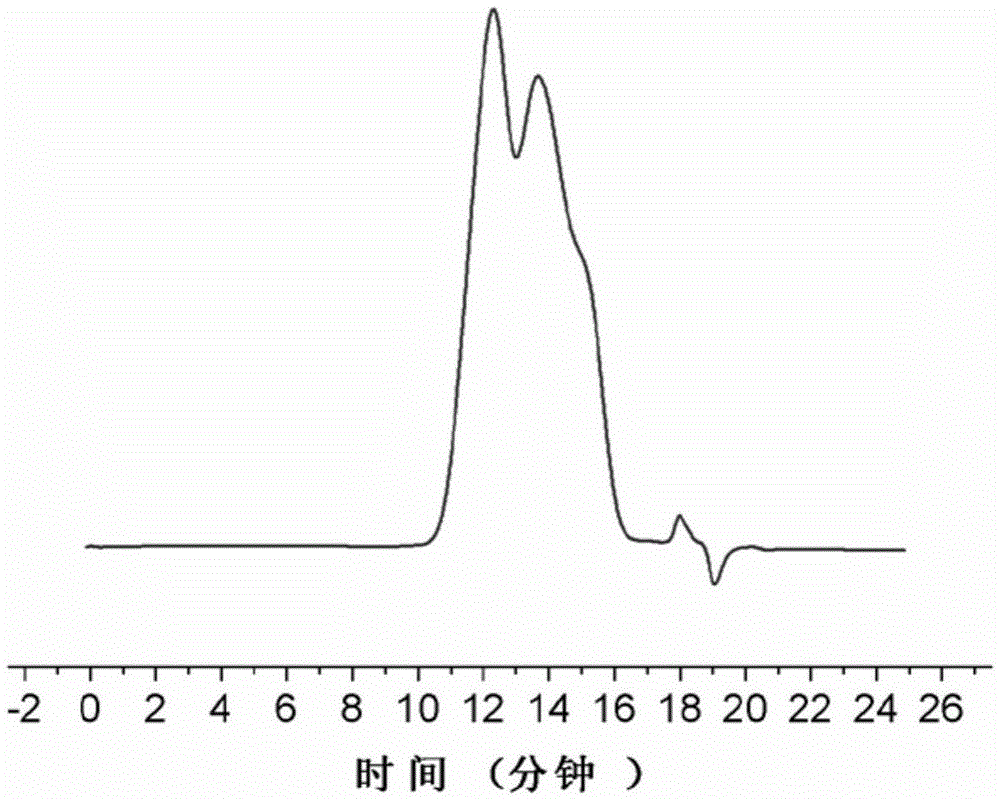

[0046] (3) Put the filtrate in a three-necked flask, vacuumize and replace nitrogen three times, then heat to 390°C under the protecti...

Embodiment 2

[0054] (1) Put 2.3kg of polydimethylsilane and 1.5L of toluene in a high-pressure reactor, vacuumize, replace with nitrogen, repeat three times, then pre-fill 0.2MPa of nitrogen in the kettle, raise the temperature to 440°C, and keep warm for reaction After 15 hours, the reaction was stopped when the final pressure rose to 11 MPa, cooled to room temperature, filtered and distilled under reduced pressure after the reaction was completed to obtain polycarbosilane-2.

[0055] (2) Dissolve 1120 g of polycarbosilane in xylene, place the solution in an autoclave, and then add 33.6 g of aluminum acetylacetonate. Vacuumize and replace nitrogen three times, then pre-fill nitrogen in the kettle to 1.5MPa, then heat to 280°C for reaction, keep warm for 5h, and the pressure is 3MPa at the end of keep warm. After the reaction, the mixture was filtered to remove insoluble matter.

[0056] (3) Put the filtrate in a three-necked flask, vacuumize and replace nitrogen three times, then heat to...

Embodiment 3

[0059] (1) Put 1.2kg of polydimethylsilane and 1.5L of xylene in a high-pressure reactor, vacuumize, replace with nitrogen, repeat three times, then pre-fill 2MPa nitrogen in the kettle, raise the temperature to 480°C, and keep it warm for 5h , stop the reaction when the final pressure rises to 15MPa, cool to room temperature, filter after the reaction, and distill under reduced pressure to obtain polycarbosilane-3.

[0060] (2) Dissolve 1140g of polycarbosilane in xylene, place the solution in an autoclave, and then add 91.2g of aluminum acetylacetonate. Vacuumize and replace nitrogen three times, then pre-fill nitrogen in the kettle to 3MPa, then heat to 320°C for reaction, keep warm for 4 hours, and the pressure at the end of keep warm is 5.2MPa. After the reaction, the mixture was filtered to remove insoluble matter.

[0061] (3) Put the filtrate in a three-necked flask, vacuumize and replace nitrogen three times, then heat to 410°C under the protection of nitrogen to rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com