Silicon carbide fibers having a low oxygen content and a preparing method thereof

A silicon carbide fiber and fiber technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of the decline of SiC fiber performance, and achieve the effect of improving mechanical properties and high temperature resistance, good high temperature resistance and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

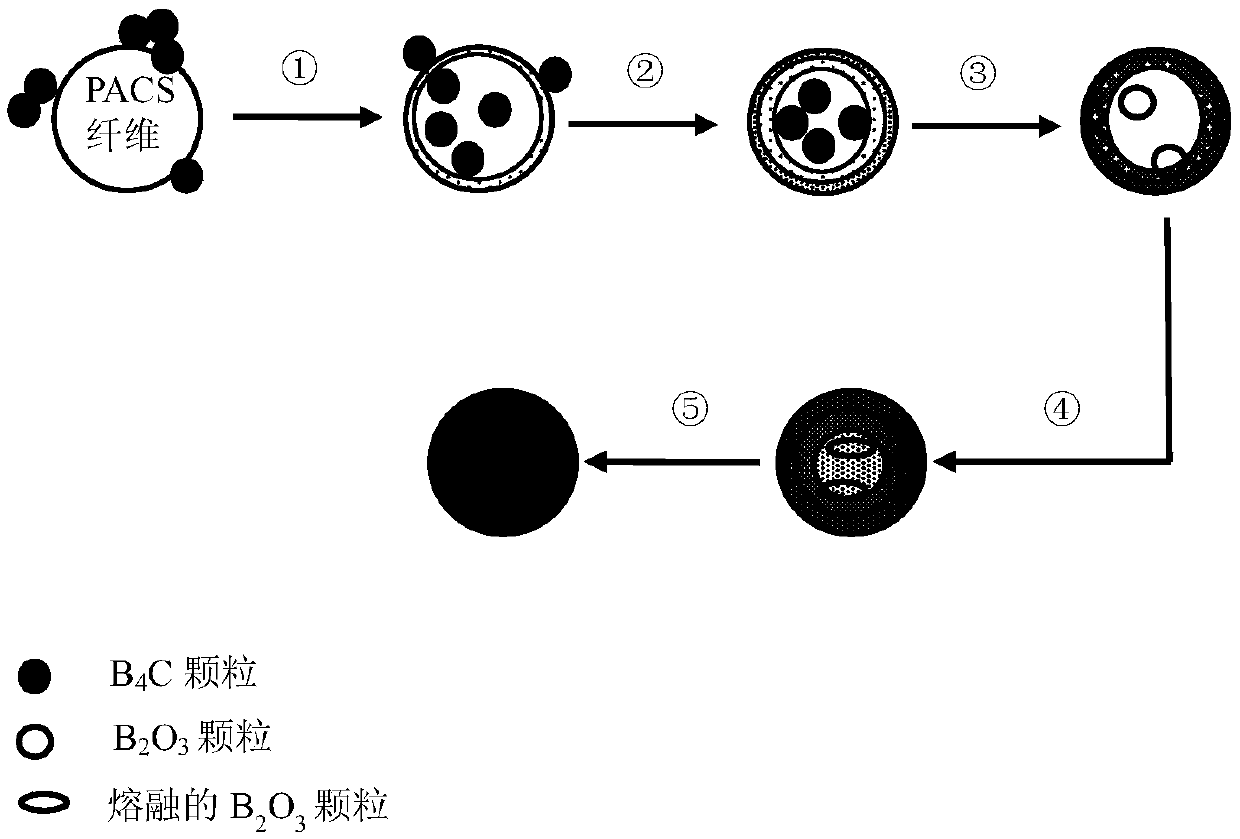

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing silicon carbide fibers with low oxygen content, comprising the following steps:

[0027] S100: Purification of raw materials

[0028] Polycarbosilane (PCS) was synthesized from polydimethylsilane (PDMS) with a molecular weight of 2500-3000, and the liquid low-molecular by-product polysilicon carbon with a softening point of 180-200°C and a number-average molecular weight of 1600-2200 was collected. Silane (PSCS); PSCS is then dissolved in an appropriate amount of xylene solvent, filtered, and distilled under reduced pressure to obtain the pure product PSCS. Wherein, the volume ratio of xylene to by-product polysilocarbosilane is (1-2):1.

[0029] S101: Preparation of polyaluminocarbosilane (PACS) precursor

[0030] Take the aluminum acetylacetonate (Al(AcAc) which is 5-10% by mass percent 3 ) placed in the autoclave, the pure product PSCS was slowly injected into the autoclave, evenly covered in Al(AcAc) 3 surface; then ...

Embodiment 1

[0040] The invention provides a method for preparing silicon carbide fibers with low oxygen content, comprising the following steps:

[0041] S100: Purification of raw materials

[0042] Synthesize polycarbosilane (PCS) with polydimethylsilane (PDMS) as raw material, collect liquid low molecular by-product polysilocarbosilane (PSCS); then dissolve PSCS in an appropriate amount of xylene solvent, filter, and distill under reduced pressure , to obtain the pure product PSCS. Wherein, the volume ratio of xylene to by-product polysilocarbosilane is 1:1.

[0043] S101: Preparation of polyaluminocarbosilane (PACS) precursor

[0044] Get mass percent concentration and be 10% aluminum acetylacetonate (Al(AcAc) 3 ) placed in the autoclave, the pure product PSCS was slowly injected into the autoclave, evenly covered in Al(AcAc) 3 surface; then pass through N 2 permutation 3 times, followed by N 2 Slowly heat to 360°C at a rate of 5°C / min under the atmosphere, and keep it warm for 6...

Embodiment 2

[0052] The invention provides a method for preparing silicon carbide fibers with low oxygen content, comprising the following steps:

[0053] S100: Purification of raw materials

[0054] Synthesize polycarbosilane (PCS) with polydimethylsilane (PDMS) as raw material, collect liquid low molecular by-product polysilocarbosilane (PSCS); then dissolve PSCS in an appropriate amount of xylene solvent, filter, and distill under reduced pressure , to obtain the pure product PSCS. Wherein, the volume ratio of xylene to by-product polysilocarbosilane is 2:1.

[0055] S101: Preparation of polyaluminocarbosilane (PACS) precursor

[0056] Get mass percent concentration and be 5% aluminum acetylacetonate (Al(AcAc) 3 ) placed in the autoclave, the pure product PSCS was slowly injected into the autoclave, evenly covered in Al(AcAc) 3 surface; then pass through N 2 permutation 3 times, followed by N 2 Slowly heat to 400°C at a rate of 10°C / min under the atmosphere, and keep it warm for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com