Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "2-mercaptobenzimidazole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Latex film compound with improved tear resistance

InactiveUS7048977B2Increase elasticityIncrease resistanceClosuresClosure using stoppers2-mercaptobenzimidazoleAntioxidant

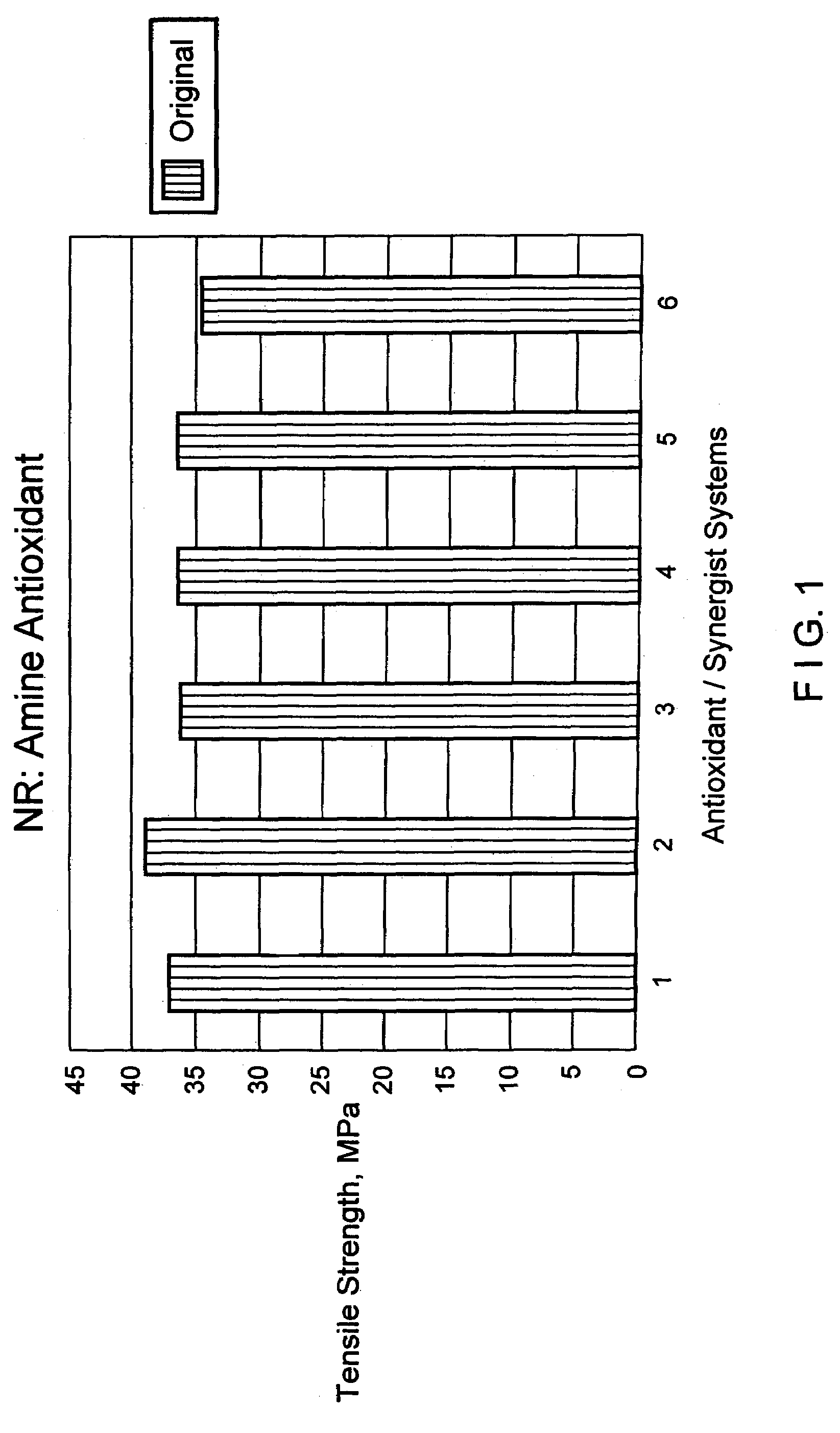

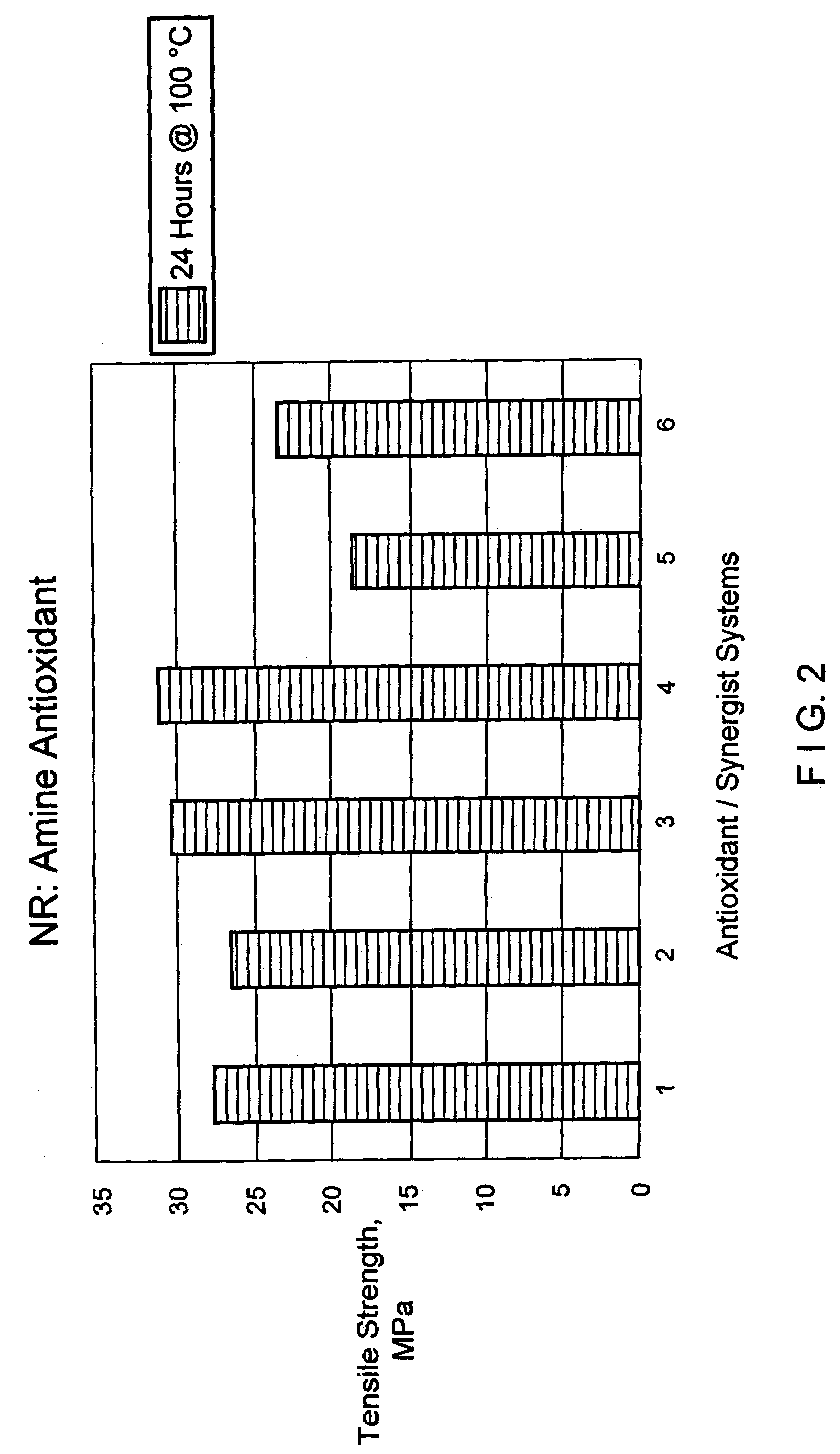

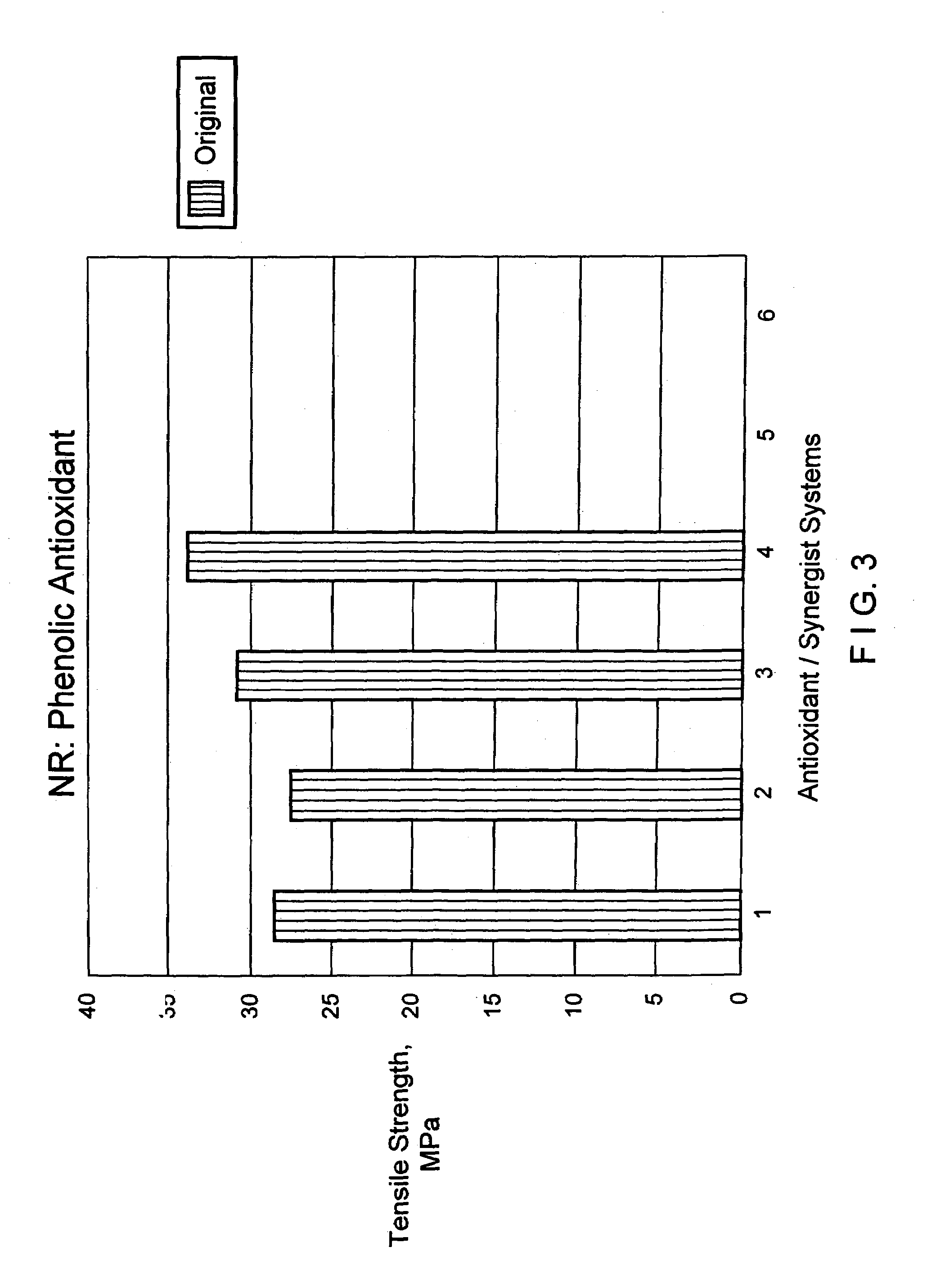

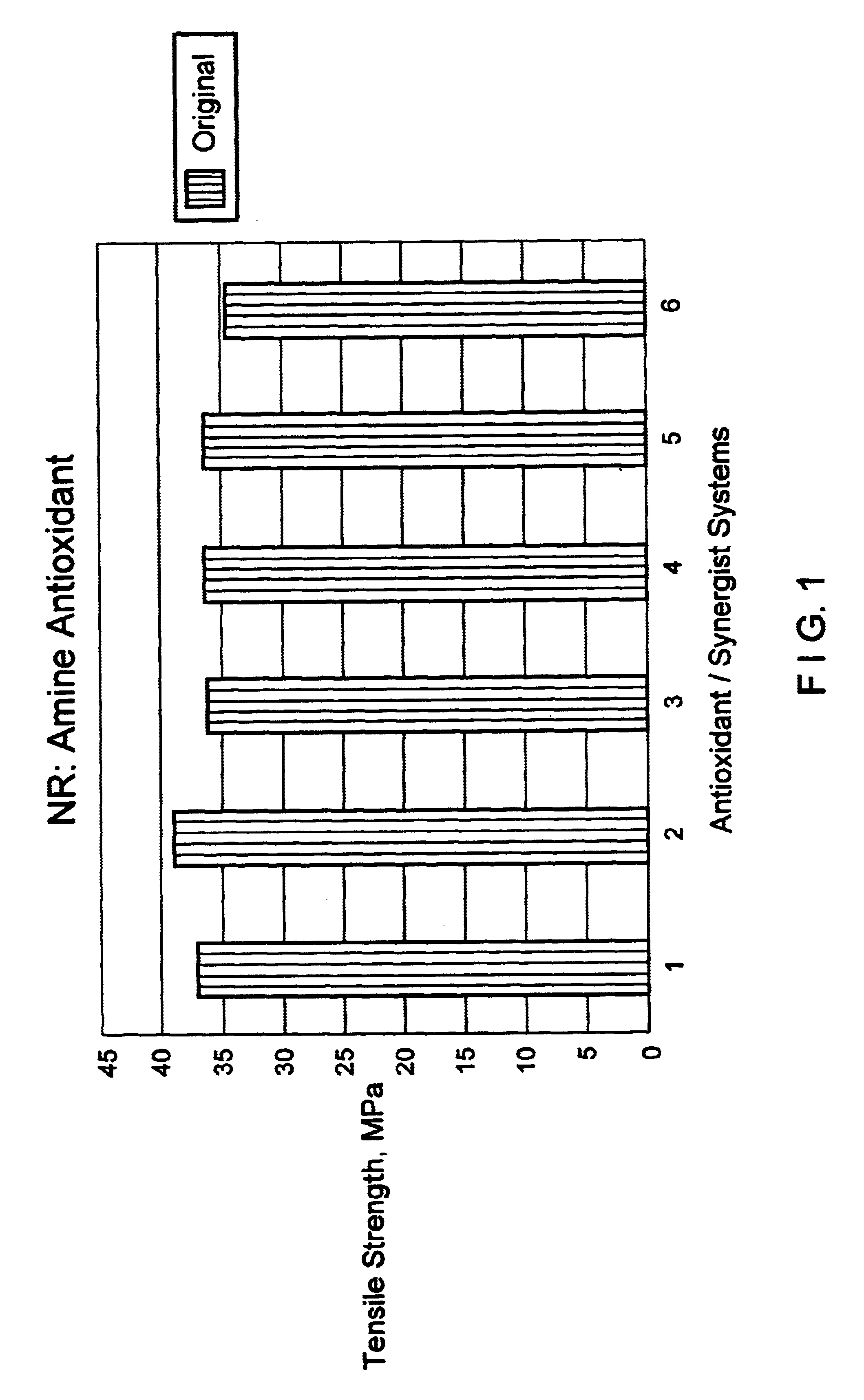

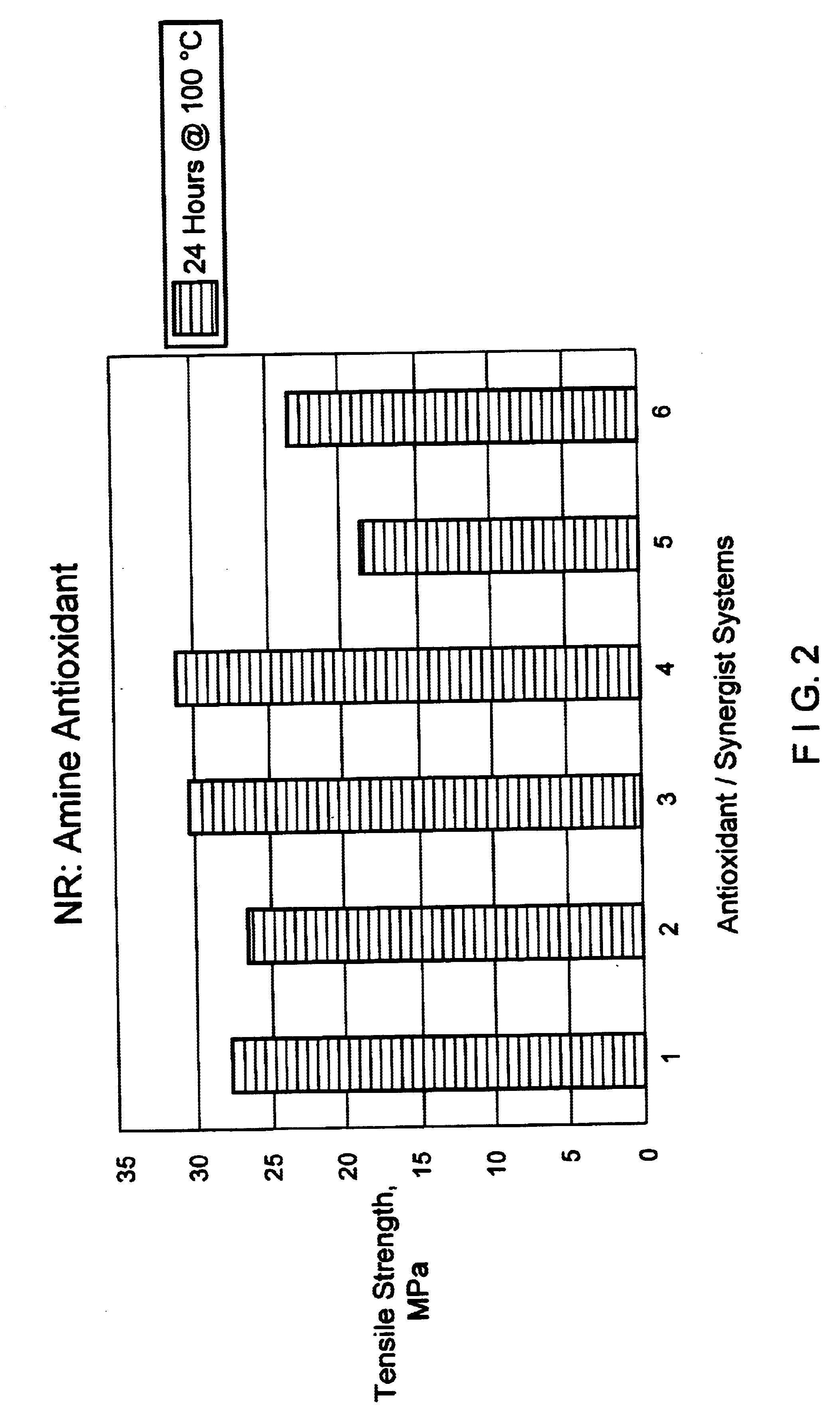

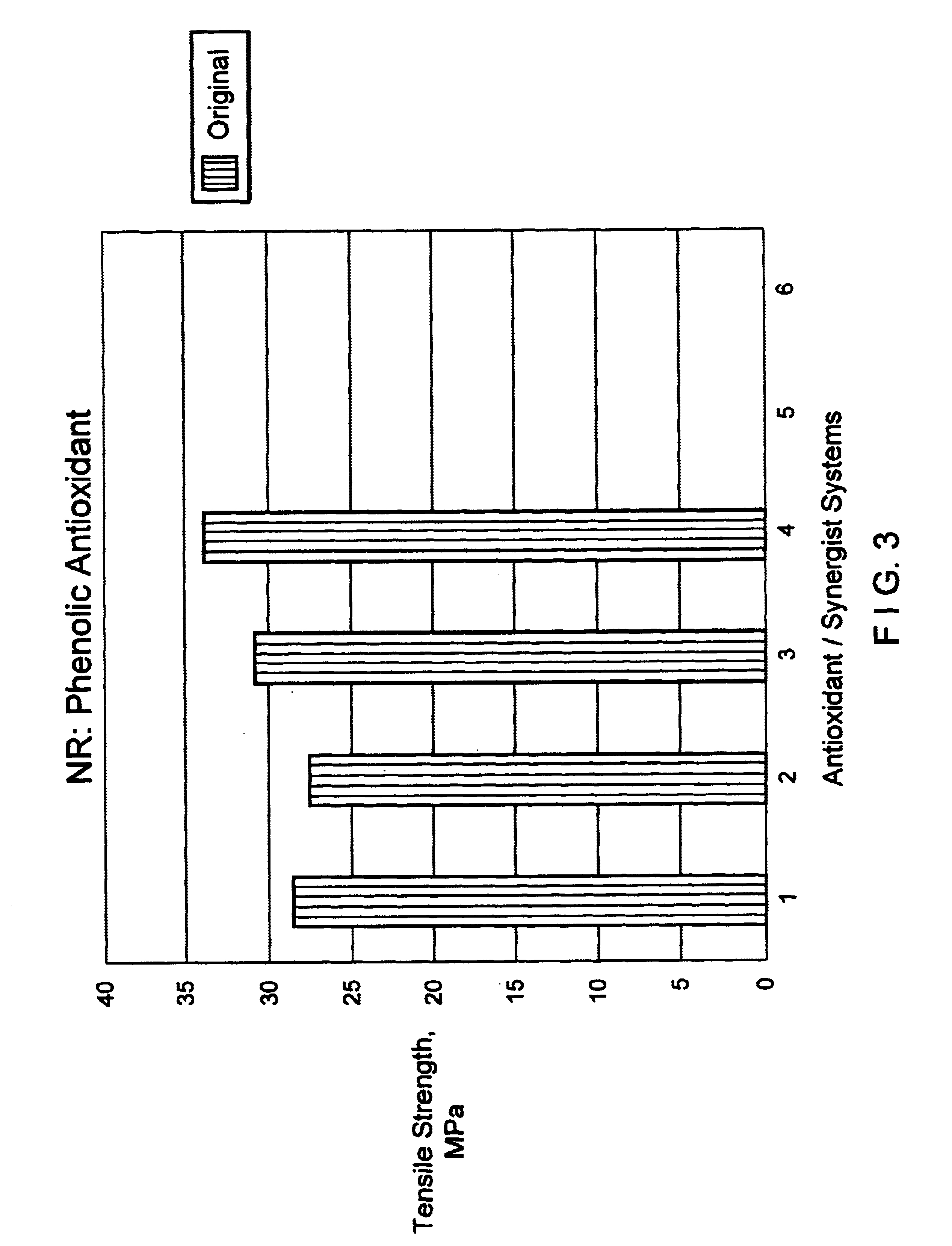

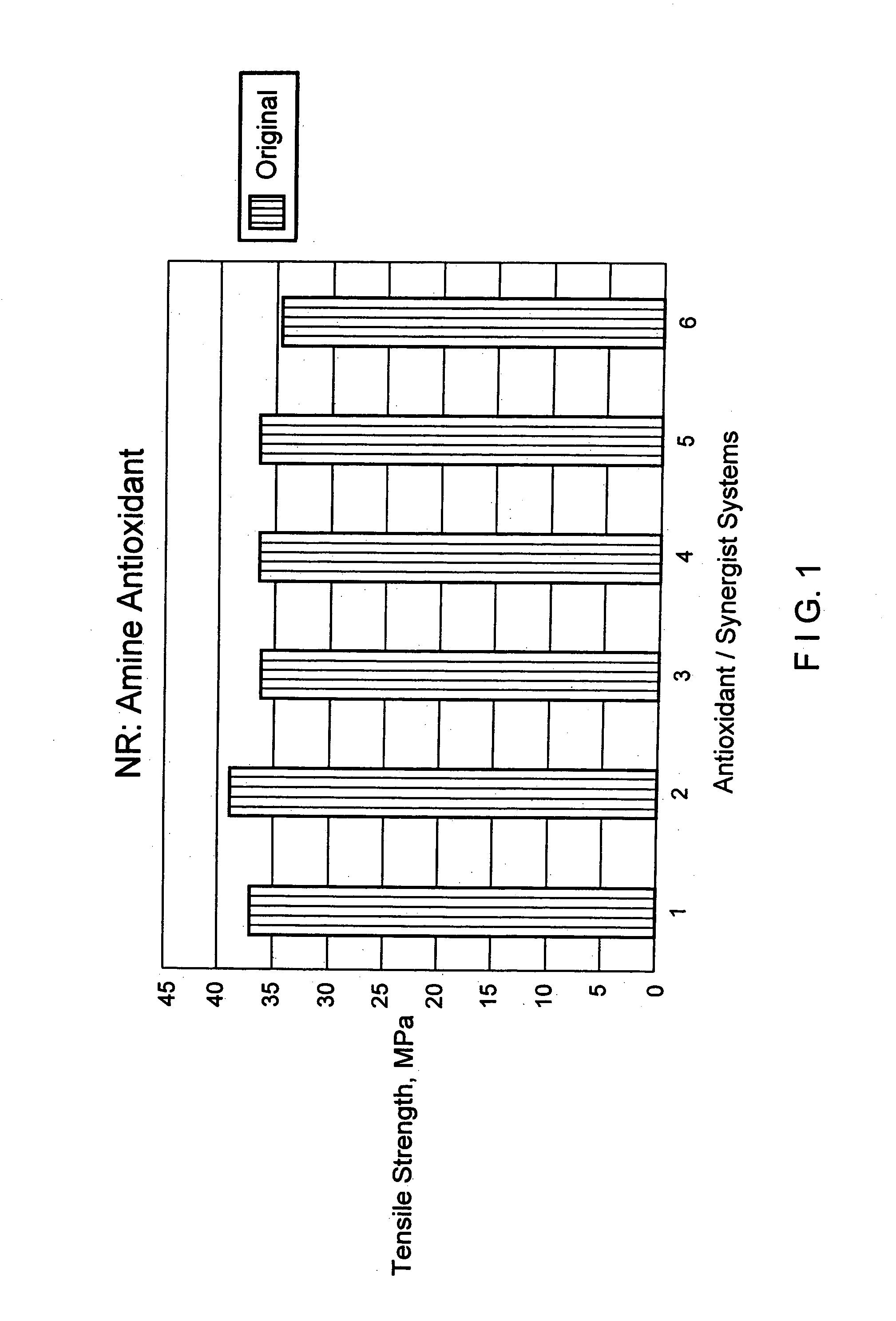

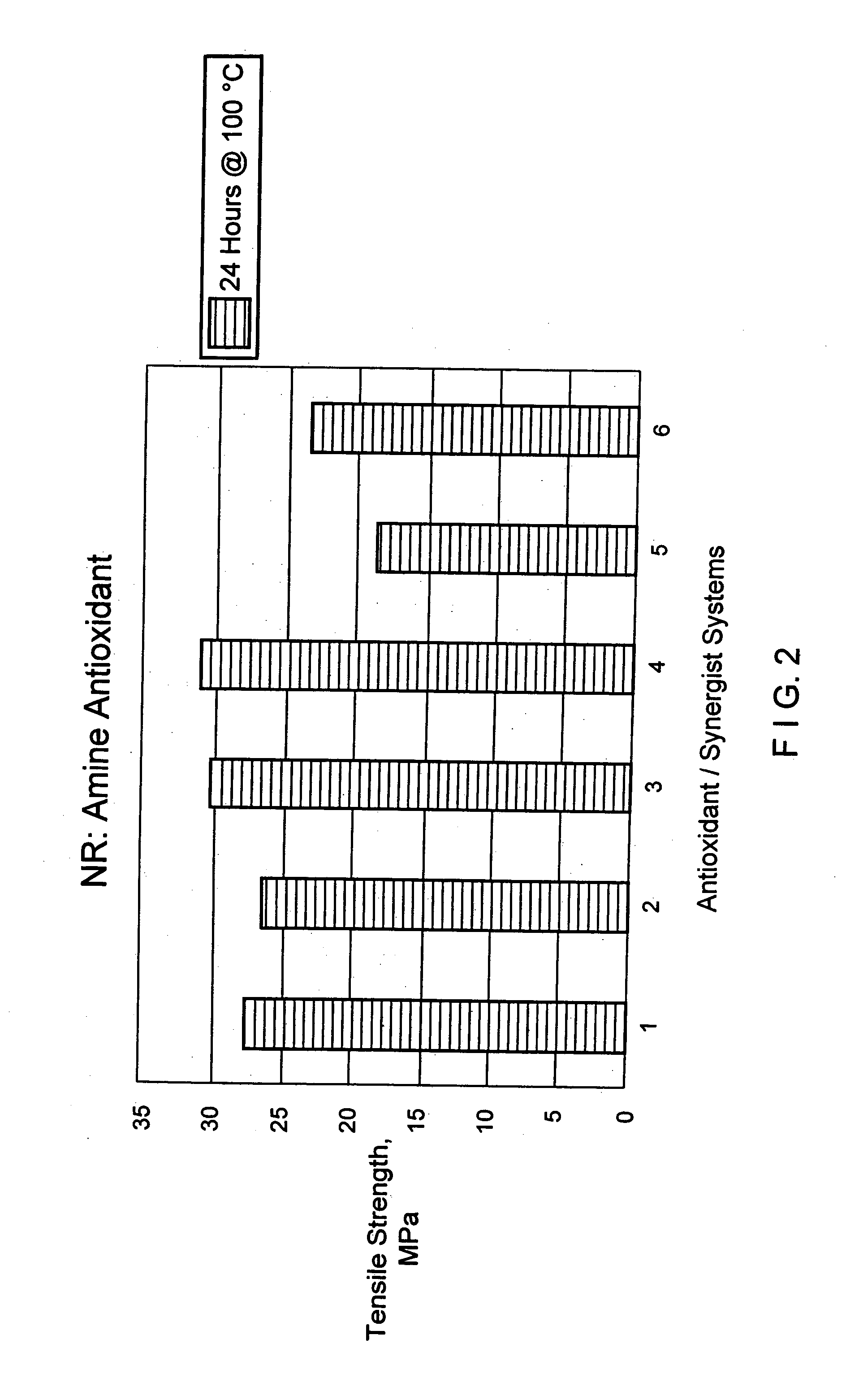

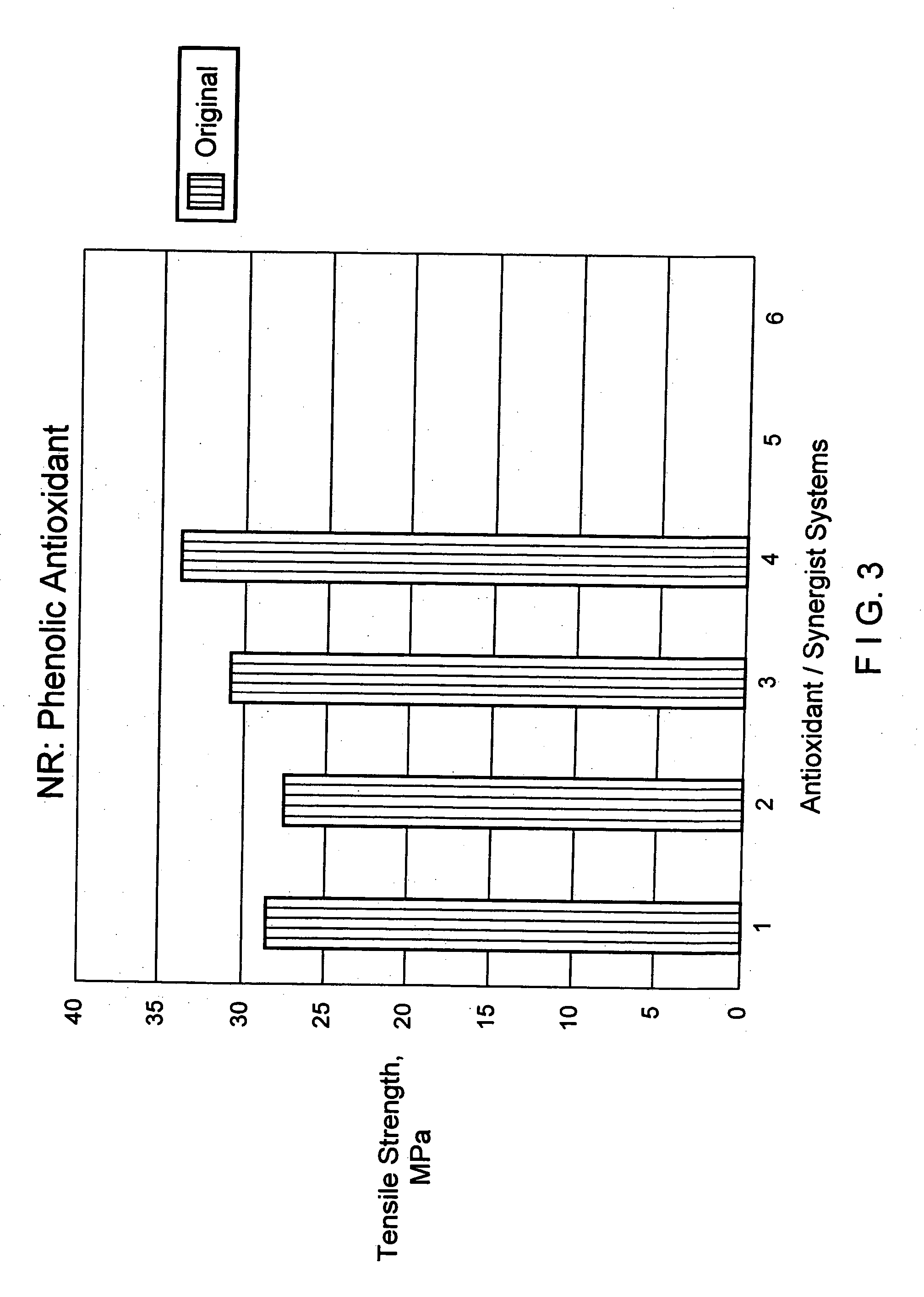

The invention relates to a method of enhancing the tear resistance, tensile strength, and the aging properties of a latex product by adding an antioxidant synergist with an antioxidant to a latex compound comprising of a polymer and a curing system comprised of an activator, crosslinker and accelerator and to the latex products formed therefrom. Antioxidant synergists which can be used with the present invention include 2-mercaptobenzimidazole (MBI), 2-mercaptotoluimidazole (MTI), zinc 2-mercaptobenzimidazole (ZMBI) and zinc 2-mercaptotoluimidazole (ZMTI). The latex products formed may be gloves but can also include threads, balloons and other latex-related products.

Owner:VANDERBILT CHEM LLC

Latex film compound with improved tear resistance

InactiveUS6653380B2Good effectDeterioration of propertyGranular deliverySolid balls2-mercaptobenzimidazoleAntioxidant

The invention relates to a method of enhancing the tear resistance, tensile strength, and the aging properties of a latex product by adding an antioxidant synergist with an antioxidant to a latex compound comprising of a polymer, a stabilizing system, a film surface conditioner and a curing system comprised of an activator, crosslinker and accelerator and to the latex products formed therefrom. Antioxidant synergists which can be used with the present invention include 2-mercaptobenzimidazole (MBI), 2-mercaptotoluimidazole (MTI), zinc 2-mercaptobenzimidazole (ZMBI) and zinc 2-mercaptotoluimidazole (ZMTI). The latex products formed may be gloves but can also include threads, balloons and other latex-related products.

Owner:VANDERBILT CHEM LLC

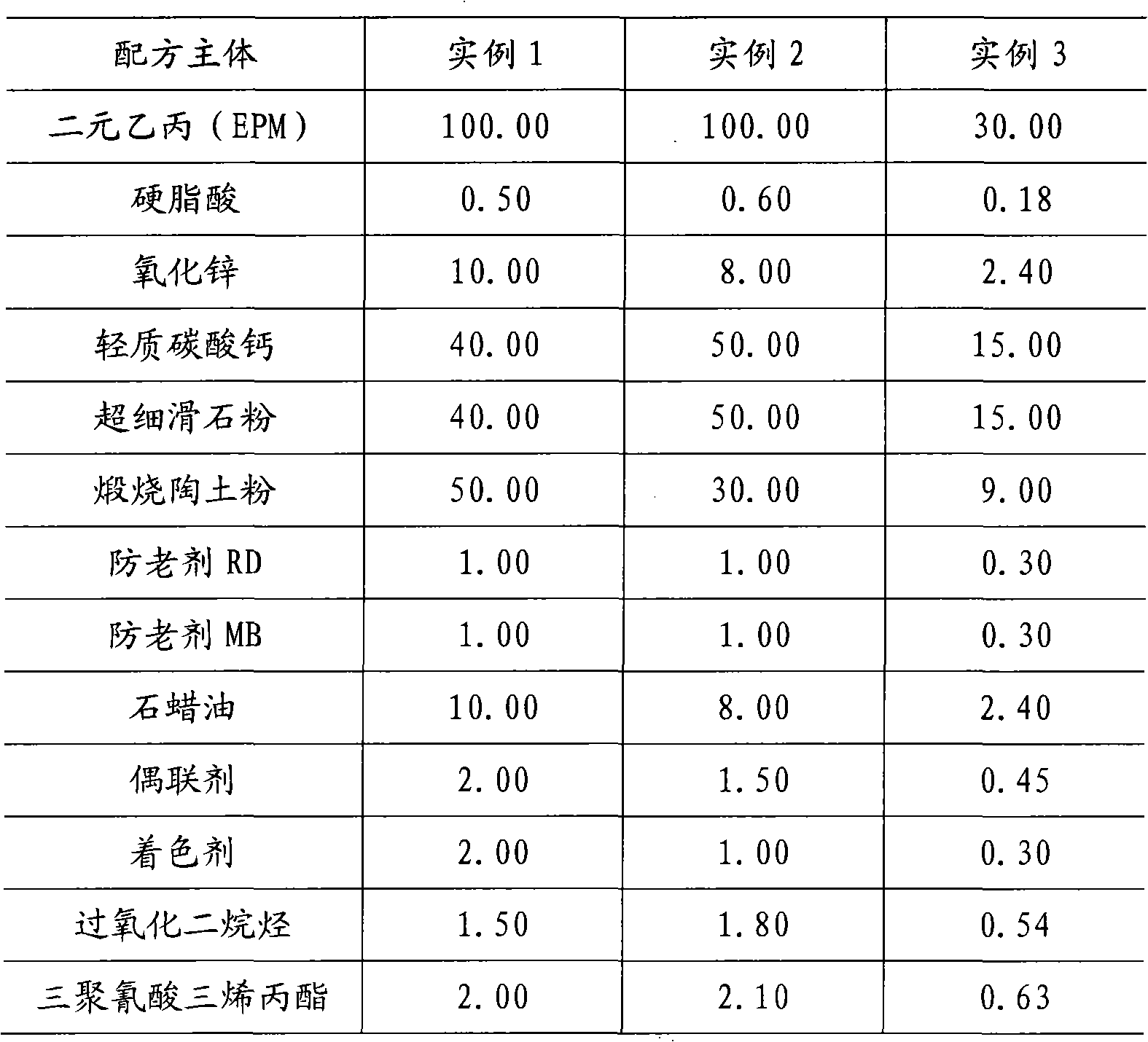

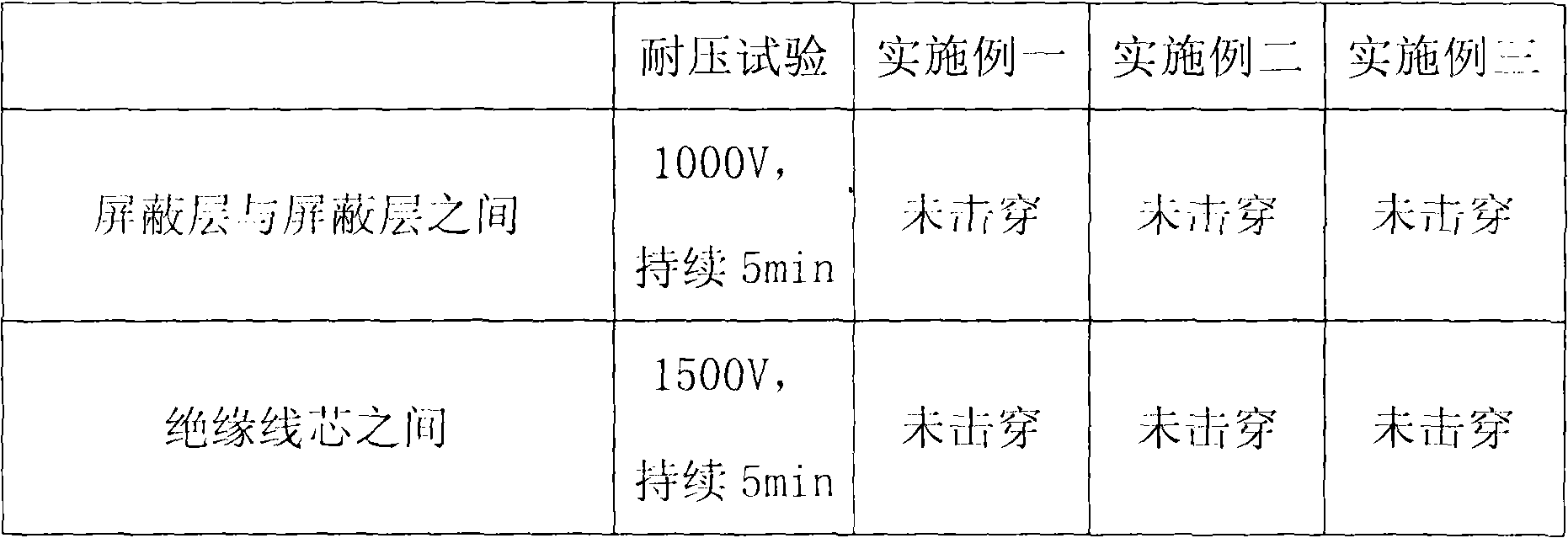

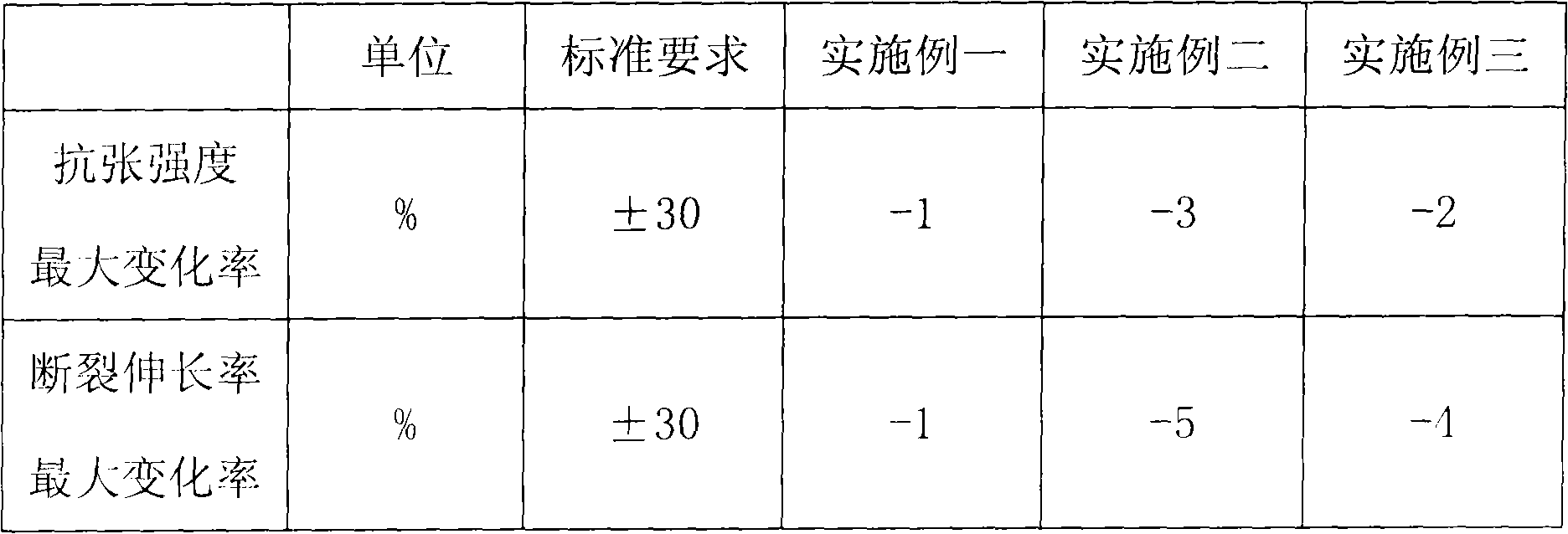

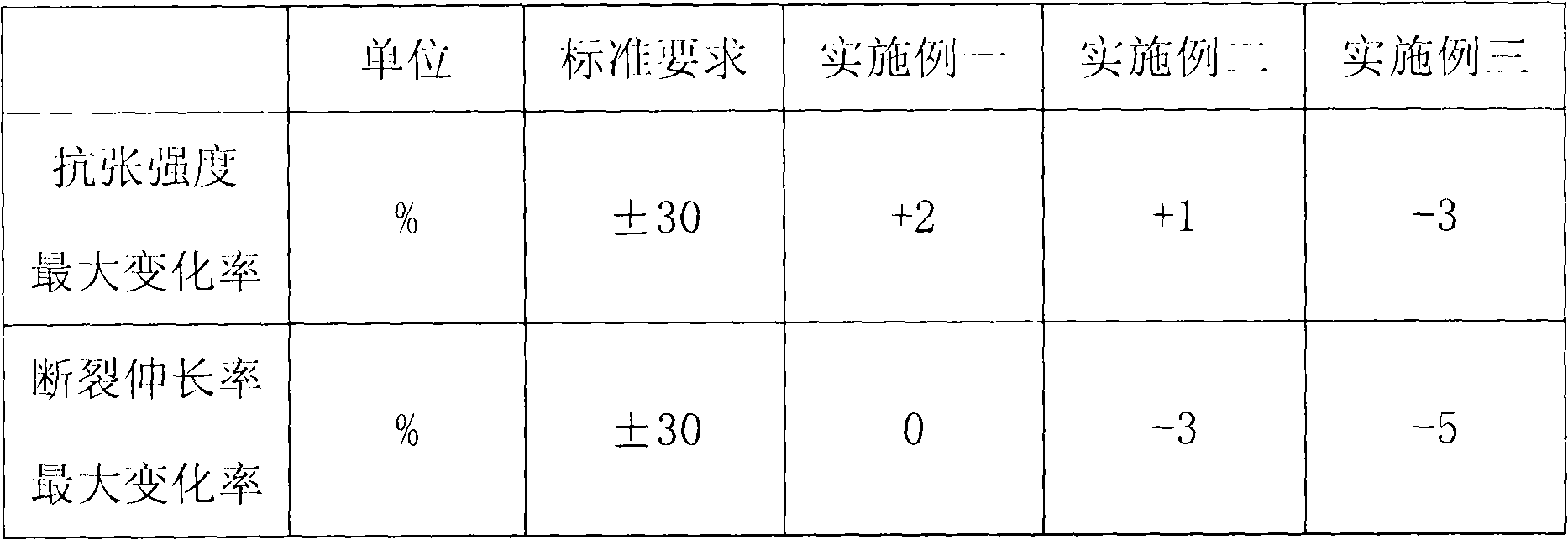

Ethyl-propylene insulating material for cable resisting temperature of 140 DEG C

InactiveCN101538390AHigh temperature resistantHigh temperature resistanceRubber insulatorsVulcanization2-mercaptobenzimidazole

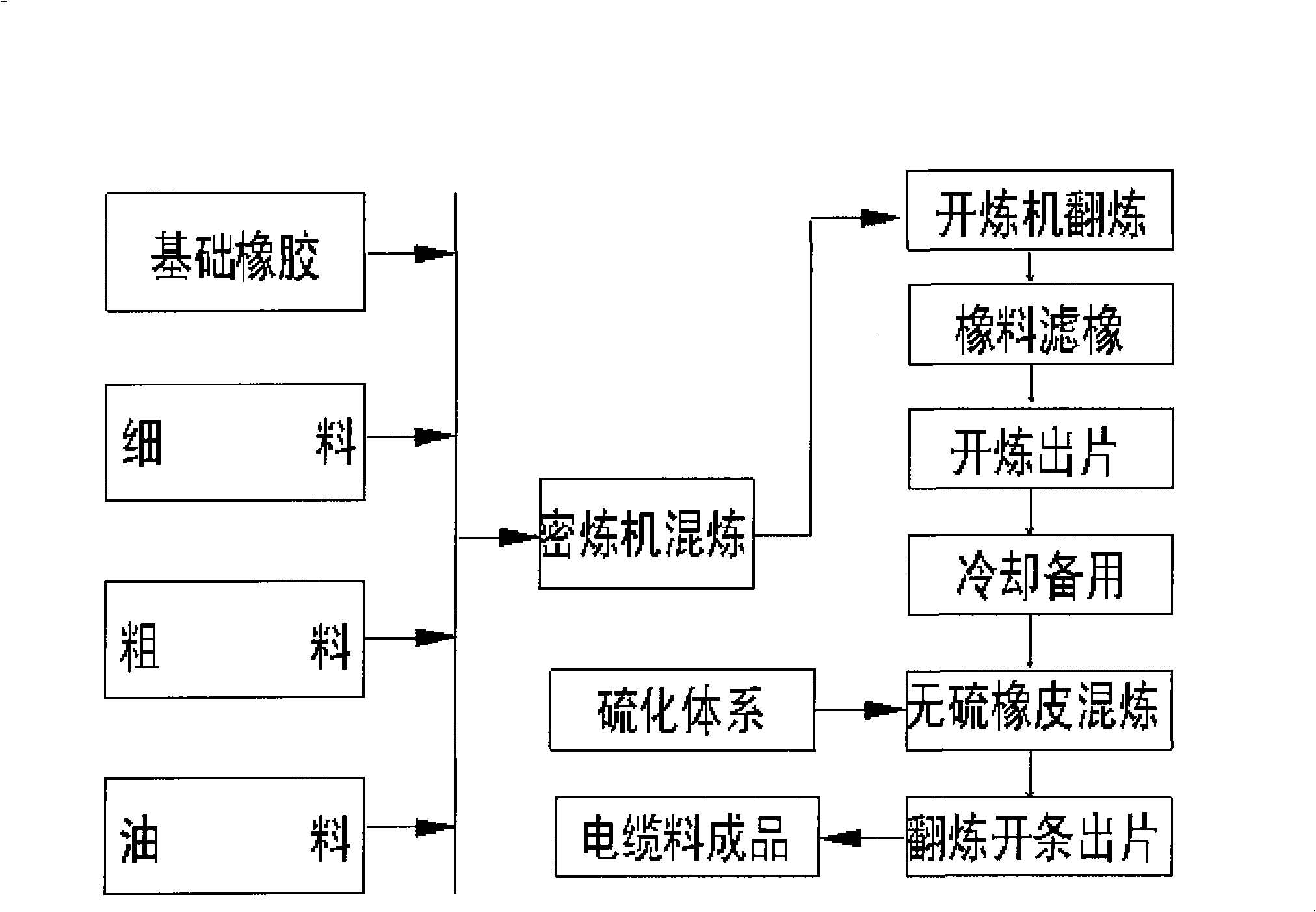

The invention discloses an ethyl-propylene insulating material for cable resisting temperature of 140 DEG C, comprising the following components by weigh parts: 100.00 parts of ethylene propylene rubber, 50.00 parts of filling agent light calcium carbonate, 50.00 parts of filling agent superfine talcum powder, 30.00 parts of reinforcing agent calcined clay powders, 5.00-10.00 parts of plasticizer paraffine, 0.50-1.00 parts of activator stearic acid, 5.00-10.00 parts of activator zinc oxide, 0.50-2.00 parts of coloring agent, 2.50-3.00 parts of 2,2,4-trimethyl-1,2-dihydroquinone and 2-mercaptobenzimidazole with the proportion of anti-ageing agent of 1:1, 1.00-1.50 parts of coupling agent Vinyl tris-beta-methoxy ethoxy silane, 1.50-2.00 parts of vulcanizing agent peroxide perkadox, and 2.00-3.00 parts of vulcanization aid cyanuric acid triallyl ester. The ethyl-propylene insulating material for the cable resisting the temperature of 140 DEG C has the advantages of excellent high-temperature resistance, high-insulation resistance, high mechanical performance, long service life, and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

High-elasticity wear-resisting flame-retardant rubber material

The invention discloses a high-elasticity wear-resisting flame-retardant rubber material. The high-elasticity wear-resisting flame-retardant rubber material is prepared from the following raw materials in parts by weight: 40-45 parts of butadiene styrene rubber, 30-36 parts of polyurethane elastomer, 10-18 parts of chloroprene rubber, 2-3 parts of vulcanizing agent BPO (benzoyl peroxide), 1.2-1.8 parts of sulphur, 2-4 parts of accelerant DM (2,2'-dibenzothiazoledisulfde), 20-25 parts of modified titanium dioxide, 10-14 parts of calcite powder, 6-10 parts of brucite powder, 4-9 parts of aluminum nitride, 14-15 parts of carbon black N660, 2-5 parts of quartz powder, 5-8 parts of zinc oxide, 9-12 parts of magnesium hydrate, 1-4 parts of single alkoxyl pyrophosphate titanate coupling agent, 2-5 parts of diphenyl phosphate, 1-4 parts of melamine, 1-3 parts of stearic acid, 1-1.3 parts of anti-aging agent 264, and 2-4 parts of anti-aging agent MB (2-mercaptobenzimidazole). The high-elasticity wear-resisting flame-retardant rubber material has high elasticity, good abrasion resistance and excellent flame retardant effect.

Owner:ANHUI HONGYI CABLE GROUP

Cable insulated rubber for ship hydrophone equipment and preparation method thereof

InactiveCN102093643AImprove insulation performanceImprove mechanical propertiesRubber insulatorsQuinonePolymer science

The invention discloses cable insulated rubber for the ship hydrophone equipment and a preparation method thereof. The rubber comprises the following components in parts by weight: 11 parts of ethylene propylene rubber 2470, 7-9 parts of ethylene propylene rubber 578K, 0.1-0.3 part of dibenzothiazyl disulfide, 1.5-2.5 parts of zinc oxide, 0.5-0.8 part of 2-Mercaptobenzimidazole, 0.4-0.7 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1-1.5 parts of titanium white powder, 1.5-2.0 parts of microcrystalline wax, 0.2-0.5 part of stearic acid, 2-3 parts of white carbon black, 8-12 parts of ultrafine coupling agent, 0.2-0.4 part of calcined clay, 5-8 parts of ultrafine talcum powder, 1-1.5 parts of red lead masterbatch, 1-1.5 parts of dicumyl peroxide and 0.15-0.25 part of quinone dioxime. The preparation method comprises the following steps: mixing ethylene propylene rubber, then adding zinc oxide and some components, filtering rubber, rolling, cooling, adding dibenzothiazyl disulfide, finally adding dicumyl peroxide and quinone dioxime, performing triangle packaging, thinning, and discharging the prepared rubber sheets. The insulated rubber of the invention has good insulating property and long service life and can meet the operational requirements of the ship hydrophone equipment.

Owner:JIANGSU YUANYANG DONGZE CABLE

Moistureproof insulation material for electrical engineering

InactiveCN104592704AHigh strengthImprove insulation performancePlastic/resin/waxes insulatorsPolyureas/polyurethane adhesivesEpoxyElectrical engineering technology

The invention discloses a moistureproof insulation material for electrical engineering. The material comprises an inner layer and an outer layer. The inner layer is prepared from the following raw materials in parts by weight: 10-16 parts of quartz sand, 16-22 parts of aluminum oxide, 16-22 parts of polyallylamine resin, 3-9 parts of dimethylformamide, 1-4 parts of butyl rubber and 3-9 parts of nano silicon dioxide. The outer layer is prepared from the following raw materials in parts by weight: 15-22 parts of epoxy resin, 10-17 parts of polyamide resin, 20-28 parts of glass fiber, 2-6 parts of ethylene propylene diene monomer rubber, 0.5-1.2 parts of 2-mercaptobenzimidazole, 1-4 parts of nano zinc oxide, 10-18 parts of silicon nitride, 2-9 parts of hydrogenated nitrile-butadiene rubber, 5-11 parts of aluminum nitride and 5-11 parts of polyethylene. The moistureproof insulation material is composed of the inner layer and outer layer; the outer layer achieves the moistureproof effect under the combined actions of the components; and the material has steady insulating property under the combined actions of the components of the inner layer.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Method for suppressing discoloration over time of adhesive preparation containing donepezil

InactiveUS20100048628A1Sufficient effectImprove stabilityBiocideNervous disorderPropanoic acidDonepezil

[Object] Discoloration, over time, of a donepezil-containing adhesive preparation is suppressed.[Solution] At least one species of stabilizer selected from the group consisting of ascorbic acid, a metal salt or an ester thereof, isoascorbic acid or a metal salt thereof, ethylenediamine tetraacetic acid or a metal salt thereof, 2-mercaptobenzimidazole, 3(2)-t-butyl-4-hydroxyanisole, 2,6-di-t-butyl-4-methylphenol, tetrakis[3-(3′,5′-di-t-butyl-4′-hydroxyphenyl)propionic acid]pentaerythritol, (±)-α-tocopherol, (±)-α-tocopherol acetate, rutin, hypophosphorous acid, a metal metabisulfite salt and a metal salt of hydroxymethanesulfinic acid, is blended in a pressure-sensitive adhesive layer containing a pressure-sensitive adhesive and donepezil.

Owner:NITTO DENKO CORP +1

Latex film compound with improved tear resistance

InactiveUS20040063832A1Good effectDeterioration of propertyClosuresClosure using stoppers2-mercaptobenzimidazoleAntioxidant

The invention relates to a method of enhancing the tear resistance, tensile strength, and the aging properties of a latex product by adding an antioxidant synergist with an antioxidant to a latex compound comprising of a polymer and a curing system comprised of an activator, crosslinker and accelerator and to the latex products formed therefrom. Antioxidant synergists which can be used with the present invention include 2-mercaptobenzimidazole (MBI), 2-mercaptotoluimidazole (MTI), zinc 2-mercaptobenzimidazole (ZMBI) and zinc 2-mercaptotoluimidazole (ZMTI). The latex products formed may be gloves but can also include threads, balloons and other latex-related products.

Owner:VANDERBILT CHEM LLC

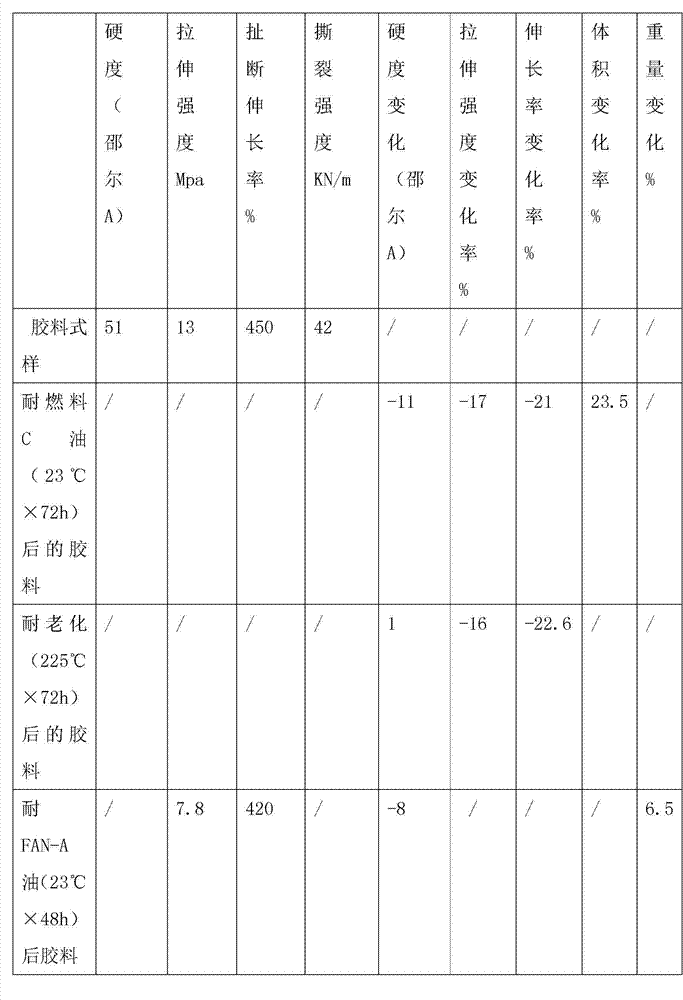

Piston rubber material for mud pumps and preparation method thereof

ActiveCN103044927AImprove performanceGood high and low temperature resistance2-mercaptobenzimidazoleDiphenylsilanediol

The invention discloses a piston rubber material for mud pumps. The piston rubber material is made from the following raw materials in parts by weight: 20-30 parts of fluorosilicone rubber, 50-60 parts of hydrogenated nitrile rubber, 15-25 parts of chlorosulfonated polyethylene rubber TS-320 (Tosoh), 2-3 parts of gamma-methacryloxypropyl trimethoxy silane, 1-2 parts of diphenyl silanediol, 14-16 parts of modified tree ashes, 2-3 parts of ferrocene, 0.2-0.6 part of dicumyl peroxide (DCP), 20-30 parts of high abrasion furnace (HAF) black N330, 20-25 parts of precipitated silica, 5-7 parts of light calcium carbonate, 2-4 parts of zinc oxide, 1-3 parts of calcium stearate, 1-3 parts of aluminum oxide, 5-8 parts of dolomite, 13-15 parts of modified iron ore tailing powder, 0.1-0.3 part of accelerant MBTS, 1-2 parts of sulfur, 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent MB, 1-2 parts of 2-mercaptobenzimidazole, 1-3 parts of methyl trimethoxysilane and 2-3 parts of paraffin wax. The rubber material disclosed by the invention has excellent resistance to high / low temperature, oil, solvents and chemicals; and meanwhile, the mechanical property is good, and the cost is low.

Owner:平湖市泓博科技有限公司

Inorganic flame retardant waterborne polyester coating and preparation method thereof

InactiveCN106085195ASmall free volumeIncreased weight loss temperatureFireproof paintsAntifouling/underwater paintsPolyesterPropanoic acid

The invention discloses an inorganic flame retardant waterborne polyester coating, which comprises the following raw materials in parts by weight: 2-3 parts of hydrated zinc borate, 35-40 parts of rosin, 8-10 parts of fumaric acid, 6-7 parts of 20-30% of sodium hydroxide solution, 20-34 parts of ethylene glycol, 0.1-0.2 part of antimony trioxide, 2-3 parts of sodium polyacrylate, 13-20 parts of zinc chloride, 80-90 parts of polyether diol, 100-130 parts of toluene diisocyanate, 2-3 parts of 2,2-dimethylol propionic acid, 4-5 parts of diethylene glycol, 1-2 parts of triethylamine, 0.2-0.4 parts of 2-mercaptobenzimidazole, 1-2 parts of talcum powder, 3-4 parts of ammonium polyphosphate, 1-2 parts of triisopropanolamine, 0.1-0.4 parts of 2-ethylhexyl epoxystearate, 0.3-1 part of lauryl dimethyl amine oxide, 1-2 parts of calcium stearate, and 1.7-2 parts of polyvinyl butyral. The hydrated zinc borate and the like are added, so that the flame retardant property of the finished coating film product can be effectively improved.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

Low-smoke halogen-free flame-retardation insulation material for class 1E category K1 cables of nuclear power station

InactiveCN103980619AFulfil requirementsSimple processRubber insulatorsInsulated cables2-mercaptobenzimidazoleNuclear power

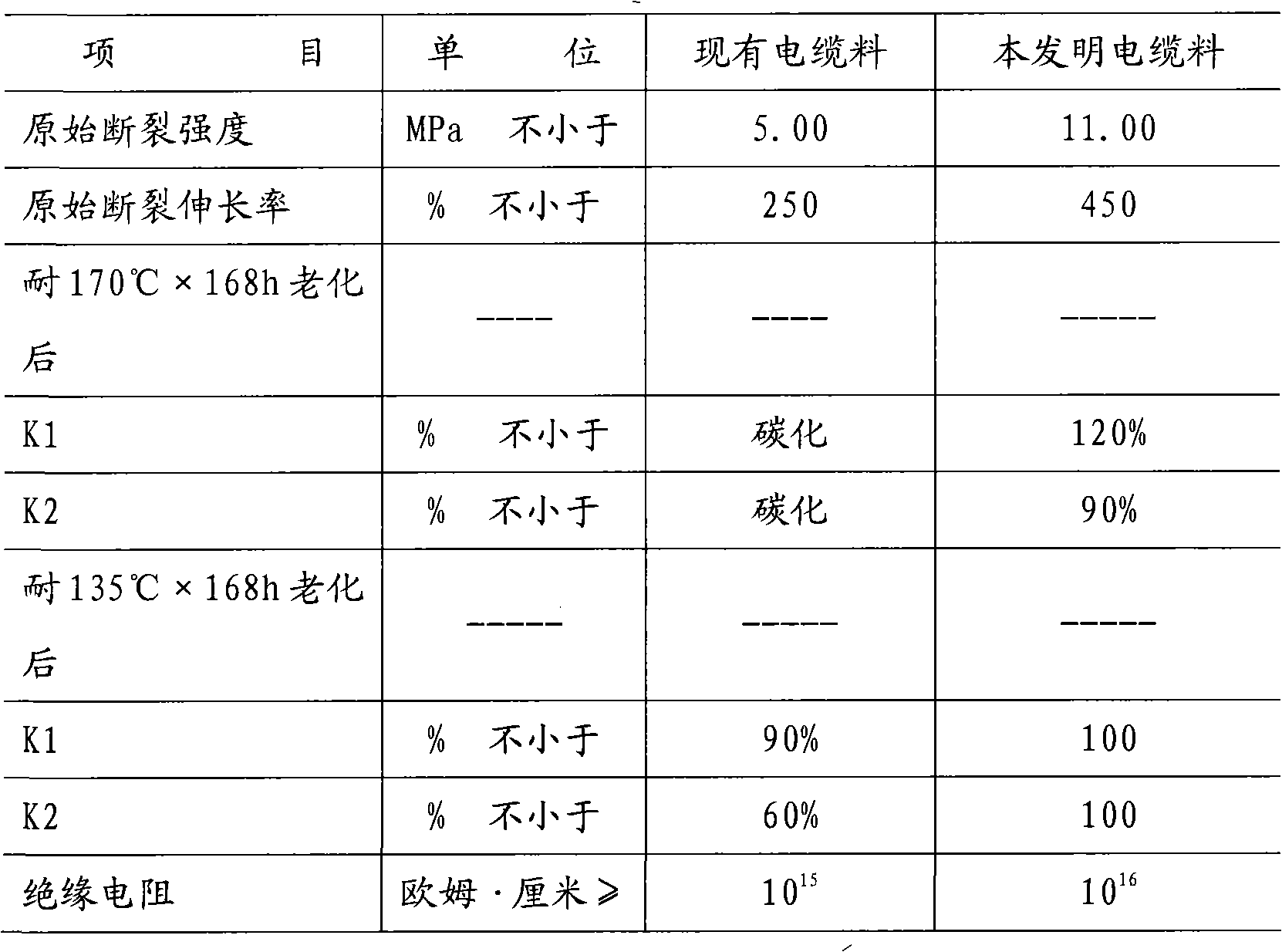

The invention discloses a low-smoke halogen-free flame-retardation insulation material for class 1E category K1 cables of a nuclear power station. The material is composed of the following compositions in parts by weight, 100 parts of ethylene-propylene-diene monomer, 5-20 parts of polyimide, 30-60 parts of magnesium hydroxide, 15-30 parts of diantimony trioxide, 2-3.5 parts of dicumyl peroxide, 8-10 parts of zinc oxide, 30-50 parts of calcined potter's clay, 2.4-2.6 parts of poly(1,2-dihydro-2,2,4-trimethyl-quinoline), 2-3 parts of 2-mercaptobenzimidazole, 1-3 parts of vinyltris(beta-methoxyethoxy)silane and 0.5-5 parts of a lubricant. The Mooney viscosity, ML(1+4)125 DEG C, of ethylene-propylene-diene monomer is less than or equal to 45, and the ethylene content of ethylene-propylene-diene monomer is more than or equal to 60%. According to the material disclosed by the invention, the flame retardation property is improved, also the insulation property is improved, and the comprehensive performances such as radiation resistance, heat resistance, high flame retardation property, high insulation property and the like of the material are improved.

Owner:中广核三角洲(江苏)塑化有限公司

Aqueous environmentally-friendly coating

InactiveCN105153838AReduce volatilityImprove surface resistanceFireproof paintsEpoxy2-mercaptobenzimidazole

The invention discloses an aqueous environmentally-friendly coating. The coating comprises, by weight, 91-100 parts of an aqueous acrylic emulsion, 1-2 parts of polydicyclopentadiene, 0.5-1 part of ammonium molybdate, 0.1-0.2 parts of iron trifluoroacetylacetonate, 1-2 parts of polypropylene glycol, 1-2 parts of potassium silicate, 2-4 parts of octyl epoxy stearate, 0.5-1 part of 2-mercaptobenzimidazole, 10-12 parts of ultrafine barium sulfate, 2-3 parts of polymethyl acrylate, 0.3-1 part of lauryl dimethyl amine oxide, 2-4 parts of a flame retardation assistant, 2-3 parts of ethylene glycol butyl ether and 20-30 parts of deionized water. Compared with solvent-based coatings, the coating disclosed in the invention has the advantages of environmental protection, low volatility, good resistance of the surface of a coating layer, good stability, certain flame retardation effect and security improvement.

Owner:ANHUI OS BUILDING MATERIAL

Modified polyvinyl chloride cable sheath material capable of resisting ultraviolet radiation aging

InactiveCN105001547AImprove performanceStable in naturePlastic/resin/waxes insulatorsInsulated cables2-mercaptobenzimidazolePolyvinyl chloride

The invention relates to a cable material, specifically to a modified polyvinyl chloride cable sheath material capable of resisting ultraviolet radiation aging. The material comprises the following raw materials by weight: 50 to 60 parts of polyvinyl chloride, 30 to 40 parts of calcium carbonate, 2 to 3 parts of an anti-oxidant 1035, 2 to 3 parts of propylene glycol, 4 to 5 parts of potash feldspar powder, 12 to 14 parts of nanometer titanium dioxide, 1 to 2 parts of copper oxide powder, 1 to 2 parts of calcium lignin sulphonate, 10 to 12 parts of rosin pentaerythritol ester, 23 to 26 parts of tributyl citrate, 1 to 2 parts of 2-mercaptobenzimidazole, 1 to 3 parts of vinyltris(beta-methoxyethoxy)silane, 1 to 2 parts of oleamide, 23 to 25 parts of dolomite, 10 to 12 parts of bauxitic clay and 14 to 16 parts of an auxiliary agent. According to the invention, the cable sheath material improves performance of traditional polyvinyl chloride materials and has improved mechanical properties; nanometer titanium dioxide can assist the material in resisting ultraviolet radiation aging; and the prepared material has heat resistance, stable properties, resistance to weathering and long service life, can be widely applied to preparation of a variety of cable sheath insulating materials and is greatly needed in market.

Owner:ANHUI TELI SCI & TECH

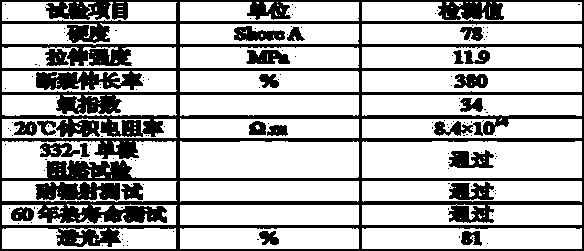

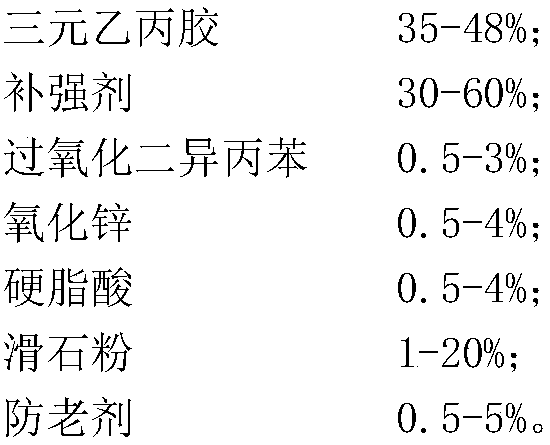

Ethylene propylene rubber and preparation method thereof

ActiveCN107815028AGood physical and mechanical propertiesImprove vulcanization efficiencyPolymer science2-mercaptobenzimidazole

The invention discloses ethylene propylene rubber and a preparation method thereof, and belongs to the rubber field. The ethylene propylene rubber includes the following raw material components by mass: 35 to 48% of EPDM rubber, 30 to 60% of a reinforcing agent, 0.5-3% of dicumyl peroxide, 0.5-4% of zinc oxide, 0.5-4% of stearic acid, 1-20% of talcum powder and 0.5-5% of an anti-aging agent. The anti-aging agent includes one or more of 2,2,4-trimethyl-1,2-dihydroquinoline polymer and 2-mercaptobenzimidazole, and the ethylene-propylene rubber includes 1-3% by mass of vinyl guanamine. The ethylene propylene rubber has the following beneficial effects: through addition of the anti-aging agent in the EPDM rubber, the oxidation of the EPDM rubber can be inhibited, the stearic acid as a surfactant can improve the uniformity of the dispersion of the anti-aging agent in the EPDM rubber and improve the connection of the anti-aging agent and the EPDM rubber, and the ethylene propylene rubber hasa better anti-aging effect.

Owner:玉环市鑫庄电子股份有限公司

Environment-friendly waterborne polyester coating and preparation method thereof

InactiveCN106147581ASmall free volumeIncreased weight loss temperatureFireproof paintsAntifouling/underwater paintsPolyesterAluminate

The invention discloses an environment-friendly waterborne polyester coating. The environment-friendly waterborne polyester coating is prepared from, by weight, 2-3 parts of oxidized polyethylene wax, 2-4 parts of calcium aluminate, 0.7-1 part of poly(butyl acrylate), 35-40 parts of rosin, 8-10 parts of fumaric acid, 6-7 parts of a 20-30% sodium hydroxide solution, 20-34 parts of ethanediol, 0.1-0.2 part of antimonous oxide, 2-3 parts of sodium polyacrylate, 13-20 parts of zinc chloride, 80-90 parts of polyether glycol, 100-130 parts of toluene diisocynate, 2-3 parts of 2,2-dimethylolpropionic acid, 4-5 parts of diethylene glycol, 1-2 parts of triethylamine, 0.2-0.4 part of 2-mercaptobenzimidazole, 0.1-0.3 part of sorbitan monooleate, 1-2 parts of tetrabutylammonium bromide, 2-3 parts of alkylolamide and 0.6-1 part of zinc diricinoleate. The coating is free of toxicity and pollution, high in safety and environmental friendliness and excellent in overall performance.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

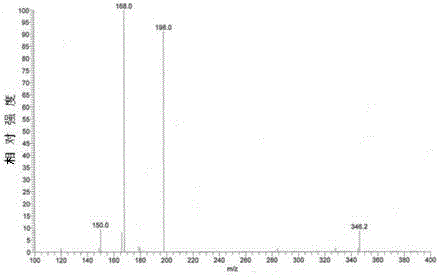

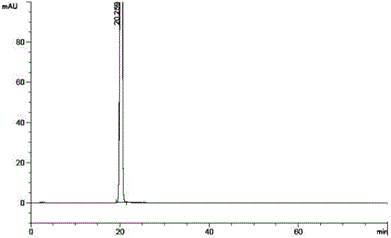

Preparation method of esomeprazole magnesium

The invention relates to the field of chemical synthesis, in particular to a novel synthesis process for active pharmaceutical ingredients of a PPI (proton pump inhibitor), and especially relates to a preparation method of esomeprazole magnesium. According to the method, 5-methoxy-2-mercaptobenzimidazole and 2-chloromethyl-3,5-dimethyl-4-methoxy pyridine hydrochloride are taken as the starting raw materials and subjected to condensation, asymmetric oxidation and salifying to prepare esomeprazole magnesium, a wet product is refined with water and methanol, an intermediate does not require crystallization, filtering and drying, the operation steps are simplified, the production cycle is shortened, material loss and energy consumption in a processing process are reduced, the yield is improved, and good economic benefits and social benefits are realized. The preparation method is good in repeatability and simple to operate, improves the yield and purity of esomeprazole magnesium and facilitates industrial production.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

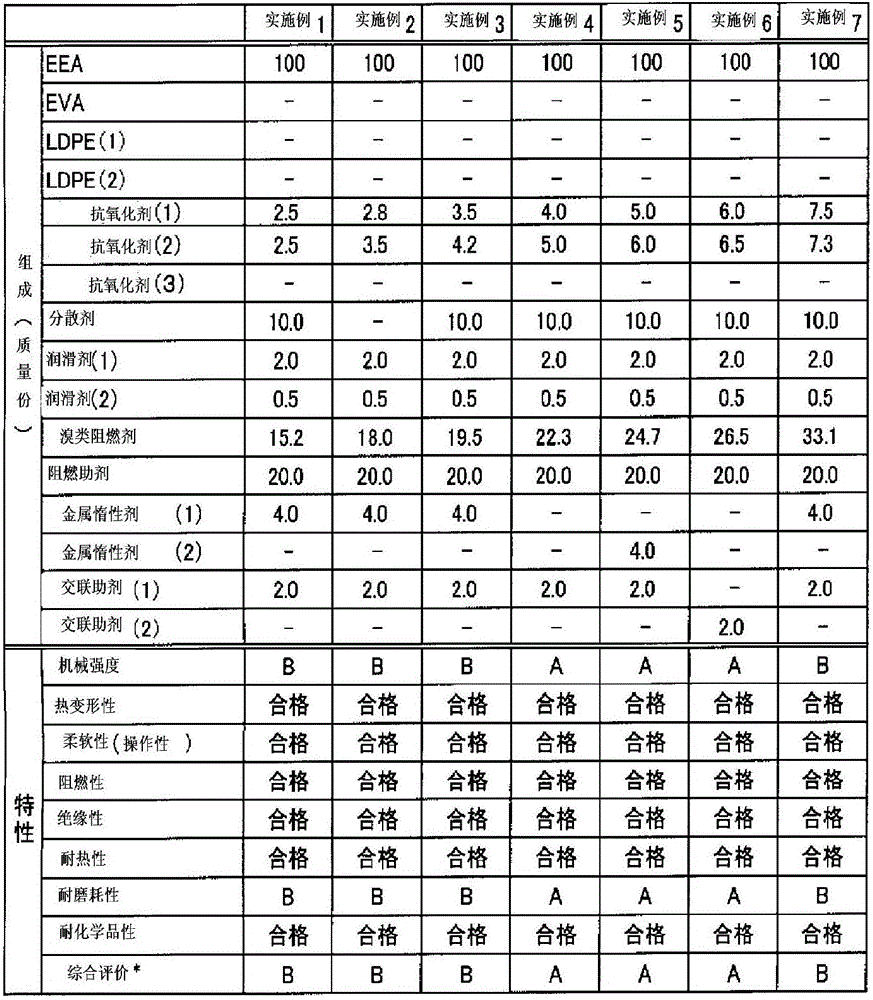

Vehicle-mounted electrical wire and cable

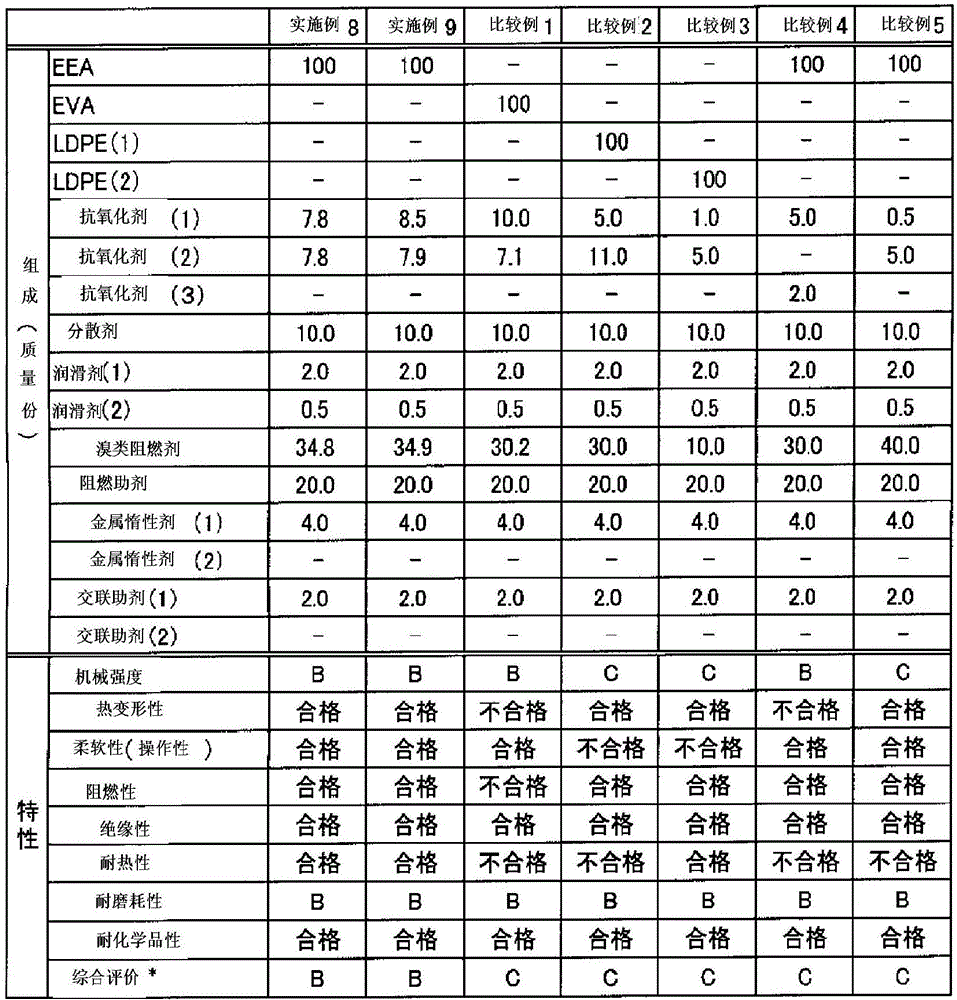

ActiveCN106463206AImprove heat resistanceGood flexibilityPlastic/resin/waxes insulatorsInsulated cablesCross-linkElectrical conductor

A vehicle-mounted electrical wire and cable, in which the outer periphery of a conductor is provided with a covering containing 2.0-9.0 parts by mass of pentaerythritol tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate] and 2.0-8.0 parts by mass of 2-mercaptobenzimidazole as antioxidants, and comprising a cross-linking body of a resin composition containing 15.0-35.0 parts by mass of 1,2-bis(tetrabromophthalimide)ethane as a flame retardant, the above amounts being given with respect to 100 parts by mass of an ethylene copolymer containing an ethylene-ethyl acrylate copolymer.

Owner:SHOWA ELECTRIC WIRE & CABLE CO

High resilience silicon rubber material and preparation method thereof

The invention discloses a high resilience silicon rubber material and a preparation method thereof. The material consists of the following raw materials by weight: 100-150 parts of methyl vinyl silicone rubber, 60-90 parts of fumed silica, 10-20 parts of hydroxy silicone oil, 0.2-0.3 part of stearic acid, 0.5-1 part of hydrogen-containing silicone oil, 1-2 parts of divinyl tetramethyl disiloxane, 10-15 parts of dipropylene glycol dibenzoate, 0.3-0.6 part of bitertanol, 3-5 parts of alkylphenate disulfide, 2-3 parts of 1,4-bis(1-(tert-butylperoxy)-1-methylethyl)-benzene, 5-10 parts of chalk, 4-6 parts of jute fibers, 1-2 parts of dipentamethylenethiuram tetrasulfide, 0.5-1 part of methyl-2-mercaptobenzimidazole, and 3-6 parts of an auxiliary agent. The silicone rubber material provided by the invention of has high resilience performance, low compression permanent deformation, good mechanical properties, good aging resistance, high temperature resistance, fatigue resistance and corrosion resistance, and can meet the special requirements of some products on the market and broaden the scope of application of silicone rubber materials.

Owner:天长市荣盛有机硅科技有限公司

Modified PVC electric cable material with characteristics of corrosion resistance and thermal insulation, and preparation method thereof

InactiveCN104817781AGood dispersionIncrease profitPlastic/resin/waxes insulators2-mercaptobenzimidazoleThermal insulation

The present invention relates to an electric cable material, particularly to a modified PVC electric cable material with characteristics of corrosion resistance and thermal insulation, and a preparation method thereof. The electric cable material is prepared from the following raw materials by weight: 50-60 parts of a PVC resin, 18-25 parts of a maleic anhydride-grafted ethylene-vinyl acetate copolymer, 20-28 parts of aluminum hydroxide, 16-22 parts of flue deposit, 4-6 parts of polyacrylamide, 6-9 parts of foam glass powder, 1-3 parts of 2-mercaptobenzimidazole, 10-12 parts of triethyl citrate, 1-2 parts of an accelerator DM, 1-2 parts of di-tert-butyl-p-cresol, 8-10 parts of a color concentrate, and 2-3 parts of an auxiliary agent. According to the present invention, the electric cable material adopts the PVC resin as the base material and is matched with the maleic anhydride-grafted ethylene-vinyl acetate copolymer, the flue deposit being subjected to the surface treatment through the polyacrylamide in the raw materials has characteristics of good dispersion property and uniform and stable reinforcing effect, and other remaining materials are combined, such that the electric cable material of the present invention has the excellent mechanical property, and further has advantages of significantly-improved heat resistance, strong corrosion resistance, uniform and stable performance, high raw material utilization rate, economy, and environment protection compared with the traditional PVC resin electric cable materials.

Owner:TONGLING CHANG JIANG COPPER IND

Methyl vinyl silicone rubber cable sheath material of modified nanocarbon, and preparation method thereof

InactiveCN103525096AHigh tensile strengthHigh elongation at breakRubber insulatorsInsulated cablesLow-density polyethylenePolymer science

The invention discloses a methyl vinyl silicone rubber cable sheath material of modified nanocarbon, and a preparation method thereof. Raw material composing the sheath material comprise methyl vinyl silicone rubber, low density polyethylene, nano-clay, modified nanocarbon, antimony trioxide, an accelerant DM, 2-mercaptobenzimidazole, vinyltri(beta-methoxyethoxy)silane, a rare earth stabilizer, resorcinol, fatty alcohol polyoxyethylene ether and tritolyl phosphate. The sheath material is based on the methyl vinyl silicone rubber, so the tensile strength, the elongation at break, the elongation at break after ageing and the insulation rate of a cable sheath are excellent; and the modification treatment of the filler nanocarbon enhances the internal connection of the cable sheath, so the break of the cable sheath can be effectively prevented, and the service life of the cable sheath is prolonged.

Owner:ANHUI MINGDU ELECTRIC WIRE

Vulcanizing latex compounds without the use of metal oxide activators or a zinc based accelerator

The present invention provides a latex compound comprising a natural rubber or a synthetic rubber material and an antioxidant comprising a zinc based synergist. The zinc based synergist may be selected from the group consisting of zinc 2-mercaptotoluimidazole and zinc 2-mercaptobenzimidazole, as well as combinations of these materials. The latex compounds may be cured without metal oxide, such as zinc oxide, and / or without zinc based accelerators. The invention further pertains to cured natural rubber or synthetic rubber material comprising the latex compounds, and curing systems and methods for curing the latex compounds without metal oxide and / or zinc based accelerators.

Owner:R T VANDERBILT CO INC

Polymer composite material and preparation method thereof

The invention discloses a polymer composite material. The polymer composite material consists of the following raw materials in parts by weight: antimony trioxide 0.8-1.5 parts, carbon nanotubes 8-10 parts, high-density polypropylene 90-110 parts, dihydrate gypsum powder 1-1.5 parts, diphenyl silanediol 4-5 parts, 2-mercaptobenzimidazole 0.4-1 part, polytetrafluoroethylene 15-20 parts, nano zinc oxide 3-5 parts, fluorinated epoxy resin 5-7 parts, tetrabutylammonium bromide 0.8-1.3 parts, fatty acid diethanol amide 0.7-1 part, aluminum ammonium sulfate 1-2 parts, p-methyl benzenesulfonic acid 1.3-1.5 parts, ethoxylated alkylphenol ammonium sulfate 0.5-1 part, methyl triethoxysilane 0.4-0.6 part, sodium myrastate 1-1.3 parts and ammonium ferrous sulfate 0.1-0.2 part. The finished product has good mechanical property, good surface hydrophobicity and excellent comprehensive performance.

Owner:NINGBO SHANGGAO NEW MATERIAL CO LTD

Lightweight polycarbonate material

The invention discloses a lightweight polycarbonate material, made from, by weight, 140-160 parts of a carbonate monomer, 2-3 parts of pyromellitic dianhydride, 1-2 parts of ammonium molybdate, 6-8 parts of oxidized polyethylene wax, 10-12 parts of polyether glycol, 0.8-1 part of ethylene bis-stearamide, 1-2 parts of calcium acetylacetonate, 10-13 parts of lightweight filler, 1-2 parts of trimethylolpropane, 0.4-1 part of 2-mercaptobenzimidazole, 3-5 parts of N-methylpyrrolidone, 0.8-1 part of sorbitan monooleate, 0.1-0.2 part of stannous sulfide, and 16-20 parts of anhydrous toluene. The lightweight filler is organically modified and is subjected to mixed esterification with acid-doped polyester, the dispersity of the lightweight filler in a polyester matrix is effectively improved, the compatibility of the lightweight filler with other materials is improved, the stability strength of a finished product is improved, and the mechanical properties of the finished product are enhanced.

Owner:苏州远略知识产权运营有限公司

Oil-resistant ethylene propylene diene monomer rubber/POE waterproof coiled material and preparation method thereof

InactiveCN106117828AImprove aging resistanceHigh strengthBuilding insulationsPolymer science2-mercaptobenzimidazole

The invention relates to an oil-resistant ethylene propylene diene monomer rubber / POE waterproof coiled material. The waterproof coiled material is characterized by being prepared from the following raw materials in parts by weight: ethylene propylene diene monomer rubber, fluorinated silicon rubber, POE, 1,3-di(tert-butylperoxyisopropyl)benzene, triallyl isocyanurate, stearic acid, 2-Mercaptobenzimidazole, lanthanum oxide, dioctyl sebacate, triethyl acetyl citrate, sodium dodecyl sulfate, zinc oxide, calcium carbonate, mica powder, dibutyl phthalate, paraffin, zinc diethyldithiocarbamate, 2,2'-dithiobis(benzothiazole), and deionized water. By properly adding fluorinated silicon rubber, the oil-resistant and anti-aging properties of the product can be improved, and the processability and impact-resistant property of the product can be enhanced.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

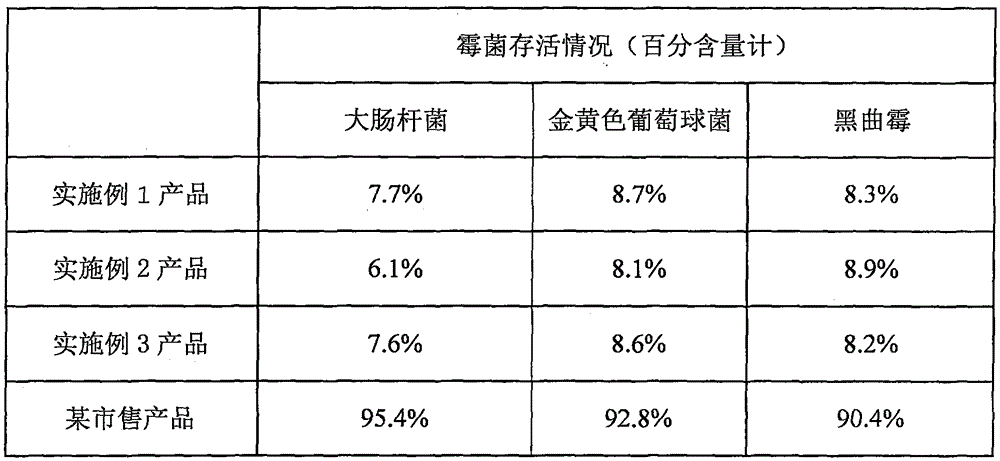

Antibacterial garment fabric coating

InactiveCN105297422AThe preparation process is simpleImprove antibacterial propertiesFibre treatmentPolyvinyl alcohol2-mercaptobenzimidazole

The present invention relates to an antibacterial garment fabric coating comprising the following components by mass: 58 to 62 parts of calcium dodecylbenzenesulfonate, 60 to 64 parts of polyvinyl alcohol, 56 to 60 parts of ammonium chloride , 60 to 64 parts of methyl cellulose, 56 to 60 parts of amino ethyl imine propyl polysiloxane, 60 to 64 parts of 2-mercaptobenzimidazole, 56 to 60 parts of dibutyl tin dilaurate, 62 to 66 parts of methyl isobutyl nitrile ketone, 56 to 60 parts of chlorothalonil, 60 to 64 parts of diisocyanate, 56 to 60 parts of sodium carboxymethyl cellulose, 60 to 64 parts of dibutyl phthalate, 56 to 60 parts of hydroxy cyclohexylbenzene, 60 to 64 parts of waterborne epoxy-modified polyurethane emulsion, 56 to 60 parts of aluminum tripolyphosphate, 60 to 64 parts of nano titanium dioxide, 56 to 60 parts of chitosan, 60 to 64 parts of poly hexamethylene guanidine phosphate, 56 to 60 parts of Cylindrin, 60 to 64 parts of sodium lauryl carboxymethyl imidazolinium acetate, 56 to 60 parts of bamboo tropolone and 60 to 64 parts of zinc pyrithione. The antibacterial garment fabric coating product has good antibacterial properties.

Owner:WENZHOU POLYTECHNIC

Attapulgite-modified pbt material and preparation method thereof

InactiveCN105838043ALarge specific surface areaMultiple potential active sitesMicro structure2-mercaptobenzimidazole

The invention discloses an attapulgite modified PBT material, which is composed of the following raw materials in parts by weight: aluminum potassium sulfate 1-2, potassium dihydrogen phosphate 3-4, caprolactam 70-80, attapulgite 10-10 13. Zinc acetate 1‑1.4, γ‑aminopropyltriethoxysilane 2‑3, oxalic acid 18‑20, polybutylene terephthalate 300‑370, monoglyceryl monostearate 2 ‑4, 2‑mercaptobenzimidazole 1.7‑2, butyl acrylate 10‑15, ethylene bisstearamide 2‑3, polytetrahydrofuran ether glycol 4‑6, quicklime 2‑3. The material of the invention can form a "micro-network" structure with the masterbatch as the core, thereby increasing the strength and toughness of the polyamide matrix material, and facilitating the dispersion of the composite material in the polyamide matrix material.

Owner:CHUZHOU YOUSHENG HIGH POLYMER MATERIAL

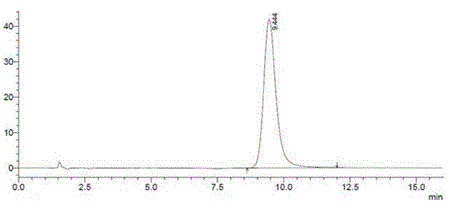

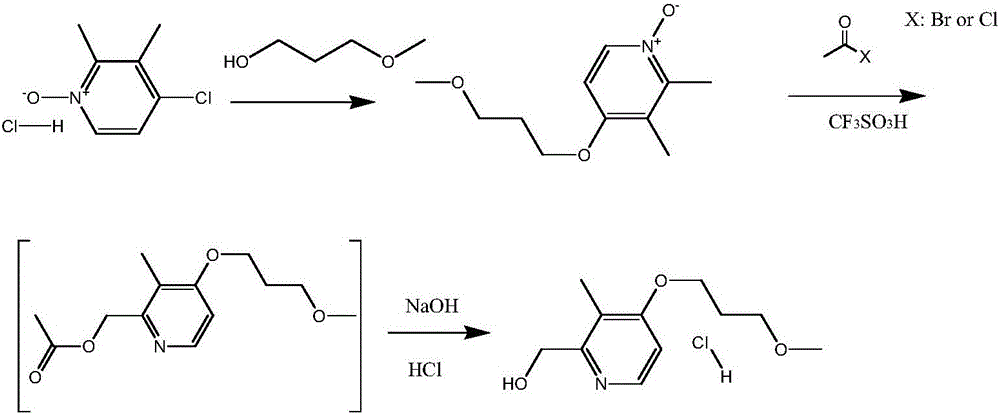

Preparation method of 2-hydroxymethyl-4-(methoxypropoxy)-3-methylpyridine hydrochloride

InactiveCN106083705AHigh purityImprove stabilityOrganic chemistry2-mercaptobenzimidazoleSolvent free

The invention relates to a preparation method of 2-hydroxymethyl-4-(methoxypropoxy)-3-methylpyridine hydrochloride. The method comprises the following steps: reacting an initial raw material 2,3-dimethyl-4-chloropyridine-N-oxide hydrochloride with 3-methoxypropanol under a solvent-free condition to obtain 2,3-dimethyl-4-(methoxypropoxy)-pyridine-N-oxide, acetylizing the 2,3-dimethyl-4-(methoxypropoxy)-pyridine-N-oxide, hydrolyzing the acetylized 2,3-dimethyl-4-(methoxypropoxy)-pyridine-N-oxide, and carrying out a salt formation reaction to obtain the 2-hydroxymethyl-4-(methoxypropoxy)-3-methylpyridine hydrochloride. The purity of 2-hydroxymethyl-4-(methoxypropoxy)-3-methylpyridine hydrochloride solid can reach 98% or above, and 2-chloromethyl-4-(methoxypropoxy)-3-methylpyridine obtained after a chlorination reaction of 2-hydroxymethyl-4-(methoxypropoxy)-3-methylpyridine hydrochloride can directly react with 2-mercaptobenzimidazole without a salt formation or purification process in order to prepare rabeprazole thioether; and the solid has good stability, has no strict requirements on transportation or storage conditions, can be stored for a long time, and is suitable for being used as a rabeprazole sodium intermediate.

Owner:LIVZON GROUP CHANGZHOU KONY PHARMA

Preparation method of cyanide-free zinc precipitator for aluminium alloy applied in aluminium hub plating

The invention provides a preparation method of a cyanide-free zinc precipitator for aluminium alloy applied in aluminium hub plating. The cyanide-free zinc precipitator for aluminium alloy is mainly prepared from the following components: 350mL / L to 450mL / L of plating bath solution, 8mL / L to 12mL / L of regulator, 120mL / L to 130mL / L of replenisher and the balance of water. The plating bath solutionconsists of 0.5g / L to 2.0g / L of copper ions, 0.1g / L to 0.8g / L of iron ions, 0.8g / L to 3.0g / L of nickel ions, 8g / L to 16g / L of zinc ions and 40g / L to 150g / L of hydroxyl ions according to sodium hydroxide; the regulator is an aqueous solution which contains at least one component among sodium nitrate, sodium nitrite, 2-mercaptobenzimidazole, benzotriazole, 2-mercaptobenzothiazole, polyethylene glycol, sodium ethylhexyl sulfate, thiourea, 1,3-diethyl thiourea, carboxymethylcellulose sodium, L-methionine, dipyridyl and sulfosalicyclic acid, and the concentration of the regulator is 150g / L to 250g / L. The preparation method adopts a process which replaces cyanide with the polynary complex additive, the cyanide-free zinc precipitator for aluminium alloy does not contain cyanide or strong complexing agent, and is nontoxic and harmless, the wastewater treatment is simple, and the preparation method is a clean production process which is vigorously and compulsorily promoted in China at present.

Owner:繁昌县晶鑫贸易有限公司

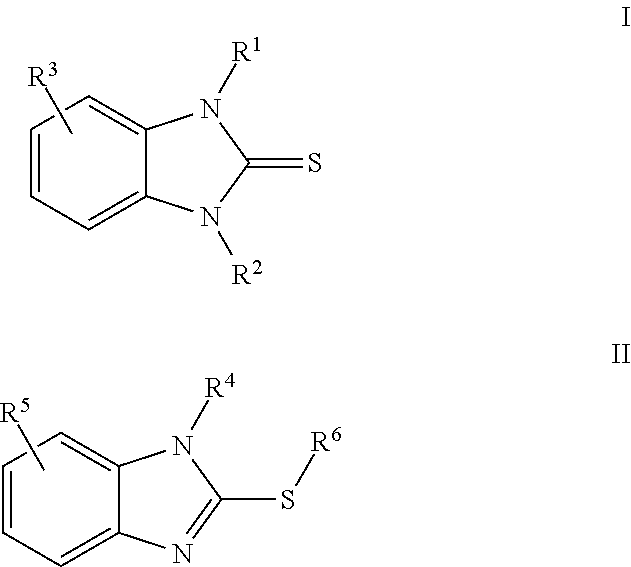

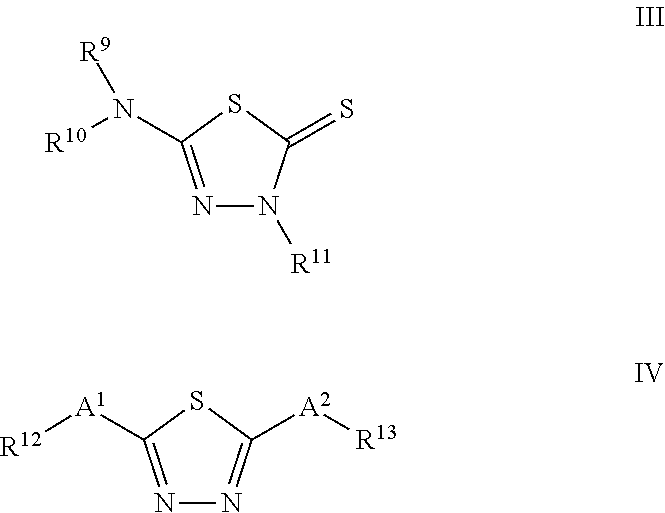

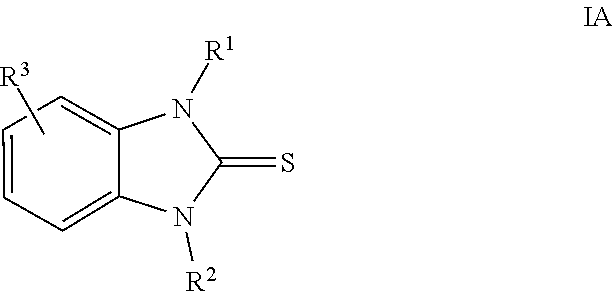

2-mercaptobenzimidazole derivatives as corrosion inhibitors

The present invention generally relates to methods and compounds for preventing metal corrosion. More specifically, the method comprises contacting a hydrocarbon-containing liquid with a composition in an effective amount to prevent metal corrosion.

Owner:ECOLAB USA INC

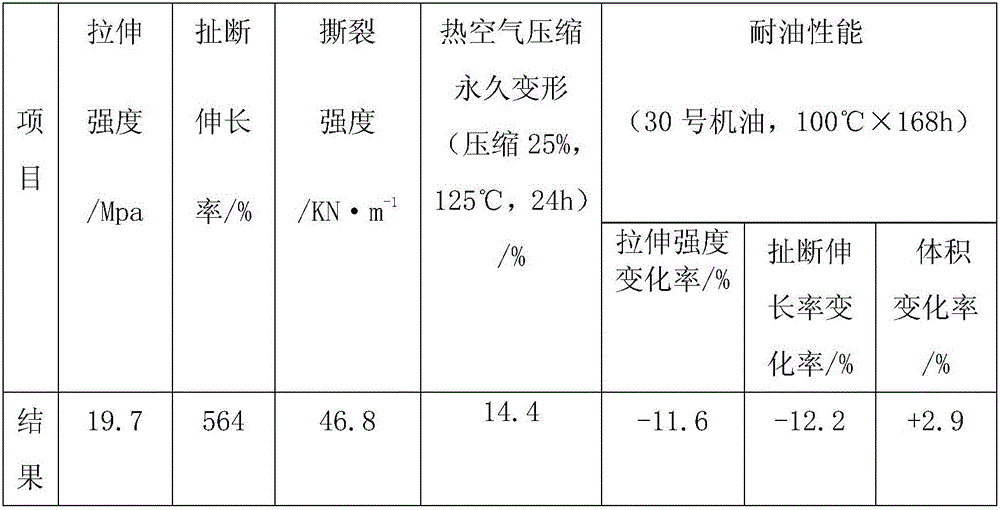

High-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket and preparing method thereof

The invention discloses a high-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket and a preparing method thereof.The high-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket is prepared from, by weight, 51-63 parts of ethylene-propylene-diene monomer rubber, 38-52 parts of polysulfide rubber, 22-34 parts of chlorosulfonated polyethylene rubber, 5-7 parts of cross-linking agent SQS350, 8-10 parts of sodium alginate, 17-24 parts of basic magnesium sulfate whiskers, 6-12 parts of naphthenic oil, 2-3 parts of tetraethylthiuram disulfide, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of brooethyl p-tert-octyl phenolformaldehyde resin, 3-7 parts of N,N'-bis(furfurylidene)acetone, 2-5 parts of zinc carbonate, 10-15 parts of bisadipate, 16-22 parts of steel slag micro powder, 2-3 parts of 2,5-ditert-butylhydroquinone and 17-21 parts of modifying agent.The high-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket has the advantages of being excellent in oil resistance, good in airtight performance, resistant to high temperature, resistant to corrosion and the like, the detect that the requirement for the oil resistance of an existing ethylene-propylene-diene monomer rubber sealing gasket can not be met is overcome, and the requirement of a market can be met.

Owner:ANHUI JINGYI GLASS MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com