Ethyl-propylene insulating material for cable resisting temperature of 140 DEG C

A technology for ethylene-propylene insulation and cables, which is applied to rubber insulators, organic insulators, etc., can solve the problems of unsatisfactory high temperature aging resistance, and achieve high physical and mechanical properties, long service life, and excellent high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

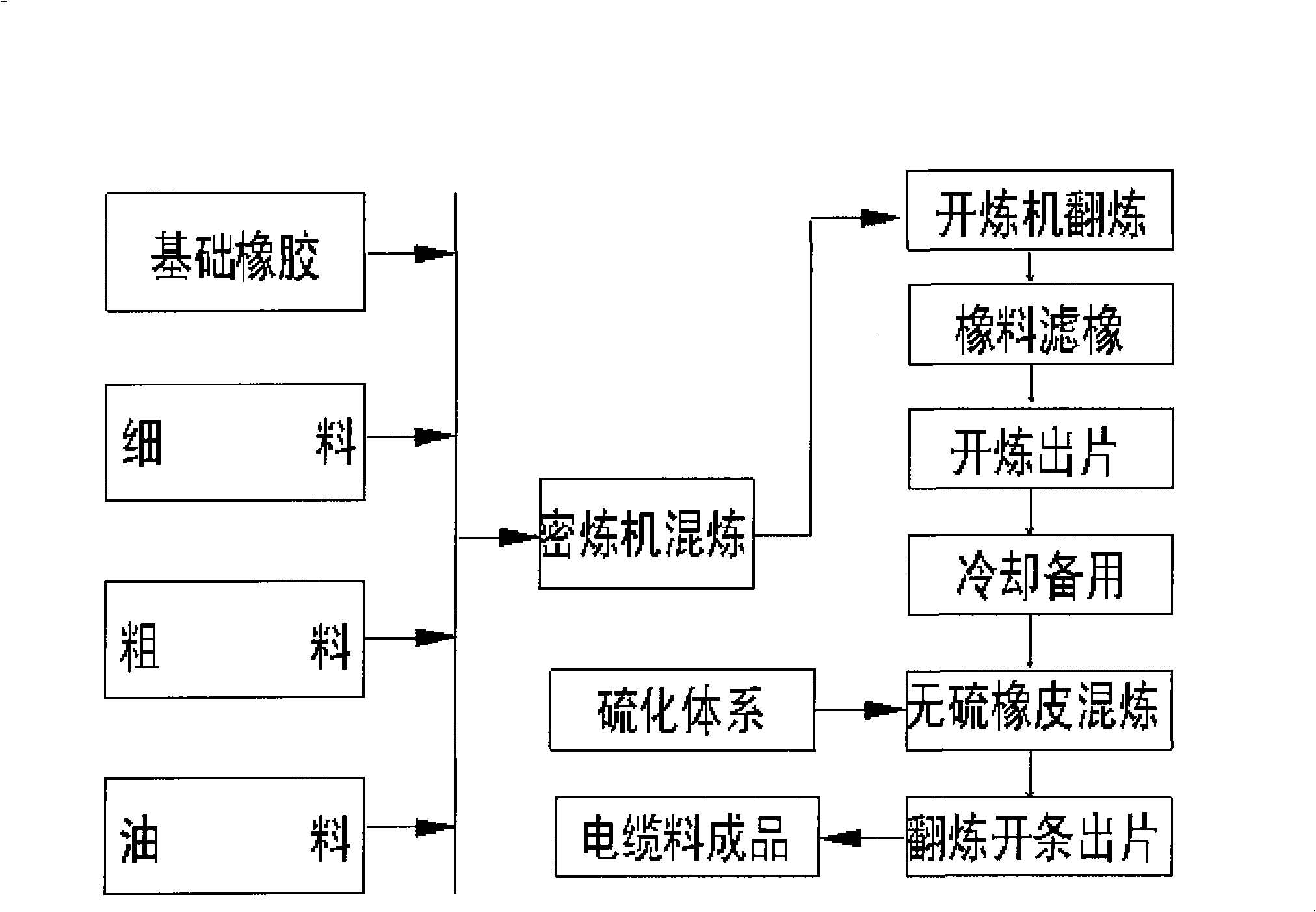

Method used

Image

Examples

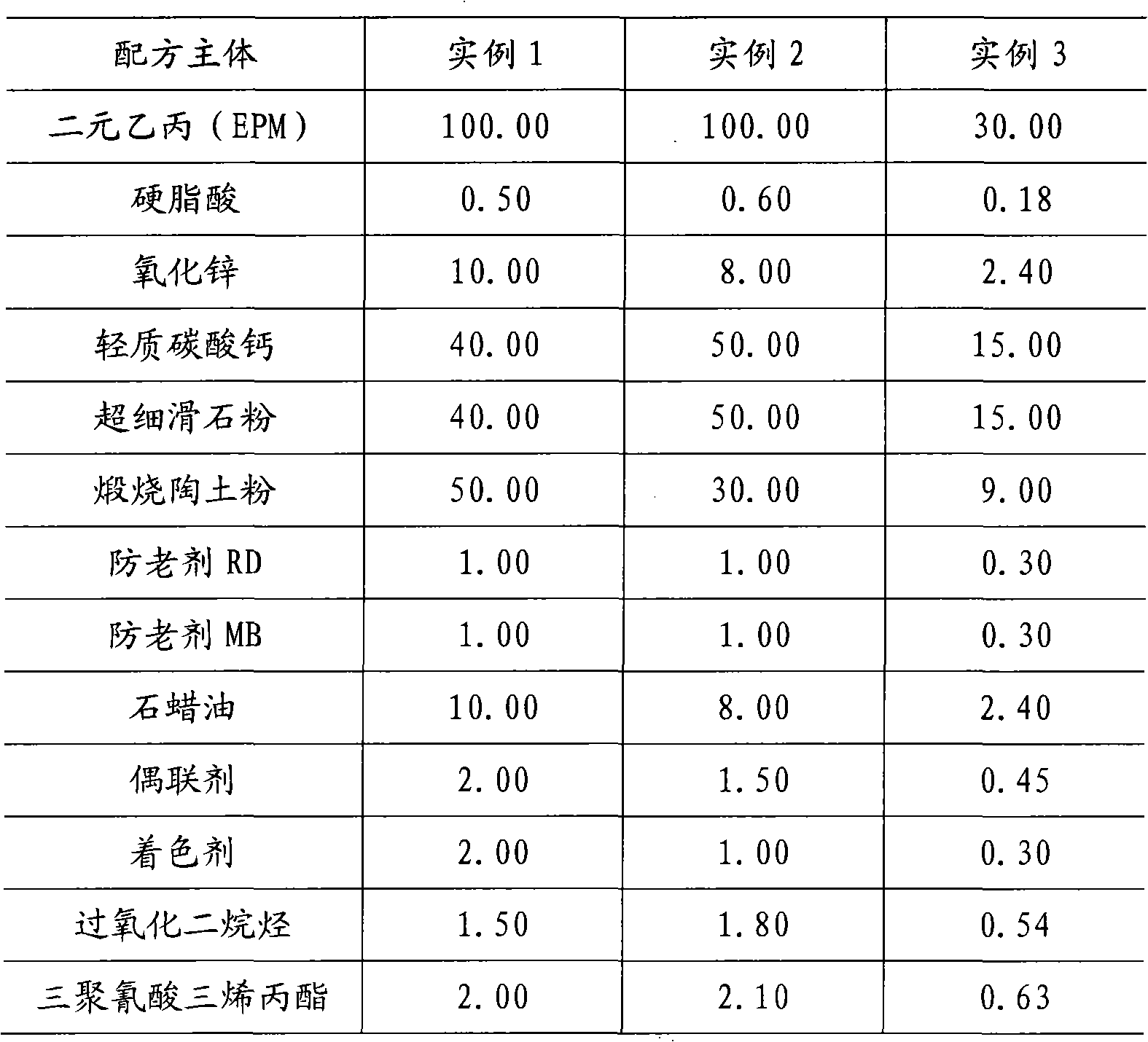

Embodiment 1

[0072] First take 400 grams of basic rubber, knead it on a small open mill, add fine materials, anti-aging agents, some fillers and plasticizers after fully covering the rolls, add the remaining coarse fillers and plasticizers after basic molding, and then After adding vulcanizing agent and vulcanizing aids for molding, the distance between the small start-up rollers is reduced, the rubber is punched into thin sheets, and the rubber is punched in triangles for at least 5 times, and then the sheets are cooled for later use.

Embodiment 2

[0074] Put 30 kg of basic rubber into the internal mixer for 50 seconds to 1.3 minutes, then add 42.50 kg of compounding ingredients such as anti-aging agent, plasticizer, filler, etc. except for vulcanizing agent, and mix for about 5 minutes, then discharge and press the tablet After stripping and filtering the rubber, cool down and release the piece for later use. The thickness of the piece is about 2mm. After parking for at least 8 hours, weigh 72.50 kg of unsulfurized rubber and put it into the internal mixer for about 3 minutes, then add 2.5 kg of vulcanizing agent and vulcanization. Auxiliary 30 seconds to 1 minute. Afterwards, the strips are turned and cooled, and the thickness of the strips is 1.00mm, and the width is 180-250mm.

[0075] Embodiment formula table 2

[0076]

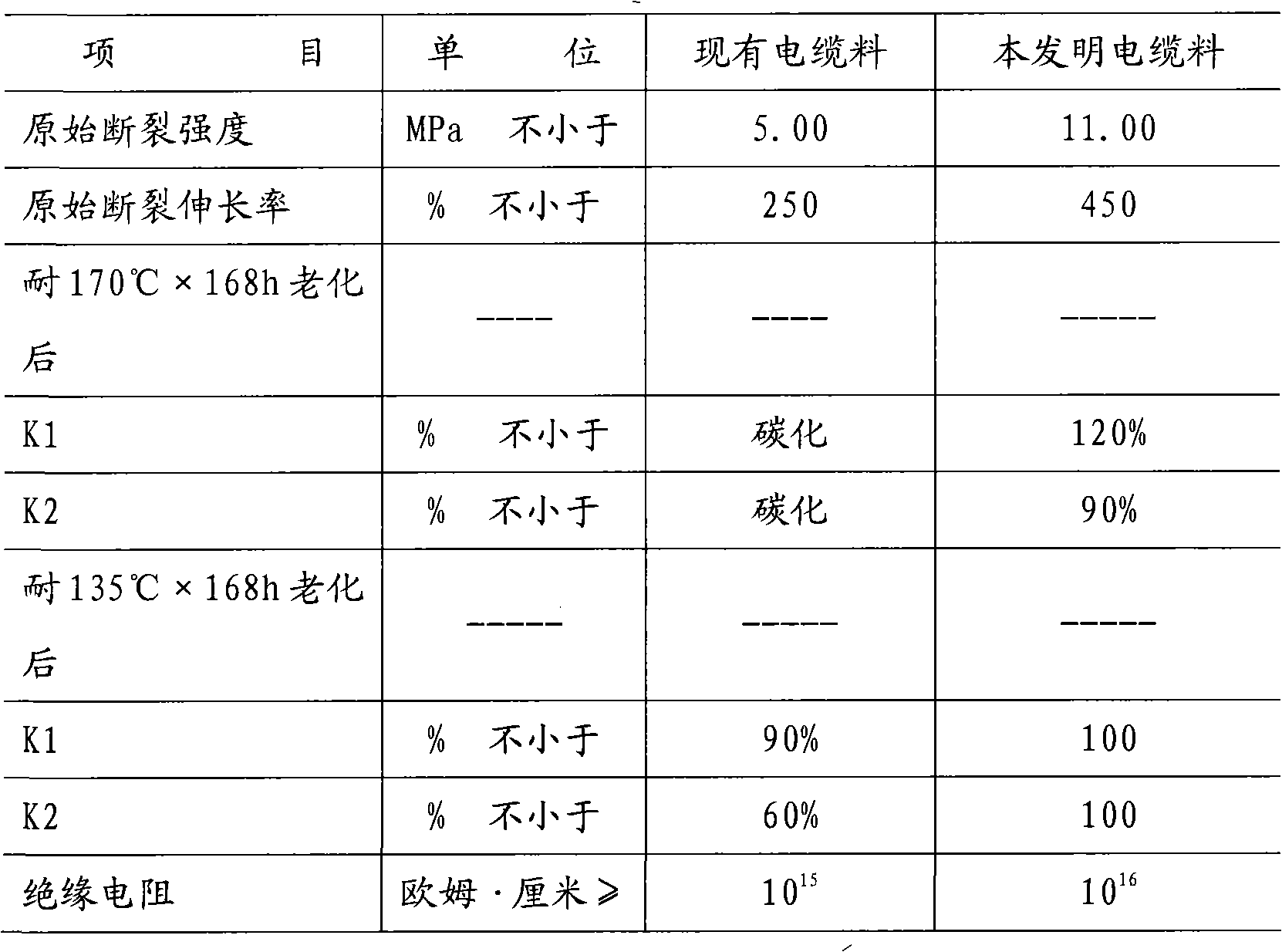

[0077] Remove a certain amount of rubber material, vulcanize on a flat vulcanizing machine for 160×40 minutes at a pressure of 25MPa, and make a 1-2mm test piece for physical and chemical perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com