Low-smoke halogen-free flame-retardation insulation material for class 1E category K1 cables of nuclear power station

A technology for nuclear power plants and insulating materials, which is applied to insulated conductors, insulated cables, rubber insulators, etc., can solve the problems of unqualified insulation performance, flame retardant performance, poor performance of high-dose radiation steam, complex production process, etc., to improve radiation resistance. , The effect of improving the thermal oxidation resistance and simplifying the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

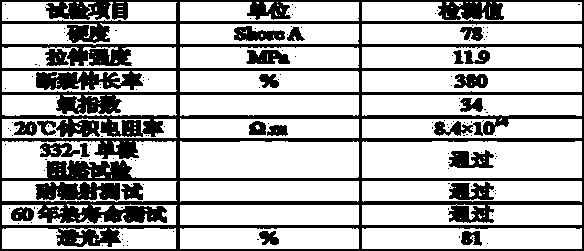

Examples

Embodiment 1

[0027] Example 1: A low-smoke, halogen-free, flame-retardant insulating material for 1E-class K1 cables in nuclear power plants, the water-resistant and flame-retardant PVC cable material is composed of the following components by weight:

[0028] 100 parts of EPDM copolymer,

[0029] 12 parts polyimide,

[0030] 48 parts of magnesium hydroxide,

[0031] 20 parts of antimony trioxide,

[0032] 2.5 parts of dicumyl peroxide,

[0034] Calcined pottery clay 50 parts,

[0035] 2.4 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer,

[0036] 2.6 parts of 2-mercaptobenzimidazole,

[0037] Vinyl tris(β-methoxyethoxy)silane 1 part,

[0038] 4 parts of PE wax;

[0039] The Mooney viscosity ML(1+4) of the above copolymer is 125°C ≤ 45, and the ethylene content of the copolymer is ≥ 60%;

[0040] The average particle diameter of the polyimide modifier is 10-20 μm, the average particle diameter of the magnesium hydroxide is 0.8-1.5 μm, and the ave...

Embodiment 2

[0048] Example 2: A low-smoke, halogen-free, flame-retardant insulating material for 1E-class K1 cables in nuclear power plants, the water-resistant and flame-retardant PVC cable material is composed of the following components by weight:

[0049] 100 parts of EPDM copolymer,

[0050]10 parts polyimide,

[0051] 43 parts of magnesium hydroxide,

[0052] 23 parts of antimony trioxide,

[0053] 3 parts of dicumyl peroxide,

[0055] Calcined pottery clay 30 parts,

[0056] 2.6 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer,

[0057] 2.4 parts of 2-mercaptobenzimidazole,

[0058] Vinyl tris(β-methoxyethoxy)silane 2 parts,

[0059] 2 parts stearic acid;

[0060] The Mooney viscosity ML(1+4) of the above copolymer is 125°C ≤ 45, and the ethylene content of the copolymer is ≥ 60%;

[0061] The average particle diameter of the polyimide modifier is 10-20 μm, the average particle diameter of the magnesium hydroxide is 0.8-1.5 μm, the average...

Embodiment 3

[0067] Embodiment 3: A low-smoke, halogen-free, flame-retardant insulating material for 1E-class K1 cables in nuclear power plants, the water-resistant and flame-retardant PVC cable material is composed of the following components by weight:

[0068] 100 parts of EPDM copolymer,

[0069] 15 parts polyimide,

[0070] 50 parts of magnesium hydroxide,

[0071] 18 parts of antimony trioxide,

[0072] 2.5 parts of dicumyl peroxide,

[0073] 9 parts of zinc oxide,

[0074] Calcined pottery clay 40 parts,

[0075] 2.5 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer,

[0076] 2.5 parts of 2-mercaptobenzimidazole,

[0077] Vinyl tris(β-methoxyethoxy)silane 2.5 parts,

[0078] 3 parts stearic acid;

[0079] The Mooney viscosity ML(1+4) of the above copolymer is 125°C ≤ 45, and the ethylene content of the copolymer is ≥ 60%;

[0080] The average particle diameter of the polyimide modifier is 10-20 μm, the average particle diameter of the magnesium hydroxide is 0.8-1.5 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com