Antibacterial garment fabric coating

An antibacterial and clothing technology, applied in the field of clothing, can solve problems such as no antibacterial function, and achieve the effects of good antibacterial performance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

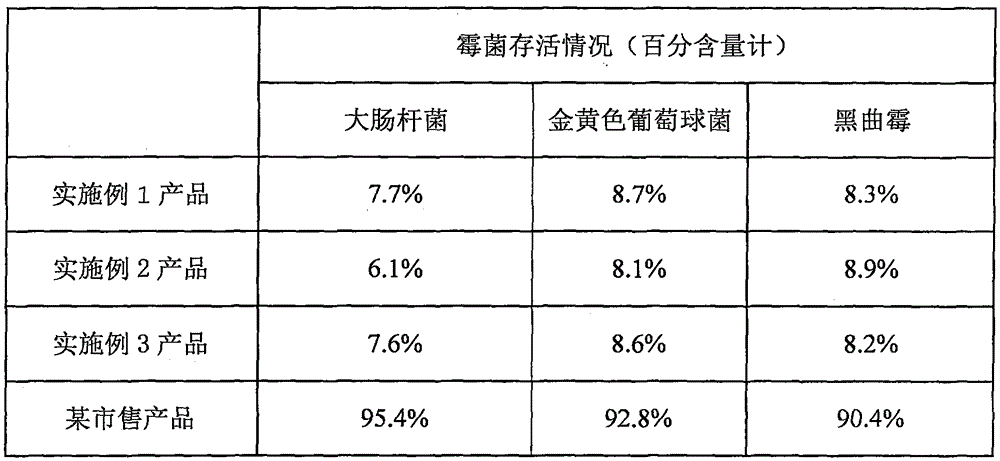

Examples

Embodiment 1

[0016] The antibacterial clothing fabric coating in the present embodiment is made up of the component of following mass fraction: 58 parts of calcium dodecylbenzenesulfonate, 60 parts of polyvinyl alcohol, 56 parts of ammonium chloride, 60 parts of methyl cellulose 56 parts, 56 parts of aminoethyl iminopropyl polysiloxane, 60 parts of 2-mercaptobenzimidazole, 56 parts of dibutyltin dilaurate, 62 parts of methyl isobutyronitrile, 56 parts of chlorothalonil, diisocyanate 60 parts, 56 parts of sodium carboxymethyl cellulose, 60 parts of dibutyl phthalate, 56 parts of hydroxycyclohexylphenyl, 60 parts of water-based epoxy modified polyurethane emulsion, 56 parts of aluminum tripolyphosphate, 60 parts of nano titanium dioxide 56 parts of chitosan, 60 parts of polyhexamethylene guanidine phosphate, 56 parts of imperata, 60 parts of sodium dodecyl carboxymethyl imidazoline acetate, 56 parts of bamboo leaf ketone, pyridine sulfur 60 parts of zinc ketone.

[0017] The steps of the pr...

Embodiment 2

[0022] The antibacterial clothing fabric coating in the present embodiment is made up of the component of following mass fraction: 60 parts of calcium dodecylbenzenesulfonate, 62 parts of polyvinyl alcohol, 58 parts of ammonium chloride, 62 parts of methyl cellulose 58 parts, 58 parts of aminoethyl iminopropyl polysiloxane, 62 parts of 2-mercaptobenzimidazole, 58 parts of dibutyltin dilaurate, 64 parts of methyl isobutyronitrile, 58 parts of chlorothalonil, diisocyanate 62 parts, 58 parts of sodium carboxymethyl cellulose, 62 parts of dibutyl phthalate, 58 parts of hydroxycyclohexylphenyl, 62 parts of water-based epoxy modified polyurethane emulsion, 58 parts of aluminum tripolyphosphate, 62 parts of nano titanium dioxide 58 parts of chitosan, 62 parts of polyhexamethylene guanidine phosphate, 58 parts of imperata, 62 parts of sodium dodecyl carboxymethyl imidazoline acetate, 58 parts of bamboo leaf ketone, pyridylsulfone Ketone zinc 62 parts.

[0023] The steps of the prepar...

Embodiment 3

[0028] The antibacterial clothing fabric coating in the present embodiment is made up of the component of following mass fraction: calcium dodecylbenzene sulfonate 62 parts, polyvinyl alcohol 64 parts, ammonium chloride 60 parts, methyl cellulose 64 parts 60 parts, 60 parts of aminoethyl iminopropyl polysiloxane, 64 parts of 2-mercaptobenzimidazole, 60 parts of dibutyltin dilaurate, 66 parts of methyl isobutyronitrile, 60 parts of chlorothalonil, diisocyanate 64 parts, 60 parts of sodium carboxymethyl cellulose, 64 parts of dibutyl phthalate, 60 parts of hydroxycyclohexylphenyl, 64 parts of water-based epoxy modified polyurethane emulsion, 60 parts of aluminum tripolyphosphate, 64 parts of nano titanium dioxide 60 parts of chitosan, 64 parts of polyhexamethylene guanidine phosphate, 60 parts of imperata, 64 parts of sodium dodecyl carboxymethyl imidazoline acetate, 60 parts of bamboo leaf ketone, pyridyl sulfide Ketone zinc 64 parts.

[0029] The steps of the preparation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com