Preparation method for die graphite material used for electrical discharge machining

A graphite material and electric spark technology, which is applied in the field of mold graphite material preparation, can solve the problem that the product cannot meet the needs of users, and achieve the effect of strong practicability, full utilization of resources and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

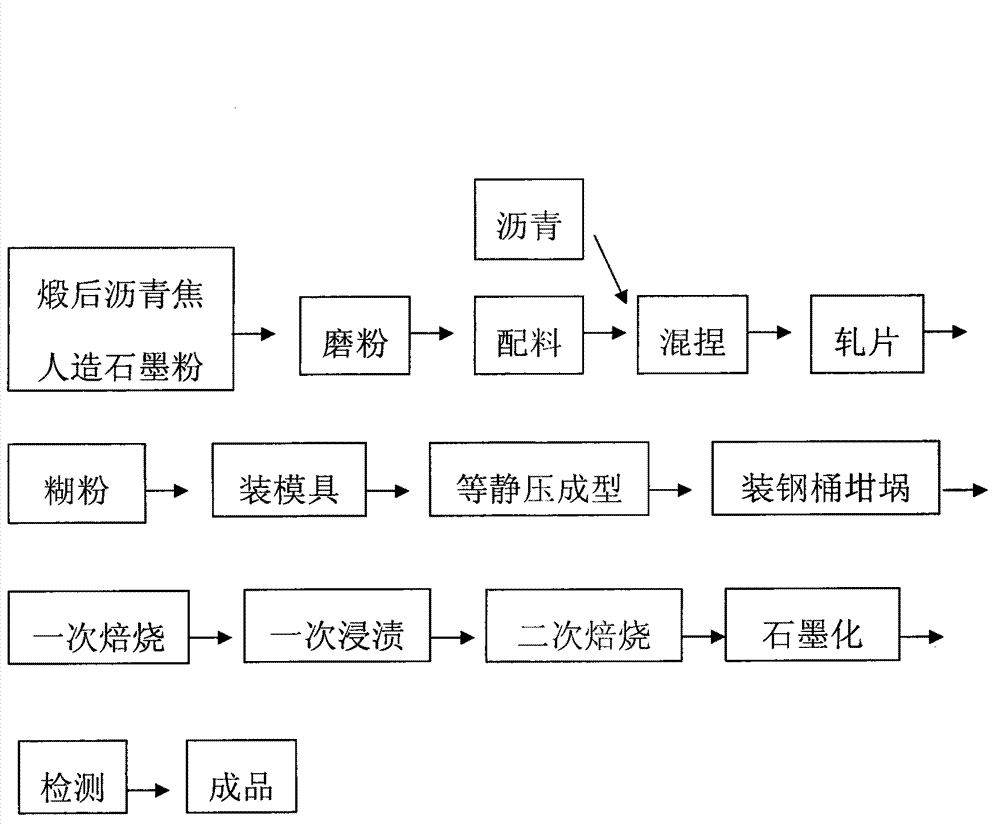

[0029] Product preparation method:

[0030] 6.5 tons of calcined pitch coke powder (primary powder) with a particle size of D50=15 μm, 0.9 tons of artificial graphite powder of D50=15 μm, mixed with 2.4 tons of molten pitch, milled after rolling and cooling, and then used cold isostatic Pressed into a 370×750×1300mm square, roasted at 950°C for 700 hours, impregnated with 2 tons of molten pitch for 5 hours, baked again at 850°C for 350 hours, and finally purified and graphitized at 2500°C for 210 hours, high-purity Graphite electrode output is 10.2 tons.

[0031] Product physical and chemical indicators:

[0032] Standard sizes 320×700×1200mm Bulk density 1.78g / cm 3 Resistivity 13.2μΩm Flexural strength 45MPa Compressive strength 83 MPa Shore hardness 55

Embodiment 2

[0034] Product preparation method:

[0035] 6.2 tons of calcined pitch coke fine powder (primary powder) with a particle size of D50=10 μm, 0.9 tons of artificial graphite powder of D50=10 μm, mixed with 2.6 tons of molten pitch, milled after rolling and cooling, and then used cold isostatic Pressed into 250×750×1300mm squares, roasted at 950°C for 700 hours, impregnated with 2 tons of molten pitch for 5 hours, baked at 850°C for 350 hours, and finally purified and graphitized at 2500°C for 210 hours, high-purity The output of graphite electrodes is 10 tons.

[0036] Product physical and chemical indicators:

[0037] Standard sizes 220×700×1200mm Bulk density 1.78g / cm 3 Resistivity 13.2μΩm Flexural strength 51MPa Compressive strength 92MPa Shore hardness 59

Embodiment 3

[0039] Product preparation method:

[0040] 6 tons of calcined pitch coke powder (primary powder) with a particle size of D50=5 μm, 0.8 tons of artificial graphite powder of D50=5 μm, mixed with 3.2 tons of molten pitch, milled after rolling, cooling, and then using cold isostatic Pressed into a 250×750×1300mm square, roasted at 950°C for 700 hours, then impregnated with 2.4 tons of molten pitch for 5 hours, baked again at 850°C for 350 hours, and finally purified and graphitized at 2500°C for 220 hours, high-purity The output of graphite electrodes was 9.9 tons.

[0041] Product physical and chemical indicators:

[0042] Standard sizes 220×700×1200mm Bulk density 1.80g / cm 3 Resistivity 15.8μΩm Flexural strength 60MPa Compressive strength 110MPa Shore hardness 65

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com