Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

224results about How to "Improve vulcanization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

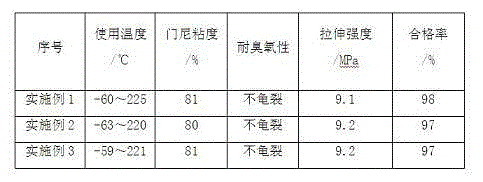

Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

The invention discloses a vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and a preparation method and a vulcanization process thereof. The vulcanized rubber isprepared from natural rubber, styrene-butadiene rubber, butadiene rubber, accelerator B, accelerator BM, accelerator DS, nanometer zinc oxide, rubber softening oil, sulphur, stearic acid, aging resister CD, carbon black N330, pine tar oil, solid coumarone, reclaimed rubber and pot clay. Compared with the prior art, the vulcanized rubber of the invention has suitable starting time of vulcanization,faster velocity of vulcanization and higher thermal oxidative aging property, the vulcanization efficiency is increased, and the heat-conducting property, processing safety and storage property of the rubber are increased in the vulcanization process; the provided vulcanization process can effectively shorten the vulcanization time, improve the vulcanization quality and increase the vulcanizationefficiency to 2-3 times of the original one.

Owner:JIHUA 3537 SHOE MAKING

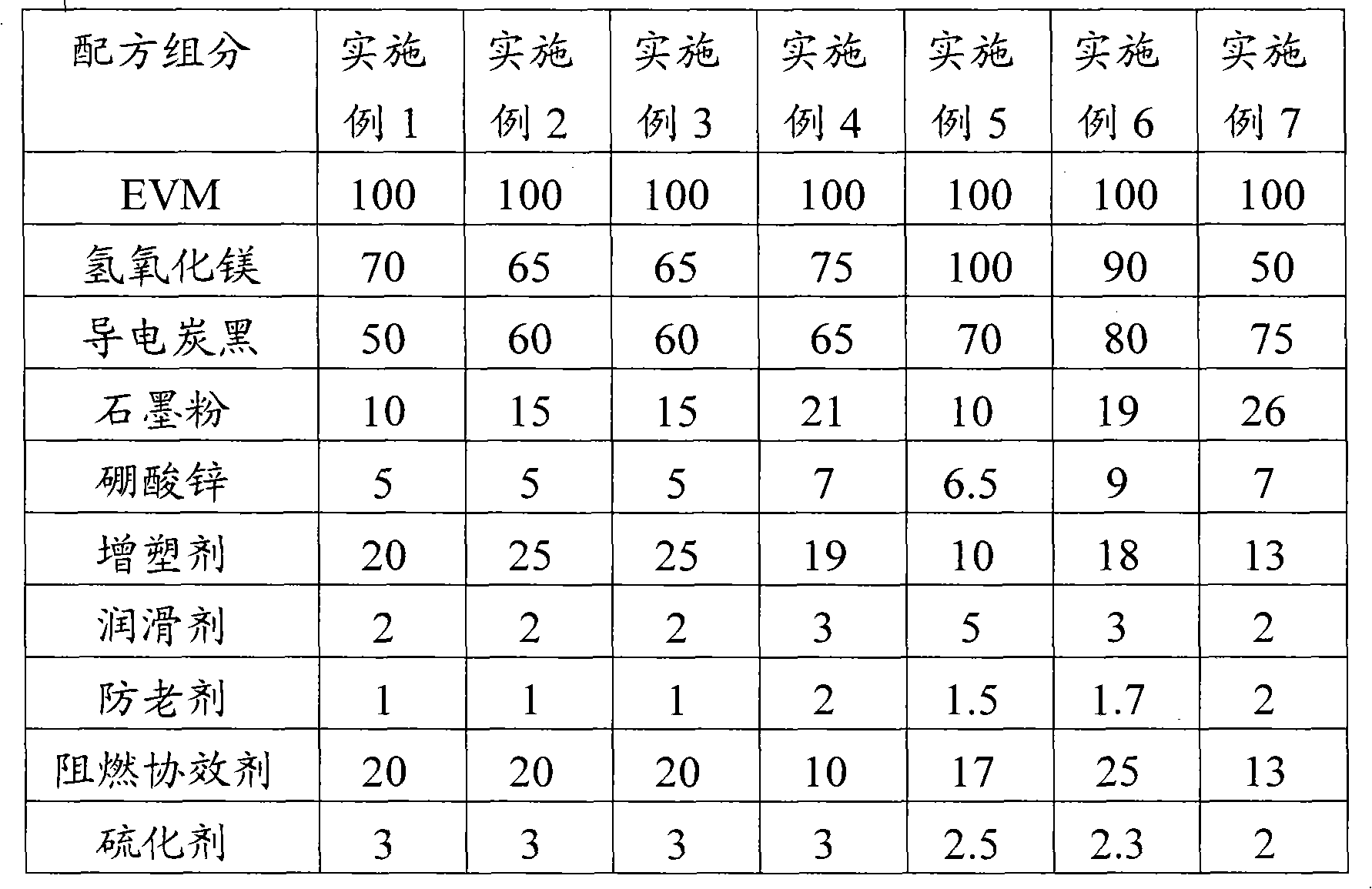

Conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and preparation method thereof

ActiveCN101942144AGood oil resistanceLow crystallization plasticizing temperatureInsulated cablesNon-conductive material with dispersed conductive materialVulcanizationHazardous substance

The invention relates to a conductive screening material, in particular to a conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and a preparation method thereof. The conductive screening material comprises the following basic components: 100 parts of ethylene-vinyl acetate rubber, 50-100 parts of magnesium hydroxide, 50-80 parts of conductive black, 10-30 parts of graphite powder, 5-10 parts of zinc borate, 10-25 parts of plasticizer, 2-5 parts of lubricant, 1-2 parts of antiager, 10-30 parts of flame retarding synergist, 2-3 parts of vulcanizer and 1-2 parts of vulcanization assistant. The preparation method comprises the four steps of material preparation, mixing, extrusion and tabletting. The conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material has the advantages of high conductivity, good oil resistivity, excellent flame retarding effect, no peculiar smell, easy stripping and high heat resistance level, and can pass the environment protection authentication of RoHS (Restriction of the use of certain Hazardous Substances Registration), REACH (Evaluation, Authorization and Restriction of Chemicals) and the like.

Owner:中广核三角洲(江苏)塑化有限公司

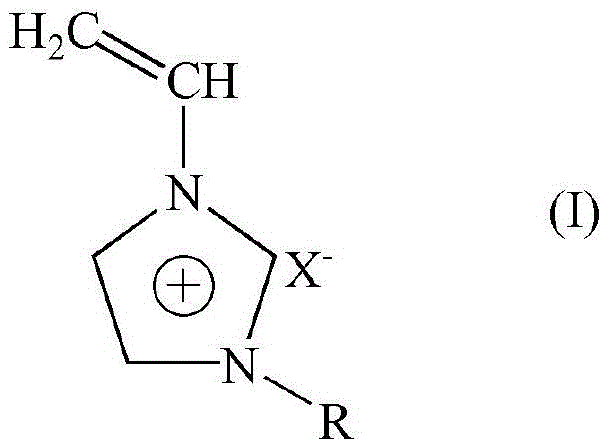

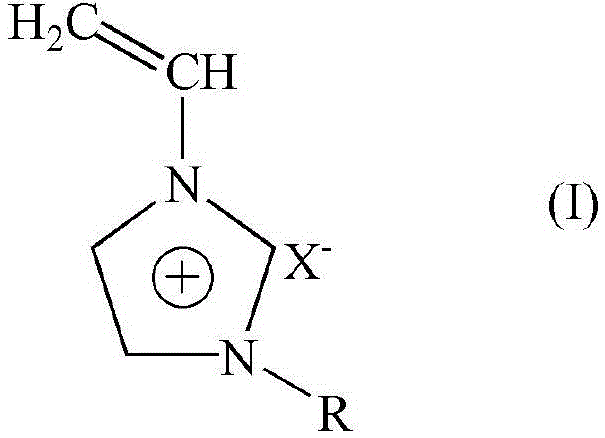

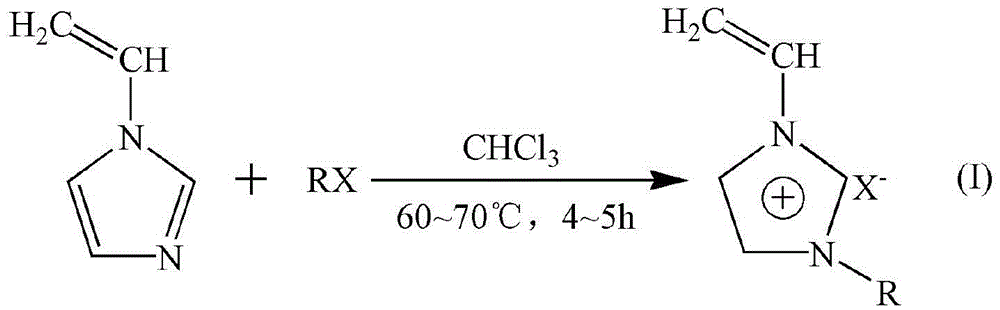

Antistatic butyronitrile gloves and preparation method thereof

ActiveCN105462006APermanent antistatic effectImprove antistatic performanceGlovesProtective garmentHigh resistanceAntistatic agent

The invention discloses a pair of antistatic butyronitrile gloves. The pair of butyronitrile gloves is mainly prepared from raw materials including butyronitrile latex, deionized water, potassium hydroxide, an accelerator, a vulcanizing agent, a catalyst, imidazolium salt type ionic liquid antistatic agents and the like. The problems that the domestic butyronitrile gloves for clean rooms have higher resistance and don't have an antistatic effect are solved; in the forming process of the gloves, the antistatic agents and butyronitrile latex have a cross-linking reaction, and the prepared butyronitrile gloves have the advantages of good antistatic effect and high cleanness and have the characteristics that the washability is good and the resistance value can be still maintained in the range from 106 omega to 108 omega after repeated ultra-clean washing. The invention further discloses a preparation method of the antistatic butyronitrile gloves. The butyronitrile gloves can be used in the environment of the clean rooms and plays a role in preventing static electricity and protecting operators and the environment of the clean rooms.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

High-strength tear-resistant modified cable material and preparation method thereof

The invention discloses a high-strength tear-resistant modified cable material. The high-strength tear-resistant modified cable material comprises the following raw materials in part by weight: 36-42 parts of polyurethane rubber, 52-56 parts of butadiene-vinylpyridine rubber, 6-9 parts of hydrogenated nitrile rubber, 10-13 parts of nano-cellulose whisker, 1.8-2.2 parts of silane coupling agent A-151, 2-2.5 parts of sulphur, 1.1-1.4 parts of accelerant TMTD (tetramethyl thiuram disulfide), 1.5-1.8 parts of accelerant AC, 7-8 parts of light calcium carbonate, 5-6 parts of modified graphene, 24-28 parts of hard clay, 20-23 parts of mica powder, 2-3 parts of diethyl phthalate DEP, 3-5 parts of epoxy butyl oleate, 2-3 parts of pentaerythritol fatty acid ester, 2.3-2.6 parts of melamine phosphate, 8-11 parts of microencapsulated red phosphorus, 11-14 parts of zinc borate, 1.5-1.8 parts of anti-aging agent ODA and 0.9-1.2 parts of anti-aging agent DFC-34. The invention discloses a preparation method of the high-strength tear-resistant modified cable material.

Owner:ANHUI ELECTRIC GRP SHARES

Modified graphene cable material

The invention discloses a modified graphene cable material. The modified graphene cable material comprises, by weight, 68-72 parts of natural rubber, 18-22 parts of nitrile rubber, 9-12 parts of ethylene-vinyl acetate copolymer, 3-4 parts of sulfur powder, 0.5-0.8 part of accelerant M, 1.1-1.4 parts of accelerant D, 1.4-1.8 parts of aluminum-zirconium coupling agent TL-5, 3-6 parts of modified graphene, 22-25 parts of sea-foam stone powder, 23-27 parts of calcined kaolin, 5-6 parts of titanium nitride, 12-15 parts of carbon black N660, 2-5 parts of triphenyl phosphate TPP, 3-4.5 parts of citrate, 2.3-3.6 parts of triazine-2,4,6-triamine phosphate, 5-8 parts of magnesium sulfate heptahydrate, 1.2-1.8 parts of anti-aging agent MBZ and 1.2-1.6 parts of anti-aging agent NBC. The modified graphene cable material has the advantages of being high in elasticity and abrasion-resisting performance and is excellent in heat resisting and flame resisting performance.

Owner:ANHUI ELECTRIC GRP SHARES

Waster rubber powder composite modified asphalt and preparation method thereof

InactiveCN107057384AFix compatibility issuesFix stability issuesBuilding insulationsPolymer scienceSulfur

The invention discloses waster rubber powder composite modified asphalt and a preparation method thereof. The waster rubber powder composite modified asphalt is prepared from, by weight, 18-32% of waste rubber powder, 58-72% of matrix asphalt, 1-3% of carbon nanotubes, 5-10% of white carbon black, 3-7% of high-density polyethylene, 2-4% of sulfur, 2-7% of stearic acid and 5-8% of zinc oxide. The preparation method includes: mixing waste rubber powder with matrix asphalt to obtain waster rubber powder mixed matrix asphalt through treatment; subjecting carbon nanotubes and white carbon black to reaction to obtain modified white carbon black; subjecting an obtained product to treatment along with high-density polyethylene, delivering to a reactor, adding sulfur, zinc oxide and stearic acid, well mixing, and stably developing and treating for a period of time at a certain temperature to obtain the waster rubber powder composite modified asphalt. The waster rubber powder composite modified asphalt prepared according to the method is excellent in comprehensive performance and applicable to fields of waterproof coils, road asphalt, special rubber products and the like.

Owner:ANHUI GVG NEW MATERIAL CO LTD

Mining anti-extrusion high-wear-resistance cable

InactiveCN105111538AEasy to fixImprove stabilityRubber insulatorsClimate change adaptationAntioxidantEngineering

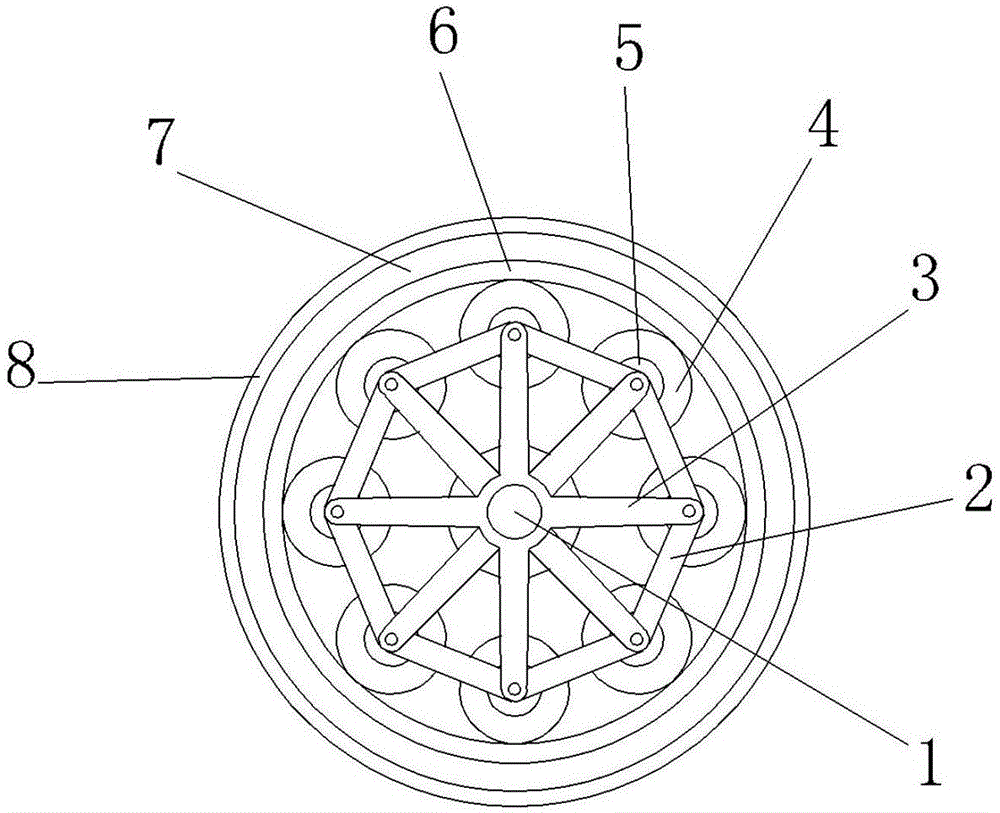

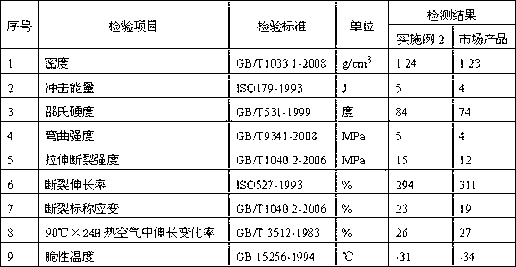

The invention discloses a mining anti-extrusion high-wear-resistance cable comprising a supporting core, a connecting ring, a supporting rod, a cable core, multiple axes, an insulating layer, a jacket layer, an armored layer and a filling body, wherein the jacket layer comprises the following raw materials in parts by weight: 90 parts of butadiene-nitrile rubber, 45 parts of chloroprene rubber, 40 parts of ethylene propylene diene rubber, 35 parts of chlorinated polyethylene, 19 parts of maleic anhydride grafted EVA (ethylene vinyl acetate copolymer), 7.5 parts of zinc oxide, 3 parts of chlorinated paraffin, 5.5 parts of calcium stearate, 7.5 parts of white carbon black, 10 parts of talc powder, 9 parts of active kaolin, 5 parts of antimony trioxide, 4.5 parts of triphenyl phosphite, 4 parts of magnesium hydroxide, 4.5 parts of aluminum oxide, 5.5 parts of an anti-aging agent RD, 3.5 parts of an N,N'-di-sec-butyl-p-phenylenediamine antioxidant, 4 parts of a curing agent DTDM and 5.5 parts of a curing agent PDM. The cable is excellent in extrusion resistance and wear resistance.

Owner:ANHUI MENTOR CABLE GROUP

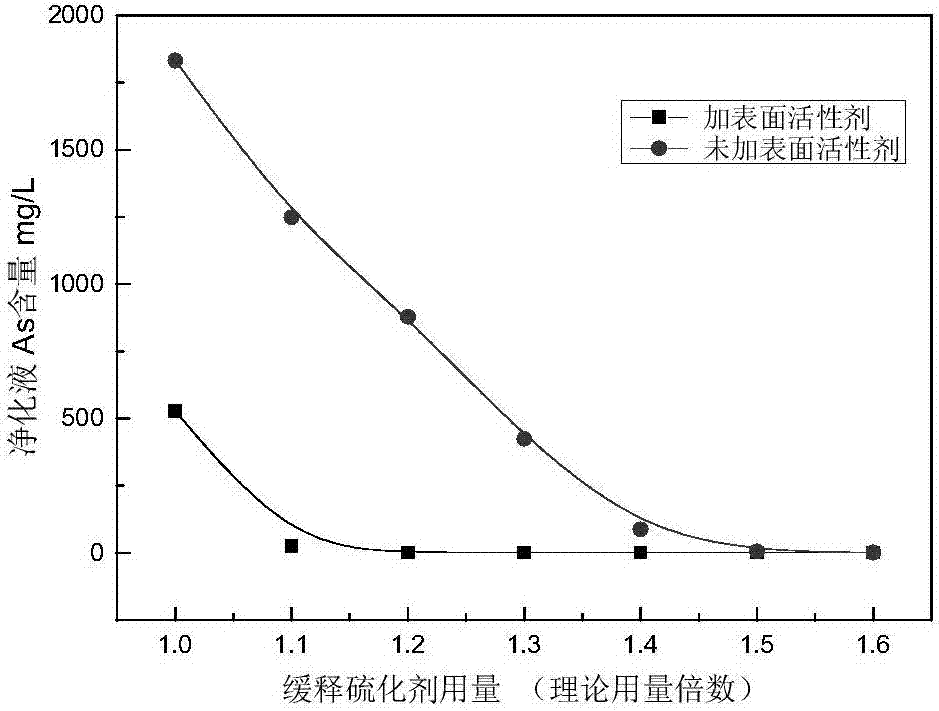

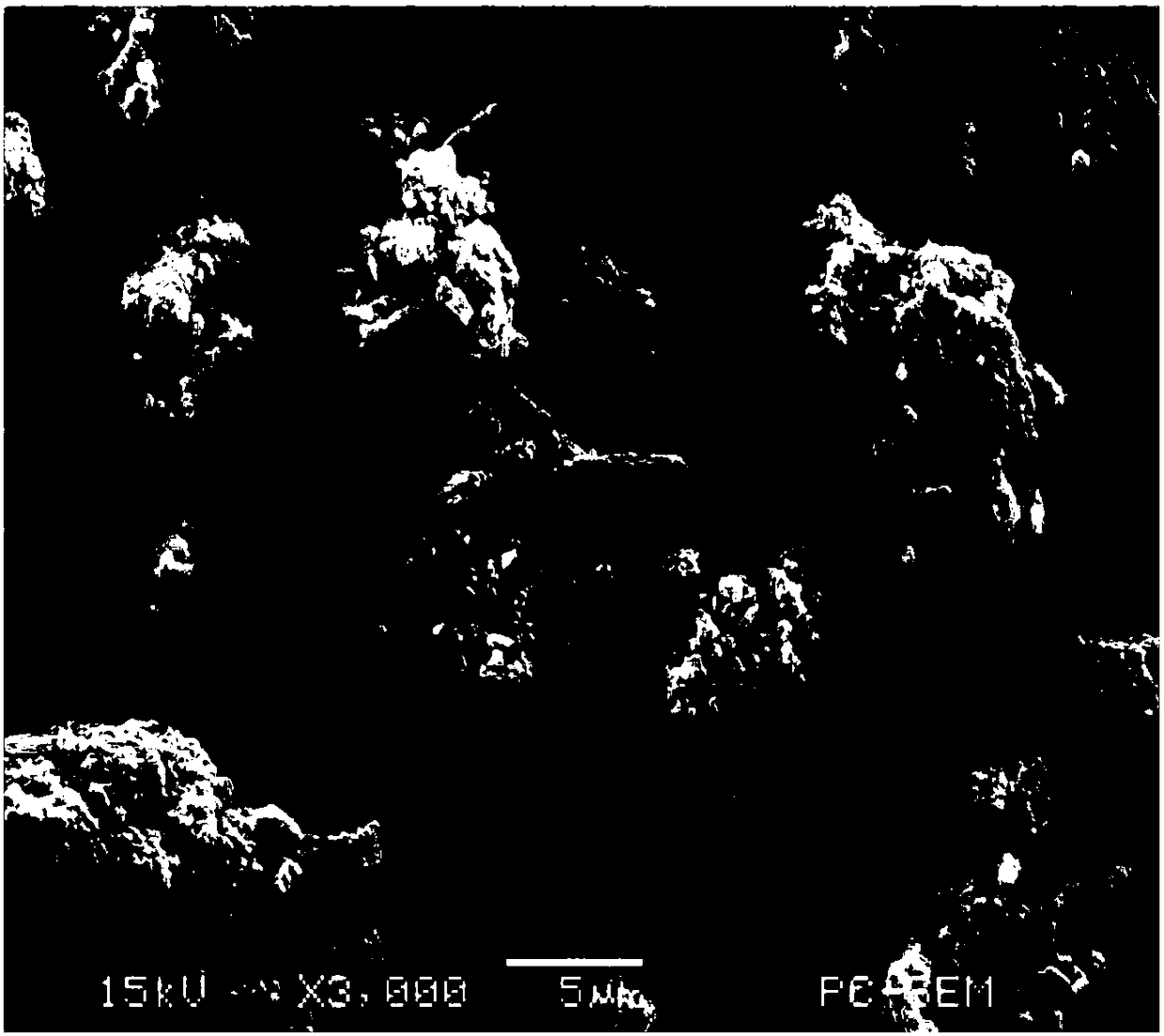

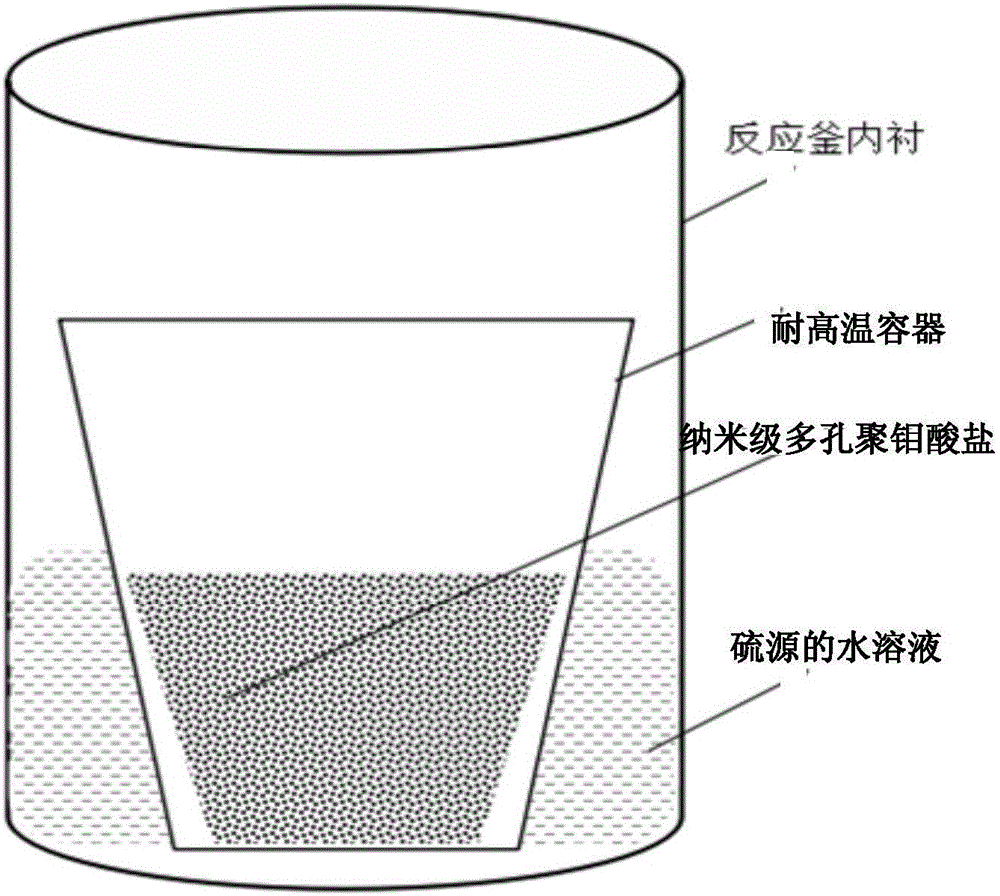

Sustained release vulcanizing agent, preparation method thereof, and method of using sustained release vulcanizing agent to remove heavy metals and arsenic from acidic solution

ActiveCN107188361ASolve the problem of easy release of hydrogen sulfideImprove acid resistanceWater treatment compoundsWater contaminantsSulfideSURFACTANT BLEND

The invention discloses a sustained release vulcanizing agent, a preparation method thereof, and a method of using the sustained release vulcanizing agent to remove heavy metals and arsenic from an acidic solution. A sulfur source and a surfactant are added into a solution containing Fe<2+>, Mn<2+>, and Zn<2+> to carry out reactions to obtain the nano-millimeter metal sulfide sol sustained release vulcanizing agent, which can slowly release S<2-> under a strongly acidic condition; the surface activity is guaranteed, at the same time, the utilization rate of S<2-> is improved; the vulcanizing agent is used to remove heavy metals and arsenic from an acidic solution and has the advantages of high removal efficiency, low using amount, and low hydrogen sulfide release amount; the problems that the using amount of a conventional vulcanizing agent is large, the utilization rate is low, and the H2S pollution is severe can be solved, and the method for removing heavy metals and arsenic from an acidic solution has the advantages of simple process and convenient operation and is suitable for industrial production.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Pre-dispersion master colloidal particles of environment-friendly comprehensive promoter used for automobile sealing strips, and preparation thereof

The invention discloses pre-dispersion master colloidal particles of an environment-friendly comprehensive promoter used for automobile sealing strips. The pre-dispersion master colloidal particles comprises, by weight, 10-30 parts of a thiazole promoter, 10-30 parts of a zinc dialkyl dithiophosphate promoter, 10-30 parts of a thiocarbamate promoter, 1-10 parts of a scorch retarder, 2-5 parts of ethylene-propylene-diene monomers and 2-5 parts of cis-polyisoprene. The invention also discloses a preparation method for the pre-dispersion master colloidal particles of the environment-friendly comprehensive promoter used for the automobile sealing strips. The pre-dispersion master colloidal particles of the environment-friendly comprehensive promoter used for the automobile sealing strips are prepared by mixing powdery comprehensive promoters with a polymer carrier, so that during a use process, the pre-dispersion master colloidal particles have better dispersibility, more excellent vulcanization efficiency, are not easy to scorch and crock, do not generate carcinogenic nitrosamine, are environment-friendly, and can increase batch qualification rate of finished products.

Owner:NINGBO ACTMIX POLYMER

Preparation method of vulcanizing activator taking metal organic framework material as carrier

ActiveCN108456331AImprove ductilityLarge specific surface areaZinc hydroxideCALCIUM HYDROXIDE SOLUTION

The invention relates to a preparation method of a vulcanizing activator taking a metal organic framework material as a carrier. The preparation method comprises the following steps: S1, enabling an alkaline solution to react with an organic carboxylate ligand to prepare a metal organic framework material precursor solution; S2, enabling a zinc salt solution to react with a metal organic frameworkmaterial precursor to generate a zinc metal organic framework compound; S3, washing and filtering the zinc metal organic framework material; S4, introducing a carrier: preparing a zinc metal organicframework compound filter cake into suspension, adding a calcium hydroxide solution, stirring the solution for certain time till calcium hydroxide and the zinc metal organic framework compound react with each other completely, generating a calcium-based organic framework compound and zinc hydroxide, and adsorbing the generated zinc hydroxide by the calcium-based organic framework compound, so as to form a supported zinc hydroxide@ calcium metal organic framework material; S5, filtering and drying a finished product, so as to prepare a micro-nano low-zinc vulcanizing activator. The preparationmethod has the advantages of being simple, convenient, low in energy consumption, easy to control, and suitable for large-scale production.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

Sizing material of high hardness rubber seal

The invention relates to a sizing material of a high hardness rubber seal. The sizing material comprises the raw material components in parts by weight as follows: 120-150 parts of 1# natural rubber, 2-3 parts of sulphur, 4-6 parts of zinc oxide, 2-4 parts of stearic acid, 1-1.2 parts of paraffin, 10-12 parts of pine tar, 80-100 parts of spraying carbon black, 1-1.2 parts of an accelerant DM (Chinese name: 2,2'-dithio di-benthothiazole, molecular formula: C14H8N2S4), and 1-1.2 parts of an antiager D (Chinese name: N-phenyl-2-naphthylamine, molecular formula: C16H13N). According to the invention, high hardness components are added in the rubber formula, and meanwhile the vulcanizing efficiency is enhanced, and the integral hardness of rubber is improved.

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

Ethylene-propylene rubber particles of active hydrogen-containing compound, and production method thereof

ActiveCN103421248AImprove adhesionImprove adhesion, its tear strengthPolyureas/polyurethane adhesivesHydrogenPolymer science

The present invention discloses ethylene-propylene rubber particles of an active hydrogen-containing compound, and a production method thereof. The ethylene-propylene rubber particles comprise color master batch of an active hydrogen-containing compound, a reinforcing agent comprising an active hydrogen bond-containing nanometer reinforcing agent and a reinforcing agent, and an activator material. The production method comprises: preparing color master batch, wherein an active hydrogen-containing compound is added to a pigment, a color master batch carrier and an anti-ultraviolet ray agent are added, complete dispersion and mixing are performed, and extrusion granulation is performed through an extruder; preparing a reinforcing agent material and an activator material; and preparing ethylene-propylene rubber color particles, wherein a vulcanizing agent is added to the color master batch while the reinforcing agent material, the activator material, an accelerator, a plasticizer and an anti-aging agent are added, opening type mixing and sealed mixing are performed through a roll mill, the obtained material enters a vulcanizing cylinder to be subjected to a vulcanizing treatment to prepare a vulcanizing film, and the vulcanizing film is broken. The ethylene-propylene rubber particles have characteristics of good cross-linking strength with the polyurethane adhesive, strong ultraviolet ray resistance, and bright color.

Owner:江阴市文明体育塑胶有限公司

Pre-dispersed master batch particle for rubber vulcanization cross-linking and preparation method of pre-dispersed master batch particle

ActiveCN104844856AImprove vulcanization efficiencyIncrease the degree of cross-linkingRubber materialDispersity

The invention discloses a pre-dispersed master batch particle for rubber vulcanization cross-linking and a preparation method of the pre-dispersed master batch particle. The pre-dispersed master batch particle comprises, by weight, 30-50 parts of trithiocyanuric acid, 20-40 parts of 1, 1'-dithiobiscaprolactam, 3-10 parts of coupling agents, 3-10 parts of inorganic fillers, 5-10 parts of softening oil, 2-5 parts of processing agents and 5-40 parts of rubber carriers. By the preparation method of the pre-dispersed master batch particle, dispersity of active components is improved, the master batch particle is uniformly discharged, the surface of the particle is smooth, the master batch particle has fine processing performance and is used for preparing rubber materials, vulcanization time is shortened, and the mechanical property of vulcanized rubber is effectively improved.

Owner:NINGBO ACTMIX POLYMER

Nano silicon dioxide-doped nanocellulose material as well as preparation method and application thereof

The invention provides a nano silicon dioxide-doped nanocellulose material as well as a preparation method and the application thereof. Nano silicon dioxide and a nanocellulose material are at least bonded by part of hydrogen bonds; based on 100% of the total mass of the nano silicon dioxide-doped nanocellulose material, the content of the nano silicon dioxide is 70-90% by mass. The nano silicon dioxide has relatively good dispersibility in rubber, so that the nanocellulose material connected with the nano silicon dioxide by part of hydrogen bonds is dispersed uniformly in the rubber, the useof a silane coupling agent and other surfactants can be reduced, and a specific gravity of the product is reduced while indirectly reducing costs of the product; moreover, the nanocellulose material is a green and environment-friendly material, so that the pressure on environments caused by traditional modified materials can be relieved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Flame-retardant ageing-resistant sealing ring rubber material

The invention discloses a flame-retardant ageing-resistant sealing ring rubber material which comprises the following raw materials in parts by weight: 80-100 parts of natural rubber, 20-40 parts of butadiene styrene rubber, 10-30 parts of ethylene propylene diene monomer, 10-30 parts of a phosphate modified polyurethane elastomer, 2-4 parts of dicumyl peroxide, 0.5-1 part of sulfur, 1-3 parts of an accelerant DM, 2-4 parts of an accelerant TAIC, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 6-10 parts of carbon black N660, 5-10 parts of titanium dioxide, 2-5 parts of quartz powder, 10-18 parts of calcite in powder, 6-15 parts of opal powder, 1-4 parts of a silane coupling agent, 2-8 parts of zinc borate, 1-4 parts of melamine, 1-2 parts of an anti-aging agent 4010NA, 2-4 parts of an anti-aging agent MB and 1-3 parts of an anti-aging agent AW. The rubber material disclosed by the invention has good flame-retardant property, ageing resistance and excellent weather resistance.

Owner:天长市康宁甘油科技有限公司

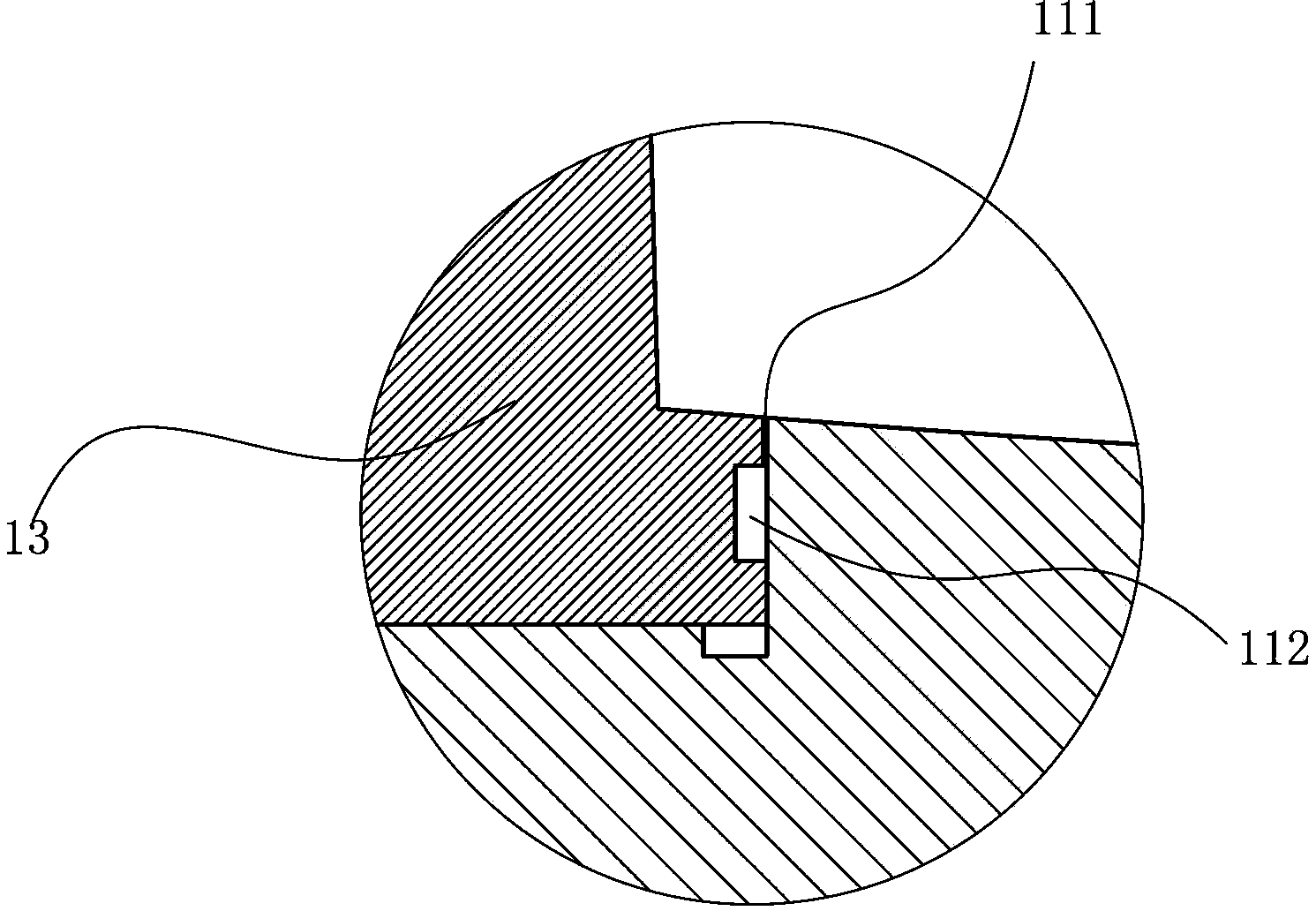

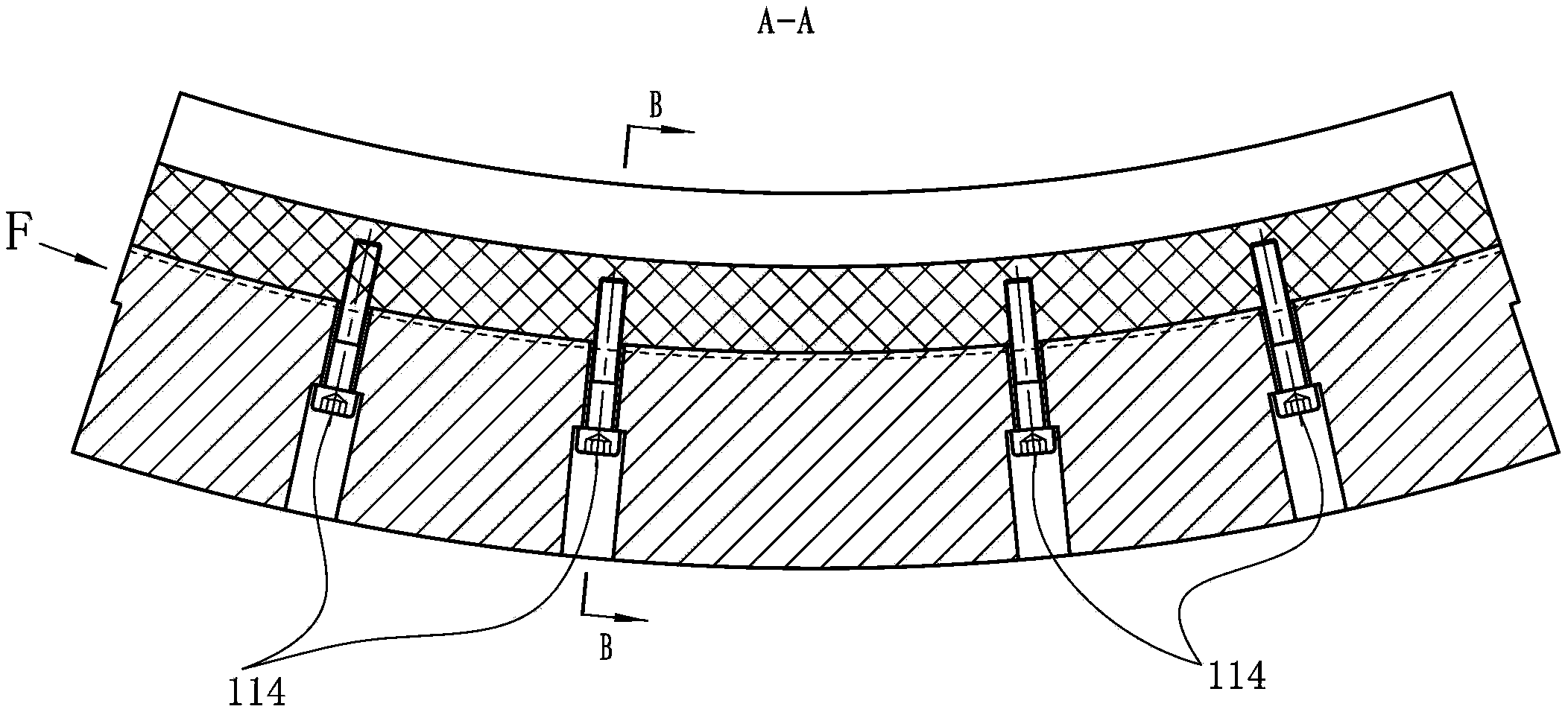

Pore-free tyre segmental mold with dual damascene composite structure, pore-free tyre segmental mold pattern block with dual damascene composite structure and method

The invention relates to a pore-free tyre segmental mold with a dual damascene composite structure, a pore-free tyre segmental mold pattern block with a dual damascene composite structure and a method. The pattern block comprises a pattern block body made of a first metal material and mosaic structures made of a second metal material, wherein the mosaic structures are inlaid in positions close to the inner peripheral surface of the pattern block body, which is used for forming a pattern surface; the pattern block is provided with an exhaust passage communicated with the inner peripheral surface and the exterior of a segmental mold cavity; the pattern block body and the mosaic structures are assembled to form the pattern block; the first metal material and the second metal material are both suitable for tyre vulcanization, and the intensity of the first metal material is higher than that of the second metal material; the exhaust passage comprises exhaust gaps formed between the mosaic structures and the adjacent pattern block body. The pattern block provided by the invention is formed by compositing the two materials; the intensity of the metal material of the pattern block body is higher than that of the metal material of the mosaic structures corresponding to ring-like pattern forming parts, all parts receiving extrusion force, friction force and the like during use are all made of the first metal material, all the pattern forming parts are made of the second metal material, the vulcanization efficiency is high and the tyre surface quality is guaranteed.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Pre-sulfurizing process of hydrogenation catalyst

InactiveCN101041143AReduce lossesReduce the impact of diffusionCatalyst activation/preparationRefining to eliminate hetero atomsOxidation stateNickel sulfide

The invention relates to a prevulcanization method of hydrogeneration catalyst. The method makes ammonium thiosulfate be loaded on oxidation state catalyst of ni-mo or ni-w and the load quantity is based on the sulfur in ammonium thiosulfate. According to the stoichiometric method, needed sulfur when molybdenum trioxide or tungten trioxide is reduced and sulfurized into molybdenum dioxide or tungten dioxide is 0.5-2 times of needed sulfur when nickel oxide is transferred to nickel sulfide and 1-2 times is selected optically. The load method is that the oxidation state catalyst of ni-mo or ni-w is dipped into the ammonium thiosulfate solution and it is dipped for 0.5-8 hours. The catalyst after dipped is dried for 1-24 hours under the room temperature to 100deg.C in air with normal pressure. The invention is provided with low price, no pollution, simple operation and short sulfurized time.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

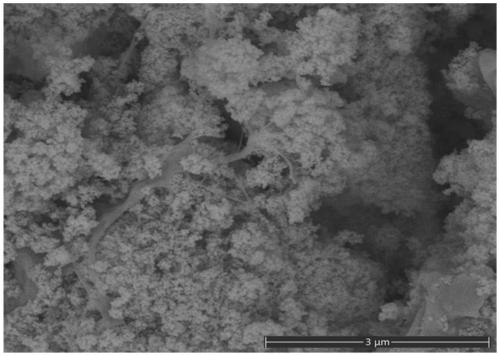

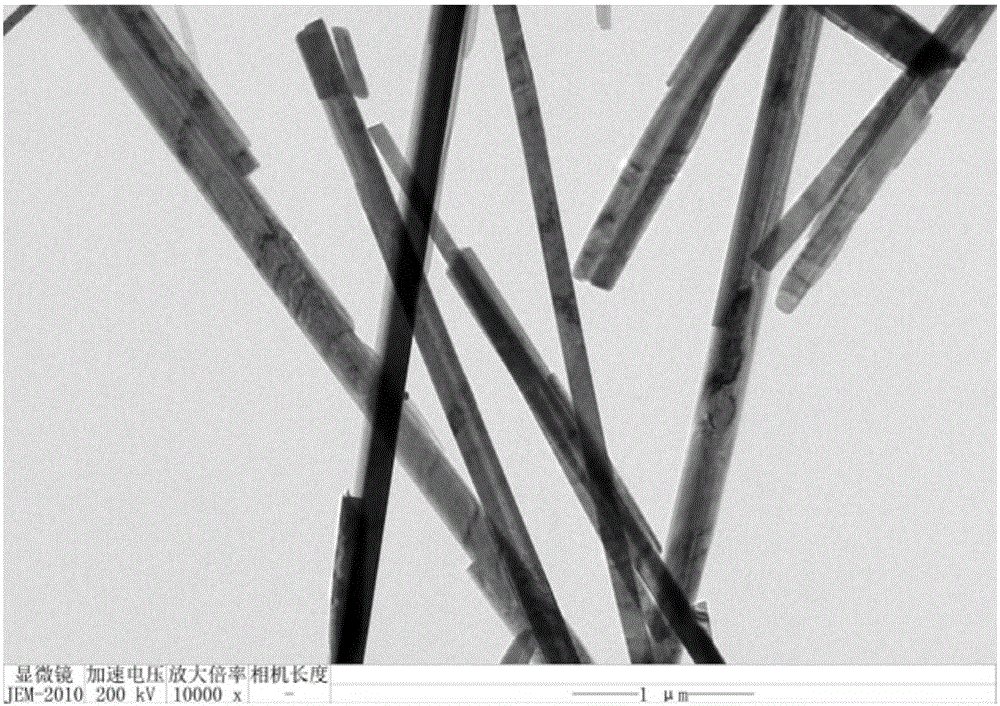

Method for preparing porous defect-enriched molybdenum disulfide

ActiveCN106186070AAvoid wastingAchieve in-situ vulcanizationPhysical/chemical process catalystsMolybdenum sulfidesMOLYBDATE IONVulcanization

The invention discloses a method for preparing a porous defect-enriched molybdenum disulfide, and is characterized in that the method comprises the steps: adding a soluble acid or a soluble salt in an aqueous solution of molybdate, then heating, and making molybdate ions subjected to stepwise polymerization into porous heterozygous ordered aggregates under induction of cation; and centrifuging, washing and drying the product, transferring the product to a reactor kettle, taking a compound containing negative bivalent sulfur elements as a sulfur source, and thus obtaining the porous defect-enriched molybdenum disulfide through a hydrothermal-gas phase in-situ vulcanization method. The method has the advantages of simple operation, and cheap and easily obtained raw materials, and the obtained product has the advantages of good morphology and large specific surface area, and can be used for large-scale synthesis.

Owner:合肥庐阳科技创新集团有限公司

Beneficiation method for recovering copper in copper smelting slag and beneficiation reagent

The invention discloses a beneficiation method for recovering copper in copper smelting slag and a beneficiation reagent. The beneficiation reagent comprises a modified activator. The modified activator is formed in a manner that Na2S or NaHS serves as a matrix, and a modifier including one or more of alkane sulfonate, alkylbenzene sulfonate, lignosulfonate, fatty glyceride, stearic acid, peroxysulphate, sulfate, sulfite, thiosulfate or other sulfohydrate and sulfide. The invention further provides the beneficiation method for recovering the copper in the copper smelting slag through the beneficiation reagent. By means of the processes of ore grinding, pulp mixing, primary roughing, at least primary concentration and at least primary scavenging flotation, final copper concentrates and final tailings are obtained. A relatively high concentrate recovering rate can be reached, meanwhile, tailing running of the tailings is greatly lowered, the reagent is environmentally friendly, and the environmental influence can be reduced to the minimum extent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

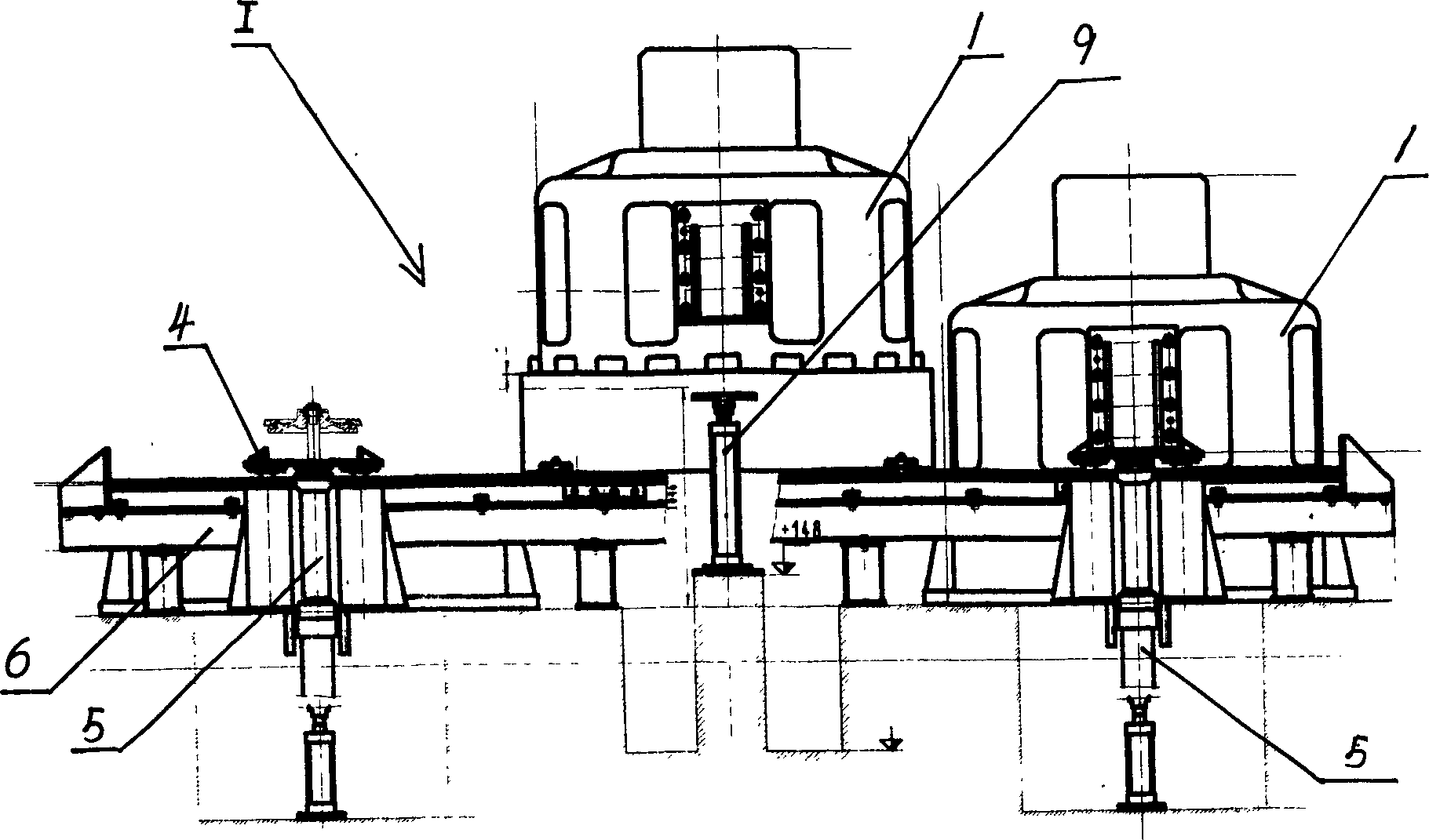

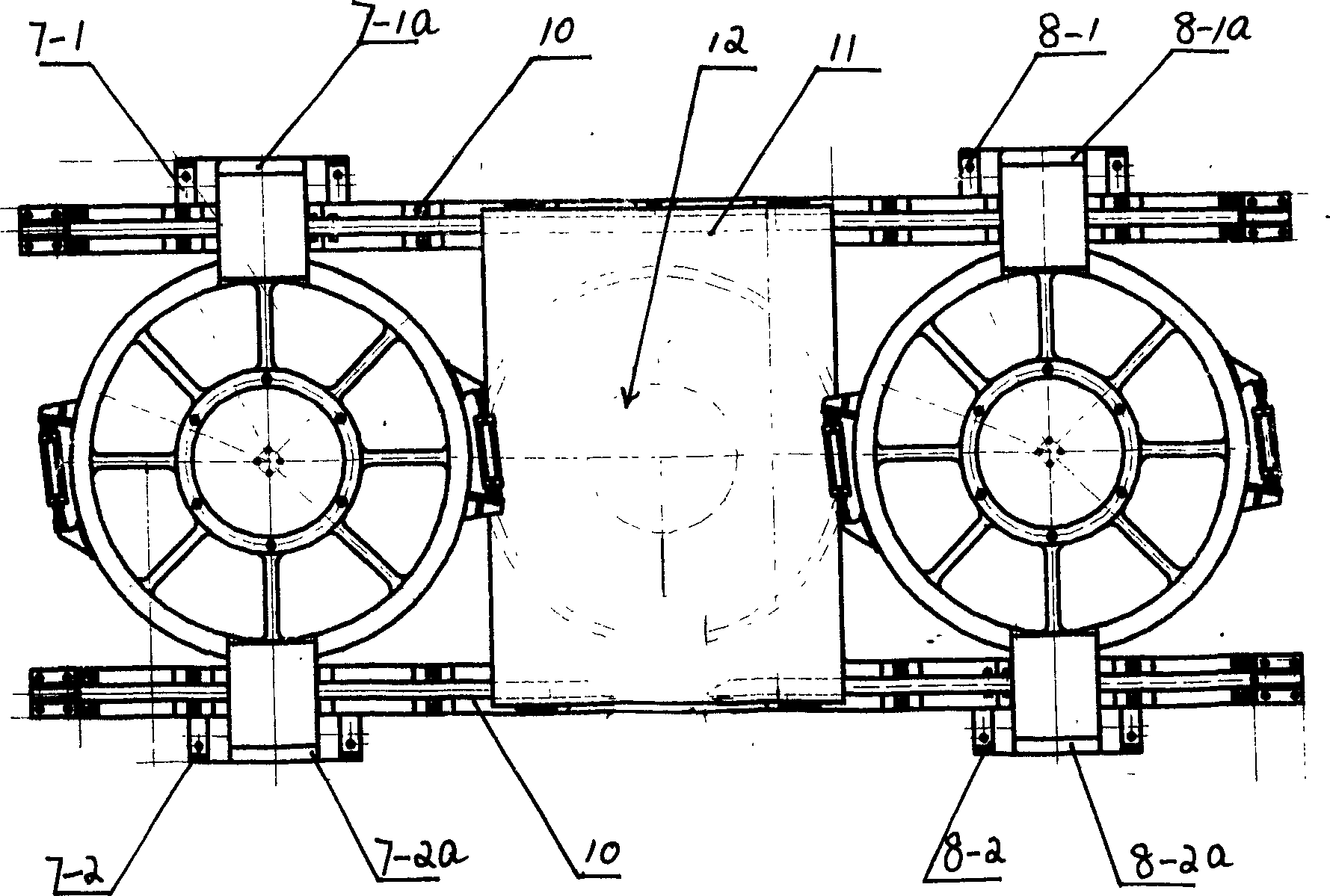

Radial tyre vulcanization production line

InactiveCN1631643AImprove vulcanization efficiencyImprove work efficiencyAutomatic controlManipulator

The invention is a radial ply tire sulfidation production line of which the features are that: several groups of radial ply tire sulfidating machine (I) links end to end, set by its side is the product transferring line (III); each sulfidating machine is equipped with a special motion machine arm (II); all the sulfidating machine share the same hydraulic pressure station (IV). The production is combined in the production scale determined by vertical elevating, horizontal displacing principle and other needs randomly. The combined production line will easily forms an integrality with various pipelines are integrated with branches and power supply and other systems, and becomes an automatic production line with an ability of auto control, and intellect adjusting automatic displaying, recording and saving for ten million sets of data through the configuration network. The system has a high sulfidating efficiency which sulfidating the tires on one side while taking out the finished tire on the other side and completing with assembling, mould clearing and other preparations. It makes full use of the space, device and man power. The device is removed of mass accessories on the original sulfidating machine which greatly lowers the production cost of the radial ply tire on the production line and increases the mercantile rate of return.

Owner:青岛国人集团有限公司

High-strength wear-resistant rubber material

The invention discloses a high-strength wear-resistant rubber material which is prepared from the following raw materials in parts by weight: 55-75 parts of epoxy natural rubber, 15-27 parts of ethylene propylene diene monomer rubber, 18-32 parts of styrene-butadiene rubber, 6-12 parts of polyurethane elastomer, 1-3 parts of carbon black N330, 3-6 parts of carbon black N660, 12-20 parts of modified reinforcing filler, 4-10 parts of light calcium carbonate, 22-28 parts of montmorillonite, 3-10 parts of polypropylene fiber, 5-8 parts of molybdenum disulfide, 0.8-3 parts of silane coupling agent, 3-8 parts of nano zinc oxide, 1.5-2.5 parts of accelerator DM, 1-3 parts of accelerator TMTM, 0.2-2 parts of sulfur, 0.5-1.5 parts of anti-aging agent, 0.1-0.5 part of anti-aging aid, 4-8 parts of trioctyl trimellitate, 1-4 parts of tributyl citrate and 3-5 parts of epoxidized soybean oleic acid butyl ester. The rubber material has the advantages of high strength, favorable wear resistance and long service life.

Owner:天长市康宁甘油科技有限公司

Repairing material for color asphalt pavement, and preparation method thereof

The invention discloses a repairing material for a color asphalt pavement, and a preparation method thereof, wherein the repairing material comprises, by mass, 10-22% of a petroleum resin, 35-50% of acompatibilizer, 2-9% of a polymer, 15-50% of a viscosity reducing agent, 0.05-1.0% of a vulcanizing agent, 0.1-1.5% of an anti-aging agent, and 0.05-1.0% of an activator. According to the present invention, the repairing material has advantages of excellent high-temperature performance, excellent low-temperature performance, good stability, high softening point, strong adhesion, high low-temperature elongation rate and high low-temperature ductility, can be stored at room temperature for more than one year, and can be well mixed with color pigments at a room temperature so as to effectively repair the color asphalt pavement with small-area damage after the mixing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of modified precipitating method white carbon black

InactiveCN108033453AThe amount of surface hydroxyl groups is reducedLower surface energySilicaAmmonium hydroxideAqueous solution

The invention discloses a preparation method of modified precipitating method white carbon black, and relates to the technical field of rubber strengthening agents. The preparation method comprises the following steps: (1) adding liquid sodium silicate into a reaction kettle, and adding nano-silicon dioxide with the mass of 0.15 to 0.18 percent of that of the liquid sodium silicate into the liquidsodium silicate; (2) adding a sulphuric acid aqueous solution into the reaction kettle, and adding bentonite of which the surface is subjected to isocyanate esterification; (3) regulating the pH value by adopting ammonium hydroxide, adding a settling agent, and continuously stirring; (4) after the reaction is ended, performing water washing and suction filtering on a reactant, and drying to obtain the modified precipitating method white carbon black. Compared with the conventional precipitating method white carbon black, the physical and chemical indicators (the BET specific surface area, theoil absorption value, the particle size and the like) of the modified white carbon black prepared by the preparation method are all improved by over 10 percent, and the yield is 95 percent.

Owner:安徽凤阳赛吉元无机材料有限公司

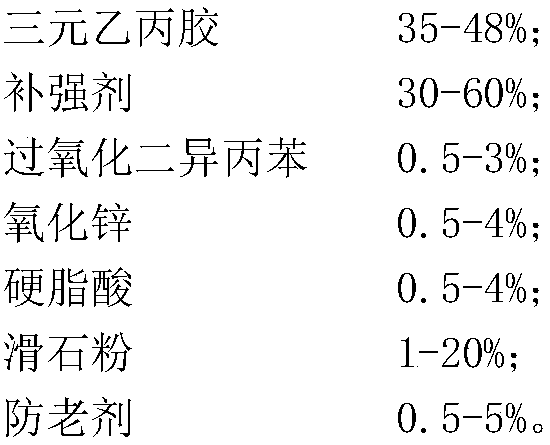

Ethylene propylene rubber and preparation method thereof

ActiveCN107815028AGood physical and mechanical propertiesImprove vulcanization efficiencyPolymer science2-mercaptobenzimidazole

The invention discloses ethylene propylene rubber and a preparation method thereof, and belongs to the rubber field. The ethylene propylene rubber includes the following raw material components by mass: 35 to 48% of EPDM rubber, 30 to 60% of a reinforcing agent, 0.5-3% of dicumyl peroxide, 0.5-4% of zinc oxide, 0.5-4% of stearic acid, 1-20% of talcum powder and 0.5-5% of an anti-aging agent. The anti-aging agent includes one or more of 2,2,4-trimethyl-1,2-dihydroquinoline polymer and 2-mercaptobenzimidazole, and the ethylene-propylene rubber includes 1-3% by mass of vinyl guanamine. The ethylene propylene rubber has the following beneficial effects: through addition of the anti-aging agent in the EPDM rubber, the oxidation of the EPDM rubber can be inhibited, the stearic acid as a surfactant can improve the uniformity of the dispersion of the anti-aging agent in the EPDM rubber and improve the connection of the anti-aging agent and the EPDM rubber, and the ethylene propylene rubber hasa better anti-aging effect.

Owner:玉环市鑫庄电子股份有限公司

Magnesium oxide and zinc oxide blended vulcanizing agent for neoprene vulcanization and preparation method thereof

The invention relates to a magnesium oxide and zinc oxide blended vulcanizing agent for neoprene vulcanization and a preparation method thereof. The vulcanizing agent is prepared from the following components, by weight, 80.0%-90.0% of a mixture of active magnesium oxide and active zinc oxide and 10.0%-20.0% of a dispersant, wherein the weight ratio of active magnesium oxide to active zinc oxide is 1:0.2-3.0. The preparation method comprises the following steps: a, mixing active magnesium oxide and active zinc oxide to obtain a substance A, and dissolving the dispersant in anhydrous ethanol to obtain a substance B; b, carrying out surface-coating modification on the substance A with the substance B to obtain a blend; and c, heating and stirring the blend to obtain an ointment-like or sticky magnesium oxide and zinc oxide blended vulcanizing agent. The vulcanizing agent provided by the invention has the following advantages: the problem that a traditional powdery vulcanizing agent is not uniformly dispersed and activity of magnesium oxide is easy to fail when the powder is added into neoprene is solved; dispersibility of zinc oxide and activity permanence of magnesium oxide are enhanced; and scorching dangerousness of a rubber compound with high mooney viscosity is reduced.

Owner:河北镁神科技股份有限公司 +1

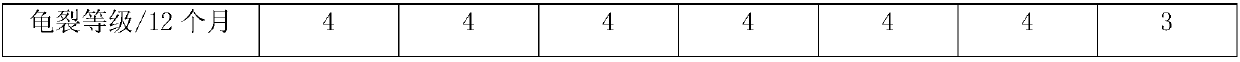

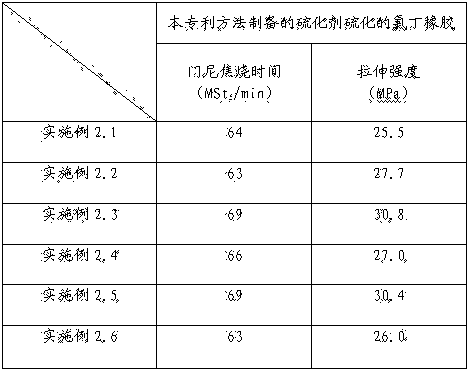

Production technology for chloroprene rubber

Relating to the rubber field, the invention discloses a production technology for chloroprene rubber. The technology comprises the processes of: rubber drying, plastication, mixing, semi-finished product cutting and vulcanization. According to the method, by strictly controlling the rubber drying temperature and time in the rubber drying process, the quality of the dried rubber material is improved. The mixing process adopts a two-stage mixing process, well controls the mixing time and discharge temperature, so that scorching phenomenon of chloroprene rubber is significantly reduced, and the rubber guiding, discharge and batch-out of an open mill are smooth, and no roll sticking phenomenon appears. The vulcanization process adopts N-tert-butyl-2-bisbenzothiazole sulfenamide as a vulcanization accelerator, which is safe and pollution-free and has no harm to the human body. The technological process adopts a drum type vulcanizing machine, the vulcanization efficiency and quality are greatly improved, and the produced product has high Mooney viscosity and good quality. The technological method has the advantages of good technology, simple operation, and good technological stability, thus being suitable for factory automation production.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

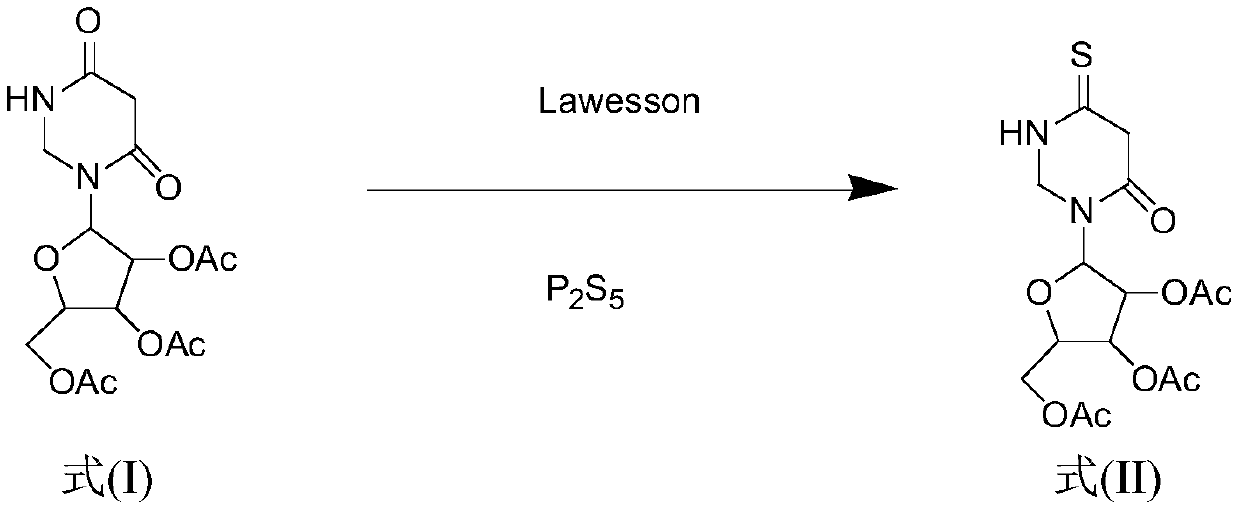

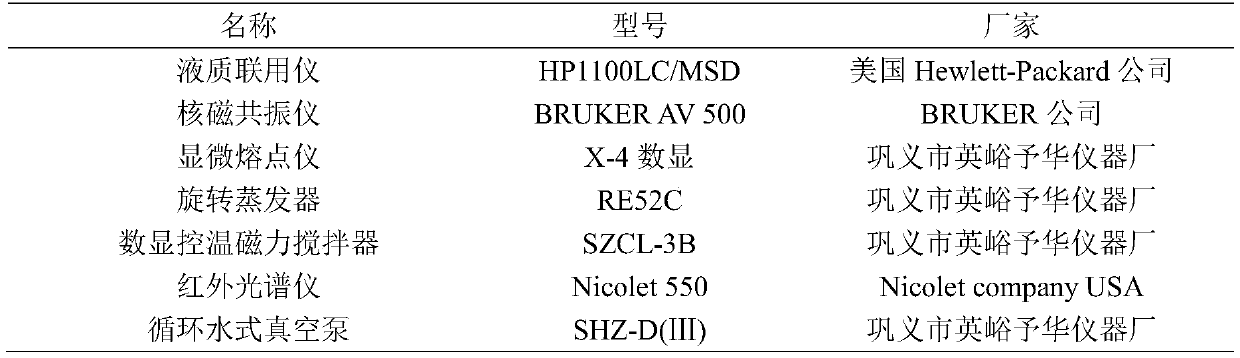

Method for synthesizing 4-S-2', 3', 5'-O-triacetyluridine

ActiveCN110204584AIncrease costShort reaction timeSugar derivativesSugar derivatives preparationChemical synthesisVulcanization

The invention belongs to the field of chemical synthesis, and discloses a method for synthesizing 4-S-2', 3', 5'-O-triacetyluridine. According to the synthesis method, a compound 2', 3', 5'-O-triacetyluridine is used as a raw material, phosphorus pentasulfide and a Lawesson's reagent are combined to be used as a vulcanizing agent, 1,4-dioxane is used as a solvent for chemical reaction, and finally4-S-2', 3', 5'-O-triacetyluridine is prepared. By the method for synthesizing 4-S-2', 3', 5'-O-triacetyluridine provided by the invention, the reaction time is shortened, and moreover, the vulcanization efficiency is greatly improved. According to the synthesis method provided by the invention, the cost is reduced, the reaction aftertreatment is simple and convenient, and meanwhile, the yield ofa reaction thionucleoside compound is improved.

Owner:DALIAN UNIV

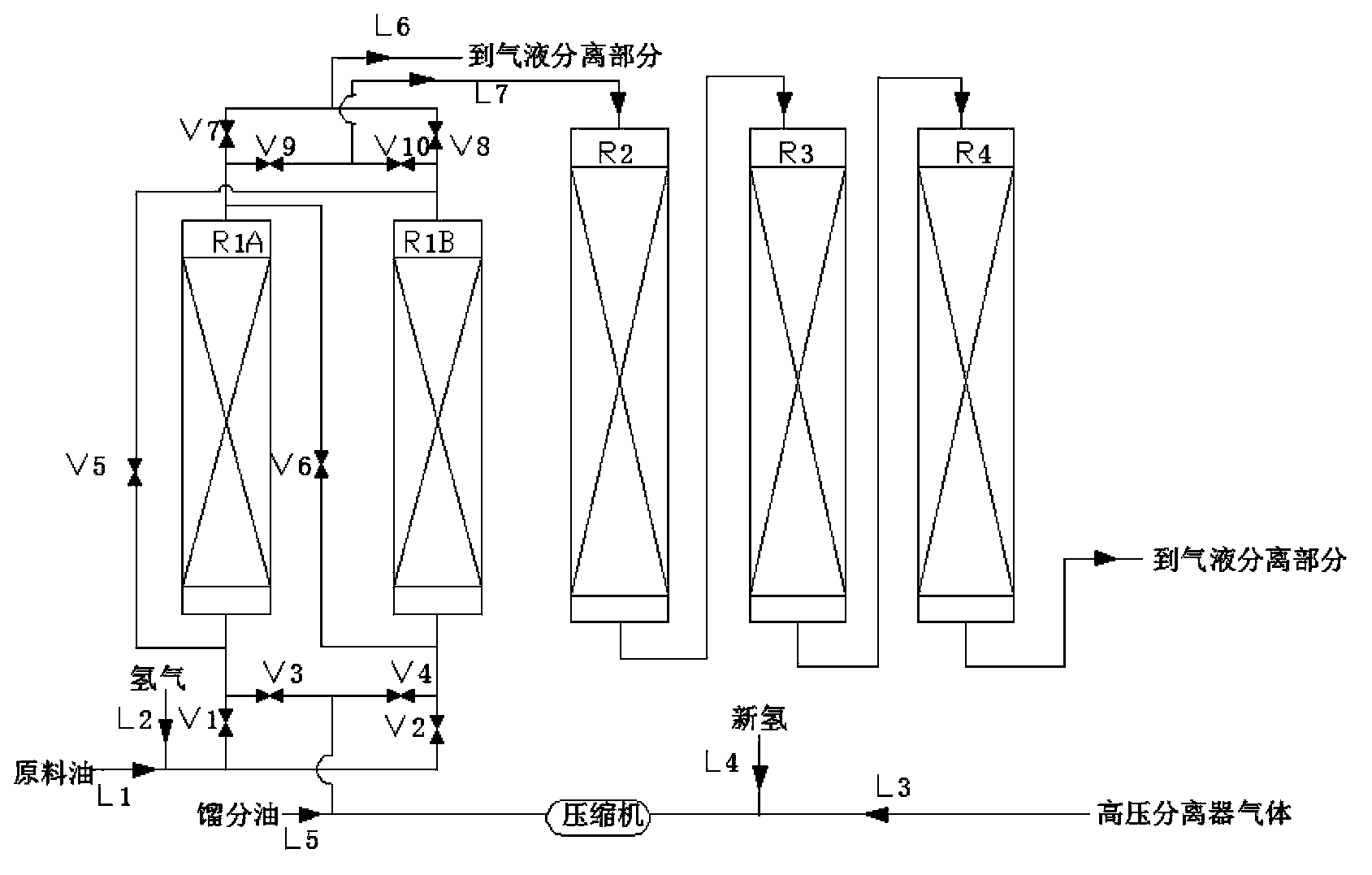

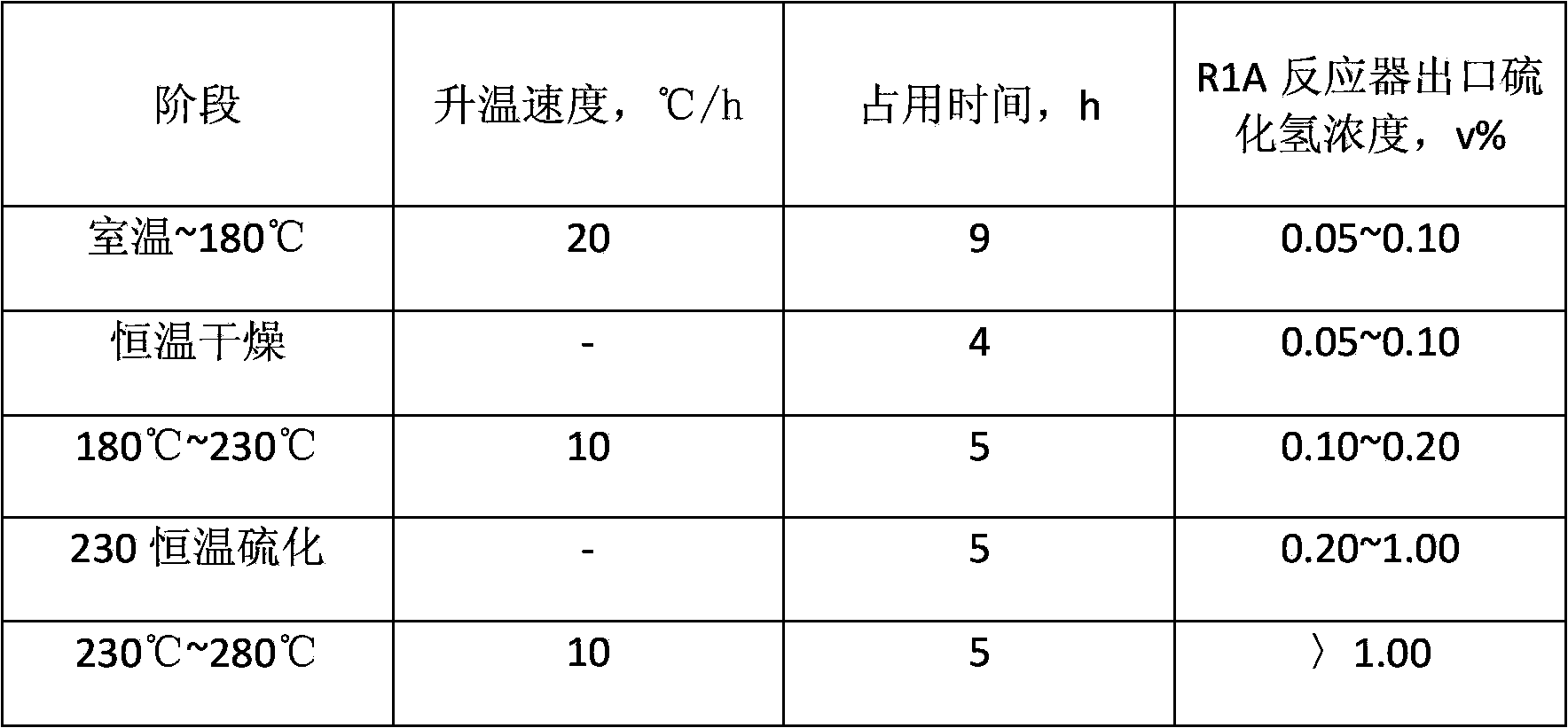

Application of hydrogenation catalyst prevulcanization method in residue hydrotreating switchable reactor system

InactiveCN103805232AImprove vulcanization efficiencyReduce vulcanization costHydrocarbon oil crackingHydrocarbon oils refiningPtru catalystFixed bed

The invention relates to an application of a hydrogenation catalyst prevulcanization method in a residue hydrotreating switchable reactor system. The application comprises the following steps: carrying out a residue hydrotreating reaction by a switchable up-flow reactor or a fixed bed reactor, prevulcanizing an online cut-in fresh catalyst, and vulcanizing the catalyst by means of H2S in a high pressure separator gas of hydrogenation equipment and sulfide in distillate with boiling range of 180-550 DEG C; adjusting concentration of hydrogen sulfide in the vulcanized gas by changing the proportion of the high pressure separator gas to the fresh hydrogen, wherein the volume ratio of the fresh hydrogen to the high pressure separator gas is 1:100-100:1, the time is 2-85 hours, the temperature is 100-450 DEG C, the volume ratio of hydrogen to oil is 50-2000, the hydrogen partial pressure is 0.1-24MPa and the liquid hourly space velocity is 0.1-5.0 / h<-1>; and loading oxides of W, Mo, Co and Ni or adding P, Si and F assistants, wherein the catalyst takes aluminum oxide as a carrier. The method is low in cost, high in efficiency and simple to operate.

Owner:PETROCHINA CO LTD

Dual damascene type pore-free tyre segmental mold, dual damascene type pore-free tyre segmental mold pattern block and manufacturing method

The invention provides a dual damascene type pore-free tyre segmental mold, a dual damascene type pore-free tyre segmental mold pattern block and a manufacturing method. The pattern block comprises a pattern block body and aluminum structures, wherein the pattern block body adopts a steel structure; the aluminum structures are inlaid in positions close to the inner peripheral surface of the pattern block body, which is used for forming a pattern surface; the pattern block body and the aluminum structures are assembled to form the dual damascene type pore-free tyre segmental mold pattern block; the pattern block body is provided with an exhaust passage communicated with the inner peripheral surface and the exterior of a segmental mold cavity. The pattern block provided by the invention is formed by compositing two materials, the intensity of steel is higher than that of aluminum, the thermal conductivity of aluminum is higher than that of steel, and the pattern block integrates the advantages of the two materials; all parts receiving extrusion force, friction force and the like during use are all made of steel, all pattern forming parts are made of aluminum, the vulcanization efficiency is high and the tyre surface quality is guaranteed.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Synthesis method for 4-S-5-Br-2',3',5'-O-triacetyluridine

ActiveCN110105416AShort reaction timeImprove vulcanization efficiencySugar derivativesSugar derivatives preparationChemical synthesisChemical reaction

The invention belongs to the field of chemical synthesis and discloses a synthesis method for 4-S-5-Br-2',3',5'-O-triacetyluridine. The synthesis method comprises the steps that a compound 5-Br-2',3',5'-O-triacetyluridine serves as a raw material, phosphorus pentasulfide and a Lawesson reagent are combined to serve as a vulcanization reagent, 1,4-dioxane serves as a solvent, and a chemical reaction is carried out to finally prepare the 4-S-5-Br-2',3',5'-O-triacetyluridine. The synthesis method for the 4-S-5-Br-2',3',5'-O-triacetyluridine has the advantages that the reaction time is shortened,and the vulcanization efficiency is greatly improved. The synthesis method reduces the cost, the treatment after the reaction is simple and convenient, and meanwhile the yield of the thionucleoside compound after the reaction is increased.

Owner:DALIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com