Semiconductive silicon rubber shielding material for radiation-resistant cable, and preparation method thereof

A technology of shielding material and silicone rubber, applied in the field of semi-conductive silicone rubber shielding material for radiation-resistant cables and its preparation, can solve the problems of intolerant radiation, shielding materials are not resistant to light, etc. Radiation performance, the effect of good production and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

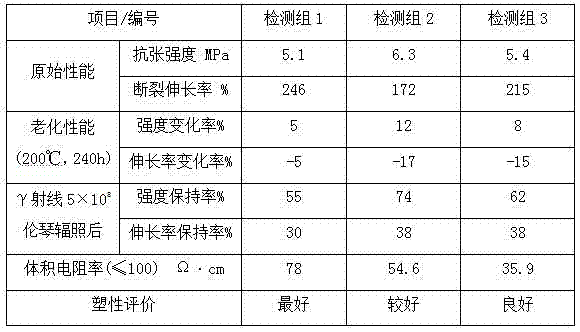

Embodiment 1

[0061] A radiation-resistant semi-conductive silicone rubber shielding material for cables, comprising the following raw material components in parts by weight:

[0062] Silicone rubber 100 parts

[0063] Conductive carbon black 20 parts

[0064] White carbon black 40 parts

[0065] Dicumyl peroxide 1.0 parts

[0066] Vulcanizing agent 2.0 parts

[0067] Diphenylsilanediol 5 parts

[0068] Stearic acid 1.0 parts

[0070] 2 parts of ferric oxide;

[0071] The silicone rubber is phenylene ether silicone rubber or phenylene silicone rubber; the co-curing agent is triallyl cyanurate.

Embodiment 2

[0073] A radiation-resistant semi-conductive silicone rubber shielding material for cables, comprising the following raw material components in parts by weight:

[0074] Silicone rubber 100 parts

[0075] Conductive carbon black 40 parts

[0076] White carbon black 50 parts

[0077] Dicumyl peroxide 2.5 parts

[0078] Vulcanizing agent 3.0 parts

[0079] Diphenylsilanediol 15 parts

[0080] Stearic acid 2.0 parts

[0081] Zinc oxide 6 parts

[0082] 5 parts of ferric oxide;

[0083] The silicone rubber is phenylene ether silicone rubber or phenylene silicone rubber; the co-curing agent is triallyl cyanurate.

Embodiment 3

[0085] A radiation-resistant semi-conductive silicone rubber shielding material for cables, comprising the following raw material components in parts by weight:

[0086] Silicone rubber 100 parts

[0087] Conductive carbon black 30 parts

[0088] White carbon black 45 parts

[0089] Dicumyl peroxide 1.75 parts

[0090] Vulcanizing agent 2.5 parts

[0091] Diphenylsilanediol 10 parts

[0092] 1.5 parts of stearic acid

[0093] Zinc oxide 5 parts

[0094] 3.5 parts of ferric oxide;

[0095] The silicone rubber is phenylene ether silicone rubber or phenylene silicone rubber; the co-curing agent is triallyl cyanurate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com