High refractive index titanium hybrid silicon resin and preparation method thereof

A technology of titanium hybrid silicon and high refractive index, which is applied in the field of new high refractive index titanium hybrid silicone resin and its preparation, can solve problems such as high shrinkage rate and defects in cured products, and achieve high reaction temperature and high refractive index. , the effect of increasing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

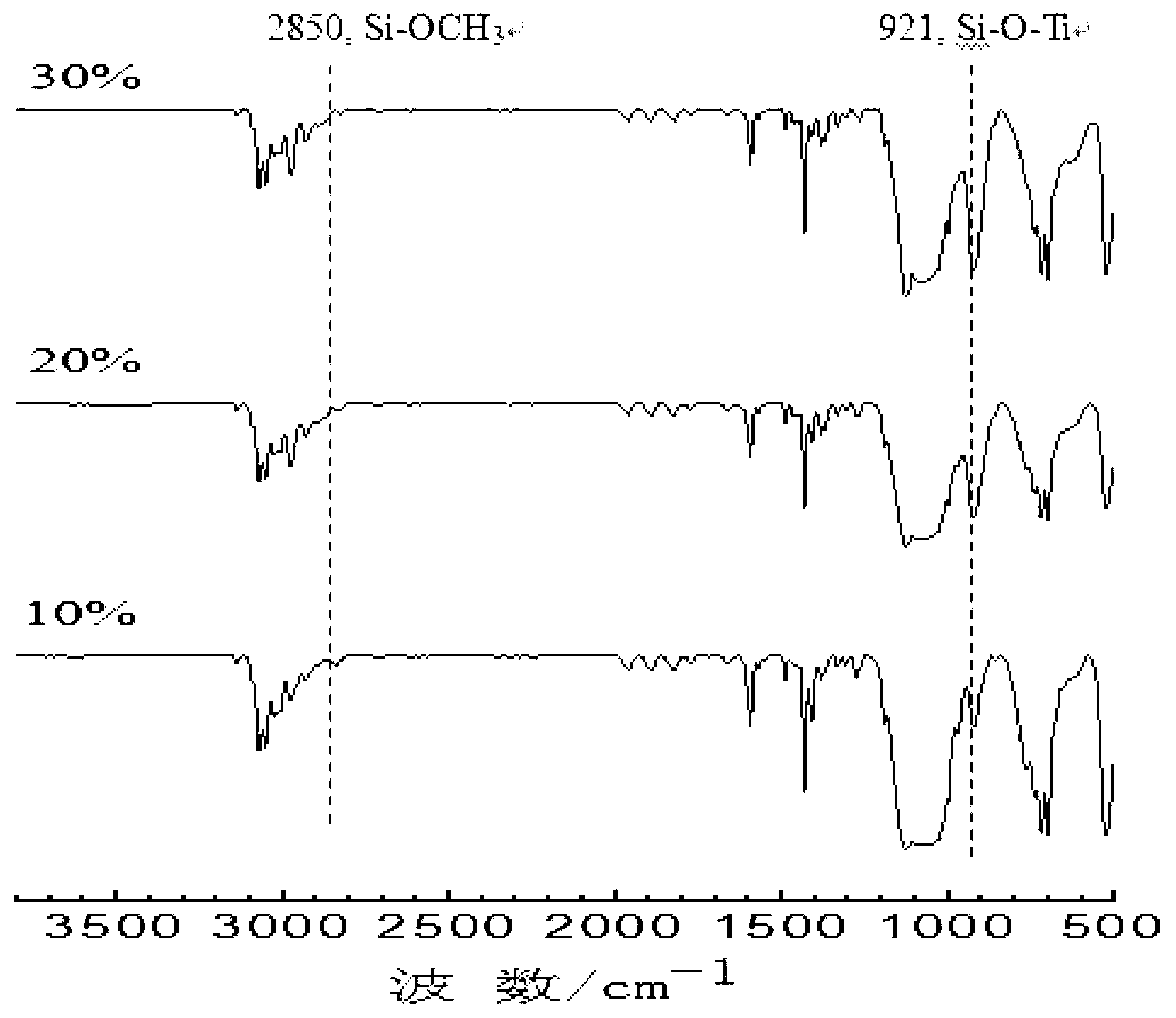

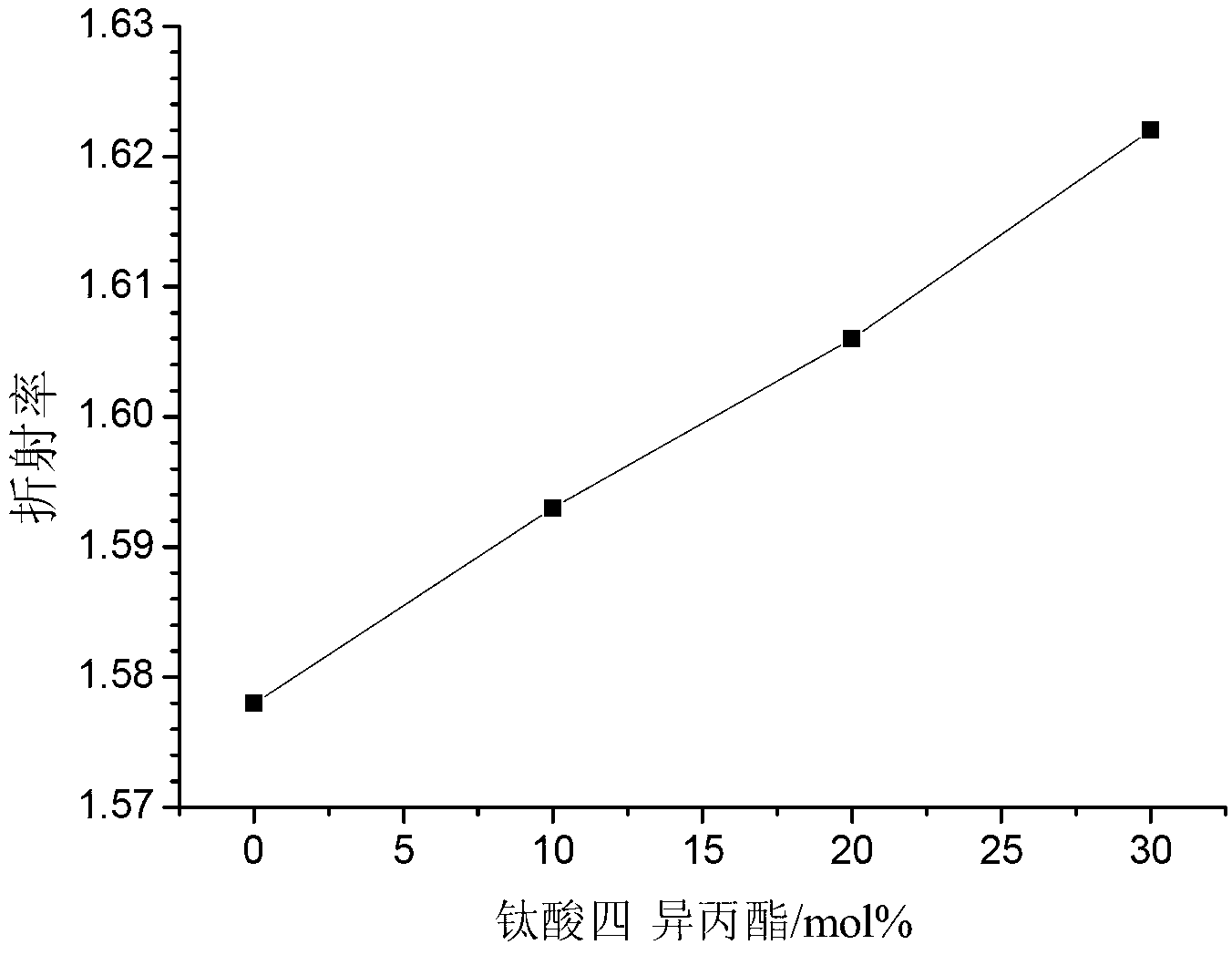

[0024] Put a 50mL three-necked bottle with a condensing device into an 80°C oil bath, then add 2.965g of vinyltrimethoxysilane, 2.5g of xylene, and 23mg of barium hydroxide monohydrate (Ba(OH) 2 ·H 2 O) and 1.895g tetraisopropyl titanate, after stirring evenly, add diphenylsilanediol in batches (approximately every 5-10min, a total of 8.652g), after all diphenylsilanediol is added , the reaction continued for 6h, and the whole reaction was carried out under nitrogen atmosphere. In the later stage of the reaction, use a water separator to separate out the small molecule alcohol compounds produced in the system. After the reaction, the hybrid resin is cooled to room temperature, and the resin is filtered with a micron-scale oily filter membrane to remove solid impurities and residual catalysts in the system. Due to the high viscosity of the resin, it needs to be diluted with a solvent (acetone, chloroform or toluene, etc.) . Finally, at 85°C, the vacuum degree is -0.09Mpa~-0....

Embodiment 2

[0029] Put a 50mL three-necked bottle with a condensing device into an oil bath at 80°C, then add 1.4825g of vinyltrimethoxysilane, 4g of xylene, and 18mg of barium hydroxide monohydrate (Ba(OH) 2 ·H 2 O) and 2.842g tetraisopropyl titanate, after stirring evenly, add diphenylsilanediol in batches (approximately every 5-10min, a total of 6.489g), after all diphenylsilanediol is added , the reaction was continued for 8h, and the whole reaction was carried out in a nitrogen atmosphere. In the later stage of the reaction, use a water separator to separate out the small molecule alcohol compounds produced in the system. After the reaction, the hybrid resin is cooled to room temperature, and the resin is filtered with a micron-scale oily filter membrane to remove solid impurities and residual catalysts in the system. Due to the high viscosity of the resin, it needs to be diluted with a solvent (acetone, chloroform or toluene, etc.) . Finally, at 85°C, the vacuum degree is -0.09Mp...

Embodiment 3

[0031] Put a 50mL three-neck bottle with a condensing device into an 80°C oil bath, then add 1.1117g of vinyltrimethoxysilane, 4g of xylene, and 26mg of barium hydroxide monohydrate (Ba(OH) 2 ·H 2 O) and 6.395g tetraisopropyl titanate, after stirring evenly, add diphenylsilanediol in batches (approximately every 5-10min, a total of 9.7338g), after all diphenylsilanediol is added , the reaction continued for 10 h, and the whole reaction was carried out in a nitrogen atmosphere. In the later stage of the reaction, use a water separator to separate out the small molecule alcohol compounds produced in the system. After the reaction, the hybrid resin is cooled to room temperature, and the resin is filtered with a micron-scale oily filter membrane to remove solid impurities and residual catalysts in the system. Due to the high viscosity of the resin, it needs to be diluted with a solvent (acetone, chloroform or toluene, etc.) . Finally, at 85°C, the vacuum degree is -0.09Mpa~-0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com