Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "No gel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

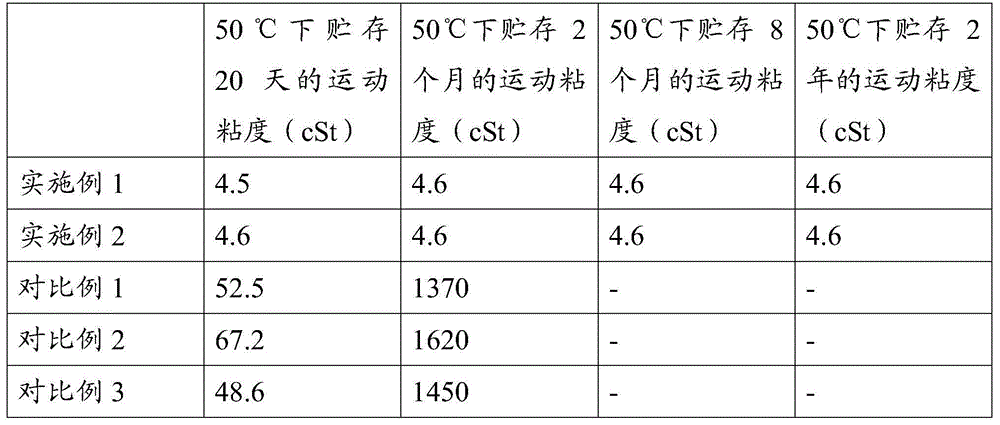

Polyvinyl alcohol, and preparation method and application thereof

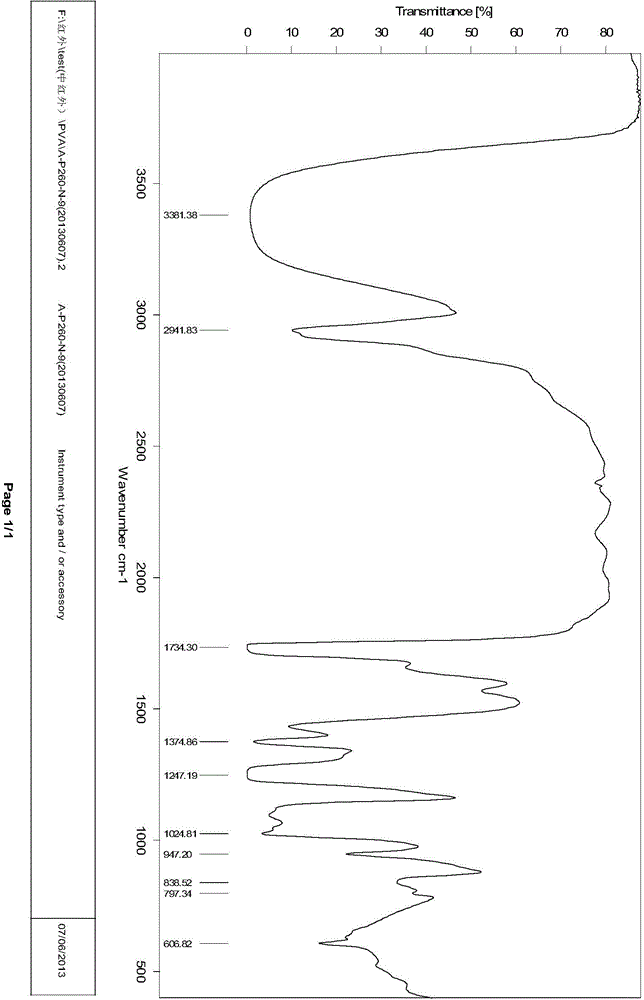

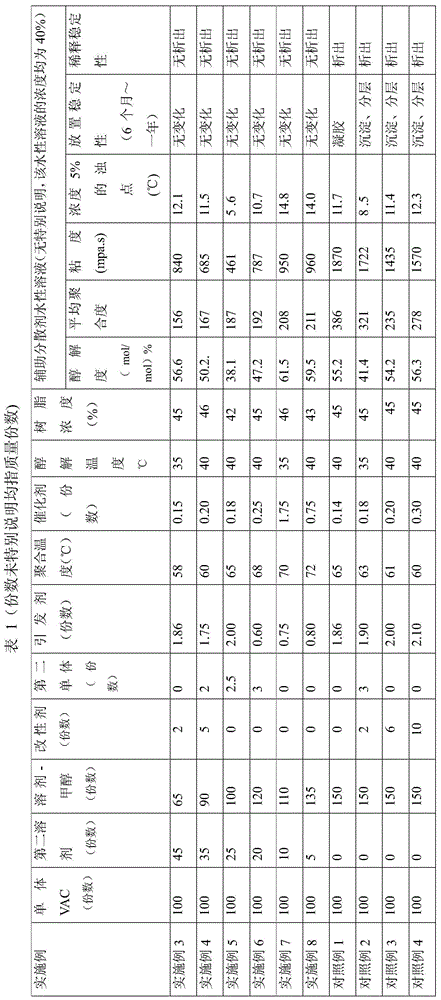

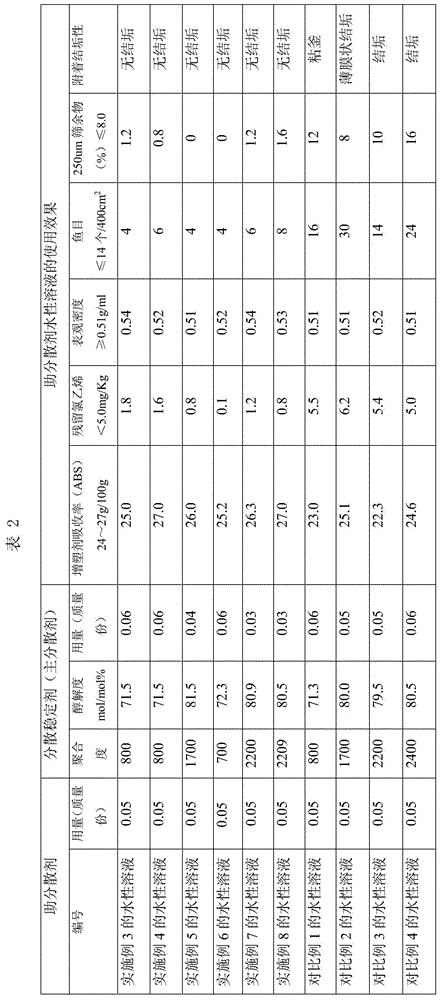

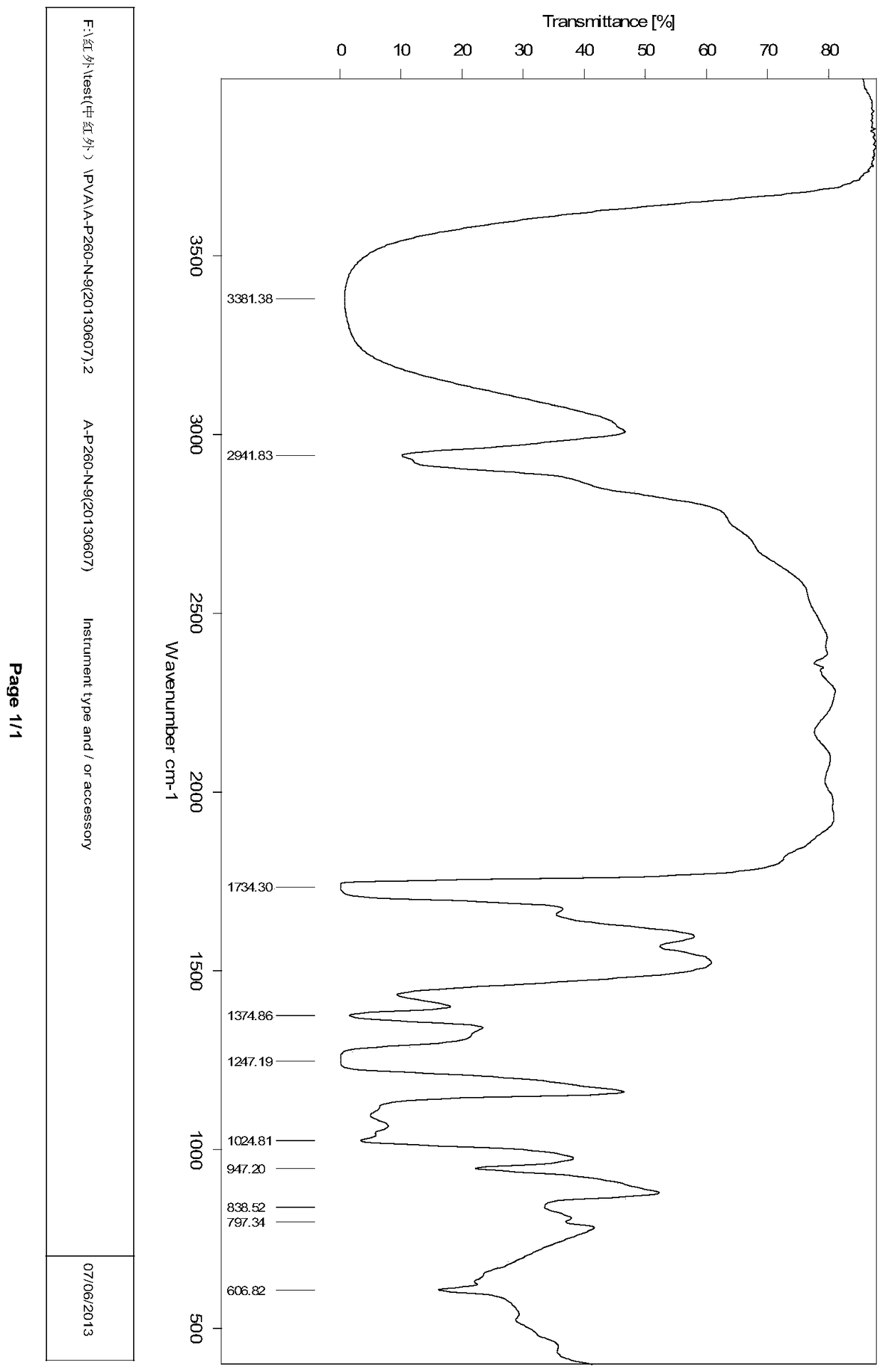

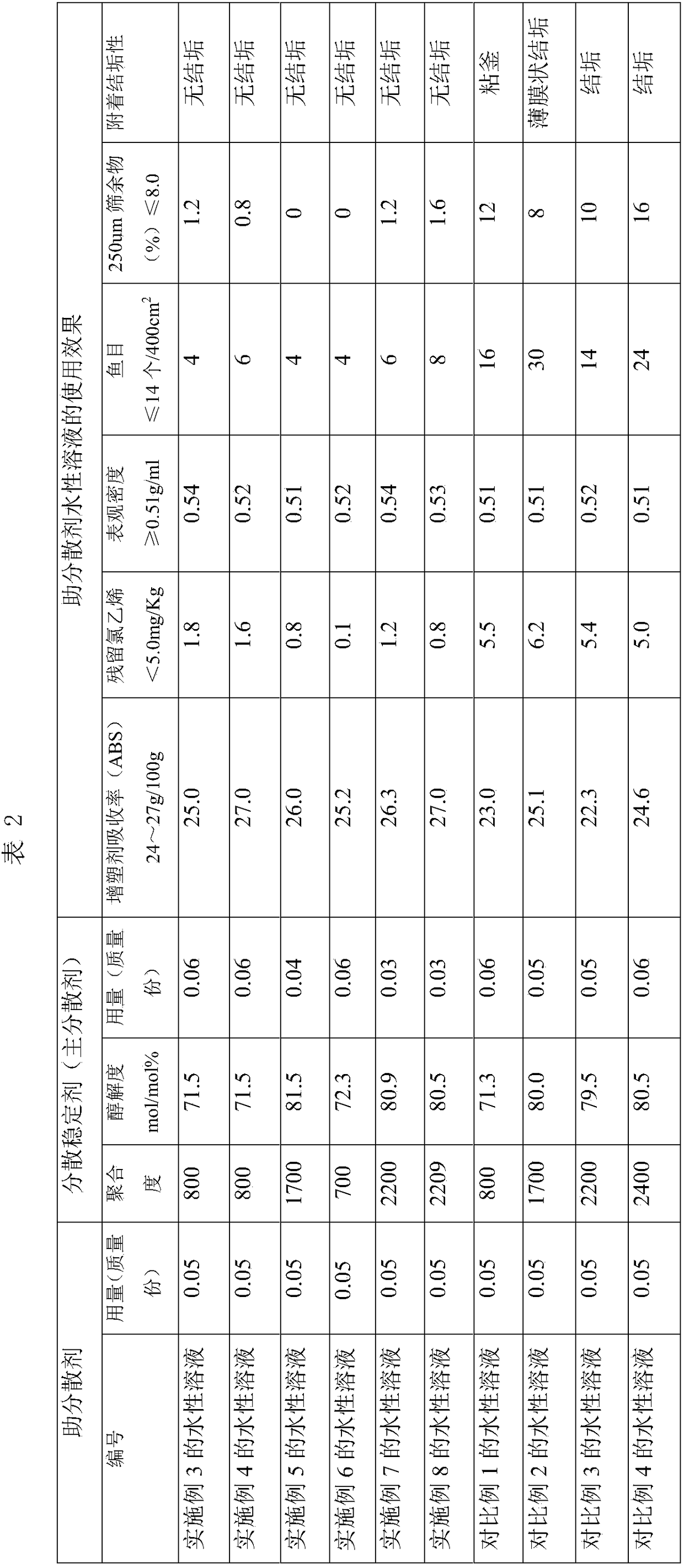

The invention provides polyvinyl alcohol, which is characterized by having the average degree of polymerization in a range of 50-500, the alcoholysis degree in a range of 30-65 mol%, and the viscosity no more than 1500 mPa*s. Polyvinyl alcohol is prepared into an aqueous solution, which is taken as an auxiliary dispersant for suspension polymerization of vinyl polymers. The cloud point of an aqueous solution, the concentration of which is 5 wt%, (that is, a polyvinyl alcohol aqueous solution of 5 wt%), is no less than 1 DEG C and less than 15 DEG C. The viscosity measured at 25 DEG C of an aqueous solution, the concentration of which is 40 wt%, is no more than 1500 mpa*s. Gel and layering don't appear in an aqueous solution, the concentration of which is in a range of 30wt%-50wt%, in at least one year, so that the aqueous solution is extremely excellent in stability.

Owner:CHINA PETROCHEMICAL CORP +1

Moisturecuring polyurethane hot-melt adhesive suitable for adhering narrow frame of mobile phone, and preparation method of moisturecuring polyurethane hot-melt adhesive

InactiveCN106753179AModerate viscosityGood compatibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a moisturecuring polyurethane hot-melt adhesive suitable for adhering a narrow frame of a mobile phone, and a preparation method of the polyurethane hot-melt adhesive. The polyurethane hot-melt adhesive is prepared by enabling polyether polyol, polyester polyol and diisocyanate to react, and adding acrylic resin, an antioxidant, tackifying resin, phosphoric acid, a catalyst and a silane coupling agent at the same time to obtain the single-component moisturecuring polyurethane hot-melt adhesive. The moisturecuring polyurethane hot-melt adhesive prepared by using the method disclosed by the invention has adjustable opening time, can be cured fast, and is free of gel and high in mobility during adhesive applying. The moisturecuring polyurethane hot-melt adhesive can be applied smoothly by using a 23# needle under a 110 DEG C heating condition, and is specially suitable for structure assembly in a production line of the narrow frame of the mobile phone.

Owner:NANTONG GAOMENG NEW MATERIAL

Epoxy oligomer chain extender and preparation method thereof

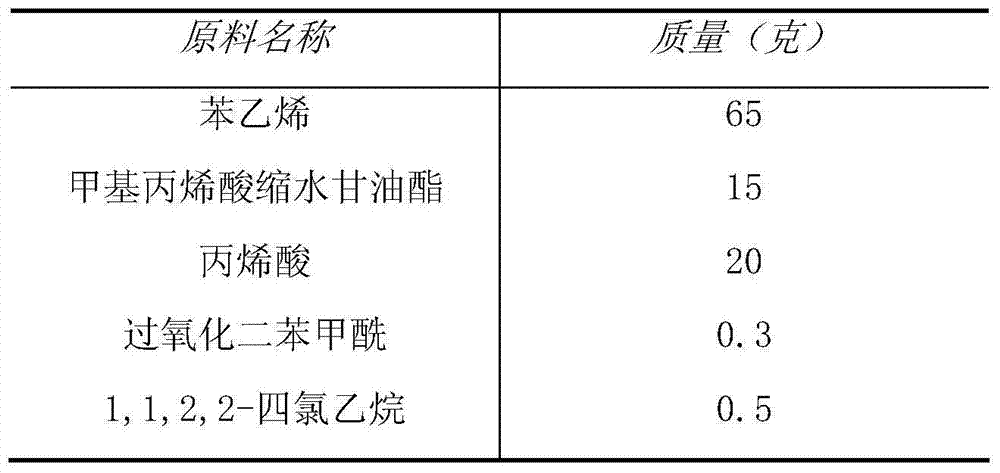

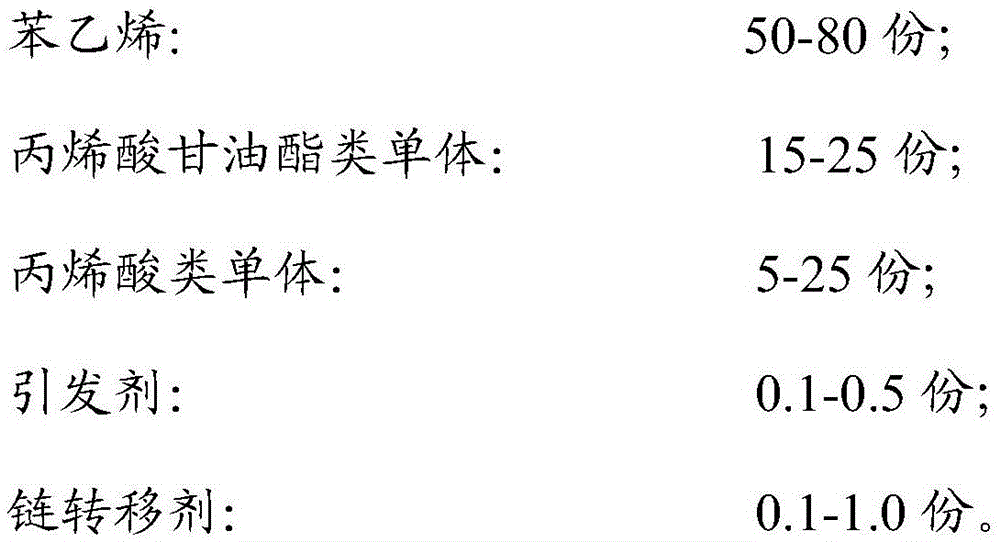

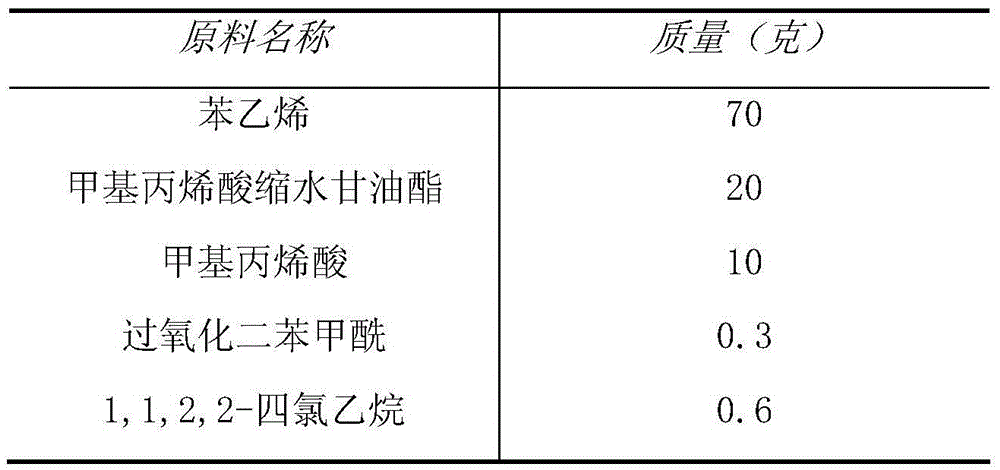

The invention provides an epoxy oligomer chain extender and a preparation method thereof. The epoxy oligomer chain extender can significantly improve the intrinsic viscosity and molecular weight of polyester and nylon type polymer materials and reduce the content of terminal carboxyl groups. The chain extender is prepared from the following components in parts by weight: 50-80 parts of a styrene monomer, 15-25 parts of an acrylic acid glyceride monomer, 5-25 parts of an acrylic acid monomer, 0.1-0.5 part of an initiating agent and 0.1-1.0 part of a chain transfer agent. The preparation method of the chain extender comprises the steps of selecting the reactive monomers and auxiliary agents, adding the monomers and auxiliary agents into a reaction kettle in sequence, and performing polymerization reaction at a certain stirring speed at 120-150 DEG C; drying the reactant to obtain a finished product which is a multi-monomer copolymerized oligomer with low molecular weight. Compared with the existing conventional micro-molecular chain extender, the epoxy oligomer chain extender provided by the invention has the characteristics of simple preparation, wide application range, safety, reliability, high chain extension efficiency, good water resistance, no generation of gel and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

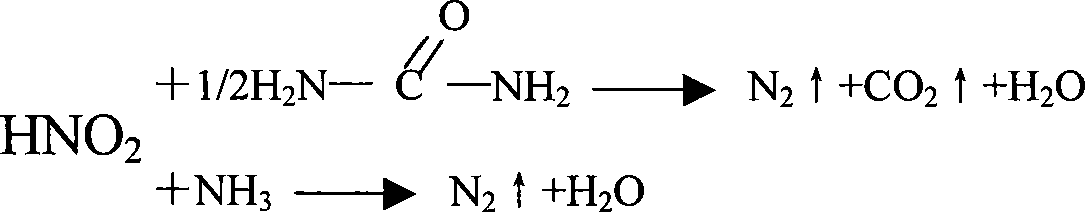

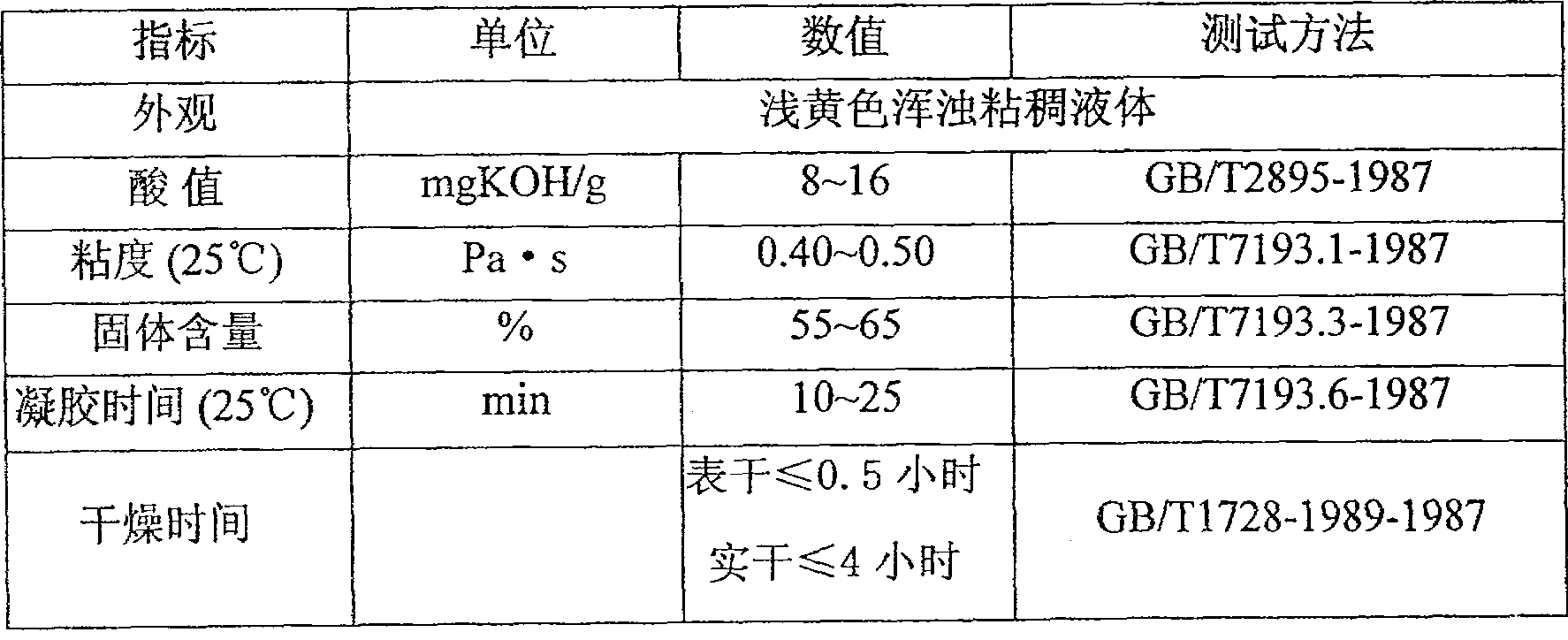

Technique for synthesizing air-dry type oxirene ester resin

This invention relates to a process for synthesizing air-drying epoxy vinyl ester resin. The process comprises: reacting bisphenol A type epoxy resins with low and high epoxy equivalent, and organic unsaturated monocarboxylic acid at 120-160 deg.C in the presence of catalyst and polymerization inhibitor, and then diluting with crosslinkable monomer. The resin has good air-drying performance, with surface drying time less than or equal to 0.5 h, and inner drying time less than or equal to 4 h. Besides, the resin has appropriate viscosity, good wettability with glass fibers and glass mats, good physical and mechanical performance, and good chemical corrosion resistance, and is suitable for various molding processes of fiber reinforced plastics such as manual pasting, coiling, drawing and spraying. The method has such advantages as simple process, low energy consumption, and stable product quality.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

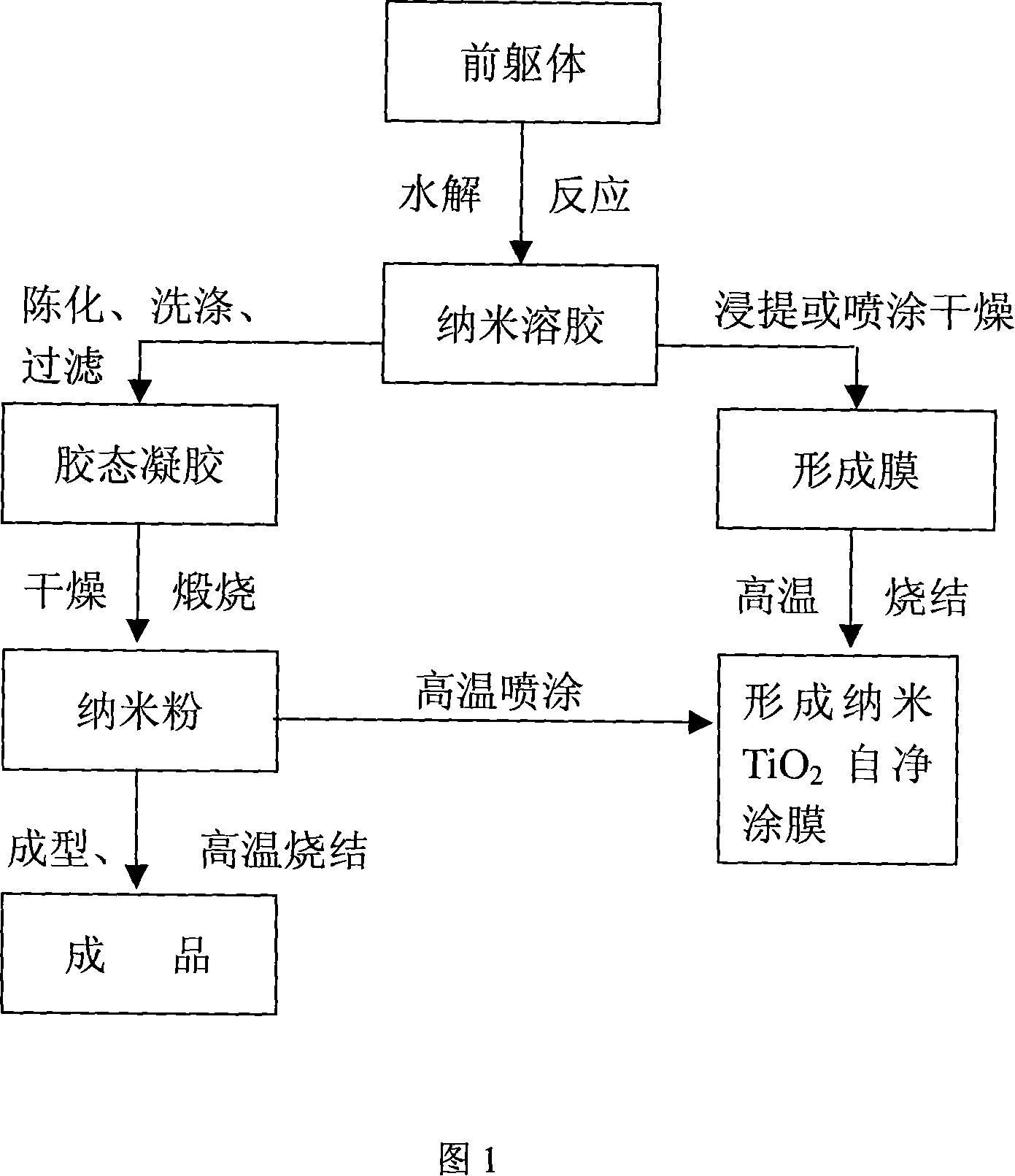

Intelligent film coating material and method for making same

The present invention relates to an intelligent paint film material and the preparation method thereof, which mainly realizes sol one-step method to prepare the sol pre-polymerization product with multi-component and multifunctional structure, which is solidified at room temperature and then forms the nanostructure intelligent paint film material. The preparation method is that: metal alkoxide and transition metal coordinated complex are refluxed, hydrolyzed and co-condensed in anhydrous alcohol solvent; or the metal alkoxide and transition metal coordinated complex are hydrolyzed and co-condensed with inorganic metallic salt; or the above composition is refluxed, hydrolyzed and co-condensed with functional sol prepared in advance under the above conditions, producing the sol which is added with stabilizer to prepare a standby product. The product has the functions of photocatalysis intelligent perceiving, self cleaning, air purifying, heat shielding and natural temperature adjusting functions, which can be widely applied to construction industry after the product is solidified and forms film at normal temperature.

Owner:陈志君

Polylactic acid material with high melt strength and preparation method thereof

The invention discloses a polylactic acid material with high melt strength and a preparation method thereof. The polylactic acid material comprises the following raw materials in percentage by mass: 95.7%-99.7% of polylactic acid(PLA), 0.1%-5% of hexamethylene diacrylate(HDDA), 0.01%-0. 4% of dicumyl peroxide(DCP) and 0-2% of processing aids, wherein with DCP as an initiator, PLA and HDDA are subjected to a fusion grafting reaction through a twin-screw extruder to obtain the polylactic acid material. The HDDA-g-PLA material has high melt strength and improves the crystallization ability of PLA. The process is very simple and favorable for large-scale production, the grafted polylactic acid material can significantly improve the melt strength, has no gel or crosslinking phenomenon, has highproduction efficiency and stable quality, and can be used for secondary processing.

Owner:XIANGTAN UNIV

Preparation process of polymer modification silicon sol

ActiveCN104150491AReduce production processIncrease mass concentrationOther chemical processesSilicon compoundsPolymer modifiedC constant

The invention discloses a preparation process of polymer modification silicon sol. The preparation process is characterized by comprising the following steps: (1) placing 2,400 mass parts of silicon sol into a reaction container, adding 240 mass parts of deionized water into the reaction container, heating until the temperature rises up to 80 DEG C, and keeping the temperature of 80 DEG C constant until the reaction is completed to form a uniform stable system; (2) keeping the temperature of the system in the reaction container to be 80 DEG C, slowly adding 72 mass parts of polymer modifier which needs to be completely added within 30 min into the reaction container under a stirring state, continuously stirring the reaction system for 5 h at a constant temperature until the reaction is completed to obtain the polymer modification silicon sol, and modifying the pH value of the reaction system to be in a range of 10-11 by using a pH modifier at time intervals of 30 min within 5 h. The process is simple and efficient, and the prepared silicon sol is high in polishing speed, good in hardness, excellent in thermal stability under a long-time storage state, and high in repeated utilization rate.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Graphene slurry for cationic waterborne polyurethane coating, and preparation method and application thereof

ActiveCN107365514ALong storage timeIncrease crosslink densityAnti-corrosive paintsPolyurea/polyurethane coatingsElastic modulusOxide

The invention discloses a graphene slurry for a cationic waterborne polyurethane coating, and a preparation method and application thereof. The graphene slurry for the cationic waterborne polyurethane coating is an aqueous dispersion of modified graphene prepared by modifying graphene oxide with carbodiimide to obtain the modified graphene and then dispersing the modified graphene in water, wherein in the aqueous dispersion of the modified graphene, a ratio of the modified graphene to water is 2-20 mg: 1 ml in terms of the dry weight of the modified graphene. The graphene slurry can be cooperated with cationic waterborne polyurethane resin, so the advantage of long-term stable dispersion is obtained, and the graphene slurry is friendly to environment, long in storage time and free of precipitation, flocculation and gelation after storage at room temperature for one year or more. A coating prepared from the graphene slurry has elastic modulus of 2.2-2.31 GPa and neutral salt spray time of 72 to 120 h.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Fluorine containing polymer concentrated dispersion liquid and method for preparing fluorine containing polymer from fluorine containing polymer concentrated dispersion liquid

The invention discloses fluorine containing polymer concentrated dispersion liquid and a method for preparing a fluorine containing polymer from the fluorine containing polymer concentrated dispersion liquid. A surfactant with the molecular structural formula being CF3{(CF2)nC(CF3)2CH2}mCOOH is used as a polymerization dispersant to prepare the fluorine containing polymer, wherein n is an integer ranging from 0 to 4, and m is an integer ranging from 1 to 2. The fluorine containing polymer concentrated dispersion liquid can be used for the process of producing the fluorine polymer through a water-phase dispersion polymerization process, and the uncontrollable molecular weight caused by a surfactant chain transfer reaction is avoided when the fluorine containing polymer concentrated dispersion liquid is especially used for TFE, TFE / HFP, TFE / PPVE and TFE / ethylene polymerization reactions; the surfactant can be used as a substitute for PFOA or one of substitute components and used for water-phase dispersion polymerization of the fluorine containing polymer, and no gel is formed by polymerized emulsion.

Owner:ZHEJIANG XINGTENG CHEM

Graphene slurry for anionic aqueous polyurethane coatings, preparation method of graphene slurry and application

ActiveCN107418256ASolve reunionSolve technical problems such as cascadingAnti-corrosive paintsPolyurea/polyurethane coatingsFlocculationDispersion stability

The invention discloses graphene slurry for anionic aqueous polyurethane coatings, a preparation method of the graphene slurry and an application. The graphene slurry for the aqueous polyurethane coatings is modified graphene aqueous dispersion, oxidized graphene is modified by carbodiimide to obtain modified graphene, and the modified graphene is dispersed into water to obtain the modified graphene aqueous dispersion. In the modified graphene aqueous dispersion, according to the dry weight of the modified graphene, the ratio of the modified graphene to water is 2-20mg: 1ml. The graphene slurry can be matched with anionic aqueous polyurethane resin to achieve the advantage of long-term dispersion stability, is environmentally friendly and long in preservation time, and is capable of being preserved for at least one year at room temperature without deposition, flocculation or gelling. After use, the elastic modulus of the finally obtained coatings can reach 2.23-2.34GPa, and neutral salt spray time can reach 60-120 hours.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Low temperature resistant protective film agent for fruit tree and preparation method thereof

InactiveCN104396983AAggregation is stableImprove the ability to deal with low temperature and freezing damageBiocidePlant growth regulatorsEnvironmental resistanceFunctional monomer

A low temperature resistant protective film agent for fruit trees and a preparation method thereof. The agent is mainly prepared from components of vinyl acetate, a soft monomer of butyl acrylate monomer, a hard monomer of methyl methacrylate, a functional monomer of acrylic acid and an emulsion synergistic agent into a copolymer emulsion. The copolymer emulsion is then supplemented with functional materials including an inorganic dispersant, an organic dispersant, a wetting agent, a film forming agent, a surface active agent, an antifreeze, a heat resistance material, a fungicide and colloidal. The invention has the advantages of simple preparation process, low cost, stable polymerization of copolymer emulsion, no gel, minimum film forming temperature of 0 DEG C, good film forming effect, solid content of 44.5% and water absorption of 19.66%, can significantly improve the resistance of fruit trees to low temperature cold damage, prevent sunburn and pumping damage, delay the germination period, and is safe and environment-friendly.

Owner:SHENYANG AGRI UNIV

Ternary iron-based catalyst and application thereof to catalyzing epoxy chloropropane and butadiene to prepare novel polymer through copolymerization

The invention relates to the field of polymer synthesis, and in particular discloses a ternary iron-based catalyst and application thereof to catalyzing epoxy chloropropane and butadiene to prepare a novel polymer through copolymerization. The application to preparing the novel polymer is characterized by comprising the following steps: enabling the ternary iron-based catalyst to react in a hydrocarbon solvent, wherein epoxy chloropropane and butadiene are adopted as reaction substrates; performing a reaction for 1-24 hours at 0-100 DEG C, terminating the reaction after polymerization is completed, washing for multiple times with ethanol, adding an anti-aging agent, and drying to obtain a target product. As the ternary iron-based catalyst (an iron compound, an organic aluminum compound and an electron donor) is adopted to catalyze copolymerization of epoxy chloropropane and butadiene, the molecular weight of an obtained polymer is 10,000 or above, the polymer is light in color, the PDI is about 1.0-2.0, and the reaction is stable and easy to control.

Owner:SHANDONG YUHUANG CHEM CO LTD

Technique for synthesizing air-dry type oxirene ester resin

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Preparation method for acrylate-modified epoxy resin cathode electrophoresis emulsion

ActiveCN108912931AReduce the chance of aggregationImprove anti-corrosion performancePaints for electrolytic applicationsOrganic acidEmulsion

The invention discloses a preparation method for an acrylate-modified epoxy resin cathode electrophoresis emulsion. The method adopts a monoprotic organic acid containing a double bond and a biproticorganic acid containing a double bond or / and an acid anhydride to react with epoxy resin, double bonds are introduced into a main chain of the epoxy resin, acrylic resin is grafted into the epoxy resin by utilizing copolymerization of the double bonds and an acrylate monomer, more acrylic resin can be introduced onto the main chain of the epoxy resin, adjustment and control of an introduction amount of the acrylate monomer are achieved through control of the content of the double bonds, and a molecular weight of the main epoxy resin is adjusted through a ratio of carboxyl to epoxy groups; themain body of the prepared product is epoxy resin, so that good anticorrosive performance of a paint film is guaranteed; and when the epoxy resin is aminated, two different organic amines are added step by step for a reaction, so that the reaction process is milder. According to the method disclosed by the invention, the acrylate-modified epoxy resin emulsion prepared by the method has good performance of a paint film and good ultraviolet and salt spray resistance, and can be used for workpieces under conditions of exposure under the sun.

Owner:吴让君

A kind of filling method of one-component sealant

ActiveCN110466813BQuality is not affectedGood filling effectPackaging under vacuum/special atmosphereLiquid materialPolymer scienceNitrogen gas

The invention provides a filling method of a single-component sealant. The filling method comprises the following steps that a) the to-be-filled single-component sealant is sealed and vacuumized, andthen nitrogen is introduced to make the pressure of the to-be-filled single-component sealant and the pressure of the outside balanced; and b) the balance of the pressure of the to-be-filled single-component sealant and the pressure of the outside is kept, a pressure plate presses downwards, and the filled single-component sealant is obtained after discharging. Compared with the prior art, the filling method adopts specific process steps, nitrogen protection is achieved, it is ensured that the whole filling process is stable under specific conditions, and it is ensured that the quality of thesingle-component sealant is not affected while air is prevented from entering the sealant. Experimental results show that the filled single-component sealant obtained through the filling method is good in filling effect and free of gel.

Owner:HANGZHOU ZHIJIANG NEW MATERIAL CO LTD +1

A low temperature resistant protective film agent for fruit trees and its preparation method

InactiveCN104396983BAggregation is stableImprove the ability to deal with low temperature and freezing damageBiocidePlant growth regulatorsFunctional monomerCarvacryl acetate

A low temperature resistant protective film agent for fruit trees and a preparation method thereof. The agent is mainly prepared from components of vinyl acetate, a soft monomer of butyl acrylate monomer, a hard monomer of methyl methacrylate, a functional monomer of acrylic acid and an emulsion synergistic agent into a copolymer emulsion. The copolymer emulsion is then supplemented with functional materials including an inorganic dispersant, an organic dispersant, a wetting agent, a film forming agent, a surface active agent, an antifreeze, a heat resistance material, a fungicide and colloidal. The invention has the advantages of simple preparation process, low cost, stable polymerization of copolymer emulsion, no gel, minimum film forming temperature of 0 DEG C, good film forming effect, solid content of 44.5% and water absorption of 19.66%, can significantly improve the resistance of fruit trees to low temperature cold damage, prevent sunburn and pumping damage, delay the germination period, and is safe and environment-friendly.

Owner:SHENYANG AGRI UNIV

A kind of graphene slurry for cationic waterborne polyurethane coating and its preparation method and application

ActiveCN107365514BSolve reunionGood dispersionAnti-corrosive paintsPolyurea/polyurethane coatingsFlocculationRoom temperature

The invention discloses a graphene slurry for a cationic waterborne polyurethane coating, and a preparation method and application thereof. The graphene slurry for the cationic waterborne polyurethane coating is an aqueous dispersion of modified graphene prepared by modifying graphene oxide with carbodiimide to obtain the modified graphene and then dispersing the modified graphene in water, wherein in the aqueous dispersion of the modified graphene, a ratio of the modified graphene to water is 2-20 mg: 1 ml in terms of the dry weight of the modified graphene. The graphene slurry can be cooperated with cationic waterborne polyurethane resin, so the advantage of long-term stable dispersion is obtained, and the graphene slurry is friendly to environment, long in storage time and free of precipitation, flocculation and gelation after storage at room temperature for one year or more. A coating prepared from the graphene slurry has elastic modulus of 2.2-2.31 GPa and neutral salt spray time of 72 to 120 h.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

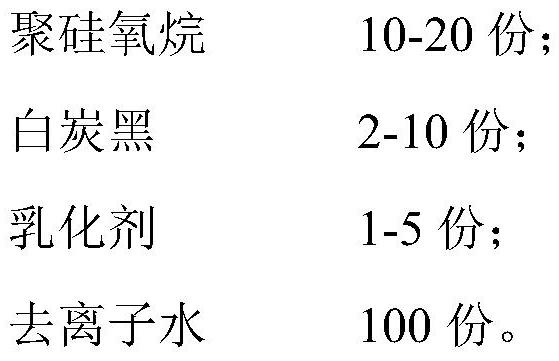

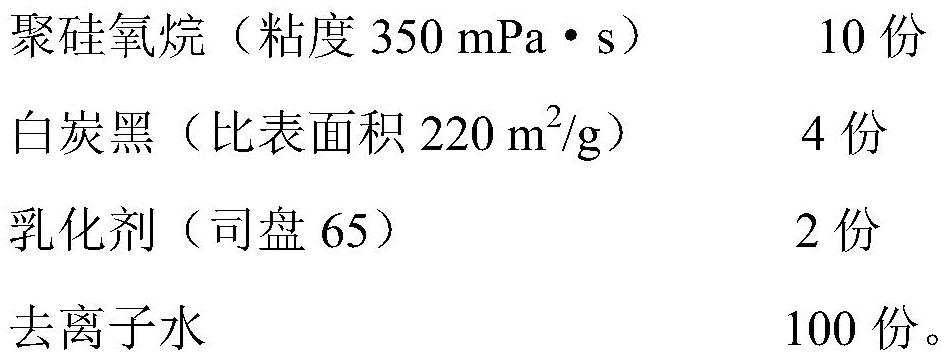

A kind of defoamer for carboxyl nitrile latex and preparation method thereof

The invention belongs to the technical field of industrial defoaming agents, and in particular relates to a defoaming agent for carboxylated nitrile butadiene latex and a preparation method thereof. The antifoaming agent for carboxylated nitrile latex is prepared from the following raw materials in parts by weight: 10-20 parts of polysiloxane; 2-10 parts of white carbon black; 1-5 parts of emulsifier; 100 parts of deionized water The preparation method is as follows: adding polysiloxane and white carbon black to the reaction kettle in turn, heating up to 110-140 ℃, reacting for 3-6 hours, cooling to 60-90 ℃, adding emulsifier and deionized water, The reaction was carried out for 20-50 minutes, and then lowered to room temperature to obtain the product. The defoaming agent of the present invention is a polysiloxane emulsion type defoaming agent, which is mainly used for eliminating foam in the production process of carboxylated nitrile butadiene latex, and is especially suitable for foaming in the process of removing monomer after polymerization. It has the advantages of fast defoaming and excellent anti-foaming, and does not cause the advantages of latex gel; its preparation method is scientific, reasonable and simple.

Owner:SHANDONG UNIV OF TECH

A kind of epoxy oligomer chain extender and preparation method thereof

The invention provides an epoxy oligomer chain extender and a preparation method thereof. The epoxy oligomer chain extender can significantly improve the intrinsic viscosity and molecular weight of polyester and nylon type polymer materials and reduce the content of terminal carboxyl groups. The chain extender is prepared from the following components in parts by weight: 50-80 parts of a styrene monomer, 15-25 parts of an acrylic acid glyceride monomer, 5-25 parts of an acrylic acid monomer, 0.1-0.5 part of an initiating agent and 0.1-1.0 part of a chain transfer agent. The preparation method of the chain extender comprises the steps of selecting the reactive monomers and auxiliary agents, adding the monomers and auxiliary agents into a reaction kettle in sequence, and performing polymerization reaction at a certain stirring speed at 120-150 DEG C; drying the reactant to obtain a finished product which is a multi-monomer copolymerized oligomer with low molecular weight. Compared with the existing conventional micro-molecular chain extender, the epoxy oligomer chain extender provided by the invention has the characteristics of simple preparation, wide application range, safety, reliability, high chain extension efficiency, good water resistance, no generation of gel and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

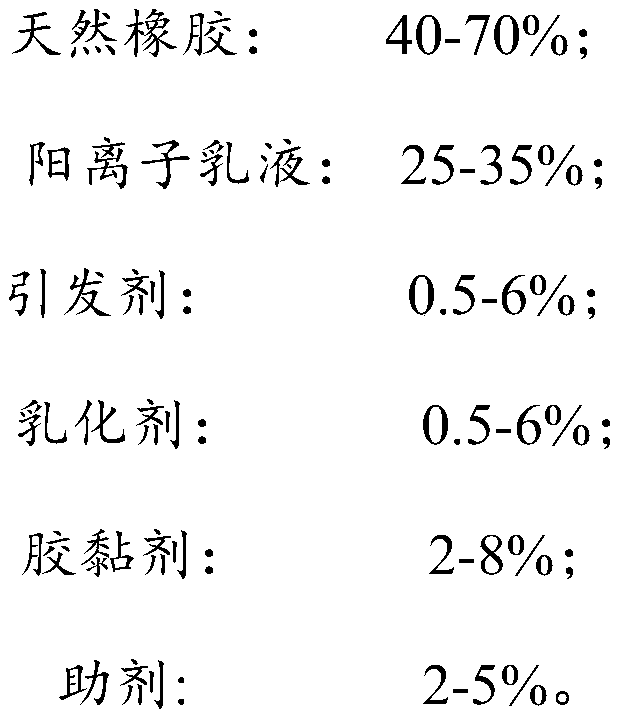

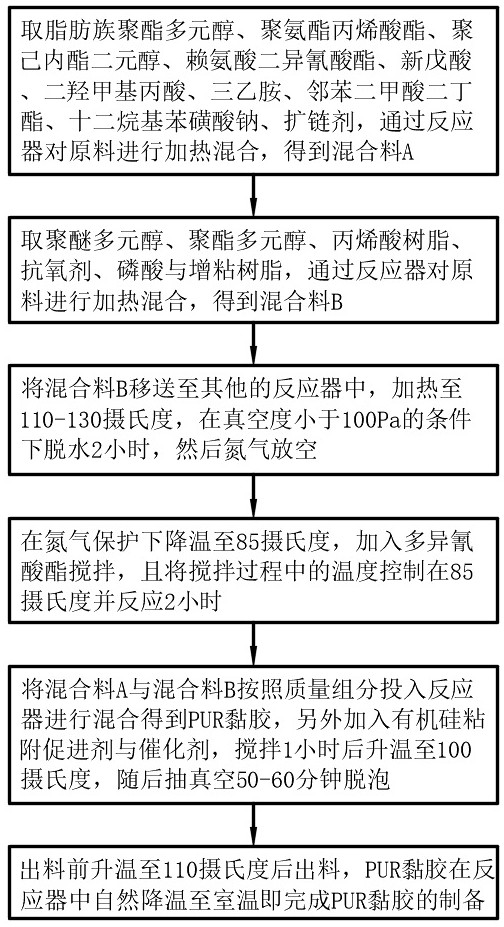

Modified natural rubber waterproof emulsion and preparation method thereof

InactiveCN110591456AImprove waterproof performanceNon-foamingNatural rubber coatingsAnti-corrosive paintsEmulsionPolymer science

The invention relates to the technical field of waterproofness and in particular to a modified natural rubber waterproof emulsion which comprises the following components in percentage by mass: 40-70%of natural rubber, 25-35% of a cation emulsion, 0.5-6% of an initiator, 0.5-6% of an emulsifier, 2-8% of an adhesive and 2-5% of aids. The modified natural rubber waterproof emulsion has excellent waterproof performance, is good in acid-alkali resistance, has properties of corrosion resistance and humidity resistance, can be rapidly formed as a film at a low temperature, is high in transparency after being dried, is free of color difference, gel or caking, and has a solid content up to 50% or greater.

Owner:王廷龙

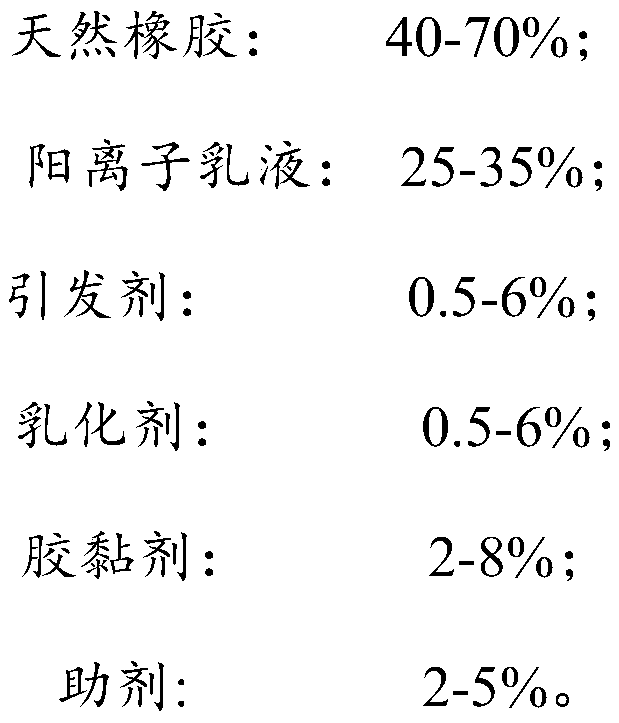

A kind of modified graphene and its preparation method and application

ActiveCN109423158BPromote flocculationImprove adsorption capacityEpoxy resin coatingsEpoxyOrganic acid

The invention provides a modified graphene and its preparation method and application, comprising: adding a dispersant and graphene to the first deionized water to obtain a graphene dispersion; adding an acid to the second deionized water to obtain an acid solution and adding the acid solution to the graphene dispersion, stirring, adding a coupling agent, and drying to obtain modified graphene, wherein the modified graphene is coated with a coupling agent and adsorbed with acid. The modified graphene prepared by the method of the present invention improves the compatibility of organic acid and inorganic acid in the epoxy resin system, and solves the compatibility between the acidic substance and the epoxy resin system in the epoxy anti-corrosion paint with rust question.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

A kind of ternary iron catalyst and its application to prepare polymer by catalyzing the copolymerization of epichlorohydrin and butadiene

The invention relates to the field of polymer synthesis, and in particular discloses a ternary iron-based catalyst and application thereof to catalyzing epoxy chloropropane and butadiene to prepare a novel polymer through copolymerization. The application to preparing the novel polymer is characterized by comprising the following steps: enabling the ternary iron-based catalyst to react in a hydrocarbon solvent, wherein epoxy chloropropane and butadiene are adopted as reaction substrates; performing a reaction for 1-24 hours at 0-100 DEG C, terminating the reaction after polymerization is completed, washing for multiple times with ethanol, adding an anti-aging agent, and drying to obtain a target product. As the ternary iron-based catalyst (an iron compound, an organic aluminum compound and an electron donor) is adopted to catalyze copolymerization of epoxy chloropropane and butadiene, the molecular weight of an obtained polymer is 10,000 or above, the polymer is light in color, the PDI is about 1.0-2.0, and the reaction is stable and easy to control.

Owner:SHANDONG YUHUANG CHEM CO LTD

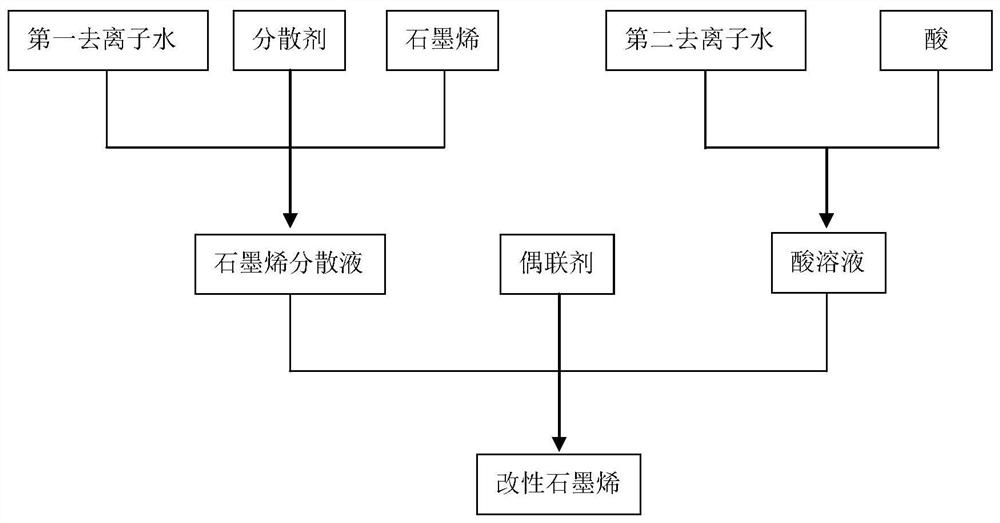

PUR adhesive for glass cover plate and middle frame and preparation method of PUR adhesive

InactiveCN113234408AGood adhesionModerate viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a PUR adhesive for a glass cover plate and a middle frame, and the PUR adhesive comprises aliphatic polyester polyol, polyurethane acrylate, polycaprolactone diol and the like according to mass components, and the steps S1 to S6 are further included. The polyurethane adhesive has a good bonding effect with various plastics and metal substrates, the viscosity of the polyurethane adhesive is appropriate, the resin selected by the system is good in compatibility, uniform in adhesive output, free of gel, good in fluidity and rapid in curing, and the performance of the polyurethane adhesive is greatly improved compared with that of the polyurethane adhesive sold in the market at present. The adhesive can meet the harsh requirements in the high-end manufacturing fields such as electronic equipment part bonding, has good melt viscosity and rapid curing characteristics, and can meet the requirements for rapid positioning and high bonding strength in the manufacturing fields such as mobile phones and other electronic consumer products; and in addition, particularly for polycarbonate and ink glass of mobile phone screen components, the polyurethane adhesive has good cohesiveness, impact resistance and aging resistance as a screen bonding adhesive.

Owner:XIAMEN WELDTONE TECH CO LTD

A kind of polyvinyl alcohol and its preparation method and application

The invention provides polyvinyl alcohol, which is characterized by having the average degree of polymerization in a range of 50-500, the alcoholysis degree in a range of 30-65 mol%, and the viscosity no more than 1500 mPa*s. Polyvinyl alcohol is prepared into an aqueous solution, which is taken as an auxiliary dispersant for suspension polymerization of vinyl polymers. The cloud point of an aqueous solution, the concentration of which is 5 wt%, (that is, a polyvinyl alcohol aqueous solution of 5 wt%), is no less than 1 DEG C and less than 15 DEG C. The viscosity measured at 25 DEG C of an aqueous solution, the concentration of which is 40 wt%, is no more than 1500 mpa*s. Gel and layering don't appear in an aqueous solution, the concentration of which is in a range of 30wt%-50wt%, in at least one year, so that the aqueous solution is extremely excellent in stability.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of graphene slurry for anionic waterborne polyurethane coating and its preparation method and application

ActiveCN107418256BSolve reunionGood dispersionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePolyurethane coating

The invention discloses graphene slurry for anionic aqueous polyurethane coatings, a preparation method of the graphene slurry and an application. The graphene slurry for the aqueous polyurethane coatings is modified graphene aqueous dispersion, oxidized graphene is modified by carbodiimide to obtain modified graphene, and the modified graphene is dispersed into water to obtain the modified graphene aqueous dispersion. In the modified graphene aqueous dispersion, according to the dry weight of the modified graphene, the ratio of the modified graphene to water is 2-20mg: 1ml. The graphene slurry can be matched with anionic aqueous polyurethane resin to achieve the advantage of long-term dispersion stability, is environmentally friendly and long in preservation time, and is capable of being preserved for at least one year at room temperature without deposition, flocculation or gelling. After use, the elastic modulus of the finally obtained coatings can reach 2.23-2.34GPa, and neutral salt spray time can reach 60-120 hours.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

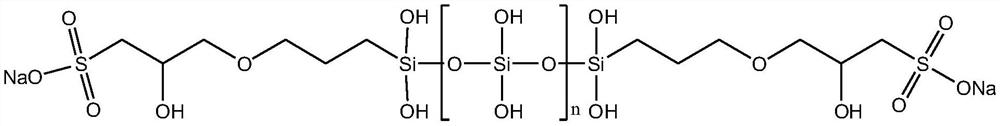

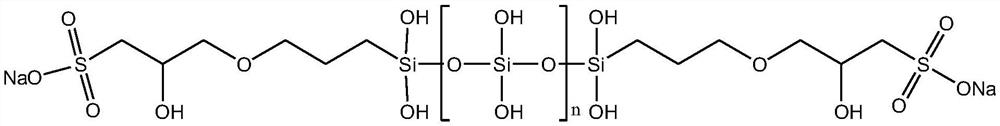

Siloxane ketone aluminum corrosion inhibitor as well as preparation method and application thereof

The invention provides a siloxane ketone aluminum corrosion inhibitor, and belongs to the technical field of aluminum corrosion inhibitors. The invention further provides a preparation method of the siloxane ketone aluminum corrosion inhibitor. The structure of the aluminum corrosion inhibitor is an organosiloxane derivative with a sodium sulfonate group, and the sulfo structure weakens the limitation of the pH of a formula system on the corrosion inhibitor, so that the aluminum corrosion inhibitor can be universally applied to metal working fluids such as an acidic cleaning agent, an alkaline cutting fluid and a refrigerating fluid without generating gel and precipitate; the organic siloxane structure increases the compatibility of the corrosion inhibitor in the formula, and the addition amount of the corrosion inhibitor in the formula can be increased so as to achieve the optimal corrosion inhibition effect.

Owner:LUOYANG INST OF SCI & TECH +1

Concentrated fluoropolymer dispersion and method for preparing fluoropolymer

Owner:ZHEJIANG XINGTENG CHEM

Filling method of single-component sealant

ActiveCN110466813AQuality is not affectedGood filling effectPackaging under vacuum/special atmosphereLiquid materialNitrogenAtmospheric pressure

The invention provides a filling method of a single-component sealant. The filling method comprises the following steps that a) the to-be-filled single-component sealant is sealed and vacuumized, andthen nitrogen is introduced to make the pressure of the to-be-filled single-component sealant and the pressure of the outside balanced; and b) the balance of the pressure of the to-be-filled single-component sealant and the pressure of the outside is kept, a pressure plate presses downwards, and the filled single-component sealant is obtained after discharging. Compared with the prior art, the filling method adopts specific process steps, nitrogen protection is achieved, it is ensured that the whole filling process is stable under specific conditions, and it is ensured that the quality of thesingle-component sealant is not affected while air is prevented from entering the sealant. Experimental results show that the filled single-component sealant obtained through the filling method is good in filling effect and free of gel.

Owner:HANGZHOU ZHIJIANG NEW MATERIAL CO LTD +1

A kind of high melt strength polylactic acid material and preparation method thereof

Owner:XIANGTAN UNIV

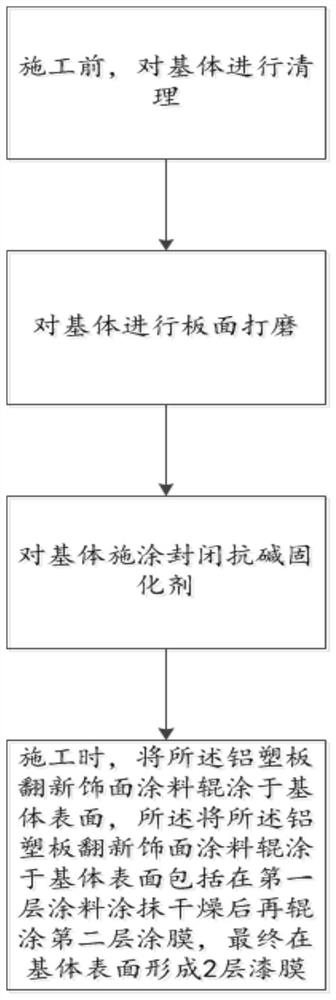

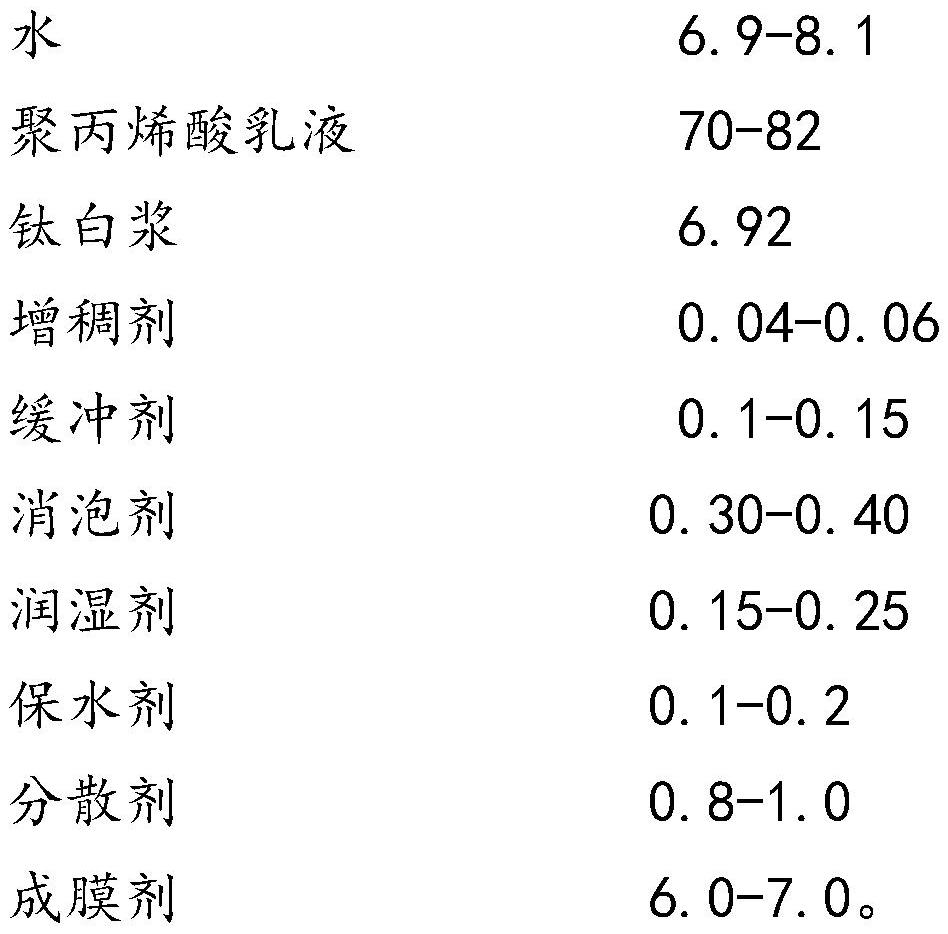

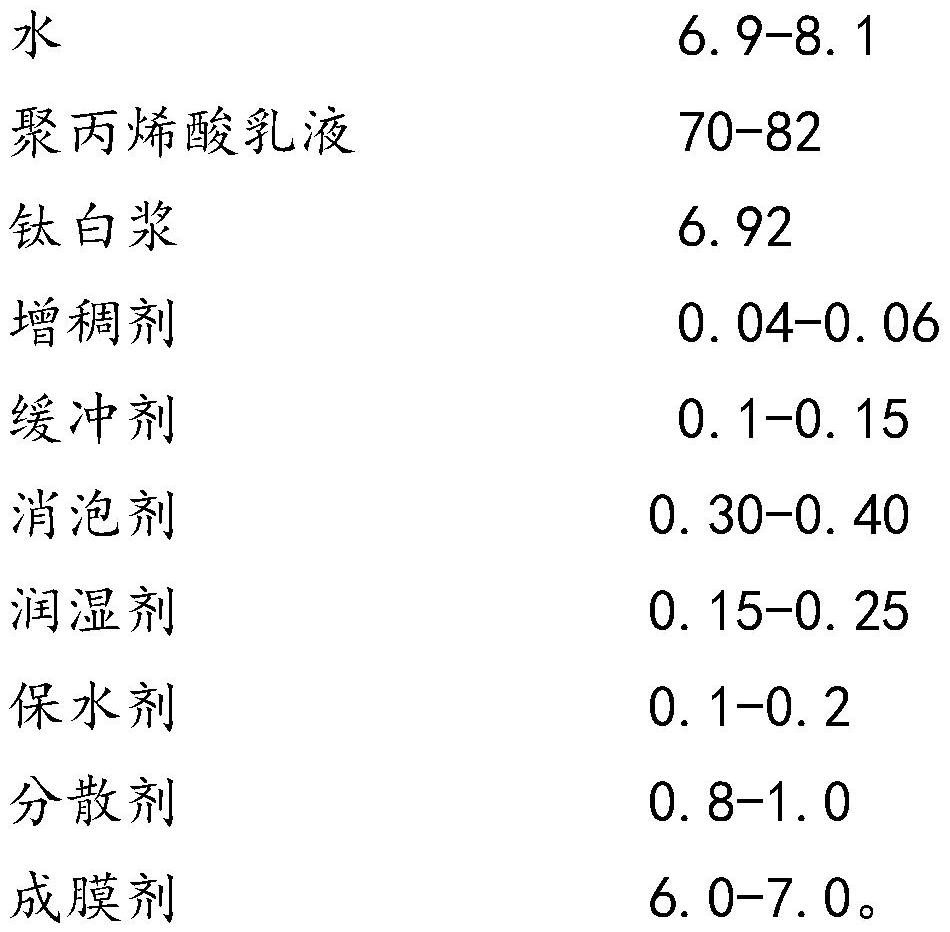

Aluminum-plastic panel refurbishing facing coating and construction method thereof

The invention discloses an aluminum-plastic panel refurbishing facing paint which is selected from the following components in parts by weight: a component A and a component B. The component A comprises predetermined parts by weight of white cement, quartz powder and cellulose ether. The component B is prepared from the following components in parts by weight: 6.9-8.1 parts of water, 70-82 parts of polyacrylic emulsion, 6.92 parts of titanium dioxide slurry, 0.04-0.06 part of a thickening agent, 0.1-0.15 part of a buffering agent, 0.30-0.40 part of a defoaming agent, 0.15-0.25 part of a wetting agent, 0.1-0.2 part of a water retaining agent, 0.8-1.0 part of a dispersing agent and 6.0-7.0 parts of a film-forming agent. The components above are stirred and mixed to prepare the aluminum-plastic panel refurbishing facing coating, and the aluminum-plastic panel refurbishing facing coating is coated on the surface of a base body in a rolling manner to finish construction. The coating is freeof gel, peeling and falling off under the condition of 100 DEG C (+ / -2), and is easy to construct.

Owner:广东彩居建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com