A kind of modified graphene and its preparation method and application

A graphene and graphene dispersion technology, applied in the field of materials, can solve the problems of limited adsorption of acidic substances, low compatibility, failure to meet the requirements, etc., and achieve the effect of improving binding force and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

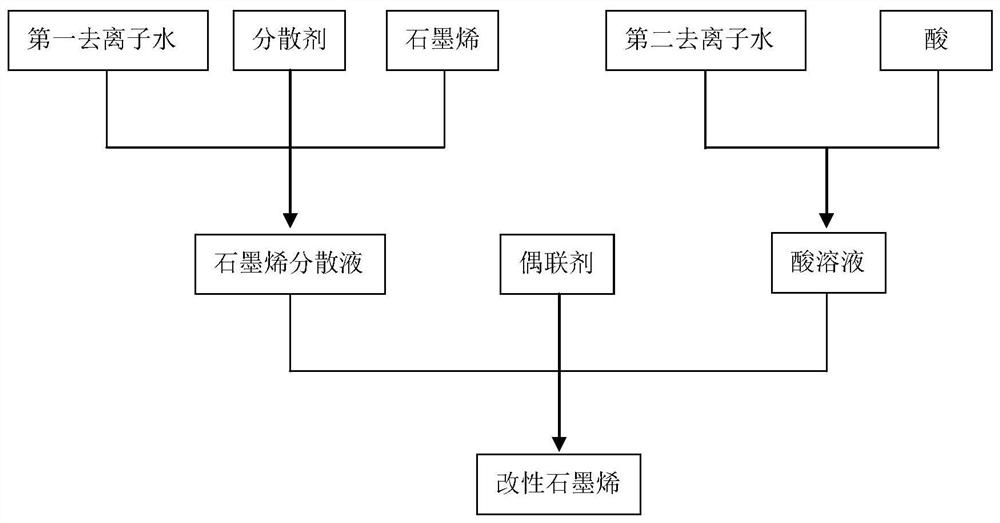

[0027] Add 0.5 parts of dispersant BYK-190 and 10 parts of single-layer graphene to 30 parts of the first deionized water, and stir at 400 rpm for 2 hours to obtain a single-layer graphene dispersion;

[0028] Add 10 parts of phosphoric acid to 20 parts of the second deionized water, and stir at 400 rpm for 1 hour to obtain a phosphoric acid solution;

[0029] Add phosphoric acid solution to the single-layer graphene dispersion, stir rapidly at 700rpm for 20min, add 2 parts of silane coupling agent KH550, and freeze-dry for 5h below 0°C to obtain modified graphene coated with coupling agent and adsorbed with acid .

Embodiment 2

[0031] Add 0.7 parts of dispersant BYK-118 and 15 parts of oligolayer graphene to 50 parts of the first deionized water, and stir at 600 rpm for 2.5 hours to obtain a oligolayer graphene dispersion;

[0032] Add 12 parts of gallic acid to 30 parts of the second deionized water, and stir at 600 rpm for 2 hours to obtain a gallic acid solution;

[0033] Add the gallic acid solution to the oligolayer graphene dispersion, stir rapidly at 900rpm for 30min, add 3 parts of silane coupling agent A-1120, and freeze-dry for 8h below 0°C to obtain a modification coated with the coupling agent and adsorbed with acid. permanent graphene.

Embodiment 3

[0035] Add 0.2 parts of dispersant BYK-2155 and 13 parts of single-layer graphene to 20 parts of the first deionized water, and stir at 500 rpm for 1.5 hours to obtain a single-layer graphene dispersion;

[0036] Add 15 parts of polyphosphoric acid to 25 parts of the second deionized water, and stir at 400rpm for 1.5h to obtain a polyphosphoric acid solution;

[0037] Add the polyphosphoric acid solution to the single-layer graphene dispersion, stir rapidly at 800rpm for 25min, add 1 part of silane coupling agent A-1130, freeze-dry below 0°C for 8h, and obtain a graphene coated with the coupling agent and adsorbed with acid modified graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com