Aluminum-plastic panel refurbishing facing coating and construction method thereof

A technology for aluminum-plastic panels and finishes, which can be used in coatings, buildings, building structures, etc., and can solve problems such as accelerated aging, poor coating effects, and laborious construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of aluminum-plastic panel refurbishment finishing paint, comprises A component and B component, wherein A component comprises white cement, quartz powder and cellulose ether of predetermined parts by weight;

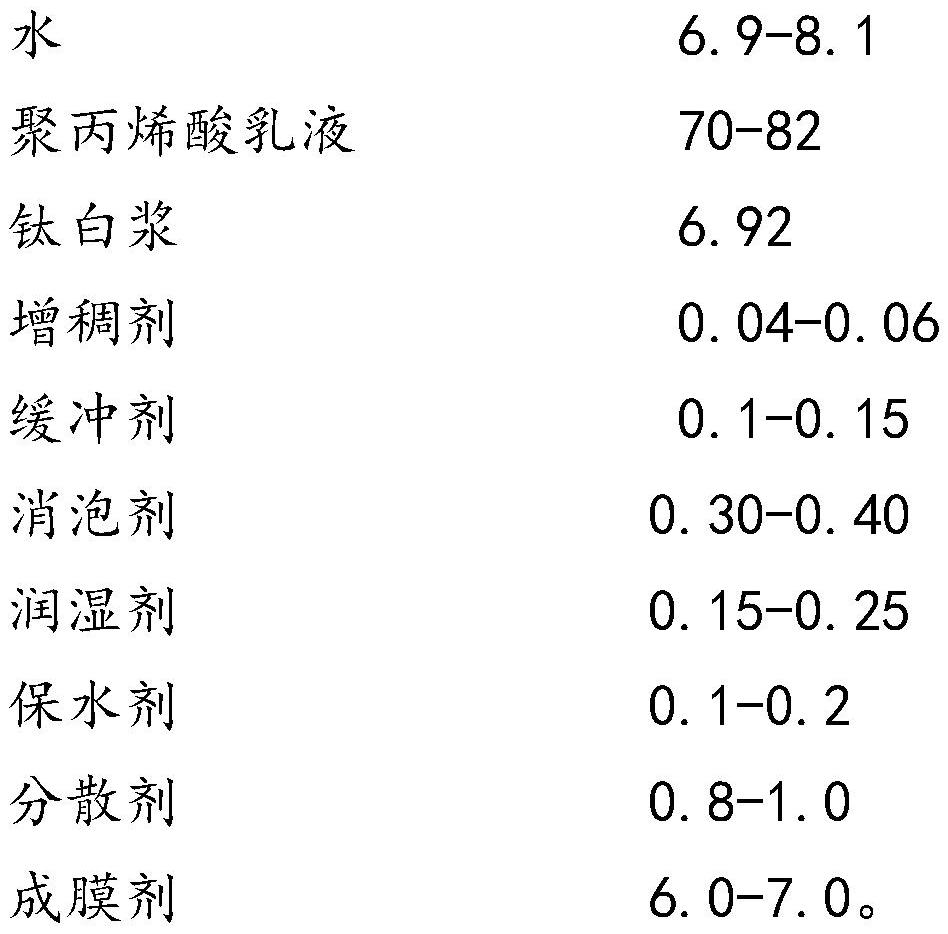

[0032] Wherein B component comprises the component of following parts by weight:

[0033]

[0034] The ratio of the A component to the B component is 0.75:1.

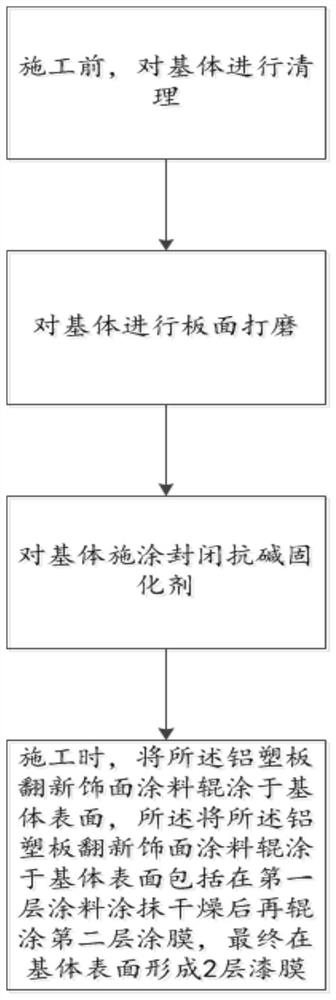

[0035] The construction method of the renovation paint for aluminum-plastic panels of the present invention comprises the following steps:

[0036] Before construction, the substrate should be cleaned,

[0037] Grinding the surface of the substrate,

[0038] Apply a closed alkali-resistant curing agent to the substrate to obtain a substrate that meets the preset roller coating requirements; during construction, roll-coat the aluminum-plastic panel renovation finish paint on the surface of the substrate, and apply the aluminum-plastic panel renovation finish The paint roller coating on the surfa...

Embodiment 2

[0041] A kind of aluminum-plastic panel refurbishment finishing paint, comprises A component and B component, wherein A component comprises white cement, quartz powder and cellulose ether of predetermined parts by weight;

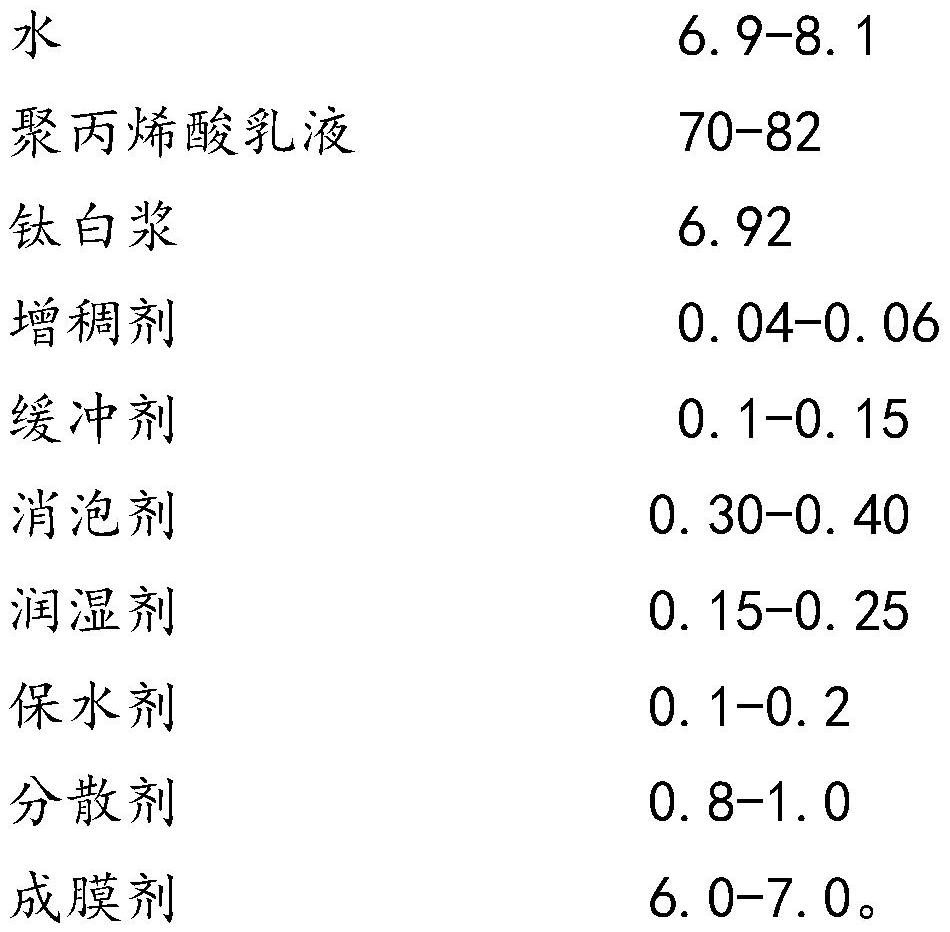

[0042] Wherein B component comprises the component of following parts by weight:

[0043]

[0044] The ratio of the A component to the B component is 0.75:1.

[0045] The construction method of the renovation paint for aluminum-plastic panels of the present invention comprises the following steps:

[0046] Before construction, the substrate should be cleaned,

[0047] Grinding the surface of the substrate,

[0048] Apply a closed alkali-resistant curing agent to the substrate to obtain a substrate that meets the preset spraying requirements; during construction, roll-coat the aluminum-plastic panel renovation finish paint on the surface of the substrate, and apply the aluminum-plastic panel renovation finish paint Roller coating on the surface of the ...

Embodiment 3

[0051] A kind of aluminum-plastic panel refurbishment finishing paint, comprises A component and B component, wherein A component comprises white cement, quartz powder and cellulose ether of predetermined parts by weight;

[0052] Wherein B component comprises the component of following parts by weight:

[0053]

[0054] The ratio of the A component to the B component is 0.75:1.

[0055]The construction method of the renovation paint for aluminum-plastic panels of the present invention comprises the following steps:

[0056] Before construction, the substrate should be cleaned,

[0057] Grinding the surface of the substrate,

[0058] Apply a closed alkali-resistant curing agent to the substrate to obtain a substrate that meets the preset spraying requirements; during construction, roll-coat the aluminum-plastic panel renovation finish paint on the surface of the substrate, and apply the aluminum-plastic panel renovation finish paint Roller coating on the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com