Siloxane ketone aluminum corrosion inhibitor as well as preparation method and application thereof

A siloxane ketone aluminum and corrosion inhibitor technology, which is applied in the field of aluminum corrosion inhibitors, can solve the problems of easy precipitation and failure of inorganic salt corrosion inhibitors, and the inability of organic phosphorus-containing corrosion inhibitors to meet the requirements of aluminum corrosion inhibition. Effects of improving corrosion protection performance, improving adhesion, and improving corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

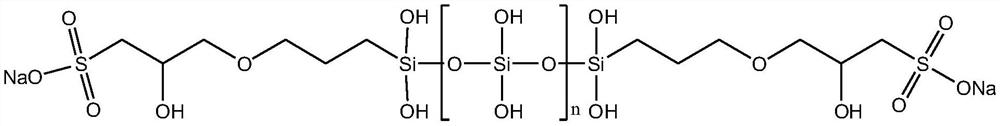

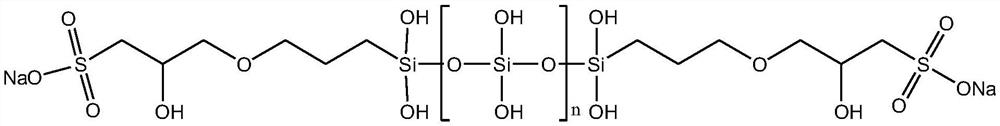

Image

Examples

Embodiment 1

[0024] A kind of siloxane aluminum corrosion inhibitor A, its synthetic steps are:

[0025] (1) Mix 150mL of methanol, 23.6g of γ-(2,3-glycidoxy)propyltrimethoxysilane and 10.4g of anhydrous sodium bisulfite in a flask equipped with a thermometer and a condenser tube under stirring , add 0.068g of benzyltriethylammonium chloride as a phase transfer catalyst, heat up to reflux, react until the solid is completely dissolved, and obtain a methanol solution of the intermediate;

[0026] (2) Add 10.4 g of tetraethyl orthosilicate to the methanol solution of the intermediate prepared in step (1), and slowly add 40 mL of acetic acid aqueous solution with a concentration of 0.01 mol / L at 40° C., and after the addition, 40 ℃ heat preservation reaction for 12h;

[0027] (3) Remove methanol and ethanol by distillation under reduced pressure, and add water to obtain an aqueous solution A of siloxane aluminum corrosion inhibitor with a concentration of 40%.

Embodiment 2

[0029] A siloxane aluminum corrosion inhibitor B, its synthesis steps are:

[0030] (1) Mix 150mL of methanol, 23.6g of γ-(2,3-glycidoxy)propyltrimethoxysilane and 10.4g of anhydrous sodium bisulfite in a flask equipped with a thermometer and a condenser tube under stirring , add 0.068g of benzyltriethylammonium chloride as a phase transfer catalyst, heat up to reflux, react until the solid is completely dissolved, and obtain a methanol solution of the intermediate;

[0031] (2) Add 20.8 g of tetraethyl orthosilicate to the methanol solution of the intermediate prepared in step (1), slowly add 40 mL of aqueous acetic acid solution with a concentration of 0.01 mol / L at 40° C., and after the addition is completed, 40 ℃ heat preservation reaction for 12h;

[0032] (3) Remove methanol and ethanol by distillation under reduced pressure, and add water to obtain an aqueous solution B of siloxane aluminum corrosion inhibitor with a concentration of 40%.

Embodiment 3

[0034] A kind of siloxane aluminum corrosion inhibitor C, its synthetic steps are:

[0035] (1) Mix 150mL of methanol, 23.6g of γ-(2,3-glycidoxy)propyltrimethoxysilane and 10.4g of anhydrous sodium bisulfite in a flask equipped with a thermometer and a condenser tube under stirring , add 0.068g of benzyltriethylammonium chloride as a phase transfer catalyst, heat up to reflux, react until the solid is completely dissolved, and obtain a methanol solution of the intermediate;

[0036] (2) Add 31.2 g of tetraethyl orthosilicate to the methanol solution of the intermediate prepared in step (1), slowly add 40 mL of acetic acid aqueous solution with a concentration of 0.01 mol / L at 40° C., and after the addition is completed, 40 ℃ heat preservation reaction for 12h;

[0037] (3) Remove methanol and ethanol by distillation under reduced pressure, and add water to obtain an aqueous solution C of siloxane aluminum corrosion inhibitor with a concentration of 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com