Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Good air drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

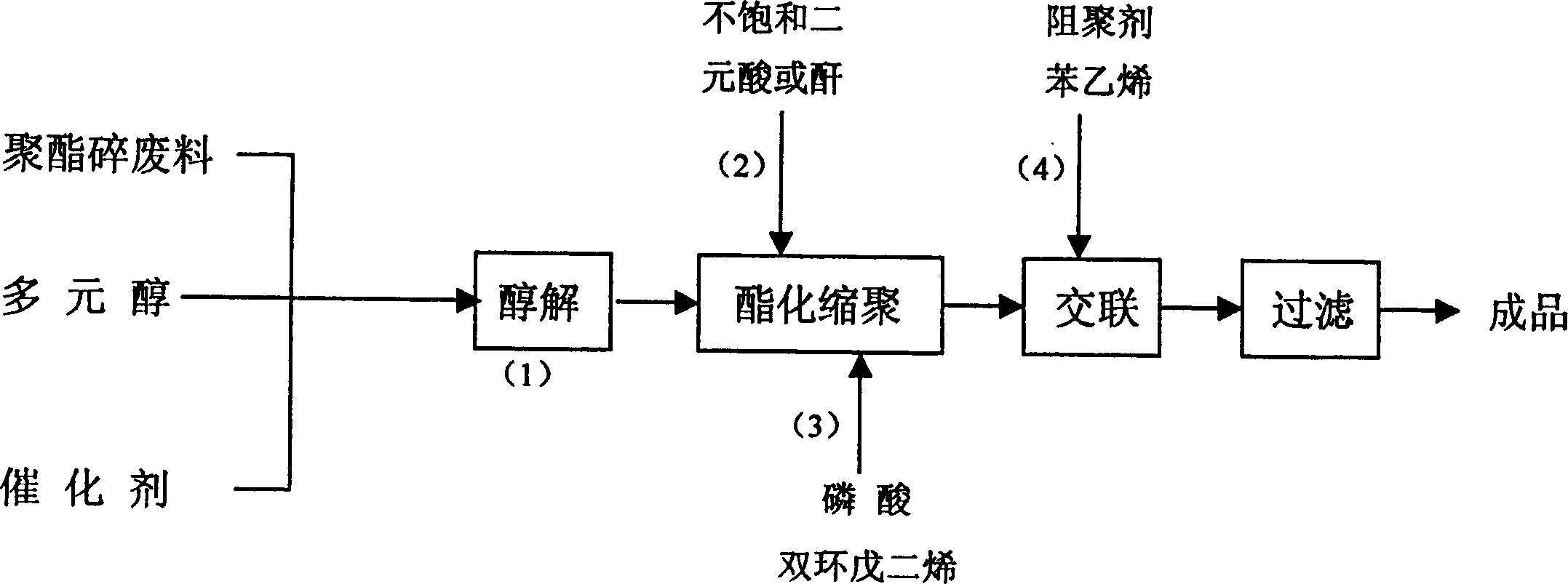

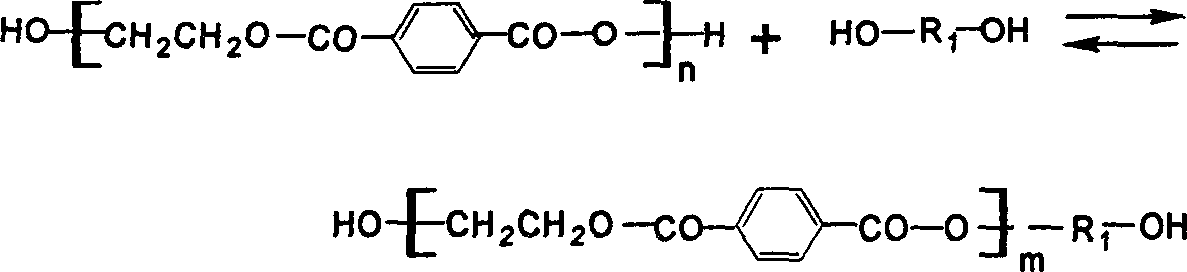

Synthesis of p-phenyl unsaturated polyester resin by using waste polyester material

The invention relates to a method for synthesizing unsaturated phenolic resin with various etherification waste, which includes the four steps: (1) etherification waste and polyhydric alcohol have alcohol sis and ester interchange with catalyst existing; (2)alcohol zed product and unsaturated binary acid or have etherification polycondensation; (3) use dicyclopentadiene (DCPD) to blocking modify in the later period of etherification polycondensation; (4) add into styrene solution for cross linking. The invention has plentiful sources of raw material, low price, decreased pollution and productive cost and energy saving, as well as eliminates the disadvantage of bad dissolubility in styrene .

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

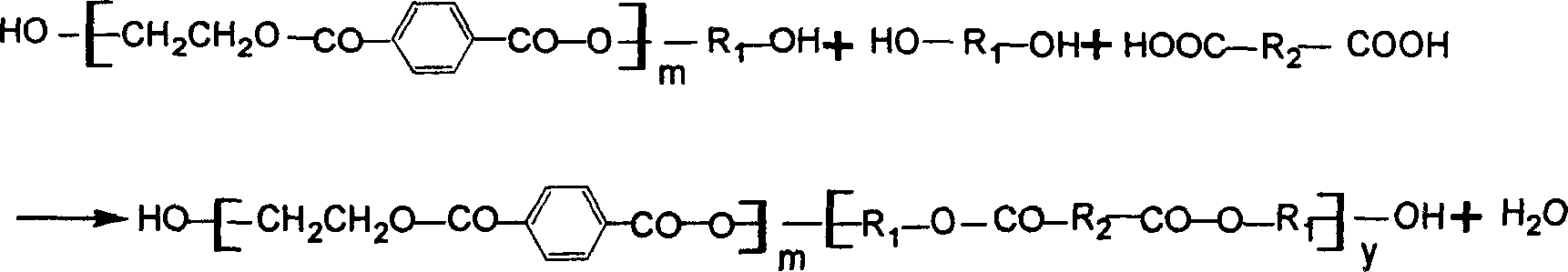

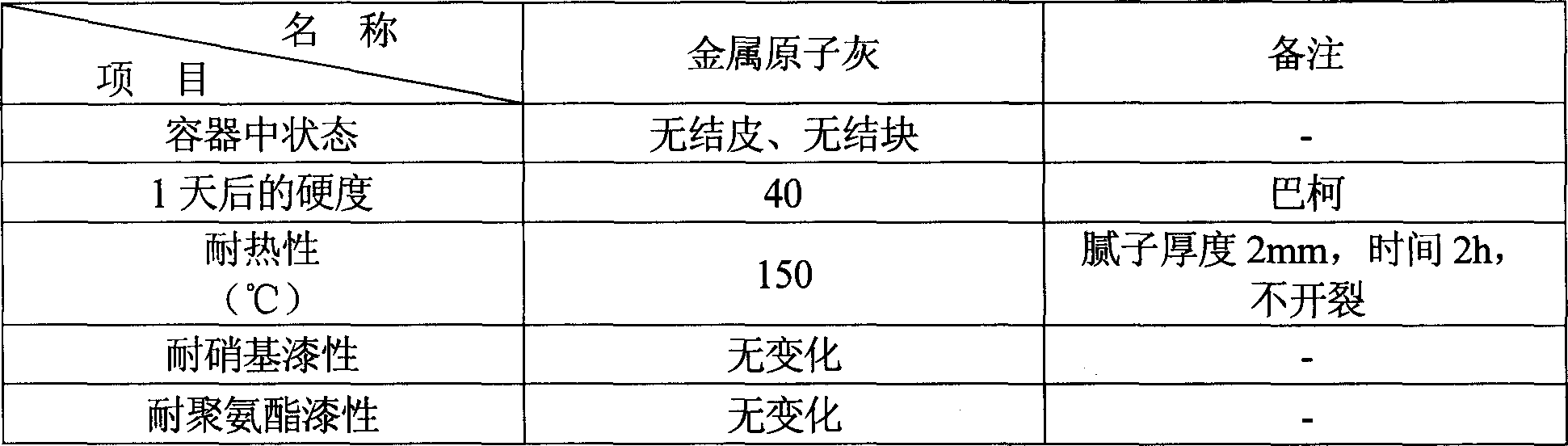

Metal atomic ash

A metal atomic ash consists of main ash and curing agent with weight ratio100:2. The main ash consists of unsaturated polyester resin: 100, improver: 3-5, phenylethylene: 3-5, filling: 120-130,and metal powder: 8-12. The curing agent consists of initiator: 100 and filling: 8-10. The production is carried out by taking special resin or special mixed resin as matrix material, and adding metal powder( iron powder, aluminum powder and copper powder etc. ) besides universal pigment and filling( titanium pigment, bentonite, French white, china clay powder, coarse whiting, and gas-phase silicon dioxide ). It achieves good combing ability, higher hardness and strength of atomic ash.

Owner:HARBIN INST OF TECH

Atomic ash special for wood decoration

The invention relates to a polymeric putty, in particular to an atomic ash specialized for carpentry decoration. The invention is specialized for meeting the using requirements of the carpentry furniture production and the interior decoration and fitment industry. The invention consists of two compositions: main ash and an evocating agent; the weight percentage of the main ash and the evocating agent is 100:2; when the invention is used, two compositions are evenly mixed according to mixture ratio. The main ash consists of the following compositions in percentage by weight: 35 to 45 portions of unsaturated polyester resin, 5 to 10 portions of saturated polyester resin, 0.003 to 0.005 portion of anti skinning agent, 8 to 12 portions of styrene, 0.3 to 1.2 portions of accelerant, 0.2 to 0.5 portion of wetting agent, 1 to 2 portions of thixotropic agent, 1 to 3 portions of zinc stearate, 5 to 8 portions of titanium pigment, 5 to 8 portions of permanent white, 20 to 35 portions of talcum powder and 8 to 12 portions of atomic powder. The evocating agent consists of the following compositions in percentage by weight: 45 to 55 portions of cyclohexanone peroxide or methyl ethyl ketone peroxide, 35 to 48 portions of dibutyl phthalate and 4 to 9 portions of SiO2. The atomic ash specialized for carpentry decoration has the following advantages that: the atomic ash has good adhesive force with various carpentry materials, good construction and flexility and shrinkage resistance and rapid drying speed and can fill up large holes or cracks; the putty film is exquisite, smooth and good in air-drying property and can be matched with wood lacquer in the market for use.

Owner:GUANGDONG SANVO CHEM IND TECH

Alloy putty

InactiveCN1664038ALow shrinkageFast dryingFilling pastesPolyester coatingsFilling materialsAcrylonitrile

The invention relates to an alloy putty which comprises main body ash and curing agent by the weight ratio of 100:2, wherein the main body ash comprises (by weight ratio) unsaturated polyester resin 100, accelerating agent 2-4, epoxy resin 4-6, carboxyl-terminated butadiene-acrylonitrile 0.5-2, pigment 5-8, filling material 80-120, while the curing agent comprises (by weight ratio) initiating agent 100, pigment 2-4, filling material 4-6.

Owner:HARBIN INST OF TECH

Method for preparing air drying epoxy vinyl ester resin

The invention relates to a preparation method for air-drying epoxy vinyl ester resin. The preparation method is as follows: bisphenol A epoxide resin, acrylic acid or methacrylic acid and boletic acid are reacted; and then the generated epoxy vinyl ester resin is modified with dicyclopentadiene; the dicyclopentadiene is added in the reaction system and reacts for 1 hour to 3 hours at the temperature of 110 DEG C to 130 DEG C till the acid value falls below 20 mg KOH / g and the reaction products are cooled below 110 DEG C; styrene is added into the products for dilution and well blended. Compared with the prior art, the invention has the advantages that the epoxy vinyl ester resin has good air-drying property; for the coating with the thickness of 0.1 mm, the surface drying time is less than and equal to 0.5 hour and the hard drying time is more than and equal to 4 hours; the surface hardness can reach 3 H; the modified raw material formulation of the dicyclopentadiene has low cost; the preparation method is simple, environmentally friendly and does not generate waster water, waste gas and industrial residue; the products have good stability, good performances of normal temperature cure, rapid curing rate, high paint film adhesion, low shrinkage factor and good corrosion resistance.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Fibrous unsaturated polyester putty

The fibrous unsaturated polyester putty is one kind of polymer putty. The fibrous unsaturated polyester putty consists of two parts, main fibrous unsaturated polyester putty and curing agent, in the weight ratio of 50. The main fibrous unsaturated polyester putty consists of unsaturated polyester resin 100 weight portions, promoter 2-4 weight portions, styrene 3-5 weight portions, fiber 0.3-0.5 weight portions, stuffing 100-120 weight portions, and pigment 3-5 weight portions. The curing agent consists of initiator 100 weight portions, pigment 3-5 weight portions, and stuffing 1-3 weight portions. The present invention has high strength, high attachment to metal material, convenient use, less shrinkage, fast drying speed, good air drying performance, high compatibility with paint, and fine and smooth film and makes it possible to fill hole as large as 10 mm in once operation.

Owner:HARBIN INST OF TECH

Flame-retarding lacquer putty and preparation method thereof

InactiveCN101696331AImprove heat resistanceImprove air drynessFilling pastesDimethylaniline N-oxideLacquer

Owner:ZHUZHOU HUALIAN HI TECH

Light putty

Disclosed is sliding atom ash, relating to a kind of polymeric putty. According to the shortage of insufficient fineness and smooth after coating and polishing of the current, the invention provides the sliding atom ash with high fineness and smooth, which comprises main body ash and firming agent with the proportion of 100:2 in mass, and the main body ash comprising the following components with the proportion in mass to be: unsaturated polyester resin, 100; accelerant, 3~5; phenylethene,3~5; pigment, 4~6; ultra-fine talcum powder, 70~90; the firming agent comprising the following components with the proportion in mass to be: initiating agent, 100; pigment, 2~4; stuffing, 4~6. The product possesses the following advantages compared with current adhesive power with the metal, fine and smooth putty surface, replenishing the opening and crack more than 5mm for one time, small degree of shrinkage, fast drying speed, heat-proof temperature being í 120 DEG C, possessing a certain degree of tarnish proofness, good air seasoning property, convenient polishing, and mating with various oil paint.

Owner:HARBIN INST OF TECH

Air-drying unsaturated polyester resin for easy-polishing gel coat, and preparation method thereof

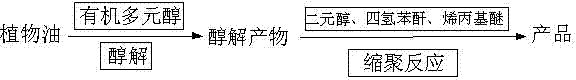

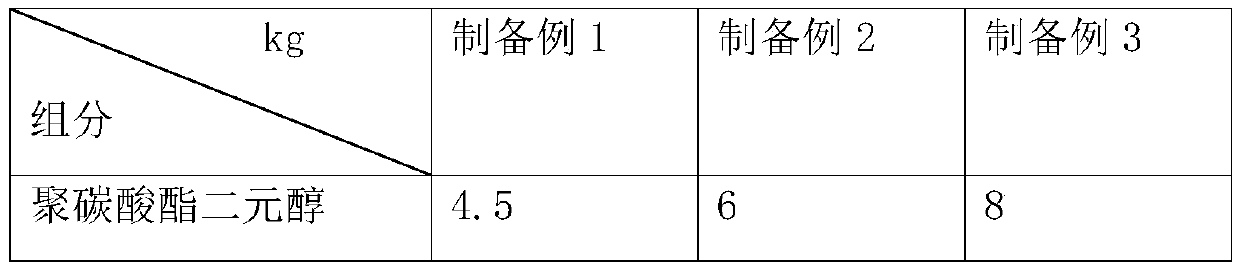

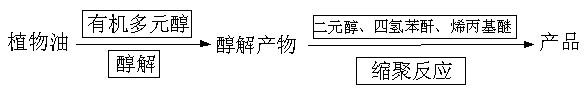

The present invention relates to the technical field of polymer material preparation, and especially to an air-drying unsaturated polyester resin for an easy-polishing gel coat, and a preparation method thereof. The resin is prepared by the following steps, wherein the steps comprise that: an organic polyol and a renewable vegetable oil are subjected to an ester exchange reaction, and then are subjected to a condensation polymerization with a small molecule dihydric alcohol or a dibasic acid, tetrahydrophthalic anhydride and allyl ether; the formed polymer is dissolved in styrene to prepare the resin. The air-drying unsaturated polyester resin of the present invention has the following advantages that: (1) the renewable vegetable oil is selected as the main component, such that the use of the toxic and harmful chemical engineering raw materials is reduced so as to meet the green environmental protection concept; (2) the vegetable oil, the tetrahydrophthalic anhydride, the allyl ether and the like in the resin component provide good air-drying properties, such that the resin can be widely applicable for the fields with high air-drying requirements. The resin of the present invention is mainly applicable for the easy-polishing gel coat with the high air-drying requirements, and has characteristics of excellent toughness, excellent adhesion, excellent weather resistance, excellent polishing property and the like. In addition, the resin of the present invention has good air-drying property, and the gel coat prepared by the resin of the present invention has characteristics of good adhesion, low porosity, easy polishing and the like.

Owner:CHANGZHOU HUAKE POLYMERS

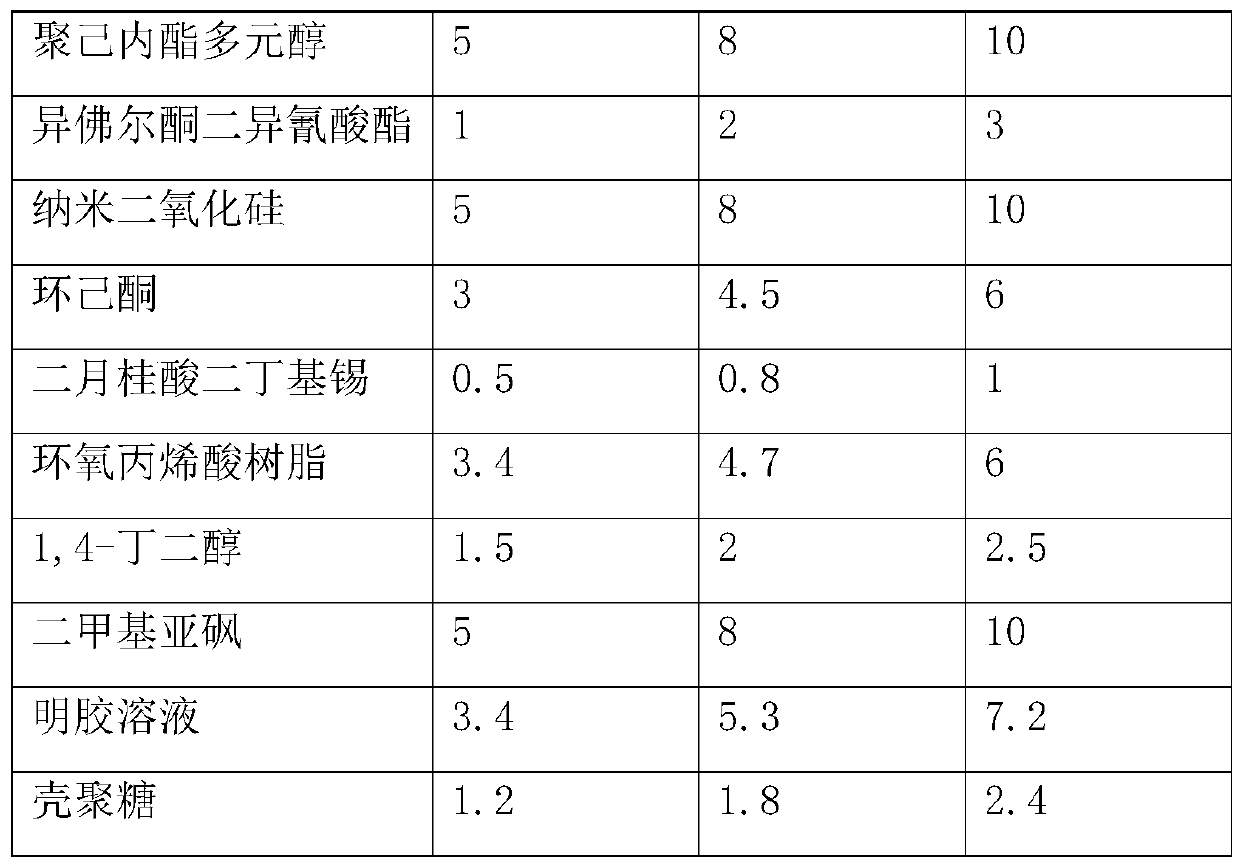

Colored pervious concrete and preparation process thereof

The invention discloses a colored pervious concrete and a preparation process thereof. The colored pervious concrete is prepared from the following raw materials in parts by weight: 260 to 340 parts of cement; 30 to 60 parts of mineral powder; 60 to 90 parts of fly ash, 20 to 45 parts of silica fume, 150 to 200 parts of water, 700 to 900 parts of a fine aggregate, 800 to 1200 parts of a coarse aggregate, 10 to 20 parts of a pigment, 8 to 16 parts of an early strength accelerator, 45 to 80 parts of bisphenol A epoxy resin, 35 to 55 parts of polyurethane modified gelatin and 60 to 90 parts of acuring accelerator; wherein the curing accelerator is prepared from 2-ethyl-4-methylimidazole, a modified anhydride curing agent and a cardanol modified polyamide in a mass ratio of 1 to (1.3 to 1.5)to (0.7 to 1). The colored pervious concrete has the advantages of being high in pervious coefficient, high in early compressive strength and breaking strength, short in curing time, capable of shortening open traffic time and good in thermal aging resistance and freezing and thawing resistance.

Owner:成都新豪鼎盛建材有限公司

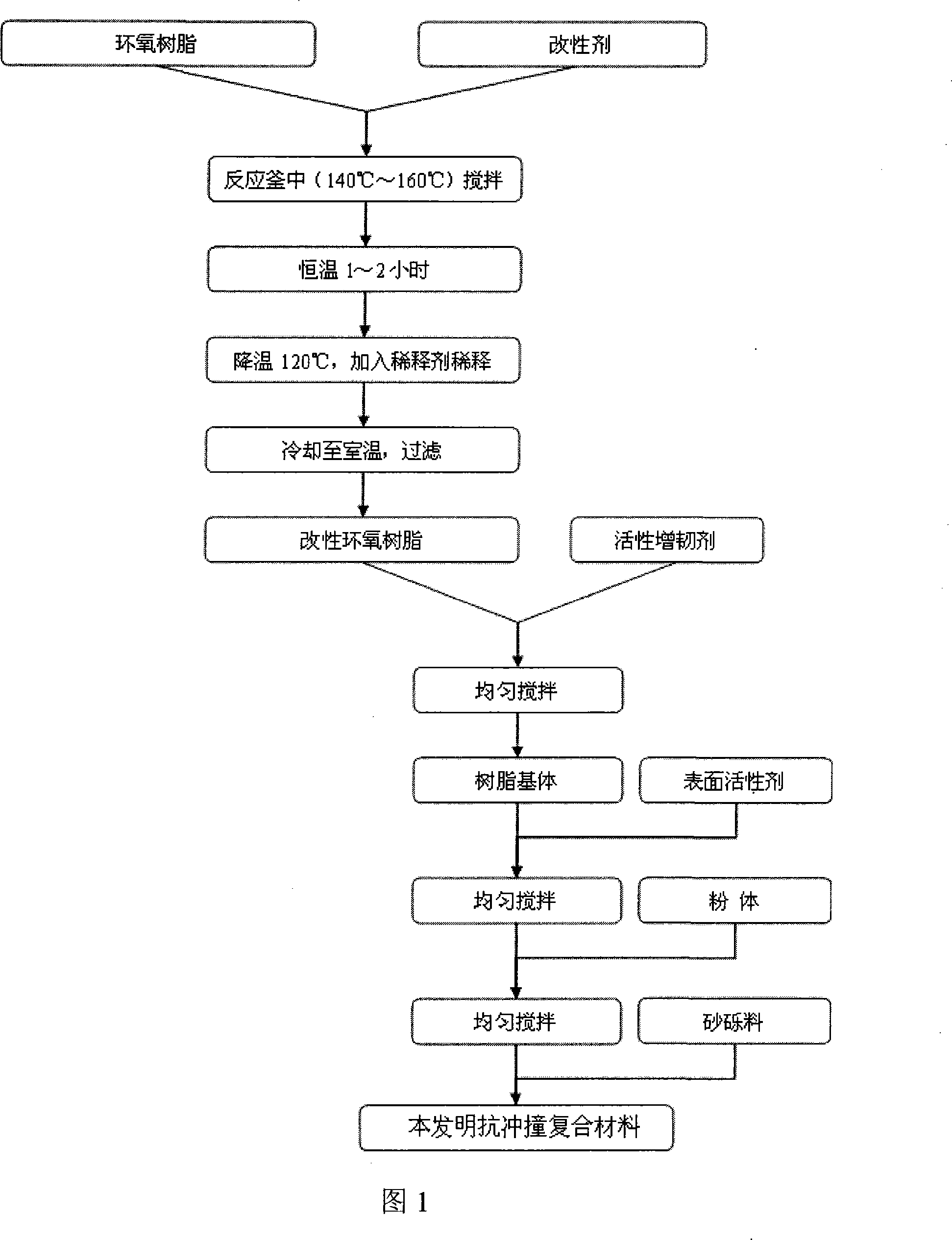

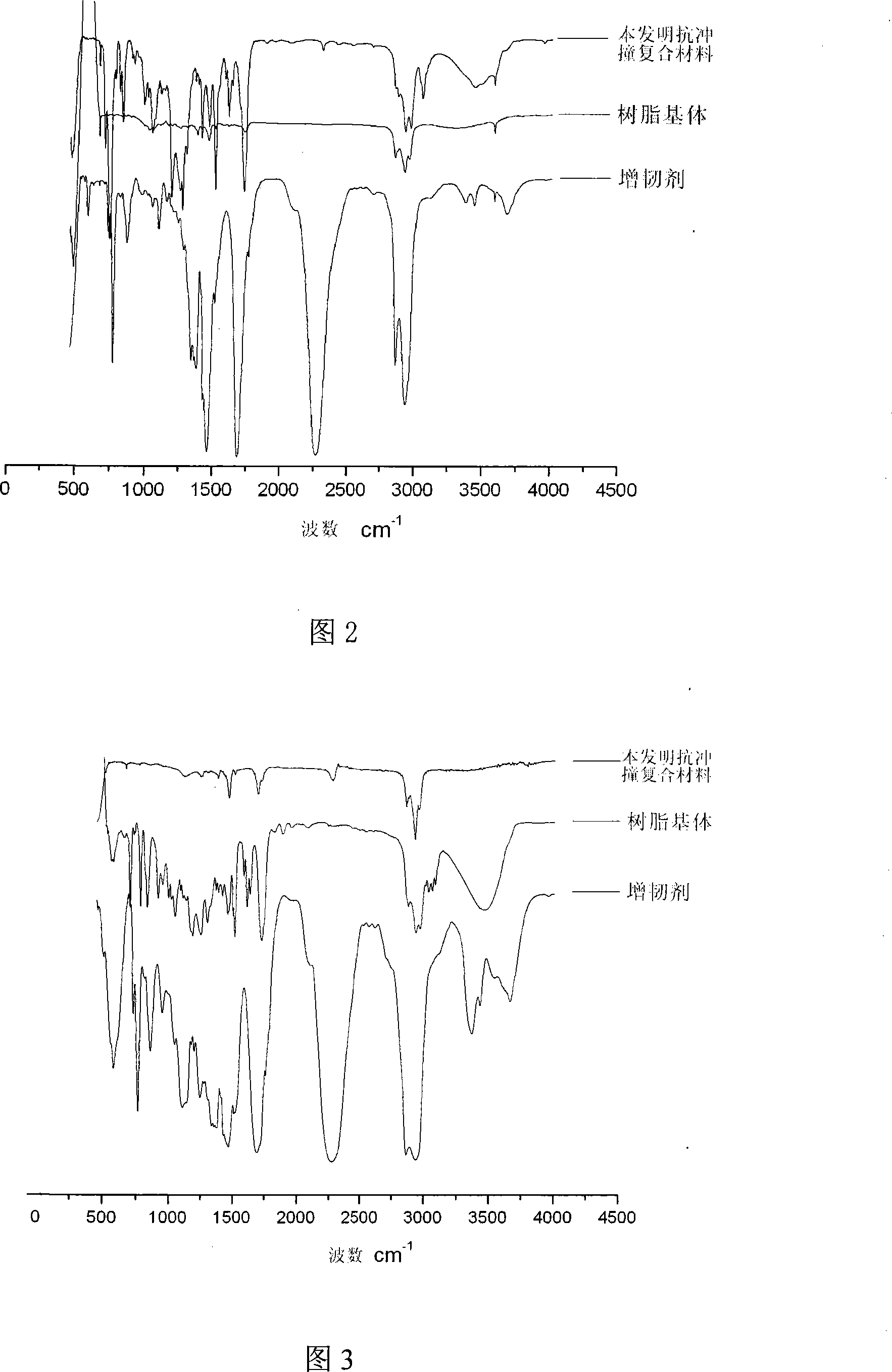

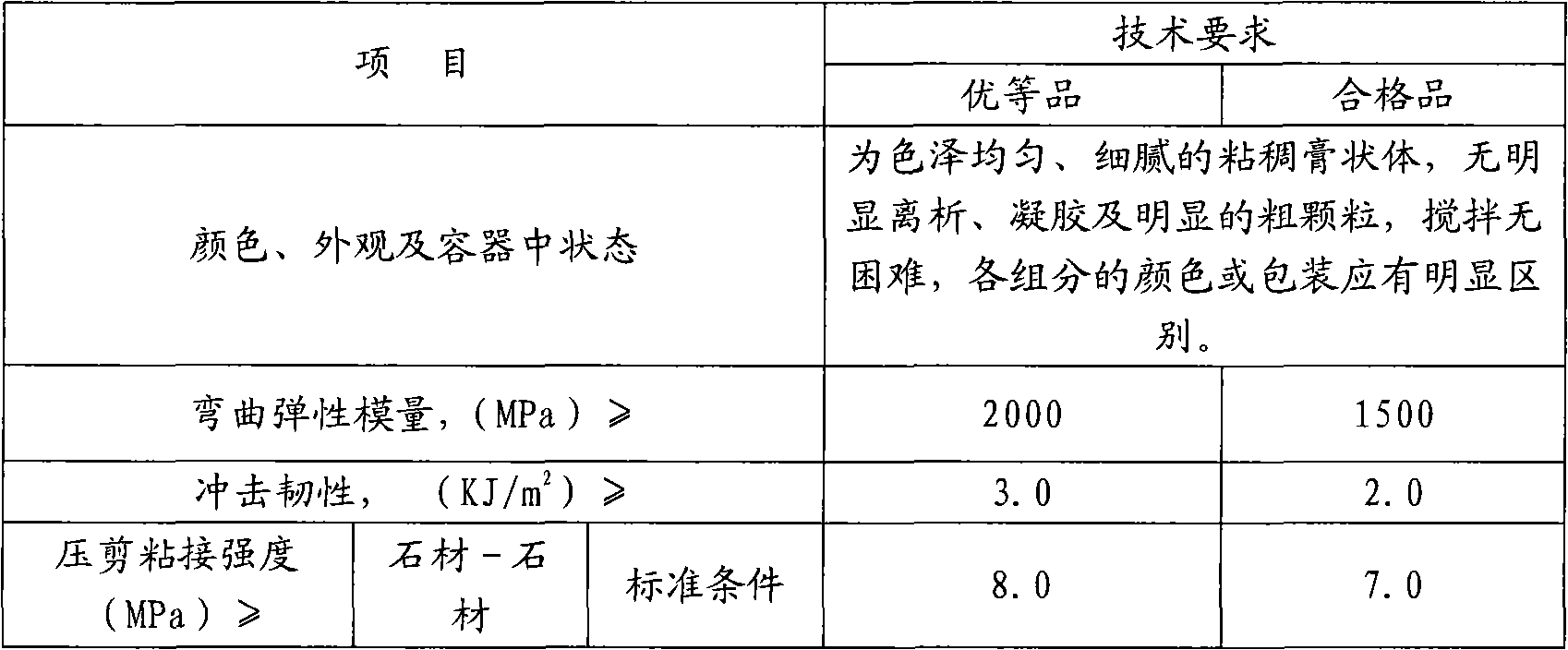

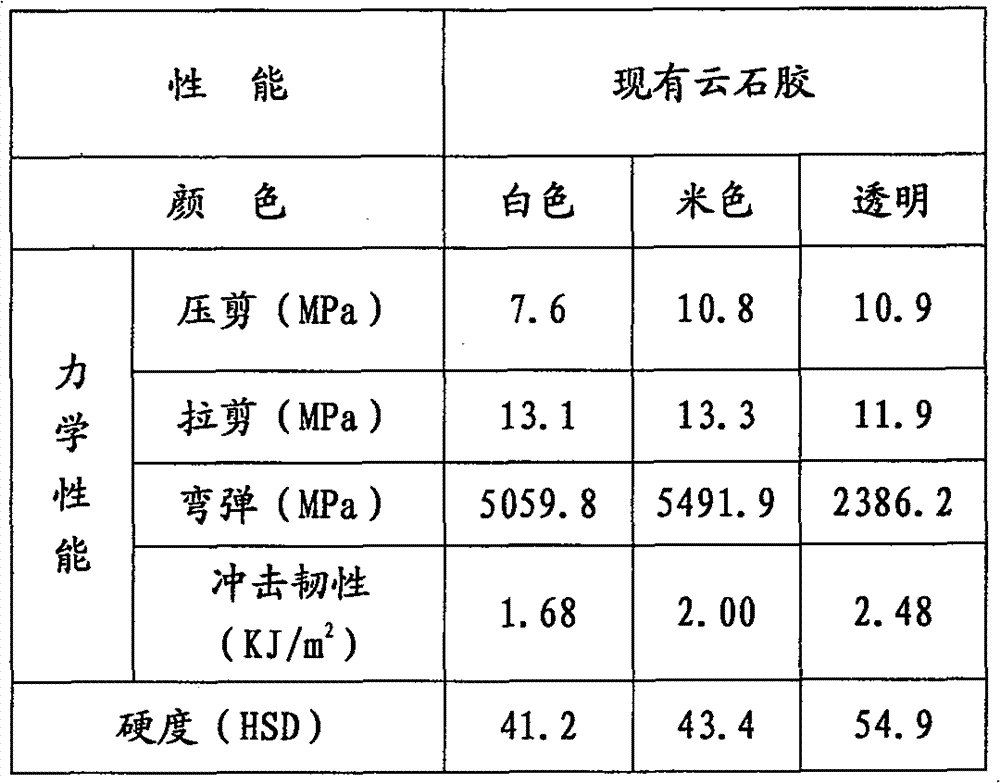

Crash resistant composite material and method for producing the same

An anti-collision composite material, which comprises 100 parts by weight of modified epoxy resin, 5-40 parts by weight of active toughening agent, 0.03-0.05 parts by weight of surfactant, 20-50 parts by weight of powder, and 10-50 parts by weight of gravel material. parts by weight. The invention overcomes the deficiencies of the existing concrete gate wall which is not resistant to collision, friction and the like, and has the characteristics of high epoxy resin hardness, strong cohesion, polyurethane toughness and wear resistance. The invention also discloses the preparation method of the anti-collision composite material.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

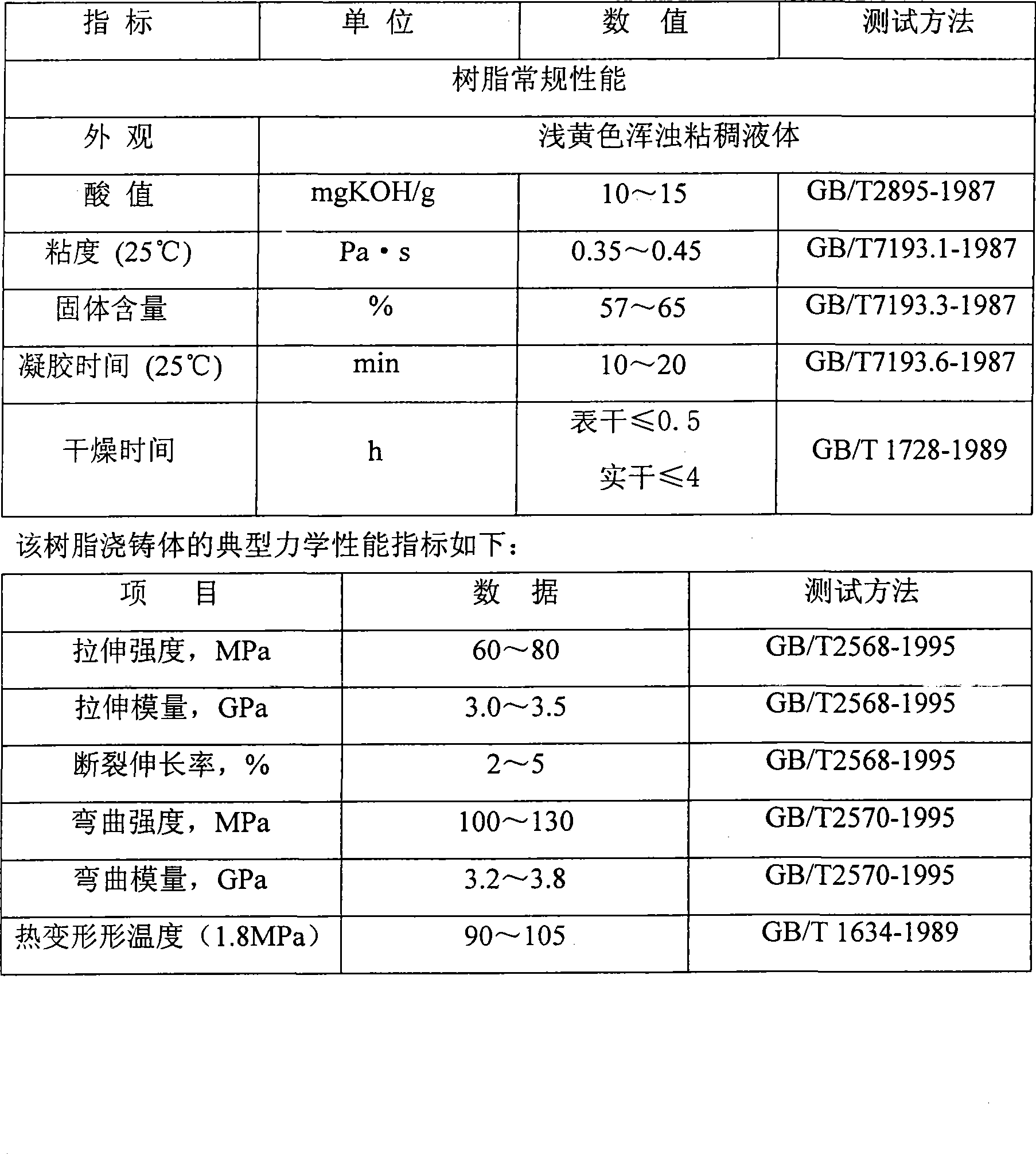

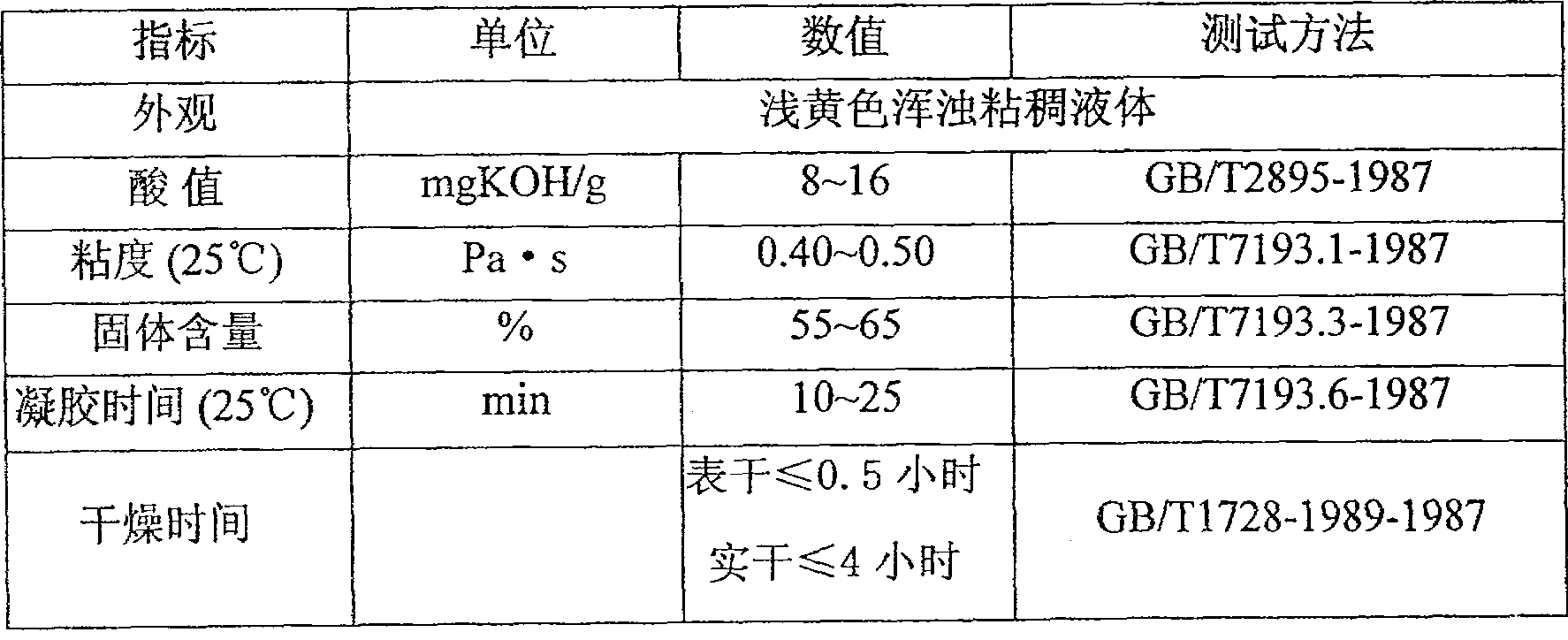

Technique for synthesizing air-dry type oxirene ester resin

This invention relates to a process for synthesizing air-drying epoxy vinyl ester resin. The process comprises: reacting bisphenol A type epoxy resins with low and high epoxy equivalent, and organic unsaturated monocarboxylic acid at 120-160 deg.C in the presence of catalyst and polymerization inhibitor, and then diluting with crosslinkable monomer. The resin has good air-drying performance, with surface drying time less than or equal to 0.5 h, and inner drying time less than or equal to 4 h. Besides, the resin has appropriate viscosity, good wettability with glass fibers and glass mats, good physical and mechanical performance, and good chemical corrosion resistance, and is suitable for various molding processes of fiber reinforced plastics such as manual pasting, coiling, drawing and spraying. The method has such advantages as simple process, low energy consumption, and stable product quality.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

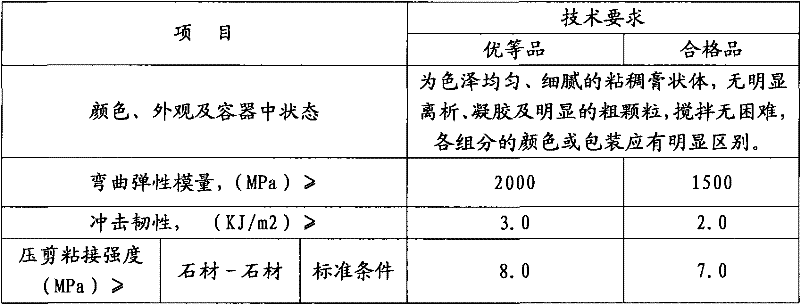

Jointing glue for stone

ActiveCN101851482ASolve the pointing problemHigh hardnessBuilding repairsAdhesivesSilicon dioxideUnsaturated polyester

The invention provides jointing glue for stone, which at least comprises the following components in parts by weight: 100 parts of an air-dried unsaturated polyester resin, 1-5 parts of hydrogenated castor oil, 0-60 parts of micron-sized silica and 1-15 parts of an antishrinking agent. The jointing glue overcomes the defects of taking the existing common marble glue as the jointing glue such as poor air-drying properties, poor antishrinking capability, poor permeability and the like. The jointing glue for stone has the advantages of good permeability, no tackiness after curing, strong antishrinking capability, glue brightness after polishing and the like. The jointing glue enriches varieties of the marble glue and solves the problem of jointing difficulty among the stone.

Owner:江苏大力士云石护理材料有限公司

Synthesis method of modified epoxy vinyl ester resin

The invention belongs to the technical field of macromolecule polymer and relates to a synthesis method of modified epoxy vinyl ester resin. The synthesis method includes the following steps: according to mass percent, adding 35-50% of epoxy resin, 8-20% of unsaturated monocarboxylic acid, 4-18% of dicyclopentadiene maleic acid, 0.1-1.0% of catalyst and 0.01-0.1% of flame retardant in a reactor. The mixture reacts at 90-120 DEG C until the acid value reduces to below 10mg KOH / g at end point of reaction. When cooled below 110 DEG C, 25-40% of crosslinking agent is added. Uniform stirring is conducted at below 70 DEG C to get modified epoxy vinyl ester resin. The advantages of the method are as follows: by replacing the unsaturated monocarboxylic acid partially or wholly with dicyclopentadiene maleic acid to react with epoxy resin, being simple in operation, little of side reaction, easy control on reaction end point, environment-friendly; and producing products fine in air drying property, quick in curing speed, high adhesion of film painting, low contractibility rate and good in corrosion resistance. The synthesis method is applicable to making various products of composite materials and dies.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Wooden furniture surface coating material

The invention relates to the technical field of furniture surface treatment, in particular to a wooden furniture surface coating material. The wooden furniture surface coating material is prepared from a main agent and a curing agent, wherein the main agent is prepared from, by weight, 50-60 parts of saturated polyester resin, 5-10 parts of dimethylglyoxime, 3-5 parts of phosphoric acid triallyl ester, 2-4 parts of white corundum, 1-6 parts of attapulgite, 0.5-1.0 part of copper naphthenate, 0.2-0.4 part of cobalt iso-octoate and 2-6 parts of titanium dioxide, the curing agent is prepared from, by weight, 10-20 parts of methyl ethyl ketone peroxide, 5-8 parts of gas phase SiO2, 15-25 parts of dibutyl terephthalate and 0.1-0.3 part of polyvinylpyrrolidone. According to the wooden furniture surface coating material, no deformation or contraction of a base material will be caused in the base material treatment process, and therefore the decorative coating is not broken.

Owner:桐乡市美意家具有限公司

Special colored stone material caulking sealant

ActiveCN101805581AImprove aging resistanceSolve the pointing problemBuilding repairsMacromolecular adhesive additivesFilling materialsSealant

The invention relates to special colored stone material caulking sealant, which at least comprises 100 weight parts of air-dried unsaturated polyester resin, 1 to 5 weight parts of hydrogenated castor oil, 10 to 250 weight parts of filling materials and 1 to 15 parts of antishrinking agents. The invention overcomes the defects of poor air-dried performance, low antishrinking capability, poor permeability and the like when the existing ordinary marble glue is used as the caulking sealant. The stone material caulking sealant of the invention has the advantages of good permeability, hand inadhesion after being cured, strong antishrinking capability, sealant brightness after grinding and the like. The invention enriches the variety of the marble glue, and solves the caulking problem between stone materials.

Owner:江苏大力士云石护理材料有限公司

Anti-cracking PE (polyethylene) primer and production method thereof

InactiveCN106833307AExcellent anti-crack functionSolve crackingFireproof paintsPolyester coatingsStearic acidDefoaming Agents

The invention relates to the field of paint, and provides an anti-cracking PE (polyethylene) primer and a preparation method thereof. The PE anti-cracking primer provided by the invention comprises the following components in parts by weight: 40-45 parts of resin, 2 parts of styrene, 0.3 part of dispersing agent, 7-8 parts of titanium white, 0.6 part of anti-settling agent, 27-30 parts of 1250-mesh talcum powder, 18-20 parts of 1250-mesh heavy calcium carbonate, 3 parts of zinc stearate, 1.8 parts of xylene, 0.1 part of defoaming agent and 0.2 part of leveling agent. Compared with the prior art, the PE primer provided by the invention has a favorable film coating effect and excellent anti-cracking performance and can be widely used for furniture painting.

Owner:江苏赛鑫树脂有限公司 +2

Unsaturated polyester resin with solid content being 100% and low-VOC odor-free PE varnish

ActiveCN107099227AImprove air drying performanceGood air dryingPolyester coatingsWear resistantSolid content

The invention discloses unsaturated polyester resin with solid content being 100% and a preparation method thereof, and a low-VOC odor-free PE varnish produced from the unsaturated polyester resin and a preparation method thereof. The low-VOC odor-free PE varnish comprises: the unsaturated polyester resin with solid content being 100%, low-odor active monomers, a food-grade antioxidant, a flatting agent, a defoamer, and an anti-sagging aid. The PE varnish is low in VOCs and has very low odor during construction, has the property of forming a thick paint film in one time just like conventional unsaturated polyester paint, has good pore-seal property, has high fullness, is wear-resistant, has high glossiness, etc.

Owner:恒昌涂料(惠阳)有限公司

Stone material caulking sealant

ActiveCN101805581BSolve the pointing problemImprove permeabilityBuilding repairsMacromolecular adhesive additivesFilling materialsSealant

The invention relates to special colored stone material caulking sealant, which at least comprises 100 weight parts of air-dried unsaturated polyester resin, 1 to 5 weight parts of hydrogenated castor oil, 10 to 250 weight parts of filling materials and 1 to 15 parts of antishrinking agents. The invention overcomes the defects of poor air-dried performance, low antishrinking capability, poor permeability and the like when the existing ordinary marble glue is used as the caulking sealant. The stone material caulking sealant of the invention has the advantages of good permeability, hand inadhesion after being cured, strong antishrinking capability, sealant brightness after grinding and the like. The invention enriches the variety of the marble glue, and solves the caulking problem between stone materials.

Owner:江苏大力士云石护理材料有限公司

Jointing glue for stone

ActiveCN101851482BSolve the pointing problemHigh hardnessBuilding repairsAdhesivesSilicon dioxideUnsaturated polyester

Owner:江苏大力士云石护理材料有限公司

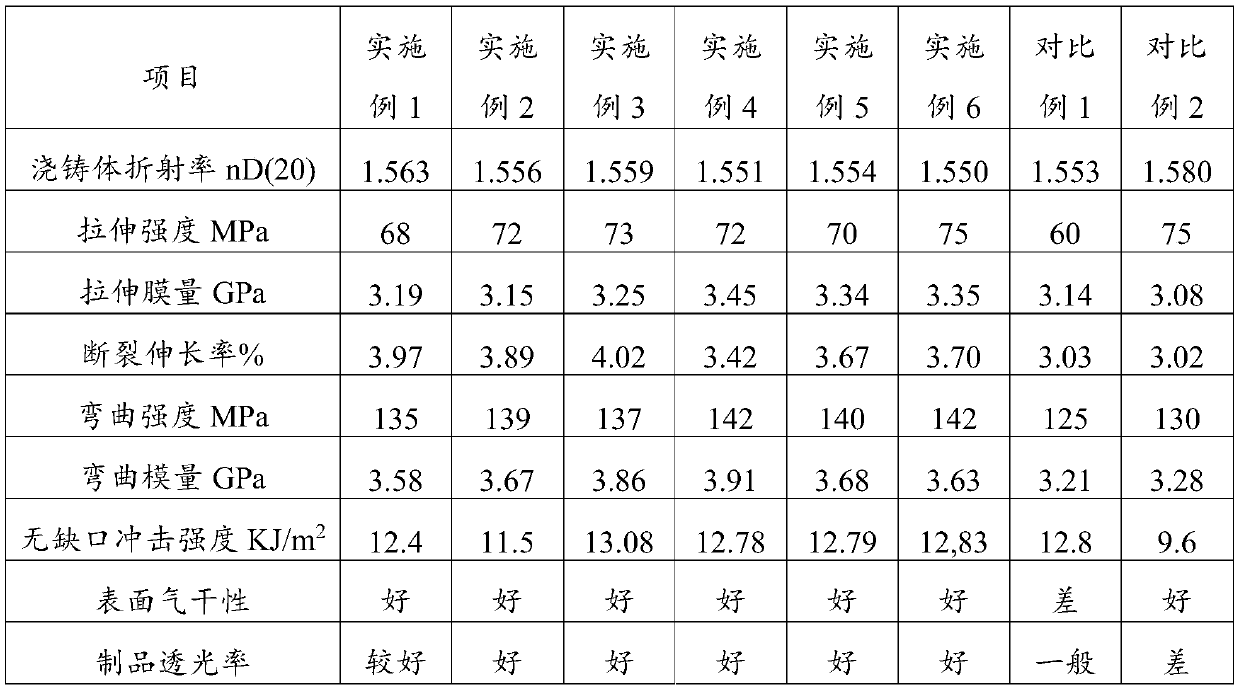

Glycerol modified unsaturated polyester resin and preparation method thereof

The invention discloses a glycerol modified unsaturated polyester resin, which comprises the following raw materials in percentage by weight: glycerol 4-10%, monoacid 6-12%, catalyst 0.02-0.05%, diol3-9%, polymerization inhibitor 0.02-0.05%, crosslinking agent 25-40%, maleic anhydride 10-20%, dicyclopentadiene 8-18%, dibasic acid 4-10%. The glycerin modified unsaturated polyester resin is appliedto the preparation of daylighting tile, which can make the daylighting tile have better toughness, higher mechanical properties, refractive index, closer to glass fiber reinforced material, and goodsurface air-dryness of the products.

Owner:JUSHI GRP CO

Method for preparing air drying epoxy vinyl ester resin

The invention relates to a preparation method for air-drying epoxy vinyl ester resin. The preparation method is as follows: bisphenol A epoxide resin, acrylic acid or methacrylic acid and boletic acid are reacted; and then the generated epoxy vinyl ester resin is modified with dicyclopentadiene; the dicyclopentadiene is added in the reaction system and reacts for 1 hour to 3 hours at the temperature of 110 DEG C to 130 DEG C till the acid value falls below 20 mg KOH / g and the reaction products are cooled below 110 DEG C; styrene is added into the products for dilution and well blended. Compared with the prior art, the invention has the advantages that the epoxy vinyl ester resin has good air-drying property; for the coating with the thickness of 0.1 mm, the surface drying time is less than and equal to 0.5 hour and the hard drying time is more than and equal to 4 hours; the surface hardness can reach 3 H; the modified raw material formulation of the dicyclopentadiene has low cost; thepreparation method is simple, environmentally friendly and does not generate waster water, waste gas and industrial residue; the products have good stability, good performances of normal temperature cure, rapid curing rate, high paint film adhesion, low shrinkage factor and good corrosion resistance.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Atomic ash for furniture and decoration

The invention discloses atomic ash for furniture and decoration. The atomic ash consists of a main body and a curing agent, wherein the main body consists of the following components in part by weight: 70 to 80 parts of air-drying unsaturated polyester resin, 5 to 7 parts of epoxy resin, 0.8 to 1.2 parts of acrylonitrile-butadiene rubber, 3.5 to 4.5 parts of cobalt isocaprylate, 1.5 to 2.5 parts of dimethylaniline, 0.8 to 1.0 part of hydroquinone, 6 to 8 parts of white carbon black, 8 to 10 parts of titanium white, 45 to 55 parts of talcpowder, 3 to 5 parts of gaseous phase SiO2, 8 to 10 parts of montmorillonite and 0.5 to 1 part of barium sulfate; and the curing agent consists of the following components in part by weight: 75 to 85 parts of benzoyl peroxide, 2 to 3 parts of acetone and 15 to 20 parts of white carbon black.

Owner:TIANCHANG CITY TONGTIAN CHEM

Furniture and preparation method of putty for decoration

The invention discloses a piece of furniture and a preparation method of putty for decoration. Based on a large number of experiments, all components of the putty are determined and are in synergic matching so that the prepared putty has good adhesion to wood or other nonmetal such as stone, is convenient to use, easy to prepare, smooth in puttying and can be molded freely; moreover, the putty is high in drying speed and can be dried in 15-20 minutes at normal temperature; and the putty has good dryness, is easy to polish, does not stick sand paper and is flat, smooth and pore-free after being polished.

Owner:TIANCHANG CITY TONGTIAN CHEM

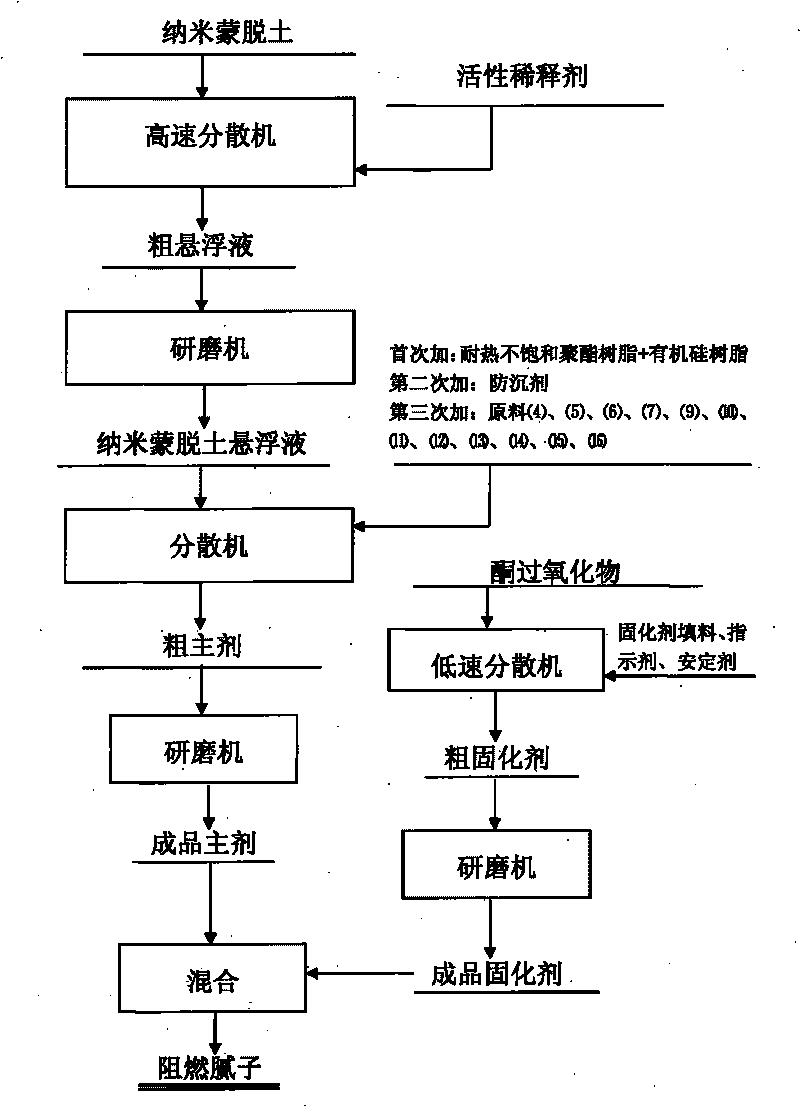

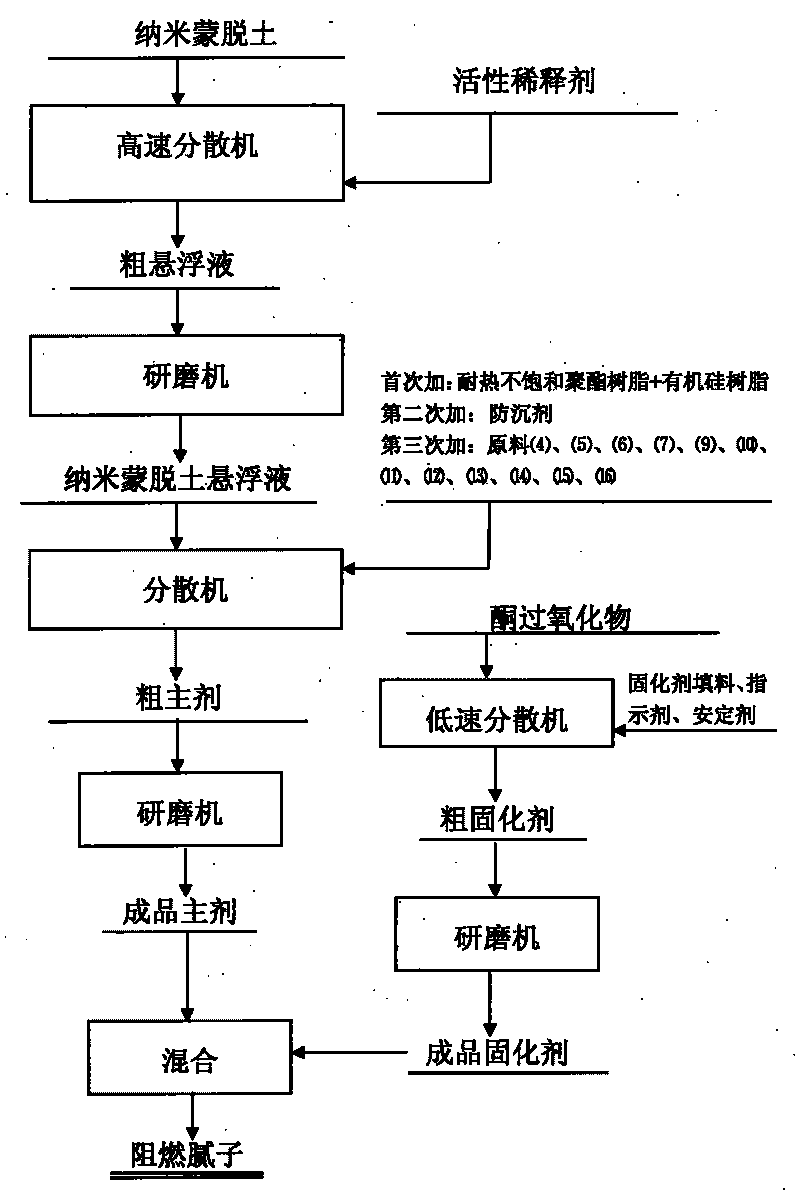

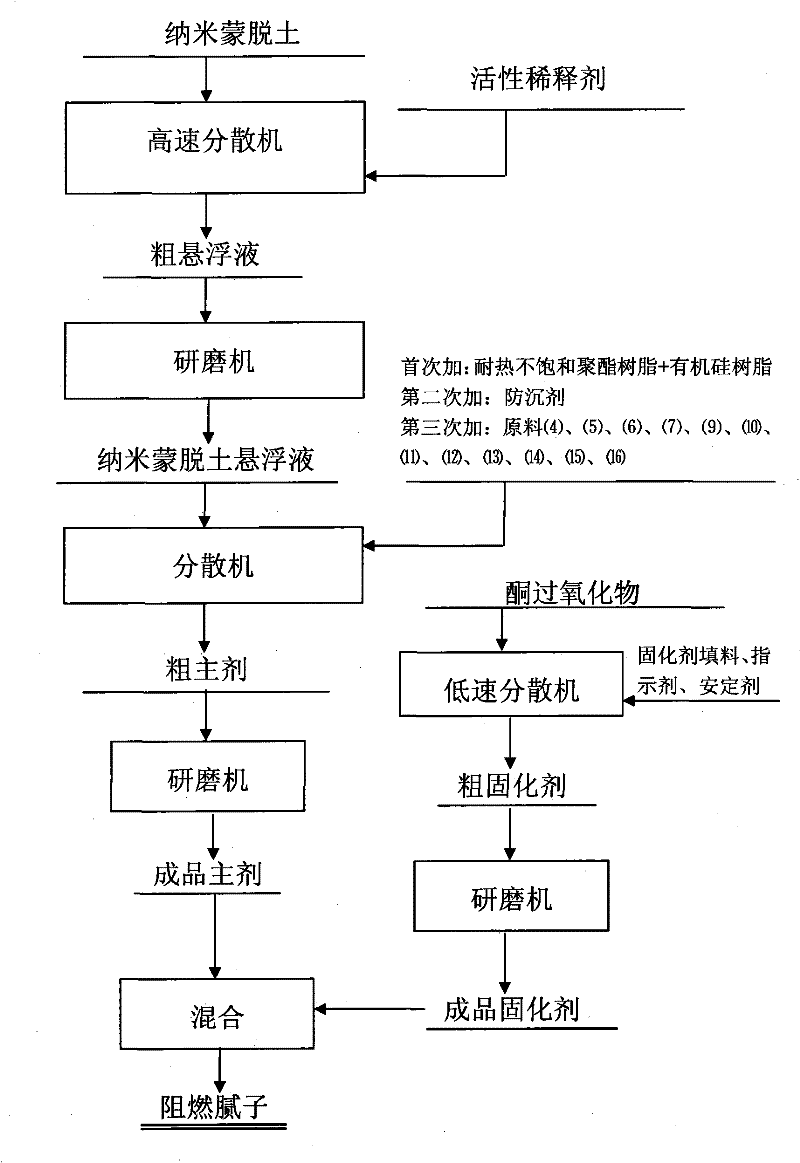

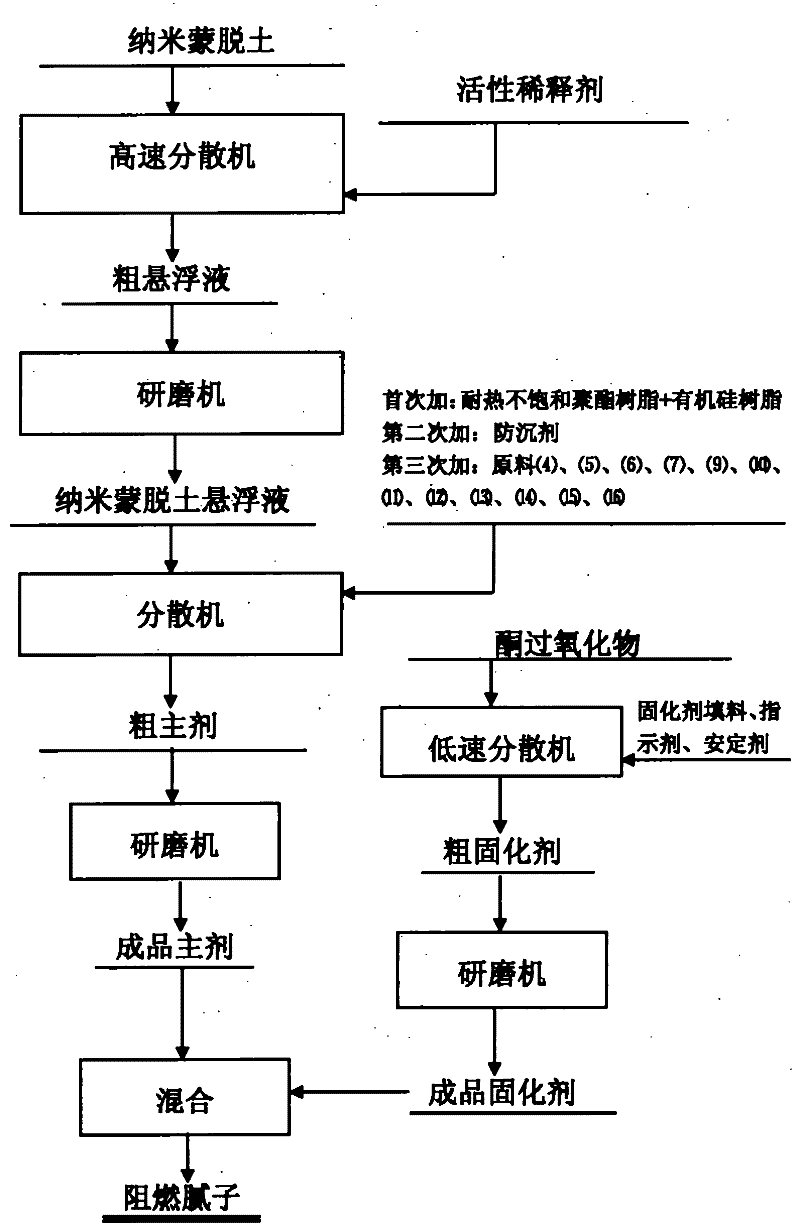

Flame-retarding lacquer putty and preparation method thereof

InactiveCN101696331BImprove heat resistanceImprove air drynessFilling pastesDimethylaniline N-oxideKetone

The invention discloses flame-retarding lacquer putty and a preparation method thereof, and aims to provide air-dried organic silicon-modified unsaturated flame-retarding lacquer putty which has good comprehensive performance, long-term use at the temperature of below 250 DEG C and self-drying property at normal temperature to meet special requirements of subway vehicles and casthouse vehicles, wheel shafts, smoke (steam) passages and the like in other high temperature places. The air-dried organic silicon-modified unsaturated flame-retarding lacquer putty is characterized by being prepared by mixing raw material nano-montmorillonite not containing a halogen element compound, reactive diluent, a heat-resistant unsaturated polyester resin, an organic silicon resin, a special filler, a flame retardant, a low shrinkage additive, a stabilizer, dimethylaniline, a dispersant, titanium dioxide, hollow glass micro-beads, a drier, molybdenum disulfide, talcum powder, ketone peroxide, a curing agent filler, quinacridone bluish red and polyvinylpyrrolidone in a certain proportion, dispersing and grinding the mixture to prepare a main agent and a curing agent, and mixing the main agent with the curing agent. The flame-retarding lacquer putty is mainly used as a bottom coating material for subway vehicles.

Owner:ZHUZHOU HUALIAN HI TECH

Technique for synthesizing air-dry type oxirene ester resin

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Preparation method of novel special unsaturated polyester resin for handicraft products

The invention discloses a preparation method of a novel special unsaturated polyester resin for handicraft products, and belongs to the technical field of unsaturated polyester resins, wherein unsaturated dibasic acid, saturated dibasic acid and diol are used as main raw materials, and are subjected to an esterification reaction to synthesize a polyester, and the polyester is diluted to obtain the novel special unsaturated polyester resin for handicraft products. According to the present invention, the novel special resin can shorten the surface drying time in a handicraft product preparation process, can maintain good flexibility, has the improved air drying performance while maintains the polishability, and can be used for producing various colors of transparent resin handicraft products so as to widen the application fields of handicraft products.

Owner:淮南舜天合成材料有限责任公司

Synthesis method of modified epoxy vinyl ester resin

The invention belongs to the technical field of macromolecule polymer and relates to a synthesis method of modified epoxy vinyl ester resin. The synthesis method includes the following steps: according to mass percent, adding 35-50% of epoxy resin, 8-20% of unsaturated monocarboxylic acid, 4-18% of dicyclopentadiene maleic acid, 0.1-1.0% of catalyst and 0.01-0.1% of flame retardant in a reactor. The mixture reacts at 90-120 DEG C until the acid value reduces to below 10mg KOH / g at end point of reaction. When cooled below 110 DEG C, 25-40% of crosslinking agent is added. Uniform stirring is conducted at below 70 DEG C to get modified epoxy vinyl ester resin. The advantages of the method are as follows: by replacing the unsaturated monocarboxylic acid partially or wholly with dicyclopentadiene maleic acid to react with epoxy resin, being simple in operation, little of side reaction, easy control on reaction end point, environment-friendly; and producing products fine in air drying property, quick in curing speed, high adhesion of film painting, low contractibility rate and good in corrosion resistance. The synthesis method is applicable to making various products of composite materials and dies.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Resource-saving low-temperature rapid curing insulating impregnated resin and preparation method thereof

The invention relates to a method for preparing resource-saving low-temperature rapid curing insulating impregnated resin by utilizing an oil refining by-product and renewable resource vegetable oil. The impregnated resin consists of the following components: 40-65 parts of DCPD (Dicyclopentadien) modified unsaturated polyester resin with 65wt%-75wt% of solid content, 15-35 parts of acrylic modified epoxy soybean oil with 75wt%-85wt% of solid content, 15-25 parts of reactive diluent, 0.5-2.0 parts of high-temperature initiator, 0.1-1.0 part of low-temperature initiator, and 0.01-0.06 part of polymerization inhibitor. The impregnated resin is stored in mono-component with long working life and can be cured at 80-100 DEG C, thus saving energy.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Air-drying unsaturated polyester resin for easy-polishing gel coat, and preparation method thereof

Owner:CHANGZHOU HUAKE POLYMERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com