Glycerol modified unsaturated polyester resin and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of glycerin modified unsaturated polyester resin and its preparation, to achieve good toughness, good transparency, and good air-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of this glycerol modified unsaturated polyester resin comprises the steps:

[0047] 1S: Crosslinker dilution:

[0048] Dissolve the cross-linking agent in 2-5 times the amount of water, stir and dilute, and set aside;

[0049] 2S: capping reaction:

[0050] Under the protection of inert gas, put glycerin, monobasic acid, and catalyst into the first reaction bottle in turn, start stirring; heat up to 165-175°C for heat preservation reaction for 1-2h; continue to heat up to 205-210°C, and wait for the reaction to reach the acid value Below 11, lower the temperature to 120-140°C to obtain the product and set it aside;

[0051] 3S: Reaction of maleic anhydride with dicyclopentadiene:

[0052] Under the protection of inert gas, put maleic anhydride and water into the second reaction bottle in turn, start stirring, raise the temperature to 120-130°C and keep it warm for 0.5-1h; then add dicyclopentadiene dropwise, and keep the temperature at 125°C du...

Embodiment

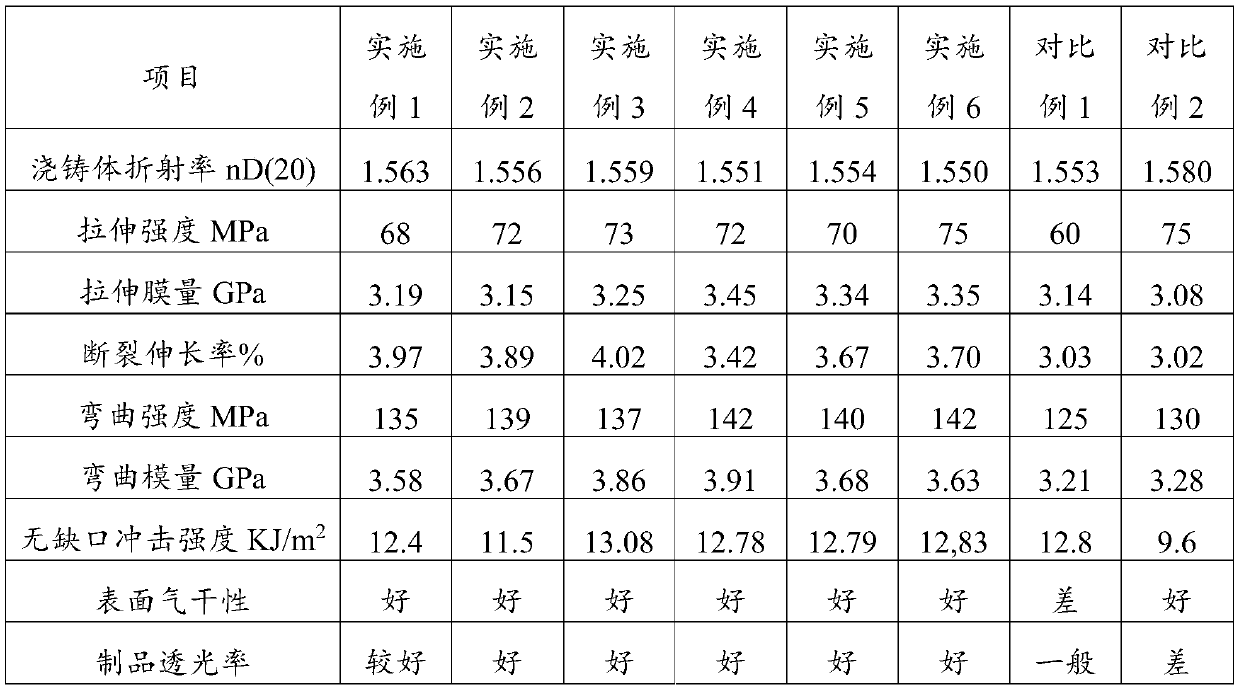

[0057] Table 1 shows specific examples of the contents of various raw materials in partially glycerin-modified unsaturated polyester resins, and the values corresponding to each raw material are percent by mass / %.

[0058] Among them, the monobasic acid is selected from benzoic acid, and the manufacturer is Jiangsu Shunfeng Chemical Co., Ltd.

[0059] The catalyst is monobutyl tin oxide, and the manufacturer is Hangzhou Yuhao Chemical Technology Co., Ltd.;

[0060] The glycol is selected from diethylene glycol (diol 1) or a combination of diethylene glycol and propylene glycol (diol 2), wherein the manufacturer of diethylene glycol is Yanshan Petrochemical, and the manufacturer of propylene glycol is Yanshan Petrochemical;

[0061] Inhibitor selects hydroquinone for use;

[0062] The cross-linking agent was selected from styrene (cross-linking agent 1) or a combination of styrene and methyl methacrylate (cross-linking agent 2).

[0063] The dibasic acid is selected from ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com