Stone material caulking sealant

A kind of jointing glue and stone technology, applied in the field of stone jointing glue, can solve the problems of poor shrinkage resistance, poor air-drying, unsatisfactory filling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

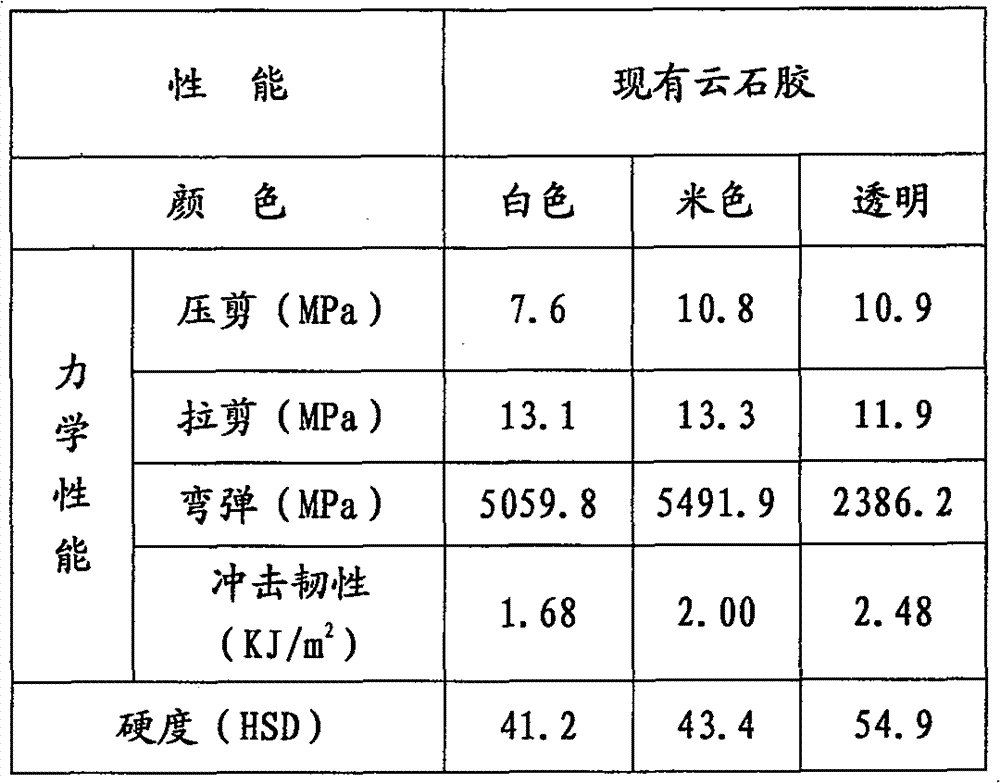

Examples

Embodiment 1

[0036] Embodiment 1 (every part is weight part, the same below)

[0037] Stone pointing glue, which consists of 100 parts by weight of air-drying unsaturated polyester resin, 5 parts by weight of hydrogenated castor oil, 50 parts by weight of 1000 mesh heavy calcium carbonate on average, 2 parts by weight of talcum powder, and 1 part by weight of anti-shrinkage agent Composition, its color is beige.

[0038] The air-drying unsaturated polyester resin is a modified unsaturated polyester resin synthesized from dicyclopentadiene by a half-esterification method, and the anti-shrinkage agent is 1 part by weight of polyacrylate.

[0039] After testing: its compressive shear strength (MPa) is: 16.8, tensile shear strength (MPa): 15.9, bending elasticity (MPa): 6306.1, impact toughness (KJ / m 2 ): 2.86, Hardness (HSD): 61.7, Shrinkage (%): 2.41.

[0040]When in use: the stone pointing glue of the present invention needs to be mixed with the curing agent and stirred evenly, and the mi...

Embodiment 2

[0042] Stone pointing glue, which consists of 100 parts by weight of air-drying unsaturated polyester resin, 1 part by weight of hydrogenated castor oil, 170 parts by weight of calcium carbonate with an average of 300 mesh, 30 parts by weight of Shuangfei powder, and 3 parts by weight of talcum powder. 15 parts by weight of agent and 5 parts by weight of reactive diluent, its color is beige.

[0043] The air-drying unsaturated polyester resin is allyl glycidyl ether modified unsaturated polyester resin, the anti-shrinkage agent is 7 weight parts of polyvinyl acetate, 8 weight parts of polypropyl acetate, and the reactive diluent is glycerin diallyl 2 parts by weight of base ether adipate, 3 parts by weight of diallyl phthalate.

[0044] After testing: its compressive shear strength (MPa) is: 13.5, tensile shear strength (MPa): 14.8, bending elasticity (MPa): 6812.2, impact toughness (KJ / m 2 ): 2.43, Hardness (HSD): 50.2, Shrinkage (%): 0.12.

[0045] Using method is the same...

Embodiment 3

[0047] Stone pointing glue, which consists of 100 parts by weight of air-drying unsaturated polyester resin, 3 parts by weight of hydrogenated castor oil, 130 parts by weight of heavy calcium carbonate of 300 mesh on average, 20 parts by weight of quartz powder, and 8 parts by weight of anti-shrinkage agent Composition, reactive diluent 3 weight parts are formed, and its color is beige.

[0048] The air-drying unsaturated polyester resin is an allyl glycidyl ether modified unsaturated polyester resin, the anti-shrinkage agent is 3 parts by weight of polyacrylate, 5 parts by weight of polyglycerol adipate, and the reactive diluent is 3 parts by weight of diallyl phthalate.

[0049] After testing: its compressive shear strength (MPa) is: 15.3, tensile shear strength (MPa): 16.2, bending elasticity (MPa): 6704.5, impact toughness (KJ / m 2 ): 2.71, Hardness (HSD): 54.8, Shrinkage (%): 0.76.

[0050] Using method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com