Method for preparing air drying epoxy vinyl ester resin

A technology of epoxy vinyl ester and epoxy resin, which is applied in the field of high molecular polymers, can solve the problems of high reaction temperature and high cost of raw materials, and achieve the effects of high adhesion of paint film, good product stability and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

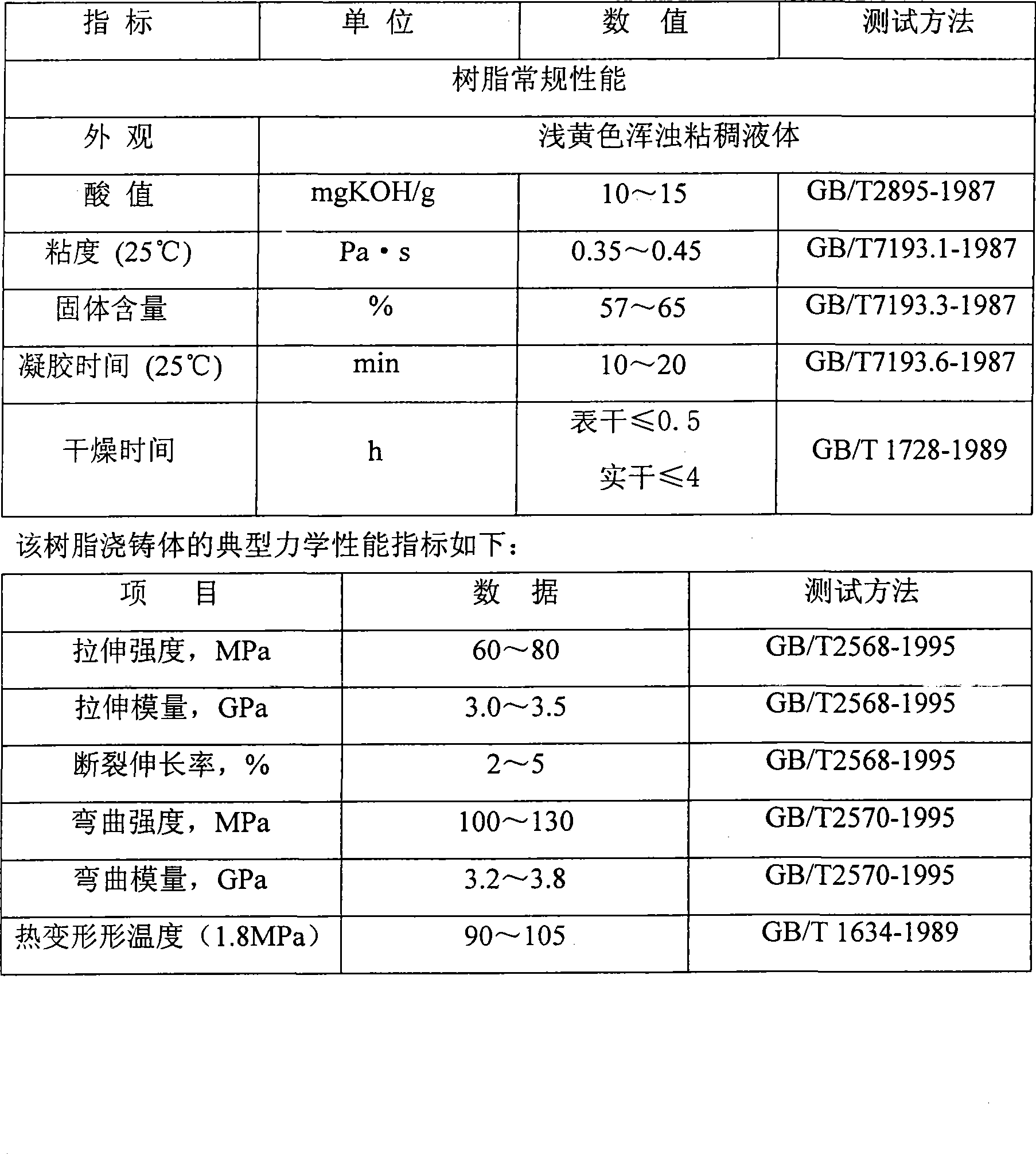

Embodiment 1

[0028] Put 196g of E51 bisphenol A epoxy resin, 70g of methacrylic acid, 23.5g of fumaric acid, 1g of benzyldimethylamine, and hydroquinone into a 500ml reactor with a thermometer, agitator, nitrogen inlet pipe and condenser 0.10g, start stirring, gradually raise the temperature, and control the reaction at 110°C for 4 hours. 28 g of dicyclopentadiene was slowly added dropwise to the reaction system, and the temperature was controlled at 110° C. for 3 hours until the acid value dropped below 20 mgKOH / g. Cool the reaction product below 110°C and add 180g of styrene, mix well, cool down to 60°C and discharge, filter to obtain a light yellow viscous liquid.

Embodiment 2

[0030] Put 392g of E51 bisphenol A epoxy resin, 160g of methacrylic acid, 24g of fumaric acid, 3g of benzyldiethylamine, and methylterephthalene into a 1000ml reactor equipped with a thermometer, stirrer, nitrogen inlet pipe and condenser. 0.24g of phenol, start stirring, gradually increase the temperature, and control the reaction at 90°C for 6 hours. 30 g of dicyclopentadiene was slowly added dropwise to the reaction system, and the temperature was controlled at 130° C. to react for 1 hour until the acid value dropped below 20 mgKOH / g. Cool the reaction product below 110°C and add 395g of styrene, mix well, cool down to 60°C and discharge, filter to obtain a light yellow viscous liquid.

Embodiment 3

[0032] 196g of E51 bisphenol A epoxy resin, 60g of methacrylic acid, 37.5g of fumaric acid, 2g of benzyltriethylammonium chloride, 4 - 0.12 g of tert-butylcatechol, start stirring, gradually raise the temperature, and control the reaction at 130° C. for 2 hours. 48 g of dicyclopentadiene was slowly added dropwise to the reaction system, and the temperature was controlled at 110° C. to react for 3 hours until the acid value dropped below 20 mgKOH / g. Cool the reaction product below 110°C and add 180g of styrene, mix well, cool down to 60°C and discharge, filter to obtain a light yellow viscous liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com