PUR adhesive for glass cover plate and middle frame and preparation method of PUR adhesive

A glass cover, adhesive technology, applied in the directions of adhesives, adhesive additives, adhesive types, etc., can solve the problems of limited application and low mechanical properties, and achieve good fluidity, good compatibility, and impact resistance. and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

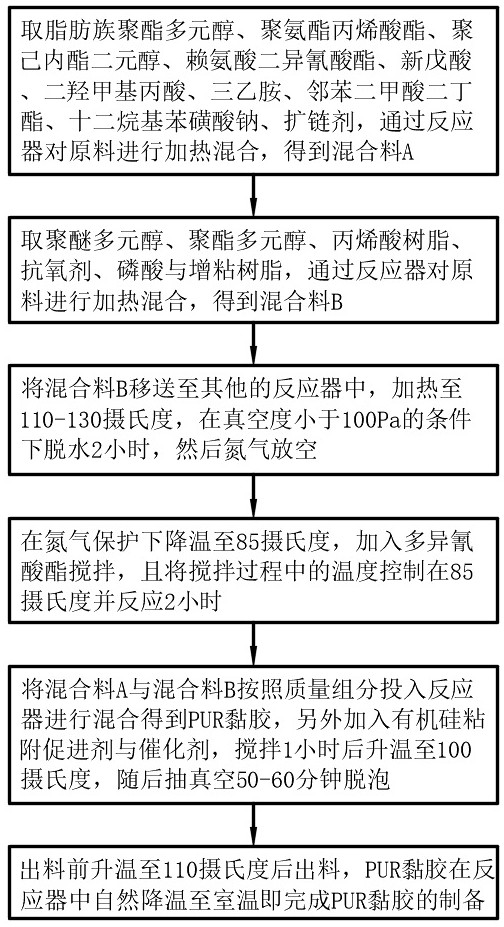

Method used

Image

Examples

Embodiment 1

[0028] A glass cover and a PUR adhesive in the box, including the following formulation according to the mass component:

[0029] According to the mass component, 90 parts of the aliphatic polyester polyol, 80 polyurethane acrylate, 12 parts of polycaprolactone diols, 1.5 lysine diisocyanate, 12 parts of new glutaic acid, two 5 parts of hydroxymethyl proppropion, 6 parts of triethylamine, 2.5 dibutyl phthalate, 2.5 parts of dodecyl benzene sulfonate, 6 chain extenders; 1.5 silicone adhesive promoters, 0.1 parts of the catalyst, 31 polyether polyols, 22 parts of the polyester polyol, 10.5 parts of acrylic resin, 0.05 parts of an antioxidant, 0.02 parts of phosphoric acid, and 15 polyisocyanate and 7 tackifumes.

[0030] The polyisocyanate is disposed as a toluene diisocyanate, a diphenyl methane diisocyanate, a multi-methylene polyphenylene polyisocyanate, a hexamethylene diisocyanate trimer.

[0031] The present invention also provides a method for preparing a glass cover and a PU...

Embodiment 2

[0040] Unlike Example 1, according to the mass component, including 99 parts of the aliphatic polyester polyol, 100 parts of polyurethane acrylate, 18 parts of polycaprolactone diol, 2.5 lysine diisocyanate, 18 parts of neutral acid, 10 parts of dihydroxymethyl proppropion, 9 serviene, dibutyl phthalate, 4.5 parts of dodecylbenzene sulfonate, 1 chain extender; organic 2.5 parts of silicon adhesion promoter, 0.5 parts of catalyst, 39 polyether polyols, 28 parts of polyester polyol, 19.5 parts of acrylic resin, 0.2 parts of an antioxidant, 0.02 parts of phosphoric acid, polyisocyanate 19 parts and tackifune 19 share.

Embodiment 3

[0042] Unlike Example 1, according to the mass component, including 95 parts of the aliphatic polyester polyol, 90 parts of urethane acrylate, 15 parts of polycaprolactone diol, 2 lysine diisocyanate, 16 parts of neutral acid, 8 parts of dihydroxymethyl proppropion, 7 serviene, 4 parts of phthalate, 3.5 parts of dodecyl benzene sulfonate, 8 coplaced agents; organic 2 parts of silicon adhesion promoter, 0.3 copies of catalyst, 35 parts of polyether polyol, 25 parts of polyester polyol, 15 parts of acrylic resin, 0.1 parts of an antioxidant, 0.02 parts of phosphoric acid, 17 parts of polyisocyanate and tackifying resin 13 share.

[0043] In summary: By taking allowance polyester polyol, polyurethane acrylate, acrylic resin, antioxidant, polyisocyanate stirring with the organic silicone adhesion promoter and catalyst, etc., additionally equipped with a vacuum deproduction process; the polyurethane The adhesive and a variety of plastic and metal substrates have a good bonding effect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com