A kind of epoxy oligomer chain extender and preparation method thereof

A technology of oligomer and chain extender, applied in the field of chain extender and its preparation, can solve the problems that the impact strength of polyester materials is not significantly improved, the development of PET recycling industry is affected, and the gel of chain extension products can be increased, and the interface can be increased. Compatibility, narrow molecular weight distribution of products, and the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

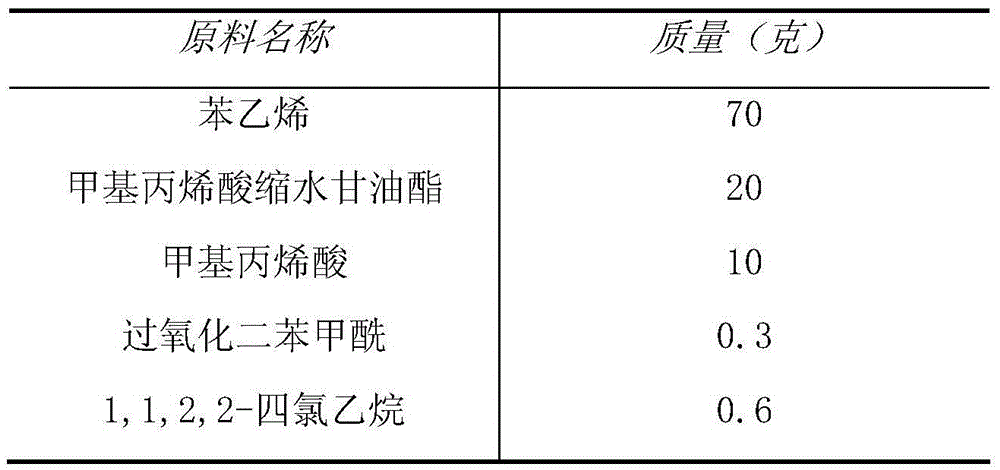

Embodiment 1

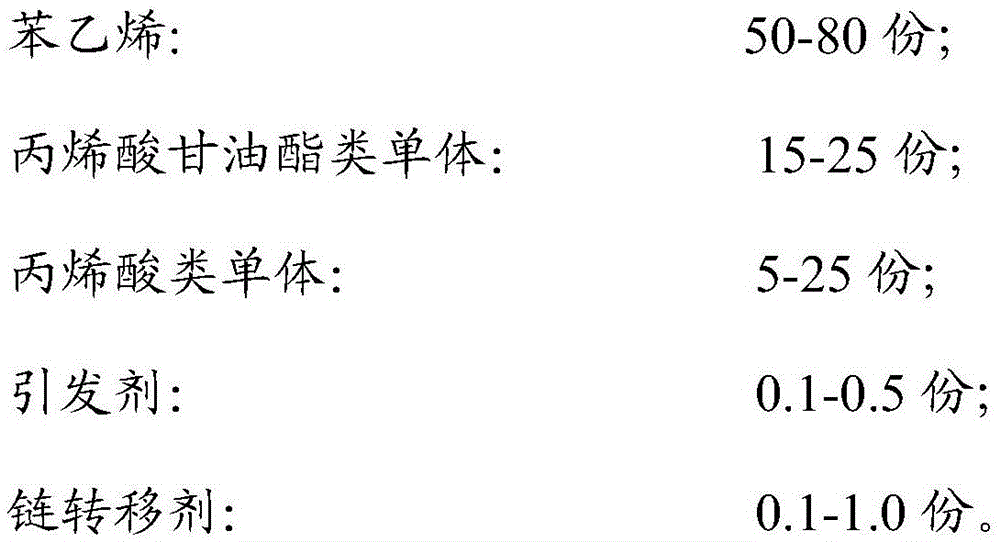

[0025] formula

[0026]

[0027] synthetic route

[0028] In a 500ml three-necked round-bottom flask, add 300ml of distilled water, and at the same time add an emulsifier with a total monomer mass of 0.2g, and heat to a constant temperature of 120°C. Then weigh the raw materials according to the above proportioning ratio, and the total mass of the monomers is 100g. After mixing the above raw materials evenly, add them into the reaction bottle at one time. N2 protection, stirring, and constant temperature reaction at 120°C for 2 hours to obtain a crude product, then collect white particles, carry out suction filtration, and wash with hot distilled water twice, and vacuum dry at 60°C for 12 hours to obtain the epoxy compound of the present invention. Oligomer chain extender products.

[0029] The epoxy oligomer chain extender of the present invention is used for the reaction extrusion chain extension of recycled PET, the recycled PET does not need to be dried, the molecula...

Embodiment 2

[0031] formula

[0032]

[0033] synthetic route

[0034] In a 500ml three-necked round-bottom flask, add 400ml of distilled water, and at the same time add an emulsifier with a total mass of 0.3g of monomers, and heat to a constant temperature of 150°C. Then weigh the raw materials according to the above proportioning ratio, and the total mass of the monomers is 100g. After mixing the above raw materials evenly, add them into the reaction bottle at one time. N2 protection, stirring, and constant temperature reaction at 150°C for 1 hour to obtain a crude product, then collect white particles, perform suction filtration, wash with hot distilled water 4 times, and vacuum dry at 60°C for 14 hours to obtain epoxy compounds of the present invention. Oligomer chain extender products.

[0035] When the epoxy oligomer chain extender of the present invention is used for reaction extrusion chain extension of recycled nylon, the molecular weight and intrinsic viscosity of recycled ...

Embodiment 3

[0037] formula

[0038]

[0039] synthetic route

[0040] In a 1000ml three-necked round-bottom flask, add 500ml of distilled water, and at the same time add 0.5g of emulsifier with a total monomer mass, and heat to a constant temperature of 130°C. Then weigh the raw materials according to the above proportioning ratio, and the total mass of the monomers is 100g. After mixing the above raw materials evenly, add them into the reaction bottle at one time. N2 protection, stirring, and constant temperature reaction at 130°C for 1.5 hours to obtain a crude product, then collect white particles, perform suction filtration, wash with hot distilled water for 3 times, and vacuum dry at 60°C for 18 hours to obtain epoxy compounds of the present invention. Oligomer chain extender products.

[0041]The epoxy oligomer chain extender of the present invention is used in PET / PA alloys. After adding the chain extender, the compatibility of the alloy is improved, and the impact strength a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com