Modified natural rubber waterproof emulsion and preparation method thereof

A natural rubber and waterproof emulsion technology, which is applied in natural rubber coatings, anti-corrosion coatings, coatings, etc., can solve the problems of high glass transition temperature, poor low-temperature film-forming property, water resistance, etc., and achieve excellent anti-aging performance, acid and alkali resistance Good performance and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

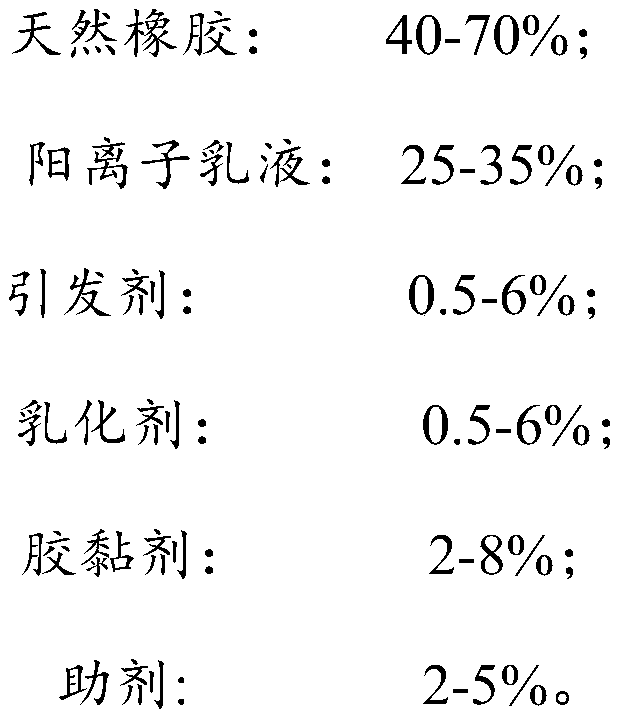

[0034] Embodiment 1 A kind of modified natural rubber waterproof emulsion, comprises each component of following mass percent:

[0035]

[0036] The emulsifier is commercially available polyurethane-acrylate composite latex. The initiator is ammonium persulfate. The adhesive is selected from chloroprene phenolic adhesives.

[0037] Described auxiliary agent comprises each component accounting for the following mass percentages of described waterproof emulsion gross mass:

[0038] Defoamer: 1%;

[0039] Stabilizer: 0.5%;

[0040] Thickener: 0.5%;

[0041] Fungicide: 0.5%;

[0042] Multifunctional additive: 0.5%.

[0043] The defoamer is a polyether silicone oil defoamer. The stabilizer is gas phase titanium dioxide. The thickener is a polyacrylate thickener. The fungicide is benzisothiazolinone. The multifunctional auxiliary agent AMP-95.

[0044] The preparation method of described modified natural rubber waterproof emulsion, comprises the steps:

[0045] (1) Th...

Embodiment 2

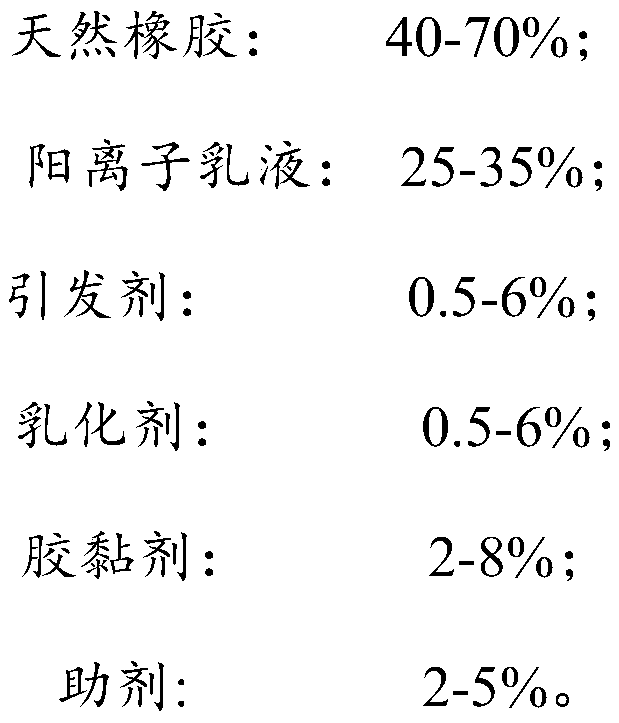

[0048] Embodiment 2 A kind of modified natural rubber waterproof emulsion, comprises each component of following mass percentage content:

[0049]

[0050]

[0051] The emulsifier is commercially available polyurethane-acrylate composite latex. The initiator is potassium persulfate. The adhesive is selected from epoxy resin adhesives.

[0052] Described auxiliary agent comprises each component accounting for the following mass percentages of described waterproof emulsion gross mass:

[0053] Defoamer: 2%;

[0054] Stabilizer: 1%;

[0055] Thickener: 0.5%;

[0056] Fungicide: -0.5%;

[0057] Multifunctional Auxiliary: 1%.

[0058] The defoamer is a silicone oil emulsion defoamer. The stabilizer is nano ceria. The thickener is a polyacrylate thickener and a polyurethane thickener. The fungicide is isothiazolinone. The multifunctional auxiliary agent AMP-96.

[0059] The preparation method of described modified natural rubber waterproof emulsion, comprises the st...

Embodiment 3

[0063] Embodiment 3 A kind of modified natural rubber waterproof emulsion, comprises each component of following mass percentage content:

[0064]

[0065]

[0066] The emulsifier is commercially available polyurethane-acrylate composite latex.

[0067] The initiator is sodium persulfate. The adhesive is polyurethane adhesive.

[0068] Described auxiliary agent comprises each component accounting for the following mass percentages of described waterproof emulsion gross mass:

[0069] Defoamer: 0.5;

[0070] Stabilizer: 0.5;

[0071] Thickener: 0.25;

[0072] Fungicide: 0.25;

[0073] Multifunctional additive: 0.5.

[0074] The defoamer is a polyether silicone oil defoamer. The stabilizer is gas phase titanium dioxide. The thickener is a polyurethane thickener. The bactericide is a mixture of isothiazolinone and benzisothiazolinone. The multifunctional auxiliary agent AMP-95.

[0075] The preparation method of described modified natural rubber waterproof emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com