Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "Strong endurance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

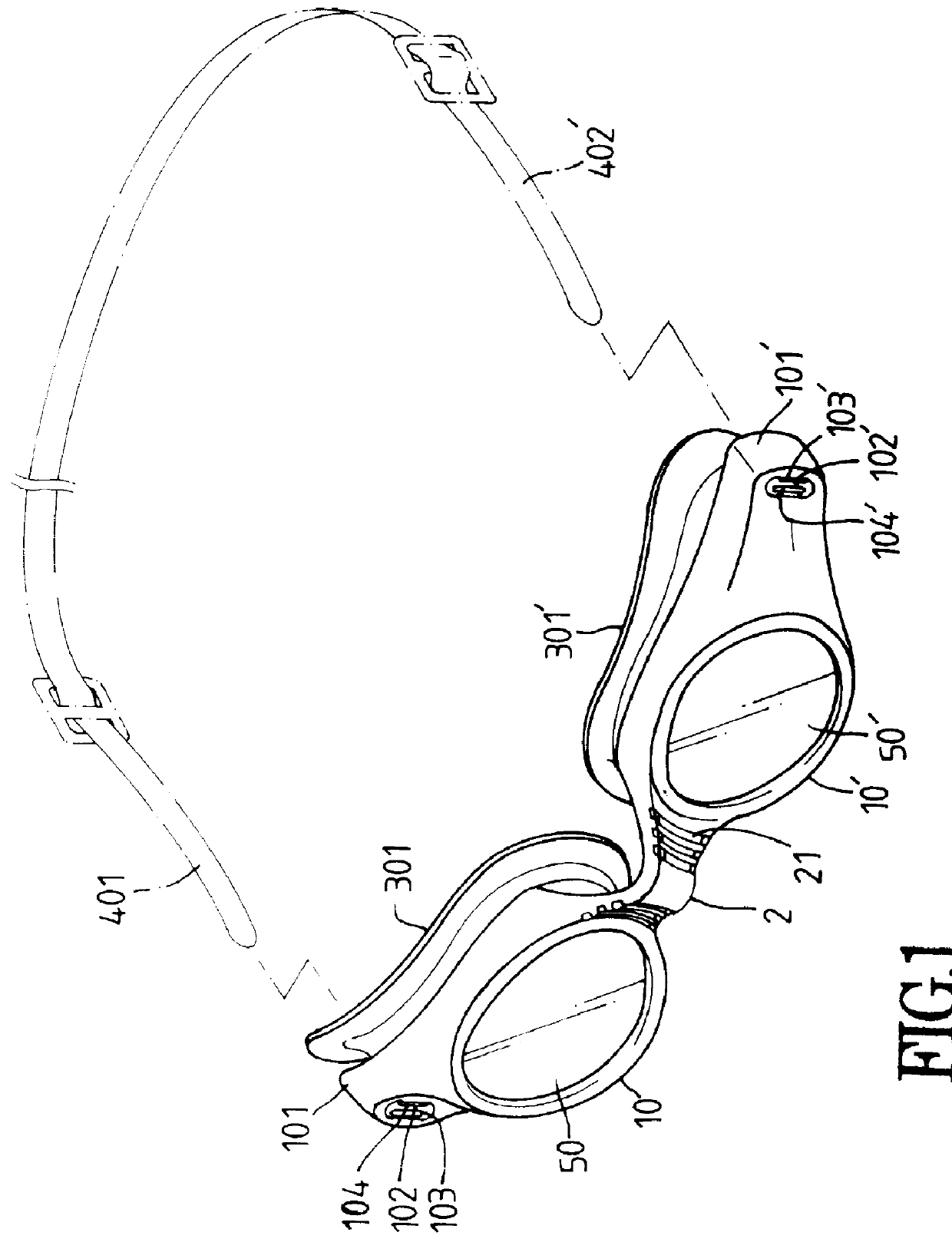

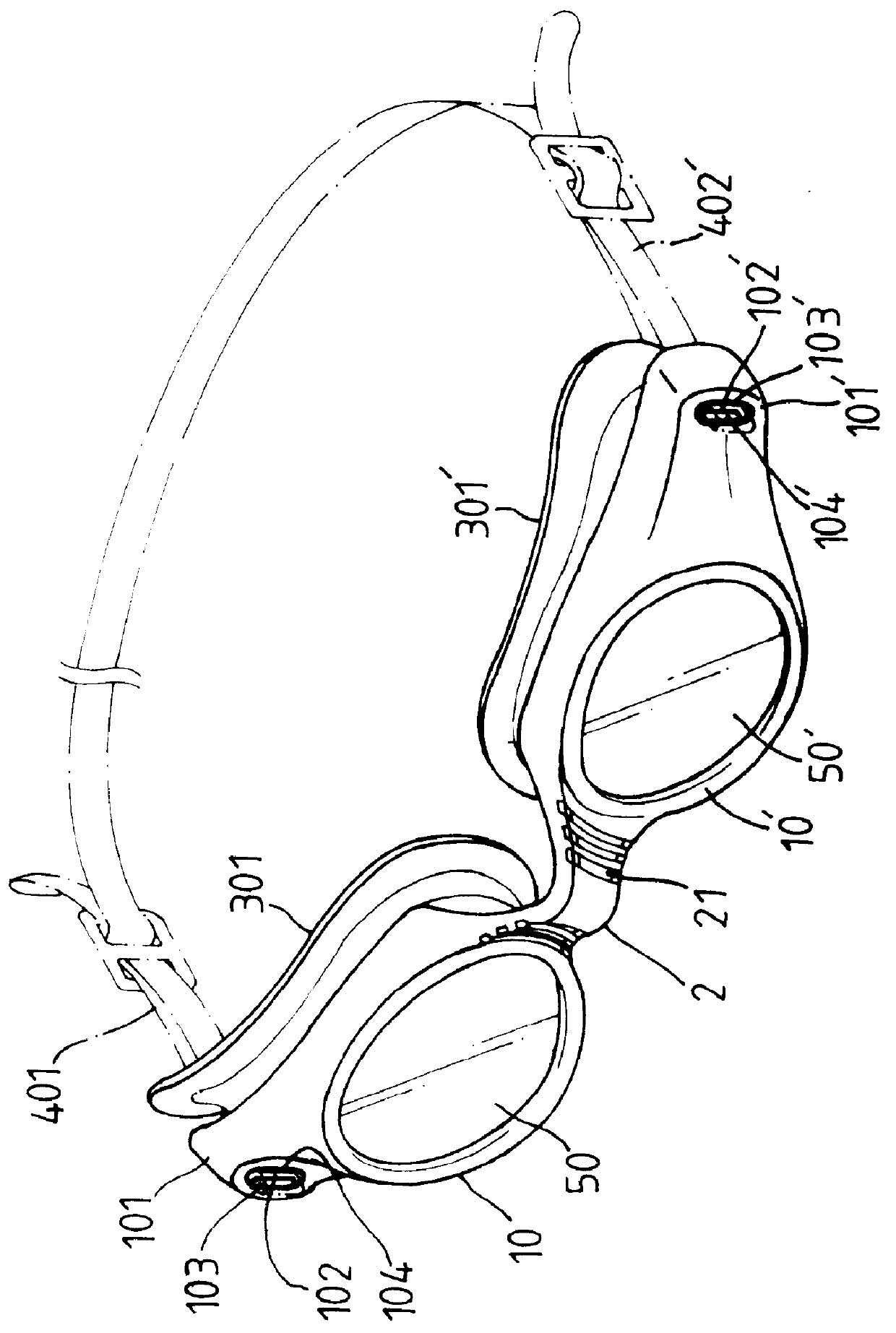

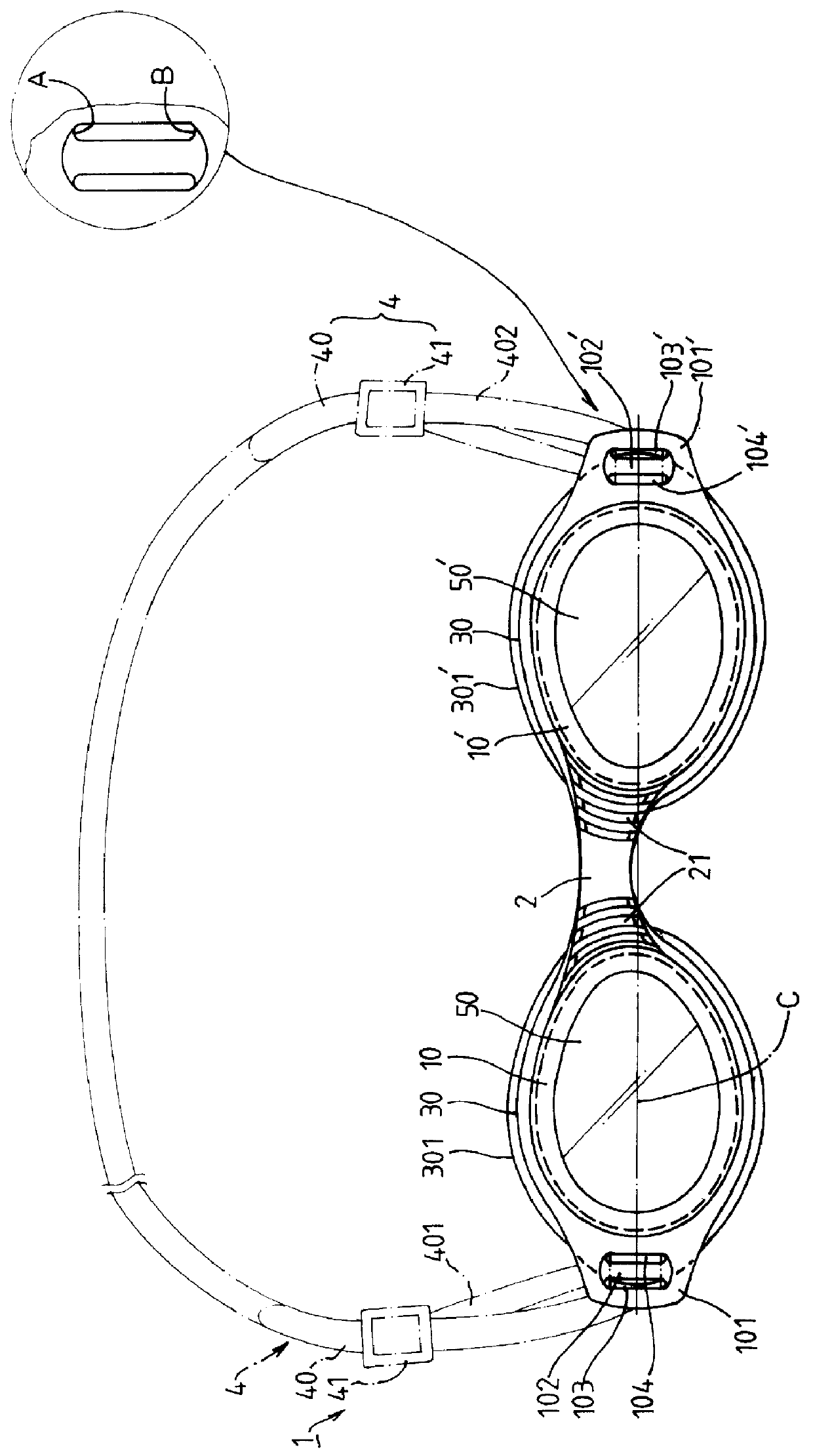

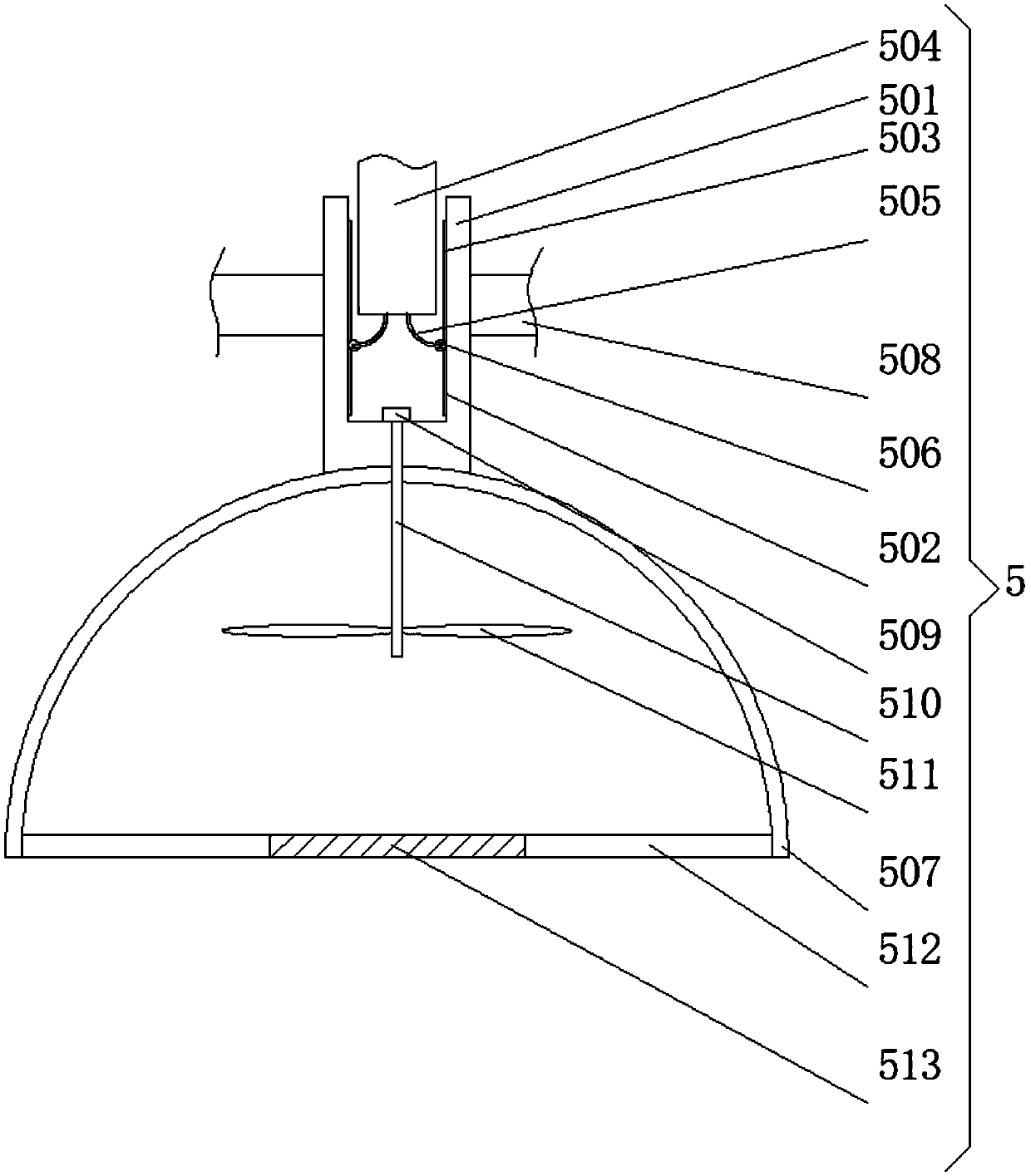

Goggles with connecting plate assembly at outer ends

The creation is to provide a type of new structure for swimming goggle. It is a one piece swimming goggle consists of the lens frames, nose rest and protective pads. The main features of the swimming goggle lies with: the combined mount of the frame comprises no less than one vertical rib in partitioning into no less than two assembly areas, and through the assembly areas, the headband of the swimming goggle can go through, and wind over the rib so that when putting on the swimming goggle, the pull force is absorbed by the rib to ensure that the frame shall not distort in achieving distributing the pull force while wearing the swimming goggle. The simplified structure shall enable cost reduction.

Owner:CHIANG HERMAN

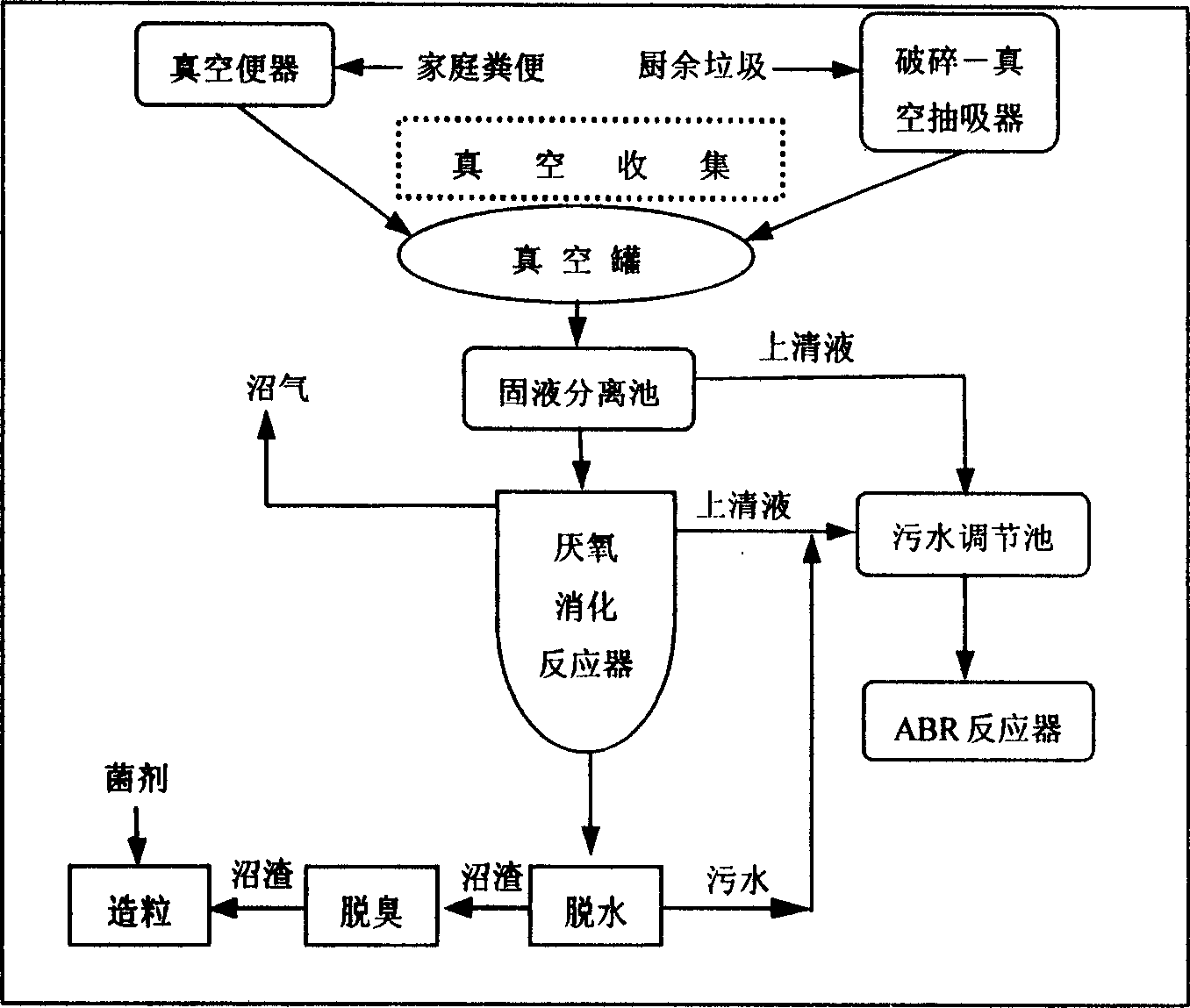

Organic refuse and fecal separating and collecting treatment

InactiveCN1644538AAvoid enteringReduce yieldBio-organic fraction processingSolid waste disposalWater dischargeFeces

A classifying collecting and treating method for organic refuse and excrement includes: 1) sucking the refuse and excrement into vacuum tubing net; 2) mixing them by vacuum pot and discharging into solid-liquid separated pool, and discharging the solid into anaerobic digesting reactor; 3) concentrating and dewatering the marsh slag discharged, adding deodorized bacterial strain, piling up and deodorizing; 4) adding digesting mud into bacterial strain cultured, culturing, drying and obtaining organic composite bacterial manure; 5) discharging the clear liquid and sewage into anaerobic and oxygen sewage treating unit, and the outlet water discharging into sewage tubing net or water body. Its advantages include lower mud output rate and mud account, and higher mud age.

Owner:HUAZHONG UNIV OF SCI & TECH

Novel high-hardness plastic shell composition for capacitor

The invention discloses a novel high-hardness plastic shell composition for a capacitor. The novel high-hardness plastic shell composition is characterized by consisting of the following components in parts by weight: 35 parts of polypropylene, 15 parts of linear polyethylene, 10 parts of a high barrier film, 5 parts of polypropylene random copolymer, 5 parts of di-tert-butyl peroxide, 2 parts of cassava flour, 5 parts of modified wood plastic powder, 2 parts of tributyl citrate, 2 parts of silicone rubber, 2 parts of glycerol, 5 parts of carbon fiber, 2 parts of a rear-earth light converter, 2 parts of diphenyl silanediol, 2 parts of a plasticizer, 2 parts of silicon carbide micro powder, 2 parts of a lubricant, 2 parts of paraffin, 2 parts of vermiculite, 2 parts of sepiolite fabric, 2 parts of glass fibers, 2 parts of rear earth and 2 parts of talcum powder. The novel high-hardness plastic shell composition disclosed by the invention is simple in component and low in cost; the prepared finished product has good toughness, strong bearing capacity and high compactness, is easy to degrade and nonhazardous under a high temperature environment; meanwhile, the conventional preparation process is changed and a freezing process is increased, so that the safety of the product is improved and the product has relatively good stable performance at a relatively high temperature.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

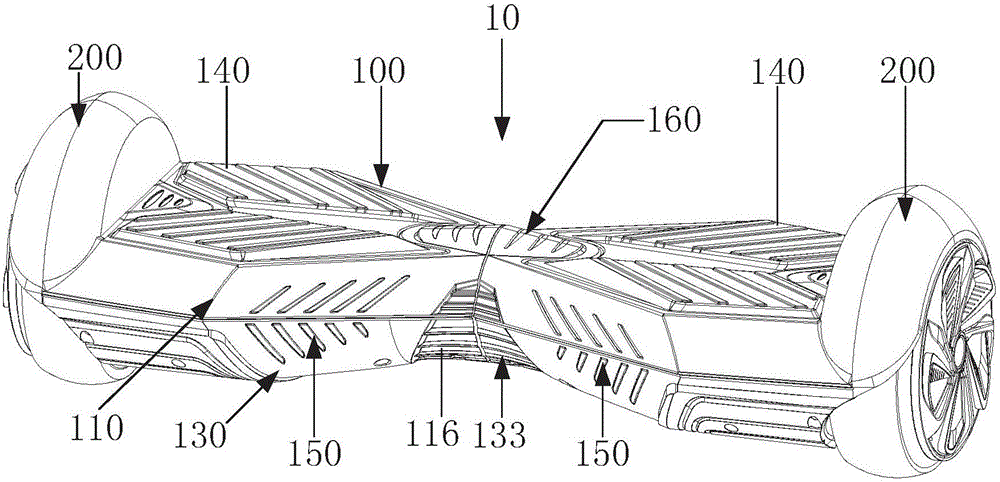

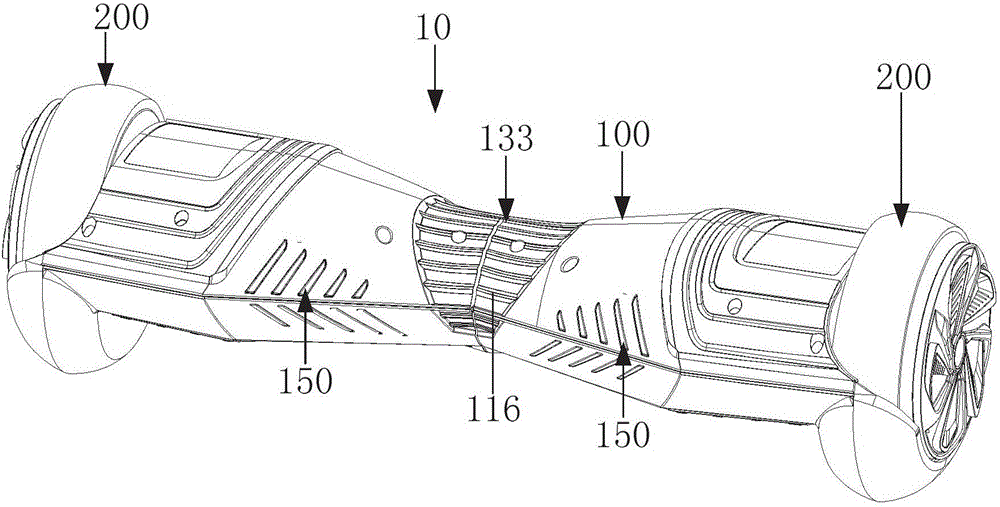

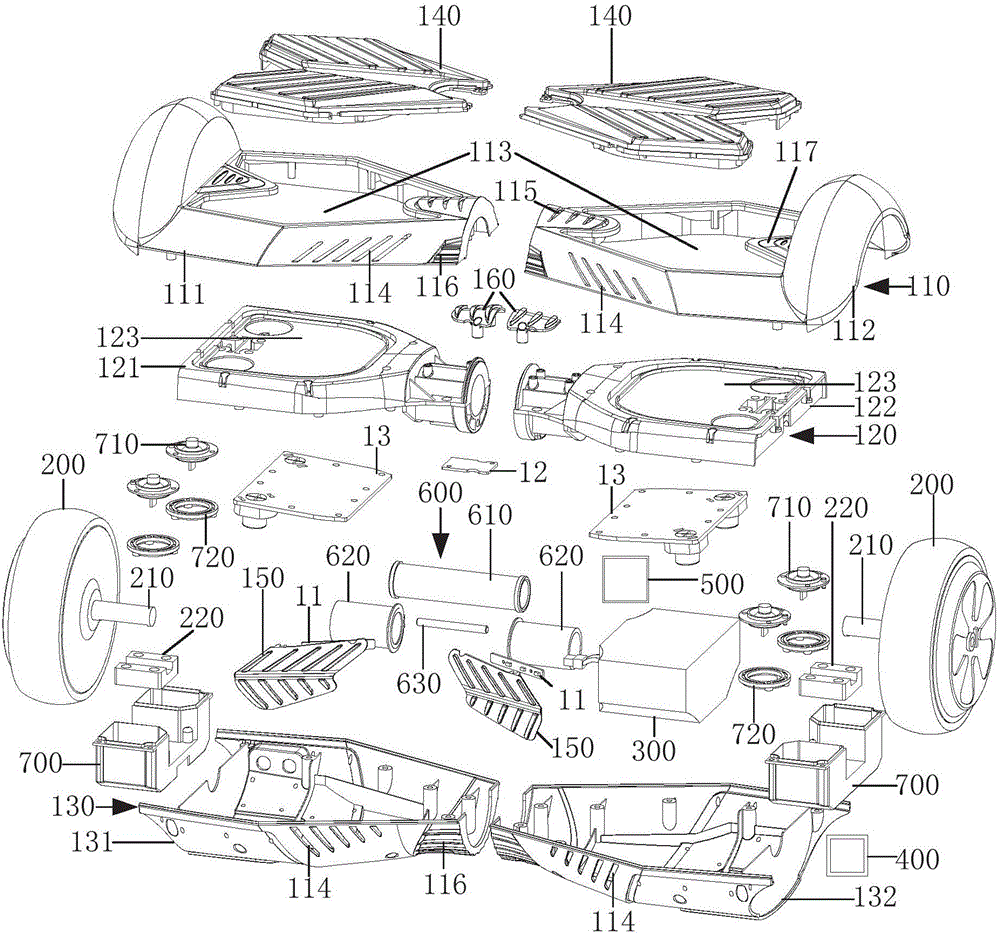

Electric balance car

The invention discloses an electric balance car which comprises a car body, wheels, a drive motor used for driving the wheels, a power supply used for providing power, a circuit board, a controller and a light-emitting lamp, wherein the circuit board is provided with a sensor, the light-emitting lamp is electrically connected with the power supply, and the controller is electrically connected with the circuit board, the power supply and the drive motor. The car body comprises an upper shell, pedals, a middle shell, a lower shell and a lampshade. The middle shell is located between the upper shell and the lower shell. The lampshade is provided with at least two light-pervious lamp strips arranged in a spaced mode. The upper shell is provided with a lamp hole used for containing one or at least two lamp strips. The lower shell is provided with a lamp hole used for containing one or at least two lamp strips. The sum of the lamp holes of the upper shell and the lower shell is the same as the number of the lamp strips. The car body is provided with at least two lamp holes when used for installing and fixing the lampshade. Compared with the structure that only one lamp hole is arranged to be matched with a lampshade, by means of the balance car, the lampshade is firmer when fixedly installed on the car body and is not likely to shake.

Owner:深圳市骜途智能科技有限公司

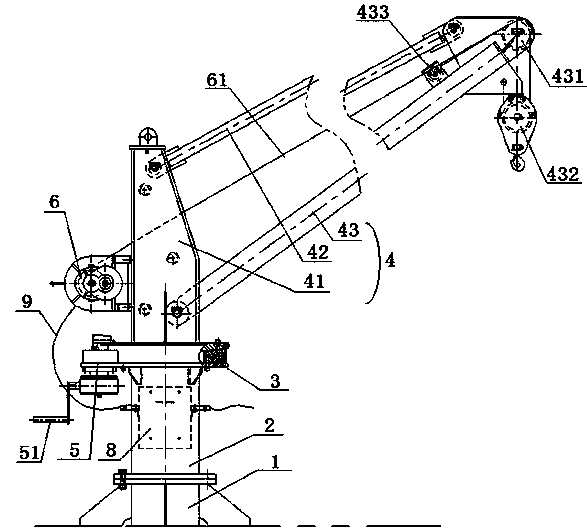

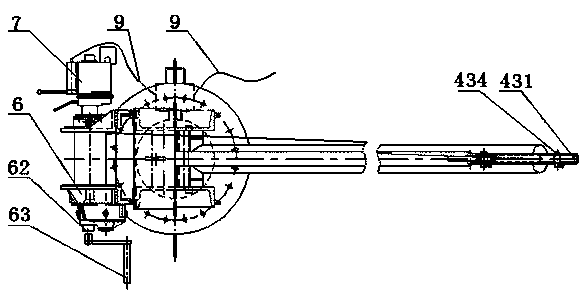

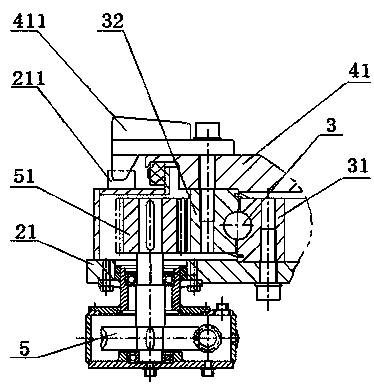

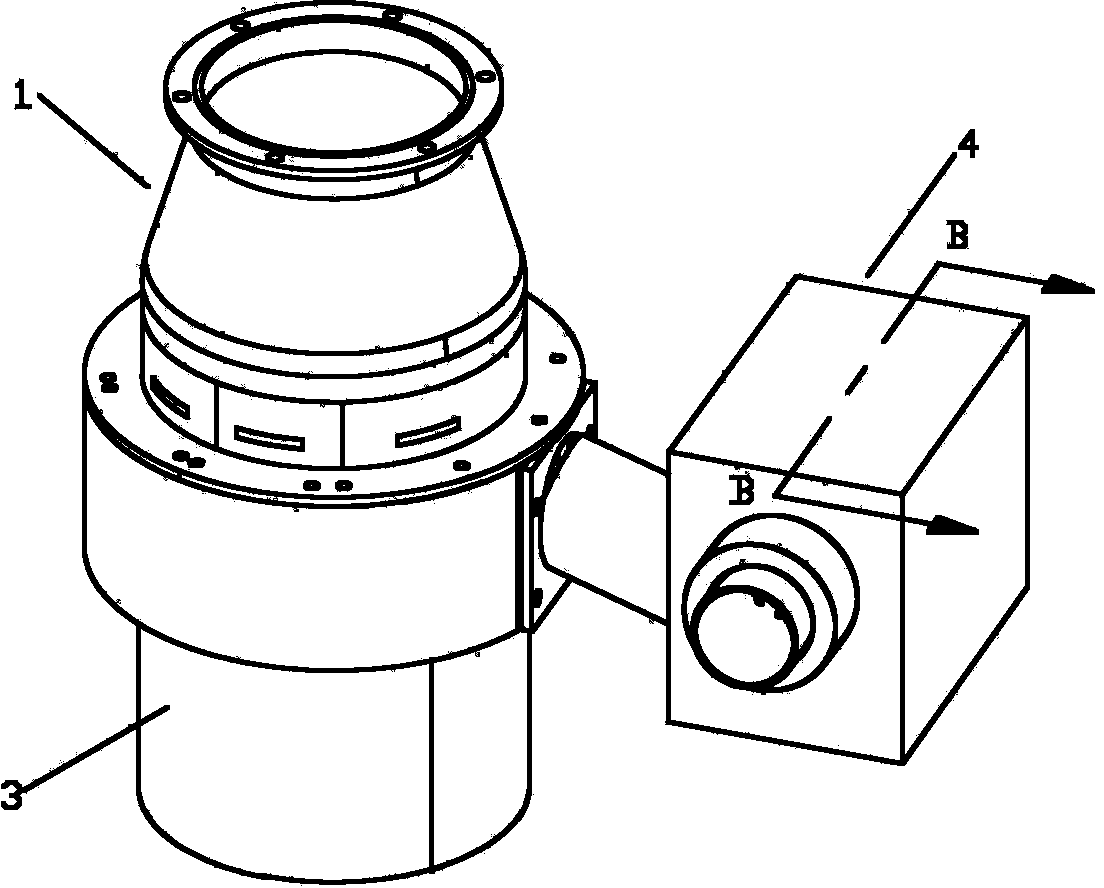

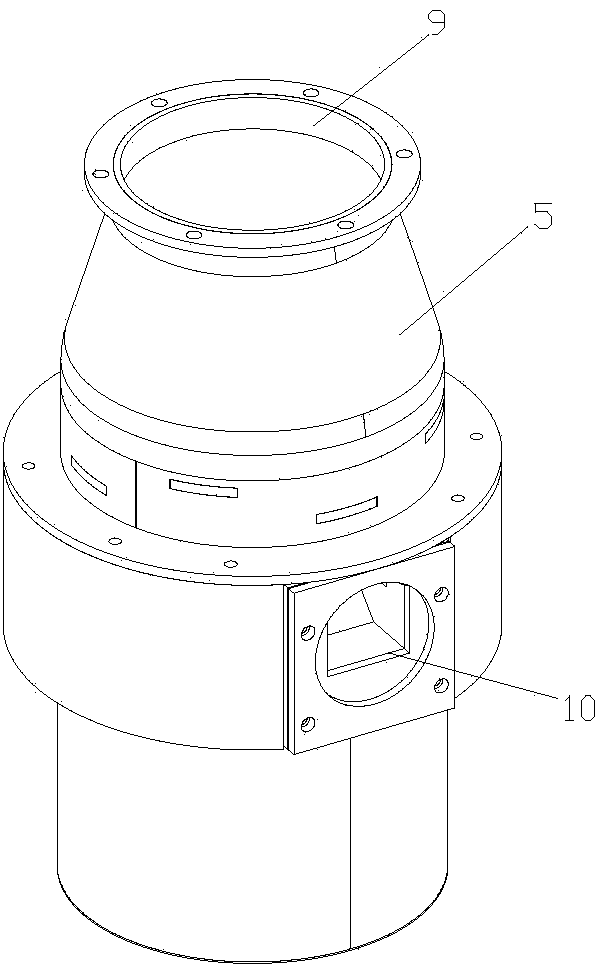

Marine fixed sundry crane

The invention discloses a marine fixed sundry crane. The marine fixed sundry crane comprises a base (1), a lifting base (2), a rotary part (4), a rotary speed reducer (5), a lifting winch (6) and a pneumatic motor (7), wherein lifting base (2) is fixedly connected with the base (1); the rotary part (4) is connected with the lifting base (2) by a rotary support (3); the rotary speed reducer (5) is meshed with the rotary support (3); the lifting winch (6) is fixedly connected with the rotary part (4); a lifting steel wire rope (61) is wound on a coiling block of the lifting winch (6); a free end of the lifting steel wire rope (61) bypasses a fixed pulley (431) along the axial direction of the support rod (43); a movable block (432) is lifted; the end part of the free end is fixed on a fixed pin shaft of the support rod (43) and is connected with an input opening of the lifting winch (6); the pneumatic motor (7) provides power for the lifting winch (7). The sundry crane is driven by the pneumatic motor, and has the advantages of safety, reliability, concise and compact structure, low manufacturing cost, operation convenience and the like.

Owner:DALIAN XINFEI MARINE MACHINERY

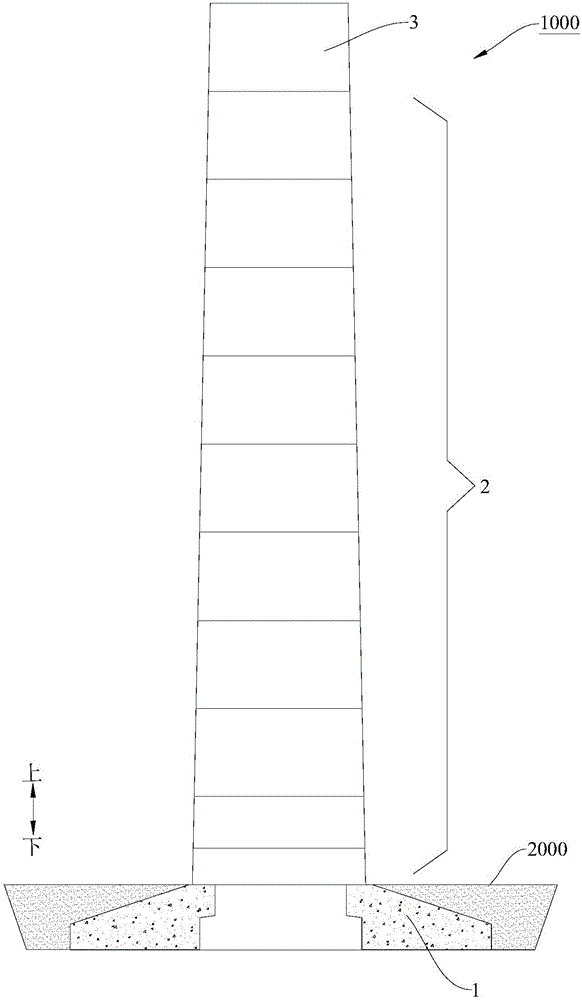

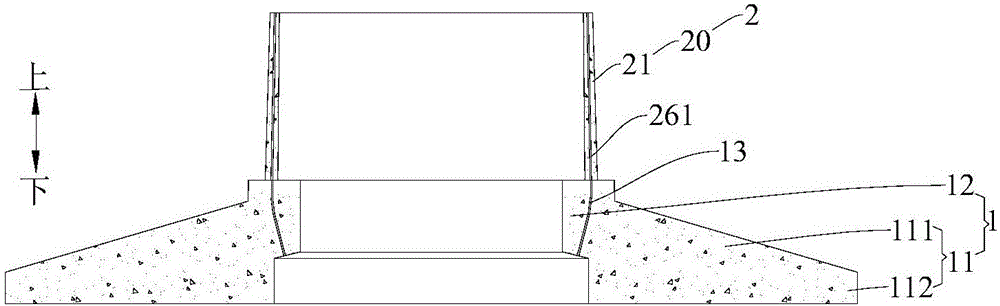

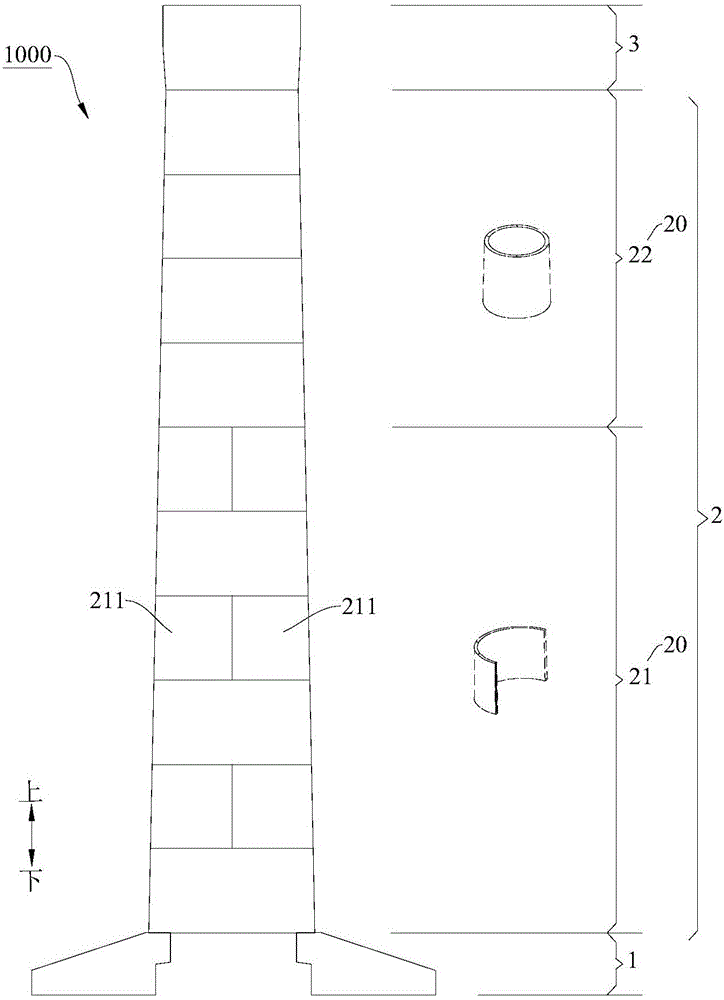

Tower drum used for wind driven generator

PendingCN106438215AEnsure safetyConducive to leveling constructionWind motor supports/mountsWind energy generationWind drivenWind force

The invention discloses a tower drum used for a wind driven generator. The tower drum comprises a tower drum foundation, a tower drum body and an adapter, the tower drum body is of a concrete structure and comprises a plurality of tower drum segments which are sequentially connected in the vertical direction, each tower drum segment comprises at least one assembling tower drum segment and at least one whole ring tower drum segment, each assembling tower drum segment is arranged on the tower drum foundation, each whole ring tower drum segment is arranged on the corresponding assembling tower drum segment, and each assembling tower drum segment comprises a plurality of tower pieces sequentially connected end to end in the circumferential direction; each whole ring tower drum segment is an integrally-formed annular part; the adapter is a metal part and arranged on the top of the tower drum body. According to the tower drum, leveling construction of the tower drum structure is facilitated, piece-by-piece prefabricating of the large-size tower drum segments in the conical tower drum structure facilitates transportation and lifting, and whole-ring prefabricating of the small-size tower drum segments can reduce construction cost and improve the construction efficiency; the adapter is arranged at the top end of the tower drum, the large weight and the large torque of the wind driven generator can be borne, and therefore safety of the tower drum is ensured..

Owner:上海风领新能源有限公司

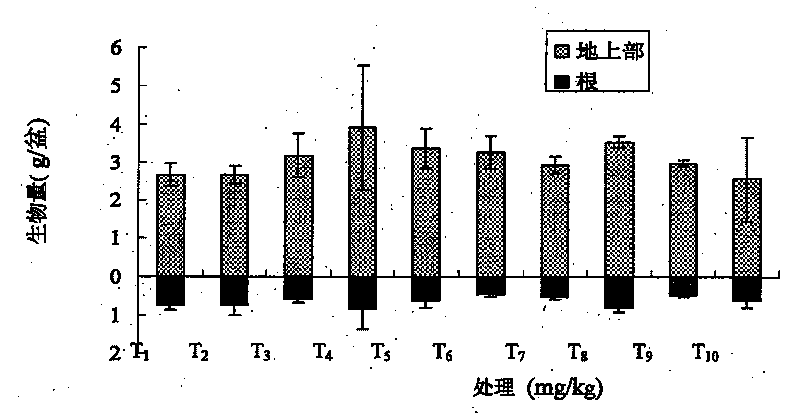

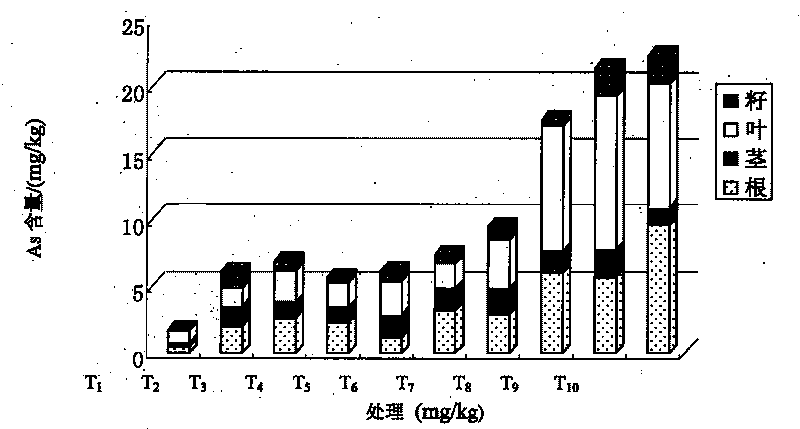

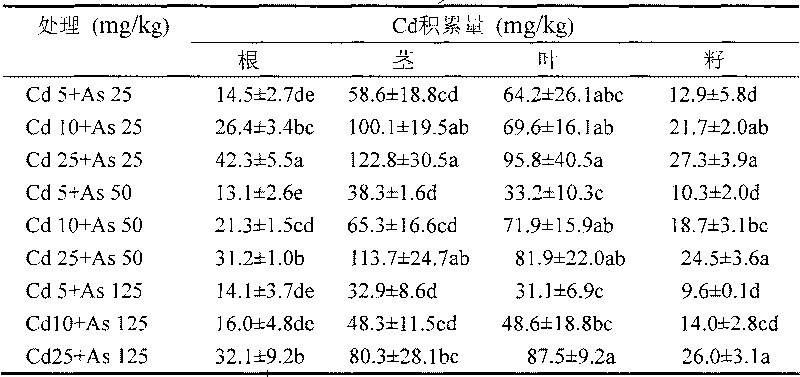

Method for repairing cadmium-arsenic polluted soil by utilizing bidens pilosa

InactiveCN101745522ADoes not destroy physical and chemical propertiesPollution stableContaminated soil reclamationBidens pilosaPolluted environment

The invention belongs to the polluted environment plant repairing technical field and in particular relates to a method for repairing cadmium-arsenic polluted soil by utilizing bidens pilosa. Bidens pilosa is planted on cadmium-arsenic polluted soil, thus realizing the aim of removing excessive cadmium-arsenic combined pollutant in soil. The invention utilizes that bidens pilosa has the cadmium hyper enrichment plant characteristic and arsenic rejection plant characteristic and is cadmium hyper enrichment and arsenic rejection plant, thus showing that the invention has strong application potential on plant repairing of cadmium-arsenic polluted soil. The invention has the advantages that work amount is less, physical and chemical properties of soil are not destroyed, no secondary pollution is produced, and water and soil can be preserved and environment can be beautified.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

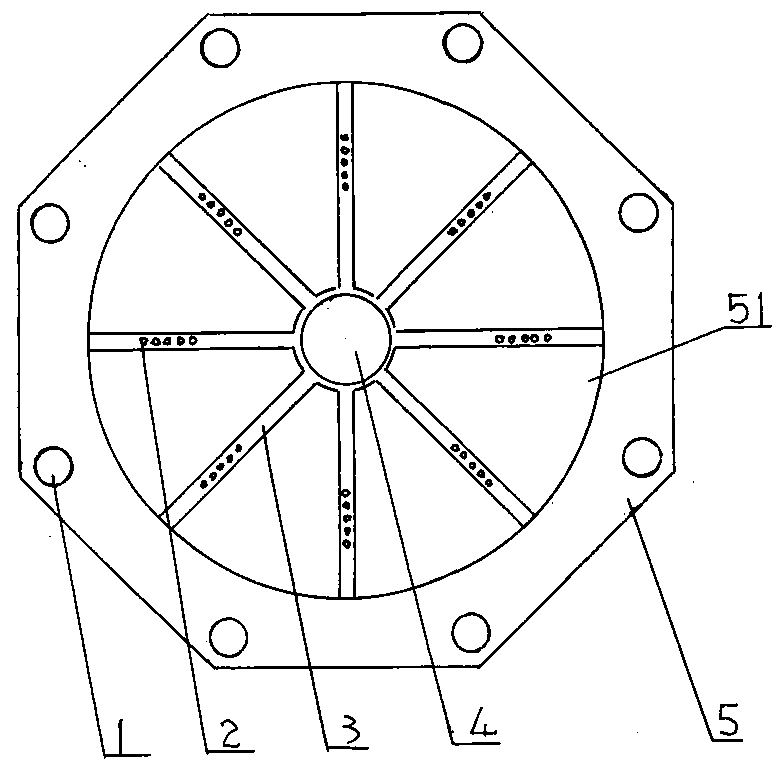

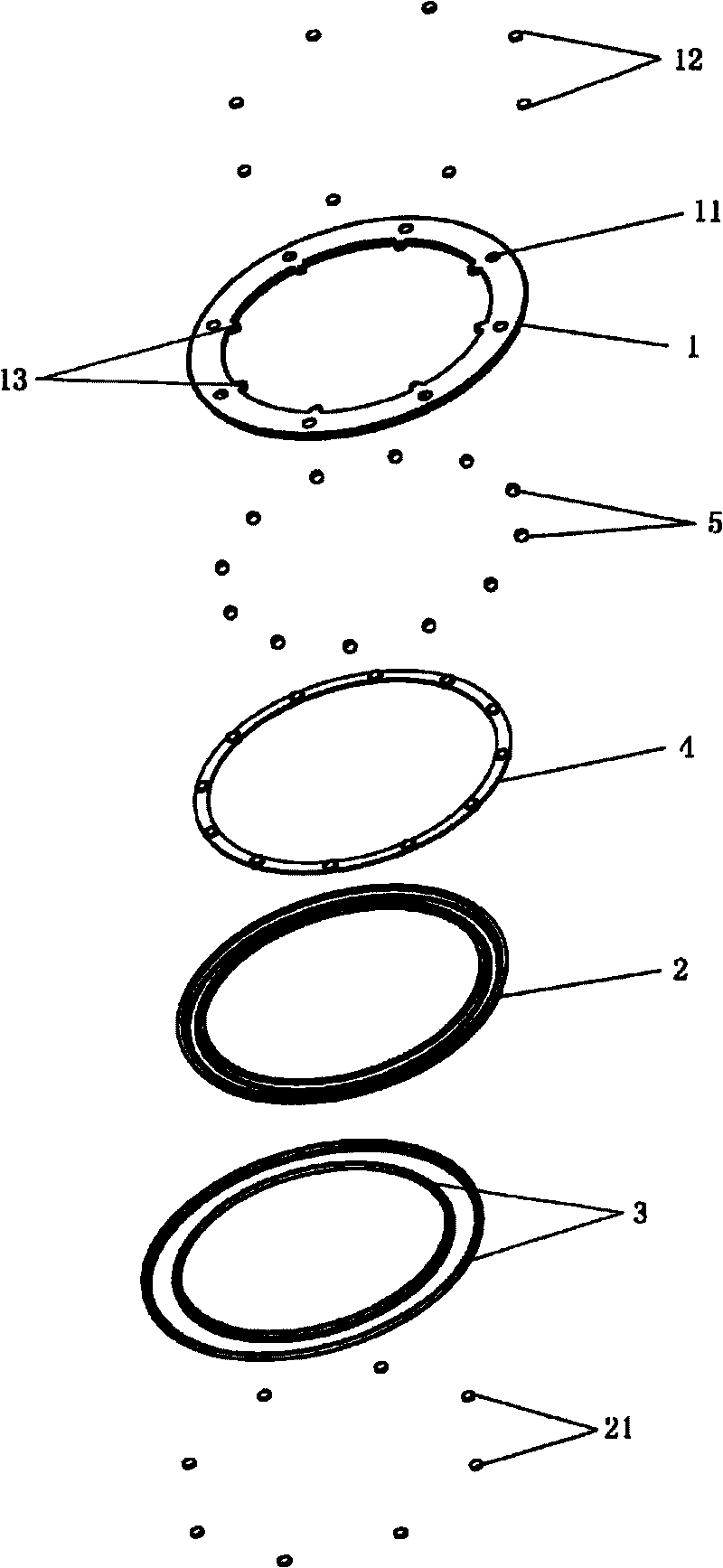

Bridge pile foundation on-site-binding reinforcement cage deviation control formwork and construction method thereof

PendingCN110468831ASolve the problem of misalignmentStrong enduranceBulkheads/pilesRebarBuilding construction

The invention belongs to a bridge pile foundation on-site-binding reinforcement cage deviation control formwork and a construction method thereof. The bridge pile foundation on-site-binding reinforcement cage deviation control formwork includes a fixed plate panel, a fixed plate supporting frame, a fixed reinforcement cage positioning plate, a mobile reinforcement cage positioning plate, a reinforcement cage positioning arc plate and a reinforcement sleeve assembly. The construction method includes the steps that the bottom of the on-site-binding reinforcement cage in a column is fixed by thefixed reinforcement cage positioning plate and reinforcement sleeves, the top of the on-site-binding reinforcement cage in the column is fixed by the mobile reinforcement cage positioning plate and the reinforcement cage positioning arc plate and reinforcement sleeves, and construction of various column bodies with different diameters is completed by changing the diameters of the mobile reinforcement cage positioning plate and the reinforcement cage positioning arc plate, and the positions of the reinforcement sleeves corresponding to the diameter of the variable diameter reinforcement cage. The bridge pile foundation on-site-binding reinforcement cage deviation control formwork can effectively control, correct and is suitable for the deviation of the on-site-binding reinforcement cage ofpile foundations with different diameters and has the advantages of simple structure, high construction speed, good quality, low production and use cost, less time and labor, and wide applicability.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

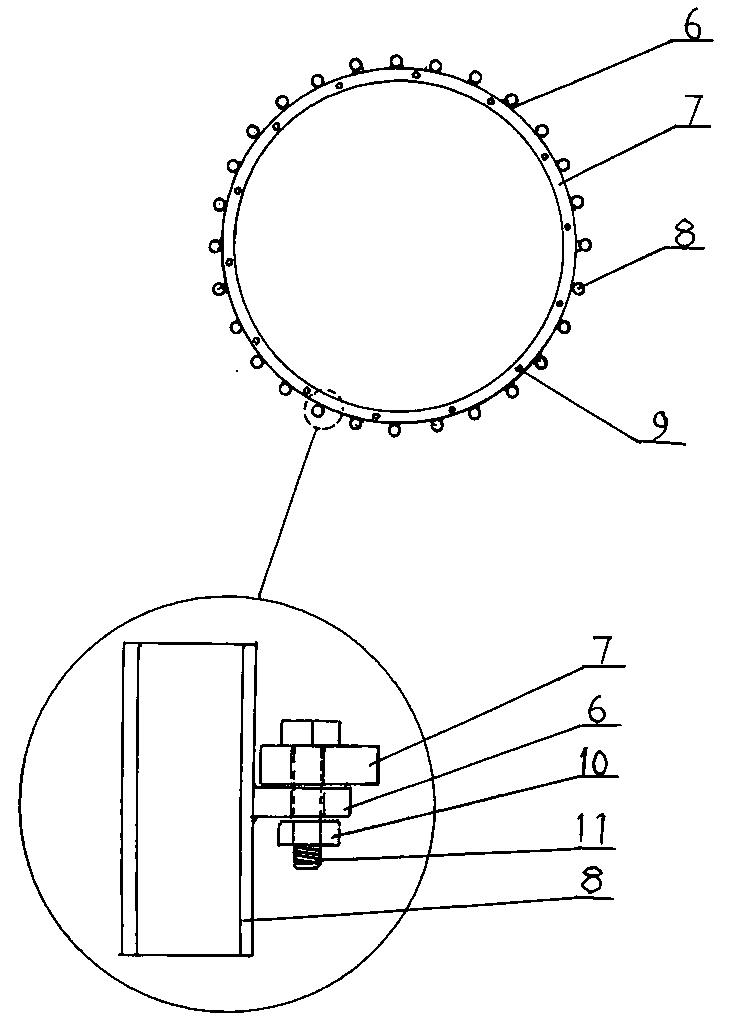

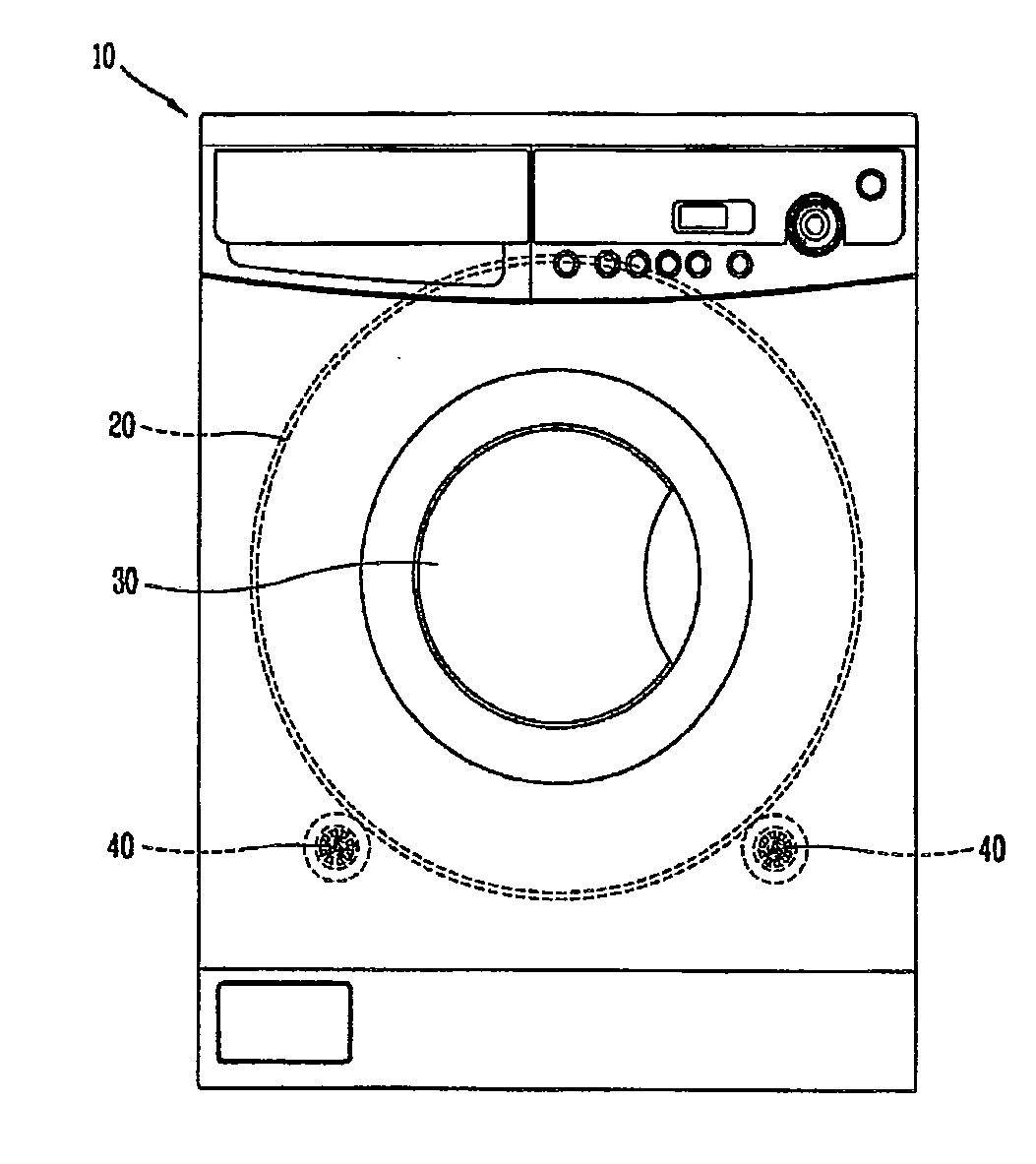

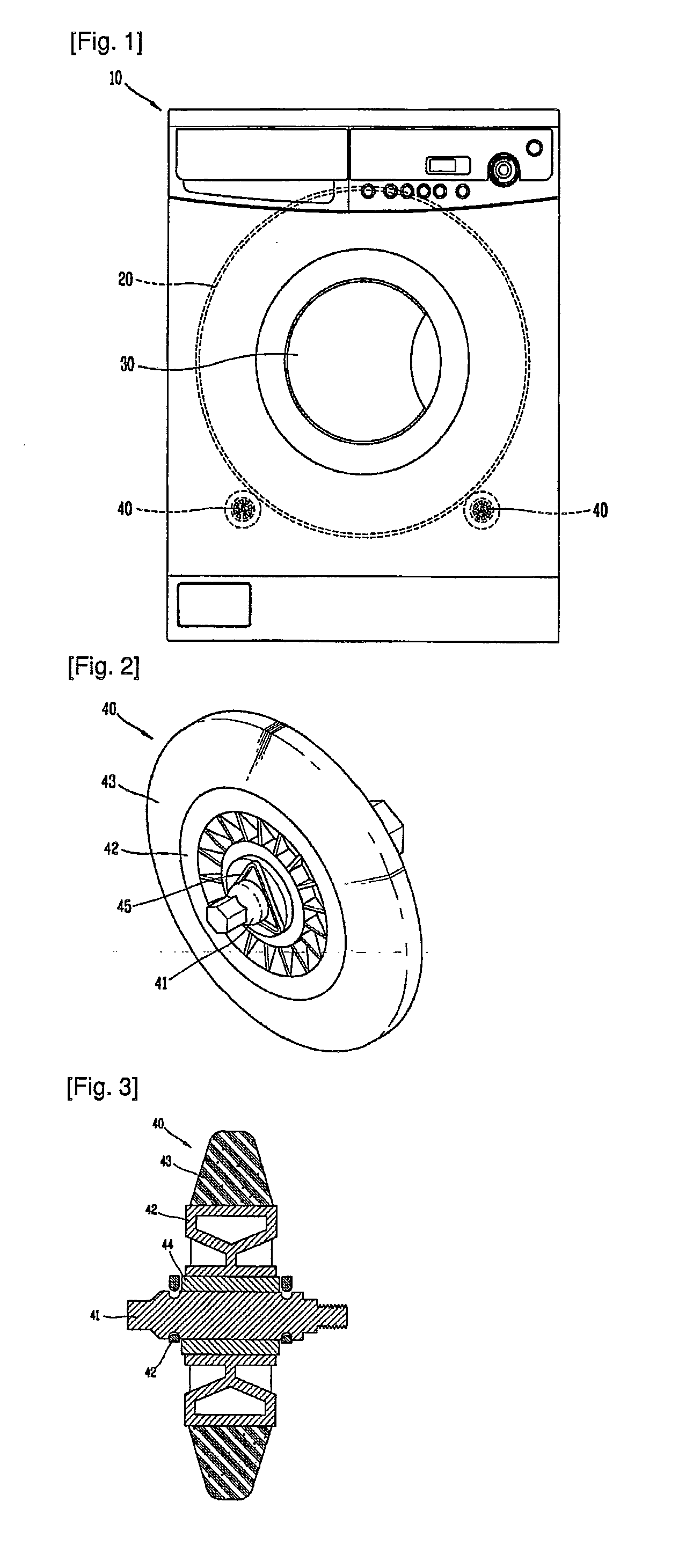

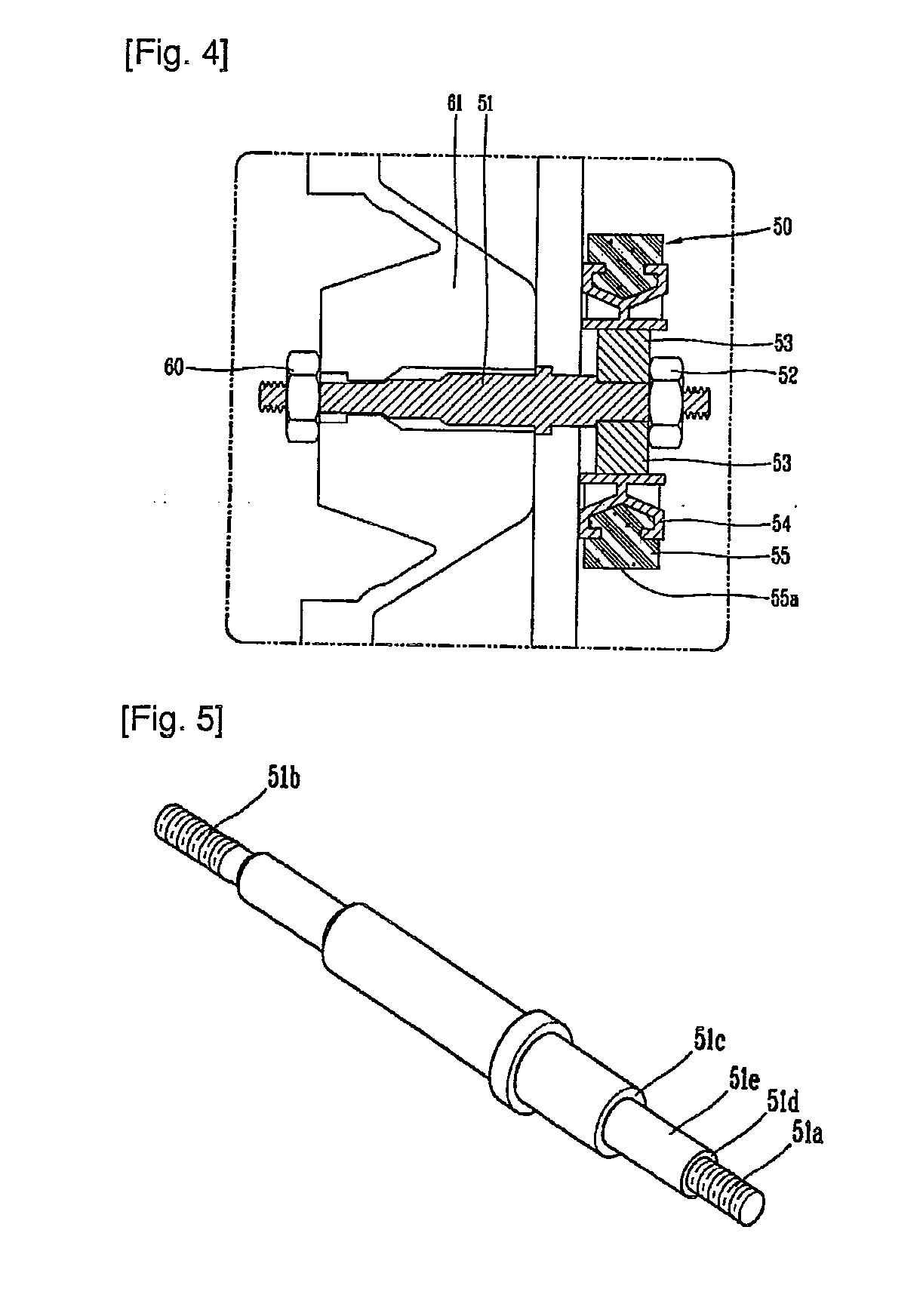

Clothes dryer

ActiveUS20110023318A1Extend your lifeAvoid stress concentrationDrying machines with non-progressive movementsTextiles and paperBall bearingEngineering

Disclosed is a clothes dryer comprising a drum rotatably disposed in a body; and a roller disposed below the drum, and configured to support the drum. The roller is mounted to a roller shaft by a ball bearing, and a contact portion of an outer circumferential surface of the roller contacting the drum is formed to be flat.

Owner:LG ELECTRONICS INC

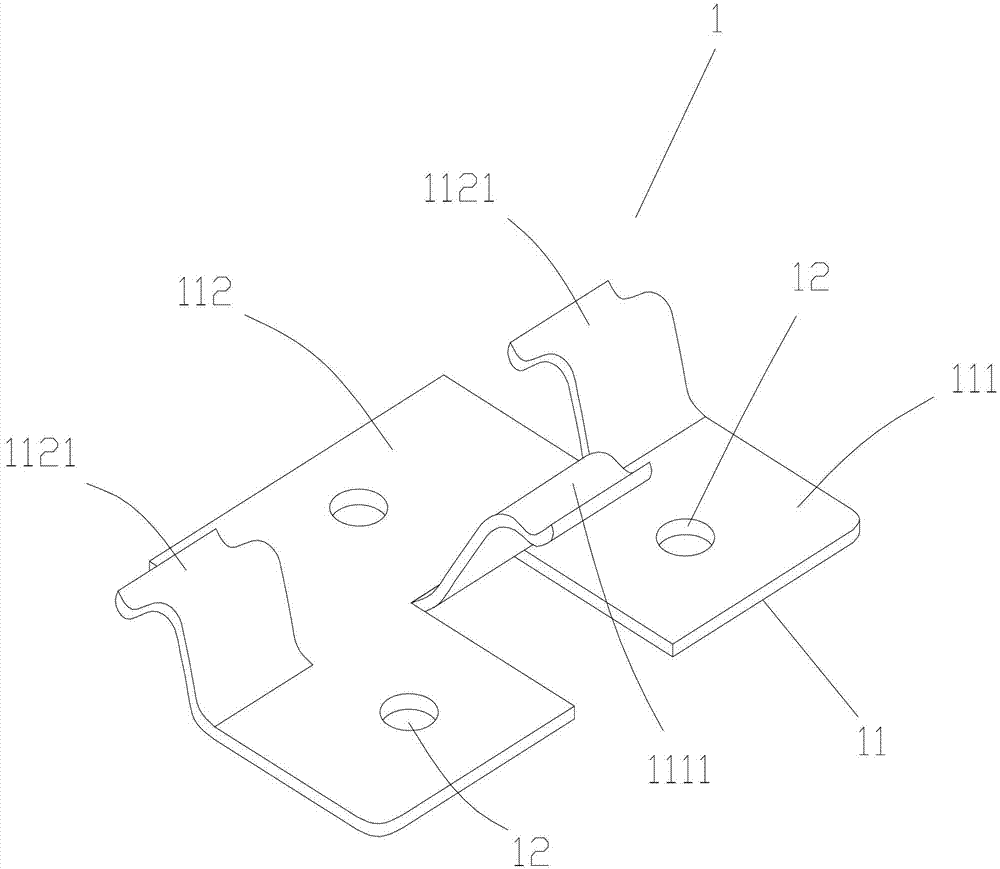

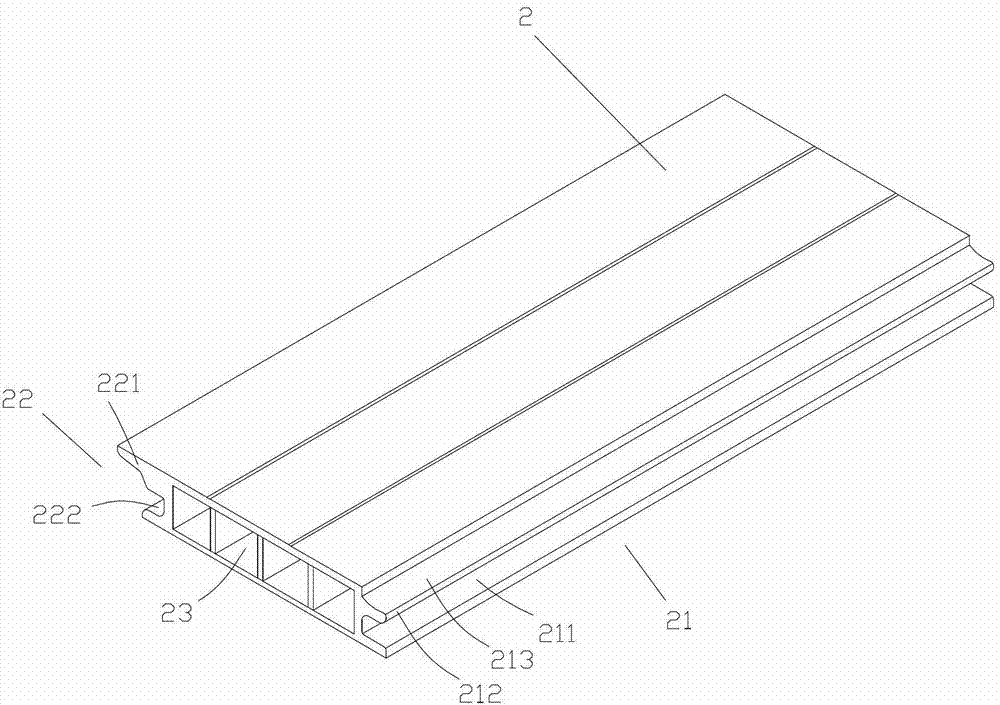

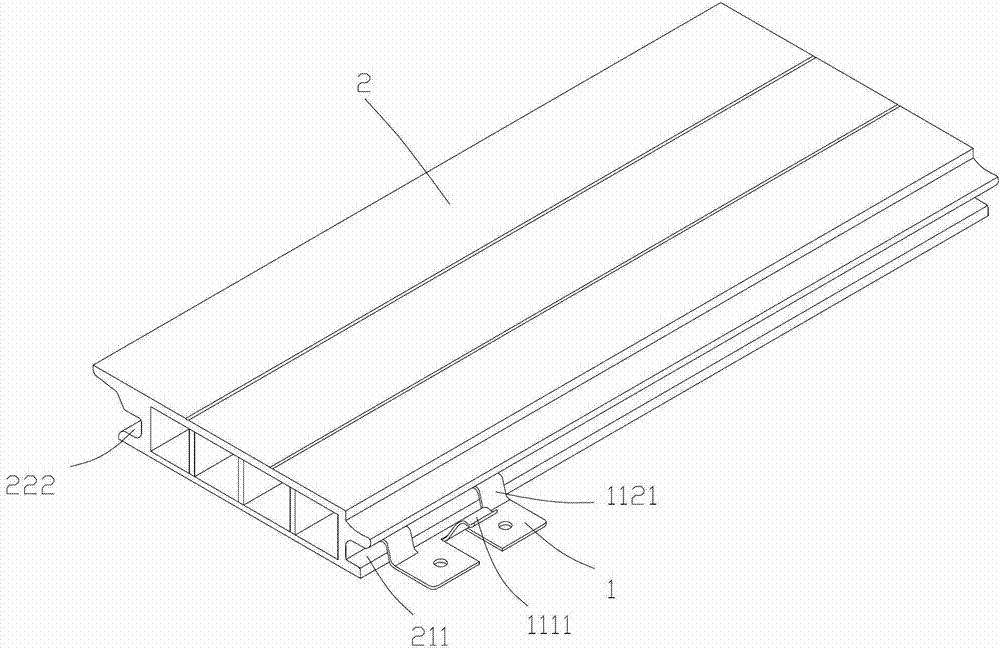

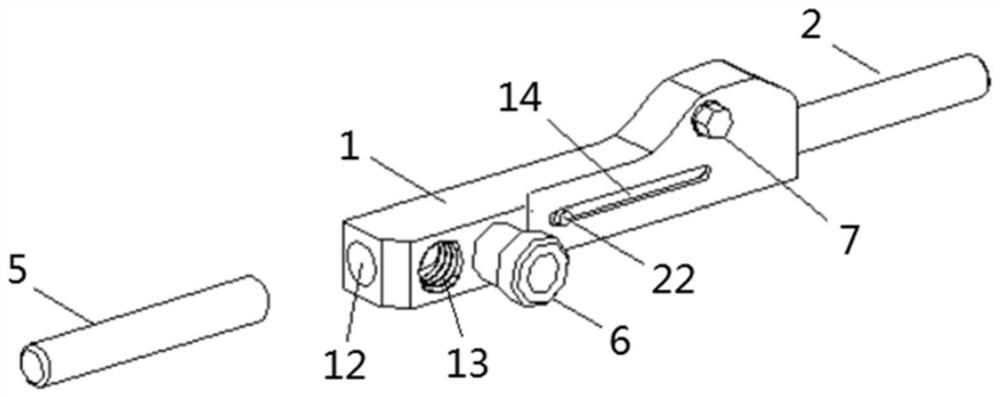

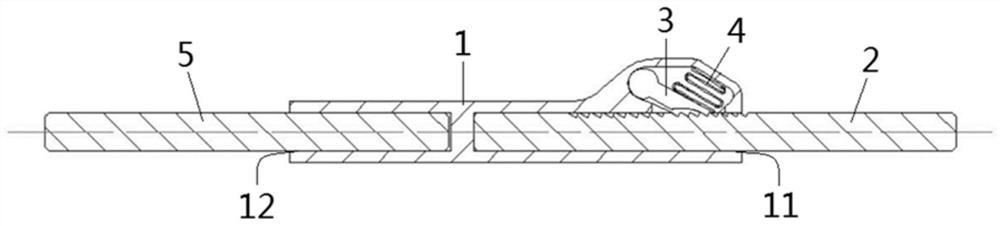

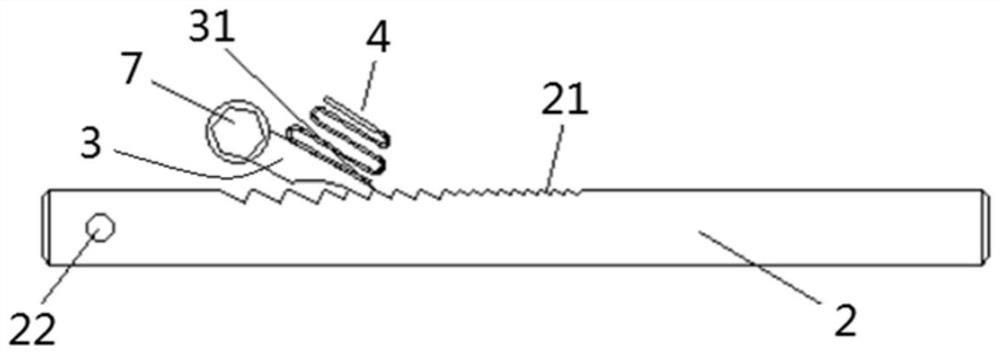

Installation structure of seamless installation clamping key and outdoor floor

The invention discloses an installation structure of a metal clamping key and a floor, and relates to the technical field of connecting pieces for floor pavement. The metal clamping key comprises a connecting plate. The installation structure is characterized in that the connecting plate is in a square structure, the connecting plate is divided into a first clamping portion and a second clamping portion with a center line of the connecting plate as a boundary line, two edges of the first clamping portion are bent upward to form two first clamping claws at the positions of the two edges of the first clamping portion and with the center line of the connecting plate as a supporting point, the middle part of the second clamping portion is bent upward to form a second clamping claw at the middle position of the second clamping portion and with the center line of the connecting plate as a supporting point, and free ends of the upper end portions of the first clamping claws and the second clamping claw are roughly in a V-shaped structure. The installation structure is simple in structure and reasonable in design, and changes the connecting method that a tenon and a mortise are adopted in a traditional floor, installation process is simpler, matching between the clamping key and the floor is close, gas between two floors is small after the floors are assembled, the fact that the clamping key cannot be corroded is well guaranteed, and the installation structure is not prone to deformation, strong in bearing capacity and attractive in appearance.

Owner:ANHUI SENTAI WPC GRP CO LTD

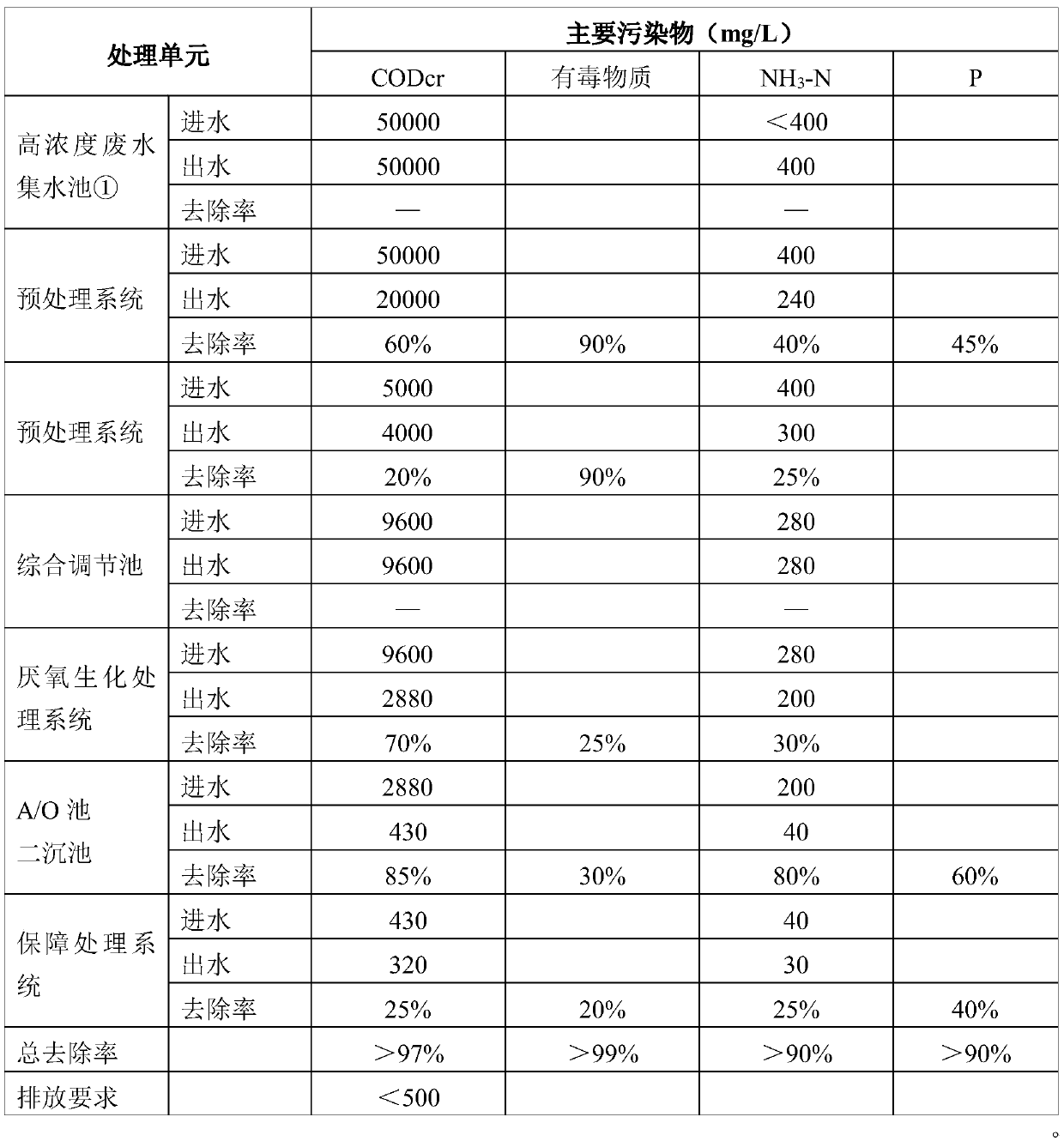

Sewage treatment process for recovering N-methyl pyrrolidone

InactiveCN110894125ASettling property without special requirementsReduce yieldFatty/oily/floating substances removal devicesWater treatment compoundsElectrolysisActivated carbon filtration

The invention discloses a sewage treatment process for recovering N-methyl pyrrolidone. The sewage treatment process comprises the following steps: pretreating high-concentration wastewater, wherein the pretreating sequentially comprises catalytic cracking, high-voltage pulse electrolysis and coagulating sedimentation; obtaining pretreated wastewater; carrying out biochemical treatment; sequentially carrying out mixing homogenization, anaerobic reaction, hydrolytic acidification and contact oxidation on the pretreated wastewater in the step (1); obtaining biochemical treatment water; ensuringtreatment; and sequentially carrying out precipitation reaction, multi-medium filtration and active carbon filtration on the biochemical treatment water in the step (2) to finish recovery. The methodhas the advantages of low process cost, high efficiency, good recovery effect and good wastewater treatment effect, and can be widely popularized and used.

Owner:镇江新纳环保材料有限公司

Turntable

The invention discloses a turntable which mainly comprises an upper cover, a lower cover, an inner fixed ring, an outer fixed ring, a steel ball fixed ring and steel balls, wherein the steel balls are arranged in the steel ball fixed ring; the steel ball fixed ring is assembled between the upper cover and the lower cover; semicircular arc positions in a complete ring are arranged in both the upper cover and the lower cover for fixing the steel balls; the inner fixed ring and the outer fixed ring are respectively connected with the upper cover and simultaneously fixed at the inner side and the outer side of the lower cover; the upper cover is provided with a plurality of small holes on which an upper antiskid mat is arranged; the lower cover is also provided with a plurality of small holes on which a lower antiskid mat is arranged; and a plurality of screw loops can be stretched from the inner rings of the upper cover and the lower cover. The invention has simple structure, good antiskid effect and convenient use.

Owner:魏少樱

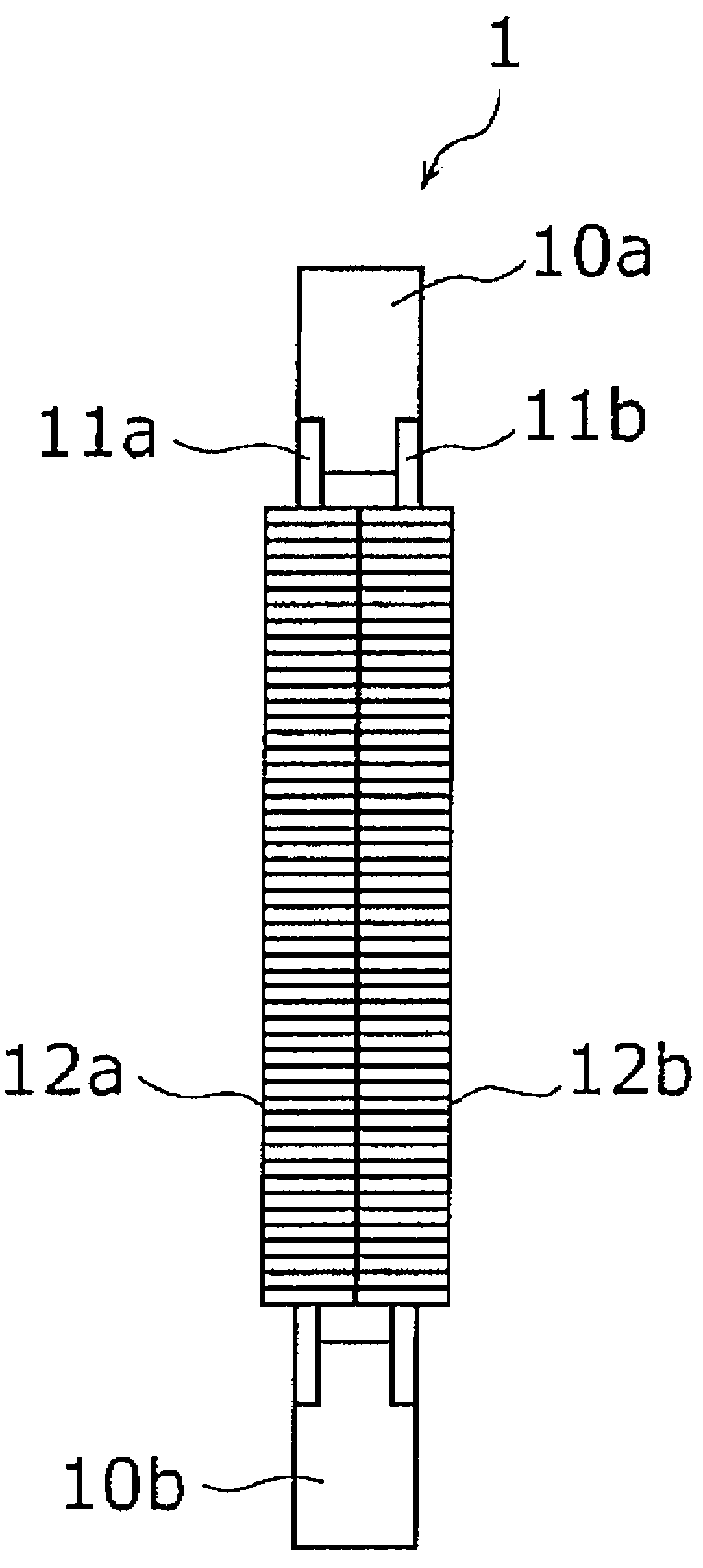

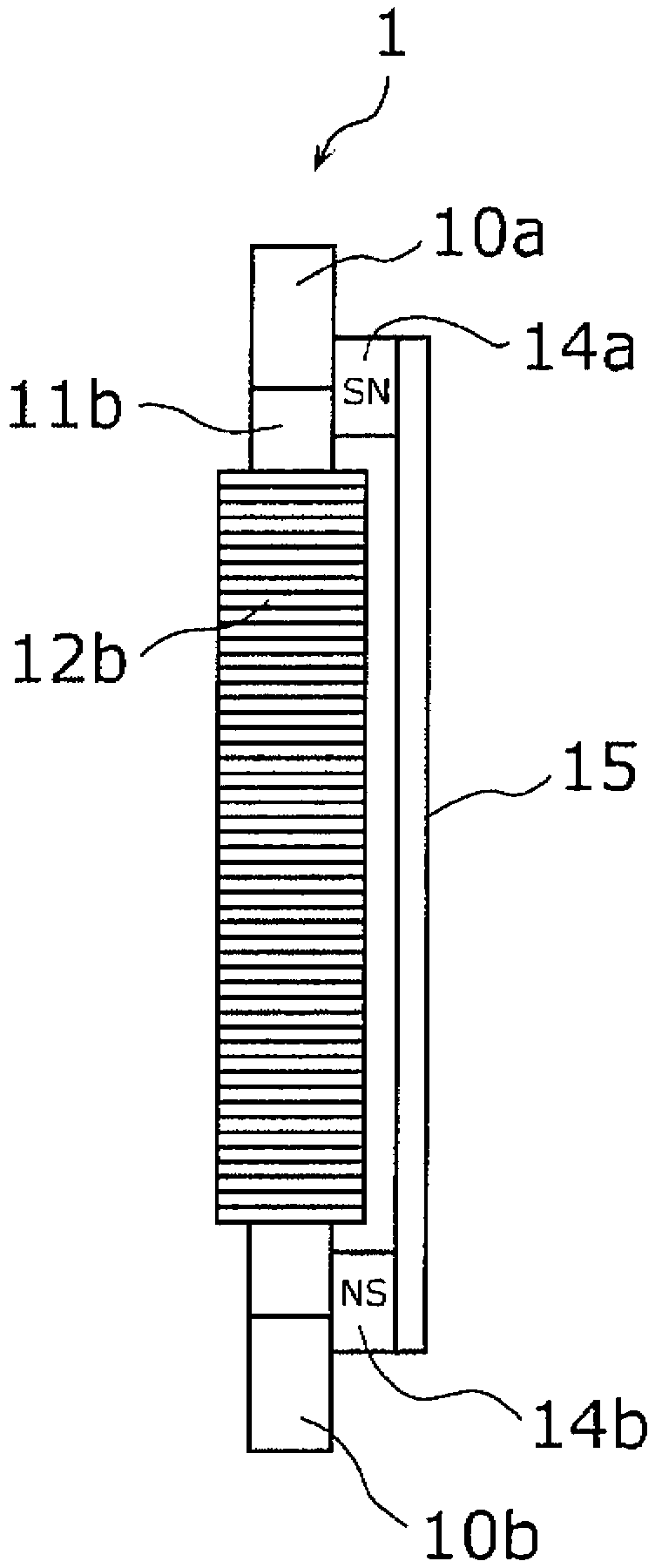

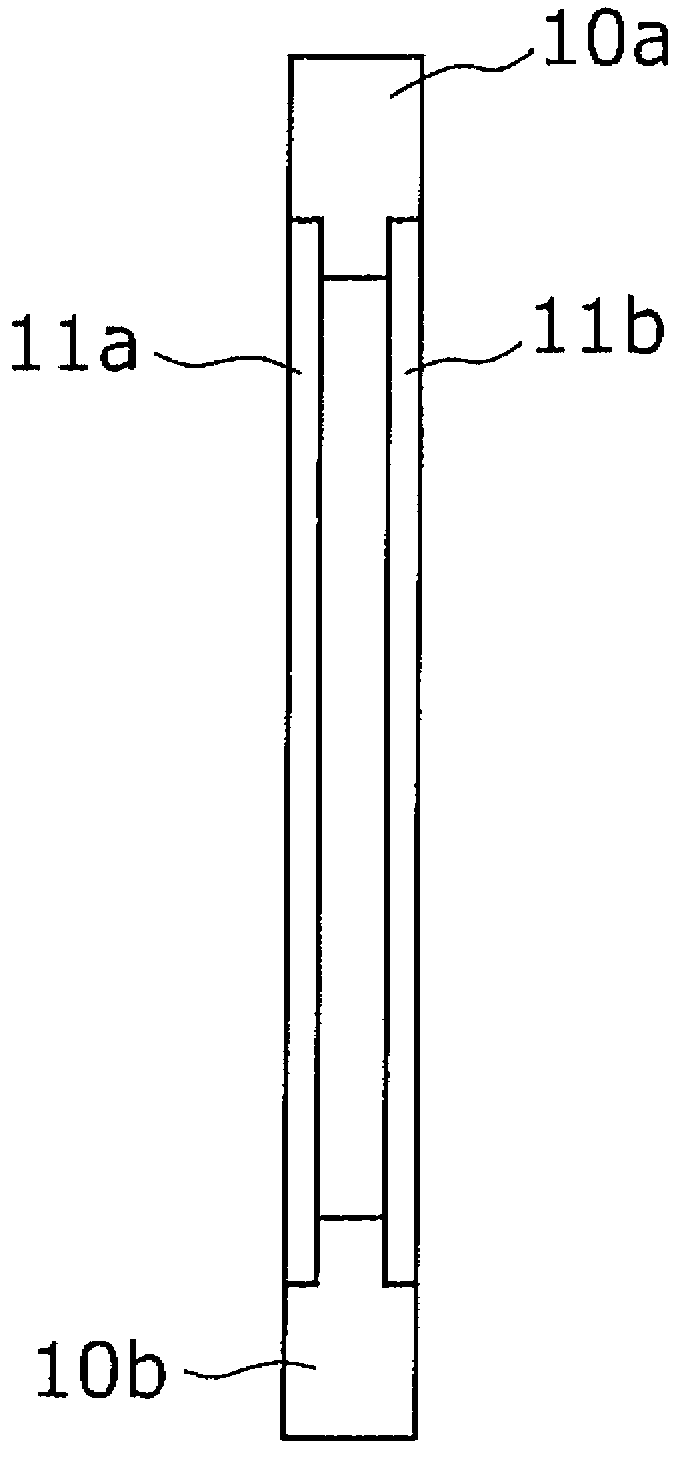

Power generation element and power generation apparatus provided with power

ActiveCN102986129AStrong enduranceIncrease power generationPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringMagnetostriction

Disclosed are: a power generation element that has a strong resistance against bending and impact, and that generates a large amount of power; and a power generation apparatus provided with the power generation element. The power generation element (1) is provided with a first magnetostriction rod (11a) comprised of a magnetostrictive material; a rigid rod (11b) that is comprised of a magnetic material having rigidity and shape necessary for applying a uniform compressive / tensile force to the first magnetostriction rod (11a), and that is arranged to be parallel with the first magnetostriction rod (11a); a first coil (12c) wound around the first magnetostriction rod (11a); and two interconnecting yokes (10a, 10b) arranged at both ends of the first magnetostriction rod (11a) and the rigid rod (11b) such that the two rods are interconnected. Power is generated, by having the first magnetostriction rod (11a) expanded or contracted with the vibration thereof in a direction perpendicular to the axis direction thereof.

Owner:KANAZAWA UNIV

Automatic growth rod and children scoliosis orthopedic system

The invention discloses an automatic growth rod and a children scoliosis orthopedic system, and belongs to the technical field of orthopedic implants. The automatic growth rod comprises an adjusting block and a toothed movable rod, a first mounting hole is formed in one end of the adjusting block, the toothed movable rod is inserted into the first mounting hole, limiting teeth are arranged on thetoothed movable rod, a pawl used for enabling the toothed movable rod to only move in the first mounting hole in the direction away from the adjusting block is hinged into the adjusting block, abutting teeth matched with the limiting teeth are arranged at the tail end of the pawl, and an elastic piece used for enabling the pawl to reset is further arranged in the adjusting block. In-vivo distraction can be achieved without an operation. Due to the fact that the pawl is matched with the toothed movable rod, the device is simple in structure, low in cost, easy to popularize, high in bearing capacity, safe and reliable.

Owner:朱晓东 +2

Dry red wine and production process thereof

The invention belongs to the technical field of wine, and particularly provides dry red wine. The dry red wine is prepared by using grapes as raw materials through the technological methods includingsoaking, fermentation, re-soaking, malolactic fermentation, aging and storage. According to the dry red wine provided by the invention, before the grapes enter into a jar, a complete state is kept, low-temperature processing is adopted as much as possible, and the nutrition of the original grapes is kept to a maximum extent, so that oxidation of the grapes is avoided; the high-quality cabernet sauvignon dry red wine which has a complicated and dense fragrance, has a layered, strong-endurance and powerful mouthfeel and has a thick, balanced and a long lasting taste is obtained, the simplification of brewing processes of the dry red wine is broken through, and the local characteristic of the grape raw materials is outstanding.

Owner:北京澳德投资集团有限公司

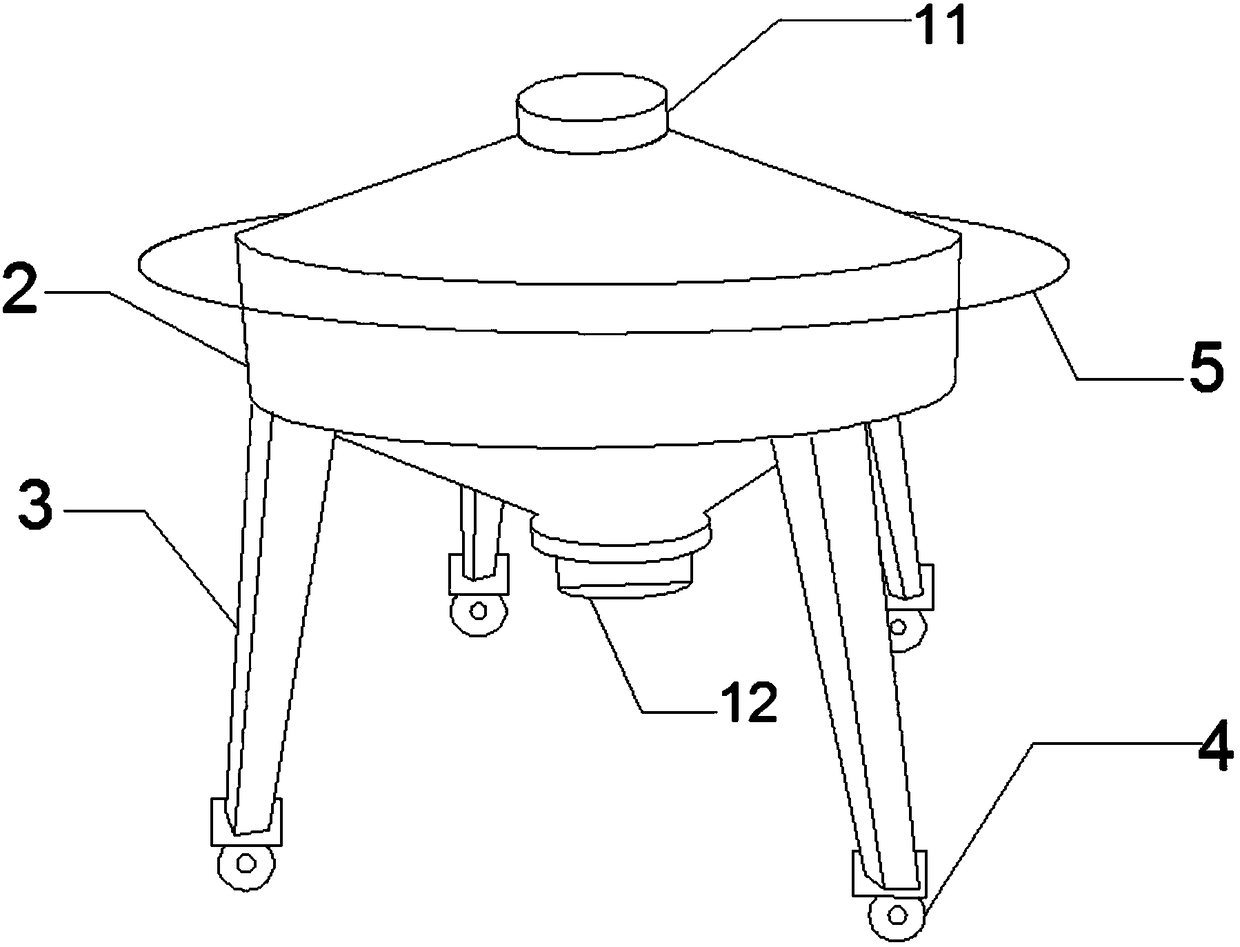

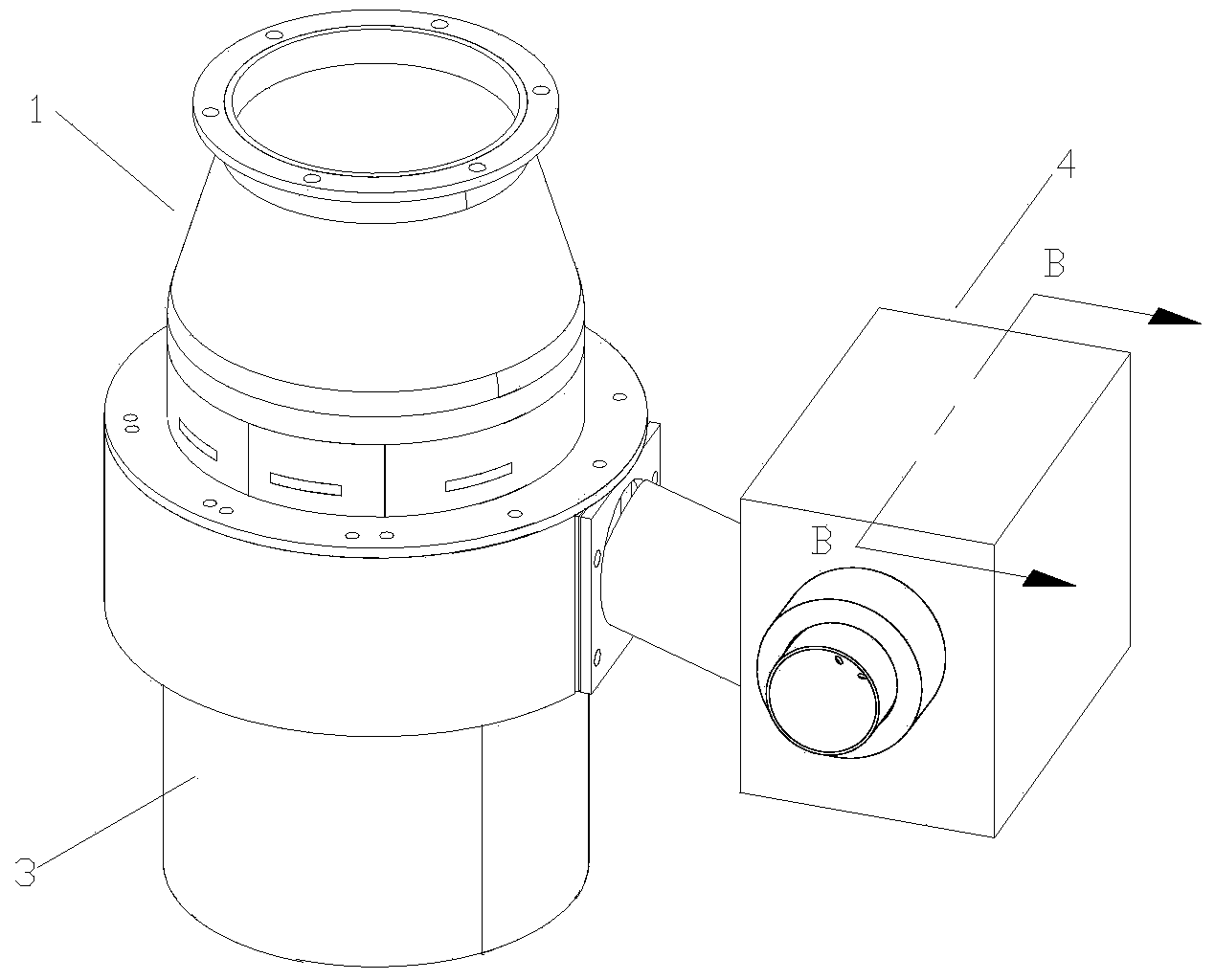

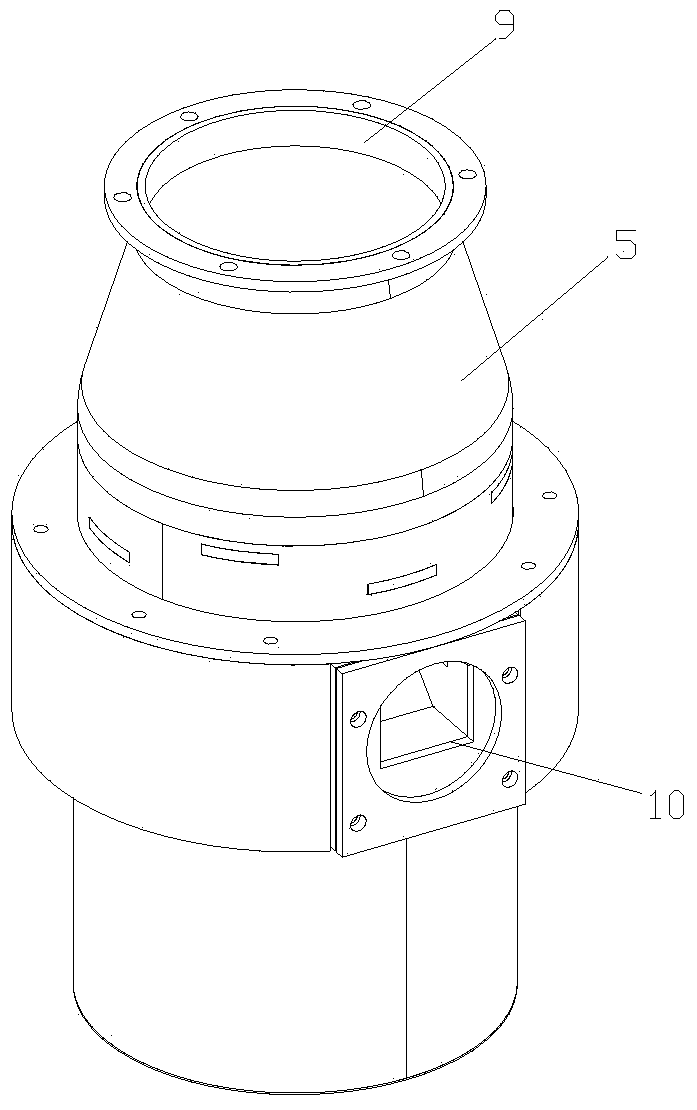

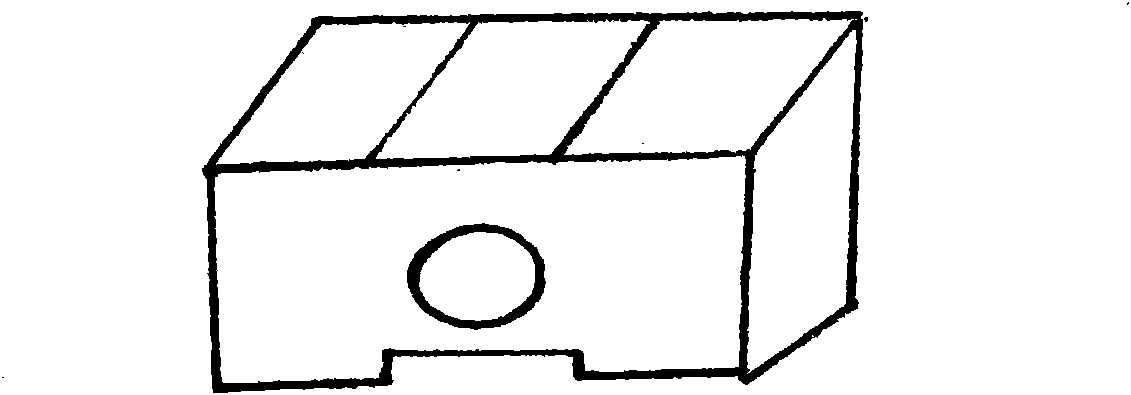

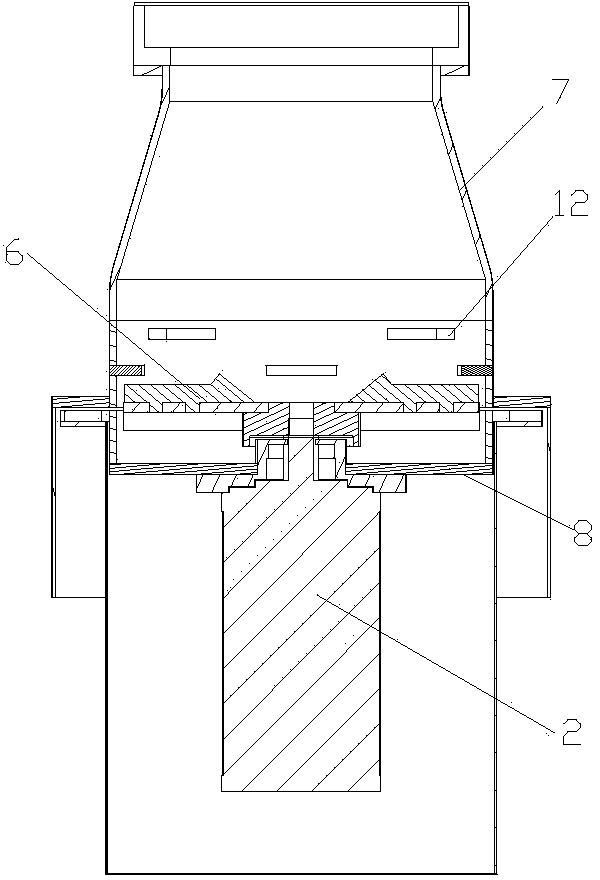

Novel garbage disposer for strain decomposition

ActiveCN104259185AEasy to disassembleStrong enduranceSolid waste disposalGrain treatmentsMotor driveDecomposition

The invention discloses a novel garbage disposer for strain decomposition. The novel garbage disposer comprises a grinding mechanism, a motor, a motor shell and a garbage decomposition box, wherein the grinding mechanism comprises a hollow grinding cavity and a grinding cutter; a feeding hole is formed in the top of the grinding cavity; a sewage draining hole connected with the garbage decomposition box is formed in the bottom of the grinding cavity; the grinding cutter is coaxially mounted in a grinding chamber; the motor drives the grinding cutter; a plurality of layers of cutter bit groups are arranged on the surface of the inner wall of the grinding cavity on the upper side of the grinding cutter; each layer of cutter bit group comprises a plurality of cutter bits which are arranged at an equal horizontal spacing angle alpha; a horizontal spacing angle beta is formed between every two adjacent layers of cutter bit groups; the garbage decomposition box comprises a box body, a sleeve, a sealing ring and a filter cartridge; a mounting hole is formed in the vertical outer wall of the box body; the sleeve which is protruded is further fixedly arranged in the mounting hole; the filter cartridge penetrates through the sleeve and extends into the box body; the sealing ring is arranged at the matching part of the filter cartridge and the sleeve; ventilation holes are formed in the surface of the filter cartridge; fermentation fungi for garbage decomposition are placed in the filter cartridge.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

Wall decoration pendant

InactiveCN101653333AEasy to installStrong enduranceKitchen equipmentDomestic articlesScrew threadPetroleum engineering

Owner:HUANGXIANG TRADE SHANGHAI

Efficient garbage crusher for decomposing strains

ActiveCN104289500AEasy to disassembleStrong enduranceSolid waste disposalDomestic plumbingCircular discCoupling

The invention provides an efficient garbage crusher for decomposing strains. The efficient garbage crusher comprises a grinding mechanism, a motor, a motor shell and a garbage decomposing box, wherein the grinding mechanism comprises a hollow grinding cavity and a grinding cutter; the inner part of the grinding cavity is a grinding chamber; a plurality of cutter heads are arranged on the surface of the inner wall of the grinding cavity on the upper side of the grinding cutter; the grinding cutter comprises a cutter disc, cutter blocks, scraping plates and a shaft coupling sleeve; the cutter disc is of a circular disc shape; one end of each cutter block is aligned with the radial edge of the cutter disc; the other end of each cutter block extends towards a central hole; one end of each scraping plate is connected with the shaft coupling sleeve and the other end of each scraping plate is aligned with the radial edge of the cutter disc; the garbage decomposing box comprises a box body, a sleeve, a sealing ring and a filter cartridge; a mounting hole is formed in the vertical outer wall of the box body; the mounting hole is internally and fixedly provided with the sleeve which protrudes out of the box body; the filter cartridge penetrates through the sleeve to stretch into the box body; the filter cartridge is in transition match with the sleeve; the sealing ring is arranged at the matched part of the filter cartridge and the sleeve; vent holes are formed in the surface of the filter cartridge; and fermentation strains for degrading garbage are arranged in the filter cartridge.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

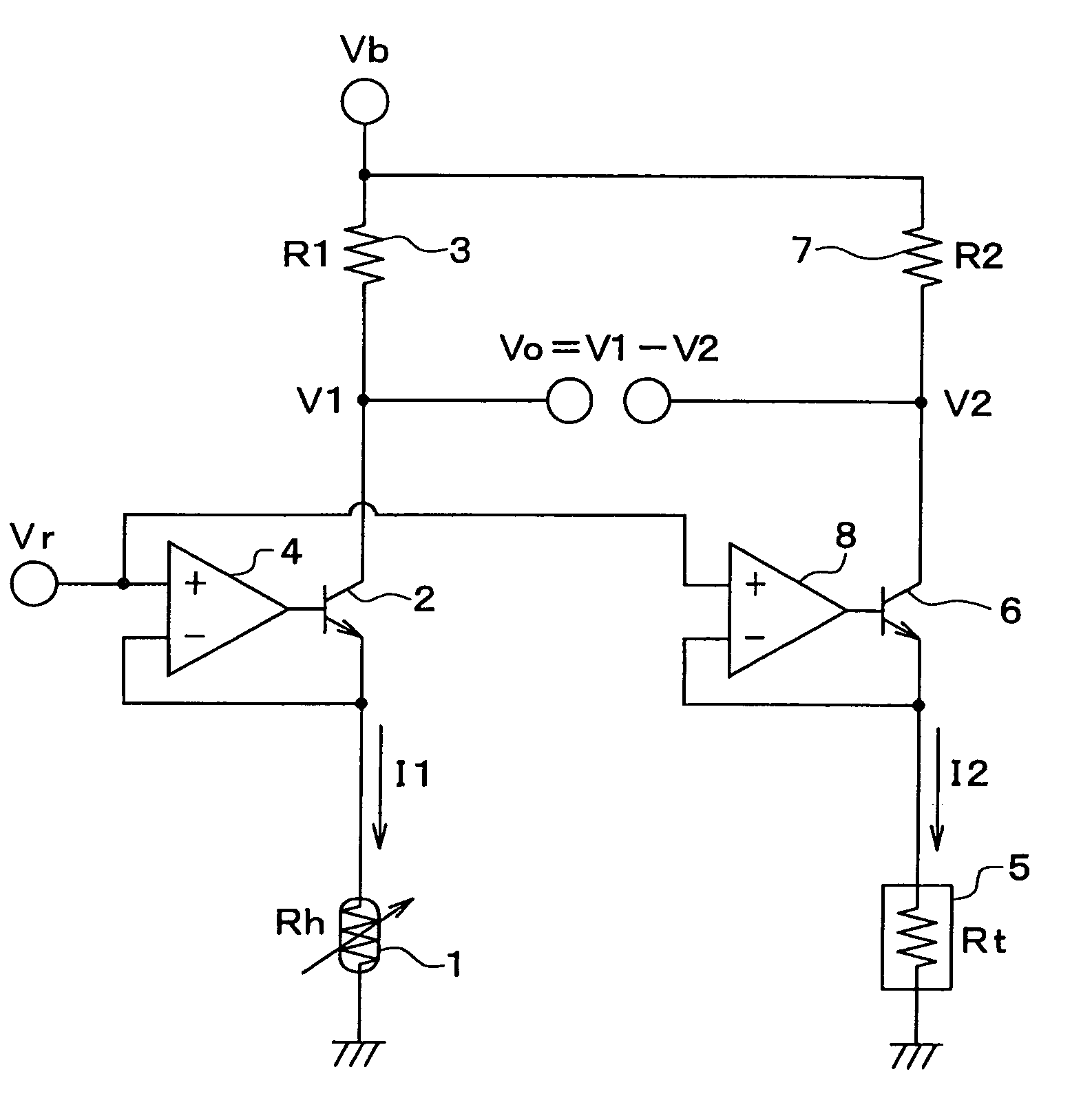

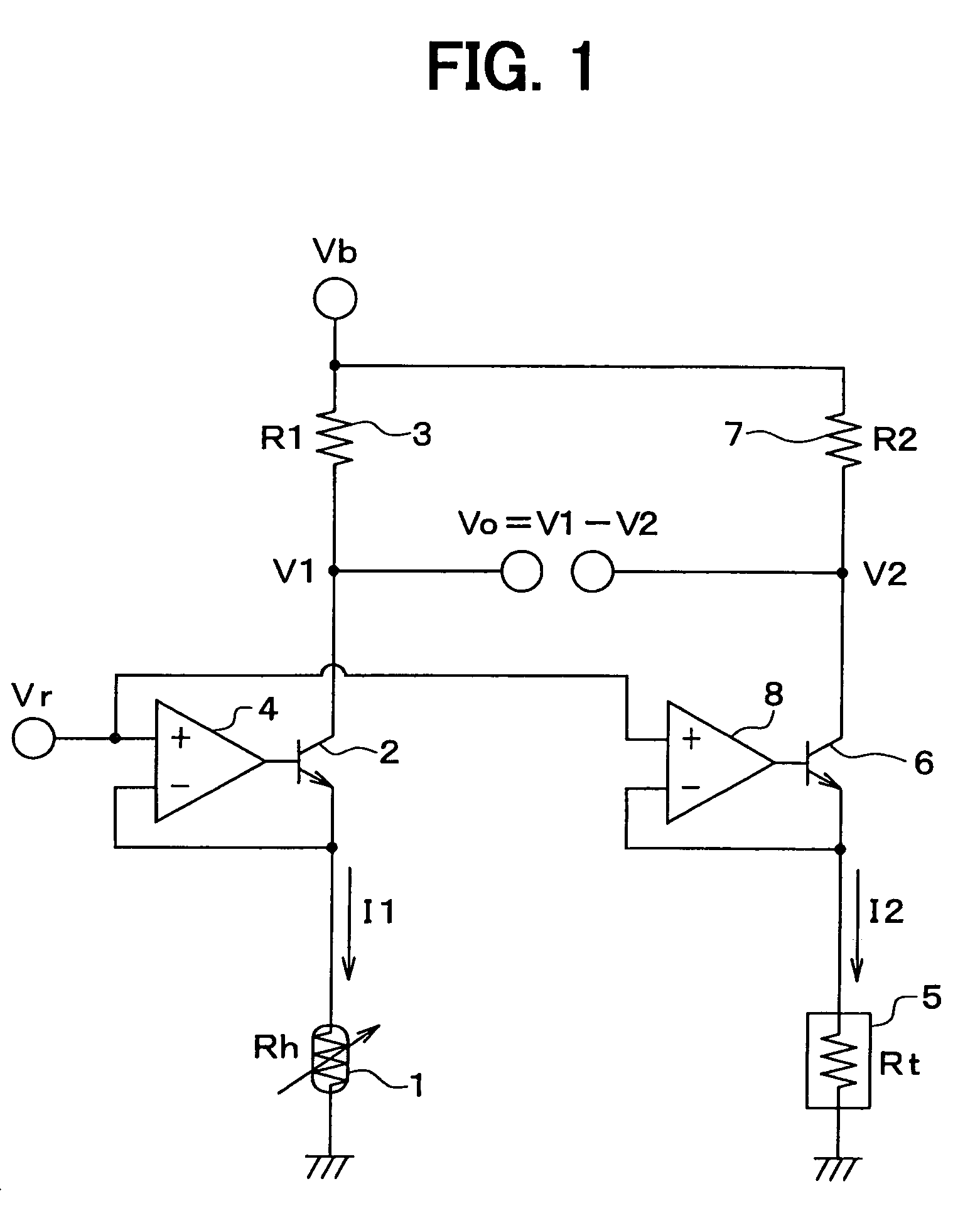

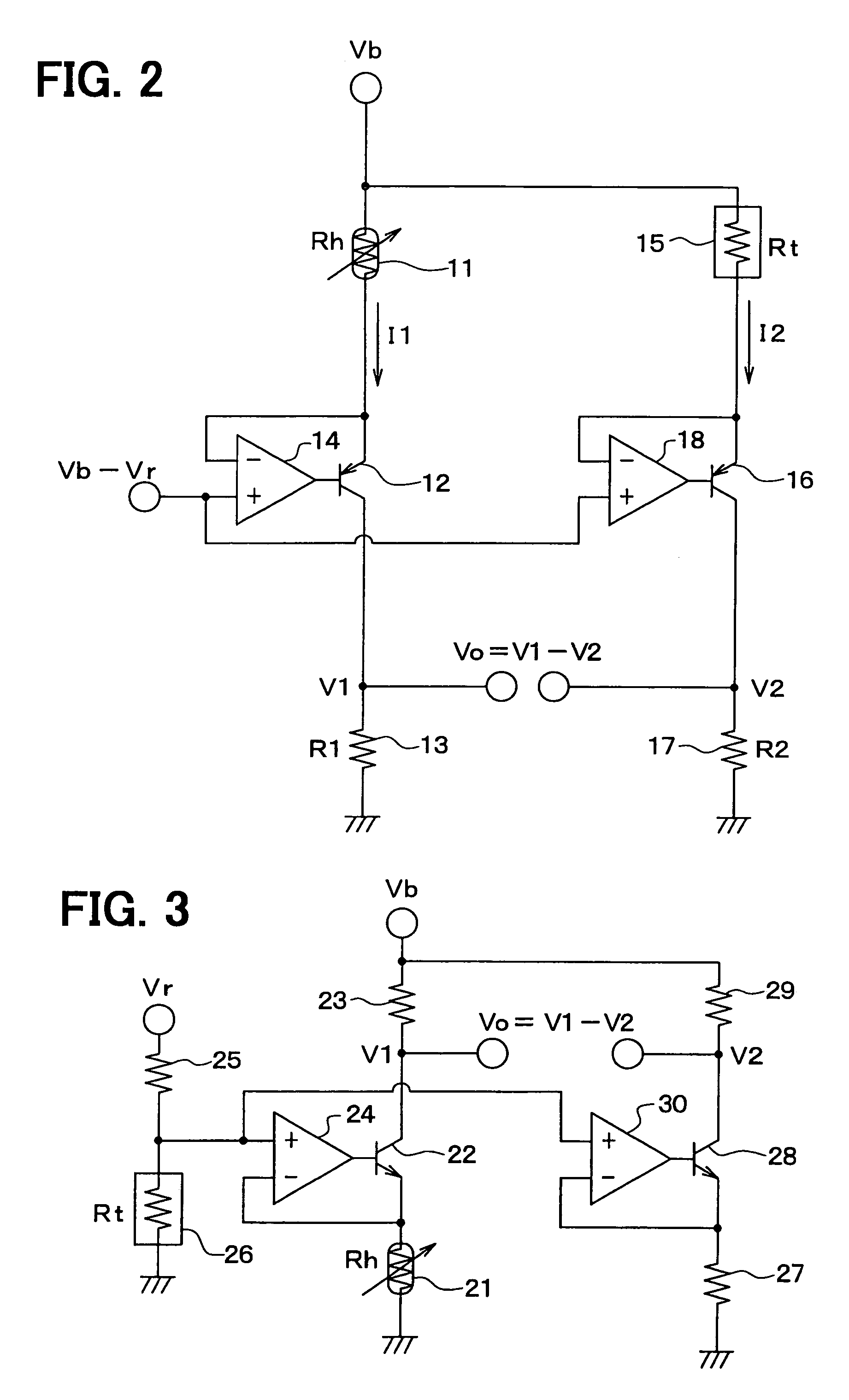

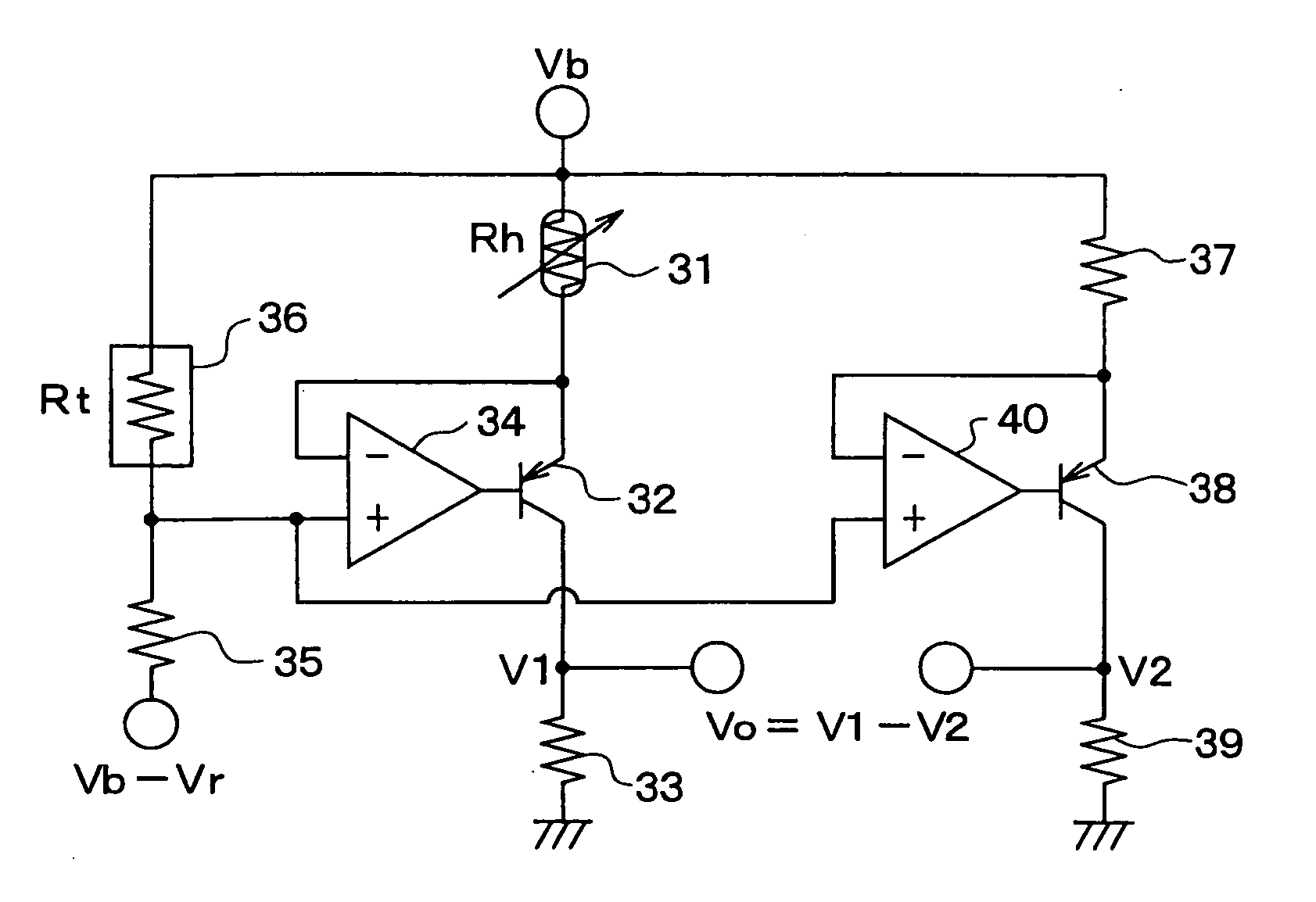

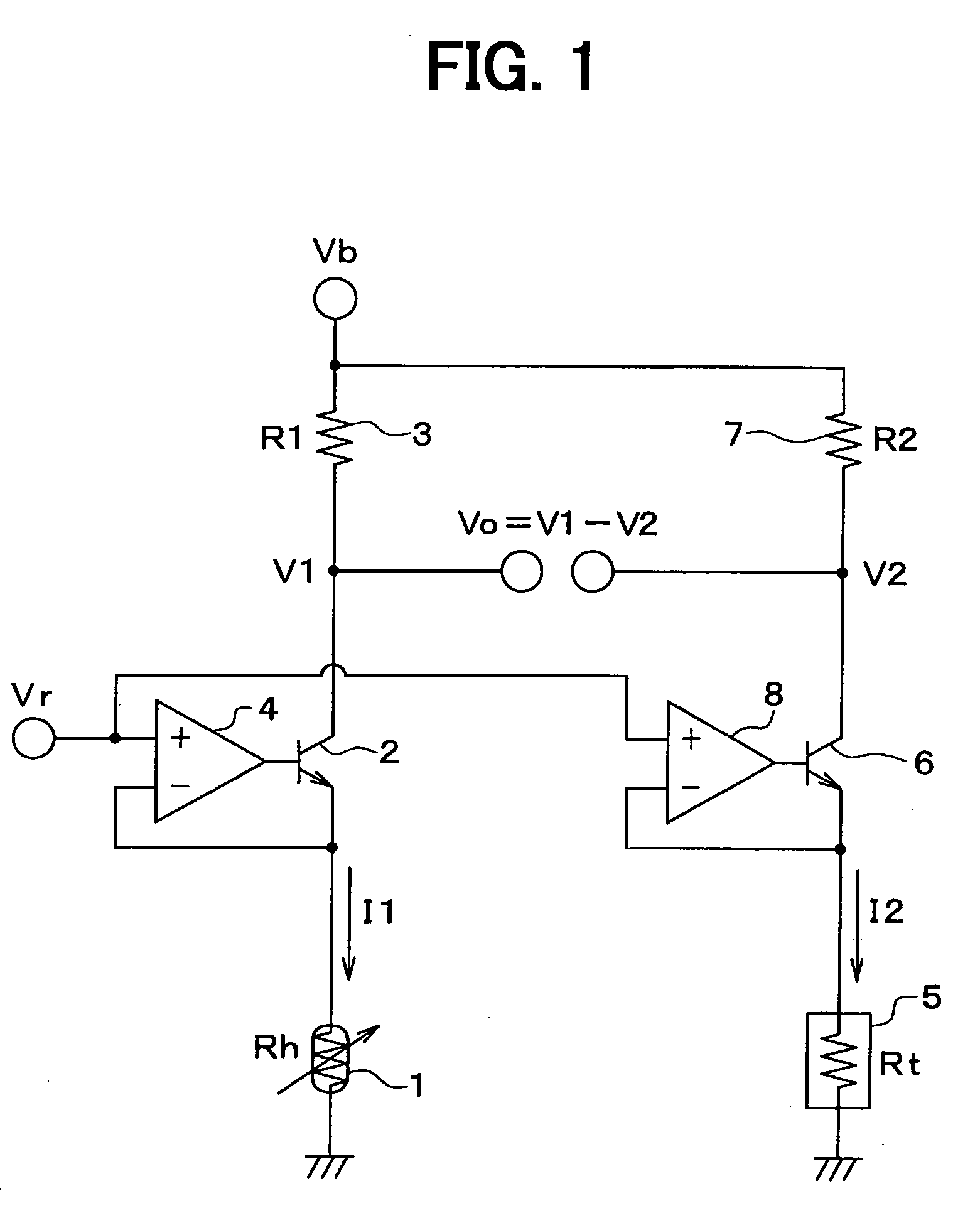

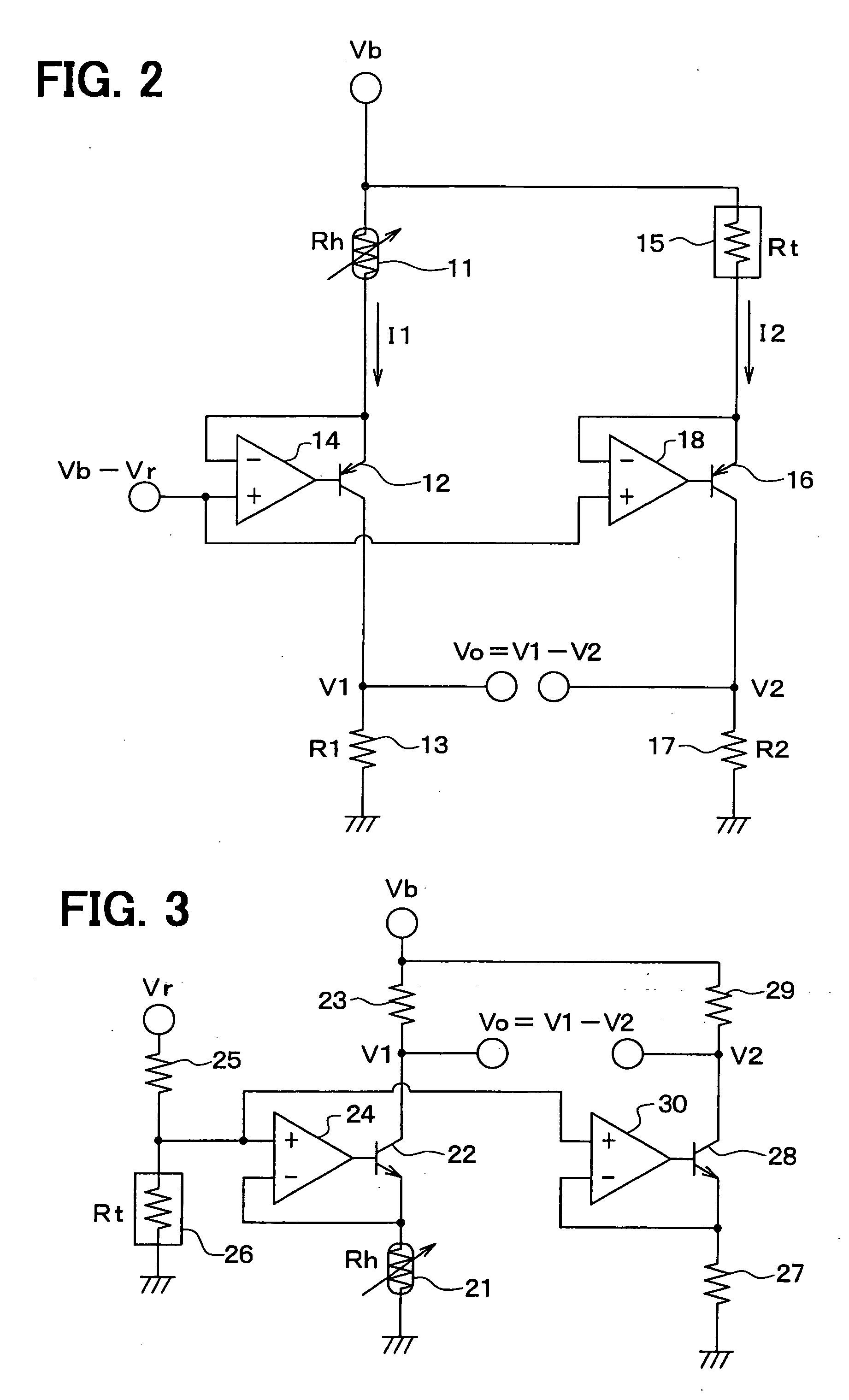

Heat-radiation type flow sensor

ActiveUS7155970B2Improve interferenceStrong enduranceVolume/mass flow by thermal effectsNegative feedbackAudio power amplifier

In a heat-radiation type flow sensor, a heater resistor is connected to a fixed resistor in series with a transistor. An electrical potential between the heater resistor and the transistor is supplied to an inverting input terminal of an operational amplifier. A reference voltage is supplied to a non-inverting input terminal of the operational amplifier. An output potential of the operational amplifier is supplied to a base of the transistor. Since the electrical potential between the heater resistor and the transistor is supplied to the inverting input terminal of the operational amplifier, the airflow sensor includes only a negative feedback circuit. Thus, the airflow sensor exhibits strong endurance against electromagnetic interferences.

Owner:DENSO CORP

Composite material for head of special vehicle

Disclosed is a composite material for a head of a special vehicle. The composite material comprises, by weight, 25-35 parts of BaO-Al2O3-SiO2, 13-29 parts of Al2O3p / NicrBSi, 7-19 parts of Cr3C2-NiCr / NiAl, 12-28 parts of Ti / SnO2-Sb, 6-16 parts of ZrB2, 18-32 parts of Cf-Zr-B and 32-47 parts of 1,2-Benzisothiazolin-3-One. In this way, the composite material is high in bearing capacity, creep resistance and wear-corrosion resistance and long in service life.

Owner:WUXI XIZHOU END SOCKET MFG

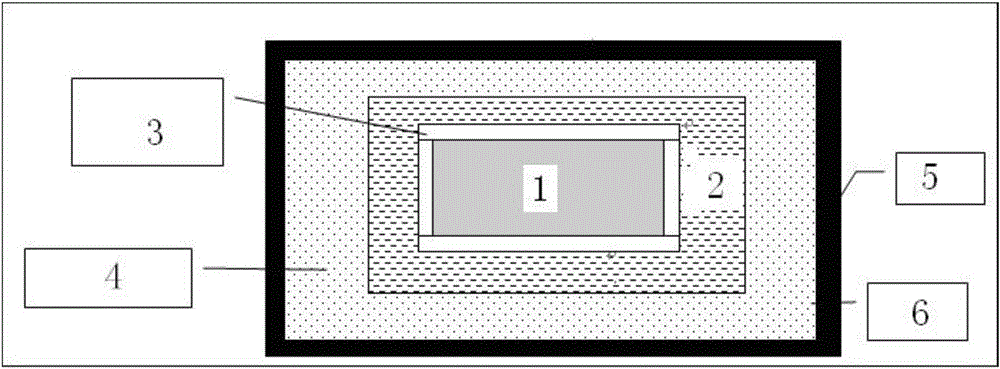

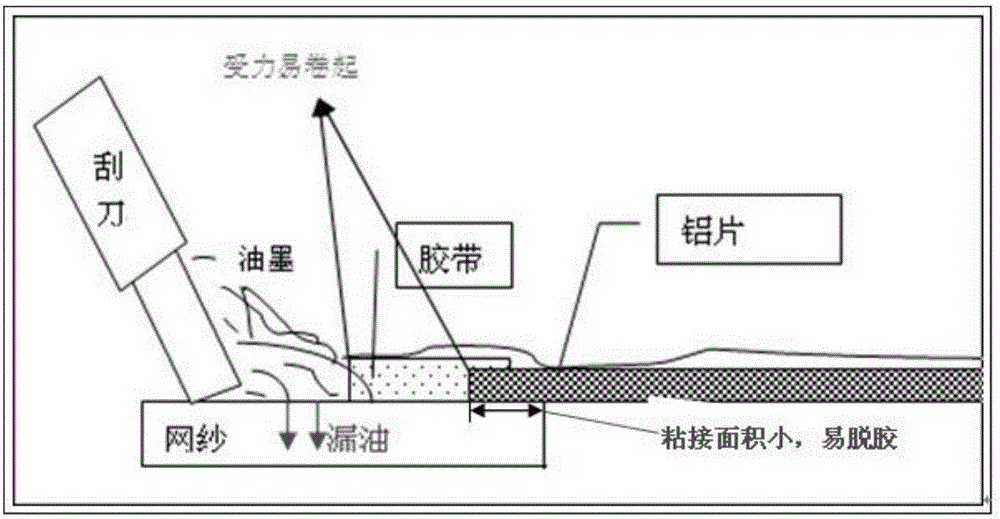

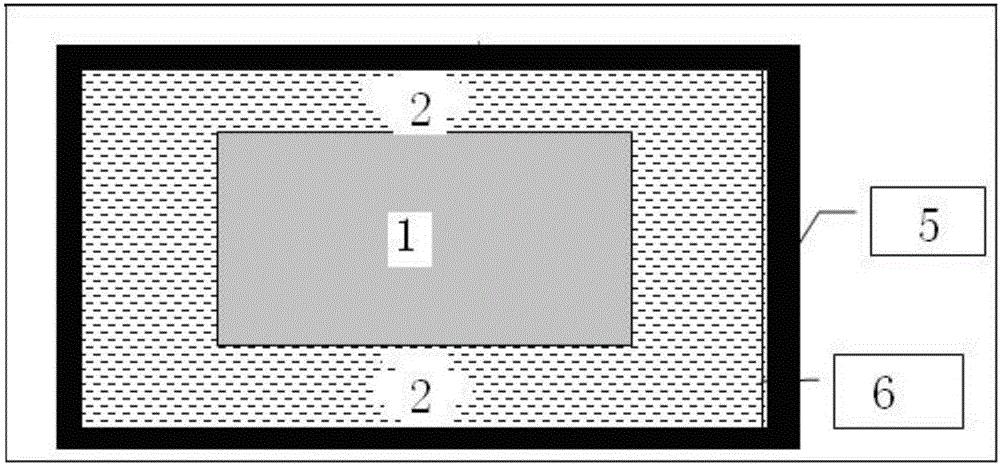

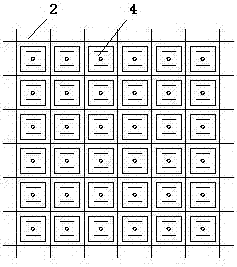

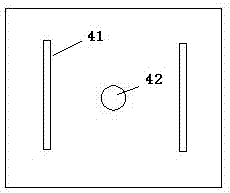

Aluminum sheet plug hole net screen

PendingCN106793518AExtended service lifeSolve the oil spill problemPrinted circuit aspectsPrinted circuit manufactureEngineeringUltimate tensile strength

The invention relates to an aluminum sheet plug hole net screen. The aluminum sheet plug hole net screen is characterized in that an aluminum sheet on a net gauze is the same with the size of the inner edge of a net framework; the length and width of the net framework are respectively 40cm more than the length and width of an aluminum sheet drilling pattern on the net screen; after the aluminum sheet is attached in the manufacturing process, one layer of resin glue is applied onto the non-aluminum sheet drilling pattern at the bottom surface of the net screen; one layer of glue is applied to a gap between the net screen and the aluminum sheet. The aluminum sheet plug hole net screen has the advantages that by arranging the plug hole net screen, a scraping area is completely located on the aluminum sheet, and the oil leakage of the net screen is avoided on the non-drilling pattern area; the adhering area between the aluminum sheet and the net gauze is large, the glue falling of the aluminum sheet is avoided, the stress of a scraping knife completely acts onto the aluminum sheet, and the resultant force borne by utilizing the strength of the aluminum sheet and the net gauze are higher than the bearing capacity of one net gauze layer, so as to effectively prolong the service life of the aluminum sheet net.

Owner:AOSHIKANG TECH CO LTD

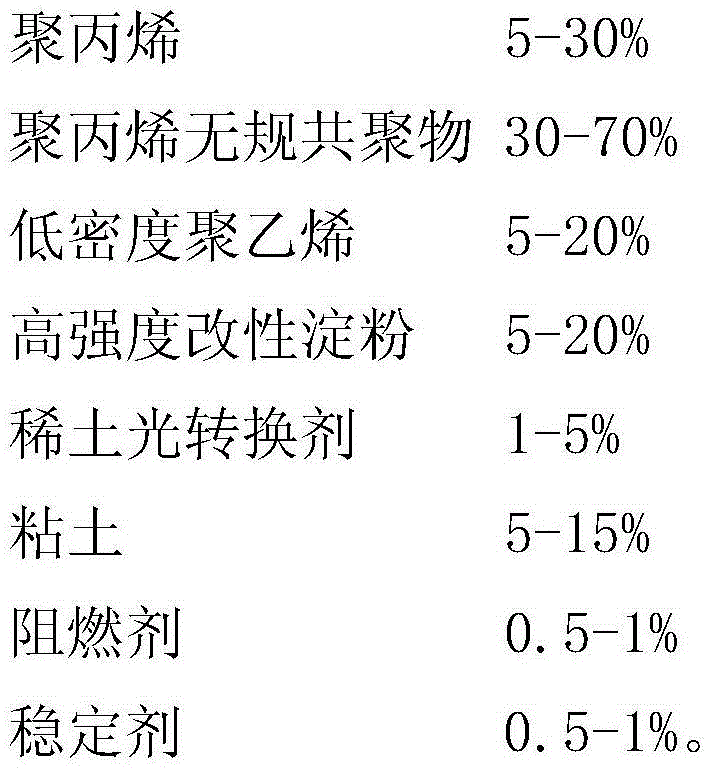

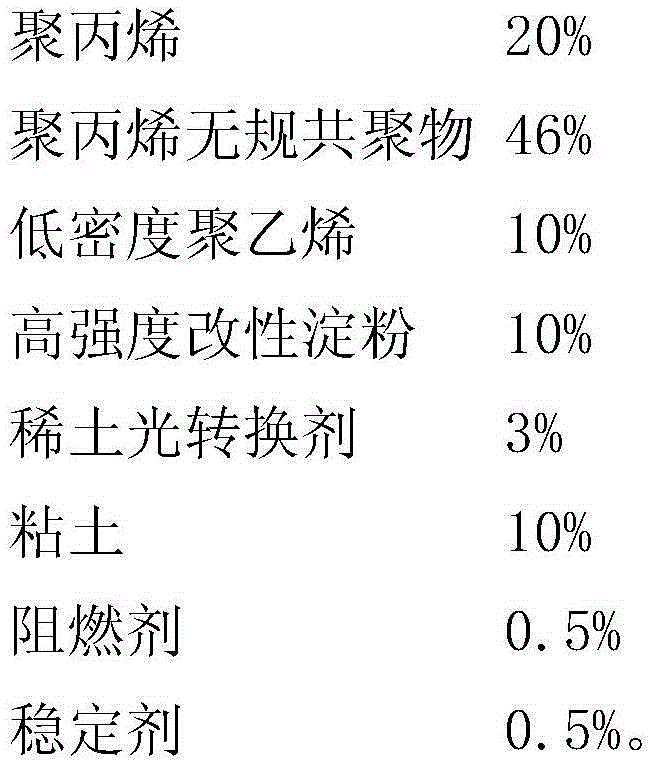

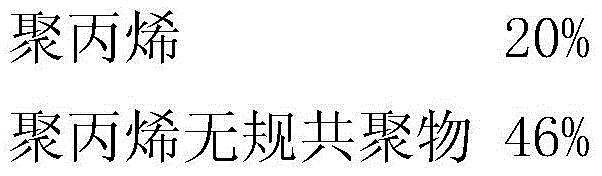

Easily degradable plastic water ladle for family life

ActiveCN103601967AImprove toughnessStrong enduranceKitchen equipmentLow-density polyethyleneChemical industry

The invention discloses an easily degradable plastic water ladle for family life, and relates to the technical field of chemical industry. The easily degradable plastic water ladle comprises, by weight, 5-30% of polypropylene, 30-70% of a polypropylene random copolymer, 5-20% of lower density polyethylene, 5-20% of high strength modified starch, 1-5% of a rare earth light conversion agent, 5-15% of clay, 0.5-1% of a fire retardation agent, and 0.5-1% of a stabilizer. According to the present invention, the components are simple, the cost is low, and the prepared finished product has characteristics of good toughness, strong bearing capability, high compactness, easy biodegradation and easy recycling; and the traditional production process is changed, and the freezing process is added, such that the product safety is improved, and the product has good stability at a high temperature.

Owner:ANHUI GUANHONG PLASTIC IND

Double-layer buffer wagon balance

InactiveCN107036694AImprove qualityHigh qualitySpecial purpose weighing apparatusHigh intensityEngineering

The invention discloses a technical field related to floor scales, in particular to a double-layer cushioned floor scale, which has an upper weighing platform and a lower weighing platform, and the lower end of the lower weighing platform is equipped with a weighing pad for reducing wear on the bottom surface of the lower weighing platform The four corners of the lower weighing platform are equipped with buffer springs, the top of the buffer springs on the four corners is installed with the upper weighing platform, and the lower weighing platform is equipped with an "L"-shaped transport protection clip, the upper weighing platform The lifting ring screw holes for fixing the lifting ring are installed on the weighing surface of the platform, and a junction box is provided on one side edge of the lower weighing platform. Cantilever alloy steel sensors are installed in the upper weighing platform and the lower weighing platform. The design has a strong sense of structure and is easy to operate, ensuring the consistent high quality of each component, thus ensuring stable and reliable measurement accuracy and measurement repeatability.

Owner:蒋丽芳

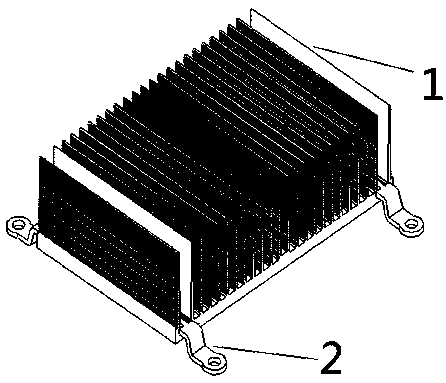

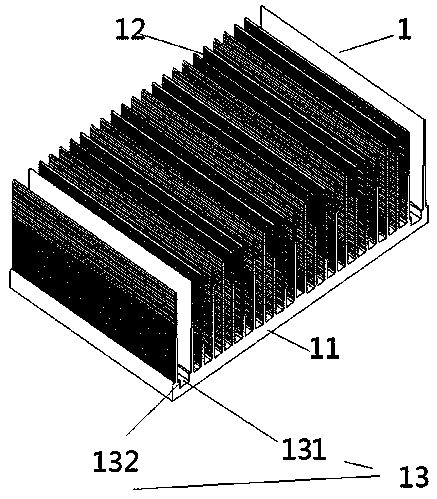

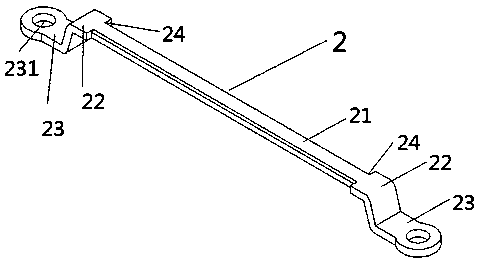

A heat sink with a riveting structure and a riveting process thereof

PendingCN109195408AImprove riveting strengthStrong enduranceModifications by conduction heat transferHeat exchange apparatusEngineeringFixed position

The invention discloses a heat sink with a riveting structure, comprising a heat sink body and a bracket, wherein the heat sink body comprises a base and a plurality of heat sink fins, wherein the heat sink fins are parallel to each other and are arranged on the base at intervals; Forming a groove body between the outermost adjacent heat dissipation fins. The bracket comprises a fixed position, two bending positions and two mounting positions, wherein the fixed position is in the shape of a strip, the bending positions are respectively located at both ends of the fixed position, and the mounting positions are respectively located at the outside of the bending position. The fixing position is riveted in the groove body. The invention also discloses a riveting process of the radiator, whichis simple in riveting process, compact in structure and high in heat dissipation effect.

Owner:THERMAL GROUP TECH HUIZHOU

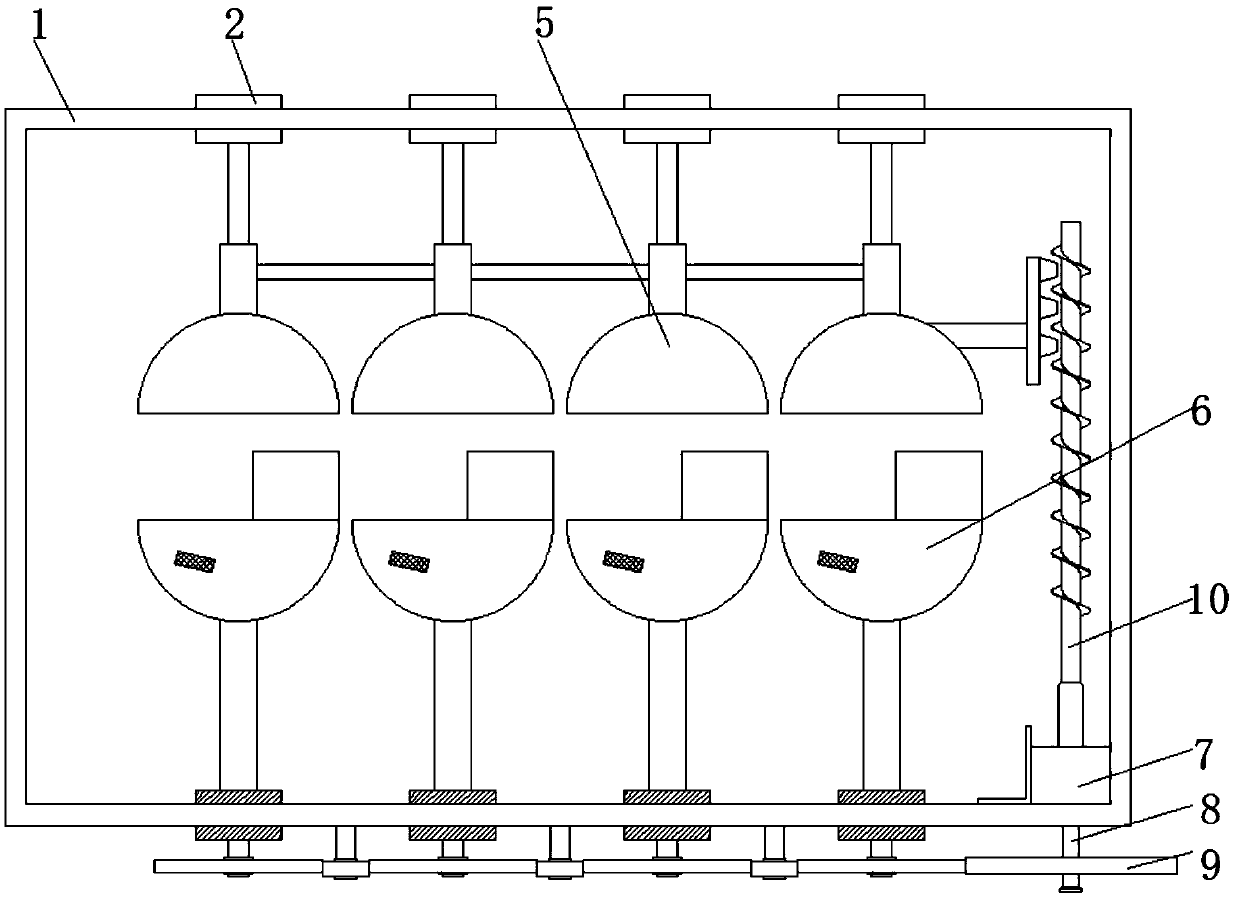

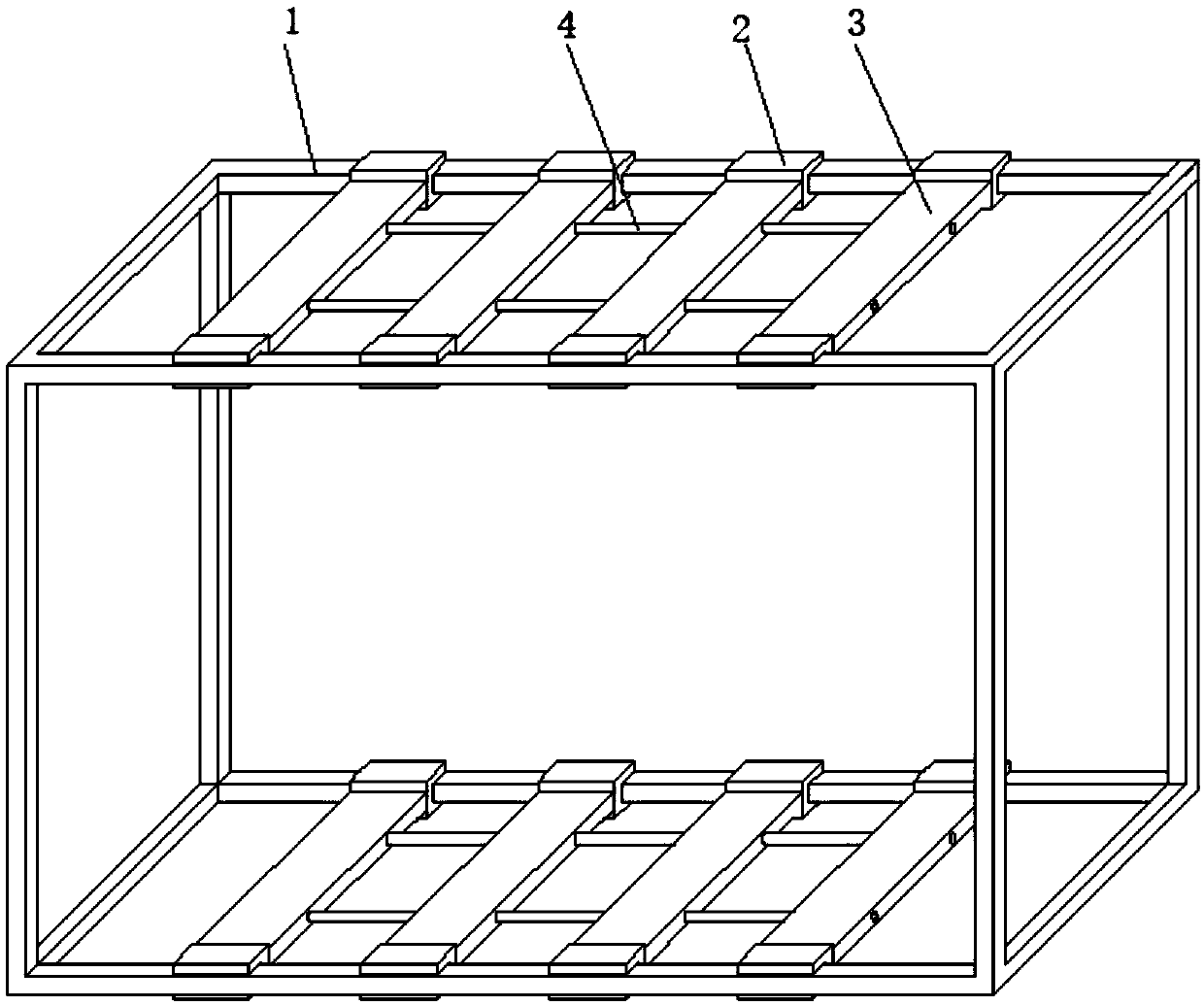

Textile yarn ball drying device capable of rotating obliquely

ActiveCN108679939AImprove cooling effectWide heating surfaceDrying gas arrangementsAir heatersVibration amplitudeTextile yarn

The invention relates to the field of textile equipment and discloses a textile yarn ball drying device capable of rotating obliquely. The textile yarn ball drying device comprises a cube frame. Two edge columns on the top of the frame are fixedly connected with 4-8 sets of C-shaped clamping plates, and the two edge columns at the bottom of the frame are fixedly connected with 4-8 sets of C-shapedclamping plates. A carrying plate is fixedly connected between every two corresponding C-shaped clamping plates located above, and a carrying plate is fixedly connected between every two correspondingly C-shaped clamping plate located below. Arc-shaped guide pipes are fixedly connected between the two adjacent carrying plates. A centralized drying treatment mechanism is arranged under each C-shaped clamping plate located above. Through the textile yarn ball drying device, the problems that yarn balls are small in heating area and are inconvenient to dry during drying operation are solved. Through cooperation of the centralized drying treatment mechanisms, acting force resistant rotating mechanisms and a vibration amplitude mechanism, the heating area of the dried surfaces of the yarn balls can be larger, and the yarn balls can be dried more rapidly, and the working efficiency can be effectively improved.

Owner:XUZHOU ZHENFANG TEXTILE CO LTD

Heat-radiation type flow sensor

ActiveUS20060075814A1Well withstand electromagnetic interferenceStrong enduranceVolume/mass flow by thermal effectsVoltage referenceAirflow

In a heat-radiation type flow sensor, a heater resistor is connected to a fixed resistor in series with a transistor. An electrical potential between the heater resistor and the transistor is supplied to an inverting input terminal of an operational amplifier. A reference voltage is supplied to a non-inverting input terminal of the operational amplifier. An output potential of the operational amplifier is supplied to a base of the transistor. Since the electrical potential between the heater resistor and the transistor is supplied to the inverting input terminal of the operational amplifier, the airflow sensor includes only a negative feedback circuit. Thus, the airflow sensor exhibits strong endurance against electromagnetic interferences.

Owner:DENSO CORP

Modified asphalt and preparation process thereof

PendingCN108410192AIncreased durabilityImprove wear resistanceBuilding insulationsModified carbonWaste rubber

The invention discloses modified asphalt which is prepared from, by weight, 6-10 parts of modified asphalt activating agents and 90-94 parts of petroleum asphalt. The modified asphalt activating agents comprise, by weight, 75-89 parts of rubber heavy oil, 3-7 parts of modified carbon black, 3-7 parts of catalysts, 2-6 parts of activating agents and 3-5 parts of surface activating agents. The invention further provides a preparation process of the modified asphalt. The preparation process includes the steps: blending and stirring the rubber heavy oil, the modified carbon black and the catalysts; adding the activating agents to react mixture for 10 hours; adding the surface activating agents, and stirring mixture to obtain modified asphalt activating agents; stirring the modified asphalt activating agents and the petroleum asphalt; heating mixture to reach the temperature of 160 DEG C-195 DEG C in a stirring manner to obtain the modified asphalt. Compared with the prior art, the preparation process avoids that waste rubber powder is desulfurized to modify the asphalt in the prior art, the process conditions are easily achieved, the process is nontoxic and free from corrosion and pollution, and a pavement laid by the modified asphalt has good durability and abrasion resistance and the advantages that the pavement cannot soften at high temperature or crack at low temperature and ishigh in bearing capacity, free from flying dust, resistant to sliding and noise and the like.

Owner:牛勇超

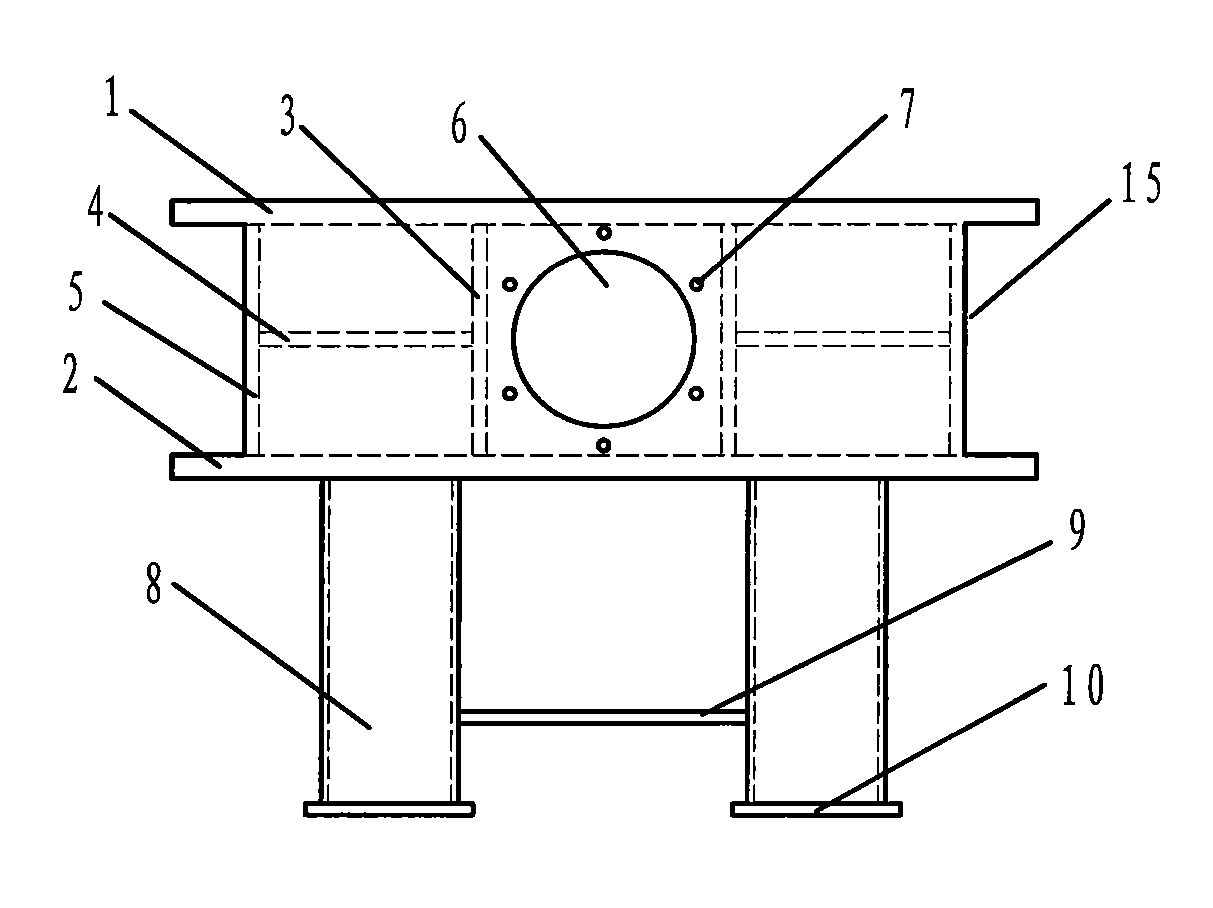

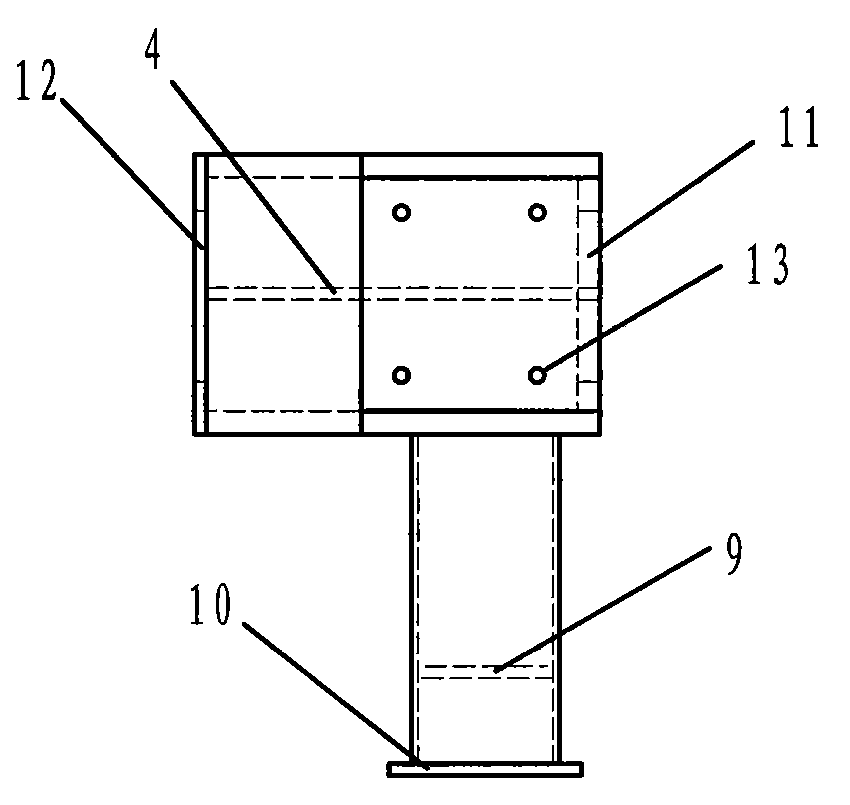

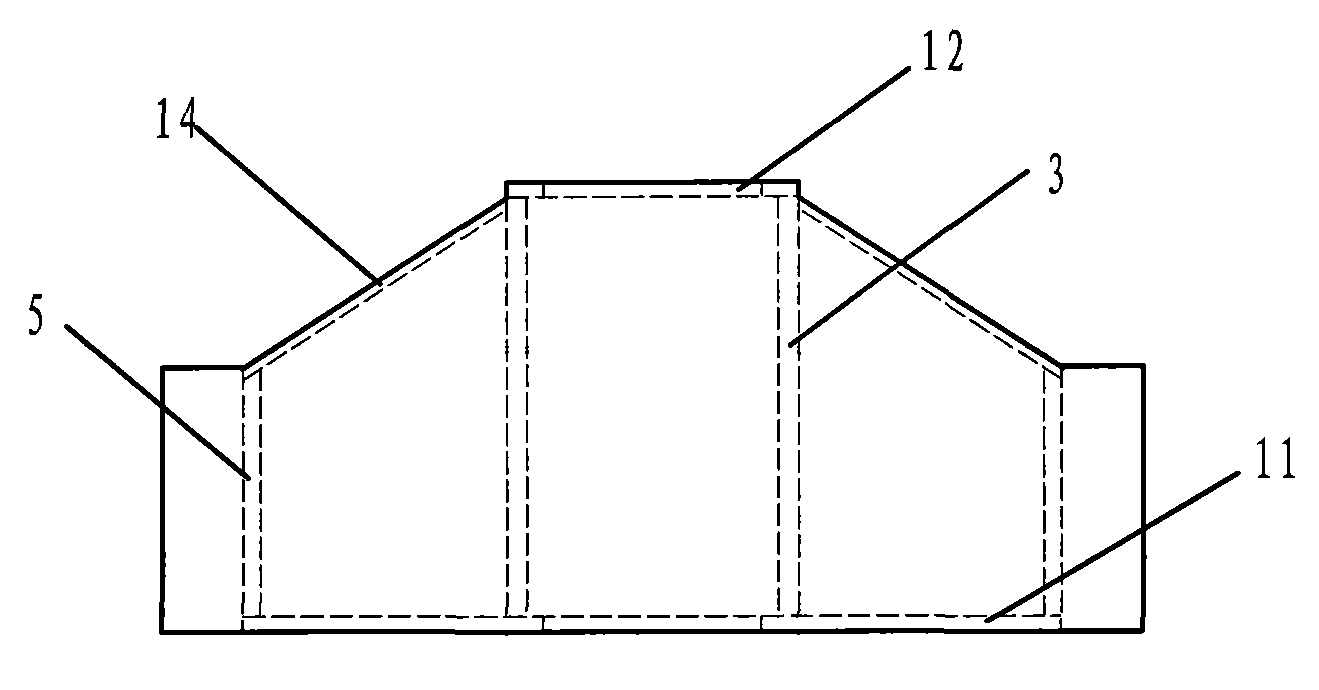

Van body type oil cylinder seat of filter press

InactiveCN103316513ASafe and reliable structureReasonable structureFiltration separationTubes typesHigh pressure

The invention provides a van body type oil cylinder seat of a filter press. The van body type oil cylinder seat is provided with an upper main plate and a lower main plate; middle parts of the upper main plate and the lower main plate are welded with a vertical rib plate and a transverse rib plate to form an oil cylinder seat main body; the two ends of the oil cylinder seat are welded with baffles to form a main beam groove; a front panel and a rear panel are welded at the two ends of the main body; the front panel and the rear panel are provided with oil cylinder body holes; closing plates are welded at the rear two sides of the main body to form the van body type oil cylinder seat; a square tube type supporting leg is arranged at the lower end of the oil cylinder seat; a transverse pull rod is arranged in the middle of the supporting leg; the lower end of the supporting leg is welded with a bottom plate. According to the van body type oil cylinder seat disclosed by the invention, the structure is reasonable and the bearing strength is great; the structure is tightly pressed by hydraulic pressure and high pressure and the fatigue durability is strong; when the van body type oil cylinder seat is tightly pressed and stressed, the oil cylinder seat is not warped and can not deform; a main beam is firmly mounted, and a pressing plate and a thrust plate reach designed parallelism; when materials are filtered, a filtering plate does not leak materials; the arranged supporting leg is welded with a transverse pull plate and a bottom plate and is mounted stably, so that the van body type oil cylinder seat is firm is structure and is safe to use.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

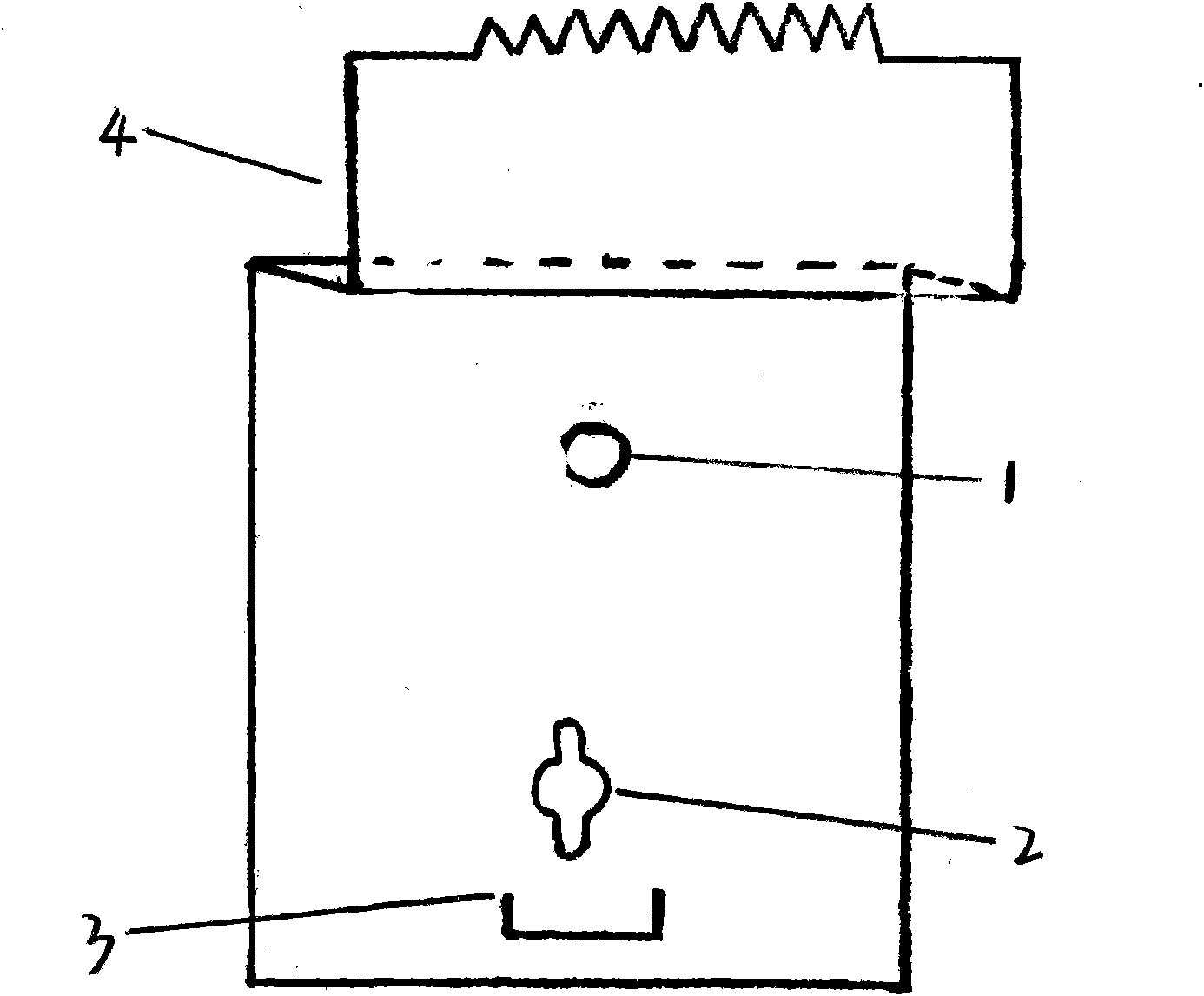

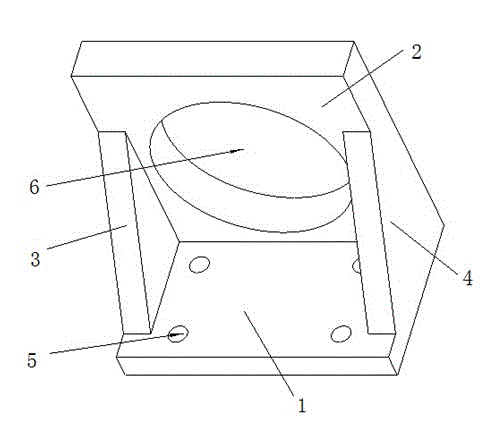

Motor seat on X axis of server

InactiveCN103337926AStrong enduranceImprove rigiditySupports/enclosures/casingsEngineeringCarbon steel

The invention provides a motor seat on an X axis of a server. The motor seat is formed by carbon steel materials through welding, comprises a bottom plate (1), a motor placement plate (2), a left end support plate (3) and a right end support plate (4) and is characterized in that the bottom plate (1) is connected with the motor placement plate (2) to form an integral L-shaped structure; the left end support plate (3) and the right end support plate (4) are connected between the bottom plate (1) and the motor placement plate (2); bolt holes (5) are formed in the bottom plate (1); a motor placement hole (6) is formed in the motor placement plate (2). The motor seat is strong in bearing capacity and good in rigidity, so that a machine is more stable during machining, the stability of the machine is improved, and the machining precision of a product is ensured.

Owner:KUNSHAN JIESHENG PRECISION HARDWARE

Cast-in-place lightweight wallboard and floor

ActiveCN107542211AGood elongation and breaking strengthGood shock resistanceConstruction materialFloorsMagnesiumWaste product

The invention discloses a cast-in-place lightweight wallboard and floor, and belongs to the field of a building material. The cast-in-place lightweight wallboard and floor comprises a plaster mortar board, a steel wire mesh and an inner mold, wherein the steel wire mesh is in a grid shape and comprises an upper layer and a lower layer; a W-shaped support steel wire is arranged between the layers;the inner mold is placed in grids of the two layers of steel wire meshes; the plaster mortar board is prepared from plaster power, pulverized fuel ash, waterproof agents, paper pulp, fiber, red mud, quartz powder, magnesium oxide, magnesium chloride, retarding agents and corrosion inhibitors; and the inner mold is a lightweight material made of expanded polystyrene particles. Waste products such as the plaster power, the pulverized fuel ash and red mud solid powder waste materials in thermal power plants and aluminum manufacturers are used as raw materials; few modified additives are added; the prepared plasterboard can form a continuous waterproof layer; good elongation percentage and breaking strength are realized; the waterproof, sound-proof and anti-seismic effects are good; the acid-resistant and alkali-resistant performance is good; the weather-resistant performance is excellent; the adhesive force is strong; the mildew proof performance, the anti-bacterial performance and the durability are excellent; and in the use process, the construction is fast and convenient.

Owner:江西省科森建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com