Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Malate fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

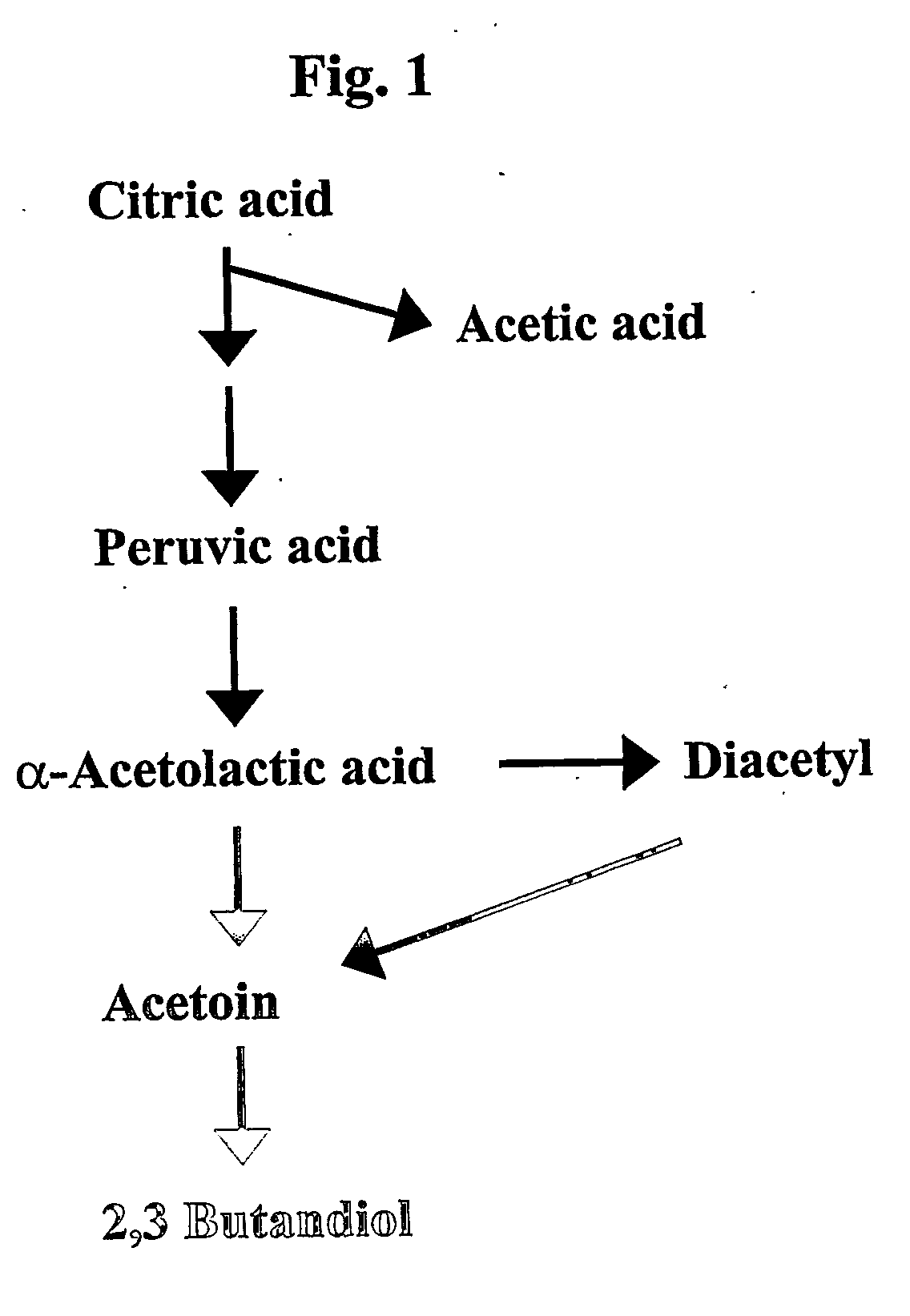

The chemical process of malolactic fermentation is actually a decarboxylation instead of a fermentation. The bacterial cell takes in malate, converts it into lactate, and releases carbon dioxide in the process.

Production method of aged dry red wine

The invention discloses a production method of aged dry red wine. The method is characterized by comprising the following steps of: removing the stem of grape and crushing; steeping at low temperature for 4-12 hours; after the steeping, separating part of the grape juice, and adding yeast into the pulp to perform temperature-controlled alcohol fermentation; meanwhile, centrifuging the separated grape juice for producing pink wine; after the alcohol fermentation, performing temperature-controlled micro-oxygenation on the separated raw wine; and then performing the processes of malolactic fermentation, clarification, freezing, filtering and the like to obtain the aged dry red wine. Through the invention, the chroma, tannin and total phenol of the produced aged dry red wine are obviously improved in comparison with the common aged dry red wine; moreover, the aged dry red wine produced by the method disclosed by the invention has stable color, full body, mellow and coordinative mouthfeel and strong structure sense; the aging potential is obviously enhanced; and the production method is simple and easy to control and suitable for industrial production.

Owner:YANTAI CHANGYU GRP CO LTD

Dry white wine and its brewing process

InactiveCN1566312APromote fermentationStrong aromaWine preparationFruit juiceLactic acid fermentation

The invention discloses a dry white wine and its brewing process which comprises, screening grape raw material, stripping and squashing, fruit juice separating and squeezing, clarifying, alcoholic fermentation, malic acid - lactic acid fermentation, ageing, stability treatment, filtering and bottling.

Owner:YANTAI CHANGYU GRP CO LTD

Method for brewing blueberry wine

ActiveCN103666922AMicroorganism based processesAlcoholic beverage preparationBiotechnologyOenococcus oeni

The invention discloses a method for brewing a blueberry wine. The method comprises the steps of selecting raw materials, selecting strains, fermenting with ethanol, carrying out malo-lactic fermentation, ageing, clarifying, stabilizing and the like. According to the method, optimized blueberries Huangshan 1# serve as the raw materials; high-temperature enzymolysis, high-temperature start-up and low-temperature long-time fermentation are carried out by using saccharomycetes RC212 as the fermentation strains; the malo-lactic fermentation is carried out by using oenococcus oeni SD-2 with high glucosidase activity; micro-aerobic ageing is utilized, so as to accelerate wine ageing and improve the quality of the wine; the blueberry wine can keep a clarified and stable state in long term by the technical means of natural clarification, cellaring, cold treatment, heat treatment, stabilizer adding, microfiltration and the like. In accordance with the method, a high-quality blueberry wine with good color, smell and taste can be obtained, and the obtained product meets the requirements of the national wine product quality standard GB2758-81.

Owner:JURONG WANSHANHONGBIAN BIOTECH

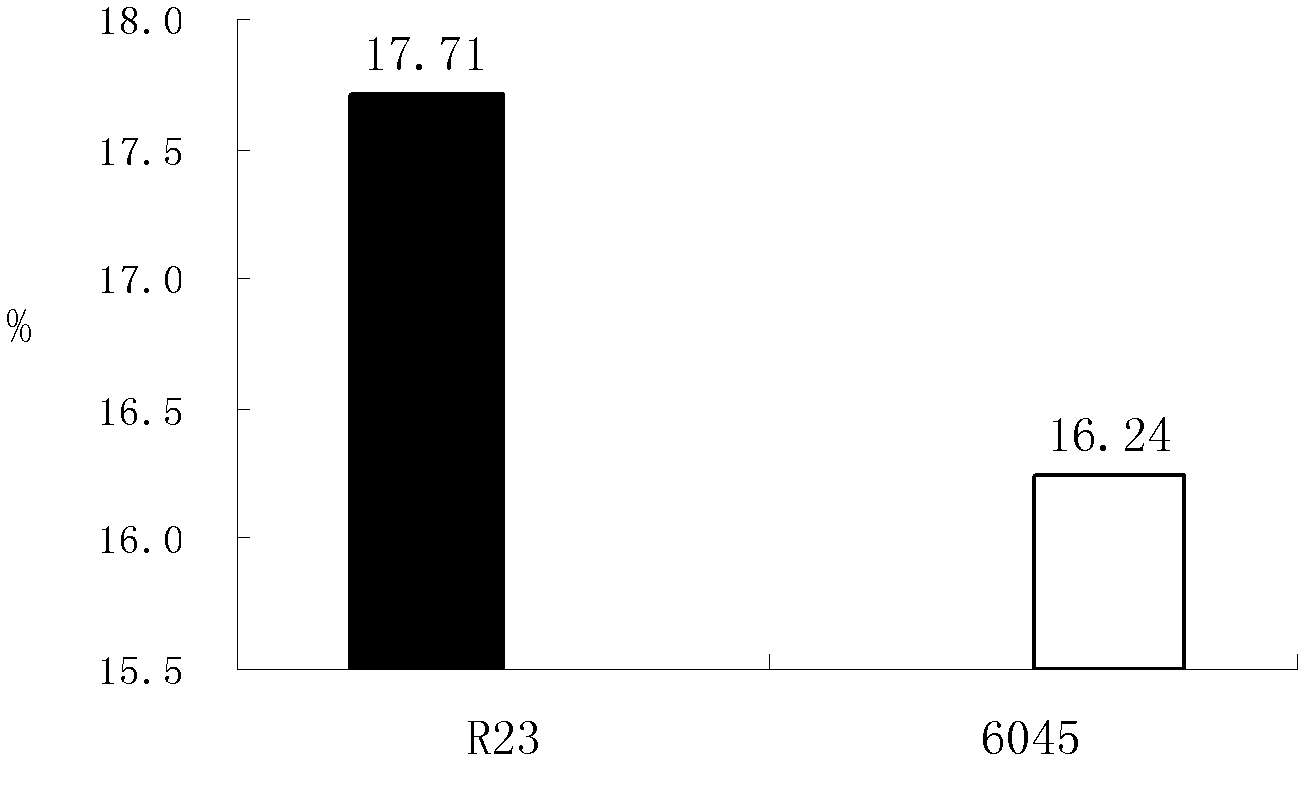

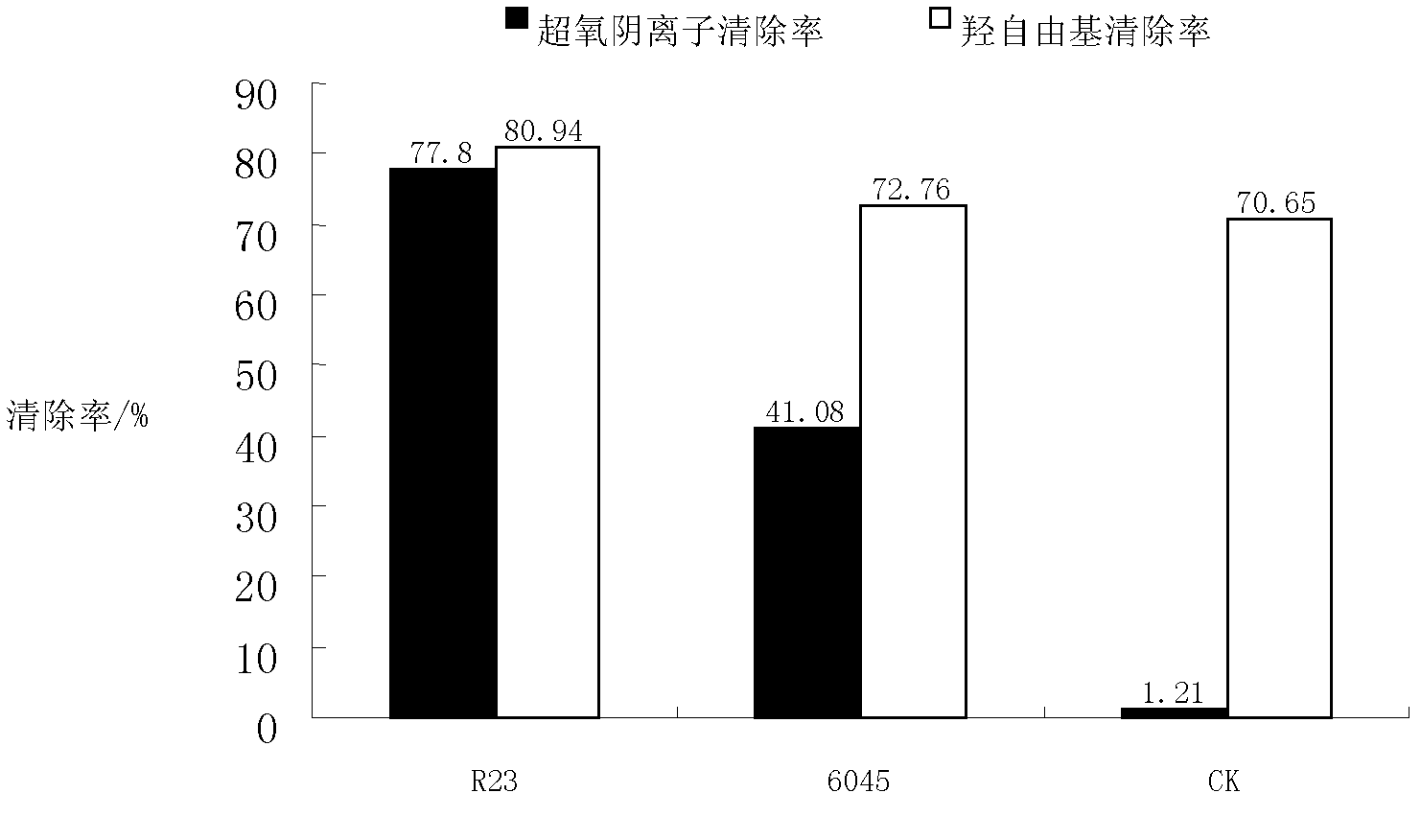

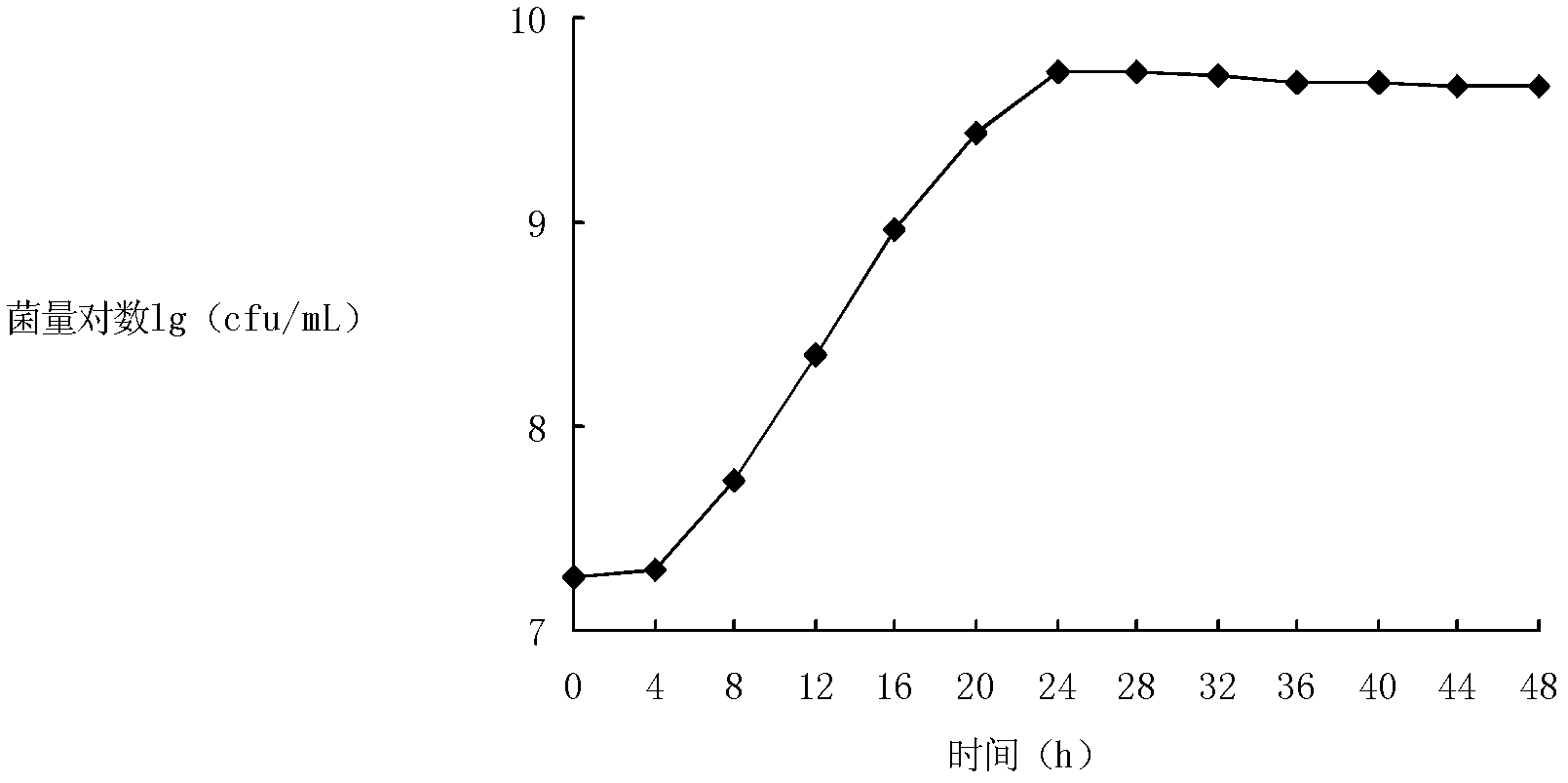

Lactobacillus plantarum R23

InactiveCN102358888AStrong Prebiotic PropertiesSoft tasteBacteriaAlcoholic beverage preparationFruit juiceMalolactic enzyme

The invention relates to Lactobacillus plantarum R23 which is characterized in that: the Lactobacillus plantarum is conserved in China General Microbiological Culture Collection (CGMCC) on August 1, 2011 with the conservation number of CGMCC No.5105. The Lactobacillus plantarum R23 not only can produce malolactic enzyme at high yield and has good biological deacidification capability, but also has the following stronger beneficial characteristics of (1) stronger resistance, (2) stronger oxidation resistance and (3) stronger adhesion capability. The Lactobacillus plantarum can utilize malic acid in priority in the fruit wine containing malic acid, and then carries out lactic acid fermentation of the malic acid to achieve biological deacidification. The Lactobacillus plantarum can be used in fruit juice beverage processing to produce fermented sterile fruit juice beverages, and can also be used in fruit juice beverage processing to produce fermented lactobacillus live bacterial beverages.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

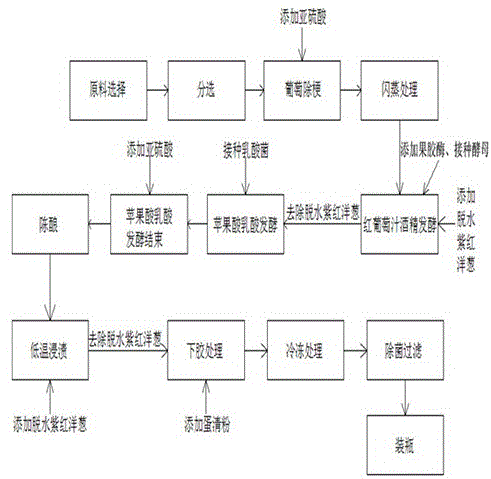

Method for brewing onion grape wine

ActiveCN104087464AHigh content of active ingredientsHigh nutritional valueMicroorganism based processesWine preparationNutritive valuesVitis vinifera

The invention discloses a method for brewing onion grape wine. The method for brewing onion grape wine comprises the following steps: (1) selecting raw materials; (2) sorting; (3) removing stems of grape and uniformly adding 0.2-0.4L / Ton of sulphurous acid on line; (4) carrying out flash evaporation; (5) carrying out alcoholic fermentation by using red grape juice; (6) carrying out malo-lactic fermentation; (7) ending malo-lactic fermentation; (8) ageing for 8-14 months; (9) dipping at the low temperature; (10) fining; (11) freezing; and (12) carrying out sterile filtration. By virtue of the onion grape wine, the onion smell in the wine is greatly reduced under the premise that the effective components of the onion are not damaged; the onion grape wine shows the fragrance similar to green onion pancakes, so that consumers accept the onion grape wine more easily; the onion grape wine is relatively easy to popularize; since the problem of thick onion smell in the wine is solved, the use amount ratio of the onion raw material in the wine brewing process can be higher; the onion grape wine is relatively high in contents of effective components of the onion, and the nutritive value and the health effect of the onion grape wine are improved.

Owner:内蒙古汉森葡萄酒销售有限公司

Saccharomyces cerevisiae and application thereof in reducing acidity in process of producing wine

InactiveCN101838615ARefreshing tasteSoft tasteFungiMicroorganism based processesSuccinic acidFood flavor

The invention discloses saccharomyces cerevisiae and application thereof in reducing acidity in the process of producing wine. The invention provides the saccharomyces cerevisiae NJZSC5 CGMCC No. 3732. The NJZSC5 has strong capacity of utilizing malic acid and citric acid, weak capacity of accumulating succinic acid, and lower lactic acid content after malolactic fermentation in the process of fermenting alcohol. The NJZSC5 can greatly reduce the whole brewing cycle (5-8d) when the wine is produced by using the NJZSC5, improves yield rate of the wine and quality of finished product wine. The NJZSC5 can solve the problems of preparing high-quality wine with relatively low acidity from grape variety with high acidity in grape production areas with high acidity. The wine produced by using the NJZSC5 has the advantages of low acidity, fresh, cool and soft mouthfeel, no astringent flavor, balanced sweetness and sourness, clear level feeling, unique feature, balanced components of volatile aroma, and obvious characteristic aroma of grapes per se.

Owner:CHINA AGRI UNIV

Process for preparing malolactic fermentation complex flavor distilled white liquor

The invention provides a process for preparing malolactic fermentation complex flavor distilled white liquor. The process comprises the following steps: (1) squeezing apple juice; (2) fermenting, namely diluting the concentrated apple juice in the step (1) into fruit juice with the sugar degree of 16-20 percent, feeding the fruit juice into a fermentation tank, adding a wine-brewing yeast to ferment into apple raw wine at low temperature; (3) sealing and storing, namely clarifying and filtering the apple raw wine, inputting the apple raw wine into an oak barrel for sealing and storing; (4) distilling; (5) inputting the raw distilled wine in the step (4) into a micro oxygen equipment for ageing; (6) inputting the distilled wine in the step (5) into a freezing tank for freezing; and (7) blending to prepare the finished wine. The white liquor is prepared by apple juice, stored in the oak barrel after fermentation, distilled and aged in the micro oxygen equipment, the content of methanol and fusel oil is greatly reduced, and due to the process for sequentially storing and distilling, the brewed white liquor is pleasant in taste, and people do not feel dizzy after drinking the white liquor.

Owner:YANTAI GISBELLE WINE

Method for brewing high-quality dry red wine

The invention provides a brewing method for a high-quality dry red wine. The brewing method comprises the following steps: (1) raw material selection and treatment; (2) crushing and pressing; (3) pulpmixing; (4) alcohol fermentation; (5) malolactic fermentation; (6) aging; and (7) clarification. The dry red wine prepared by using the method of the invention is deep ruby red, and has mature andrich grape berry fragrance and black gooseberry fragrance and the sweet vanilla flavor of oak; and the dry red wine has varying compound fragrance, thick wine body, plump, harmonious and powerful taste and lingering aftertaste.

Owner:TIANJIN AGRICULTURE COLLEGE

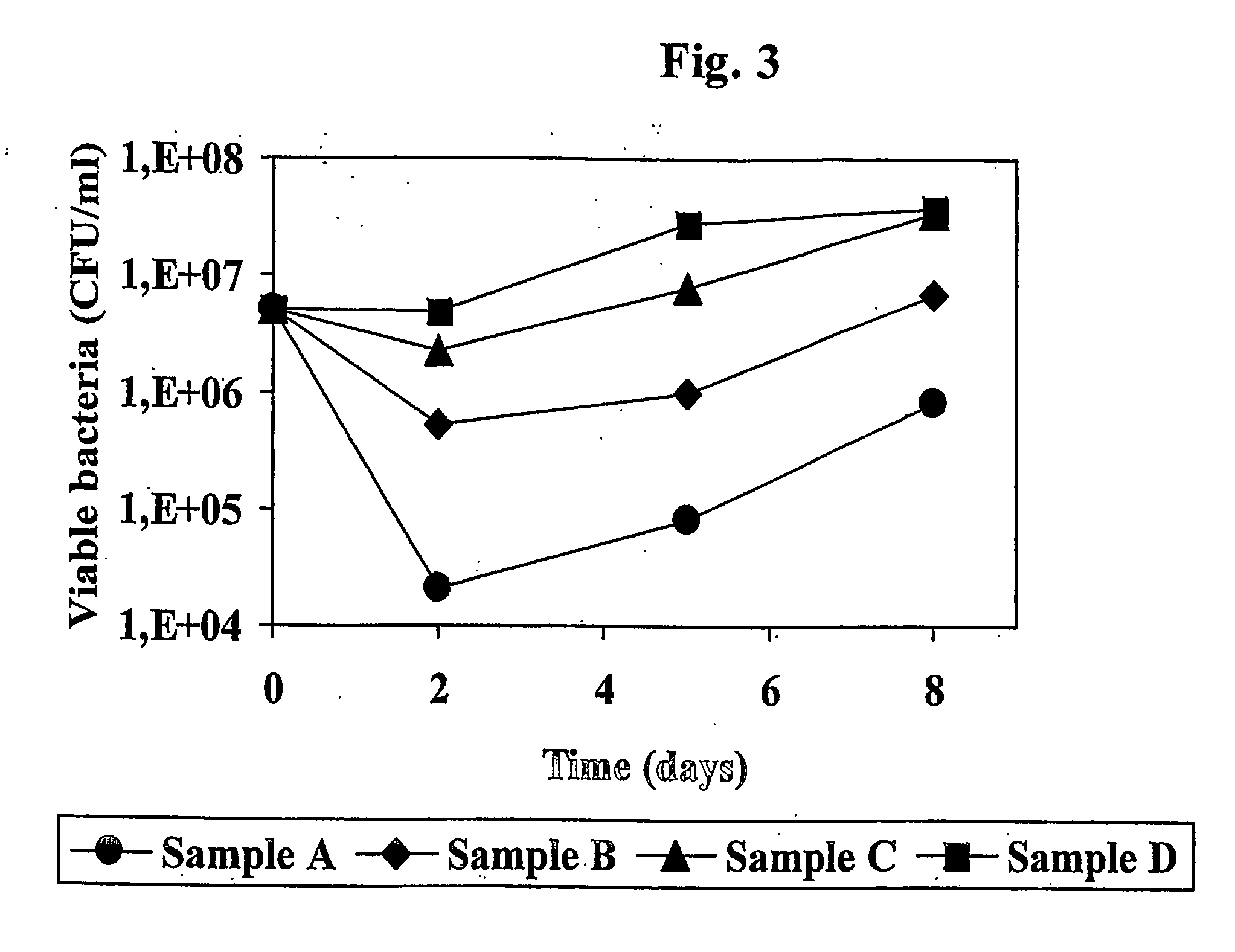

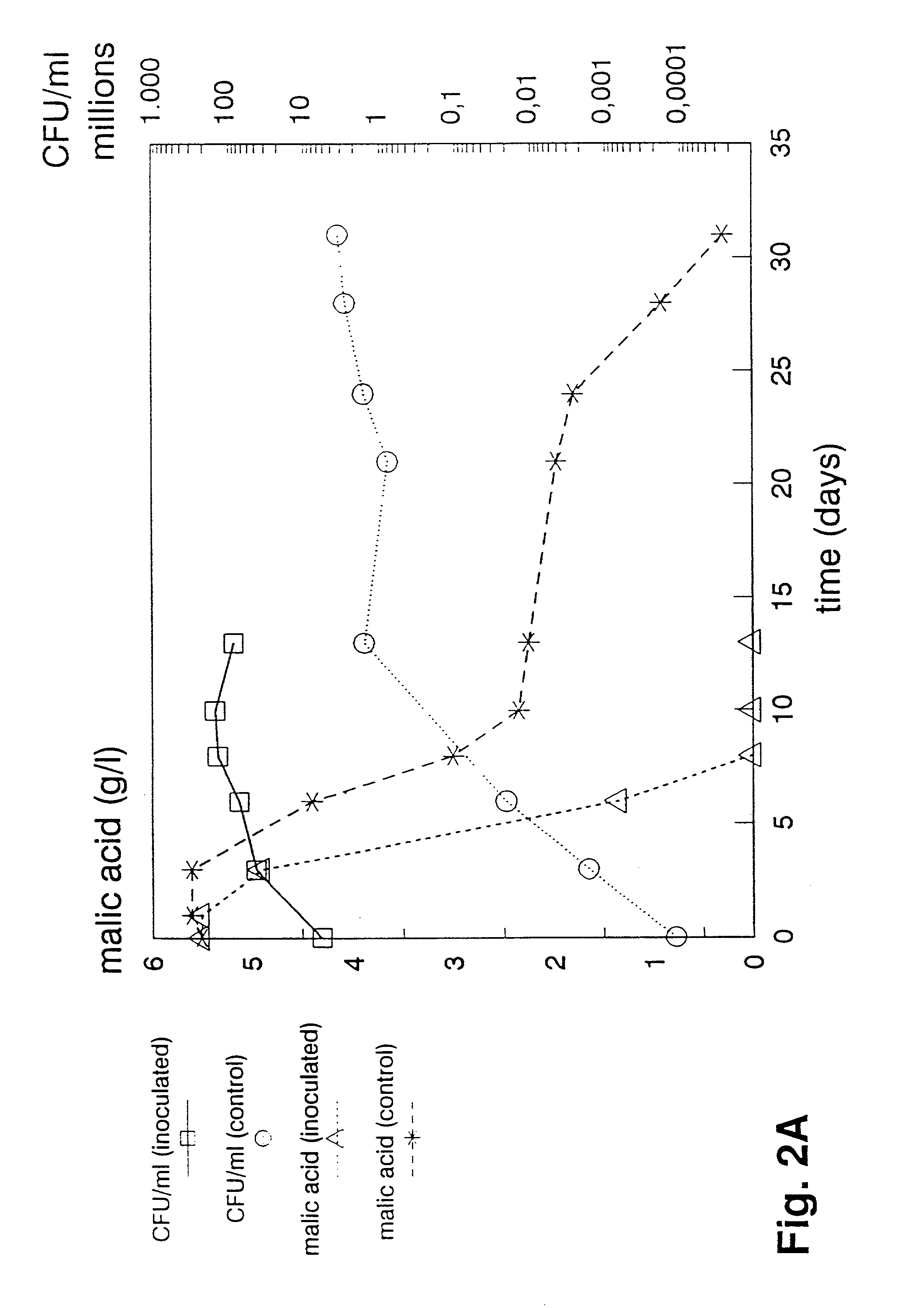

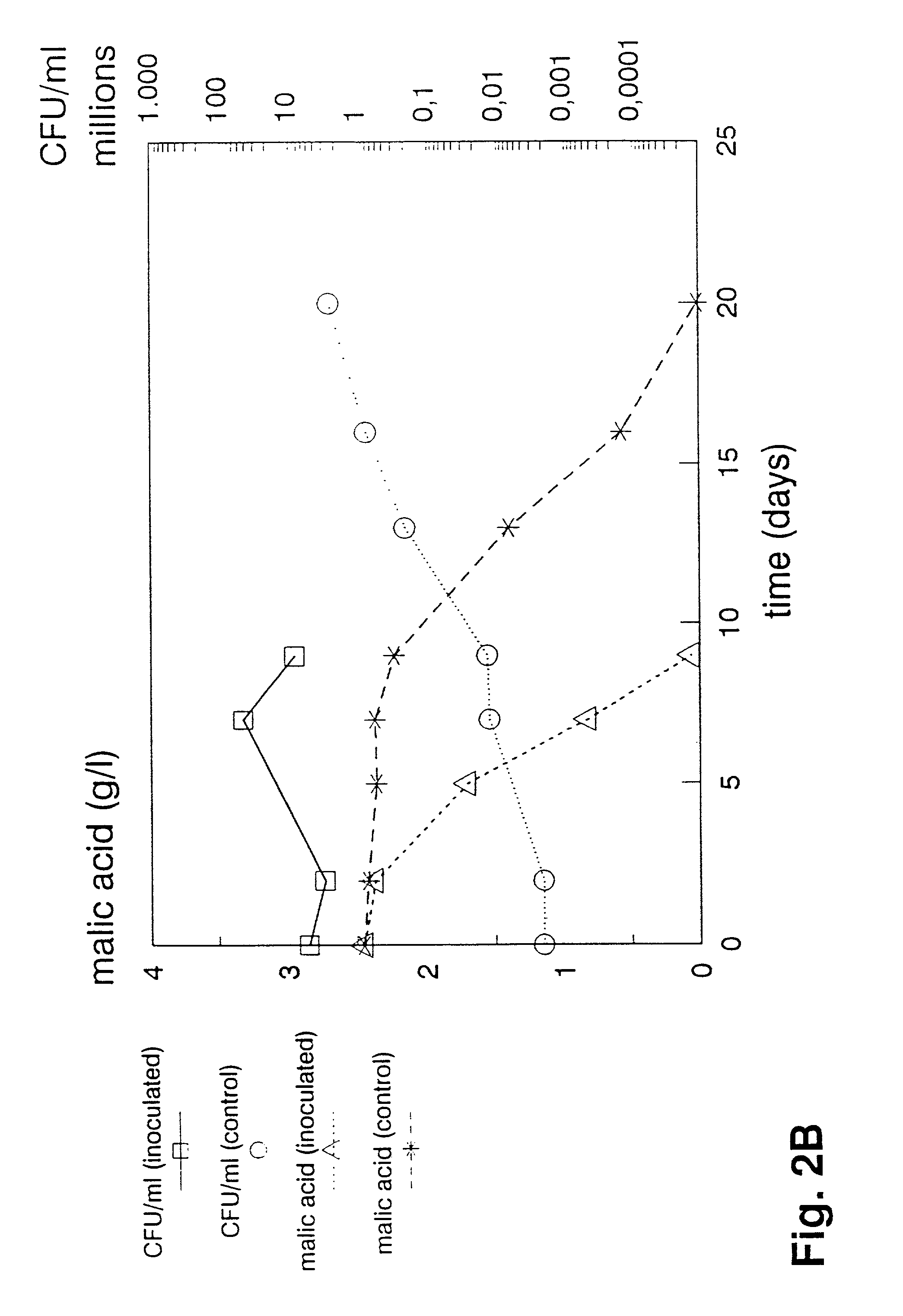

Method of inducing malolactic fermentation in wine or fruit juice by direct inoculation with a non-activated started culture

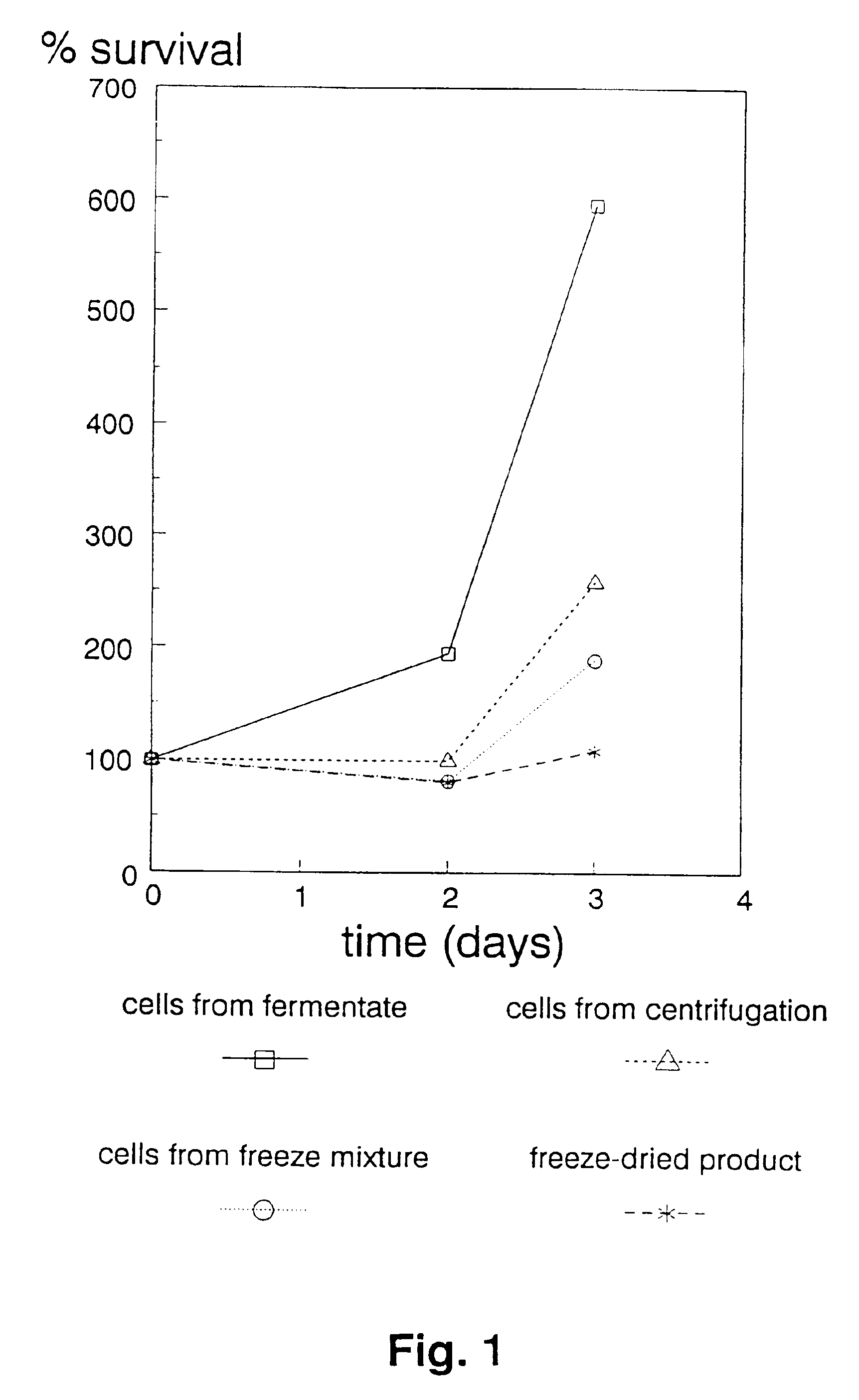

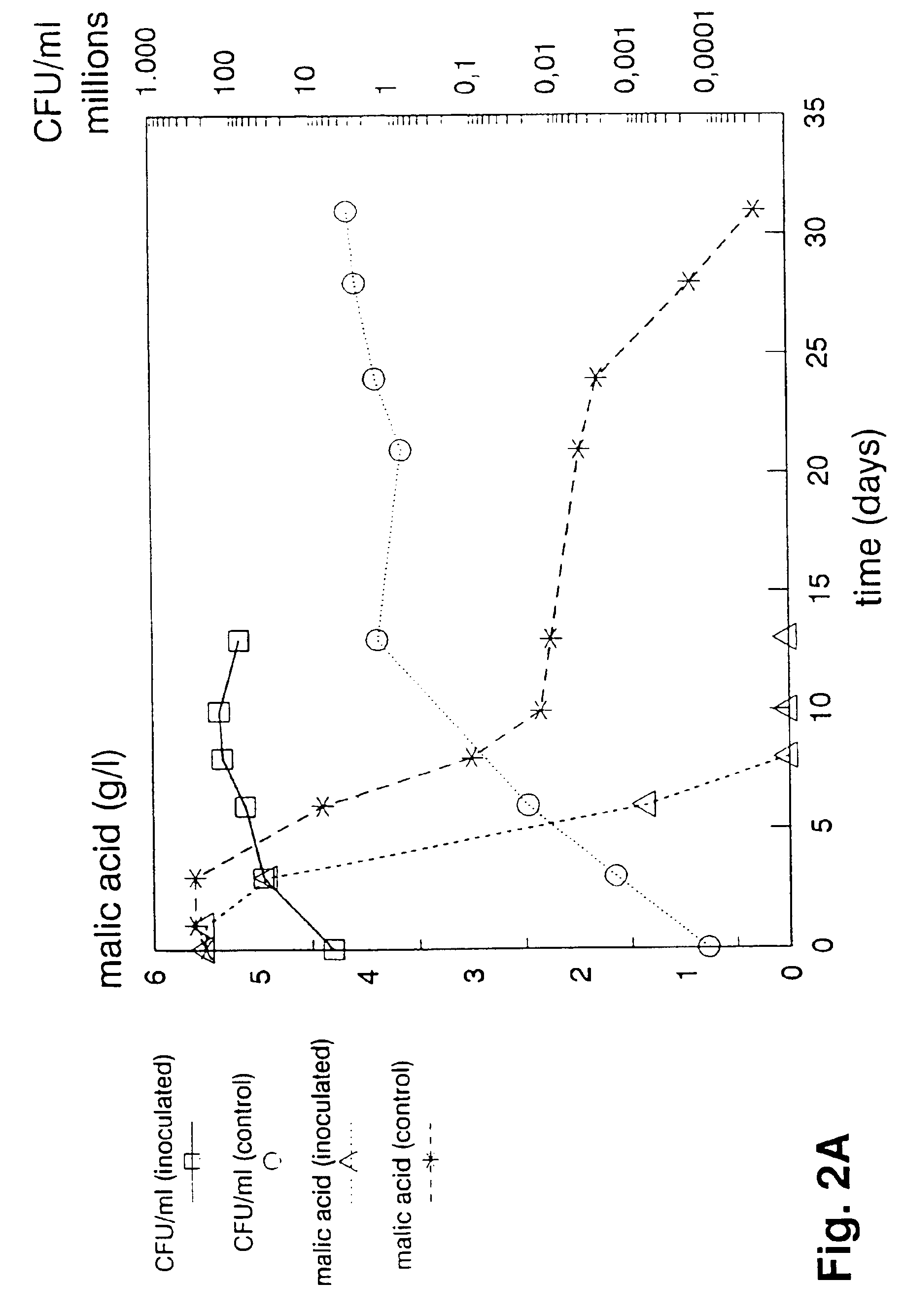

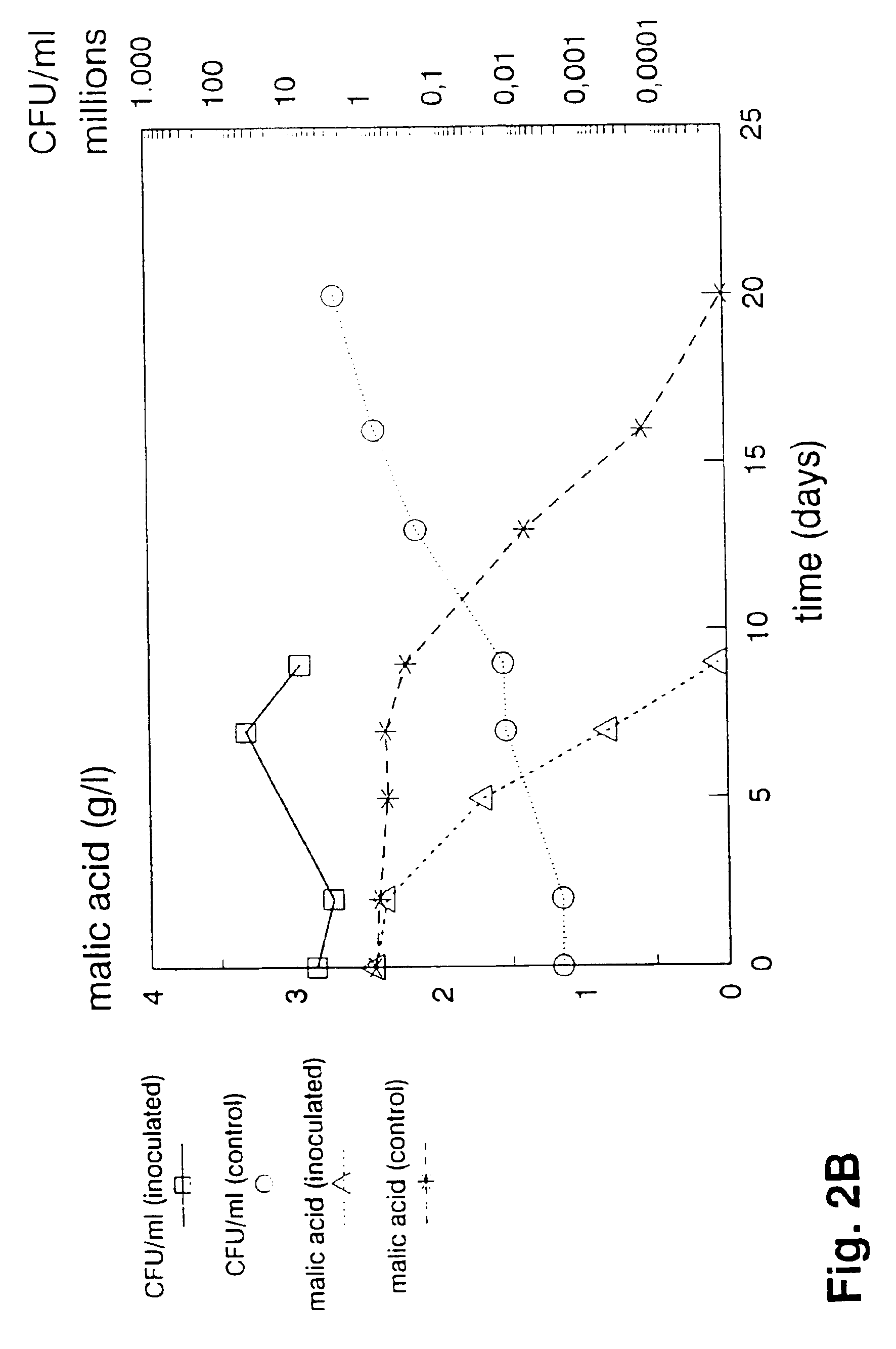

InactiveUS7112346B2Lower pHIncrease contentMicroorganismsBeer fermentationFruit juiceLactic acid fermentation

A selected malolactically active Ln. oenos strain which is useful for inducing malolactic fermentation in wine or fruit juice by the direct inoculation of a concentrate of a starter culture containing the strain, the strain having a survival rate of at least 80% when inoculated directly into a wine having a pH of 3.2 or lower and containing at least 25 mg SO2 per l and at least 12 vol % ethanol, and capabl, of starting malolactic fermentation when added directly to the wine or fruit juice at a concentration of less than 107 colony forming units per ml. There is also provided a method of isolating such a strain and a method for producing a culture of the strain.

Owner:CHR HANSEN AS

Preparation method of Zinfandel pink wine

InactiveCN103146520AThe wine is transparent and brightDistinctive yellow fruit aromaWine preparationBrewingMalate fermentation

The invention relates to the technical field of wine brewing, in particular to a preparation method of Zinfandel pink wine. At present, according to the pink wine brewing technique, the preparation technique of malo-lactic fermentation is adopted, and the wine produced by the technique is lack of refreshing taste and pleasant fragrance. In addition, the skin soaking time of pink wine is about 36 h in general, the skin soaking temperature is 20 DEG C in general, and the fermentation temperature is 18-20 DEG C. Not only is energy wasted, but also the technological process is long. According to the preparation method of Zinfandel pink wine, soaking for 26.5 h to brighten color is carried out at the low temperature of 13.5 DEG C, alcoholic fermentation is carried out at the temperature of 16.5 DEG C, and the procedure of malo-lactic fermentation is omitted. The product wine has refreshing taste and pleasant fragrance.

Owner:CHINA GREAT WALL WINE CO LTD

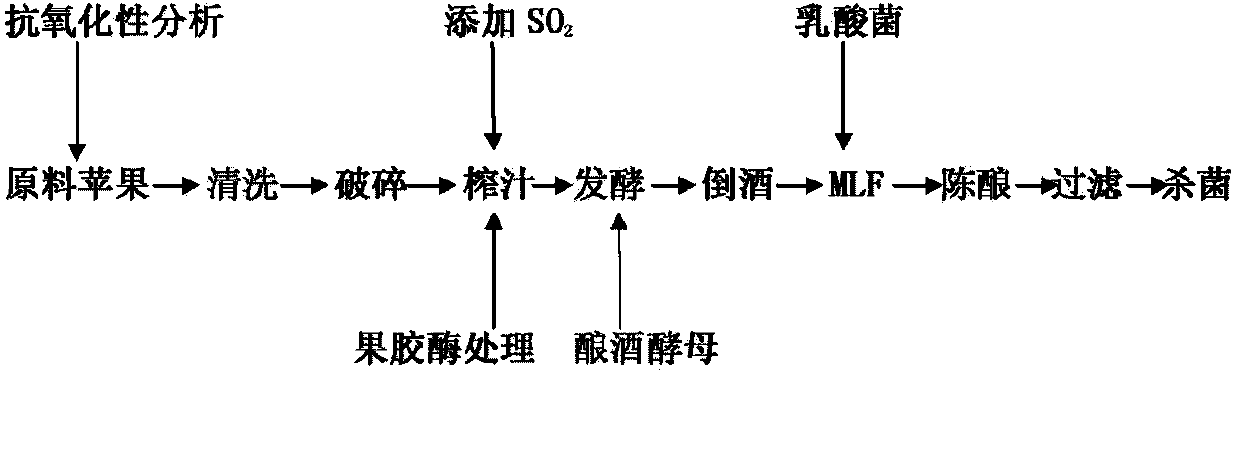

Brewing method of cider

InactiveCN103374490ABalanced wineModerate alcoholMicroorganism based processesAlcoholic beverage preparationStrong ciderProcess engineering

The invention discloses a brewing method of a cider, and belongs to the technical field of food, and in particular relates to a brewing process of the cider. The cider provided by the invention is prepared from the raw material of a fresh apple, and is good in taste, and nutrient-rich. The process steps of the brewing method disclosed by the invention comprises the following steps of: extracting juice by crushing; causing the juice to stand still to obtain clear juice; carrying out alcoholic fermentation; carrying out malolactic fermentation; carrying out aging and clarification.

Owner:庄芳

Wild cherry fruit wine deacidifying method

InactiveCN104830626AMellow tasteAroma harmonyAlcoholic beverage preparationMicroorganism based processesSodium bicarbonateLactarius

The invention provides a wild cherry fruit wine deacidifying method. The wild cherry fruit wine deacidifying method includes a), mixing wild cherry fruit wine obtained after alcoholic fermentation with sodium bicarbonate and performing primary deacidification; (b), subjecting the wild cherry fruit wine subjected to primary deacidification to malolactic fermentation. The wild cherry fruit wine deacidifying method has the advantages that tartaric acid is removed by chemical deacidification, the sodium bicarbonate and the tartaric acid react to produce carbon dioxide, and accordingly, the wild cherry fruit wine deacidifying method is good in deacidifying effect and high in deacidifying speed and can avoid precipitation; malic acid is removed by chemical deacidification and can be decomposed into monocarboxyl lactic acid by means of applying an MLF (malolactic fermentation) bio-deacidification technology, so that the fruit wine has a soft and rounded mouthfeel and is lower in acerbic feeling; the concentration of trace compositions such as aldehydes, lipids, amino acid, other organic acids and vitamins in the fruit wine is changed by means of metabolic activity of lactic acid bacteria, so that wine body flavor complexity forming is benefited, wine body biological stability can be enhanced, a flavor modification function is achieved and softness of the wild cherry fruit wine is improved.

Owner:小金冰峰酒业有限公司

Initiation of fermentation

ActiveUS20070009631A1Simple methodAvoid the lag and dead phaseBacteriaUnicellular algaeBiotechnologyMicroorganism

The present invention discloses microbial organisms capable of fermenting malic acid to lactic acid having impaired capability of degrading citric acid. These microbial organisms are for example useful in methods of preferentially degrading malic acid over citric acid in a liquid composition or in methods of inducing malolactic fermentation during wine production. The invention also discloses a concentrate of these microbial organisms and methods of preparing such a concentrate. The present invention furthermore relates to an activation solution useful for incubation of microbial organisms prior to inoculation into a liquid composition, such as wine.

Owner:CHR HANSEN AS

Preparation technology for calcium fruit icewine

The invention relates to preparation technology for fruit wines, in particular to the preparation technology for a calcium fruit icewine, which solves the problem about acid control in processing the calcium fruit wine. The preparation technology for the calcium fruit icewine comprises the following steps: breaking fresh calcium fruits and mixing fruit juice, adding pectin clastic enzyme for enzymolysis treatment and then adding calcium carbonate for deacidification, inoculating saccharomycetes for fermentation, adding potassium bicarbonate to neutralize part of acid after the fermentation, then performing malolactic fermentation, and finally adding 10% mixed juice for blending so as to balance the taste; moreover, fining and filtering, cooling at subzero 5 to subzero 4 DEG C for 10 days, naturally storing in a can for ageing for 3 -5 mouths, filtering and canning, so as to obtain the calcium fruit wine at last. The wine body is transparent and clear, tastes full-bodied, is elegant and agreeable to the taste of sour and sweet, and smells nice.

Owner:山西智创园科技有限公司

Dry red wine and production process thereof

The invention belongs to the technical field of wine, and particularly provides dry red wine. The dry red wine is prepared by using grapes as raw materials through the technological methods includingsoaking, fermentation, re-soaking, malolactic fermentation, aging and storage. According to the dry red wine provided by the invention, before the grapes enter into a jar, a complete state is kept, low-temperature processing is adopted as much as possible, and the nutrition of the original grapes is kept to a maximum extent, so that oxidation of the grapes is avoided; the high-quality cabernet sauvignon dry red wine which has a complicated and dense fragrance, has a layered, strong-endurance and powerful mouthfeel and has a thick, balanced and a long lasting taste is obtained, the simplification of brewing processes of the dry red wine is broken through, and the local characteristic of the grape raw materials is outstanding.

Owner:北京澳德投资集团有限公司

Grape wine direct-adding type fermentation agent and preparation method thereof and fermentation method of grape wine

InactiveCN105670950AHigh in nutrientsThe wine is delicate and mellowFungiBacteriaLactobacillus rhamnosusFreeze-drying

The present invention provides a kind of wine direct throw starter, comprises component A and component B, wherein, described component A is made up of saccharomyces cerevisiae freeze-dried powder and Loggery yeast freeze-dried powder; Said component B is made up of It consists of lyophilized powder of Lactobacillus rhamnosus, lyophilized powder of Oenococcus oeni, lyophilized powder of Lactobacillus acidophilus and lyophilized powder of Lactobacillus brevis. The invention also provides a preparation method of wine direct throwing starter. The invention also provides a wine fermentation method. In the wine direct-throwing starter provided by the invention, component A is used for alcoholic fermentation, and component B is used for post-fermentation, that is, malolactic fermentation, which can greatly increase the nutrients in dry red wine and make dry red wine The wine is delicate and mellow, with a noble aroma. The experimental results show that when the wine is fermented with the wine direct-injection starter provided by the invention, the content of gamma-aminobutyric acid and resveratrol in the obtained wine is relatively high, and the wine is fine and mellow with a noble aroma.

Owner:TARIM UNIV

Blueberry fruit wine brewing technology

InactiveCN109456869APreserve the flavorEnsure freshnessAlcoholic beverage preparationMicroorganism based processesFruit wineLactarius

The invention discloses a blueberry fruit wine brewing technology. The blueberry fruit wine brewing technology comprises the following steps that blueberry raw materials are selected, specifically, the blueberry raw materials are selected from wild blueberries of xiaoxing'an mountains; crushing is performed, specifically, the blueberry raw materials are subjected to crushing treatment; early-stagefermentation is performed, specifically, brewing yeast is added to the raw materials obtained after the crushing; malolactic fermentation is performed, specifically, lactic acid bacteria are added inliquor to be subjected to malolactic fermentation to obtain raw wine; stabilization and filtering are performed, specifically, the aged raw wine is clarified by freezing and then filtered; and filling and bottling are performed, specifically, the clarified raw wine is filled and bottled to obtain blueberry fruit wine. The blueberry fruit wine brewing technology has the advantages that the finallyobtained blueberry fruit wine has a rich dark purple color, retains the nutrition and taste of the original wild blueberries and is clear and translucent, and the taste is relatively sweet.

Owner:北京欧菲堡酒庄有限公司

Method for producing malic acid

ActiveCN113321580AIncrease enzyme activityHigh yieldMicroorganism based processesFermentationActivated carbonMicrofiltration membrane

The invention belongs to the technical field of biology, and discloses a method for producing malic acid. The method comprises the following steps: taking malic acid fermentation liquor, centrifuging to remove precipitate, collecting supernatant, adding activated carbon, stirring, adding diatomite, uniformly stirring, filtering by a plate frame, collecting filtrate, filtering by a micro-filtration membrane, collecting micro filtrate, absorbing malic acid through a chromatographic column filled with strong-base and weak-acid type amphoteric ion exchange resin, then eluting the malic acid adsorbed on the resin with hot water, performing elution repeatedly, mixing obtained eluates, and carrying out reduced pressure distillation and vacuum drying to obtain the malic acid product.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

Malolactic fermentation of wine

A method for improving the malolactic fermentation in wines comprising conducting the malolactic fermentation using lactic acid bacteria with organic alkaline or neutral dispersing agent.

Owner:SANDT ASSOC

Method and strain for reducing by-product succinic acid in L-malic acid fermentation process and application

ActiveCN113846023AIncreased purification process costsLow costFungiMicroorganism based processesIndustrial fermentationFlavolipin

The invention discloses an Aspergillus niger engineering strain for reducing by-product succinic acid in the fermentation process of L-malic acid. Fumaric acid reductase frdA and fumaric acid reductase flavin protein subunit frdB are knocked out of the Aspergillus niger engineering strain at the same time. The invention provides the Aspergillus niger engineering strain with frdA and frdB genes knocked out and a method for greatly reducing a by-product succinic acid in the Aspergillus niger fermentation process. The by-product succinic acid accumulated in the process of producing malic acid through Aspergillus niger fermentation is obviously reduced, the cost in the downstream separation and purification process of malic acid is reduced, and an excellent strain is provided for industrial fermentation production of malic acid.

Owner:南京昊禾生物科技有限公司

Seedless xiahei semi-sweet low-foam pink wine and preparation method thereof

The invention discloses seedless xiahei semi-sweet low-foam pink wine and a preparation method thereof. Seedless xiahei grapes as a table grape variety are selected as liquor-making raw materials. The preparation method includes the steps that the grapes are harvested, subjected to threshing and sorting and then crashed, and potassium metabisulfite is added into grape juice; pectinase and yeast are added, and dipping and fermenting are carried out at the same time; then, free run wine is instantly released and transferred into a freezing tank to be refrigerated in a sealed mode; after freezing, the wine is left in the freezing tank to be sealed and transferred into a storing tank after being unfrozen at room temperature; the wine is filtered and then subjected to membrane filtering through a filtering membrane. The seedless xiahei grapes as the table grape variety are creatively adopted as the liquor-making raw materials, dipping and fermenting are carried out for a short time at the same time at low temperature, the sealing-freezing-filtering mode is adopted, malo-lactic fermentation is not carried out, and therefore the wine keeps a bright color, full-bodied flowery flavor, a suitable sugar degree and suitable alcohol content and contains an appropriate quantity of bubbles and suitable acidity.

Owner:HUNAN AGRICULTURAL UNIV

Method of inducing malolactic fermentation in wine or fruit juice by direct inoculation with a non-activated starter culture

A selected malolactically active Ln. oenos strain which is useful for inducing malolactic fermentation in wine or fruit juice by the direct inoculation of a concentrate of a starter culture containing the strain, the strain having a survival rate of at least 80% when inoculated directly into a wine having a pH of 3.2 or lower and containing at least 25 mg SO.sub.2 per l and at least 12 vol % ethanol, and capable of starting malolactic fermentation when added directly to the wine or fruit juice at a concentration of less than 10.sup.7 colony forming units per ml. There is also provided a method of isolating such a strain and a method for producing a culture of the strain.

Owner:CHR HANSEN AS

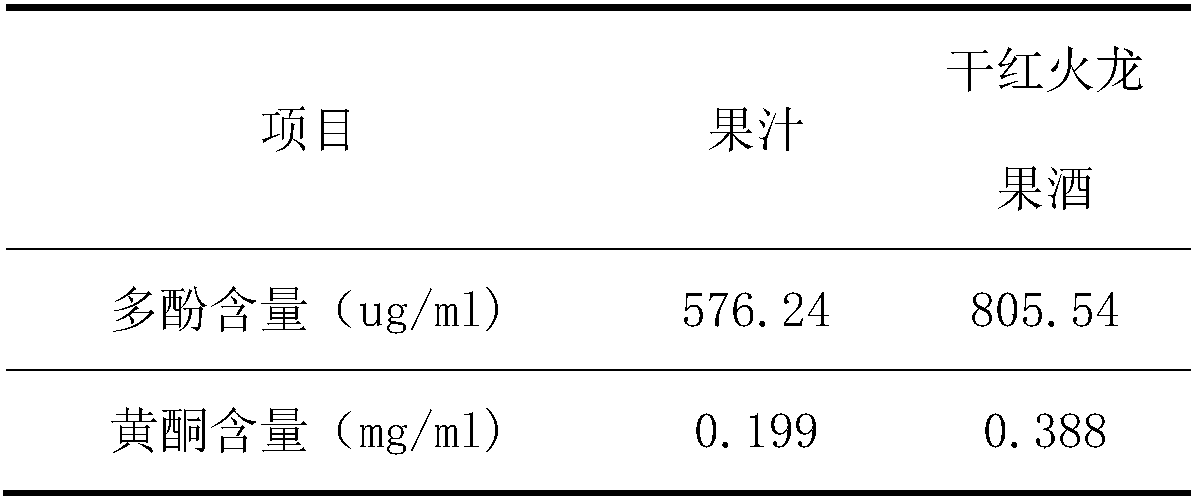

Dried red pitaya fruit wine and brewing method thereof

The invention relates to the technical field of wine brewing and discloses a dried red pitaya fruit wine and a brewing method thereof. The brewing method of the dried red pitaya fruit wine comprises the following steps of pitaya concentrated juice preparation, non-saccharomyces cerevisiae fermentation, alcohol fermentation, malolactic fermentation as well as clarification and filtering of wine liquid after separation. Non-saccharomyces cerevisiae fermentation comprises the following steps of mixing a sulfur-free pitaya juice and activated non-saccharomyces cerevisiae to prepare a yeast suspension, uniformly mixing the yeast suspension and the pitaya concentrated juice, and performing fermentation. The wine brewing technology comprises multiple fermentation technologies; as the non-saccharomyces cerevisiae fermentation process produces more fragrance and less acid, the wine liquid is rich and pleasant in fragrance; subsequent alcohol fermentation enables the wine liquid to be mellow intaste; and malolactic fermentation enables the taste to be finer and smoother and the equilibrium to be better. Therefore, the dried red pitaya fruit wine prepared by the wine brewing technology is pleasant in fragrance and better in flavor.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Making method for improving flavor and quality of red wine with specific glycosidase

ActiveCN106190682AAdd flavorImprove featuresMicroorganism based processesWine preparationDisaccharidaseFree state

The invention discloses a making method for improving flavor and quality of red wine with specific glycosidase and belongs to the technical field of wine making. The method includes alcoholic fermentation, malolactic fermentation, enzymolysis treatment, fining and clarification, stability treatment and aseptic filling. Enzymolysis treatment of glycosidase soured from CGMCC 3.6328 is performed after malolactic fermentation of red wine, and the glycosidase is short in enzymolysis treatment time and less in required consumption, and can act aiming at combined-state flavor substances composed of fragrances of main grape varieties and combined-state phenolic substances of important functional components of wine. Compared with the process without enzymolysis treatment, the fermentation process has the advantages that fragrance of wine is stronger, the variety and content of free-state phenolic substances are increased, flavor of wine is improved, and functional components and quality of wine are improved as well.

Owner:JIANGNAN UNIV

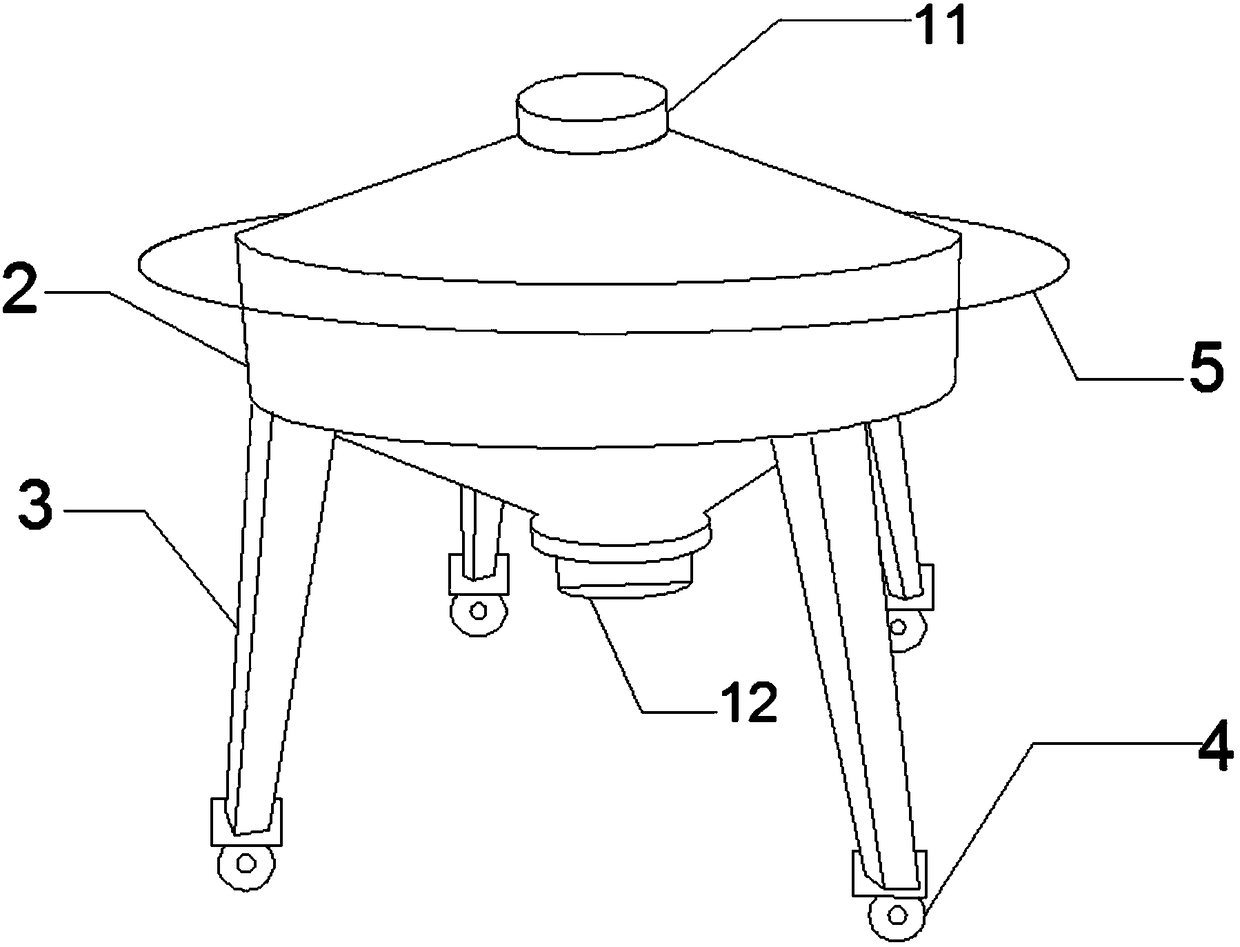

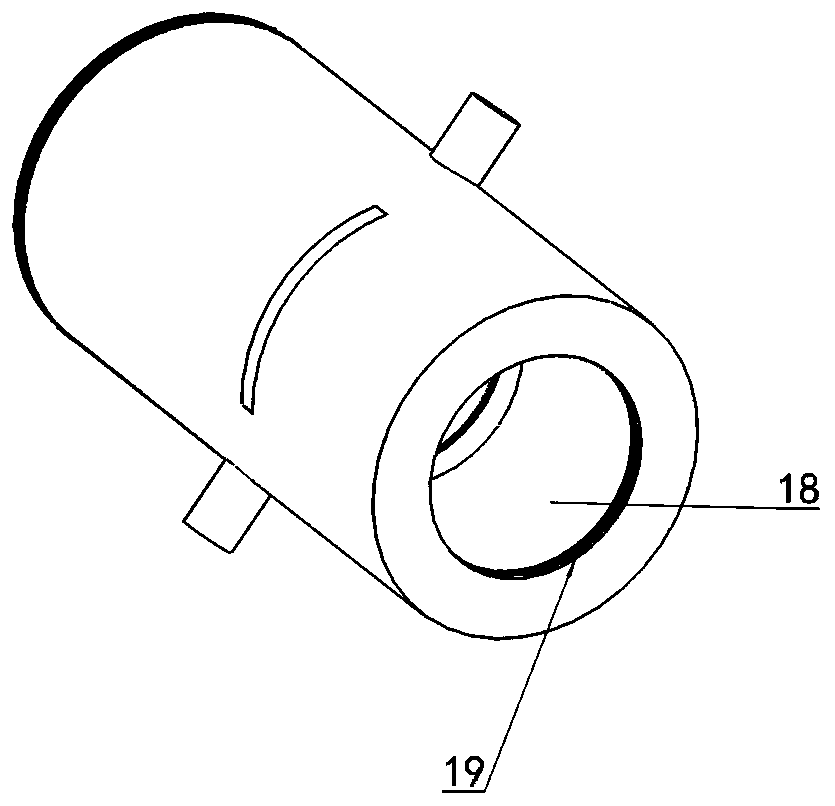

Turnover household wine fermentation device

The invention discloses a turnover household grape wine fermentation device, and belongs to the technical field of small grape wine fermentation devices. The fermentation device comprises a fermentation tank, a supporting assembly and a squeezing assembly. A malic acid fermentation cavity and an alcohol fermentation cavity which are communicated are formed in the middle of the tank body of the fermentation tank. The port of the malic acid fermentation cavity of the tank body is detachably and hermetically connected through a top cover, and the port of the alcohol fermentation cavity is detachably and hermetically connected through a bottom seal. An overturning shaft is arranged in the middle of the side surface of the tank body and is connected with the supporting seat of the supporting assembly, so that the tank body can be overturned up and down to realize conversion between alcohol fermentation and malic acid fermentation. Fermentation liquors can be filtered through filter screensdivided from the alcohol fermentation cavity and the malic acid fermentation cavity, and skin residues in the alcohol fermentation cavity are extruded through the squeezing assembly. After the skin residues are extruded and compressed in the cavity of the squeezing assembly, the squeezing assembly which is hermetically inserted into the side surface of the tank body is pulled out, so that the skinresidues are separated.

Owner:HARBIN UNIV

Lactobacillus plantarum and application thereof

ActiveCN113046269AEfficient fermentation capacityIncrease varietyBacteriaAlcoholic beverage preparationBiotechnologyFruit wine

The invention discloses a lactobacillus plantarum B3 and application thereof. The lactobacillus plantarum B3 is separated from blueberry juice, and the preservation number of the lactobacillus plantarum B3 is CGMCC NO.21610. The lactobacillus plantarum has efficient malic acid fermentation capacity, and has remarkable wine body aroma performance and stable color performance after fruit wine fermentation.

Owner:BEIJING FORESTRY UNIVERSITY

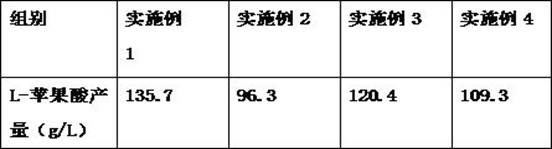

A process for producing malic acid by fermenting Aspergillus oryzae

ActiveCN106929548BHigh yieldImprove filtration efficiencyMicroorganism based processesFermentationBiotechnologyMicroorganism

The invention belongs to the technical field of microbial fermentation, and discloses a technology for producing a malic acid employing fermentation of aspergillus oryzae. The technology comprises the following steps of preparing an aspergillus oryzae seed solution, preparing the malic acid through fermentation, adding calcium carbonate and CTAB in the fermentation process, and adjusting the pressure intensity and the temperature. Through on permeability treatment on a bacterial strain, the technology is simple, the cost is low and the yield of the malic acid is improved.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

Method for brewing blueberry wine

ActiveCN103666922BAlcoholic beverage preparationMicroorganism based processesBiotechnologyOenococcus oeni

The invention discloses a method for brewing a blueberry wine. The method comprises the steps of selecting raw materials, selecting strains, fermenting with ethanol, carrying out malo-lactic fermentation, ageing, clarifying, stabilizing and the like. According to the method, optimized blueberries Huangshan 1# serve as the raw materials; high-temperature enzymolysis, high-temperature start-up and low-temperature long-time fermentation are carried out by using saccharomycetes RC212 as the fermentation strains; the malo-lactic fermentation is carried out by using oenococcus oeni SD-2 with high glucosidase activity; micro-aerobic ageing is utilized, so as to accelerate wine ageing and improve the quality of the wine; the blueberry wine can keep a clarified and stable state in long term by the technical means of natural clarification, cellaring, cold treatment, heat treatment, stabilizer adding, microfiltration and the like. In accordance with the method, a high-quality blueberry wine with good color, smell and taste can be obtained, and the obtained product meets the requirements of the national wine product quality standard GB2758-81.

Owner:JURONG WANSHANHONGBIAN BIOTECH

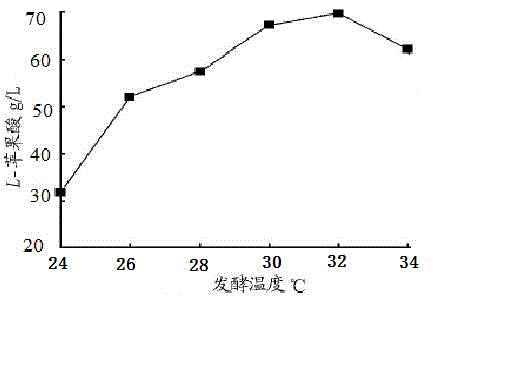

Method for fermenting L-malic acid by utilizing aspergillus flavus

The invention provides a method for fermenting L-malic acid by utilizing aspergillus flavus. According to the method, the aspergillus flavus is used as a starting strain, and the influence of carbon sources, nitrogen sources, temperature and CaCO3 on the fermentation of L-malic acid by the strain is studied.

Owner:太仓市茂通化建有限公司

Method for improving fermentation property of malic acid

ActiveCN108587923AReduce usageIncrease the number ofFungiMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a method for improving the fermentation property of malic acid, belonging to the field of microorganism. An aspergillus oryzae strain FMME 338 is assigned with the accession number of CCTCC NO:M 2016401. The invention also discloses a method for fermentation production of L-malic acid, the temperature is 30 DEG C, the rotation speed of a shaking table is 200r / min, the fermentation period is 120h, finally, the yield of the L-malic acid through fermentation can achieve 129.2g / L, and the strain belongs to an excellent wild strain with high yield of L-malic acid. The methodfor fermentation production of L-malic acid is simple and feasible in technological operation, the cost of the culture medium is low, meanwhile, the purity of L-malic acid in the fermentation liquidis high, the amount of heteroacid is little, the fermentation period is short, and the method is suitable for industrial production.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com