Aluminum sheet plug hole net screen

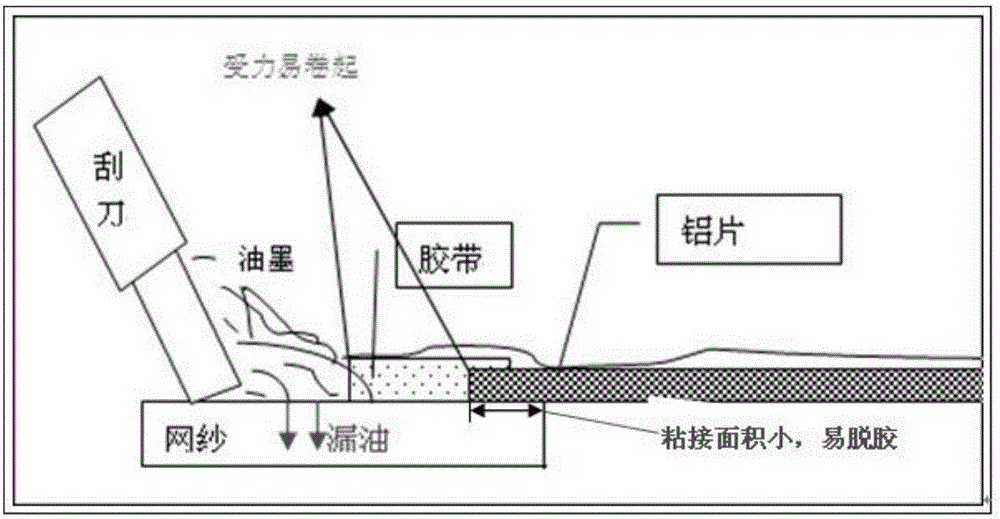

An aluminum sheet and screen technology, applied in electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of falling off printing dirt, easy degumming, oil leakage, etc., to prevent degumming problems, increase bonding area, optimize The effect of the network process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

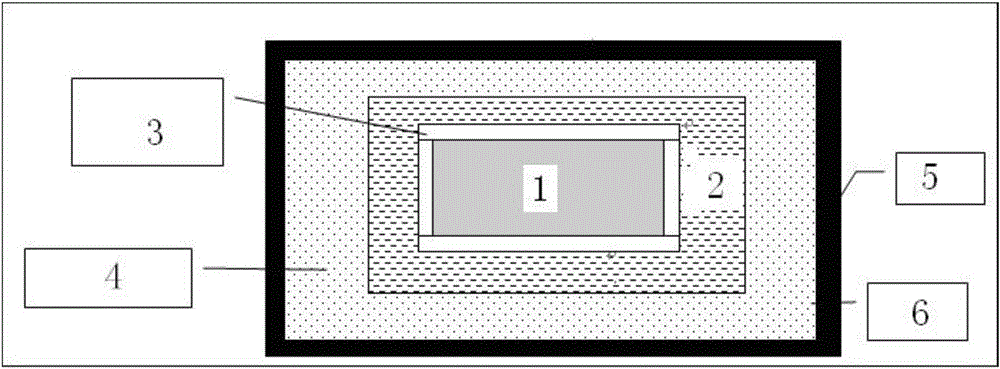

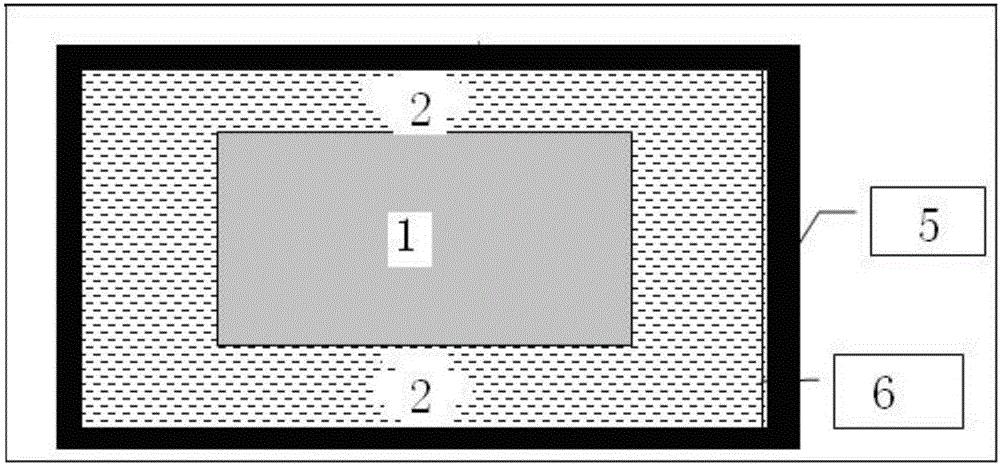

[0014] In the aluminum sheet plug hole screen plate of the present embodiment, the aluminum sheet 2 attached to the mesh 6 is equivalent in size to the inner edge of the screen frame 5 (the distance is 0.8 cm); the screen frame is longer than the aluminum sheet drilling pattern area 1 on the screen plate The average width is 42cm; after the aluminum sheet is pasted during production, a layer of resin glue is applied to the non-aluminum sheet drilling pattern area on the bottom surface of the screen; a layer of glue is applied to the gap between the screen frame 5 and the aluminum sheet 2.

[0015] In this embodiment, the size of the aluminum sheet attached to the mesh is equivalent to that of the inner edge of the screen frame, that is, the size of the aluminum sheet is extended to the inner edge of the screen frame, so that the operation of the scraper is carried out within the range of the aluminum sheet during the entire working process, and the imperviousness of the aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com