Marine fixed sundry crane

A sundry and hoist technology, applied to cranes and other directions, can solve problems such as cumbersome operation, prone to mechanical failure, and low safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

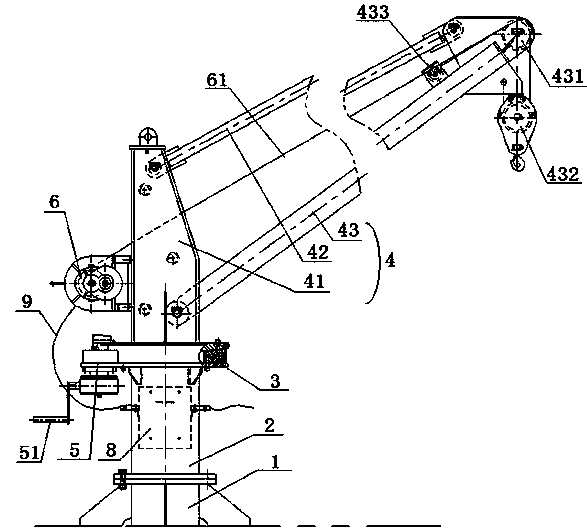

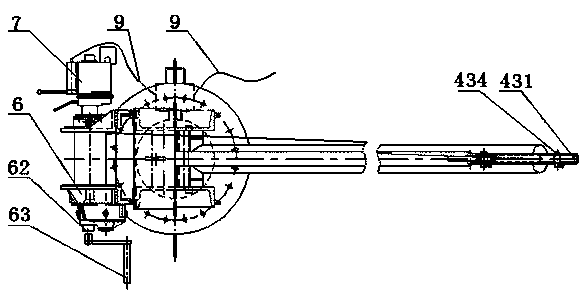

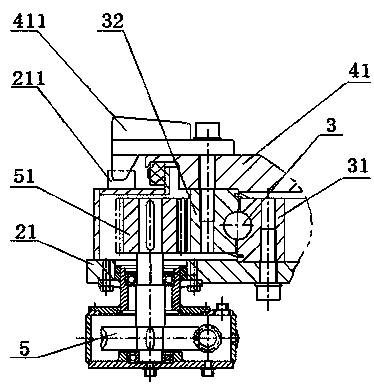

[0028] Such as figure 1 Shown is a marine fixed debris crane, the crane includes a base 1, a suspension base 2 is fixedly arranged above the base 1, and the base 1 and the suspension base 2 are connected by high-strength bolts, Above the suspension base 2, there is a rotary part 4 that can rotate axially relative to the suspension base 2. The rotary part 4 is connected to the suspension base 2 through a rotary support 3, wherein the specific structure of the rotary support 3 includes inner rings that are rotatably connected to each other. 31 and the outer ring 32, the inner ring 31 is fixedly connected with the upper bottom plate 21 of the suspension base 2 through high-strength bolts, and the outer ring 32 is also fixedly connected with the rotating body 41 of the rotating part 4 through high-strength bolts. At the same time, the suspension base 2 The upper base plate 21 is also fixedly connected with a rotary reducer 5 through high-strength bolts, the output gear 51 of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com