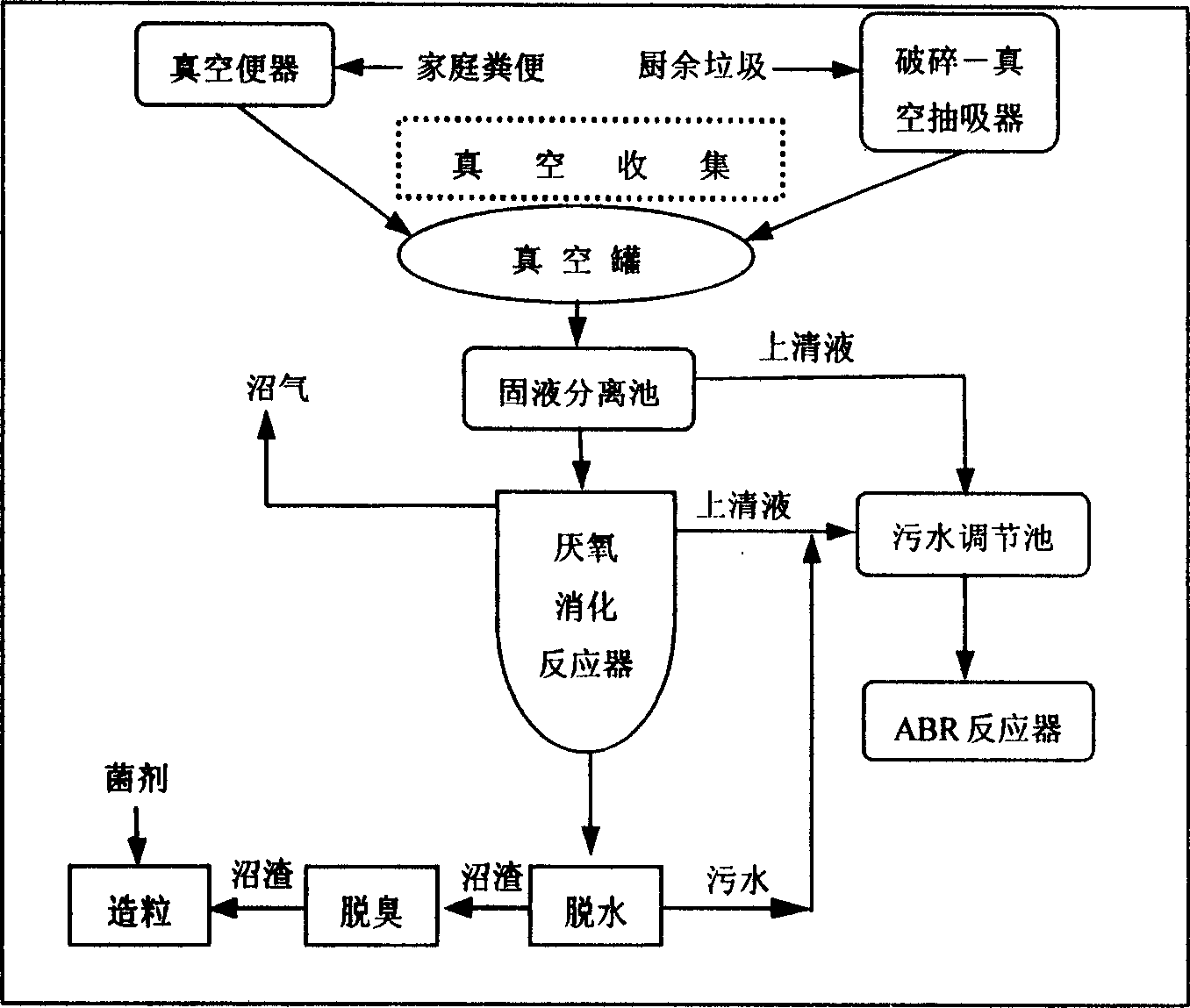

Organic refuse and fecal separating and collecting treatment

A technology of organic waste and treatment method, which is applied in the field of collection and treatment of household waste or the like, can solve the problems of resource utilization of polluted environment, reduce the amount of waste transportation, waste of fertilizer resources, etc. The effect of entering the water body and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The biogas residue discharged from the anaerobic digestion reactor enters the granulation and fertilizer making part: the exogenous deodorizing strains (Bacillus, Streptomyces, Micropolyspora, Trichoderma and Cellulomonas) are mixed according to the ratio of 1:1:1: The ratio of 1:1 is added to the dehydrated biogas residue, and the mixing amount is 0.5% of the weight of the dehydrated biogas residue. After 4 days of stacking, the odor is determined to be Msl level, that is, the odor can be barely felt, and the deodorization The effect is better. Experimental research shows that after deodorization, the phosphorus-solubilizing and potassium-solubilizing Bacillus (Bacillus.sp) strains isolated and preserved by themselves can be further domesticated and cultivated in biogas residues to obtain phosphorus- and potassium-solubilizing abilities suitable for dehydrated biogas residues. strains. The phosphorus-solubilizing and potassium-solubilizing bacteria obtained through do...

Embodiment 2

[0032] The biogas residue discharged from the anaerobic digestion reactor enters the granulation and fertilizer making part: the exogenous deodorizing strains (Bacillus, Streptomyces, Micropolyspora, Trichoderma and Cellulomonas) are mixed according to the ratio of 3:1:1: The ratio of 1:1 is added to the dehydrated biogas residue, and the mixing amount is 1% of the weight of the dehydrated biogas residue. After 3 days of stacking, it is measured that the odor is MsO level, that is, no odor, so as to achieve odor removal the goal of. Experimental research shows that after deodorization, the phosphorus-solubilizing and potassium-solubilizing Bacillus (Bacillus.sp) strains isolated and preserved by themselves can be further domesticated and cultivated in biogas residues to obtain phosphorus- and potassium-solubilizing abilities suitable for dehydrated biogas residues. strains. The phosphorus-solubilizing and potassium-solubilizing bacteria obtained through domestication were pic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com