A heat sink with a riveting structure and a riveting process thereof

A technology of riveting structure and radiator, which is applied in heat exchange equipment, modification through conduction heat transfer, cooling/ventilation/heating transformation, etc. It can solve the problem of unstable installation, affecting the heat dissipation effect of the radiator, and the radiator is easy to fall off, etc. Problems, to achieve the effect of improving product quality, strong bearing capacity, and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

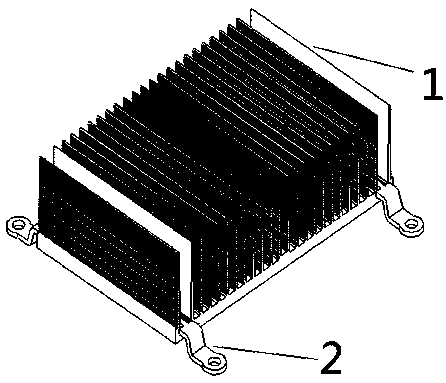

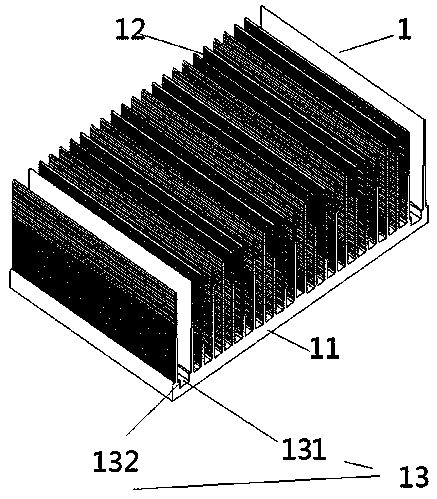

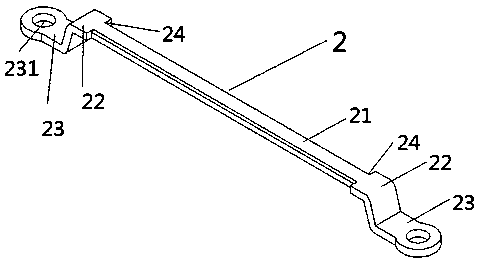

[0033] Figure 1-Figure 3 The schematic diagram of the structure of the radiator with riveted structure, the schematic diagram of the radiator body, and the schematic diagram of the bracket structure of this embodiment are respectively given, combined with reference Figure 1-Figure 3 , a heat sink with a riveting structure, including a heat sink body 1 and a bracket 2; wherein, the heat sink body 1 includes a base 11 and a plurality of cooling fins 12, the cross section of the cooling fins 12 is square, and each cooling fin 12 is parallel to each other, and Vertically arranged on the base 11 at intervals; a groove body 13 is formed between the outermost adjacent heat sinks 12; the groove body 13 includes a mounting groove 131 and a pre-cut groove 132, the mounting groove 131 is located on the base 11, and the pre-cut groove 132 is located on the Both sides of the installation groove 131, and the position of the pre-cut groove 132 is higher than the installation groove 131; th...

Embodiment 2

[0039] Figure 4-6 Partial cross-sectional views of the heat sink with riveted structure in this embodiment at the beginning of riveting are given respectively Figure 1 , Partial cross-section in the process of deformation riveting Figure II , Partial cross-section after deformation riveting Figure three , combined with reference Figure 4-6 , the present embodiment provides a riveting process for a heat sink with a riveting structure, comprising the following steps,

[0040] S1. Process an installation groove 131 and a pre-cut groove 132 in the tank body 13, the installation groove 131 is located on the base 11, the pre-cut groove 132 is located on both sides of the installation groove 131, and the position of the pre-cut groove 132 is higher than the installation groove 131;

[0041] S2. Process the punching head 31 corresponding to the pre-cut groove 132 at the lower end of the riveting punch 3;

[0042] S3. Put the radiator body 1 on the stamping equipment, and put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com