Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Improve riveting strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

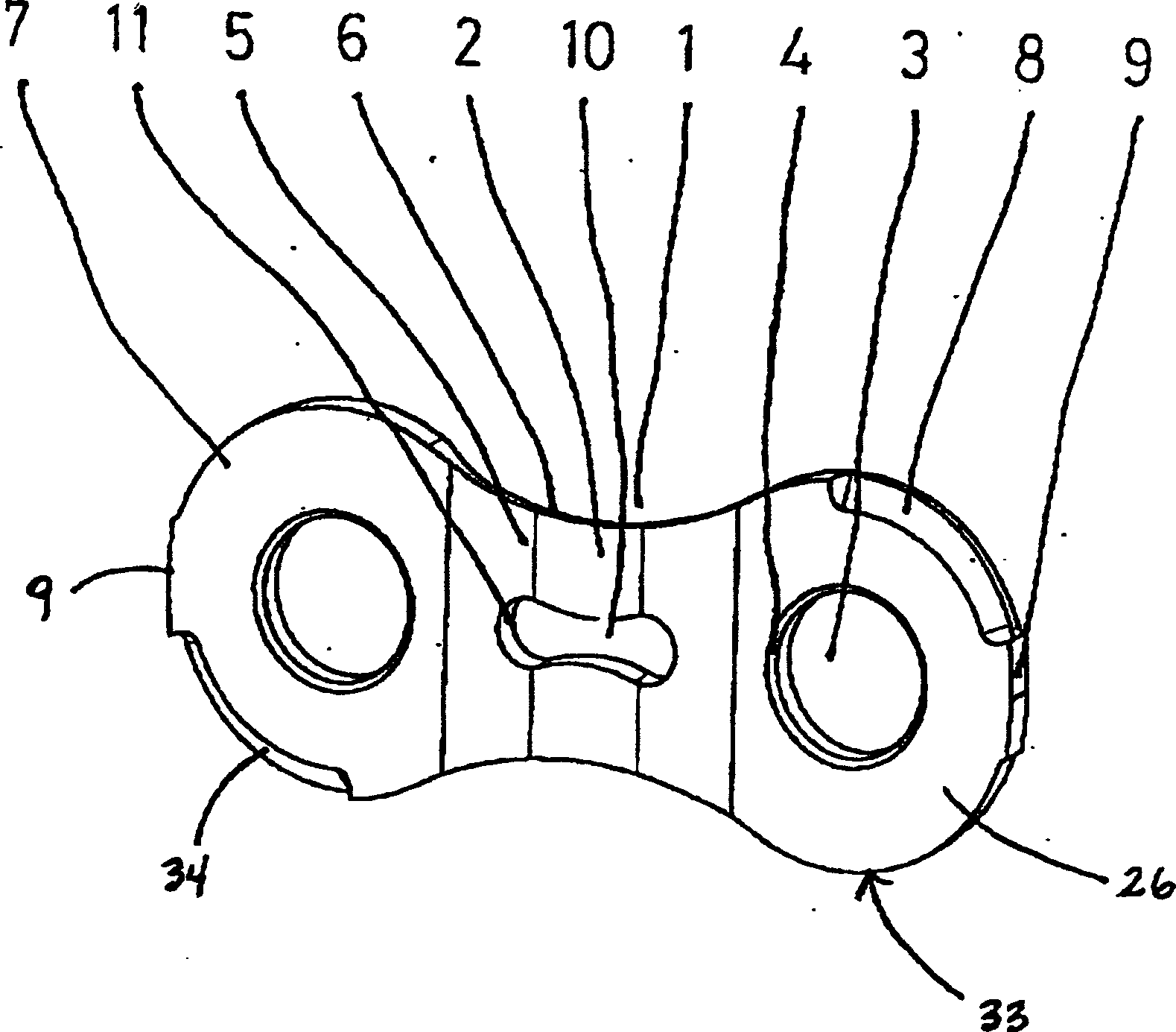

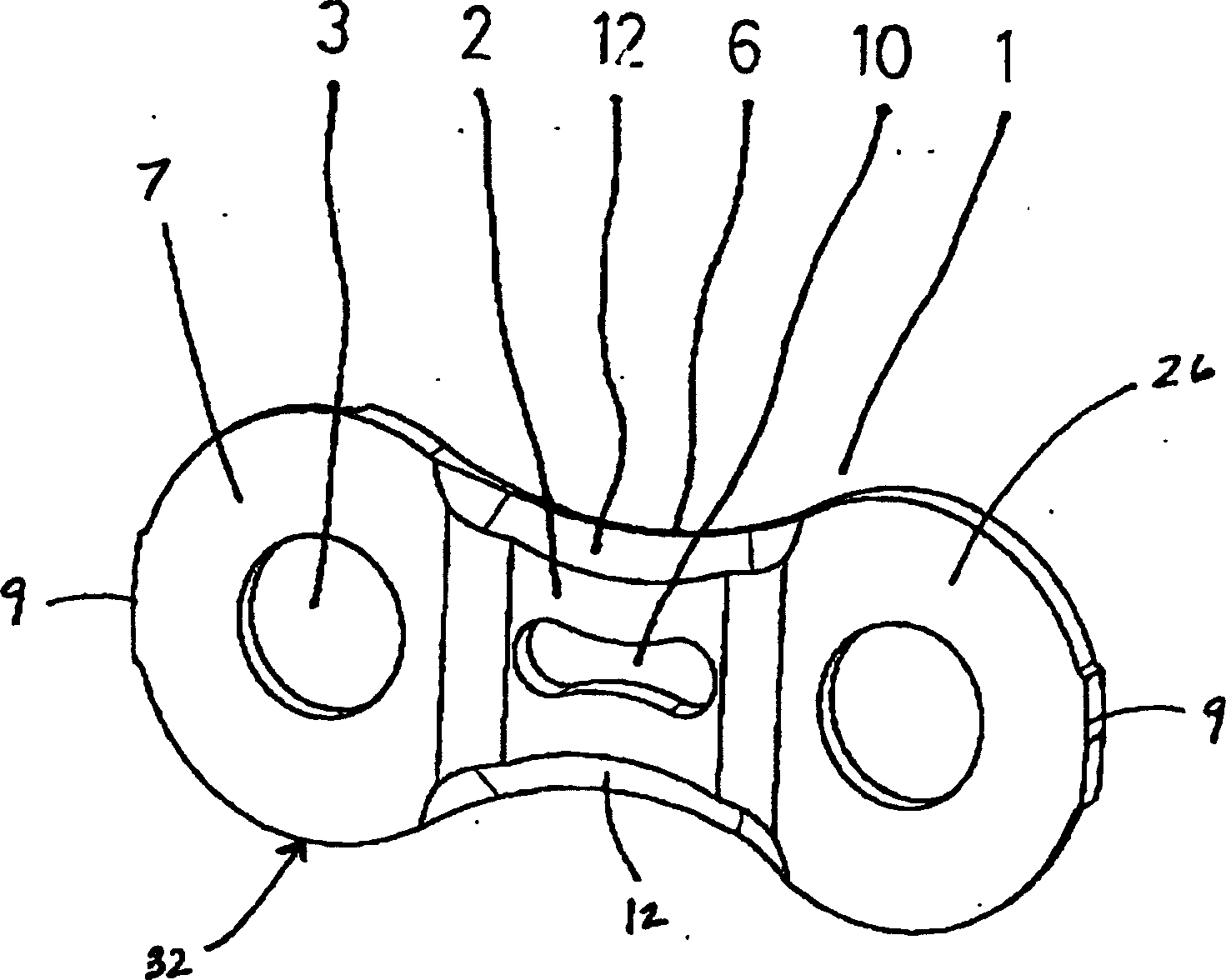

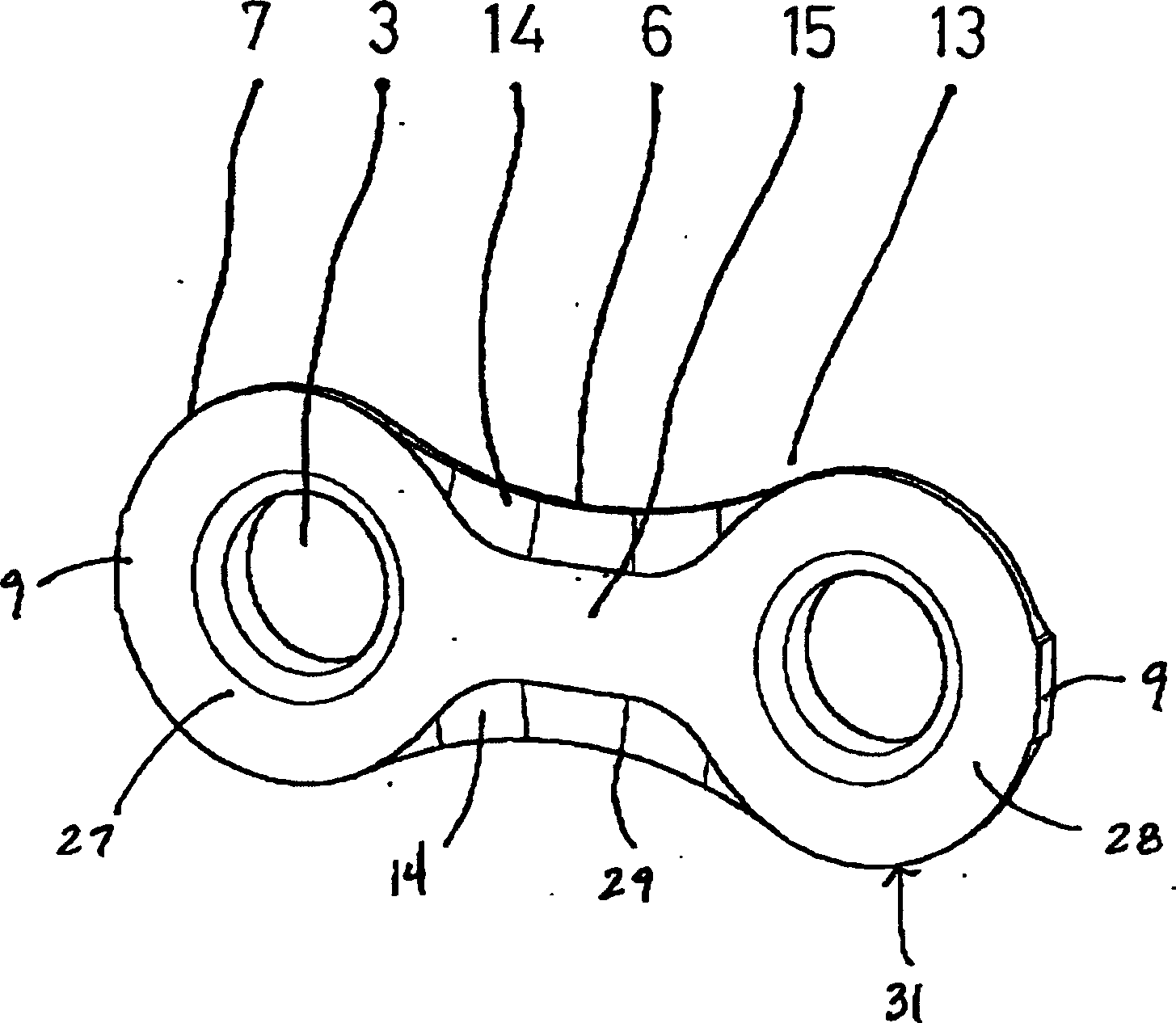

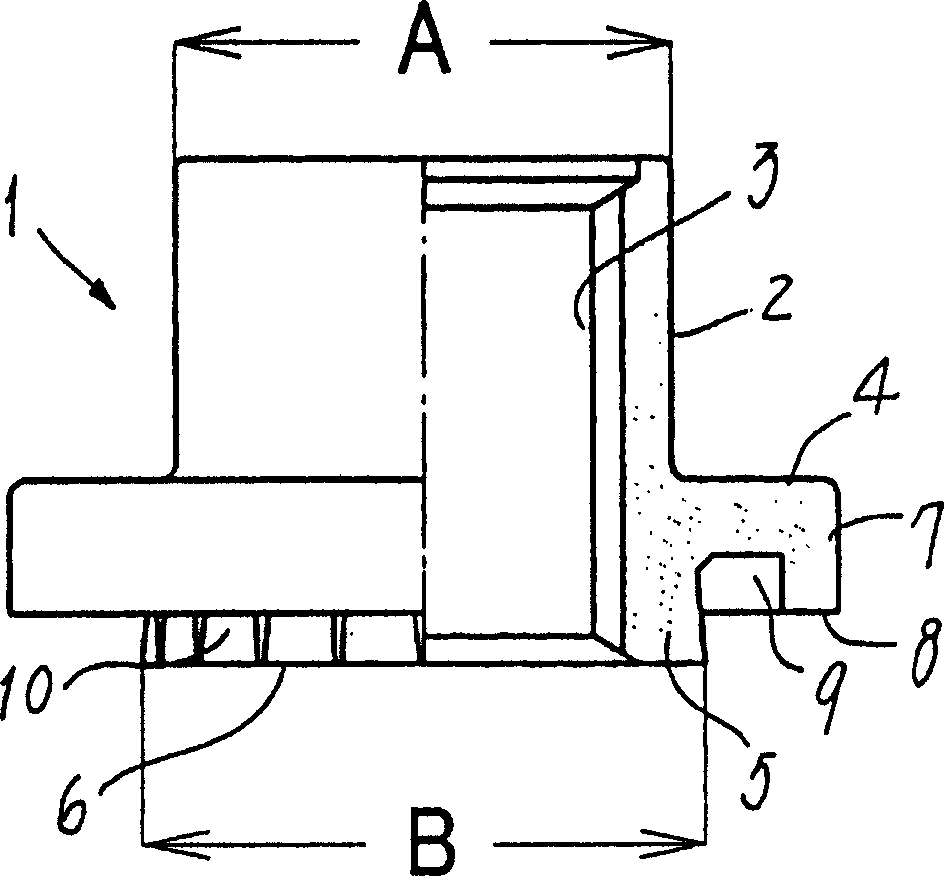

Bicycle driving chain

InactiveCN1667294AEasy to operateImproved shifting operationChain/belt transmissionDriving chainsSprocketEngineering

Owner:SRAM

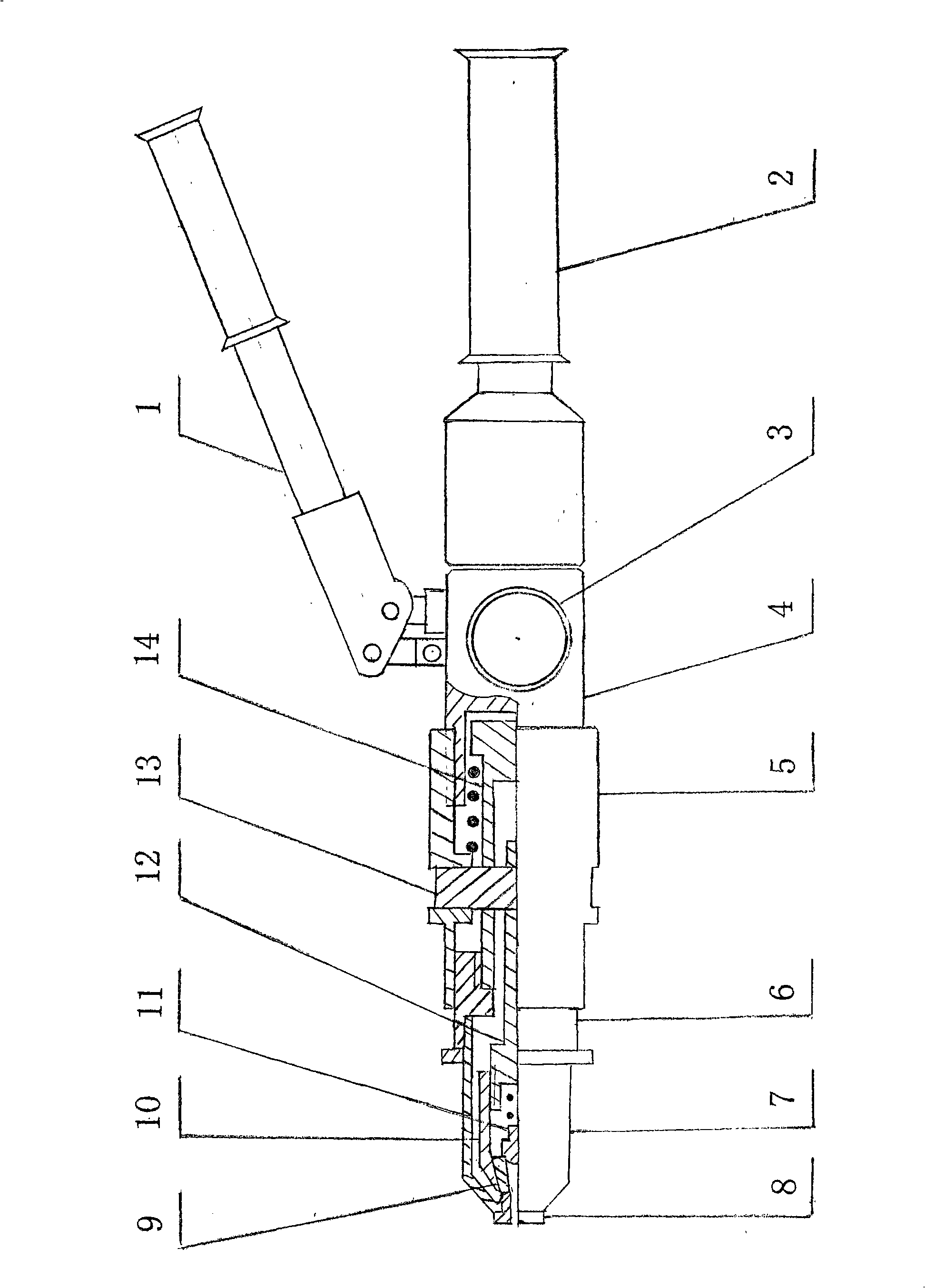

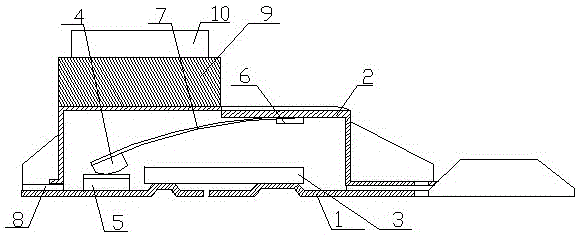

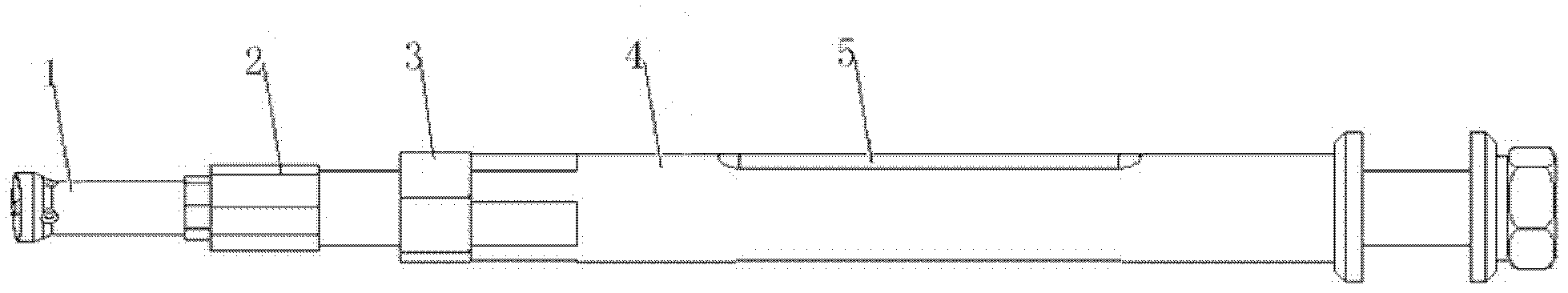

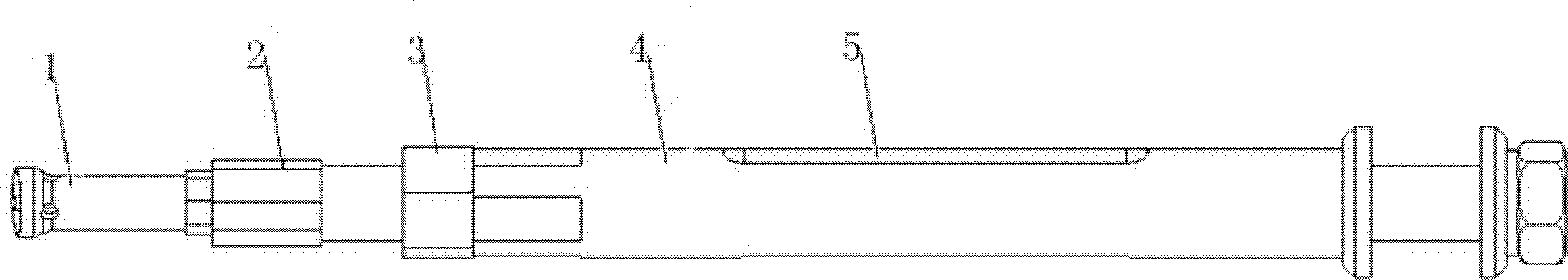

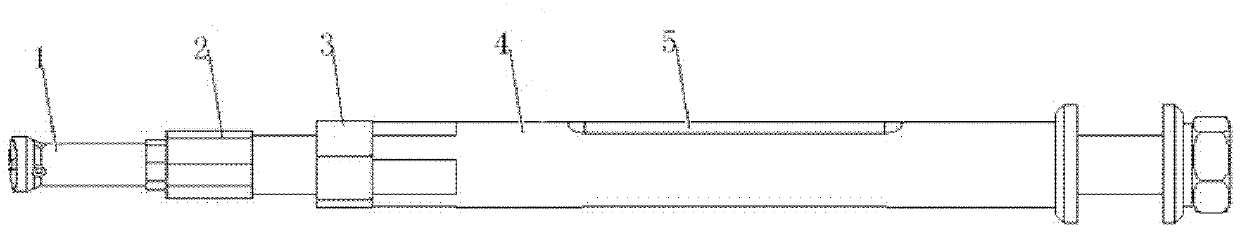

Manual hydraulic pressure strong pulling rivet gun

The invention belongs to a powerful hand riveter and particularly relates to a manually-operated hydraulic powerful riveter, which comprises a machine body, a push-and-pull switching device and a riveter head, and is characterized in that the machine body is a hydraulic machine body mainly composed of a fixed handle, a movable handle, an oil storage bag and an oil return valve. The push-and-pull switching device consists of a piston, a cylinder sleeve, a bar, a rigging screw and a connecting sleeve. The riveter head mainly comprises a clamping sleeve, a three-jaw, a top core and a riveter head sleeve. The hand riveter has the beneficial effects that the structure is unique; the riveting action is completed by using the reinforcement of the hydraulic machine body for the first time; the exerted force is strong; the use is convenient; the hand riveter can be used for large-diameter self-plugging rivets, particularly for the riveting of steel rivets; the riveting strength is enhanced; the scope of riveting application is expanded; no electricity or compressed air is needed for supplying power; the hand riveter is energy-saving, environment-friendly, and particularly suitable for use in operation places such as the field, high altitude, underwater, etc.

Owner:孟信芳

Rivet

The invention discloses a rivet comprising a rivet body with a rivet cap at one end and a hollow turning structure at the other end away from the rivet cap. A guiding post is also arranged at one side of the rivet body with the turning structure which is arranged on the periphery of the guiding post to form a clearance fit with the guiding post; the guiding post and the rivet body are coaxially arranged; and the end of the turning structure extends out of the top end of the turning structure. The invention is provided with the guiding post on the rivet, can guide a turning tool to carry out even turning treatment to the turning structure so that the rivet after the turning treatment has favorable riveting strength and facilitates the turning treatment.

Owner:CAMA JIAHUA LUOYANG NEW ENERGY

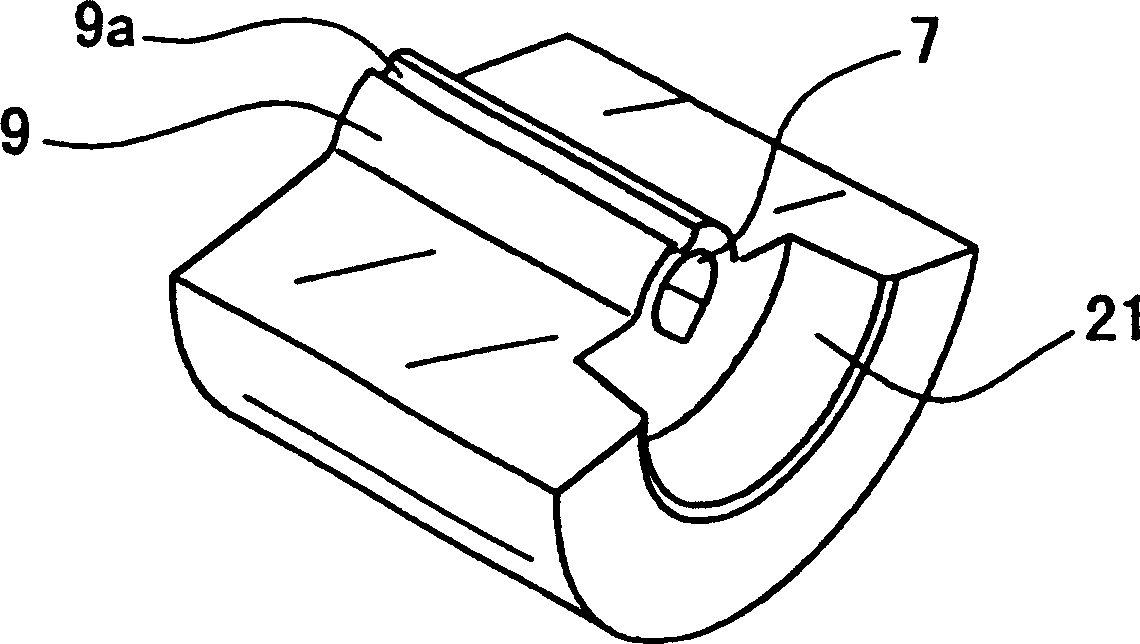

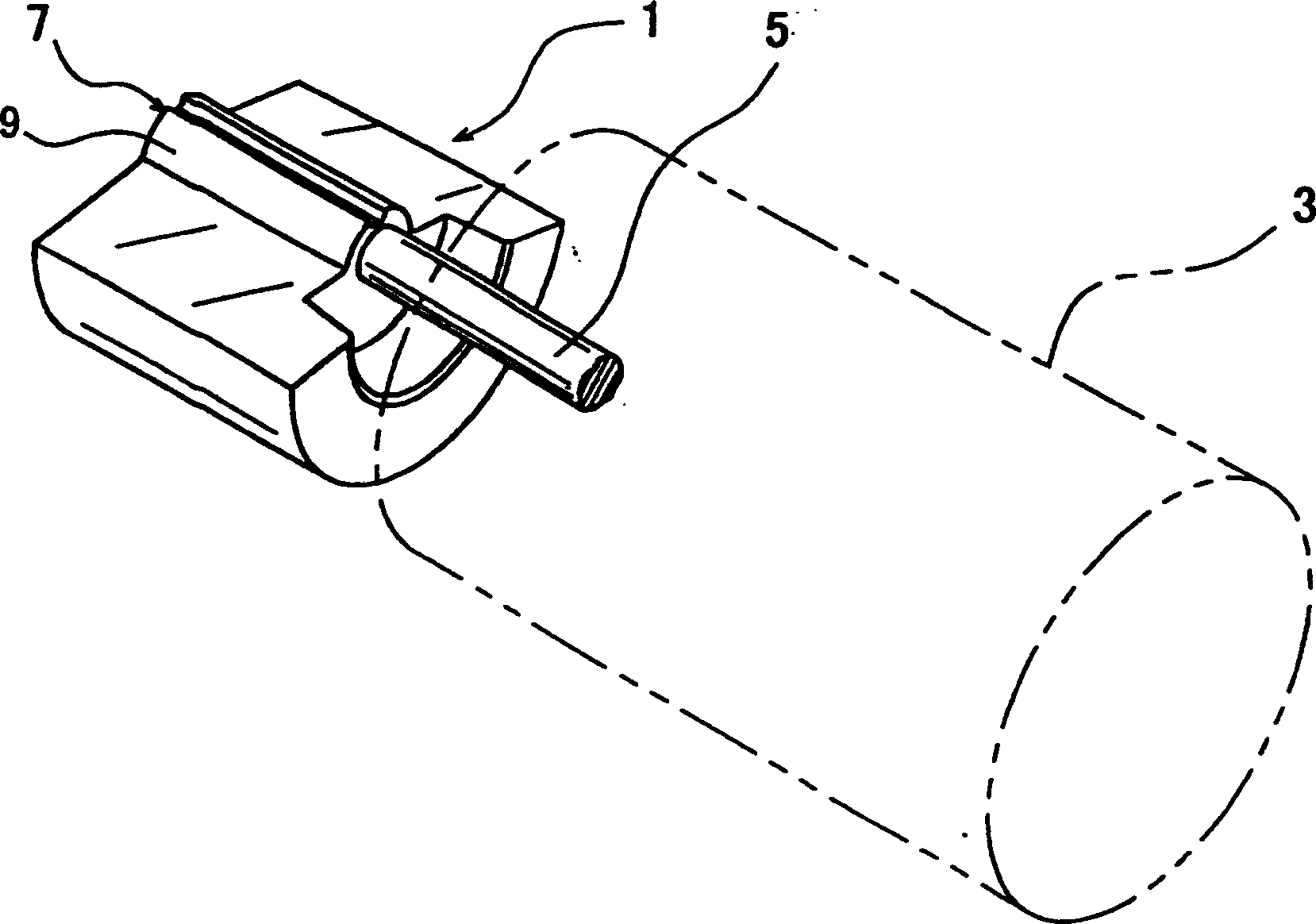

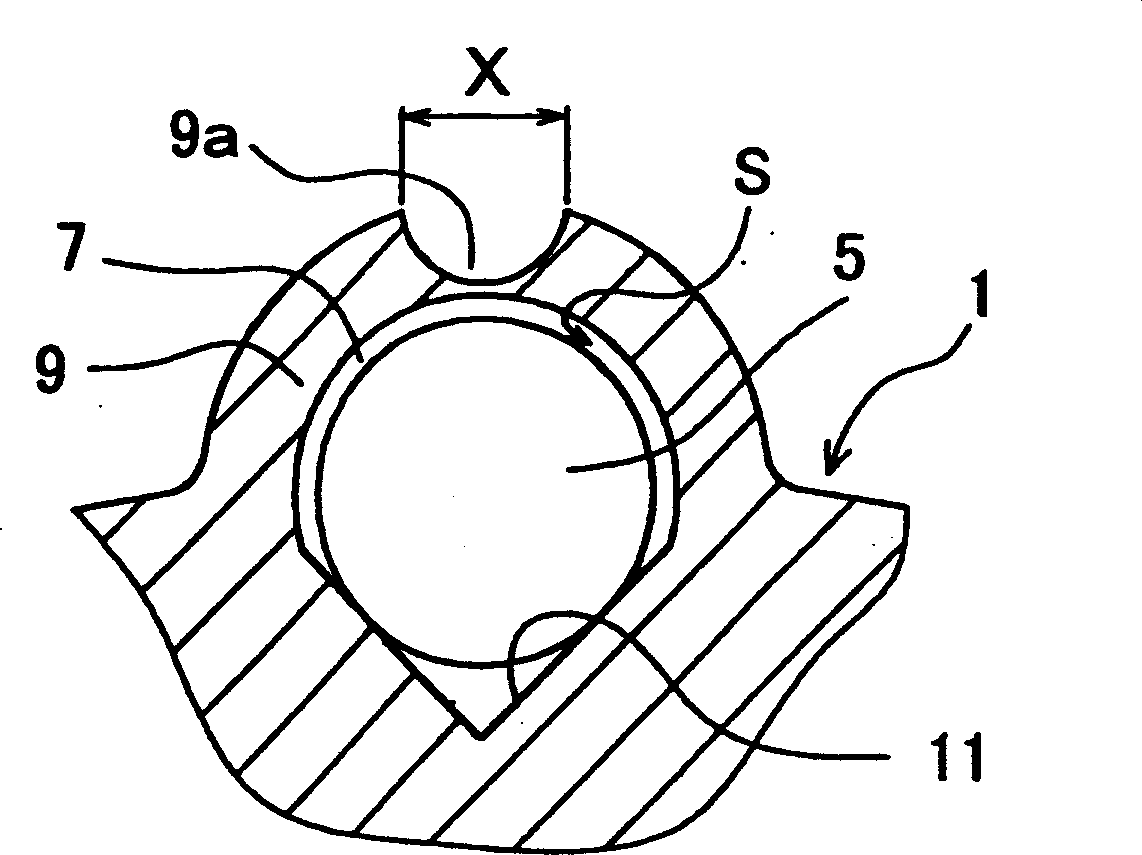

Self-piercing nut

Owner:SHINJO MFG CO LTD

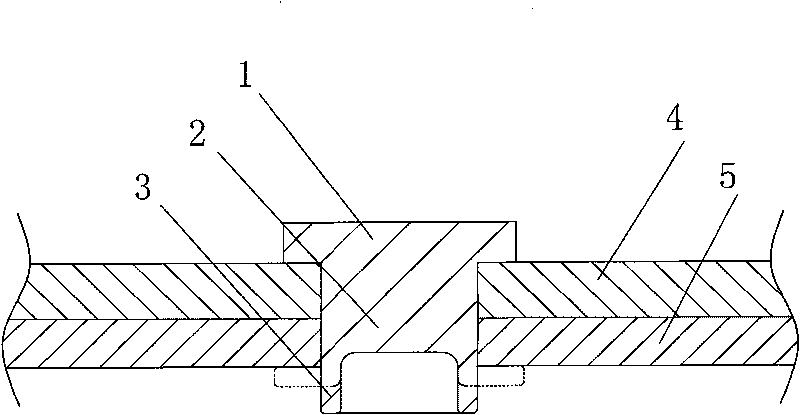

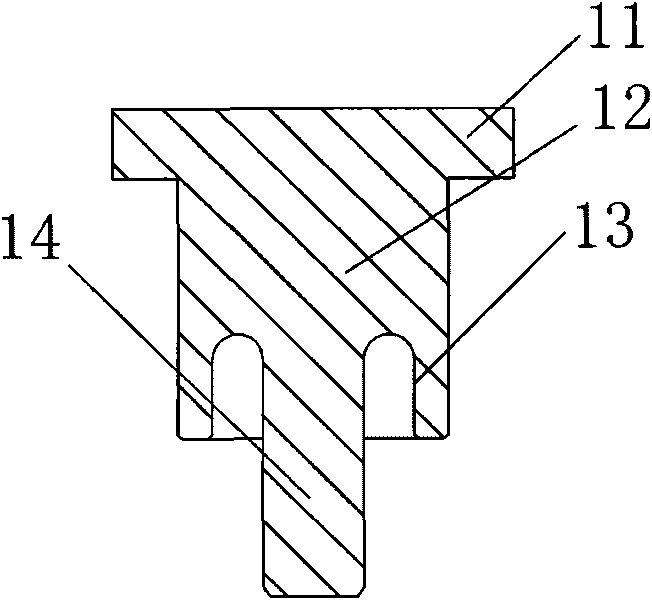

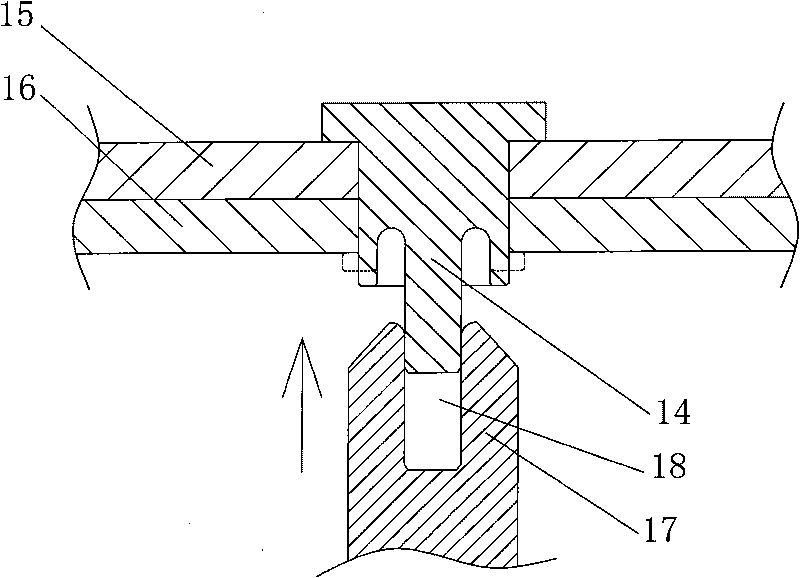

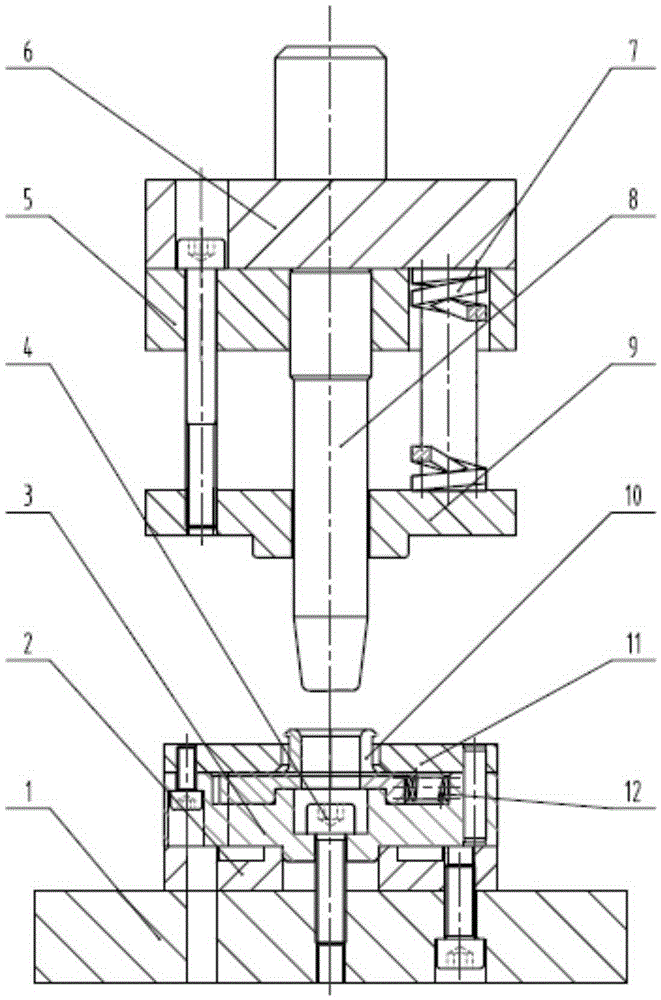

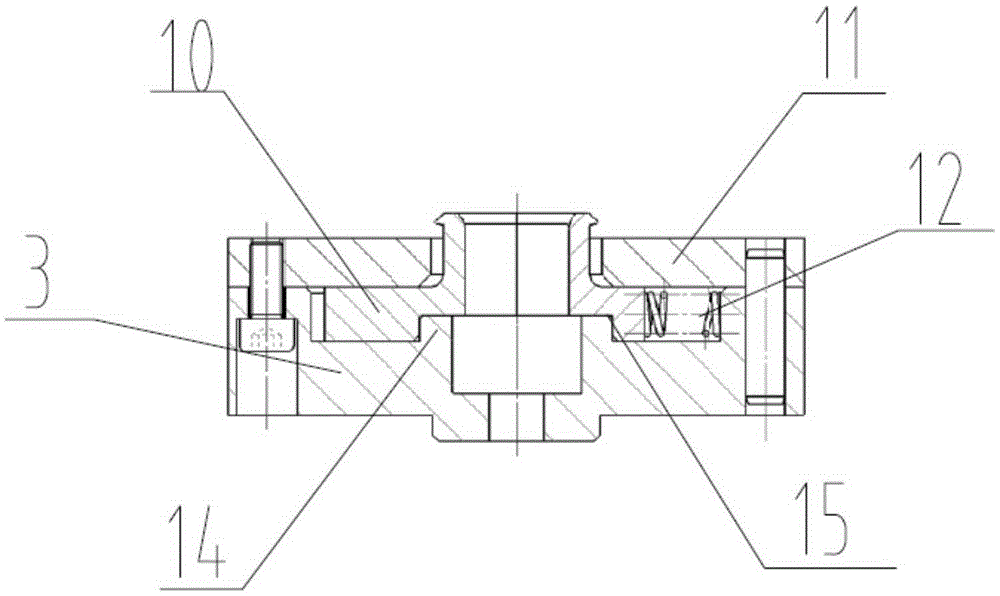

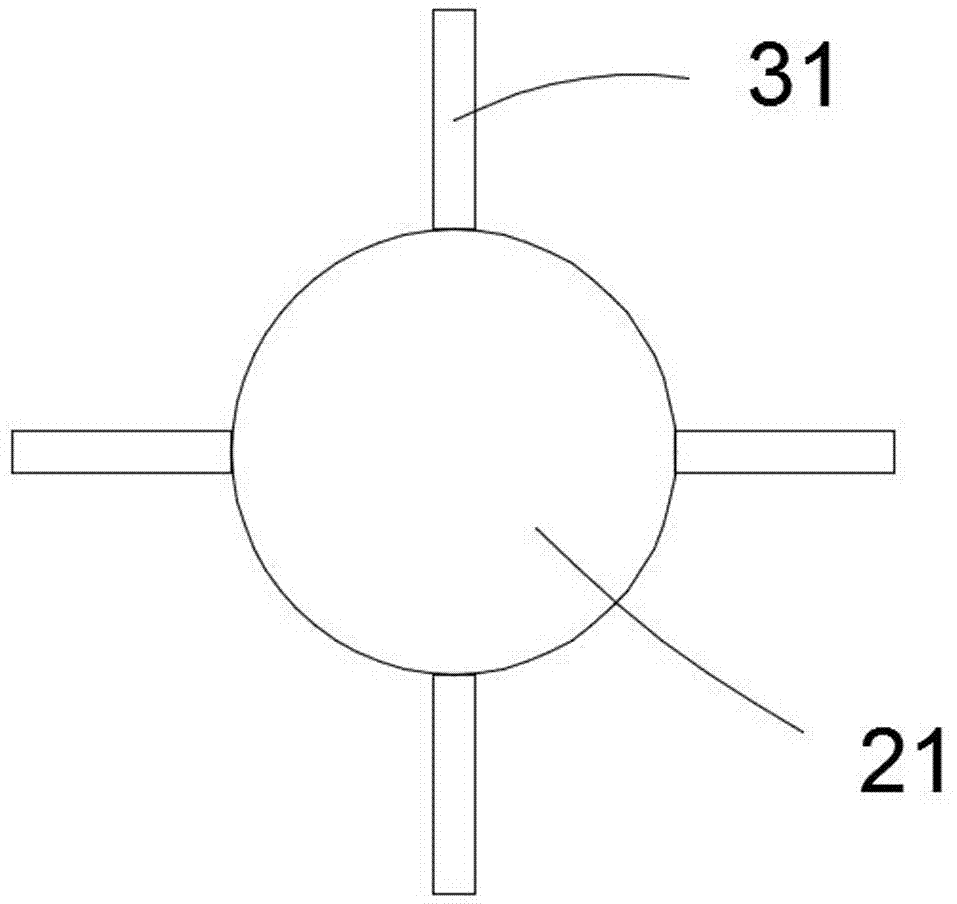

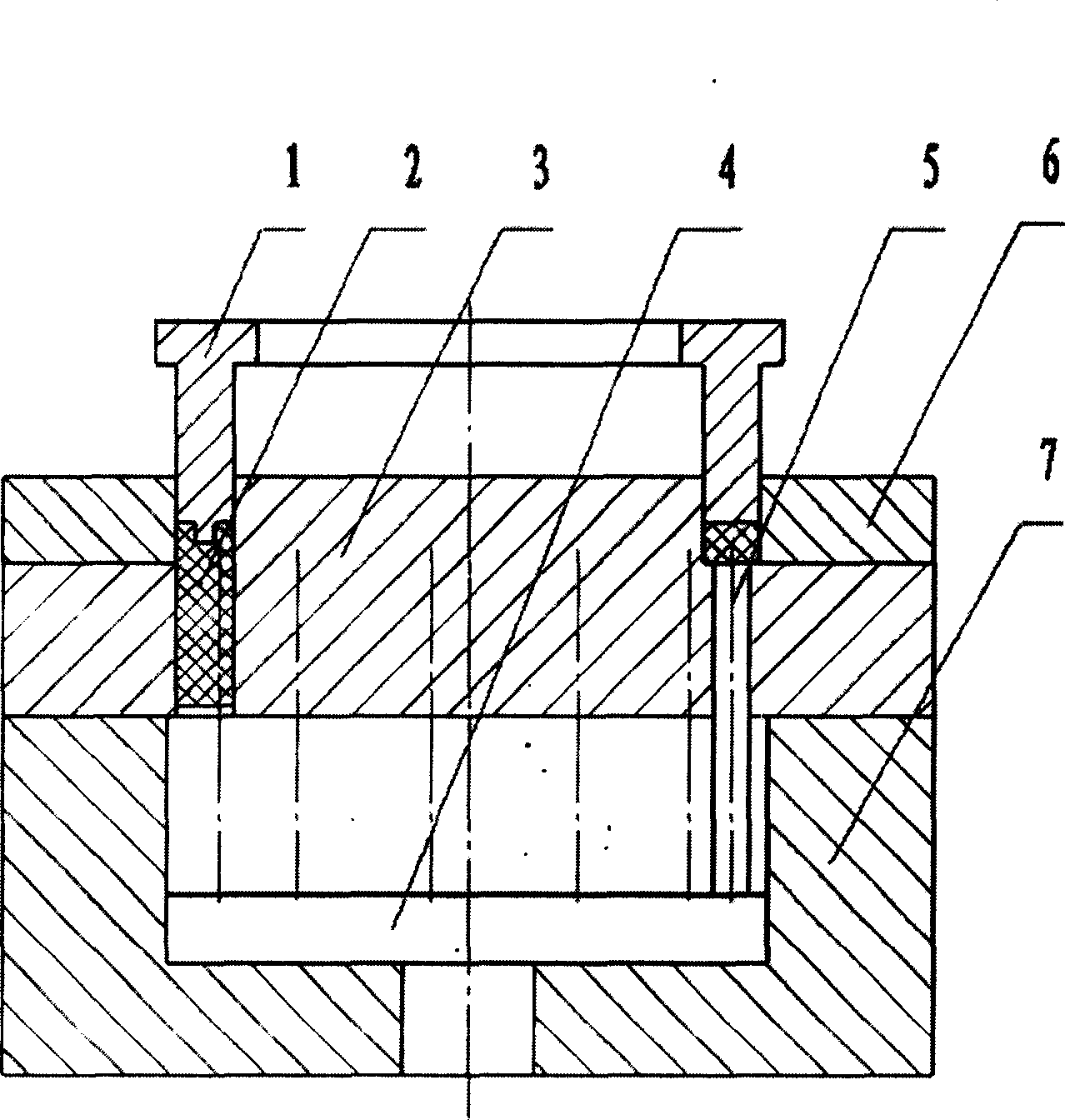

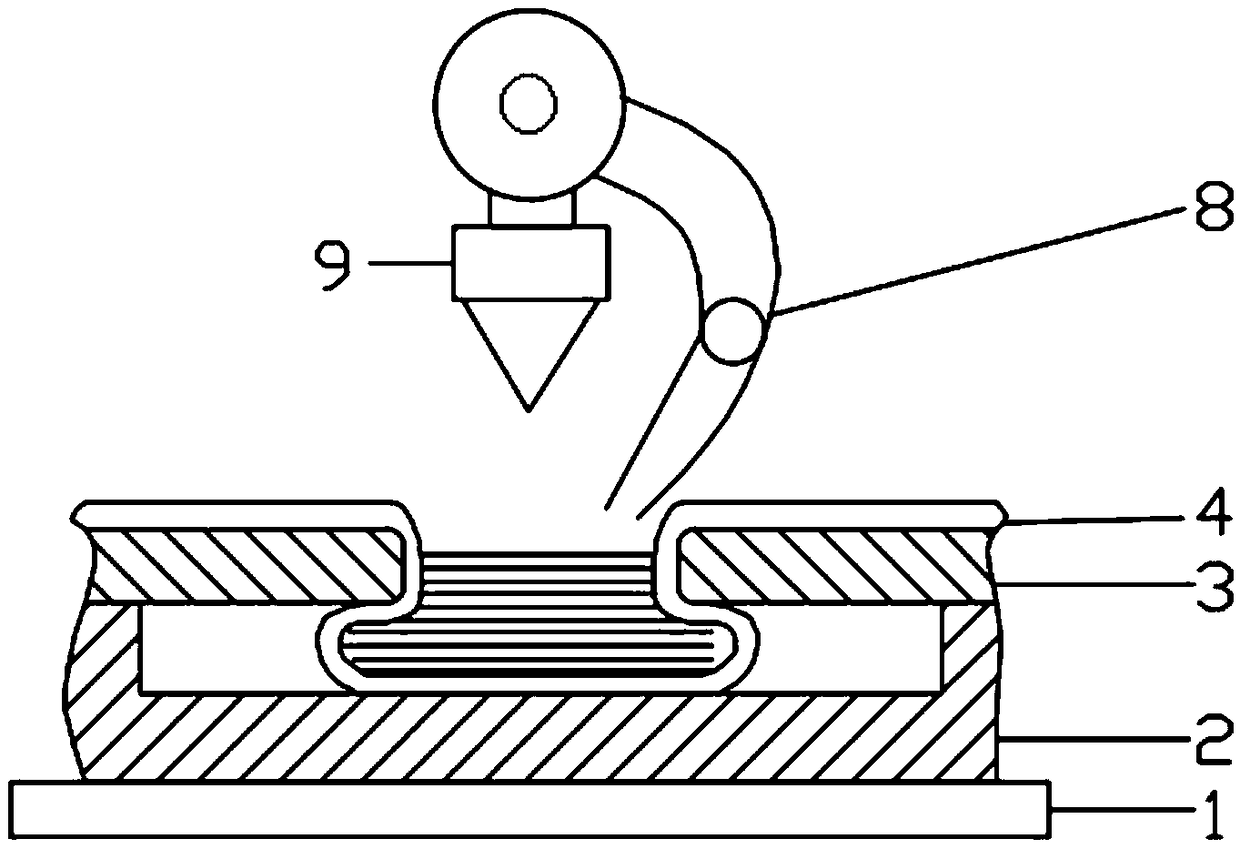

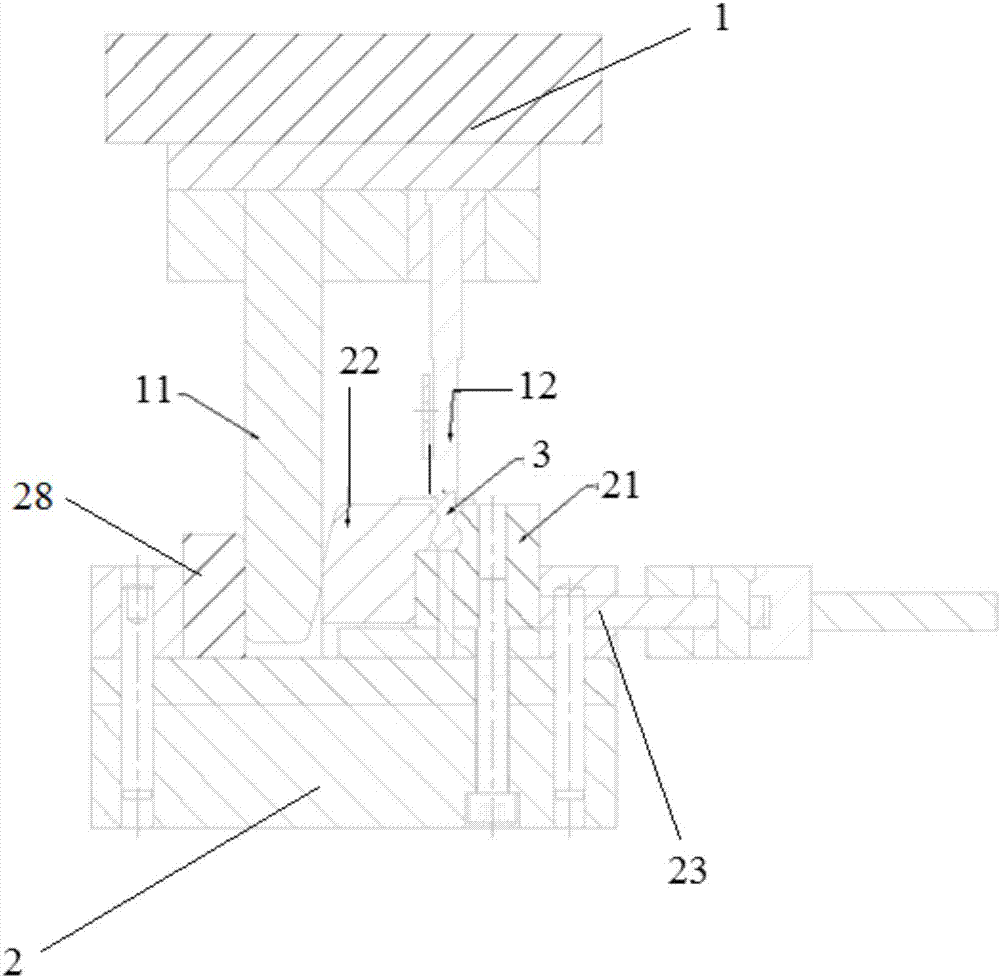

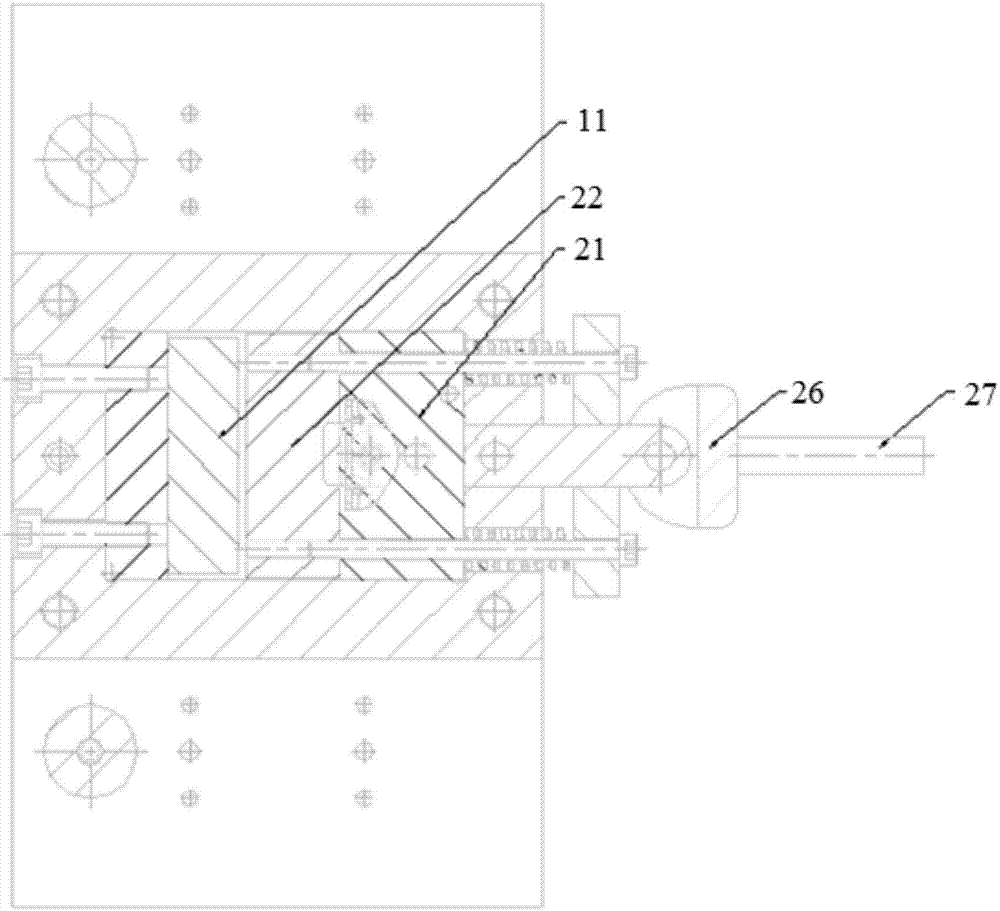

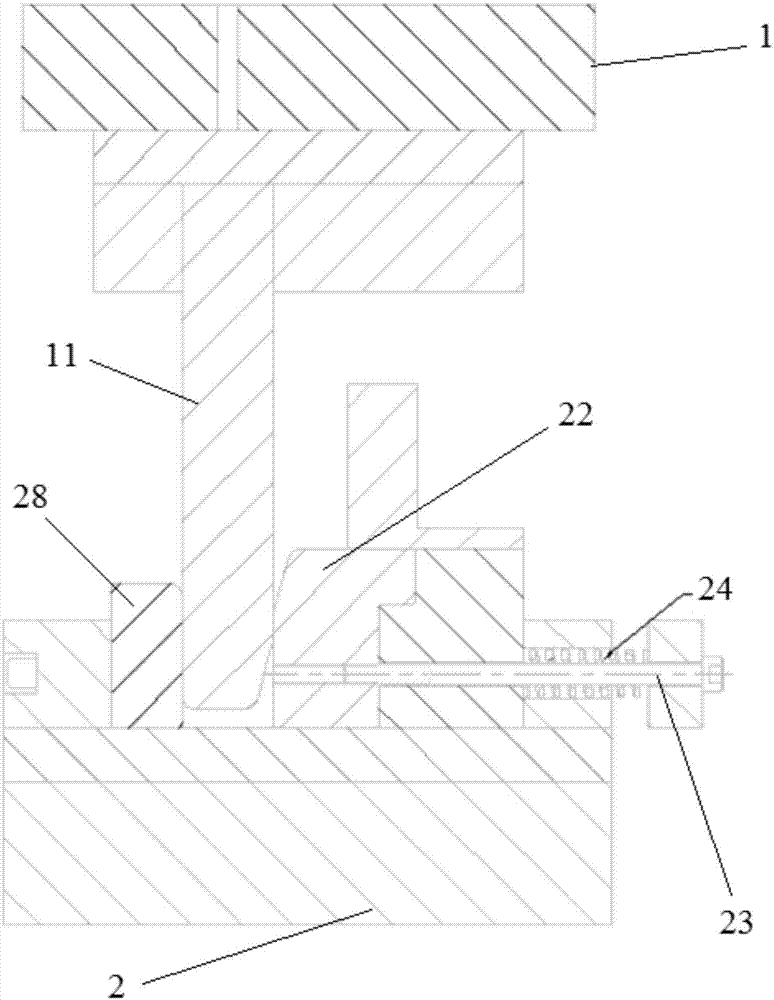

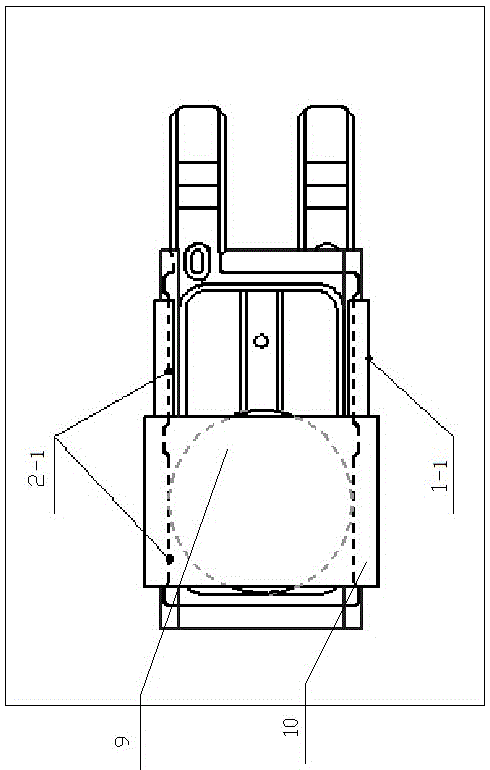

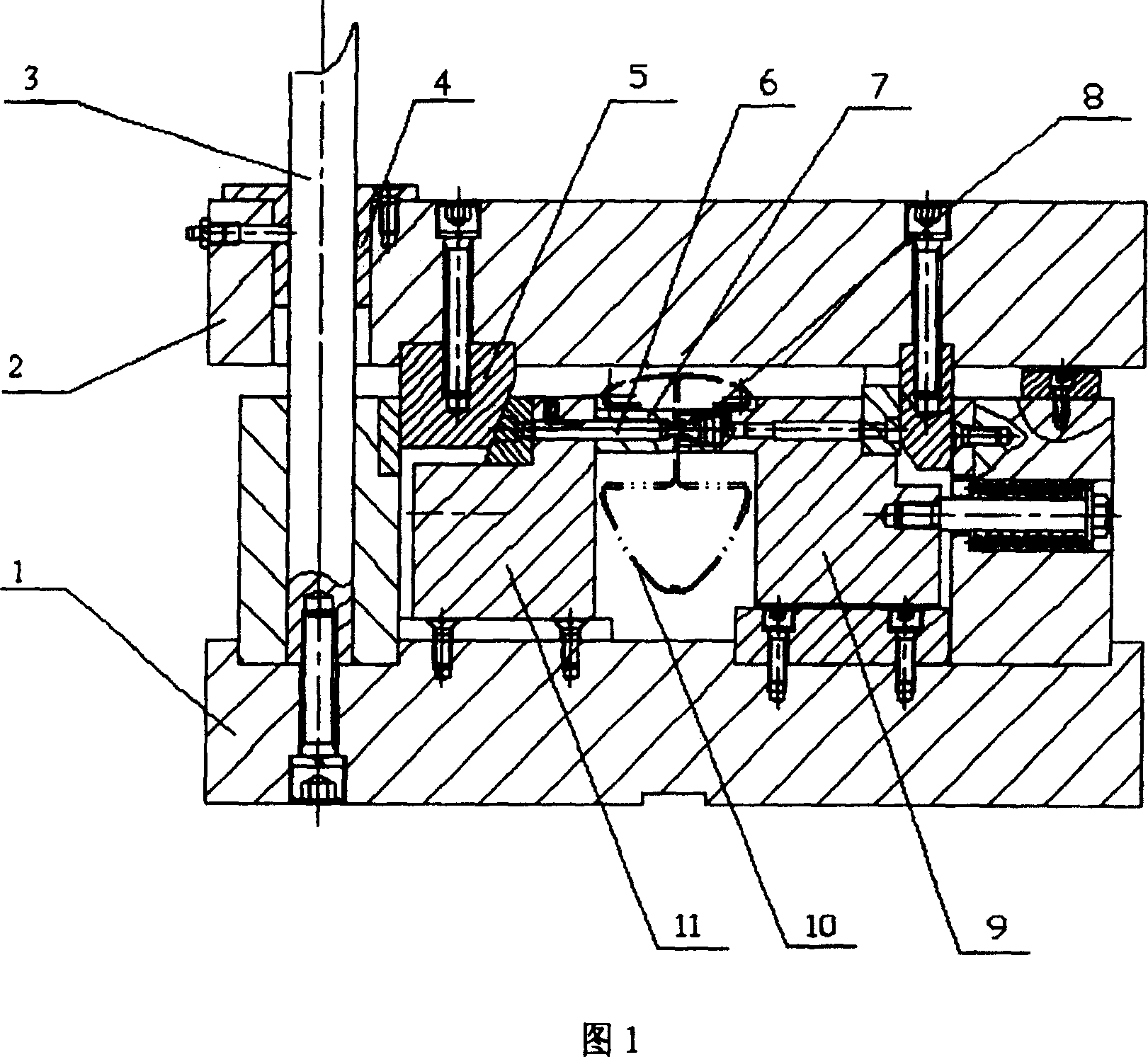

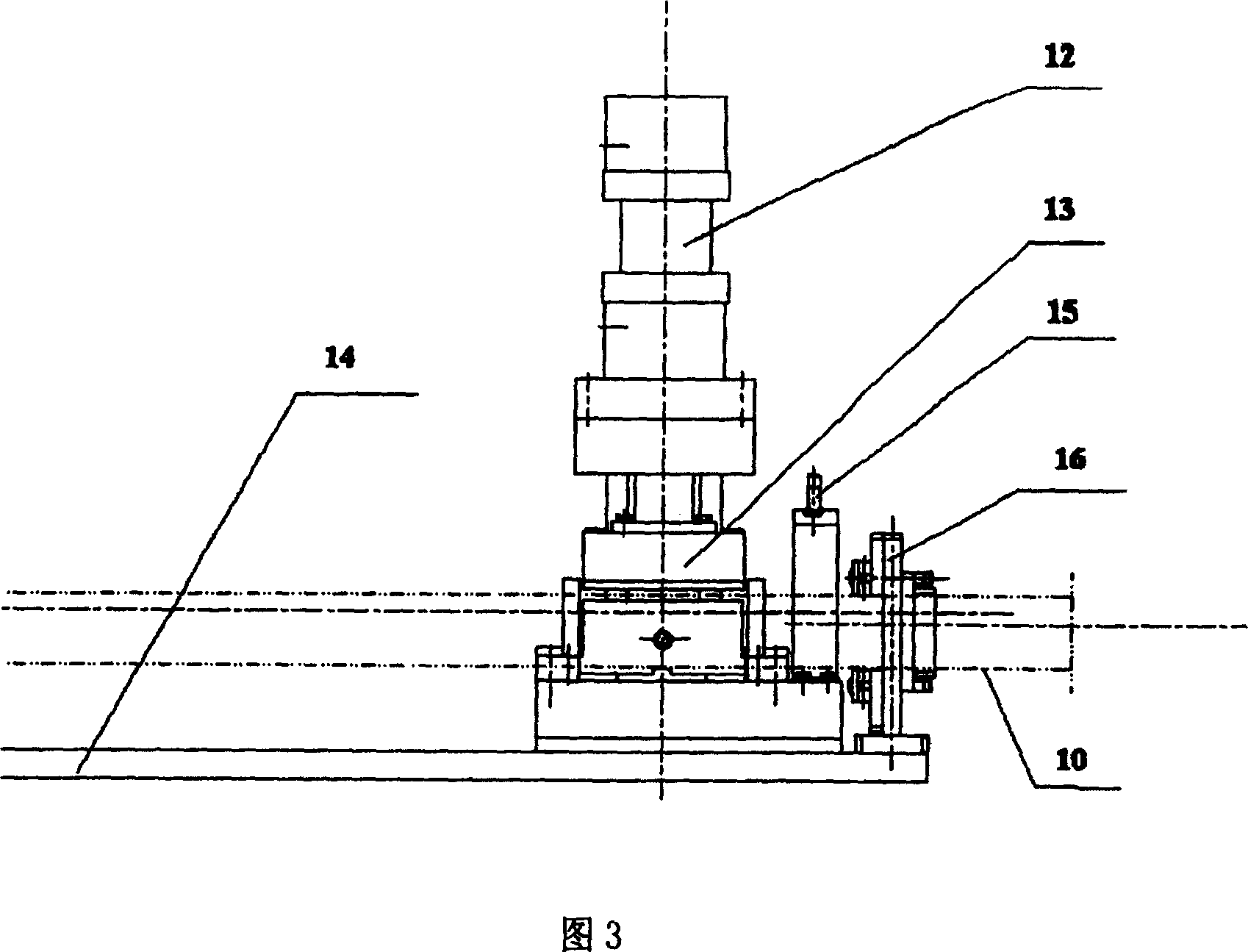

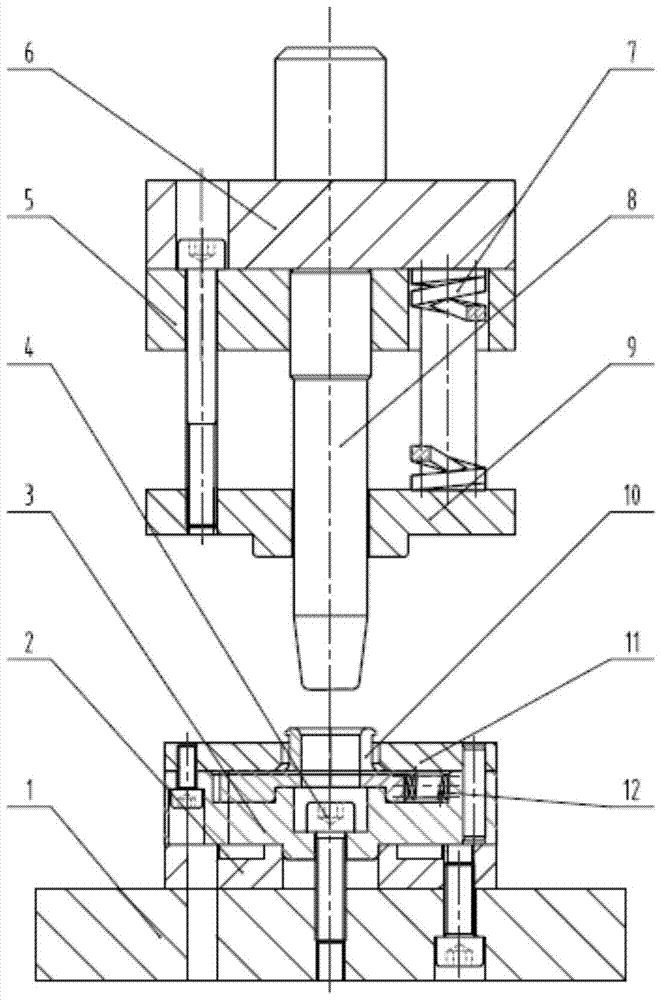

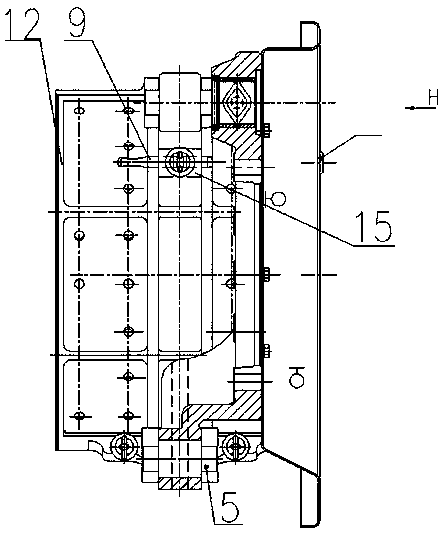

Inside riveting die of hydraulic clutch bearing gland

The invention relates to an inside riveting die of a hydraulic clutch bearing gland. A lower fixing plate is arranged on the upper end face of a bottom plate. A lower die fixing plate is arranged on the upper end face of the lower fixing plate. A split lower die insert is embedded in the middle of the upper end face of the lower die fixing plate. A cylindrical protrusion is arranged in the middle of the upper end face of the split lower die insert. The outer ring of the upper end of the cylindrical protrusion is bent outwards. A locating through hole is formed in the cylindrical protrusion of the split lower die insert. The split lower die insert is evenly divided into multiple fan-shaped columns. The lower portion of each column is transversely provided with a reset spring. A core rod moving up and down is arranged above the locating through hole in the split lower die insert. The lower end of the core rod is of a circular truncated cone columnar structure matched with the locating through hole, wherein the diameter of the lower end of the structure is smaller than that of the upper end of the structure. The inside riveting die of the hydraulic clutch bearing gland has the beneficial effects of being simple in structure, convenient to use, capable of being suitable for hydraulic release bearings of different models, increasing the riveting speed of the bearing glands greatly and meanwhile, improving the riveting strength of the glands and the like.

Owner:NINGBO HONGXIE CLUTCH

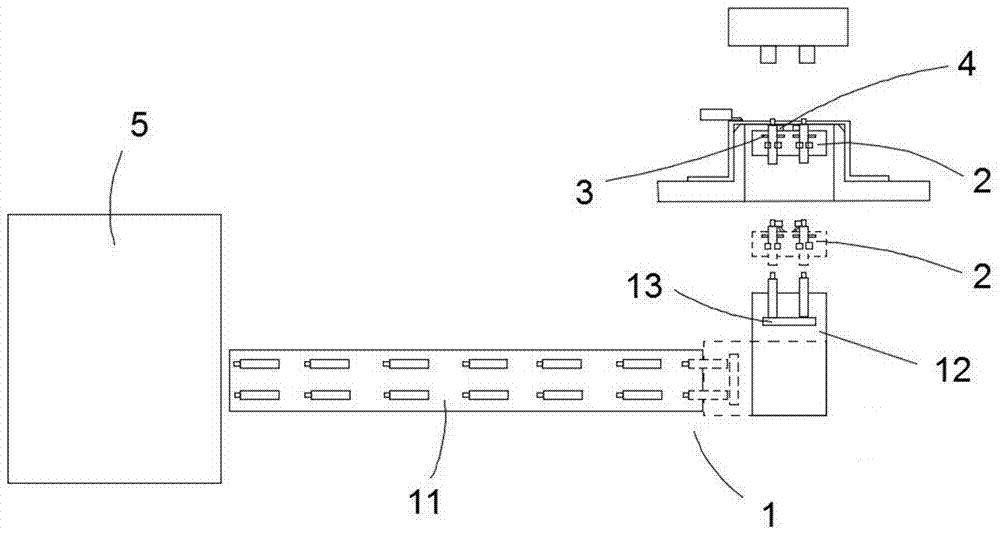

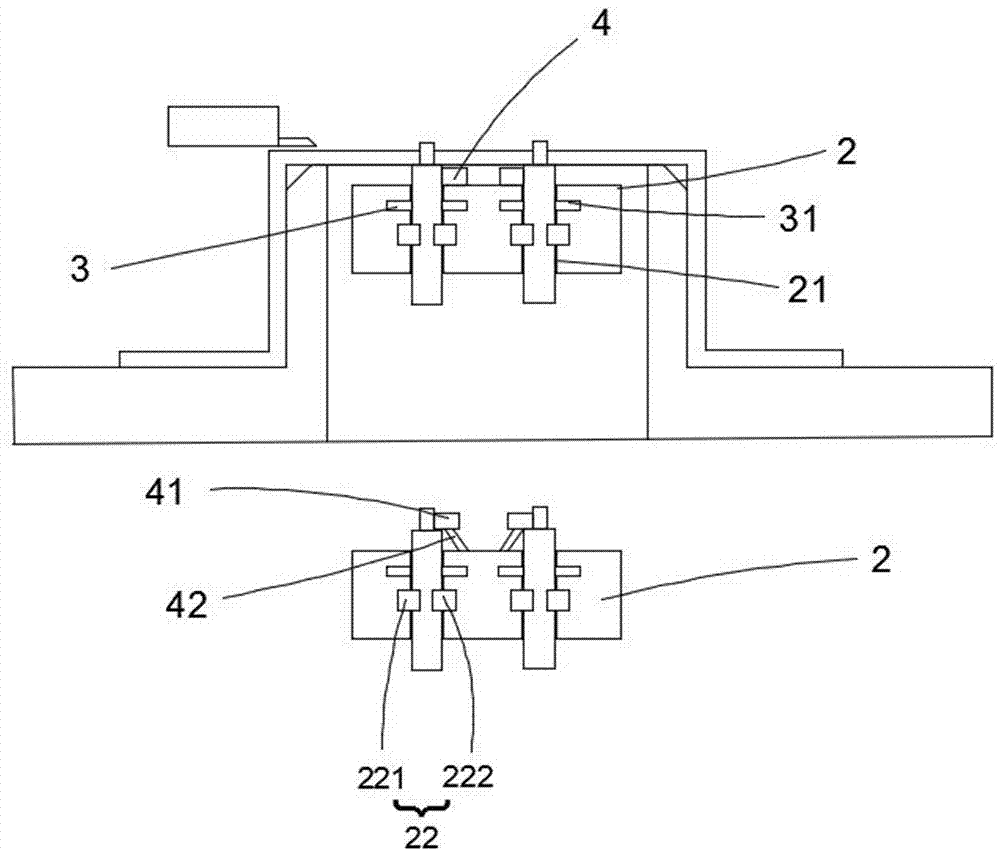

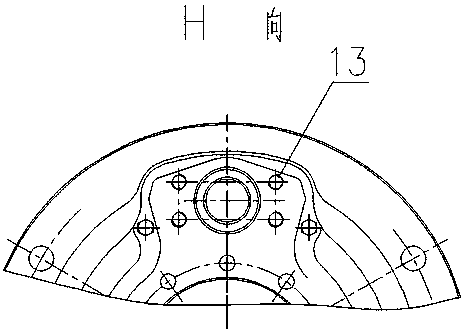

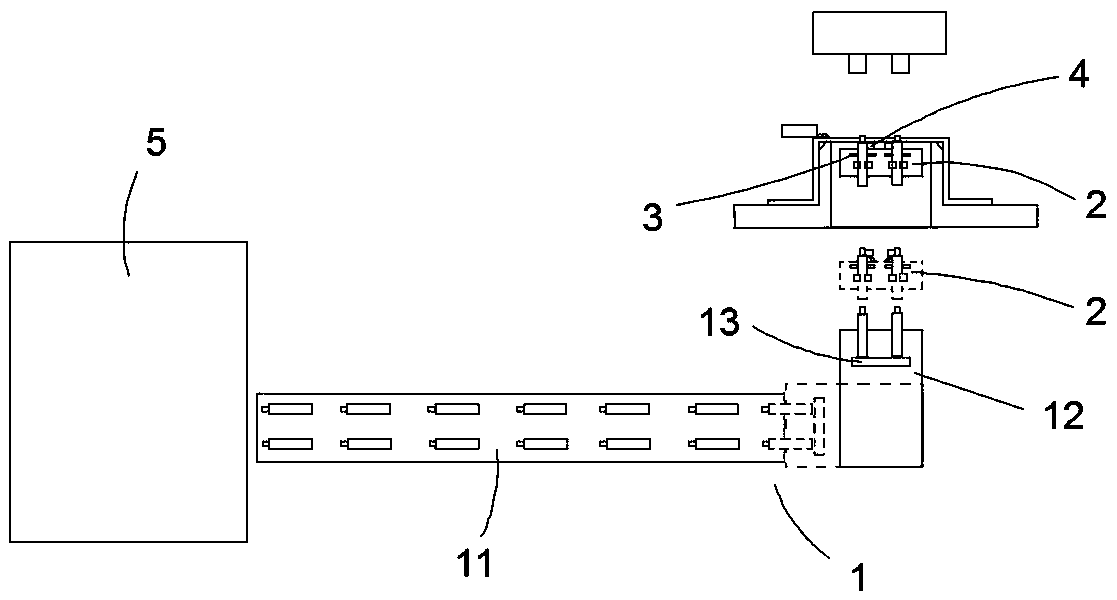

Feeding, heating and auxiliary riveting method for riveting shafts

The invention discloses a feeding, heating and auxiliary riveting method for riveting shafts. The method comprises the steps as follows: a grabbing manipulator grabs a group of riveting shafts from a conveying belt, rotates and sends the riveting shafts to the position below a clamping and feeding device; a pushing driving device drives a pushing device to rise to push the group of riveting shafts into a group of shaft accommodating cavities; when the riveting shafts reach the set positions, a clamping driving device operates, and clamping devices clamp the riveting shafts; a telescoping driving device drives telescopic arms of heating devices to extend, and heating ends make contact with riveting parts of the riveting shafts for heating; a feeding driving device operates, the clamping and feeding device moves to the position below to-be-machined sheet metal at a riveting station; and the feeding driving device operates continuously, and the clamping and feeding device drives the group of riveting shafts to be embedded in corresponding riveting holes. The production efficiency and the automation degree of production are increased; fine adjustment of the perpendicularity is performed while the shafts are clamped, and the riveting precision is guaranteed; riveting is performed after heating, and thus the riveting precision and strength are enhanced.

Owner:太仓市华天冲压五金制品厂

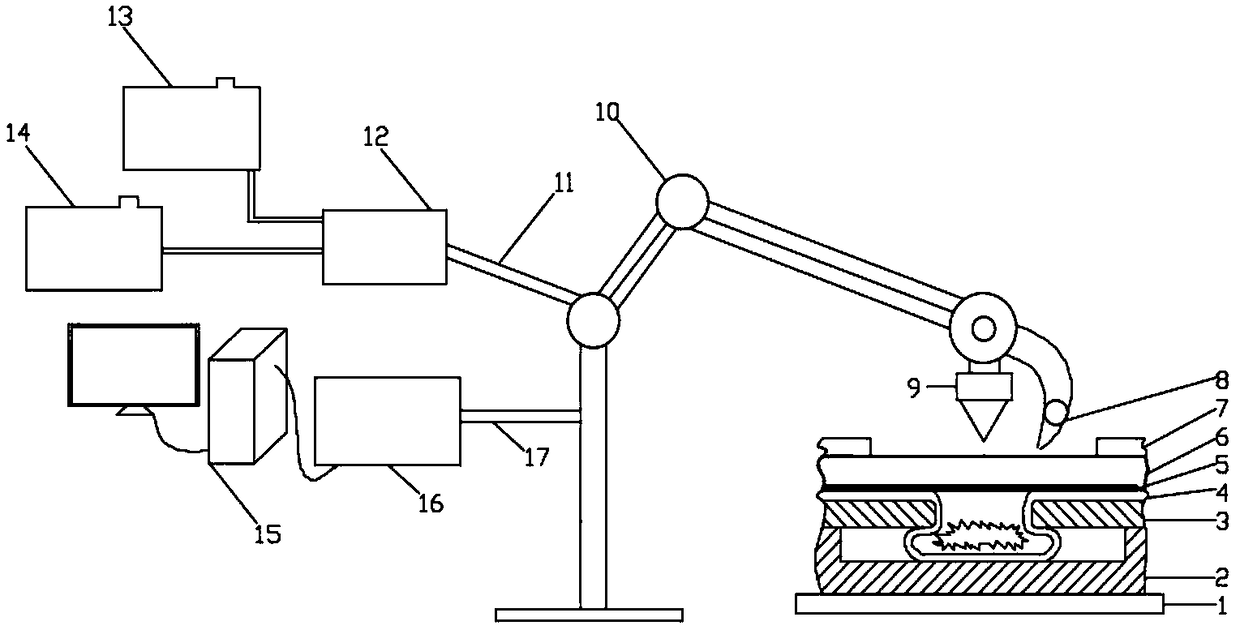

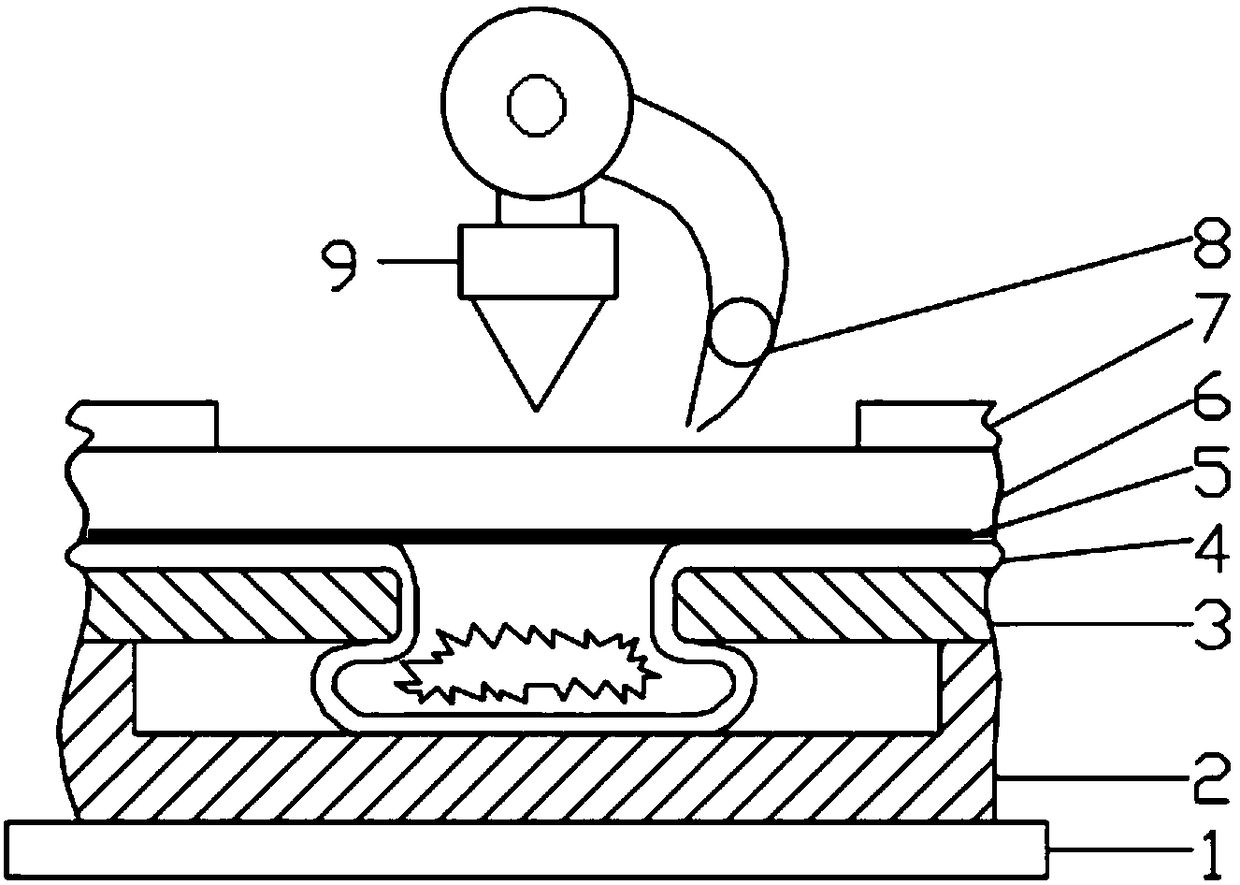

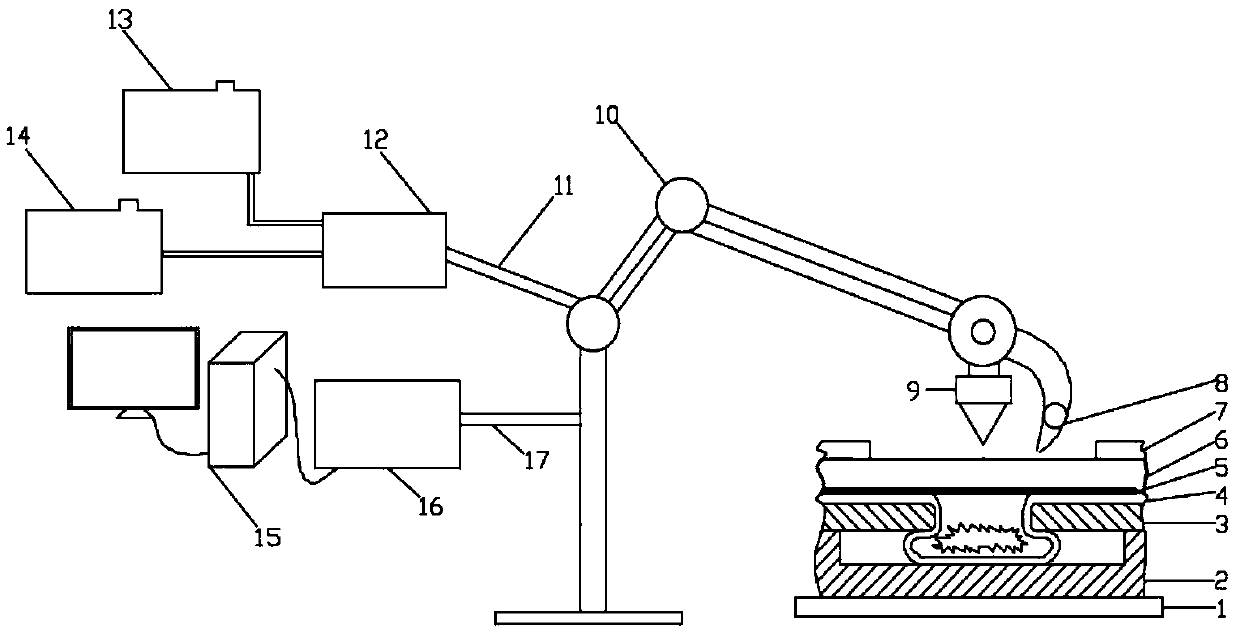

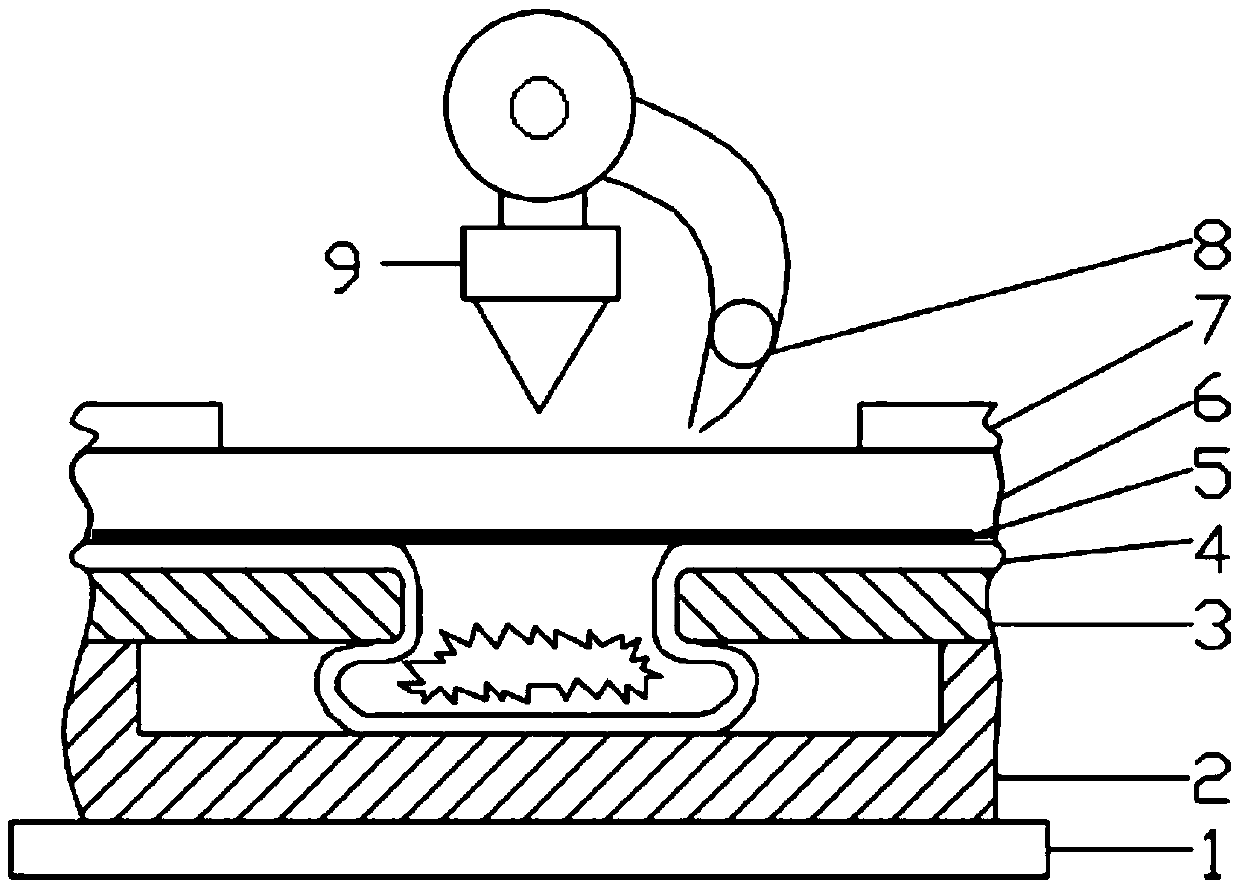

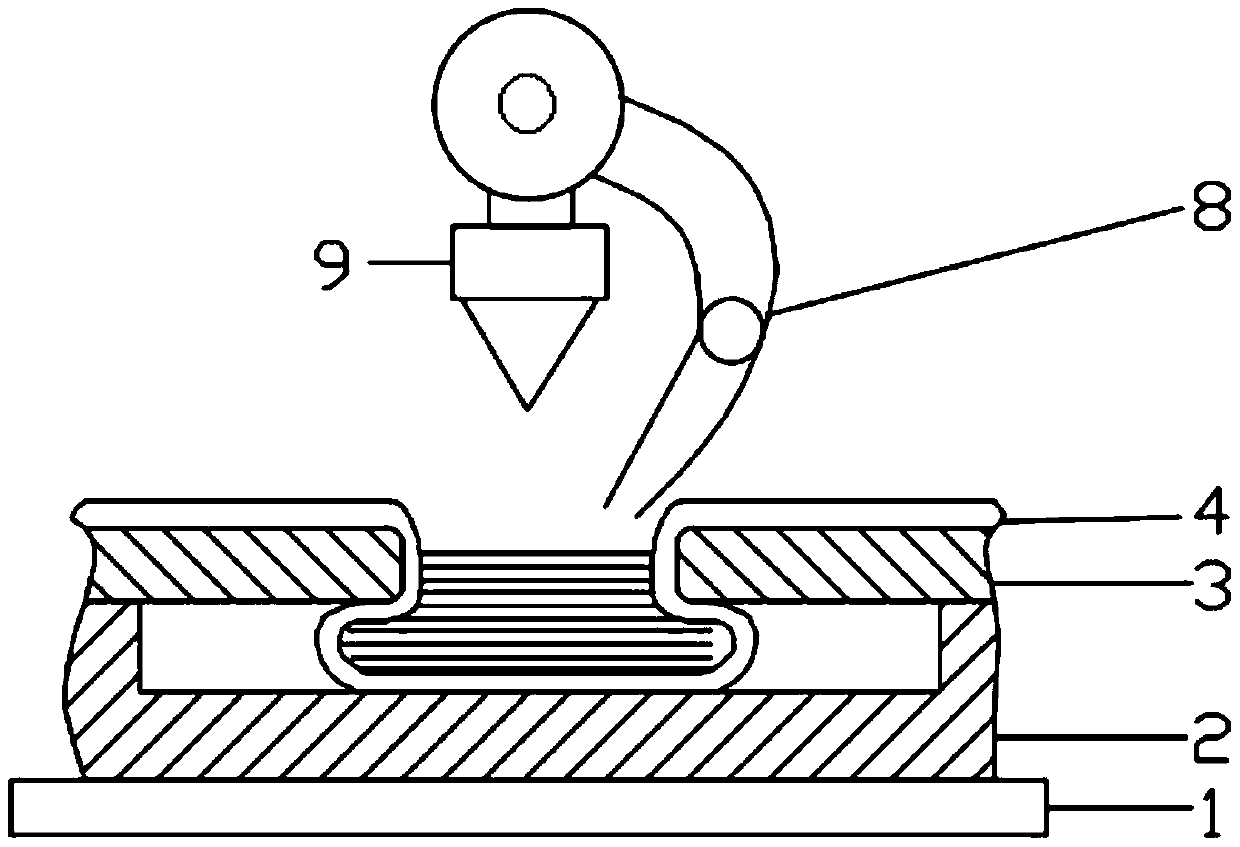

Method and device for improving laser shock riveting forming connecting strength

The invention discloses a method and device for improving the laser shock riveting forming connecting strength. The method includes the following main steps that firstly, a resin mixture and a curingagent are mixed according to a certain proportion, and a formed pasty mixture serves as a filling material; afterwards, a central controller controls a laser device to transmit laser beams, the laserbeams are transmitted to a worktable through a light guide arm and a focus head to excite an adsorption layer material to be plasma shock waves to shock an upper layer plate, and a hollow riveting structure is formed by the upper layer plate and a trepanned lower layer plate under the constraint of a lower female die; and the central controller adjusts a peristaltic pump to extrude the filling material so that the filling material can be injected into the hollow riveting structure through a material spraying nozzle, after the filling material is solidified, hollow riveting becomes solid riveting, when the riveting structure is subjected to the effect of normal force and shearing force, the cured filling material can have a supporting effect on the riveting structure, and therefore the riveting connecting strength is greatly improved.

Owner:SHANDONG UNIV

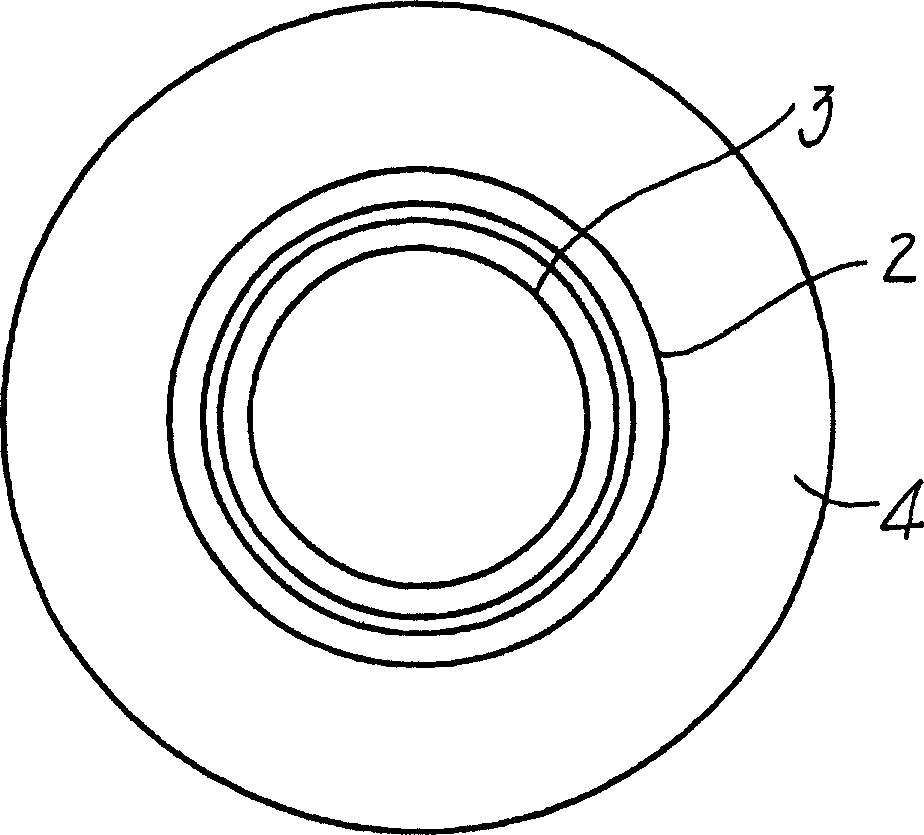

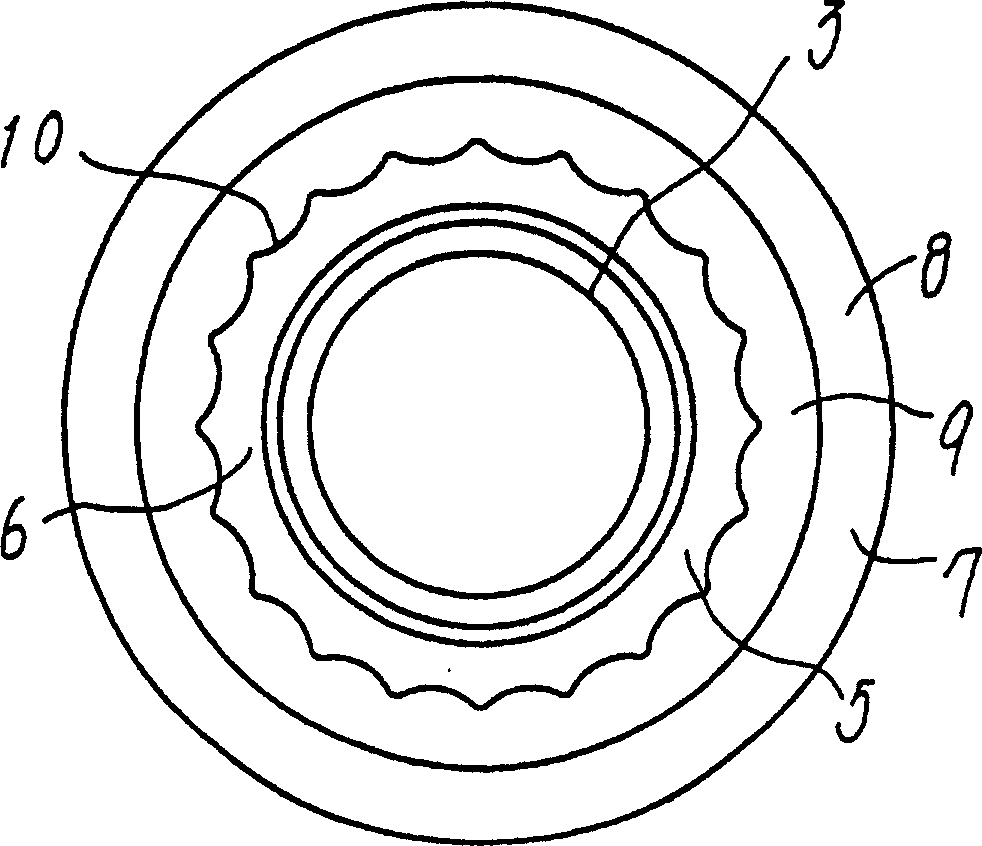

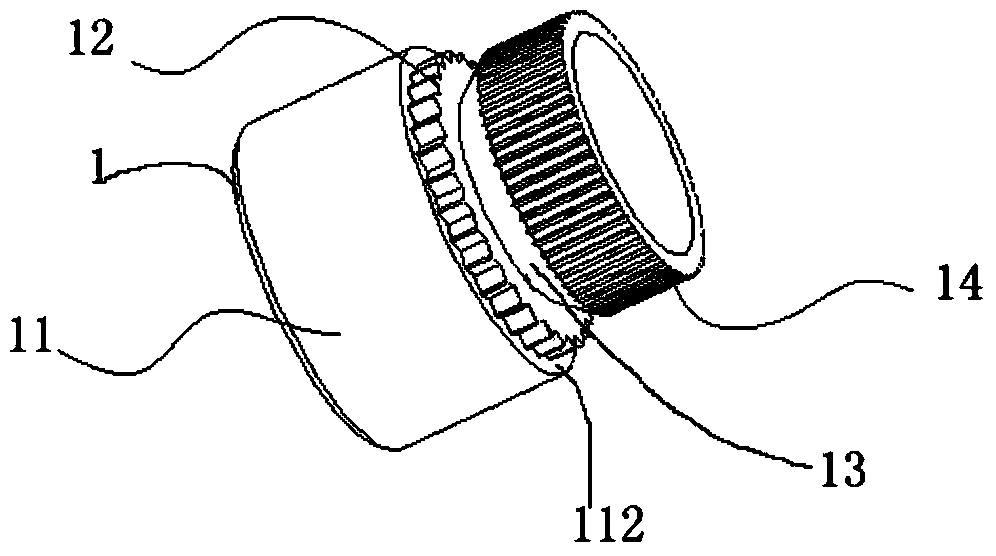

Pressuring riveting and rising riveting integrated nut and combination and riveting technology thereof

The invention relates to a pressuring riveting and rising riveting integrated nut which comprises a nut section located on a lower end surface, a first knurled section arranged on the lower end surface of the nut section, a second knurled section arranged on the first knurled section, and a groove section formed between the first knurled section and the second knurled section. The invention also relates to a combination and riveting technology of the pressuring riveting and rising riveting integrated nut. The pressuring riveting and rising riveting integrated nut is provided with a plurality of sections with different structures, so that the connection force between a riveting nut and a riveted part is improved, the phenomenon that the riveting nut rotates and falls off when the riveting nut bears larger external force or torque is prevented, and safety performance and stability performance are assured. In addition, the pressuring riveting and rising riveting integrated nut has the advantages of being simple in technology, low in cost, and convenient to mass manufacture, popularize and apply to antennas.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

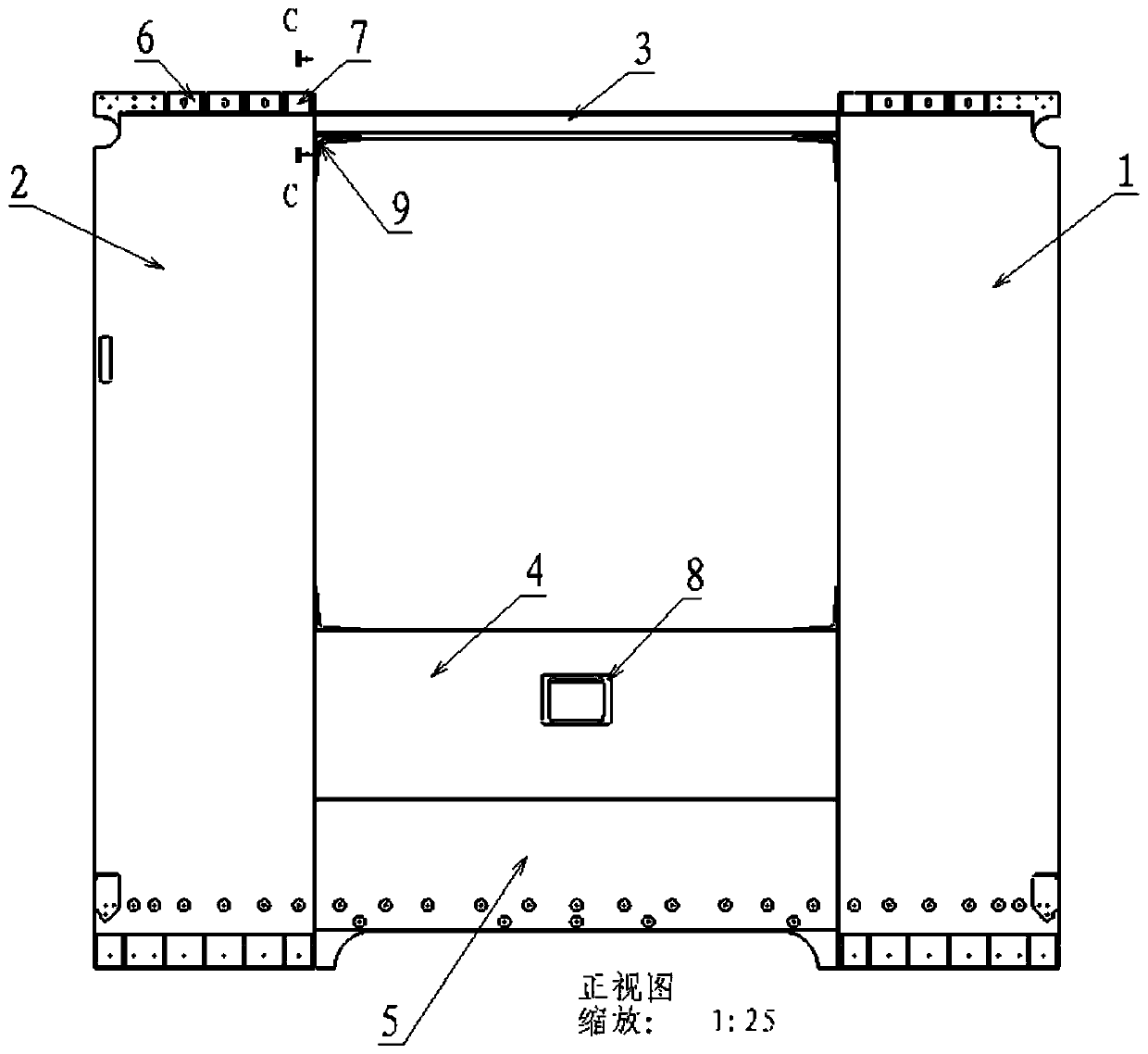

Novel aluminum alloy profile tailor-welded side wall structure and assembly welding process thereof

ActiveCN110860815ANo wasteAvoid deformationAxle-box lubricationVehicle componentsStructural engineeringUltimate tensile strength

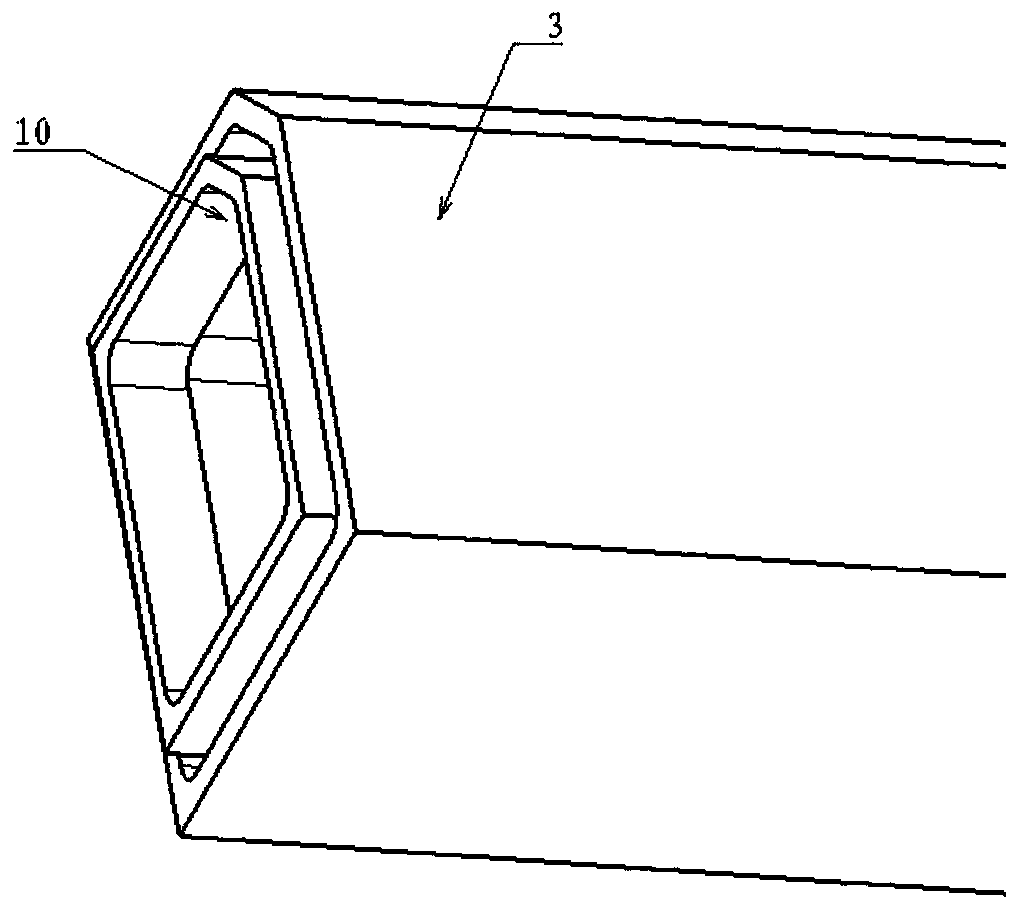

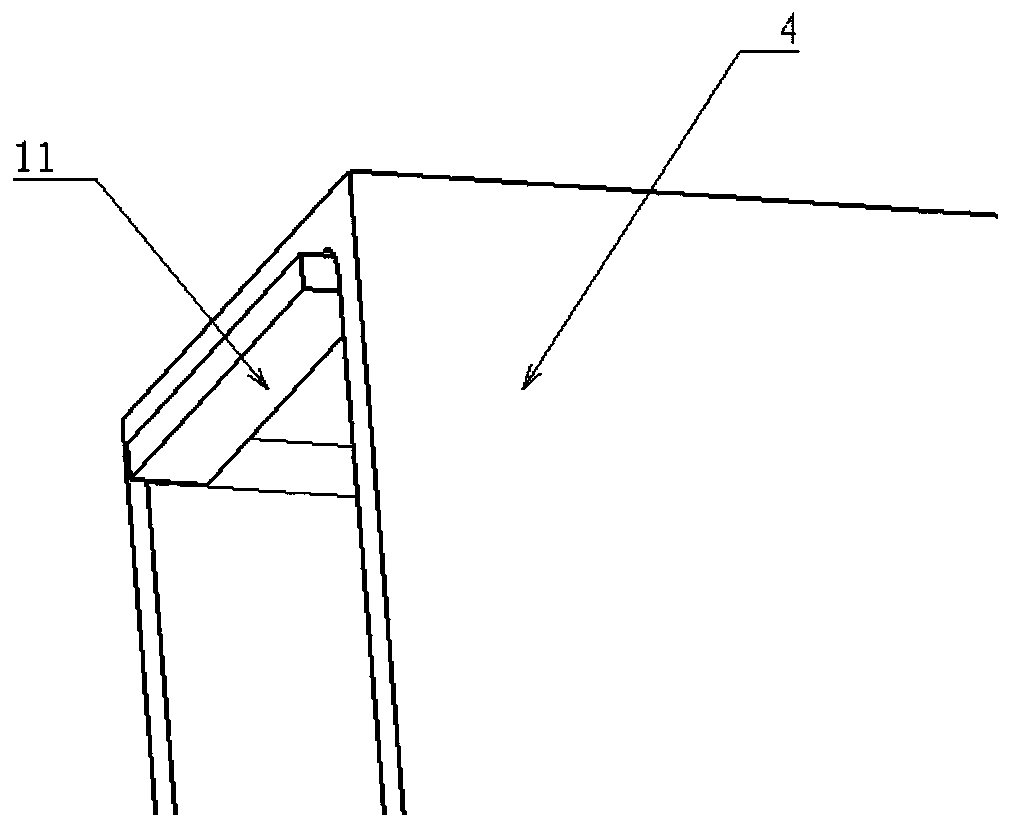

The invention discloses a novel aluminum alloy profile tailor-welded side wall structure. The novel aluminum alloy profile tailor-welded side wall structure is formed by tailor-welding a plurality ofaluminum alloy profiles and comprises a first stand column, a second stand column, a window frame upper portion, an upper embedded plate, a lower embedded plate, a base plate, a bent base plate, an mounting plate and a welding base plate. The novel aluminum alloy profile tailor-welded side wall structure is formed through reasonable component planning, the phenomenon of material waste is avoided,and cost is low. The side wall structure product is not prone to deformation, and due to the design that the base plate and the bent base plate are additionally arranged on the top of a side wall, theriveting strength can be effectively improved. The invention further discloses an assembly welding process of the side wall structure. Through a special welding tool, a specific welding process and awelding sequence, the size of the side wall obtained after welding can be well controlled, the welding quality of the side wall structure can be well guaranteed, the flatness of the side wall structure is guaranteed, and the side wall structure is not prone to deformation.

Owner:安徽雷尔伟交通装备有限公司

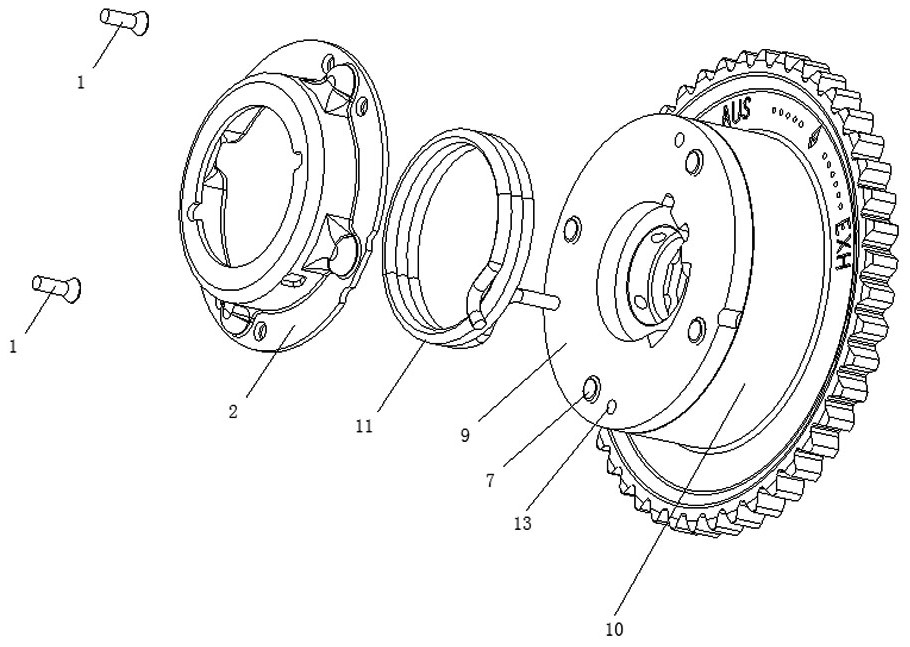

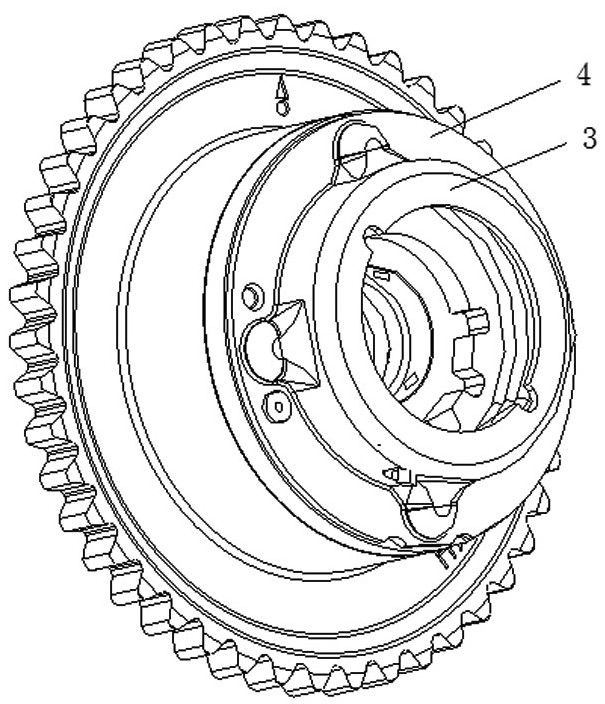

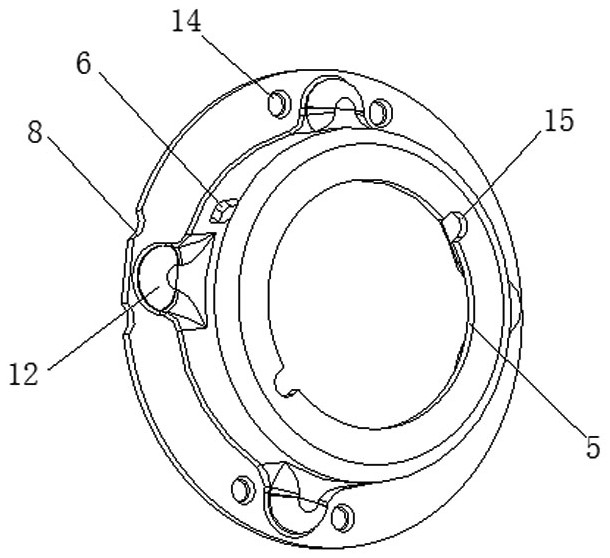

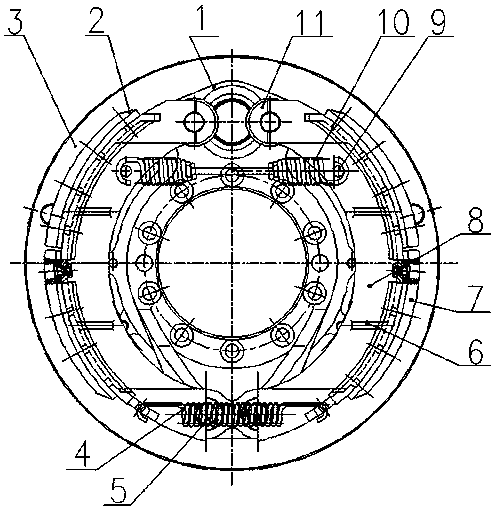

Assembly method of open plate in camshaft decompression mechanism

InactiveCN101362180AAvoid deflectionEasy to useValve arrangementsMachines/enginesHigh volume manufacturingNeck parts

The invention discloses an assembly method of an open plate in a camshaft decompression mechanism, wherein, the open plate is riveted onto a camshaft body by a rivet which is processed into an eccentric stepped rivet; the eccentricity of the rivet body to a neck part is e which equals to 0.1 to 0.3mm; the body is preferably provided with a taper angle, and in the assembly, the height from the highest point of the open plate to a basic circle of an exhaust cam in the decompression mechanism is controlled to be 1.15 to 1.30mm by turning the rivets and combining with the measurement of detection tools, and finally the open plate is riveted and fixed by a press. The method which is used for assembling camshaft components of gasoline engines saves time and labour, is high in production efficiency and suitable for mass production; furthermore, the method does not damage a surface hardened layer of the open plate, ensures the assembly quality as well as the service performance and the service life of the camshaft decompression mechanism.

Owner:TAIZHOU HONGXIANG POWER MACHINERY

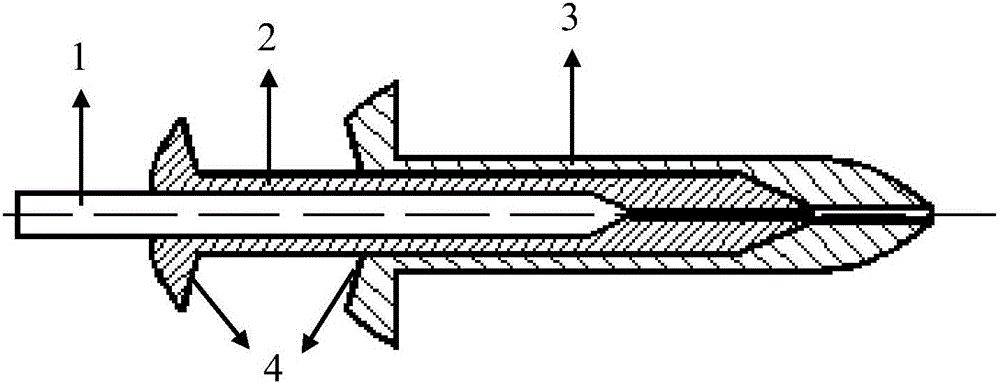

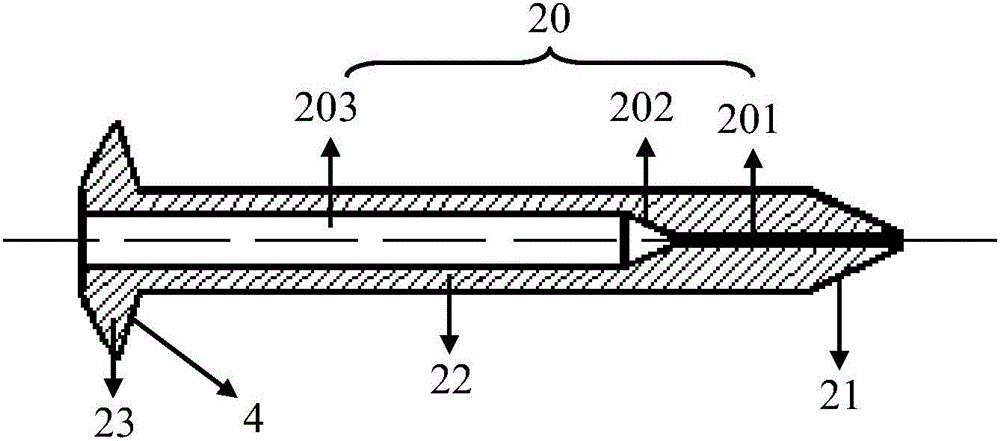

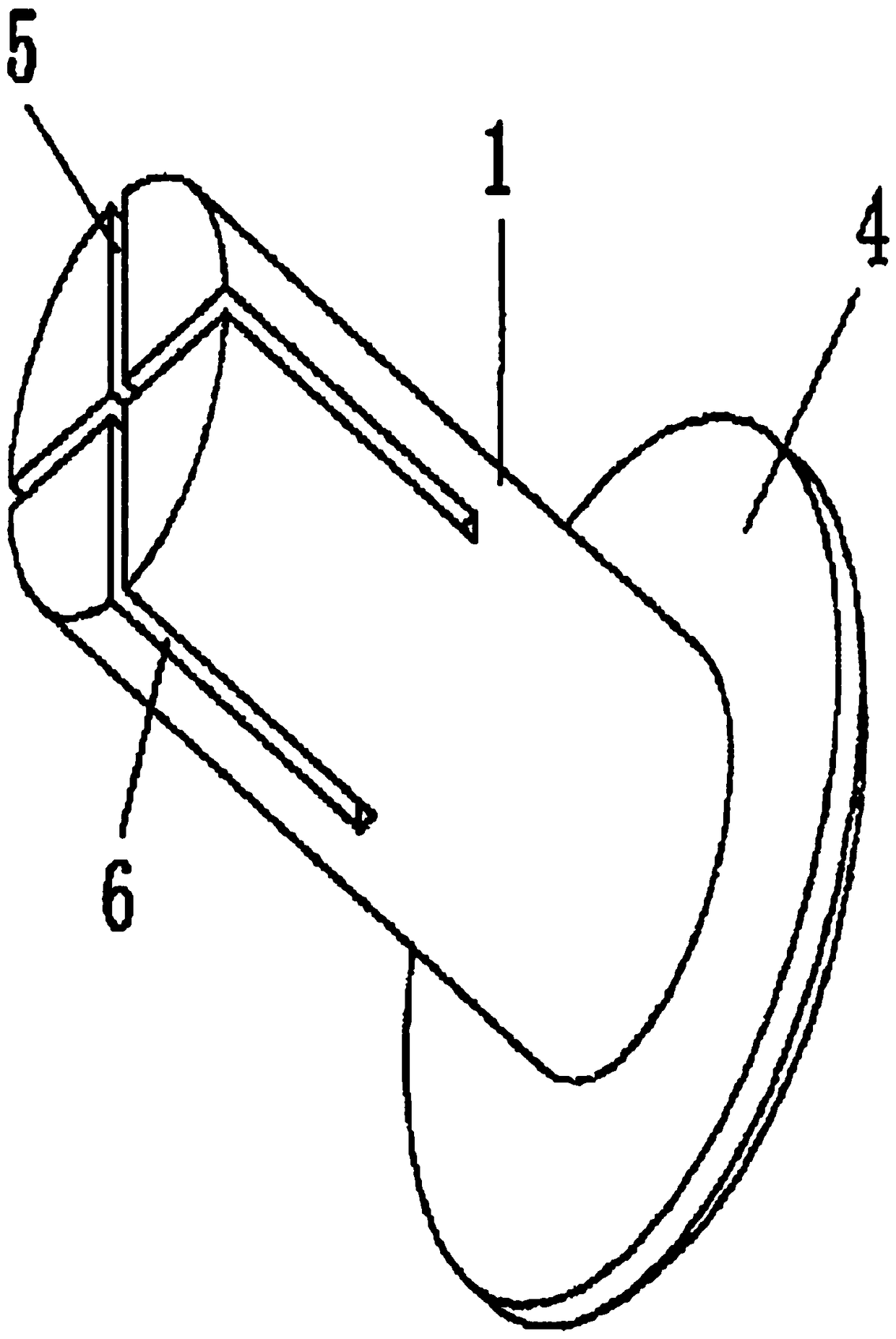

Two-stage pushing and pressing rivet

The invention provides a rivet which comprises a core rod, a rivet inner sleeve and a river outer sleeve which are coaxially sleeved in sequence from inside to outside. The core rod is provided with a first gradually-thin section and a rod section. The river inner sleeve is provided with a second gradually-thin section and an inner sleeve rod section and further provided with an inner sleeve through hole along the axis. The inner sleeve through hole sequentially comprises an inner sleeve thin hoe section, an inner sleeve gradually-thin hole section matched with the first gradually-thin section of the core rod, and an inner sleeve straight hole section matched with the portion, in the rivet inner sleeve, of the rod section of the core rod. The rivet outer sleeve is provided with an outer sleeve head and an outer sleeve rod section and further provided with an outer sleeve through hole along the axis. The outer sleeve through hole sequentially comprises an outer sleeve thin hole section, an outer sleeve gradually-thin section matched with the second gradually-thin section of the rivet inner sleeve, and an outer sleeve straight hole section matched with the portion, in the rivet outer sleeve, of the inner sleeve rod section of the rivet inner sleeve. Resources can be saved, and an enough expansion diameter can be obtained at the installation blind end.

Owner:AEROSPACE PRECISION PROD INC LTD

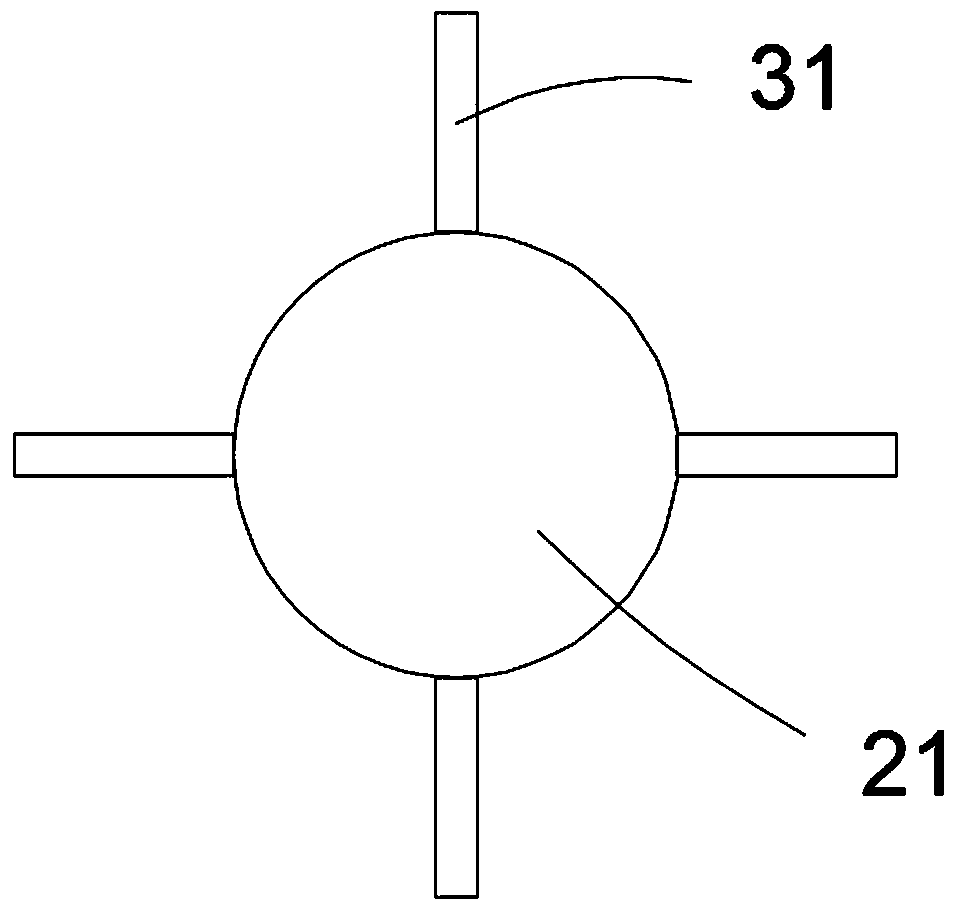

Eccenterfixed on vibrating motor

InactiveCN1540840AAvoid damageImprove riveting strengthMechanical energy handlingEngineeringVibration motor

Owner:SHICOH MOTOR (SHANGHAI) CO LTD

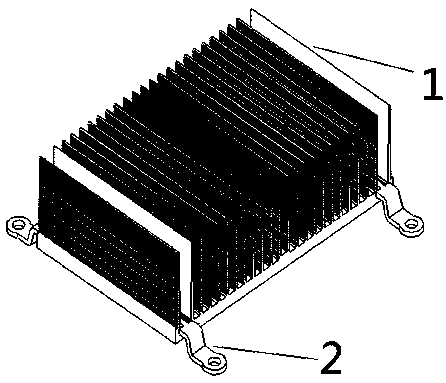

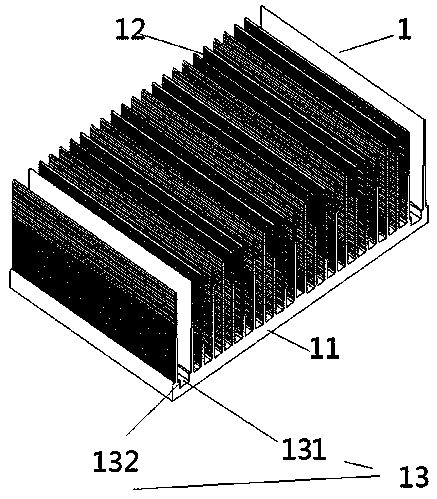

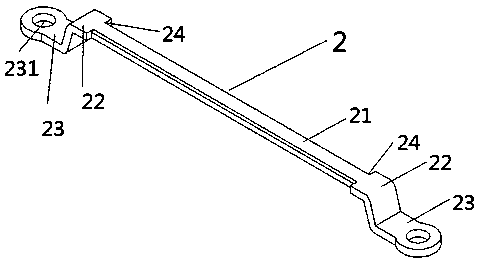

A heat sink with a riveting structure and a riveting process thereof

PendingCN109195408AImprove riveting strengthStrong enduranceModifications by conduction heat transferHeat exchange apparatusEngineeringFixed position

The invention discloses a heat sink with a riveting structure, comprising a heat sink body and a bracket, wherein the heat sink body comprises a base and a plurality of heat sink fins, wherein the heat sink fins are parallel to each other and are arranged on the base at intervals; Forming a groove body between the outermost adjacent heat dissipation fins. The bracket comprises a fixed position, two bending positions and two mounting positions, wherein the fixed position is in the shape of a strip, the bending positions are respectively located at both ends of the fixed position, and the mounting positions are respectively located at the outside of the bending position. The fixing position is riveted in the groove body. The invention also discloses a riveting process of the radiator, whichis simple in riveting process, compact in structure and high in heat dissipation effect.

Owner:THERMAL GROUP TECH HUIZHOU

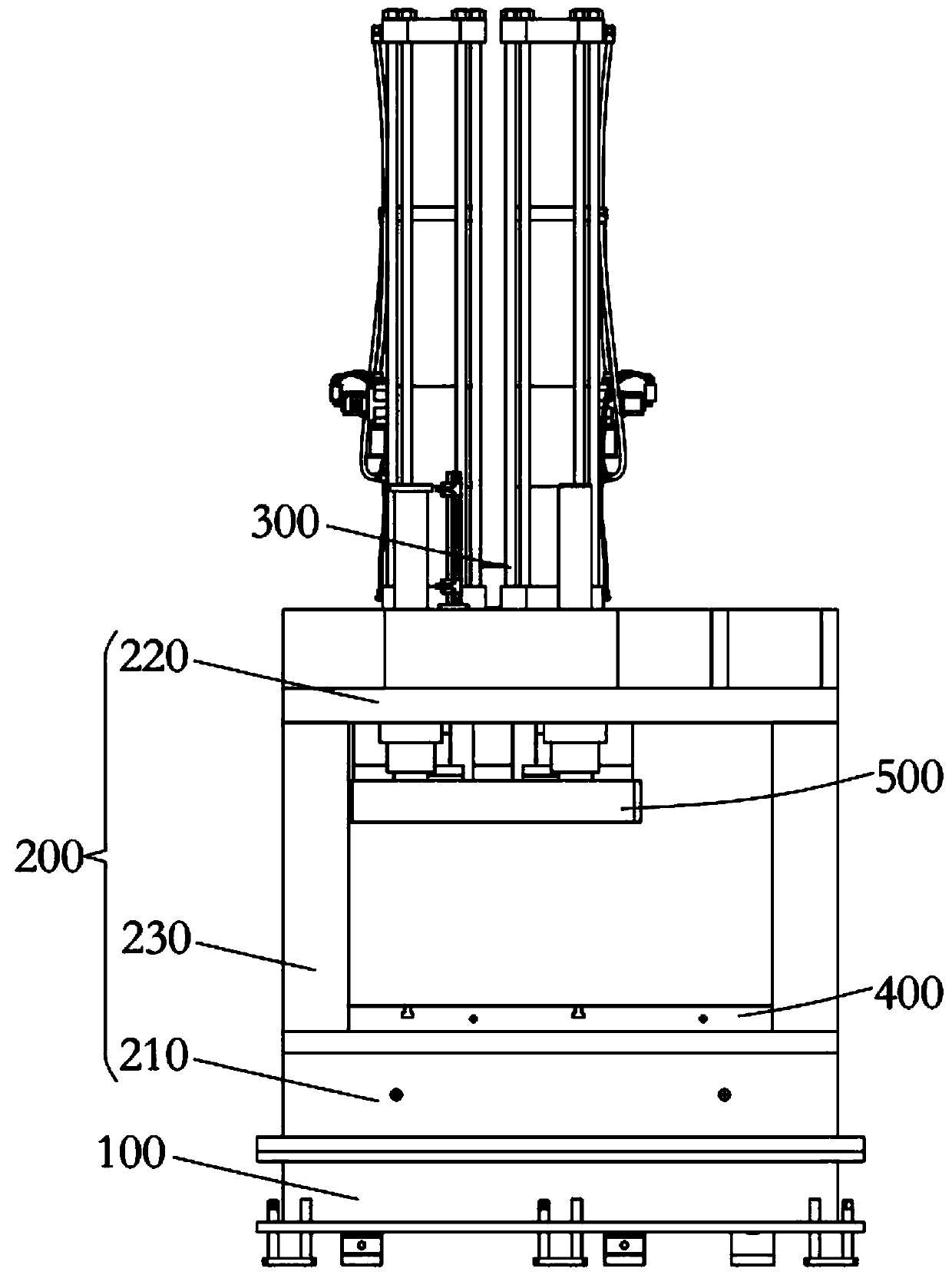

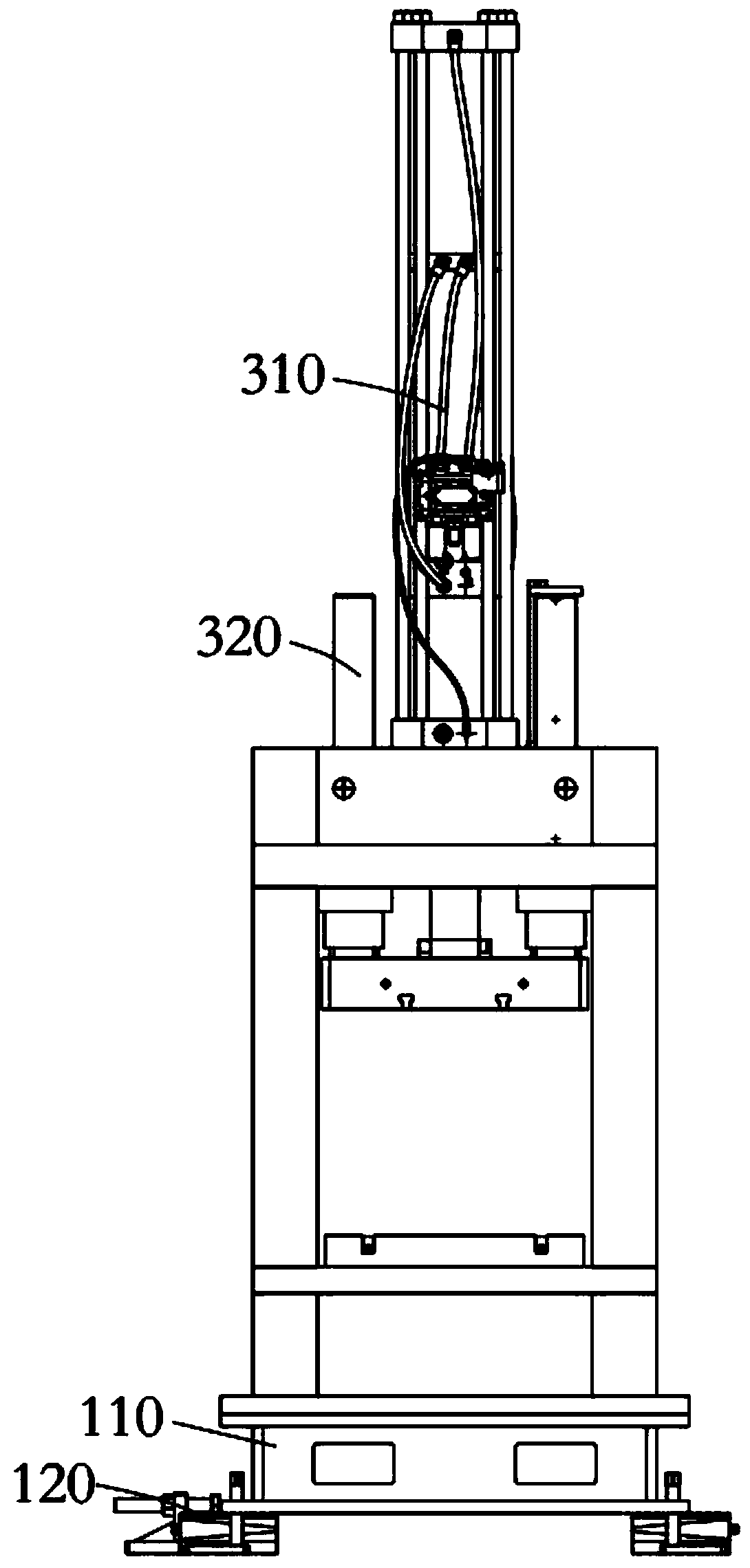

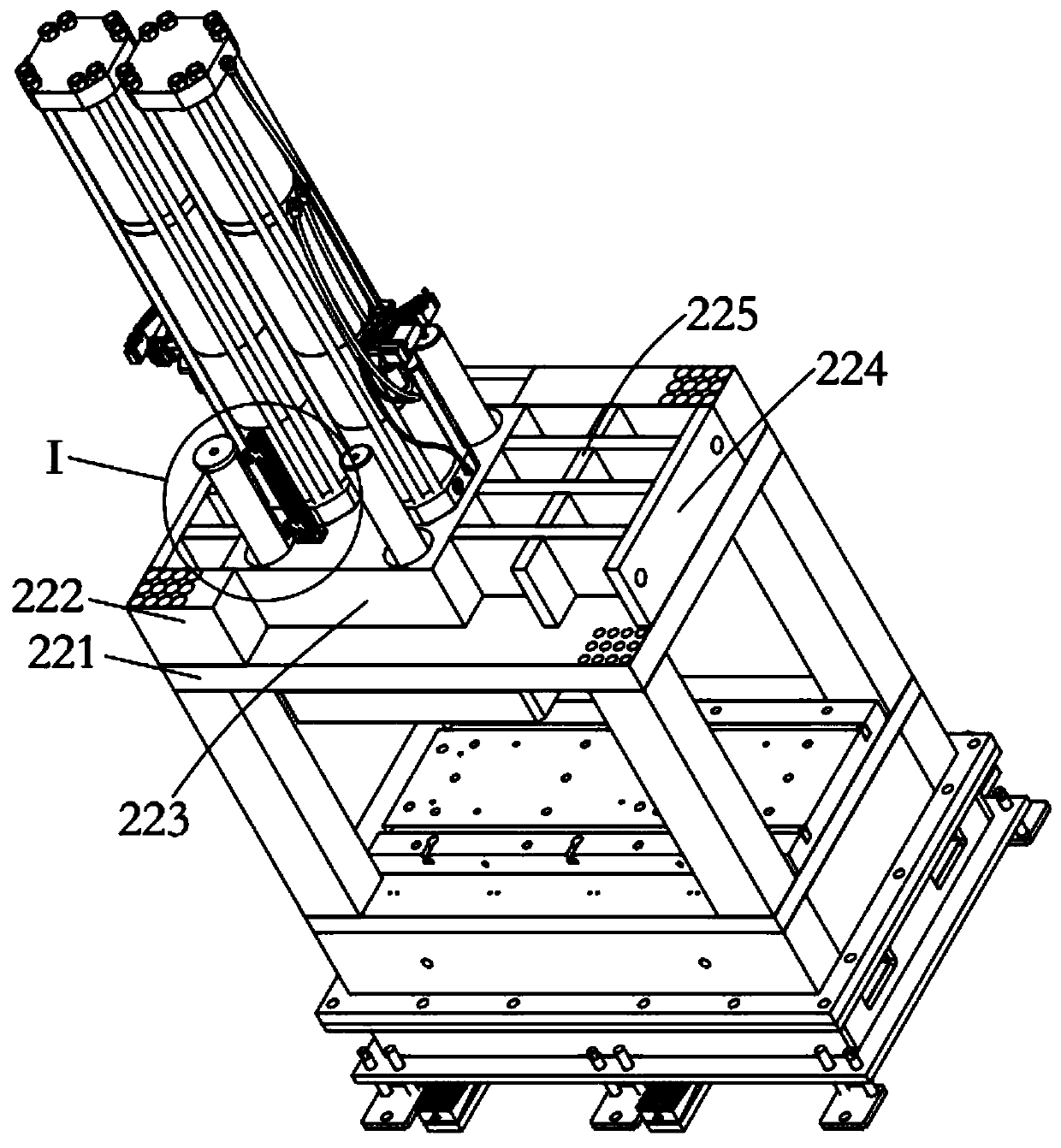

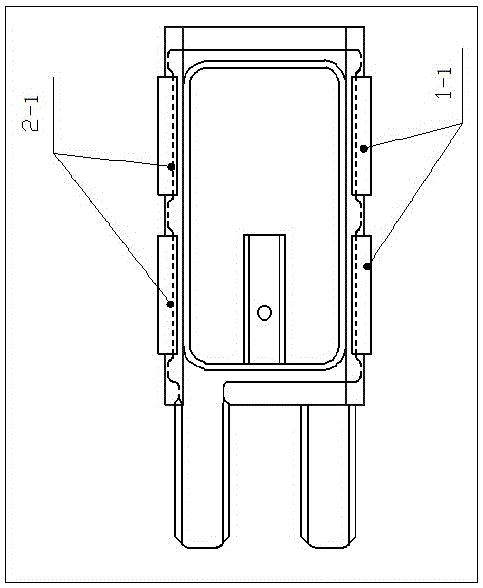

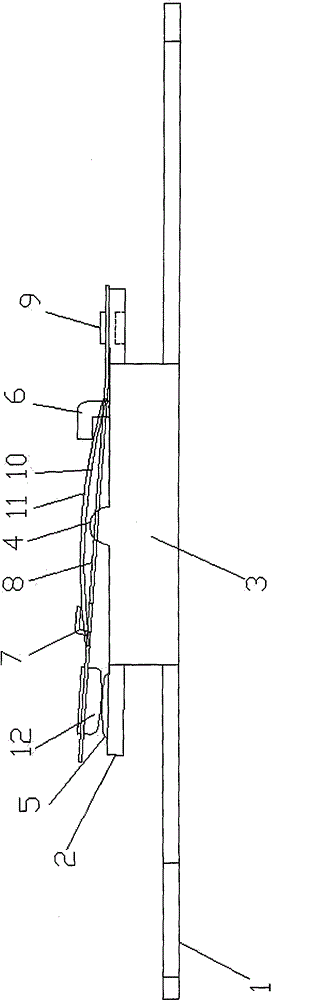

Dual-drive riveting machine

The invention discloses a dual-drive riveting machine comprising a horizontally arranged support seat, a rack fixed on the support seat, and a driving device fixed on the rack. The rack comprises a lower table face and an upper table face which are arranged in a spaced mode. The driving device is fixed to the top end of the upper table face. The bottom end of the lower table face is fixed to the support seat. The upper table face is arranged over the lower table face through support columns. The top face of the lower table face is provided with a lower template. An upper template capable of moving up and down is arranged below the upper table face. The driving device comprises two pressure cylinders arranged in parallel. The tail ends of piston rods of the two pressure cylinders penetrate through the upper table face and are connected to the upper template at the same time. The dual-drive riveting machine is simple in structure, the two pressure cylinders are utilized as the driving device, riveting force is improved, and the application range of the riveting machine is widened.

Owner:SUZHOU SIMITCH MASCH CO LTD

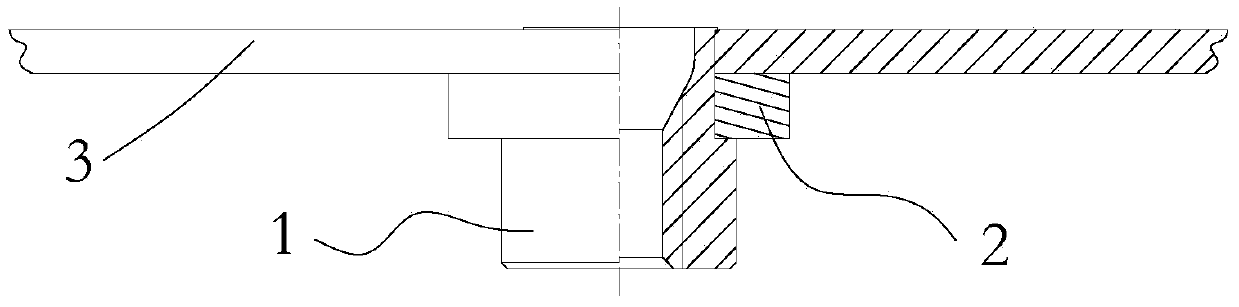

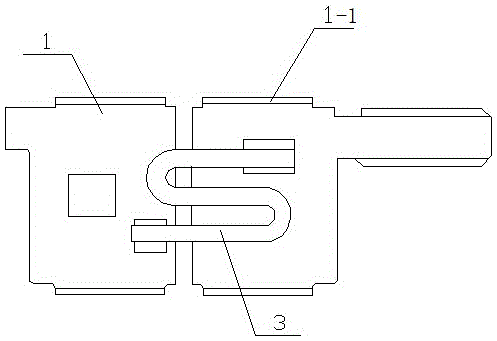

Riveting die used for ball head rivet and sheet metal part

The invention relates to a riveting die used for a ball head rivet and a sheet metal part. The riveting die comprises an upper die and a lower die. A riveting punch used for pressing the ball head rivet and the sheet metal part for achieving riveting is arranged on the lower surface of the upper die. A clamping block assembly used for clamping and placing the ball head rivet and the sheet metal part is machined on the upper surface of the lower die. The clamping block assembly comprises a static clamping block and a movable clamping block which are in butt joint and are matched to form a riveting cavity matched with the ball head rivet and the sheet metal part. A guide hole is formed in the lower die in the horizontal direction, and a push rod moving along the guide hole is installed in the guide hole. One end of the push rod stretches out of the lower die, and the other end of the push rod is connected with the movable clamping block and drives the movable clamping block to move on the lower die. Compared with the prior art, the contact area between the ball head rivet and the clamping block assembly is large, during riveting punching, the ball head deformation of the ball head rivet is small, the size is stable, the riveting strength is also greatly improved, and the ejecting force and torsion are improved, are stable and the like.

Owner:SHANDONG AOLIN CAR FITTINGS

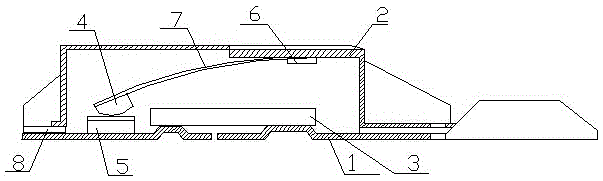

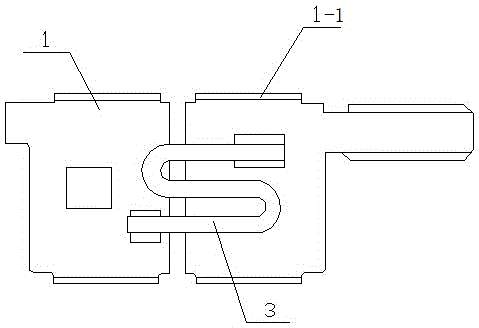

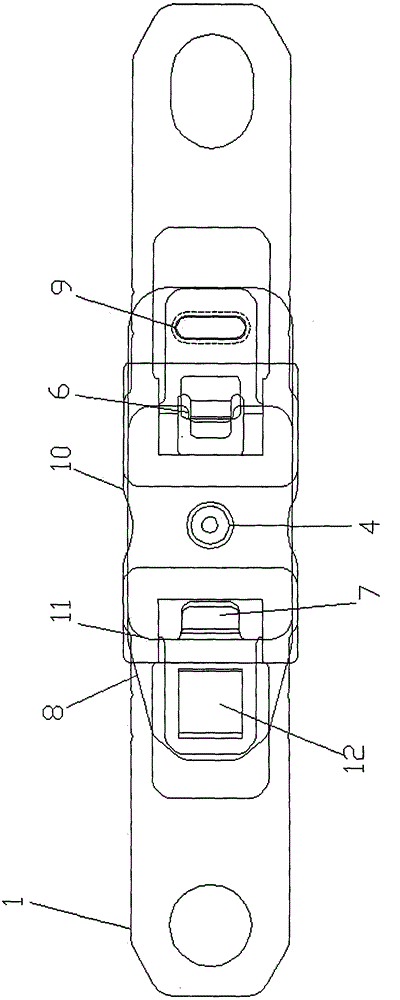

Small high-efficiency overcurrent and overheat protector

InactiveCN106504945AImprove riveting strengthSimple structureThermal switch detailsOvercurrentPulp and paper industry

The invention discloses a small high-efficiency overcurrent and overheat protector, and relates to the technical field of design of overcurrent and overheat protectors for home appliance motors such as an automobile, a vacuum cleaner and a soya bean milk machine. The small high-efficiency overcurrent and overheat protector comprises two bottom boards, a shell, a heating wire, a moving contact, a static contact, a fixing board, a bimetallic strip, and an insulating paper, wherein the two bottom boards are connected through the heating wire; the shell is arranged above the two bottom boards; the static contact is arranged above one bottom board; the moving contact is arranged at one end of the bimetallic strip and is arranged above the static contact in an opening and closing mode; the other end of the bimetallic strip is connected with the inner top of the shell via the fixing board; the insulating paper is arranged between the two bottom boards and the shell; and edges at two sides of the shell are provided with limiting grooves respectively, two sides of the two bottom boards are provided with riveting lugs matched with the limiting grooves, and the riveting lugs are clamped in the corresponding limiting grooves respectively. As two sides of the shell are provided with the limiting grooves, the riveting lugs of the bottom boards are just clamped in the corresponding limiting grooves in the case of assembly, and thus, the riveting strength between the shell and the bottom boards is enhanced.

Owner:YANGZHOU BAOZHU ELECTRIC APPLIANCE CO LTD

Reinforced precision cast brake shoe assembly

PendingCN107387606AIncrease stiffnessExtended service lifeBraking membersFriction liningClassical mechanicsEngineering

A reinforced precision cast brake shoe assembly is formed by connection of an arc shoe panel and two shoe rib plates in parallel arrangement on the inner arc surface of the shoe panel. The inner surface of the shoe panel is peripherally provided with a first reinforcement rib in a full-surrounded structure, and a plurality of groups of second reinforcement ribs perpendicular to the shoe rib plates are arranged on the inner side of the first reinforcement rib and positioned on the inner surfaces of the shoe rib plates. The inner surface of each shoe rib plate is provided with a plurality of rivet holes parallel to the center line of the corresponding shoe rib plate, and the inner surface of each shoe rib plate is provided with two rows of rivet holes in staggered distribution on two sides of the corresponding shoe rib plate. Due to addition of a row of the rivet holes in the middle of a shoe, integral riveting strength of a friction plate and a brake shoe is improved, a riveting gap is reduced, and the service life of the friction plate on the brake shoe is prolonged while braking effects are improved. By appropriate reduction of wall thickness at the riveting joint of the brake shoe and the friction plate, the integral weight of the brake shoe is reduced, and heat radiation effects of a whole product are improved.

Owner:JIANGSU SANZHI BRAKES CO LTD

Delay reset current sensitive type thermal protector

InactiveCN106504944AImprove riveting strengthSimple structureThermal switch detailsMetal sheetHeat sensitive

The invention discloses a delay reset current sensitive type thermal protector, and relates to the design technical field of the delay reset current sensitive type thermal protector with temperature and current control and protection functions and applied to motors of domestic appliances, such as a dust collector, a soybean milk machine, a juicer and the like. The delay reset current sensitive type thermal protector comprises two bottom plates, a shell, heating wires, a movable contact, a static contact, a fixed plate, a dual-metal sheet and insulating paper, wherein limiting grooves are formed in the two side edges of the shell respectively; riveting ears matched with the limiting grooves are arranged on the two sides of the two bottom plates respectively; the riveting ears are clamped in the corresponding limiting grooves respectively; a thermal sensitive ceramic sheet is arranged on the external top of the shell; and the thermal sensitive ceramic sheet is fixed on the shell through a spring clamp. The delay reset current sensitive type thermal protector is high in sensitivity, installation stability and safety, and capable of satisfying use requirements in a variety of fields.

Owner:YANGZHOU BAOZHU ELECTRIC APPLIANCE CO LTD

Backpack-type thermal protector

InactiveCN104576195AWell positionedContact stabilityThermal switch detailsTemperature senseEngineering

The invention discloses a backpack-type thermal protector which comprises a base. The base comprises an upper base body, a lower base body and a base injection molding part, a base supporting point is arranged in the middle of an upper end surface of the upper base body, a static contact is arranged on one side of the upper end surface of the upper base body, a movable contact piece is arranged on the upper base body, a movable contact corresponding to the static contact is arranged on one side of a lower end surface of the movable contact piece, the other end of the movable contact piece is fixed by a rectangular boss stretching out from the upper end surface of the upper base body, a base clamp is vertically and fixedly arranged between the rectangular boss and the base supporting point, the upper part of the base clamp extends out of the upper end surface of the upper base body and penetrates through the movable contact piece, and the lower part of the base clamp extends to the lower base body; an elastic piece clamp is arranged on an upper end surface of the movable contact piece between the movable contact and the base supporting point, a temperature sensing piece and an elastic piece are arranged above the movable contact piece between the elastic piece clamp and the base clamp, the elastic piece is arranged above the temperature sensing piece, and two sides of the elastic piece and two sides of the temperature sensing piece are clamped and connected to the insides of the base clamp and the elastic piece clamp respectively. The backpack-type thermal protector is stable in structure and convenient to assemble.

Owner:何春武

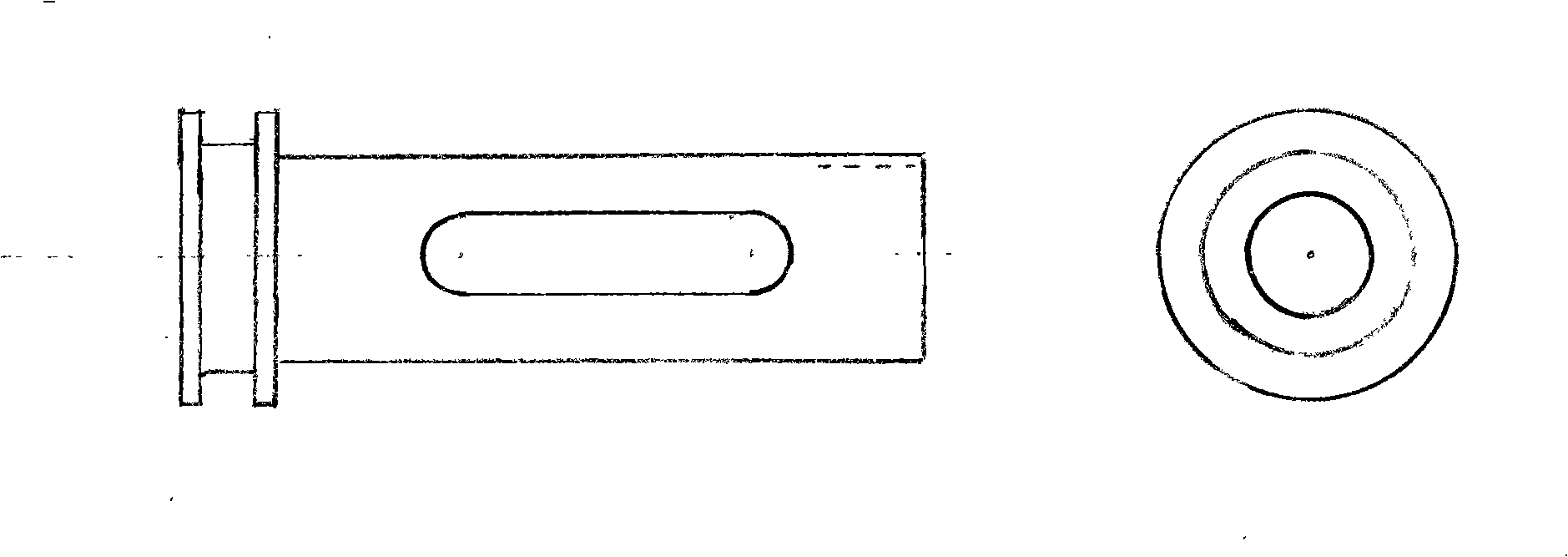

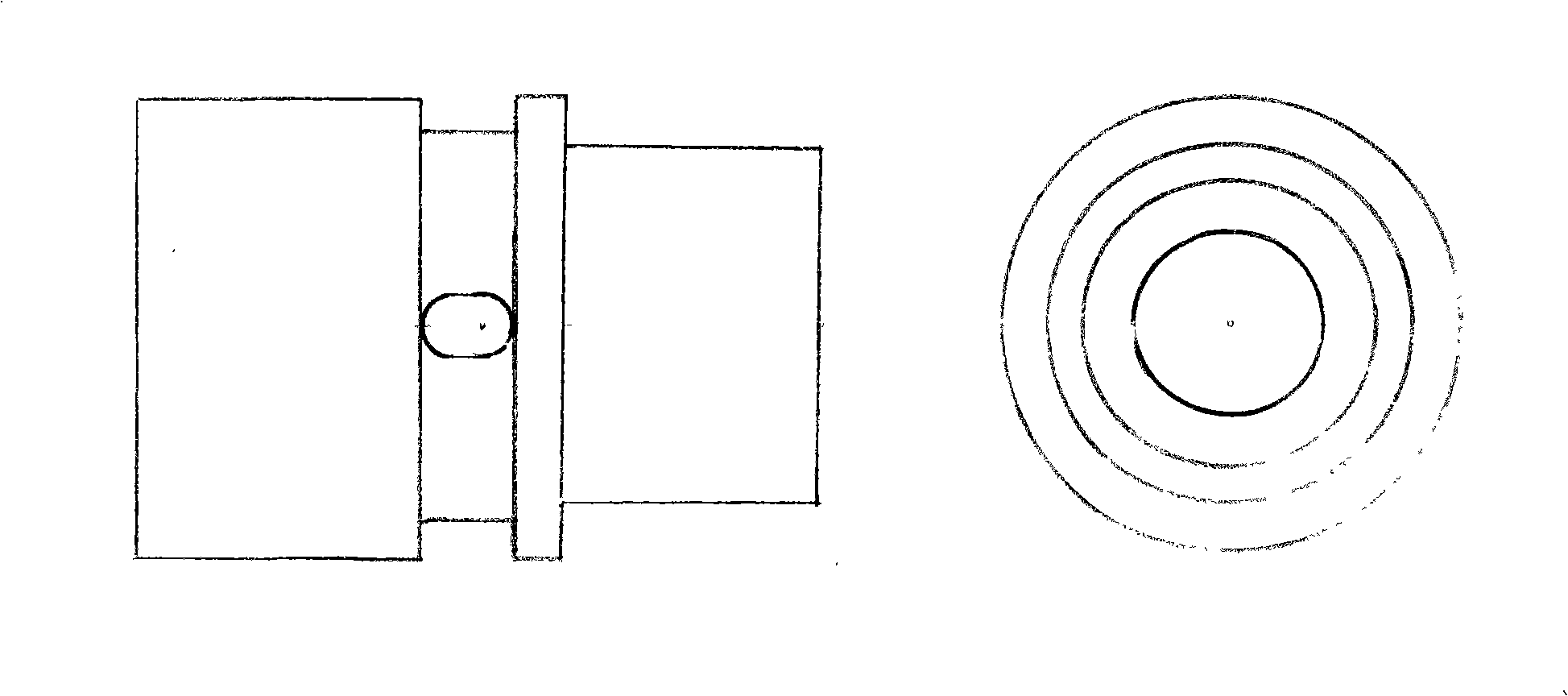

Hot riveting rod for hot riveting machine

The invention discloses a hot riveting rod for a hot riveting machine. The hot riveting rod for the hot riveting machine comprises a riveting rod body, wherein one end of the riveting rod body is provided with a hot riveting head, and the other end of the riveting rod body is connected onto a riveting rod supporting column; the riveting rod body is made of a stainless steel material, and a waist-shaped groove is arranged on the riveting rod supporting column; and the hot riveting head is in a mushroom shape, and is made of beryllium copper. According to the hot riveting rod for the hot riveting machine provided by the scheme of the invention, the heat insulation effect of the riveting rod body is added, so that the heat of a heating tube is mostly concentrated on the hot riveting head, the hot riveting head is heated faster and the temperature is more stable, the riveting strength of the hot riveting machine is increased, the cost is reduced, the smooth appearance of riveting points is ensured, the shape is stable, and the welding strength is high.

Owner:SUZHOU KEBER PRECISION MACHINERY

On-line cold bending steel fast punching and riveting mold and its punching and riveting method

The present invention provides on-line cold bent steel fast punching and riveting mold and method, and belongs to the field of plastic forming technology for metal. The punching and riveting mold includes two parts, the upper and the lower molds, guided with guide column and guide sleeve, the male punching and riveting mold with holder on its one side and the female punching and riveting mold are fixed onto the left block and the right block of the lower mold, and the male punching and riveting mold and the female punching and riveting mold are shifted horizontally by means of one inclined wedge and the left block and the right block. The cold bent shaped steel are punched and riveted by means of the hydraulic cylinder and the punching and riveting mold. The shaped steel is located precisely so as to realize the fast on-line fast punching and riveting. The present invention has the advantages of simultaneous connection of several points, high punching and riveting quality, long mold life, etc.

Owner:UNIV OF SCI & TECH BEIJING

Hot riveting rod for hot riveting machine

The invention discloses a hot riveting rod for a hot riveting machine. The hot riveting rod for the hot riveting machine comprises a riveting rod body, wherein one end of the riveting rod body is provided with a hot riveting head, and the other end of the riveting rod body is connected onto a riveting rod supporting column; the riveting rod body is made of a stainless steel material, and a waist-shaped groove is arranged on the riveting rod supporting column; and the hot riveting head is in a mushroom shape, and is made of beryllium copper. According to the hot riveting rod for the hot riveting machine provided by the scheme of the invention, the heat insulation effect of the riveting rod body is added, so that the heat of a heating tube is mostly concentrated on the hot riveting head, the hot riveting head is heated faster and the temperature is more stable, the riveting strength of the hot riveting machine is increased, the cost is reduced, the smooth appearance of riveting points is ensured, the shape is stable, and the welding strength is high.

Owner:SUZHOU KEBER PRECISION MACHINERY

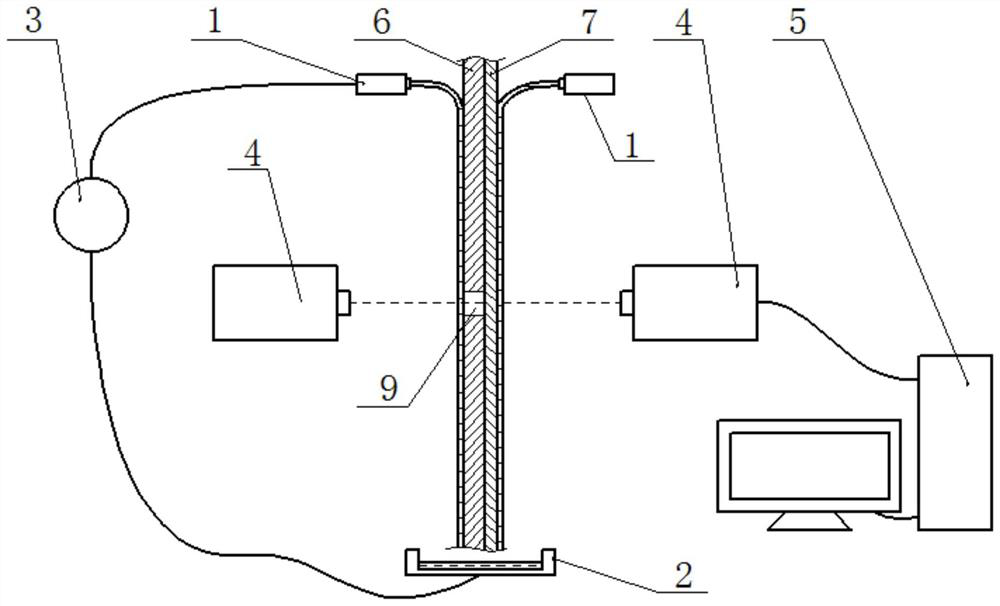

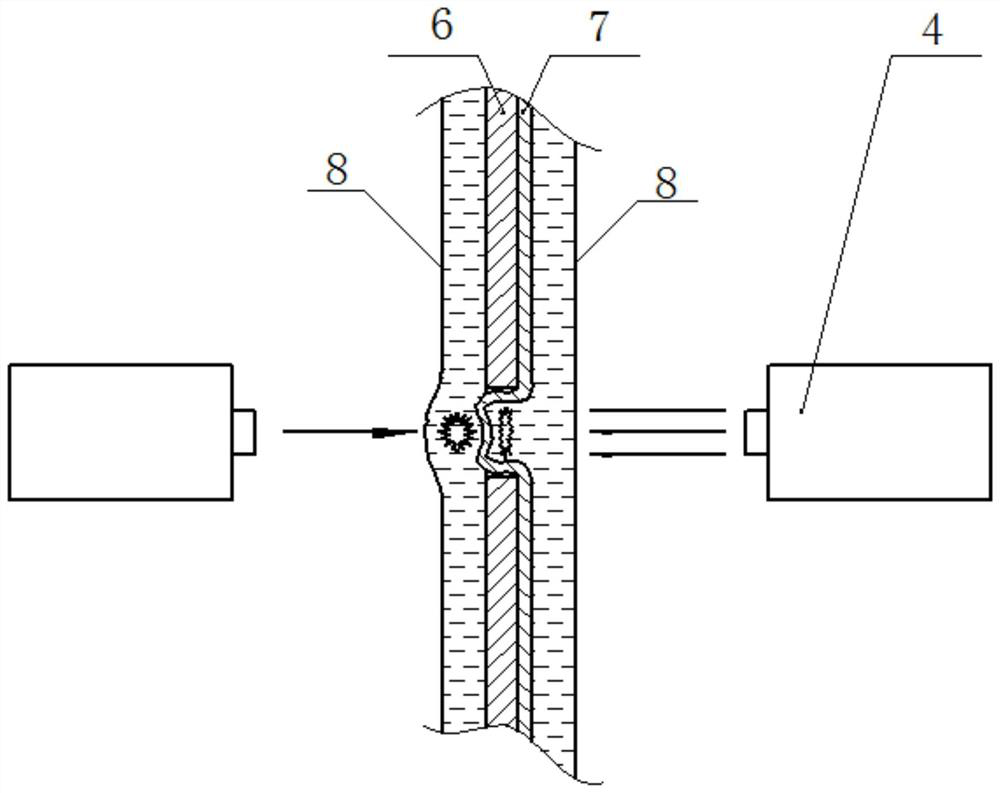

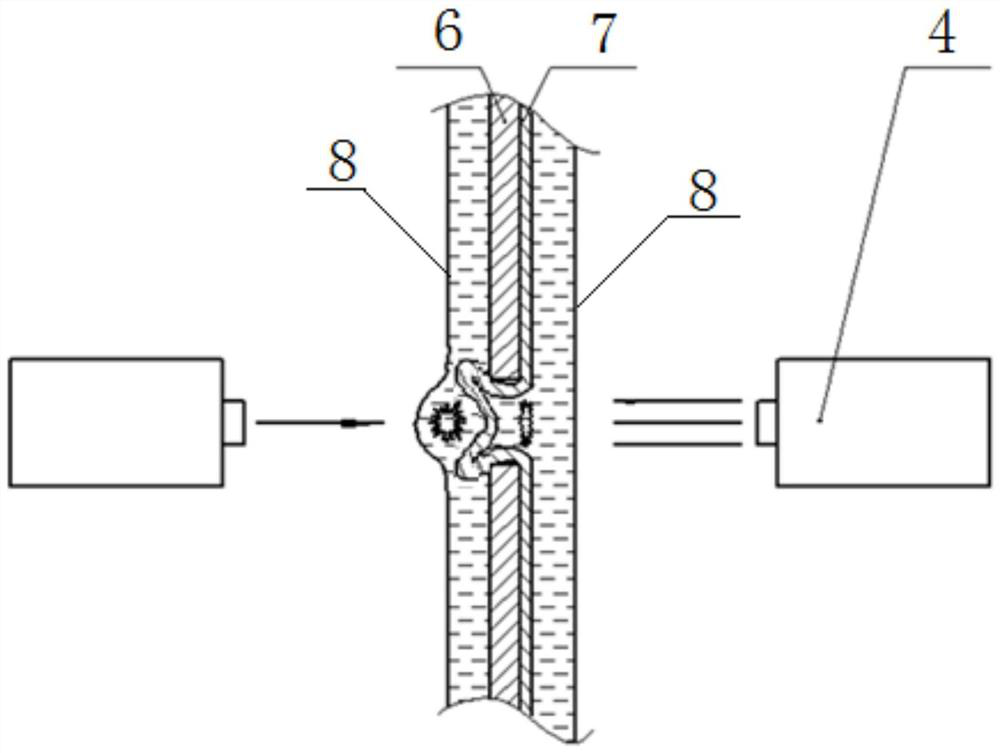

Laser butt riveting method and device for ultra-thin plates

ActiveCN110948108BStrong rivetingStrong riveted structureWelding/soldering/cutting articlesMetal working apparatusComputer terminalErbium lasers

The invention relates to the technical field of ultrathin plate riveting, in particular to a laser opposite impacting and riveting method and device for ultrathin plates. The device comprises a watercurtain generator, a water tank, a water pump, pulse laser devices and a computer terminal. The water curtain generator is mounted above the water tank, and the water pump is arranged on a connectingpipeline between the water curtain generator and the water tank, so that water in the water tank is cyclically utilized. The two pulse laser devices are symmetrically arranged on the left side and theright side of a water curtain formed by the water curtain generator. The computer terminal is used for controlling the pulse laser devices. By means of the method, lasers are emitted from the left side and the right side at the same time to impact the plate on the right side, the deformation mode of traditional laser impacting forming is changed, plate deformation is increased, then the embeddedamount of the interlocking structure is increased, the rivet-buckling structure is optimized, the connecting strength of riveted positions is improved, and forming efficiency is high.

Owner:SHANDONG UNIV

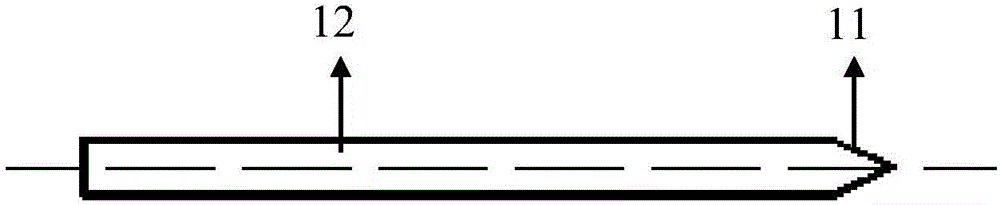

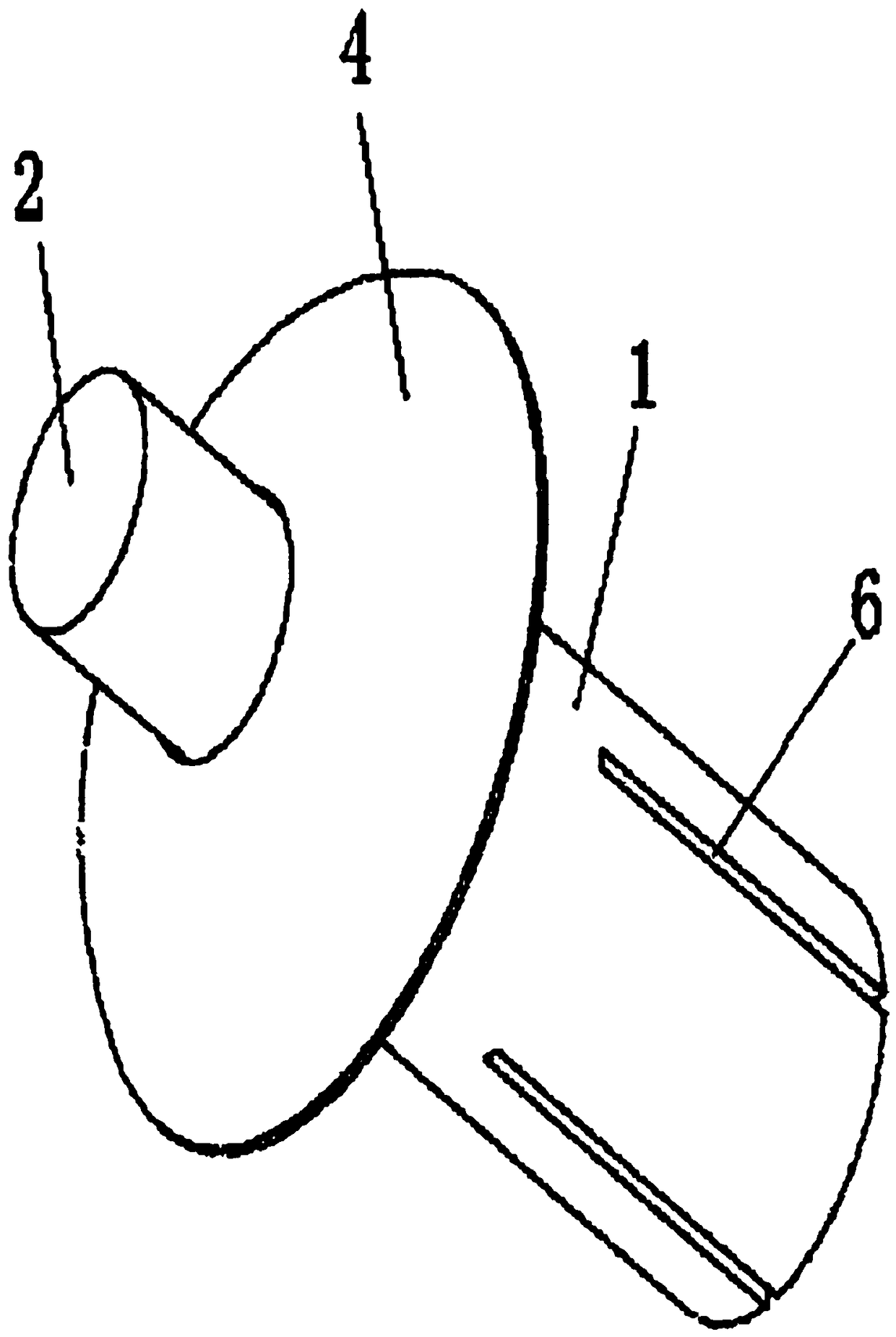

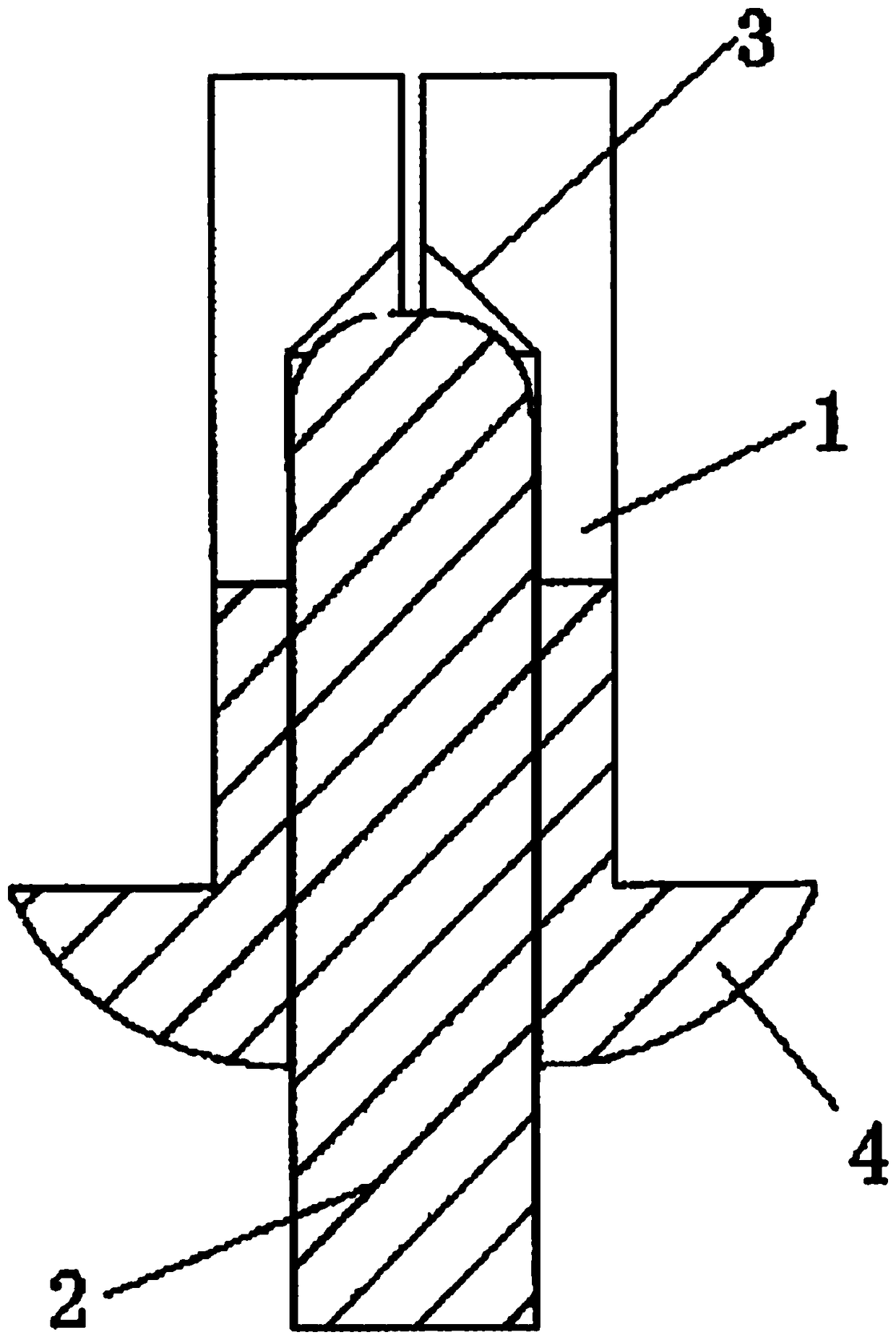

Drive rivet

A drive rivet comprises a pipe cap; cracks are formed in the pipe cap; the pipe cap comprises an inserting cavity; a rivet core is inserted in the inserting cavity; and the bottom surface of the inserting cavity is in the conical shape with the conical tip facing outwards. The bottom surface of the inserting cavity is in the conical shape with the conical tip facing outwards, so that when the rivet core is struck, the acting force of the rivet core on the pipe cap is very large, the pipe cap can be blasted enough, and the riveting strength can be enhanced.

Owner:陈业国

An internal riveting die for hydraulic clutch bearing gland

Owner:NINGBO HONGXIE CLUTCH

A method and device for improving the connection strength of laser shock riveting

The invention discloses a method and device for improving the laser shock riveting forming connecting strength. The method includes the following main steps that firstly, a resin mixture and a curingagent are mixed according to a certain proportion, and a formed pasty mixture serves as a filling material; afterwards, a central controller controls a laser device to transmit laser beams, the laserbeams are transmitted to a worktable through a light guide arm and a focus head to excite an adsorption layer material to be plasma shock waves to shock an upper layer plate, and a hollow riveting structure is formed by the upper layer plate and a trepanned lower layer plate under the constraint of a lower female die; and the central controller adjusts a peristaltic pump to extrude the filling material so that the filling material can be injected into the hollow riveting structure through a material spraying nozzle, after the filling material is solidified, hollow riveting becomes solid riveting, when the riveting structure is subjected to the effect of normal force and shearing force, the cured filling material can have a supporting effect on the riveting structure, and therefore the riveting connecting strength is greatly improved.

Owner:SHANDONG UNIV

Guard for securing the torsion spring at the front end of the camshaft phaser

ActiveCN106762004BSolve the problem of loosening riskReduce centrifugal forceValve arrangementsMachines/enginesEngineeringCentrifugal force

The invention relates to a shield for fixing the torsion spring at the front end of a camshaft phase adjuster, which has a shield which is pressed by stacking the tail of the rivet and riveted with the cover plate of the phaser; The clad outer ring is integrally formed in a "convex" shape, and the center of the shield is provided with an avoidance hole for easy assembly and disassembly of the central bolt; the torsion spring cover is provided with a torsion spring fixing port; the clad outer ring has a ring array There are four avoidance grooves which facilitate full threaded contact between the mounting screw and the cover plate and increase the screw tightening force, and four shield rivet holes which are concentric with the rivet holes on the cover plate of the phaser and correspond one-to-one. The present invention not only solves the problem of poor fit between the central bolt and the phaser and large leakage, but also solves the problem of difficulty in installing the torsion spring and the risk of loosening during installation and transportation of the torsion spring. At the same time, the cylindrical torsion spring The structure reduces the centrifugal force of the torsion spring and improves the service life and safety performance of the torsion spring.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

MAN rear enhanced precision double-open casting brake

A MAN rear reinforced precision double-open casting brake includes brake base plates, friction plates, and a left brake shoe and a right brake shoe which are symmetrically disposed. The friction plates are disposed on outer surfaces of the left brake shoe and the right brake shoe. The brake base plates are disposed on the same straight line and pass through front and back sides of the left brake shoe and the right brake shoe. The friction plates are disposed on the outer surfaces of the left brake shoe and the right brake shoe. Two ends of a holding spring are respectively hooked in spring holes corresponding to the left and right brake shoes. Rotating shaft ends of the brake base plates are provided with stepped double cylindrical shoe shafts. A return spring pin mechanism is disposed between reinforcing ribs of the left brake shoe and the right brake shoe. The MAN rear-reinforced precision double-open casting brake has the advantages that according to the left brake shoe and the right brake shoe, through cooperation of the U-shaped steps, the return spring pin and arc grooves, return spring shifting is prevented, and strength of the brake shoes and rigidity of the whole brake areincreased; the brake effect of the brake shoes is improved, the service lifetime of the brake shoes is prolonged, and the brake shoes are easy to disassemble and replace.

Owner:JIANGSU SANZHI BRAKES CO LTD

Feeding heating and auxiliary riveting method for riveted shaft

The invention discloses a feeding, heating and auxiliary riveting method for riveting shafts. The method comprises the steps as follows: a grabbing manipulator grabs a group of riveting shafts from a conveying belt, rotates and sends the riveting shafts to the position below a clamping and feeding device; a pushing driving device drives a pushing device to rise to push the group of riveting shafts into a group of shaft accommodating cavities; when the riveting shafts reach the set positions, a clamping driving device operates, and clamping devices clamp the riveting shafts; a telescoping driving device drives telescopic arms of heating devices to extend, and heating ends make contact with riveting parts of the riveting shafts for heating; a feeding driving device operates, the clamping and feeding device moves to the position below to-be-machined sheet metal at a riveting station; and the feeding driving device operates continuously, and the clamping and feeding device drives the group of riveting shafts to be embedded in corresponding riveting holes. The production efficiency and the automation degree of production are increased; fine adjustment of the perpendicularity is performed while the shafts are clamped, and the riveting precision is guaranteed; riveting is performed after heating, and thus the riveting precision and strength are enhanced.

Owner:太仓市华天冲压五金制品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com