Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Improve riveting precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

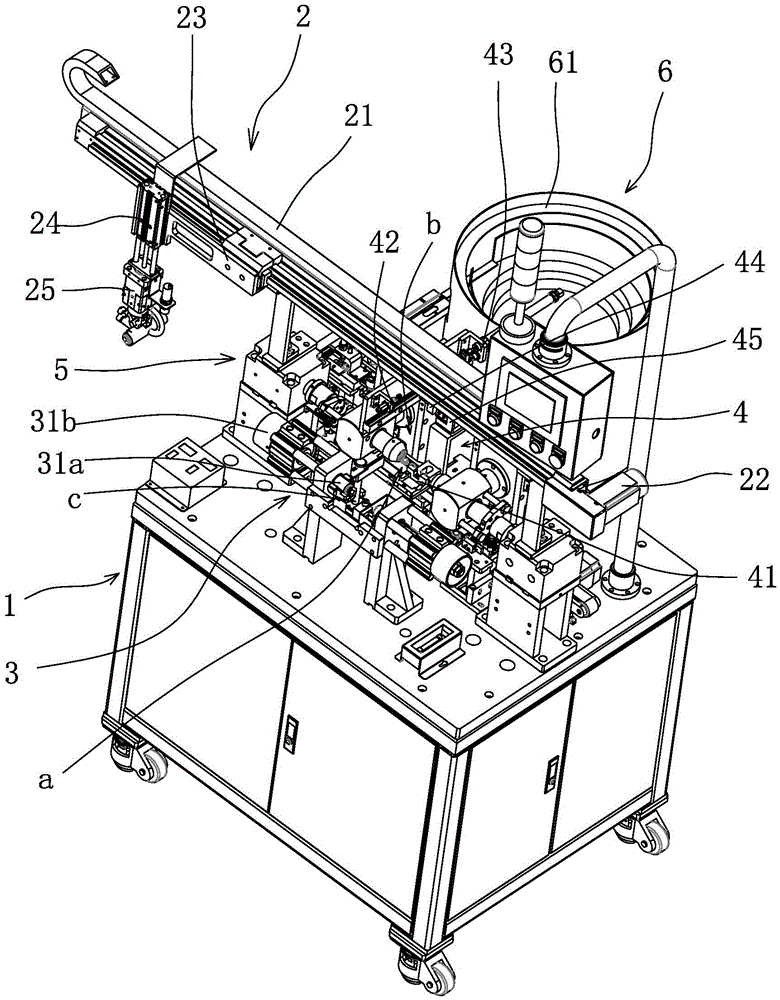

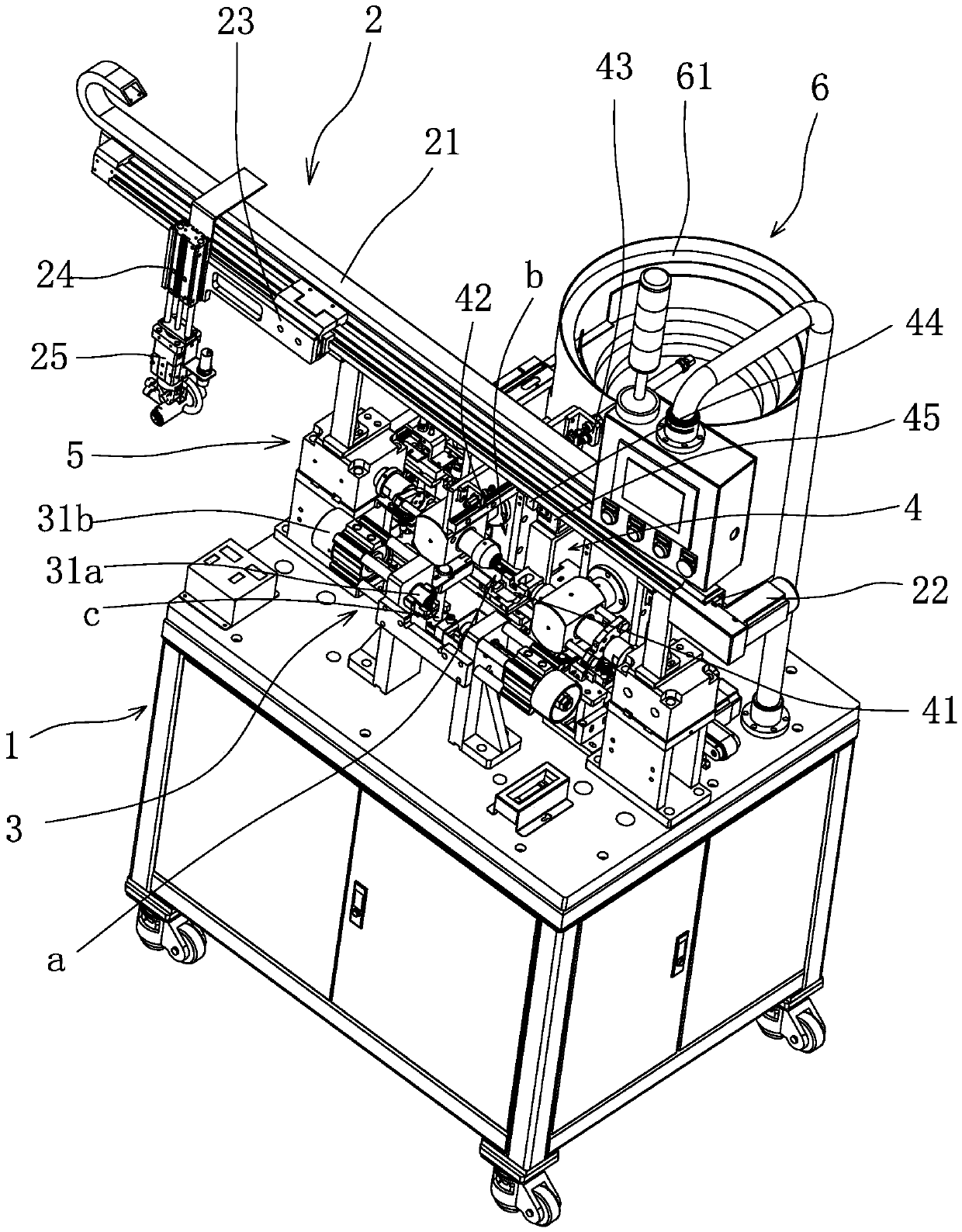

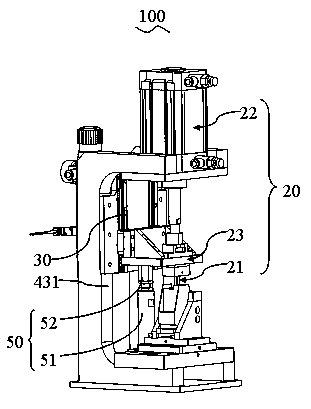

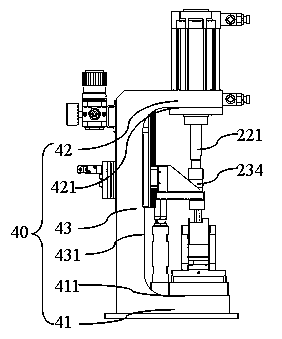

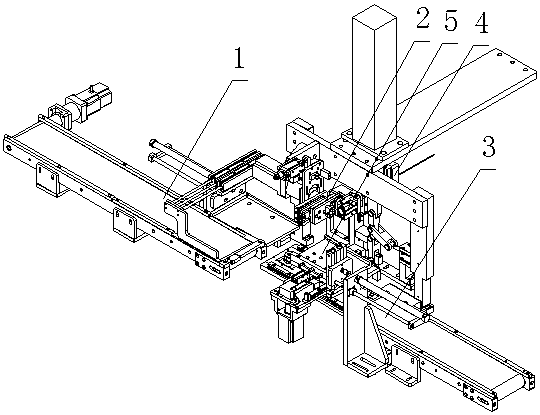

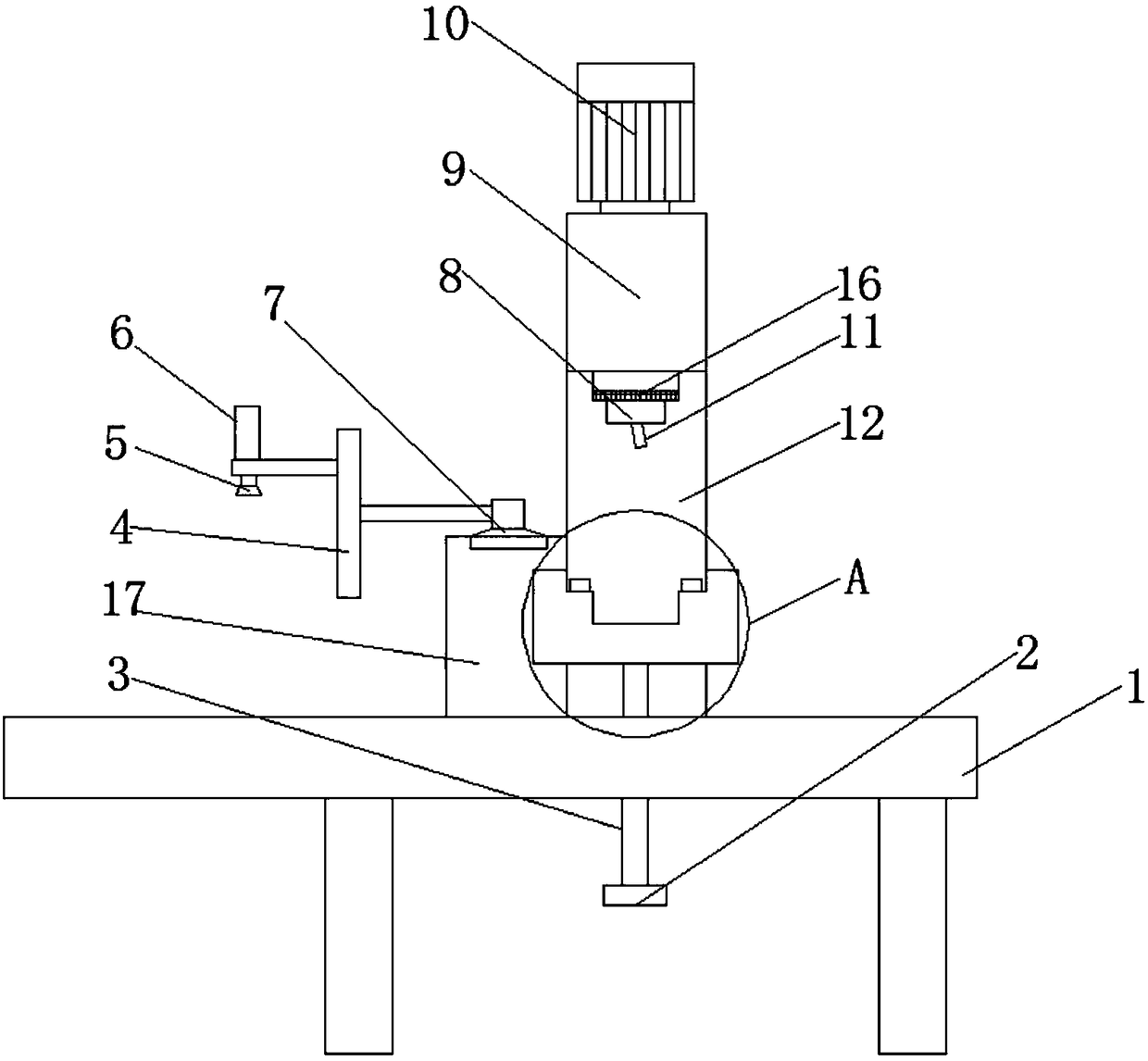

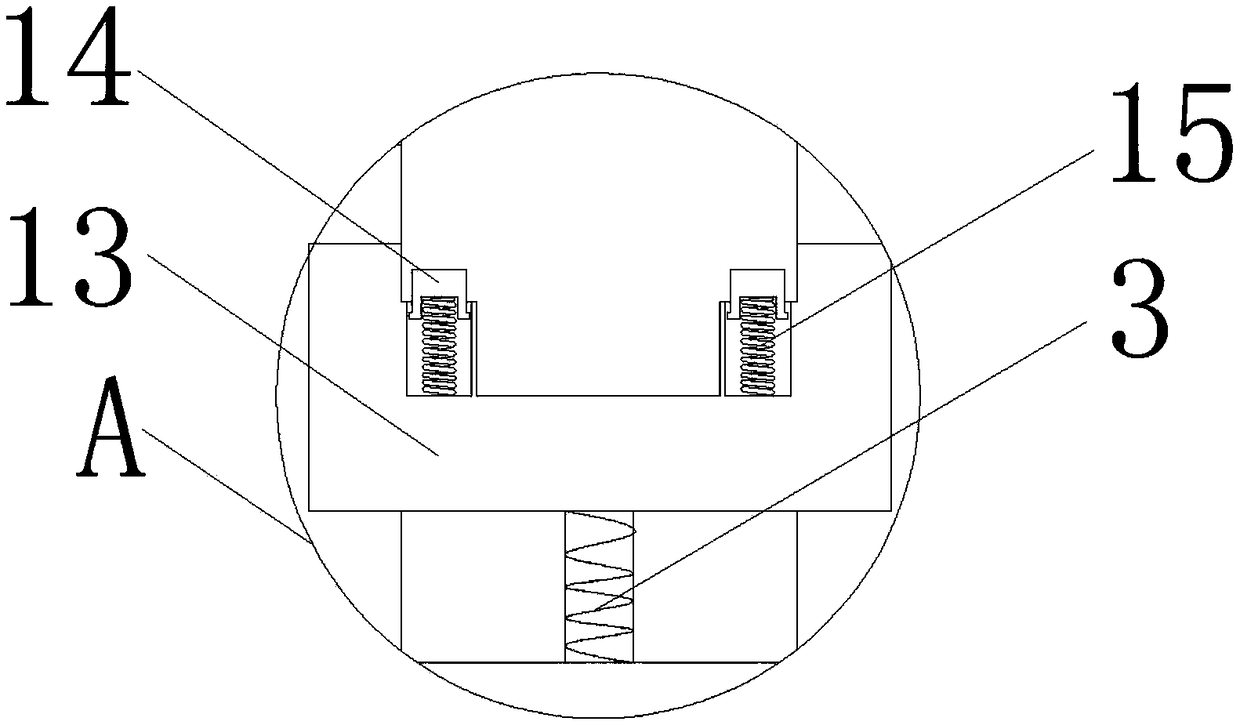

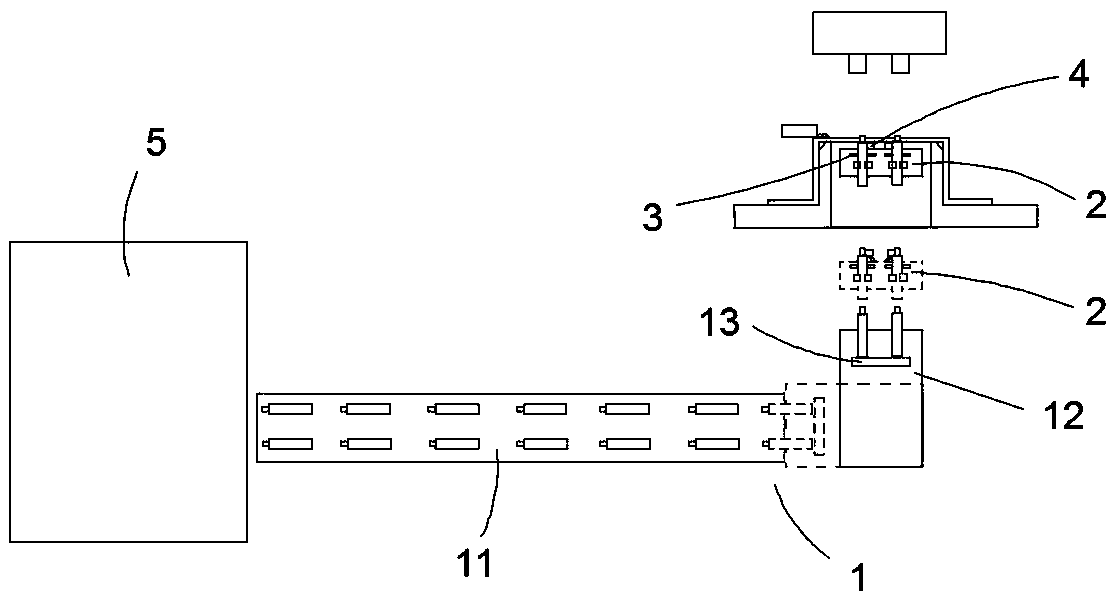

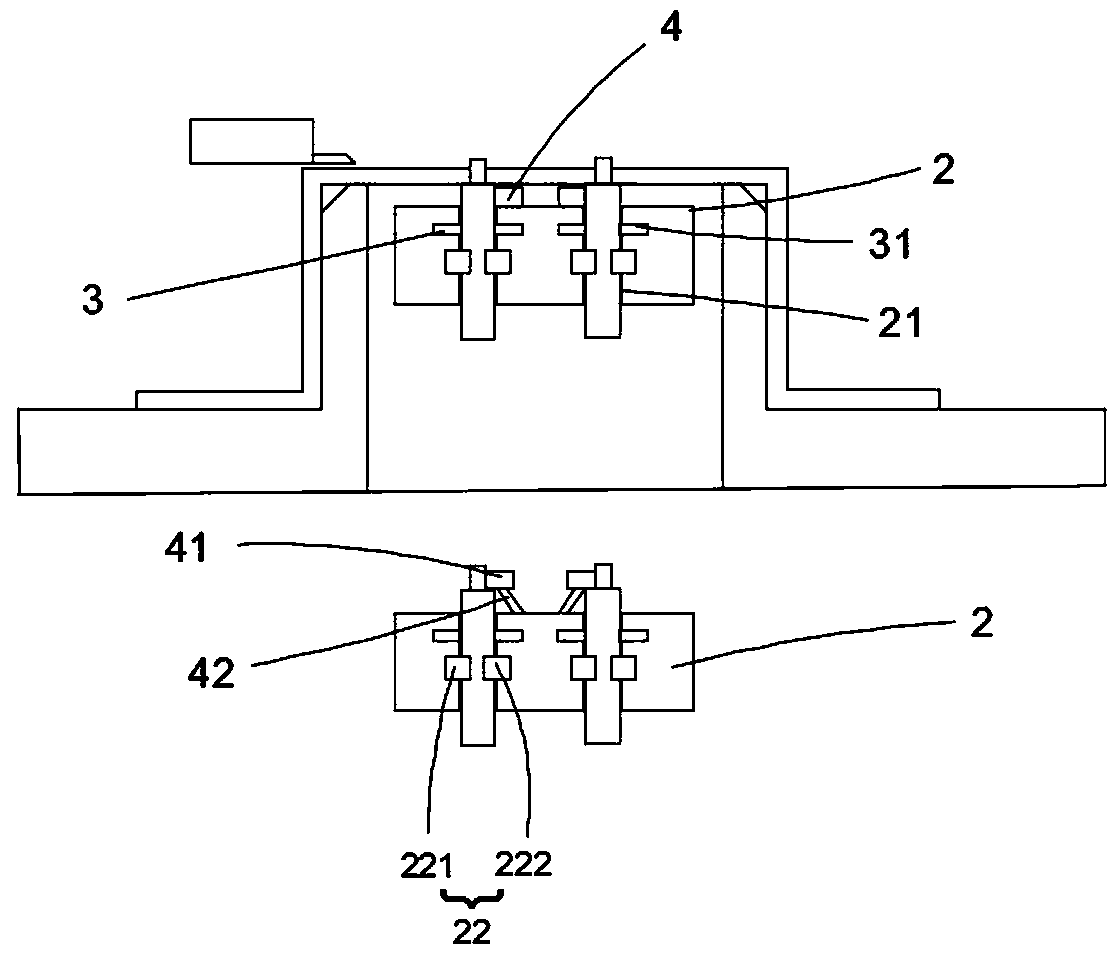

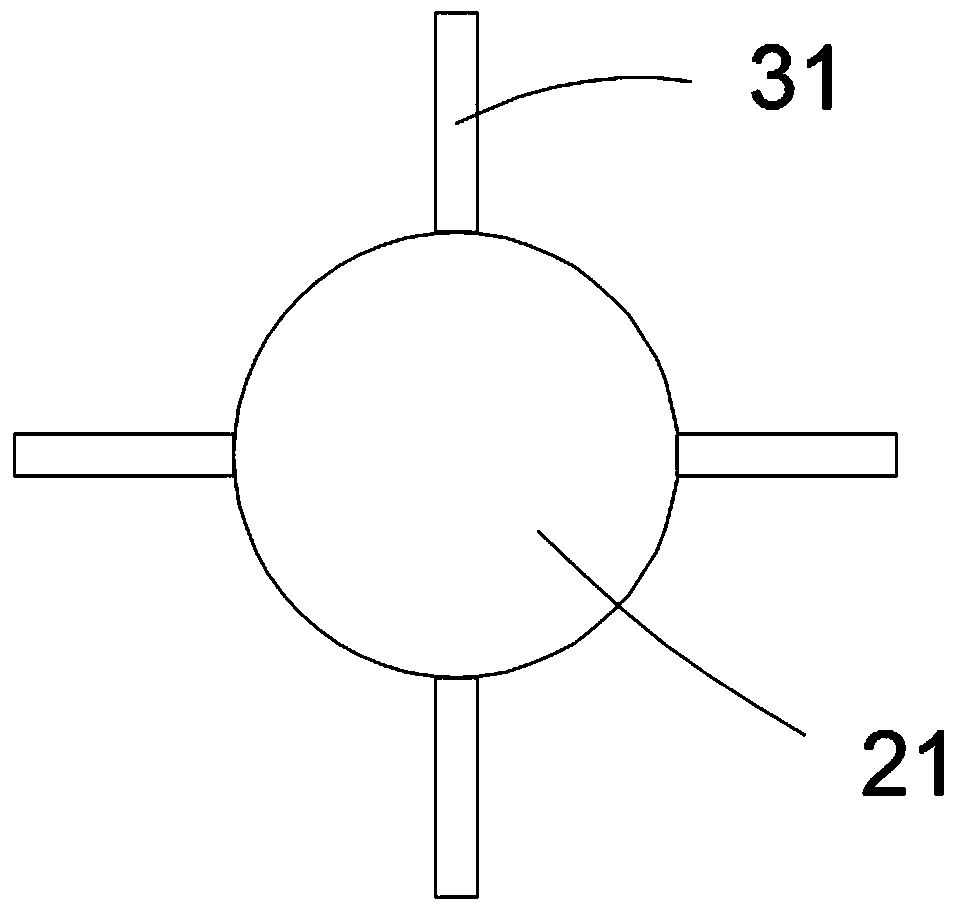

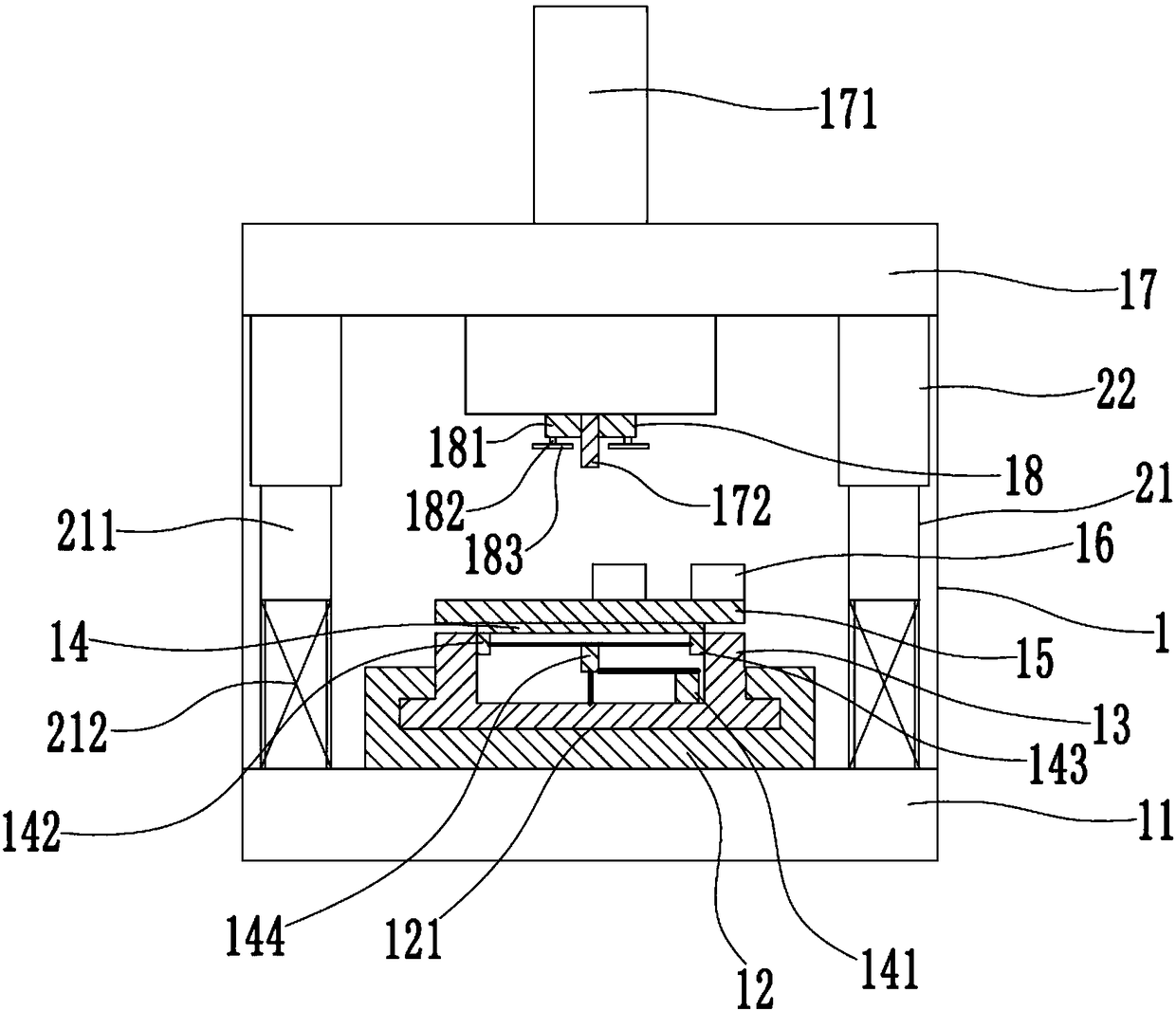

Riveting machine for end cap of four-way pipe

ActiveCN105619050AImprove work efficiencyImprove riveting precisionMetal working apparatusMechanical engineeringRiveting machines

The invention provides a riveting machine for an end cap of a four-way pipe. The riveting machine comprises a machine base and is characterized in that a first feed mechanism used for conveying the four-way pipe is arranged on the machine base; the first feed mechanism conveys the four-way pipe to a shaping mechanism for end opening shaping, and the four-way pipe subjected to end opening shaping is conveyed to a riveting station through a supporting mechanism; the riveting station is provided with a feed riveting mechanism; the feed riveting mechanism can suck up the end cap conveyed to a feed station through a second feed mechanism and rivet the end cap to the four-way pipe; and the feed station is provided with a detection device capable of adjusting the placing angle of the end cap. The riveting machine has the advantages of being high in production efficiency and riveting quality.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

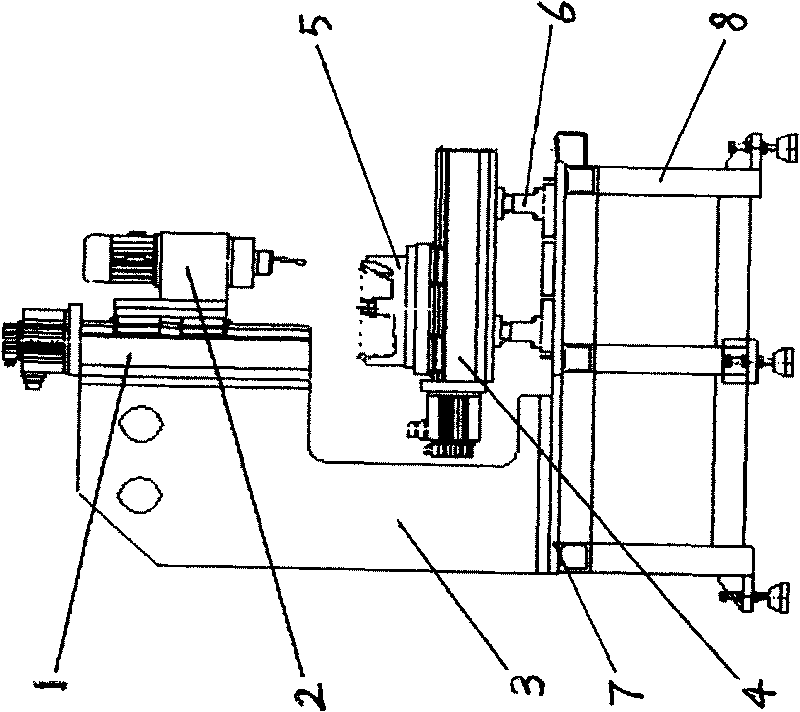

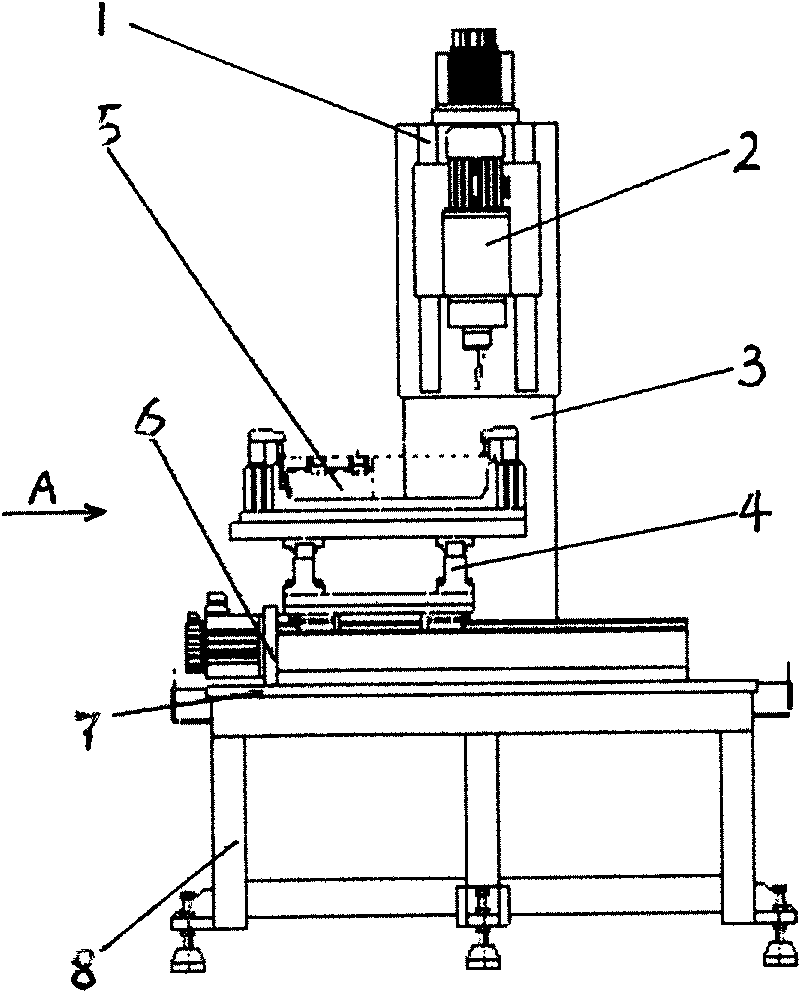

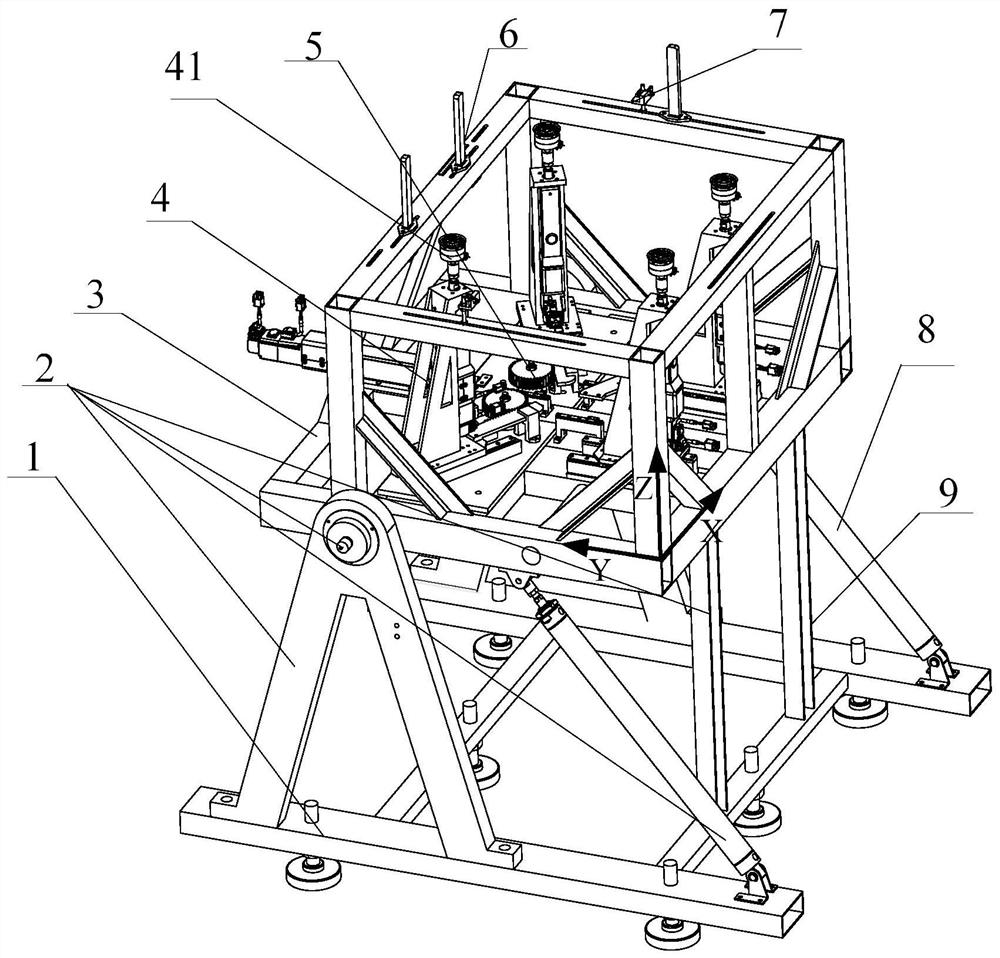

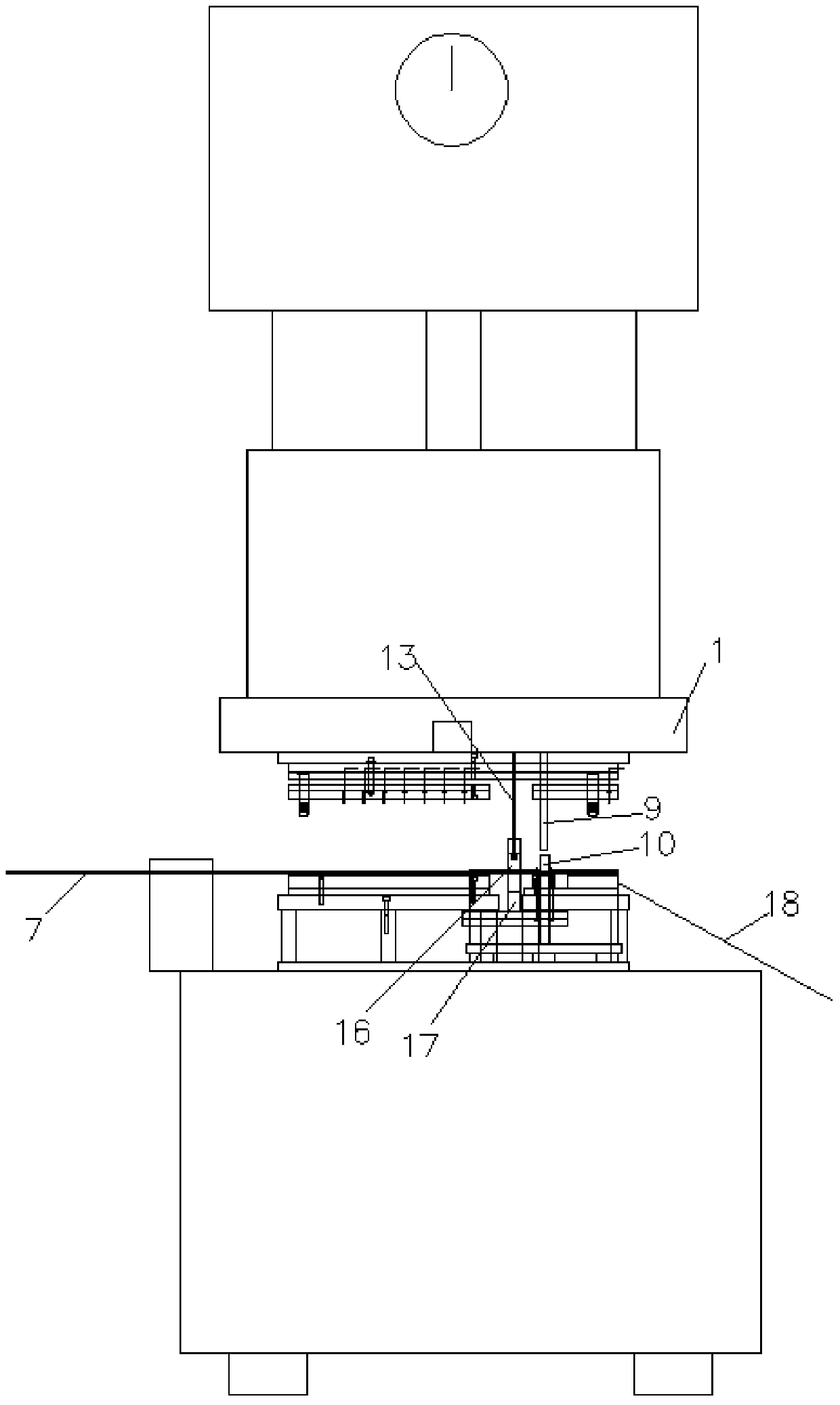

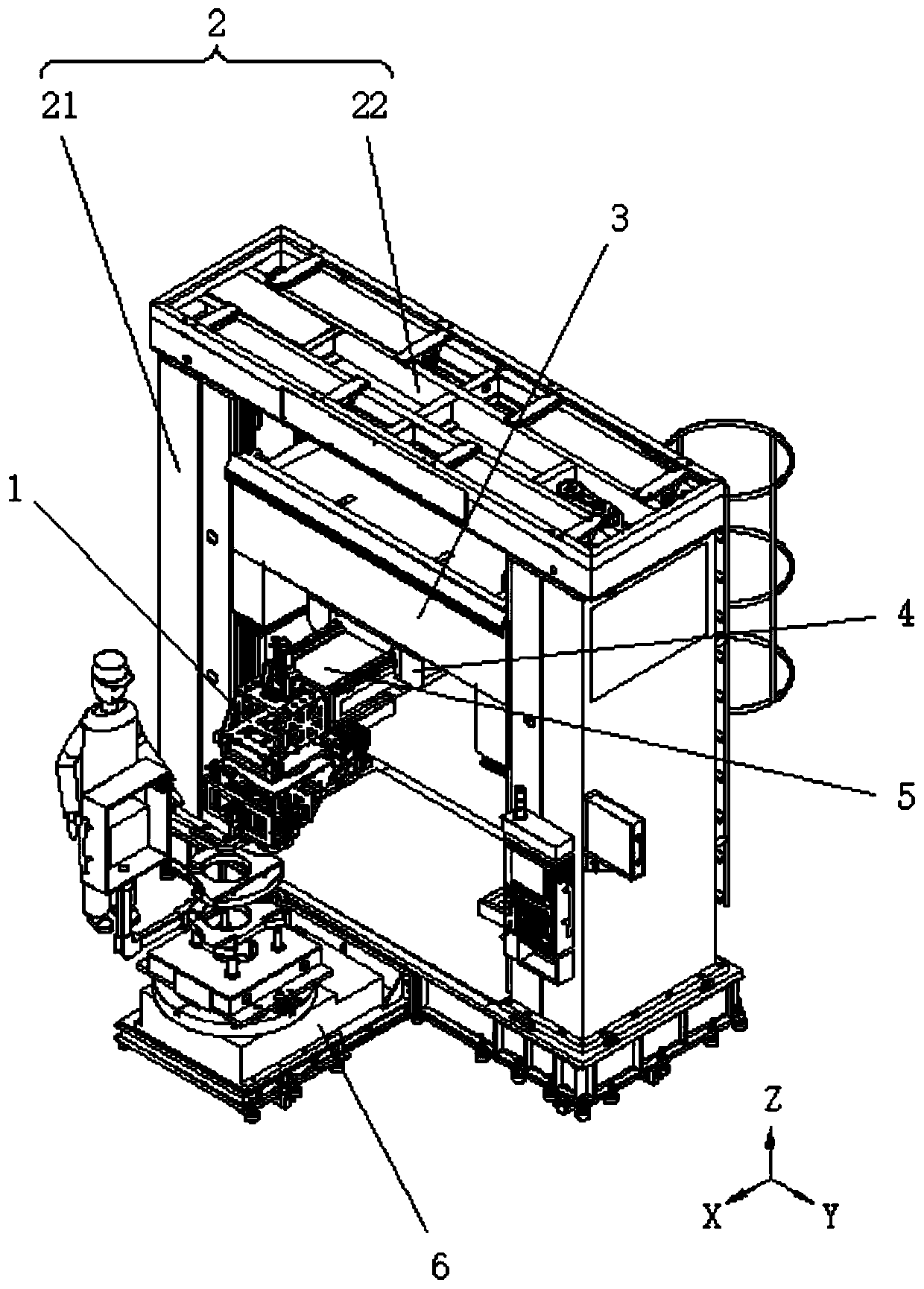

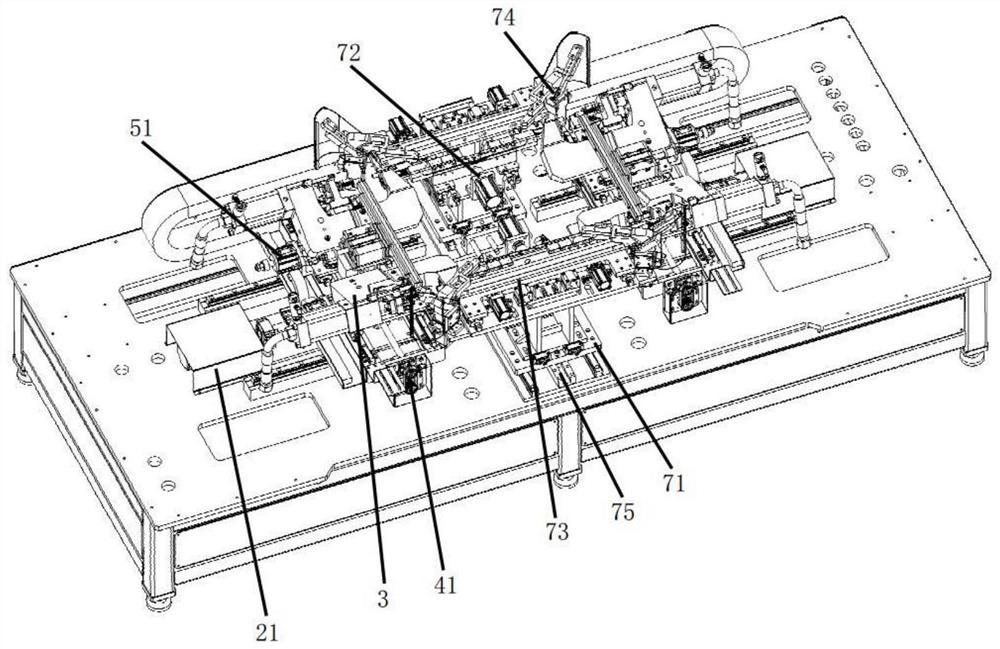

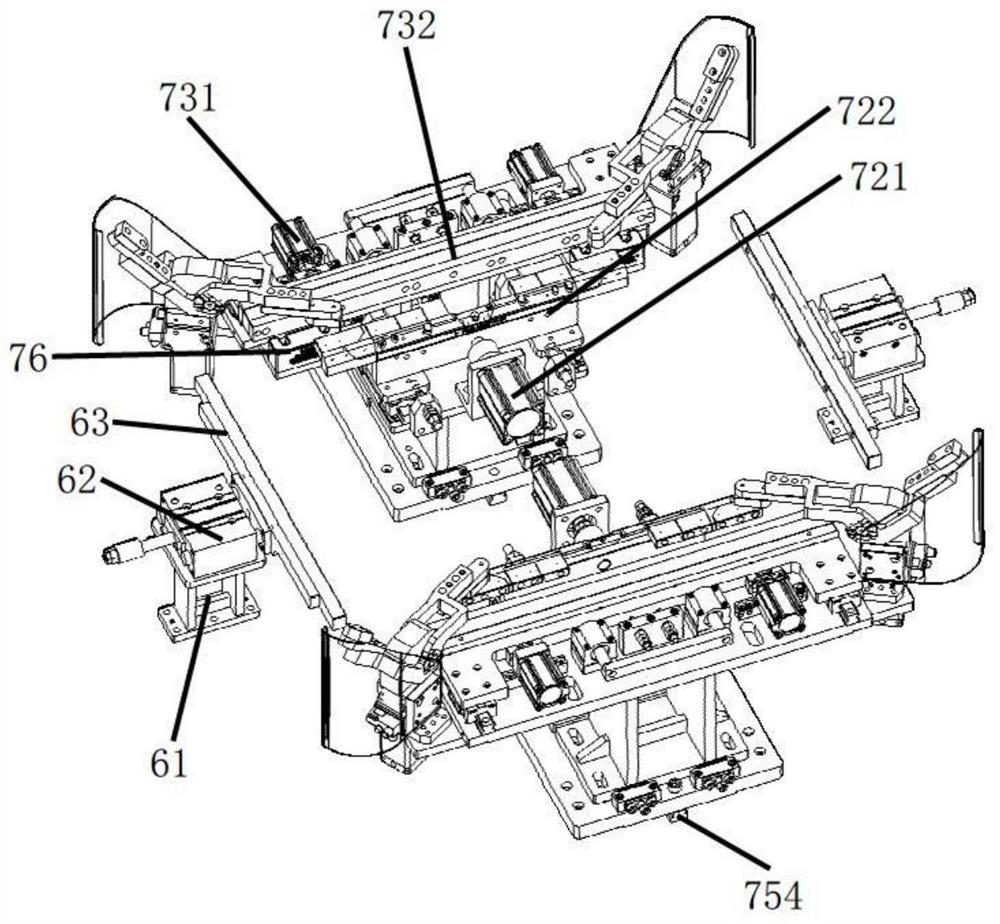

Full-automatic three-dimensional multipoint cold riveting assembly process engineering of die-casting aluminum alloy

The invention discloses a full-automatic three-dimensional multipoint cold riveting assembly process engineering of die-casting aluminum alloy which relates to a full-automatic three-dimensional multipoint cold riveting special device. In the special device, a sliding table power mounting base and a workbench panel are respectively installed on a rack, a spin rivet power system is installed on a vertical Z-direction servo linear sliding table which is installed on the sliding table power mounting base, a workpiece spin rivet gripper is installed on a horizontal Y-direction servo linear sliding table which is installed on a horizontal X-direction servo linear sliding table, the X-direction servo linear sliding table is installed on the workbench panel, and the spin rivet power system is positioned above the workpiece spin rivet gripper. Compared with the prior art, the riveting speed of the invention is improved by 1.5-2 times, and the invention has the advantages of high riveting quality, high connection soundness, low error probability, wide adaptation range of product specification, high production efficiency, long life of snap heads, high riveting accuracy and the like.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

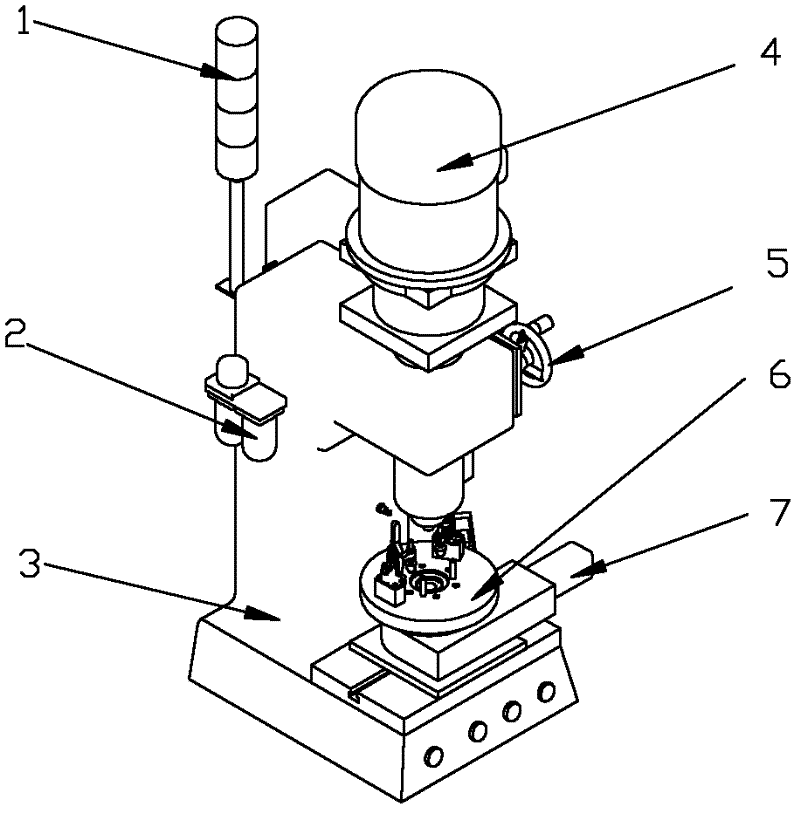

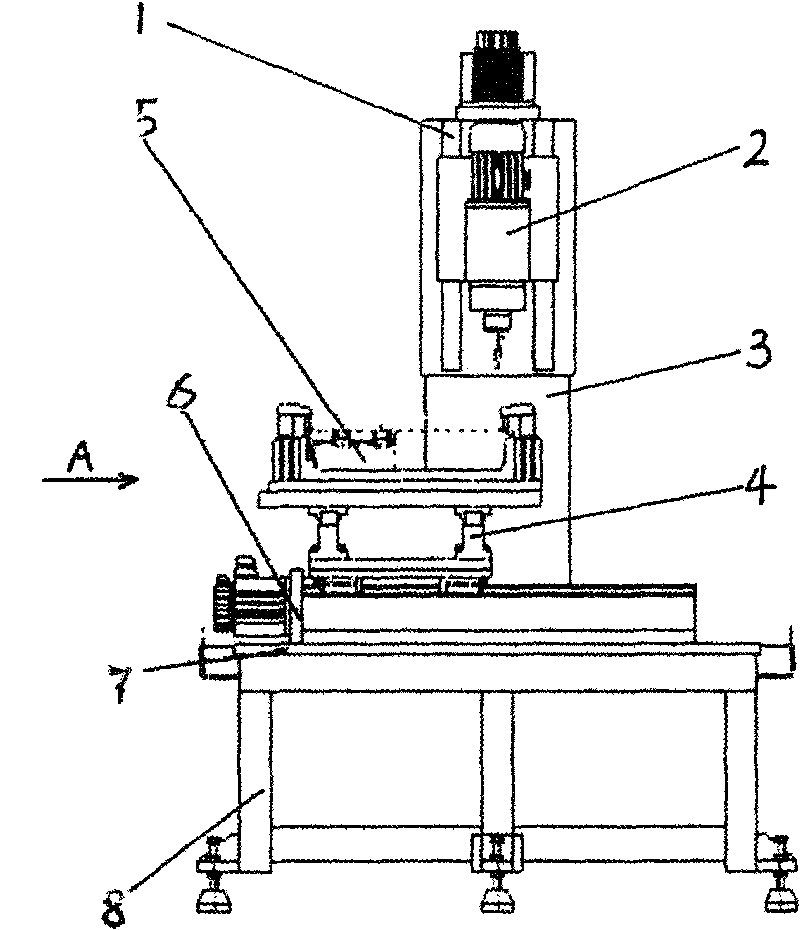

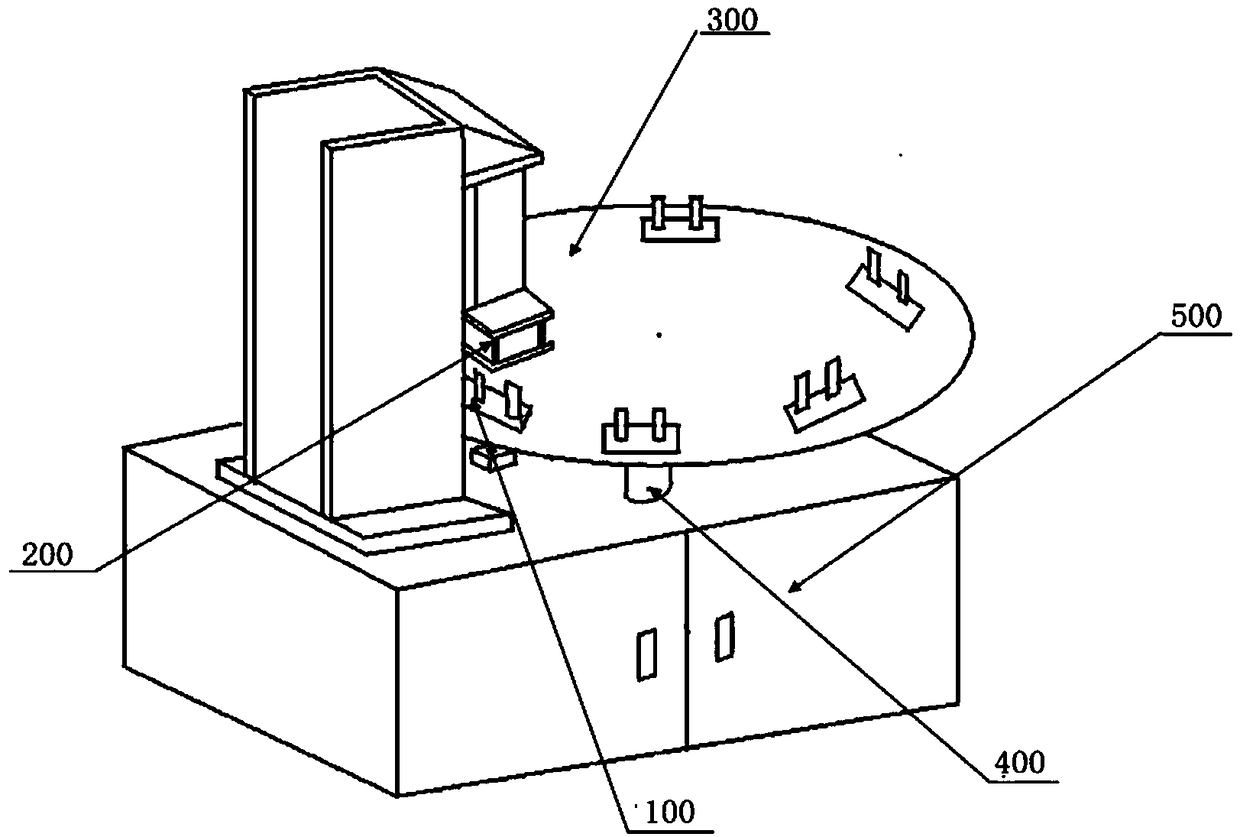

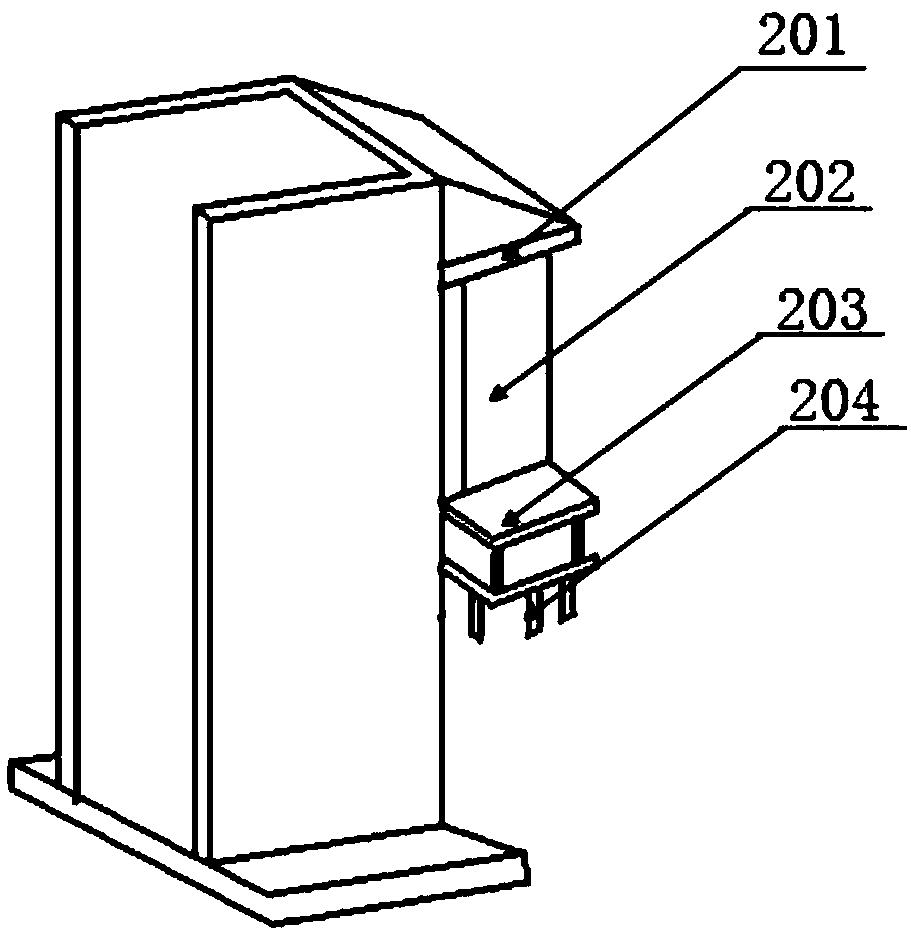

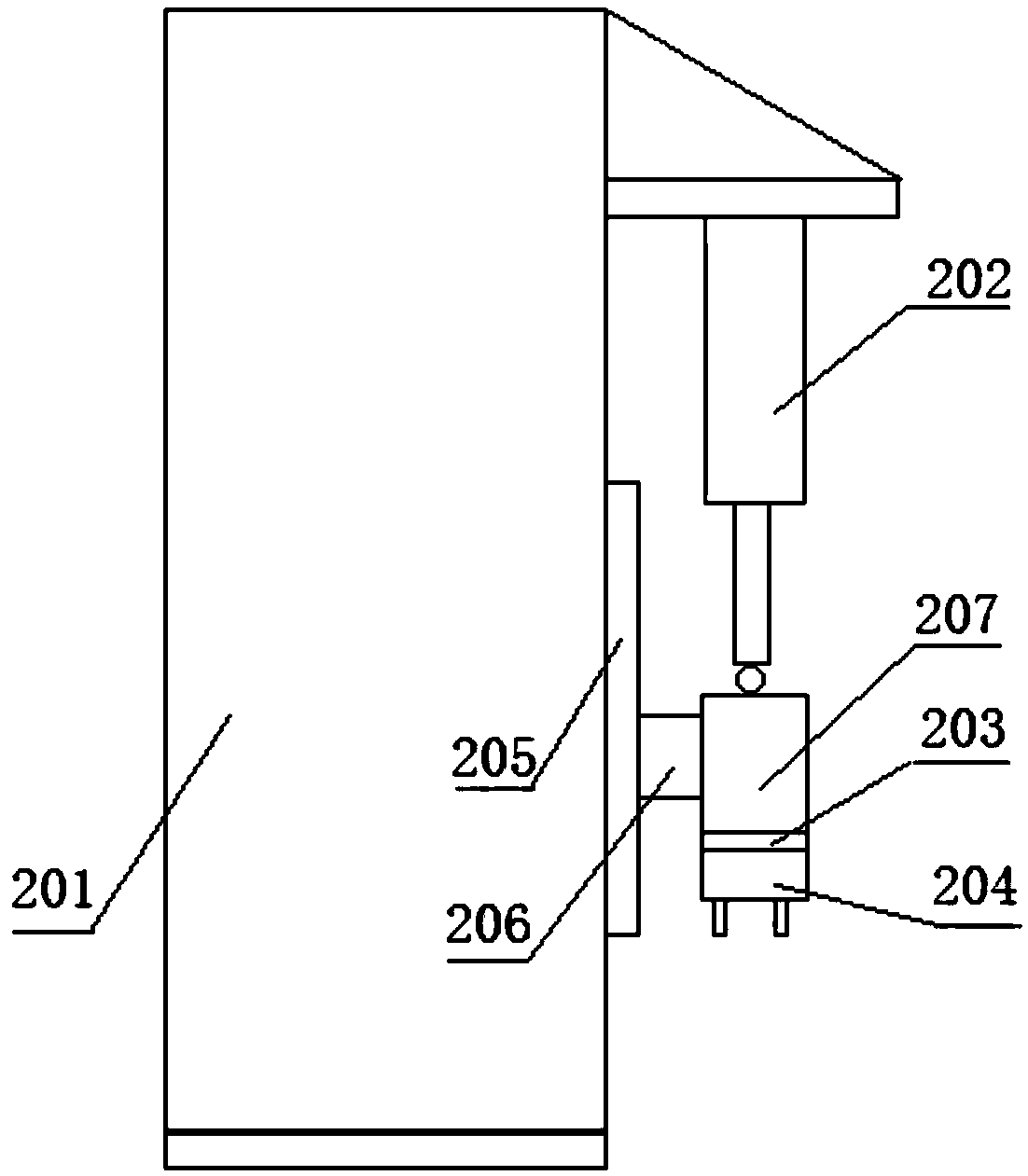

Multi-station full-automatic pneumatic rotating riveting machine

The invention provides a multi-station full-automatic pneumatic rotating riveting machine, which comprises a machine base and further comprises an indicator lamp, a pressure adjusting valve, a motor, a manual lifting turntable, a graduated disk, an air cylinder and an electric box which are mounted on the machine base, wherein a rotating riveting head is mounted on the motor and a rotating riveting rod is mounted on the rotating riveting head. The multi-station full-automatic pneumatic rotating riveting machine is characterized in that the air cylinder and the graduated disk are mounted on the machine base under the rotating riveting rod; the graduated disk is connected to the air cylinder and is driven to rotate by the air cylinder; a position-limit switch is mounted between the air cylinder and the graduated disk; the position-limit switch is driven by the air cylinder and is matched with limit teeth on the graduated disk for positioning; a control line of the air cylinder is connected to a signal output end of a master control board in the electric box; and an instruction input end of the master control board is connected to various operation keys on the surface of the electric box. The multi-station full-automatic pneumatic rotating riveting machine has the advantages that accuracy and efficiency for riveting a workpiece are promoted, structure is simple, maintenance is convenient, processing cost is low, and the like.

Owner:TIANJIN RENYIHE AUTOMATION TECH

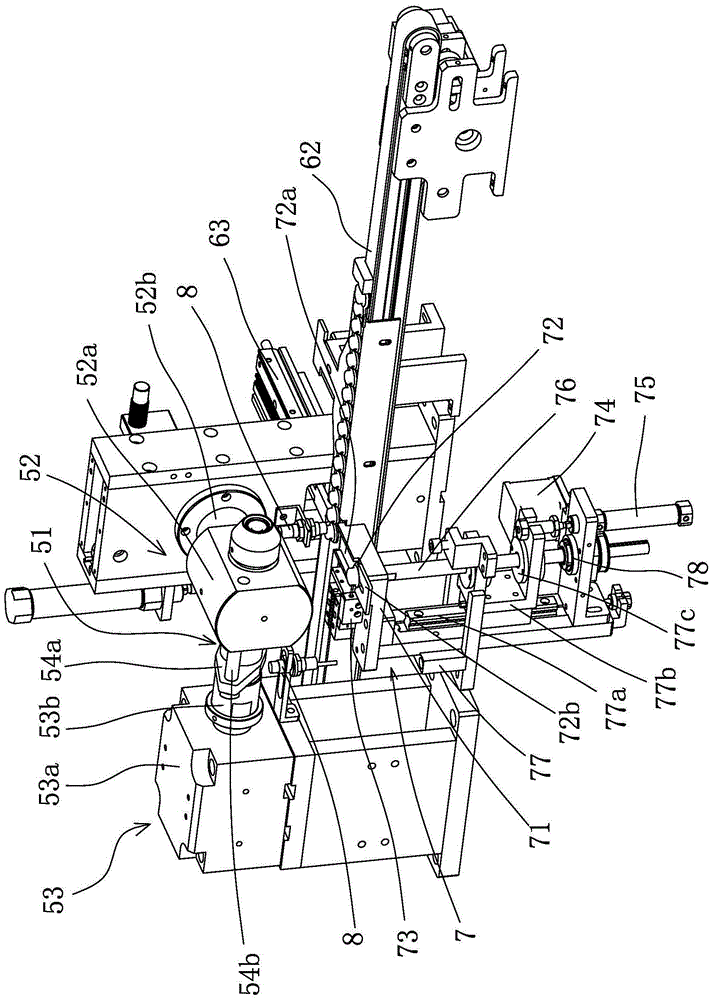

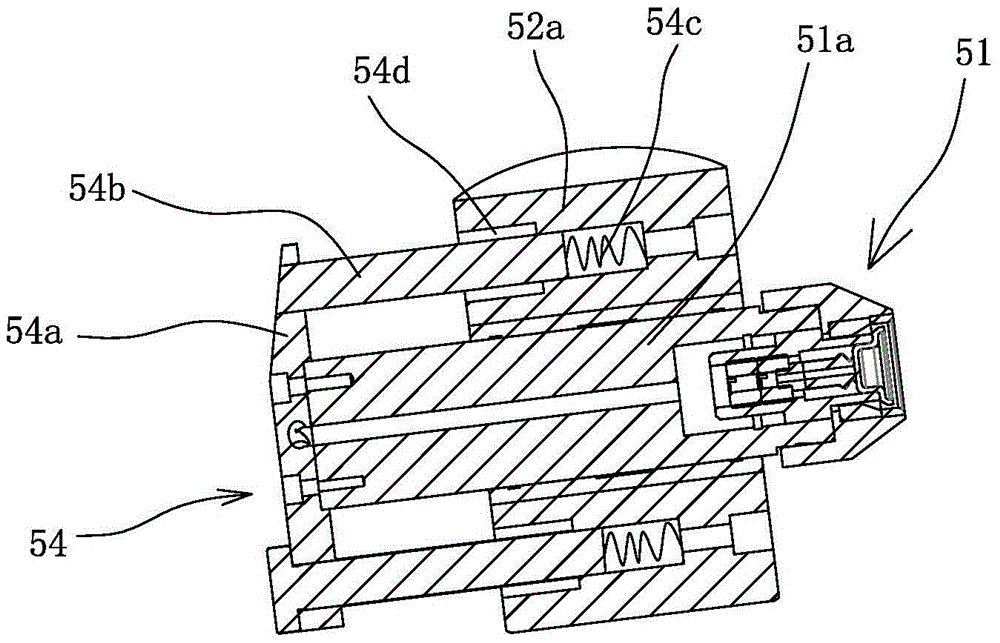

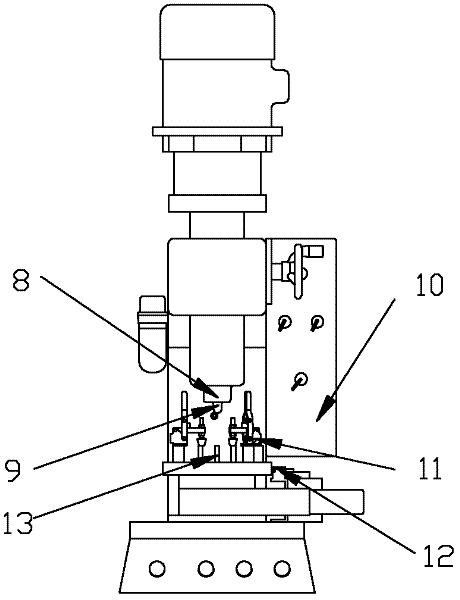

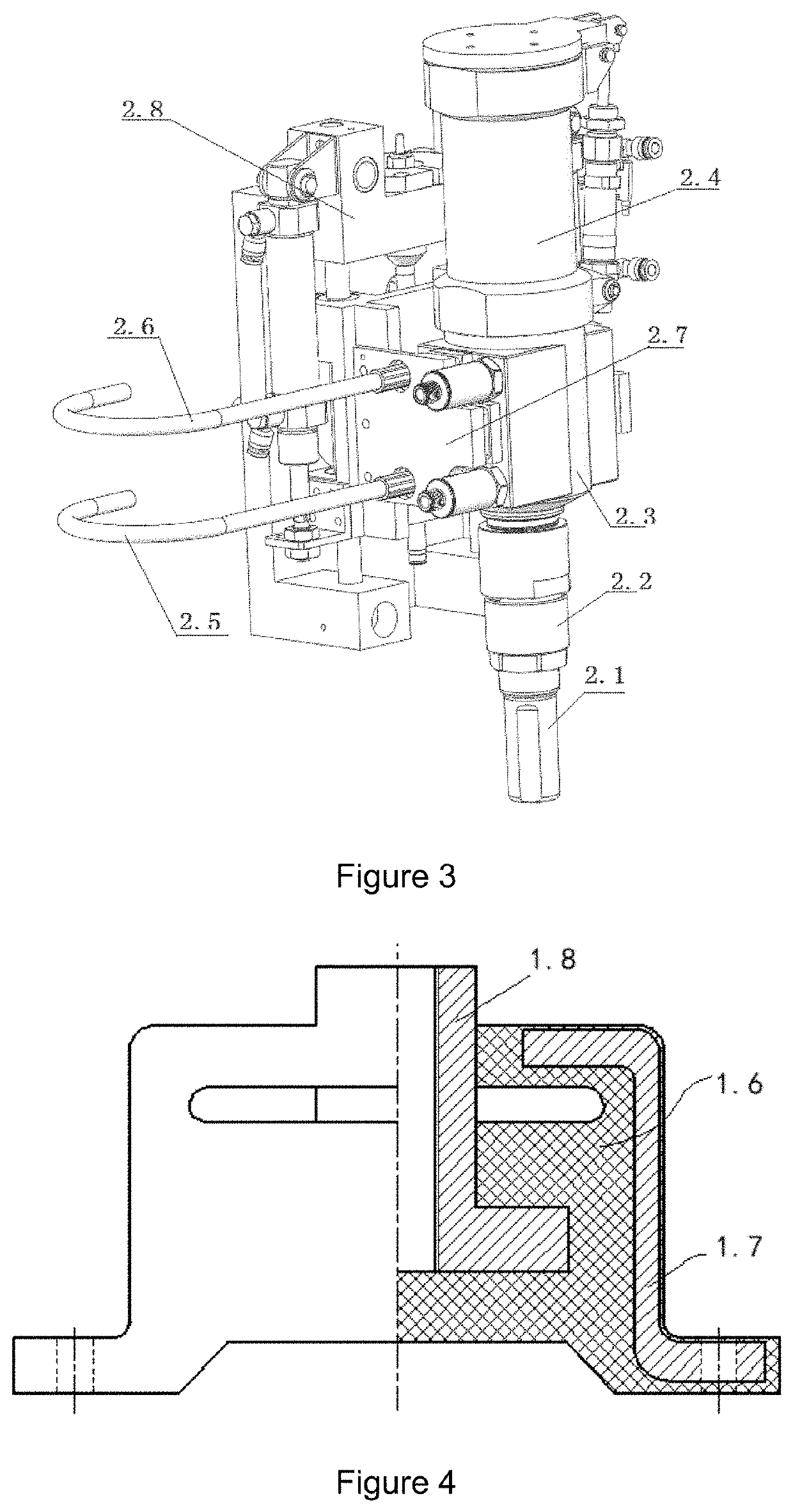

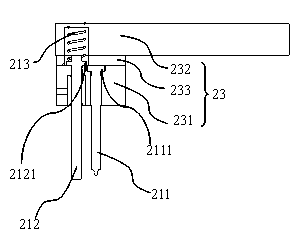

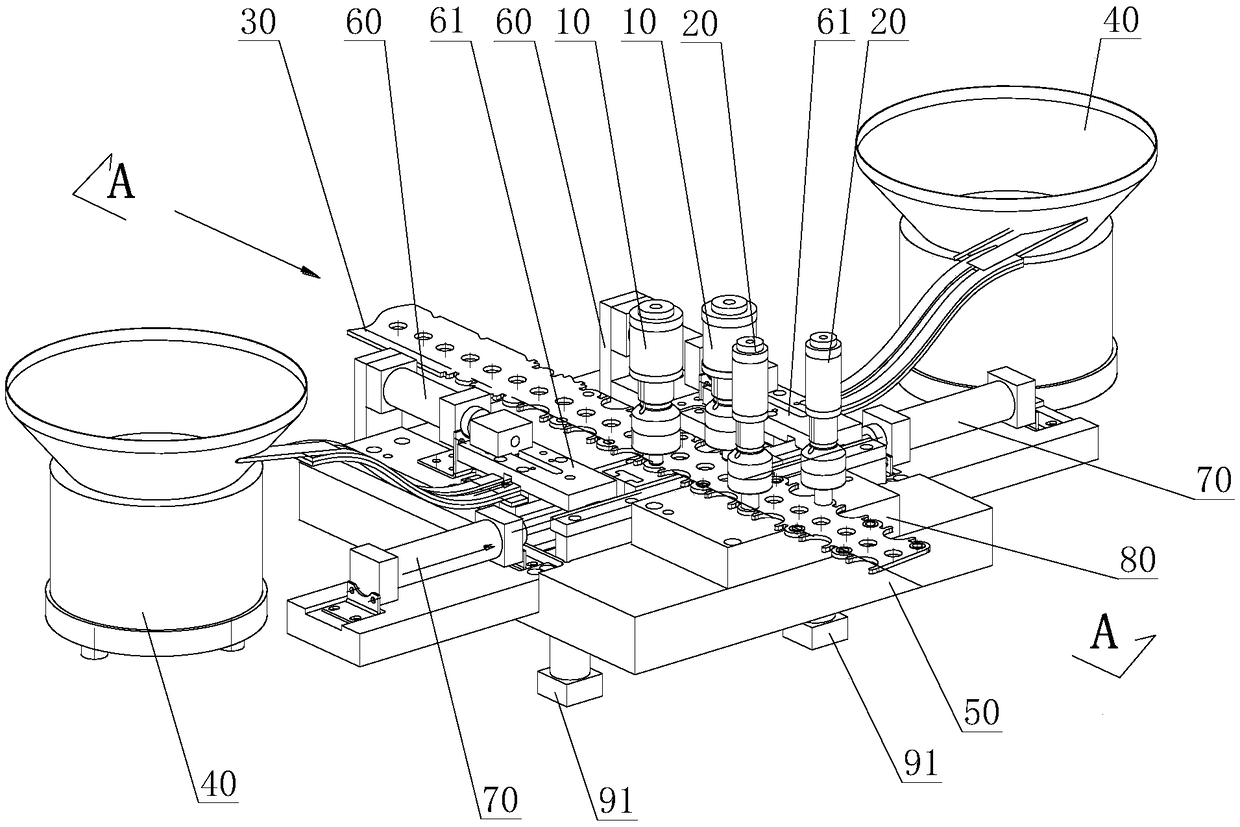

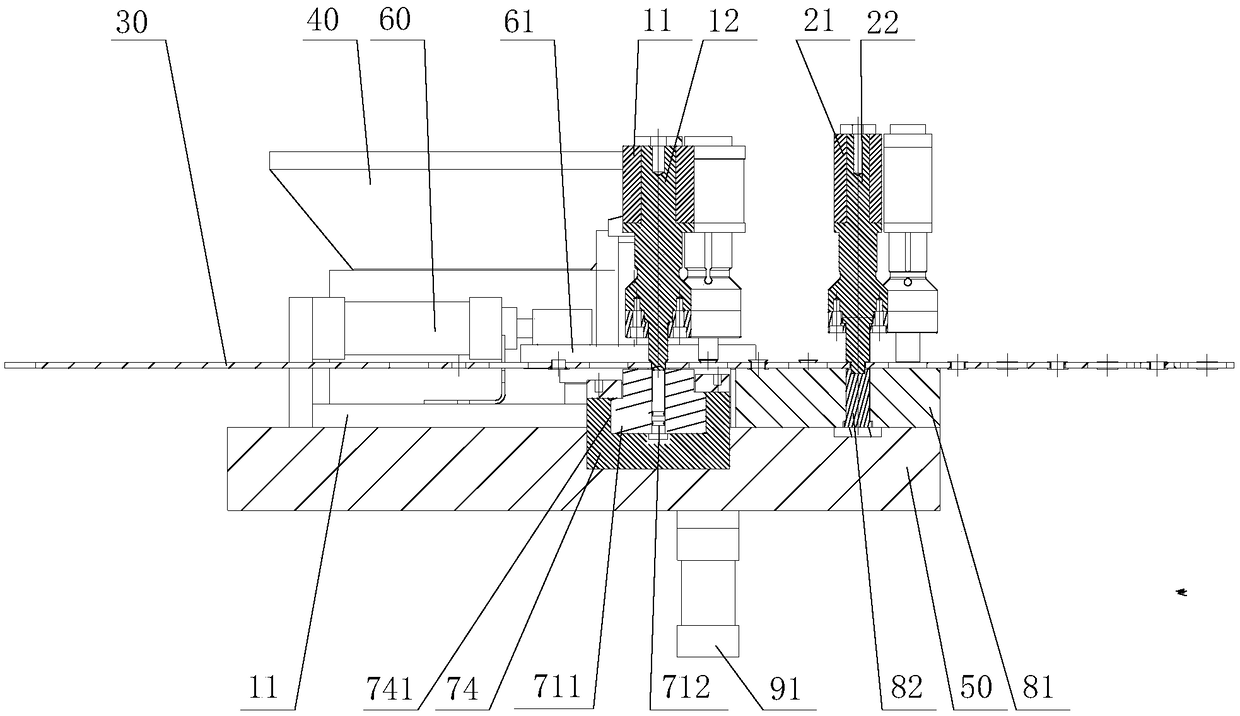

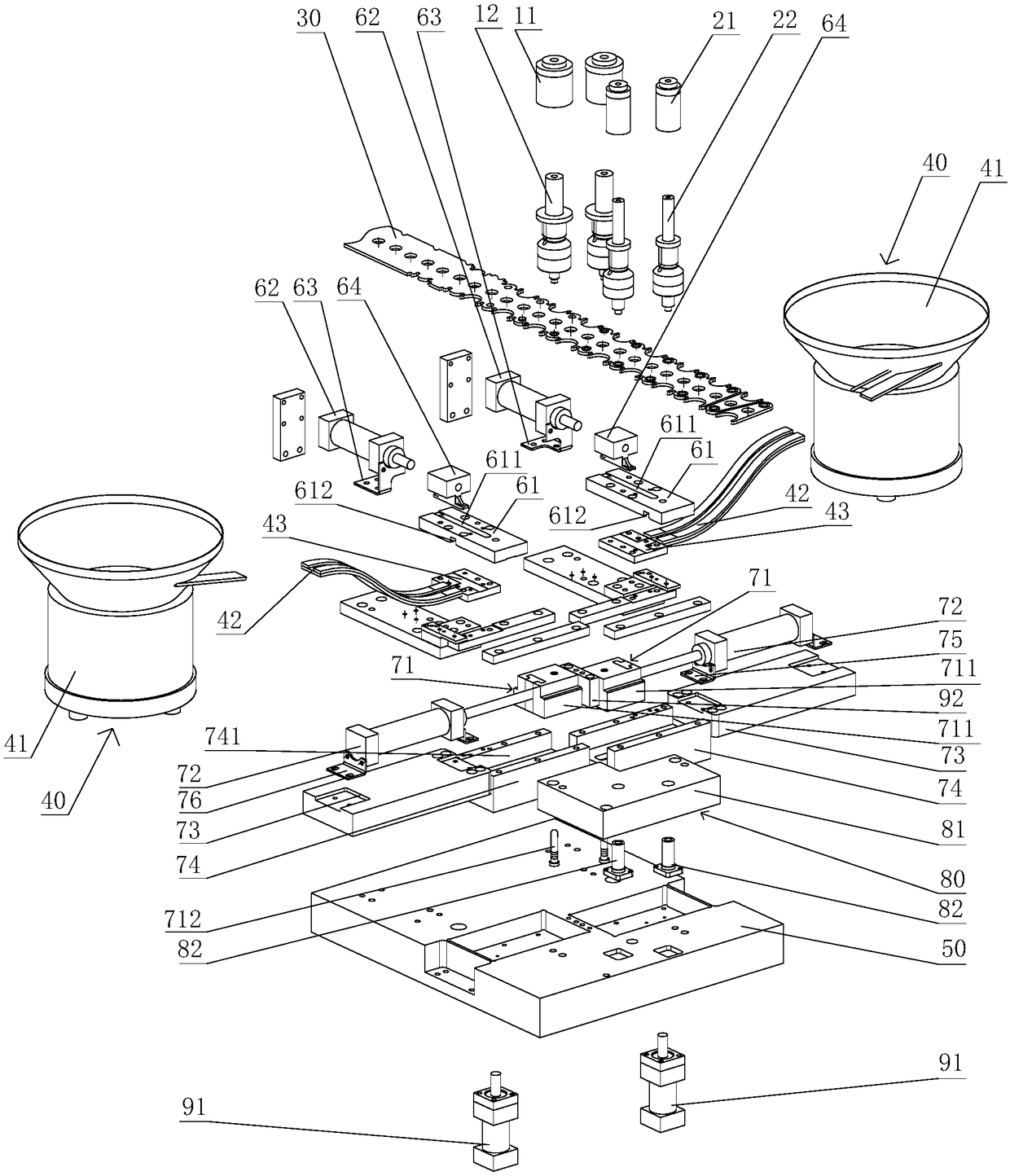

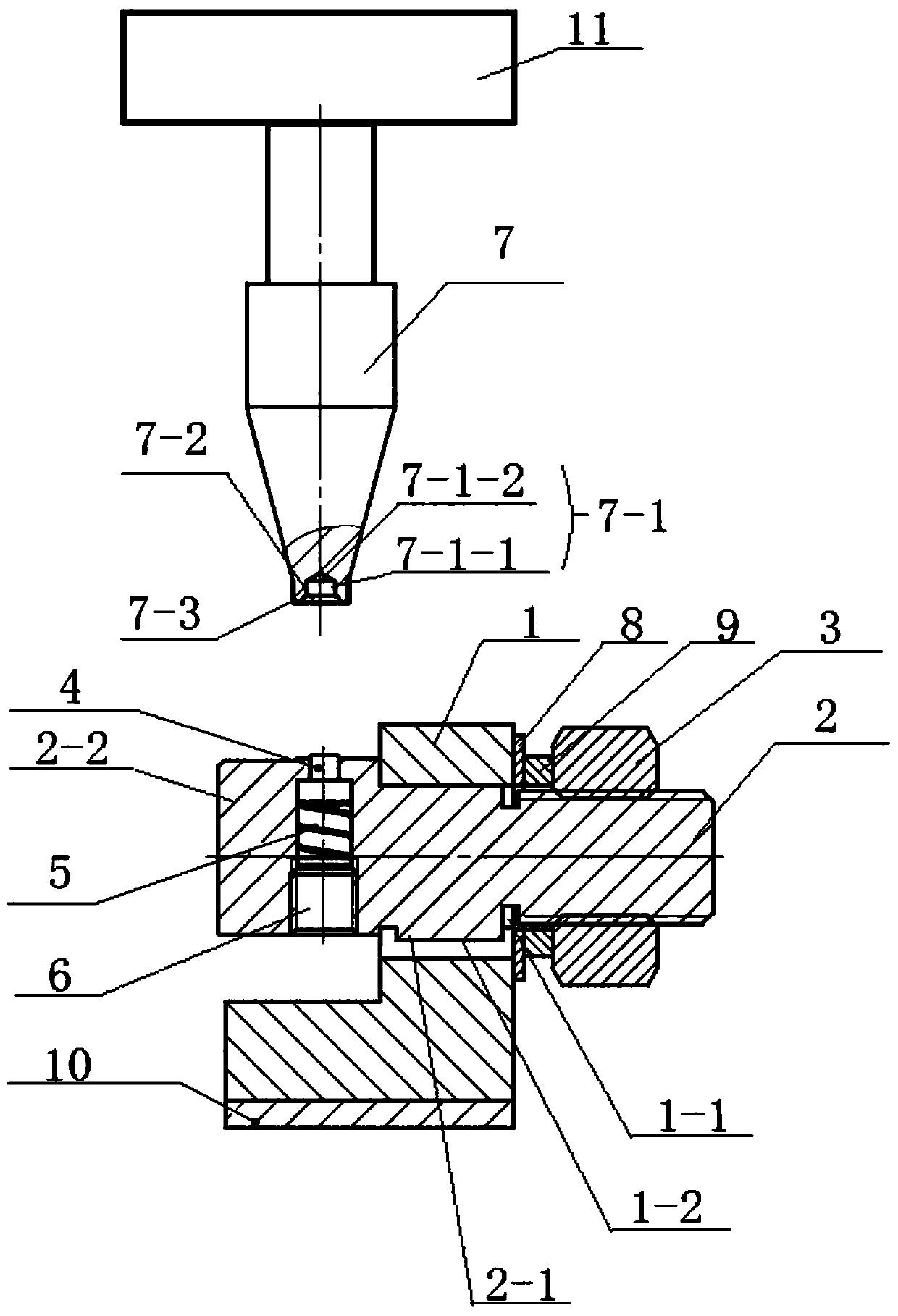

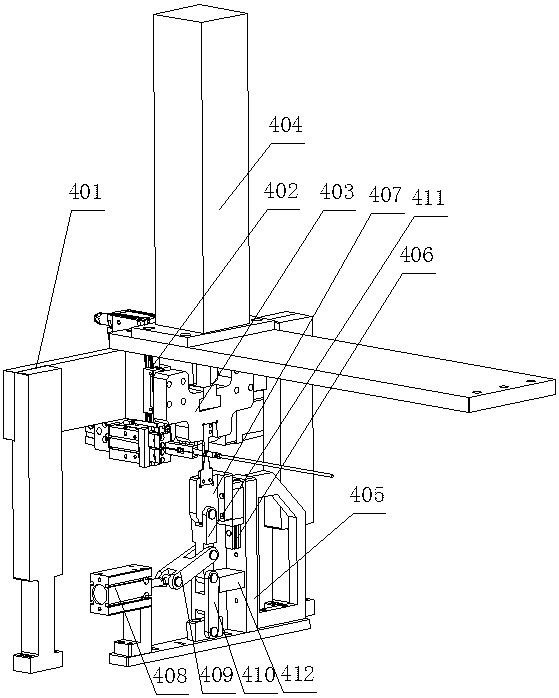

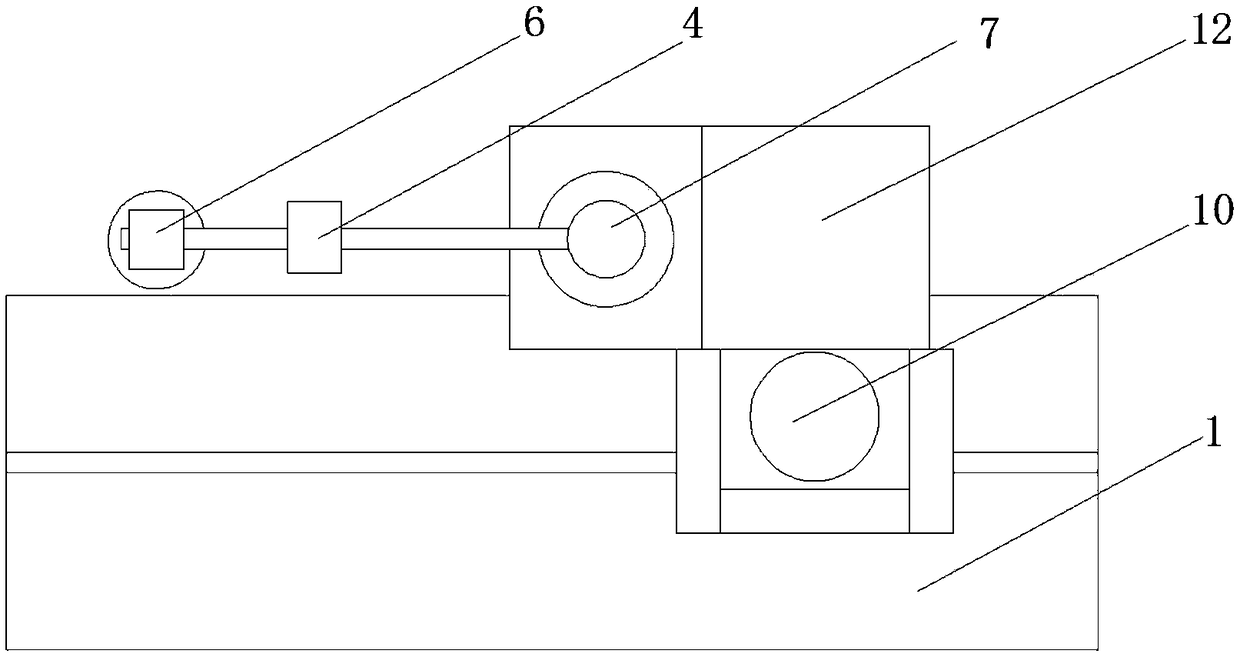

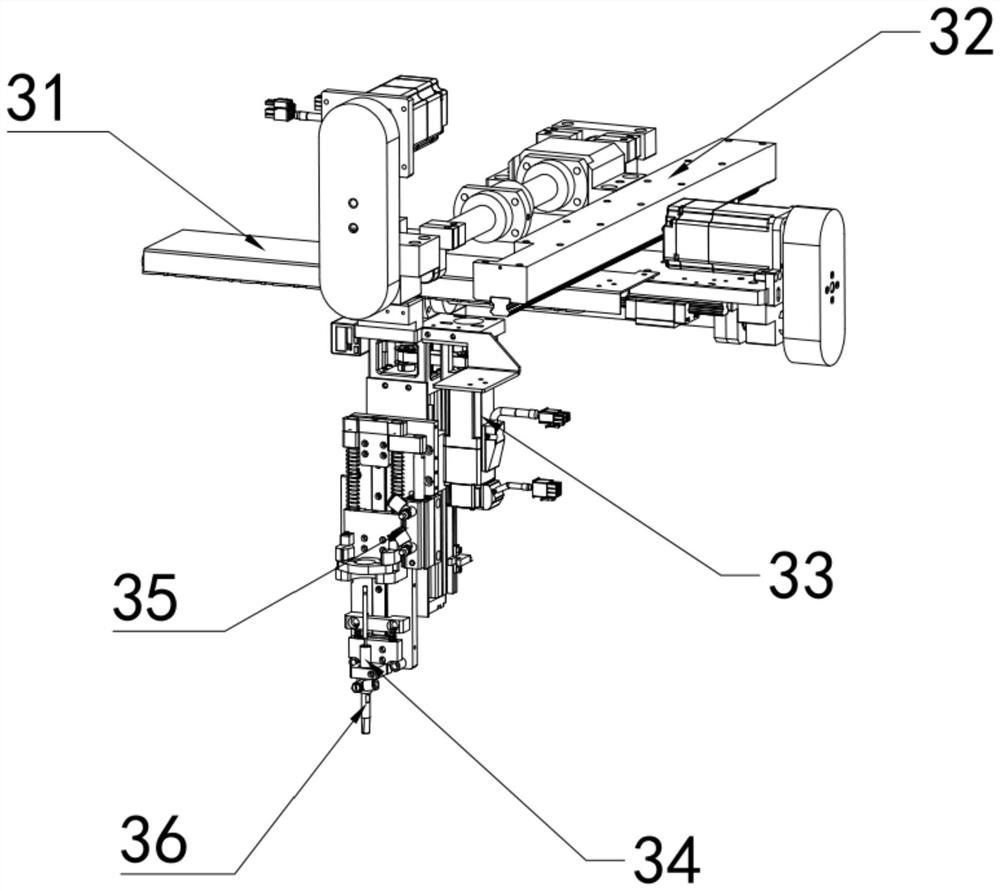

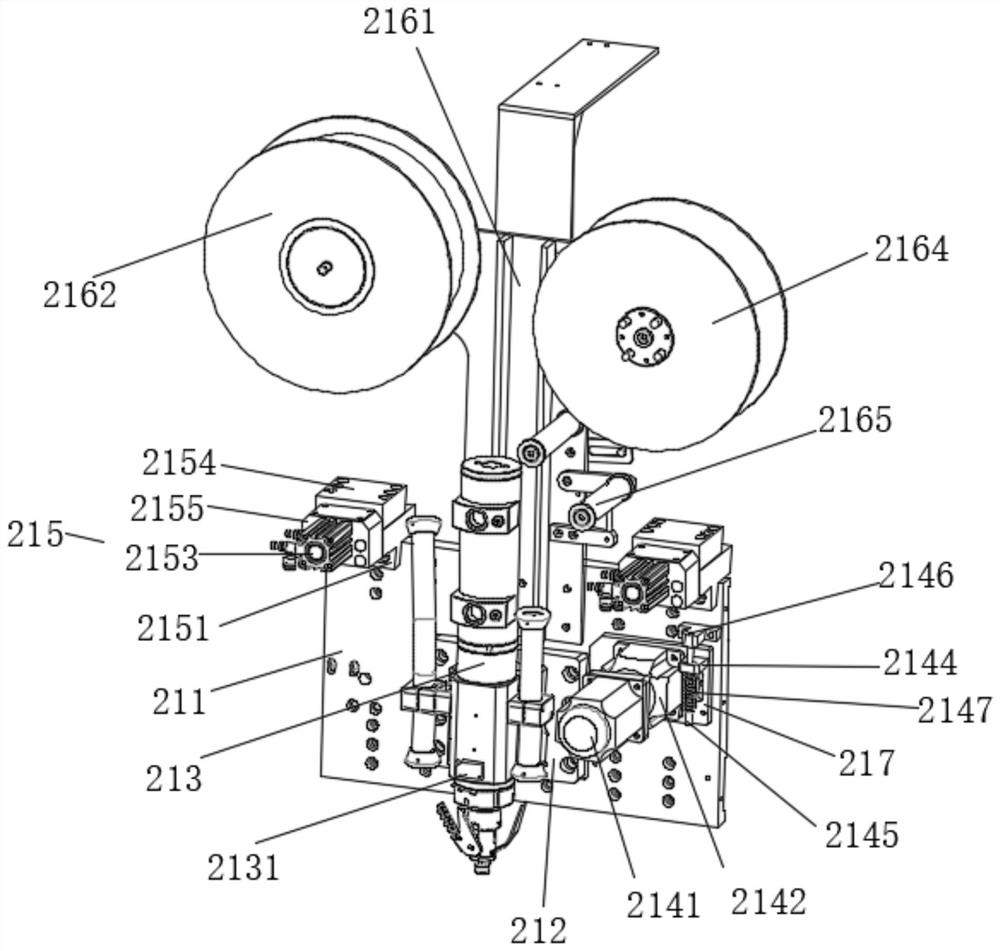

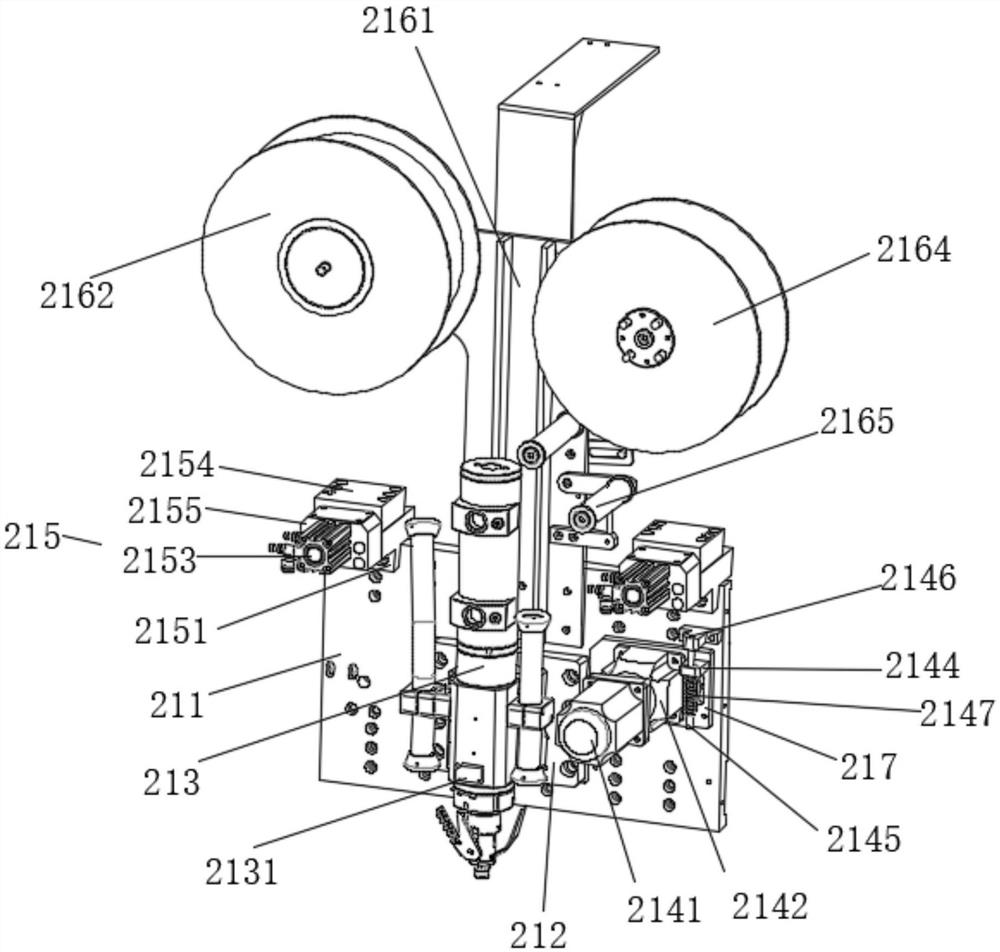

Charging and riveting mechanism for end caps of four-way pipe

PendingCN105537903AImprove work efficiencyImprove riveting precisionMetal working apparatusEngineeringPunching

The invention provides a charging and riveting mechanism for end caps of a four-way pipe. The charging and riveting mechanism comprises a stand, and is characterized in that the stand is provided with a detecting platform; the detecting platform is provided with a detecting seat body used for carrying the end covers; one side of the detecting seat body is provided with a sensor used for judging whether a setting angle of each end cap meets the requirement or not; the detecting seat body is provided with a first rotation driving mechanism capable of adjusting the setting angle of each end cap; a material sucking assembly capable of sucking the end caps is arranged above the detecting platform; the stand is provided with a drive assembly capable of driving the material sucking assembly to a punching work station; one side of the material sucking assembly is provided with a punching assembly capable of riveting the end caps at the punching work station. The charging and riveting mechanism disclosed by the invention has the advantages that production efficiency is high, and a riveting effect is good.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

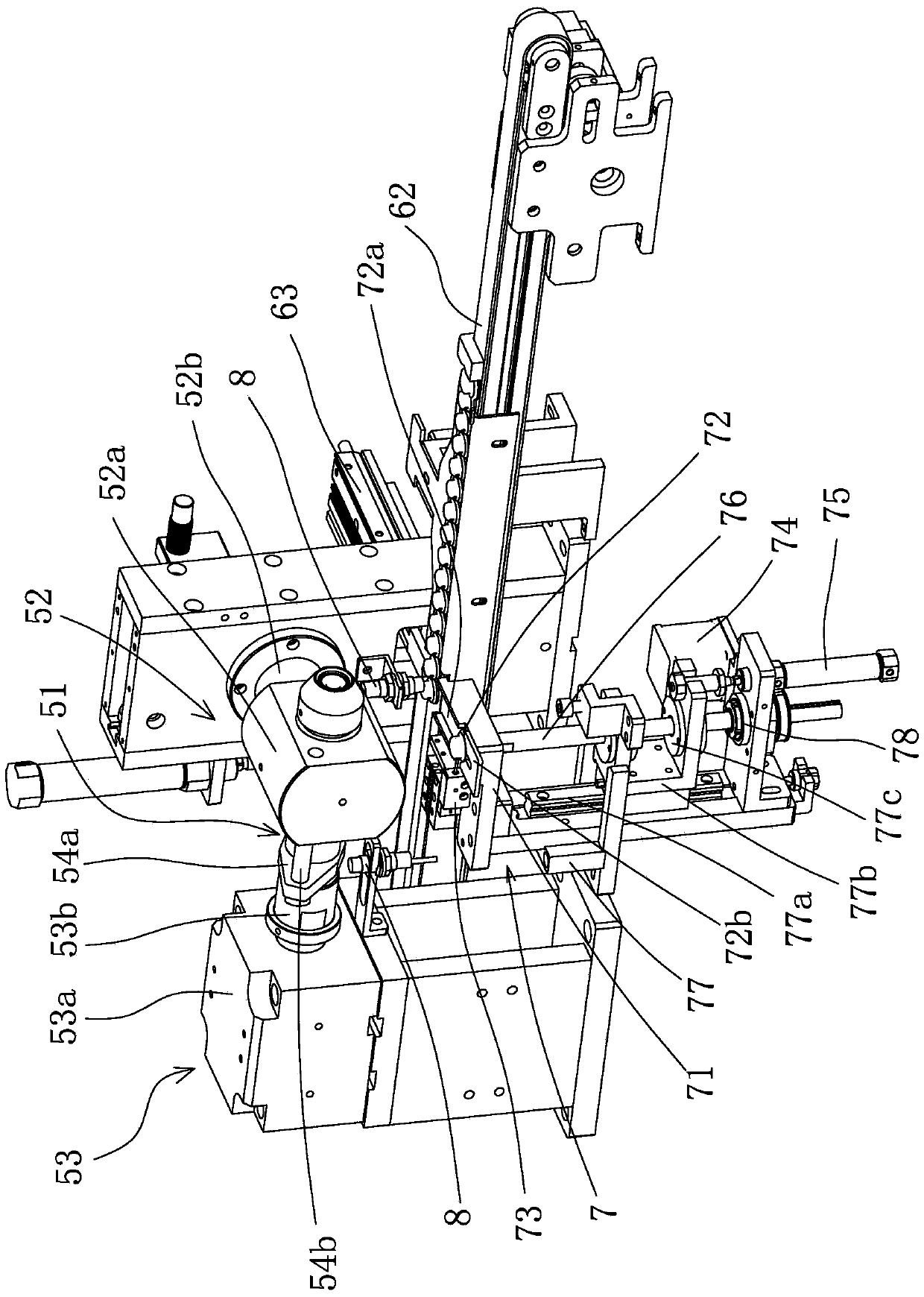

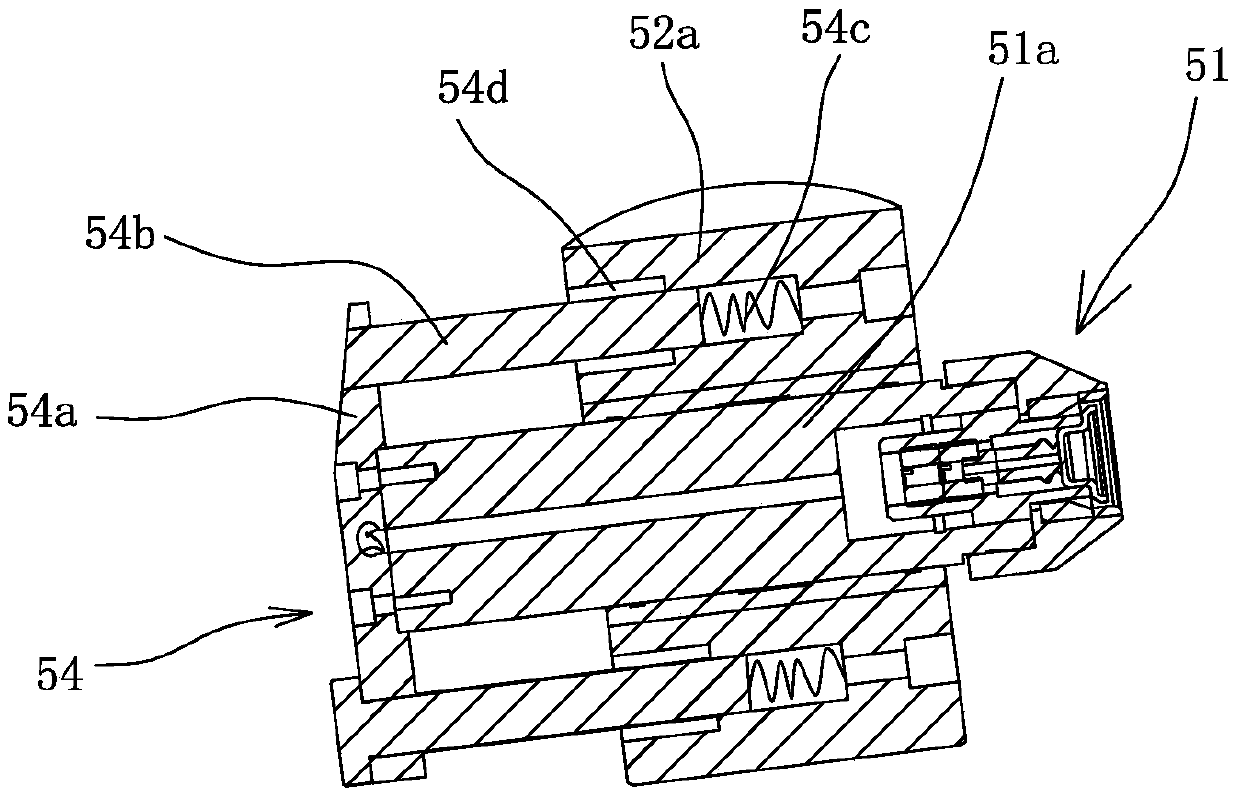

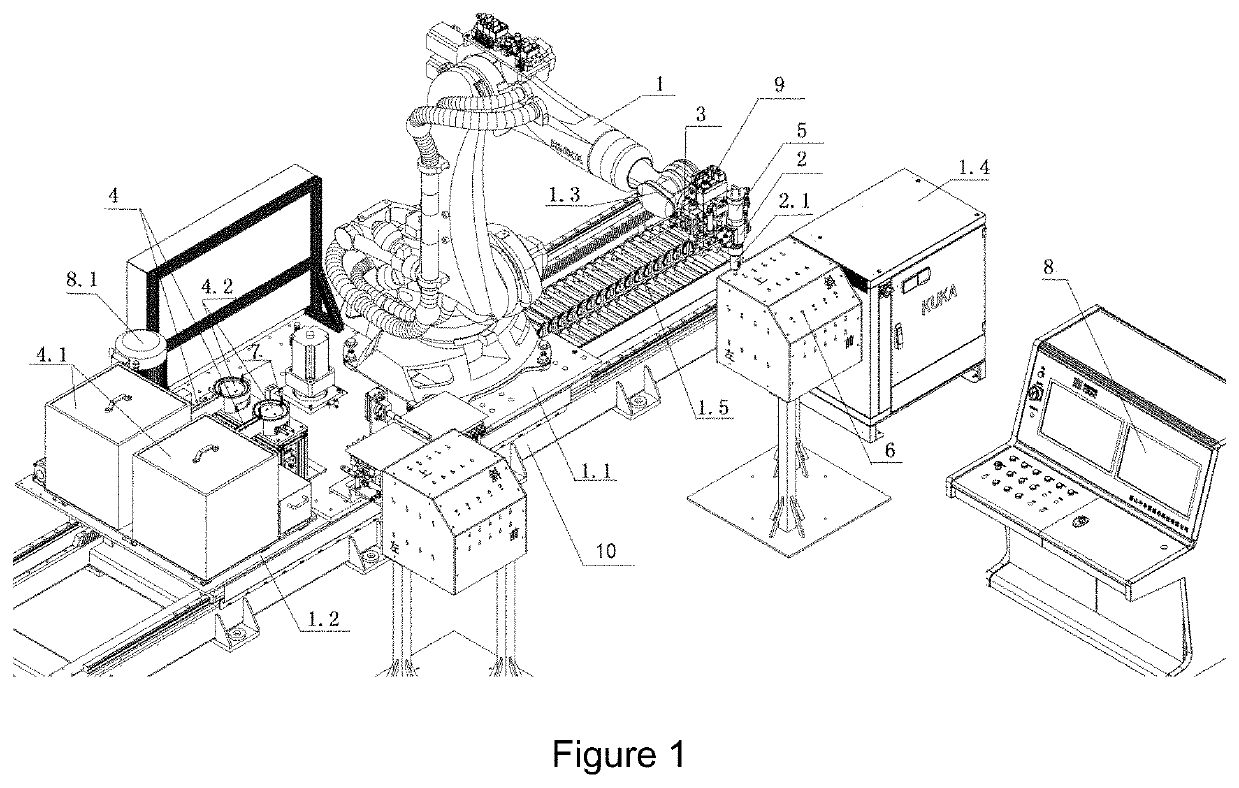

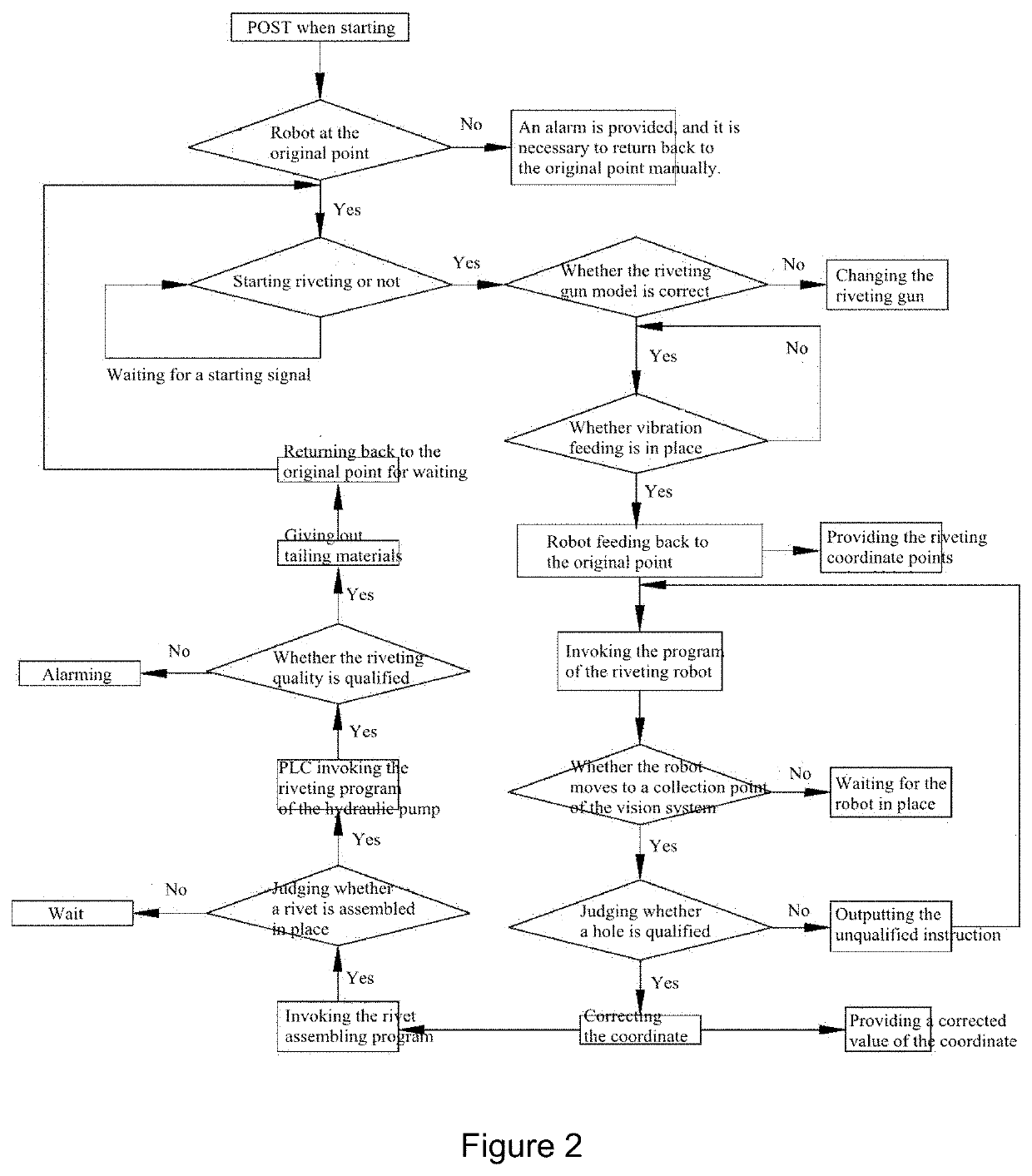

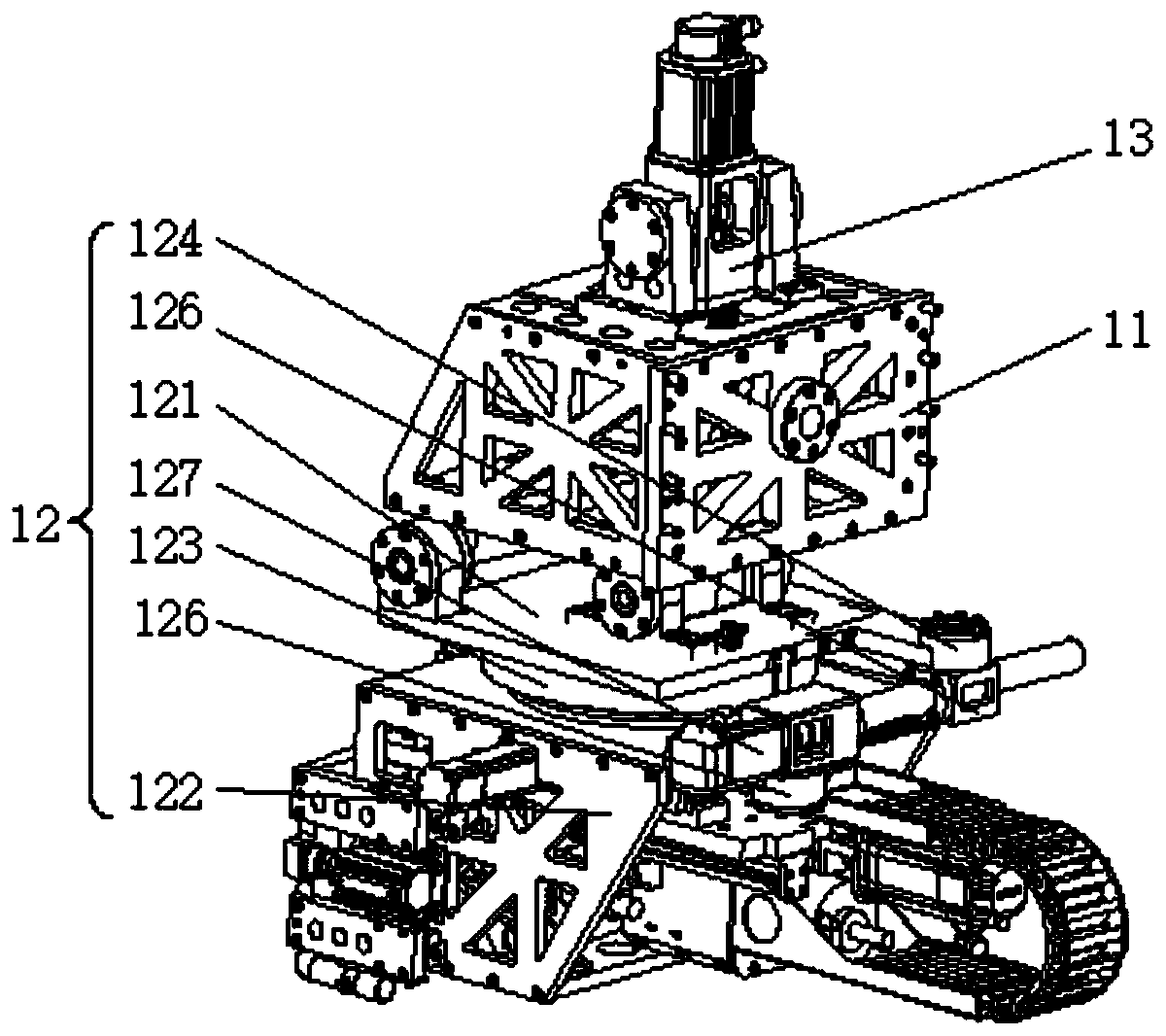

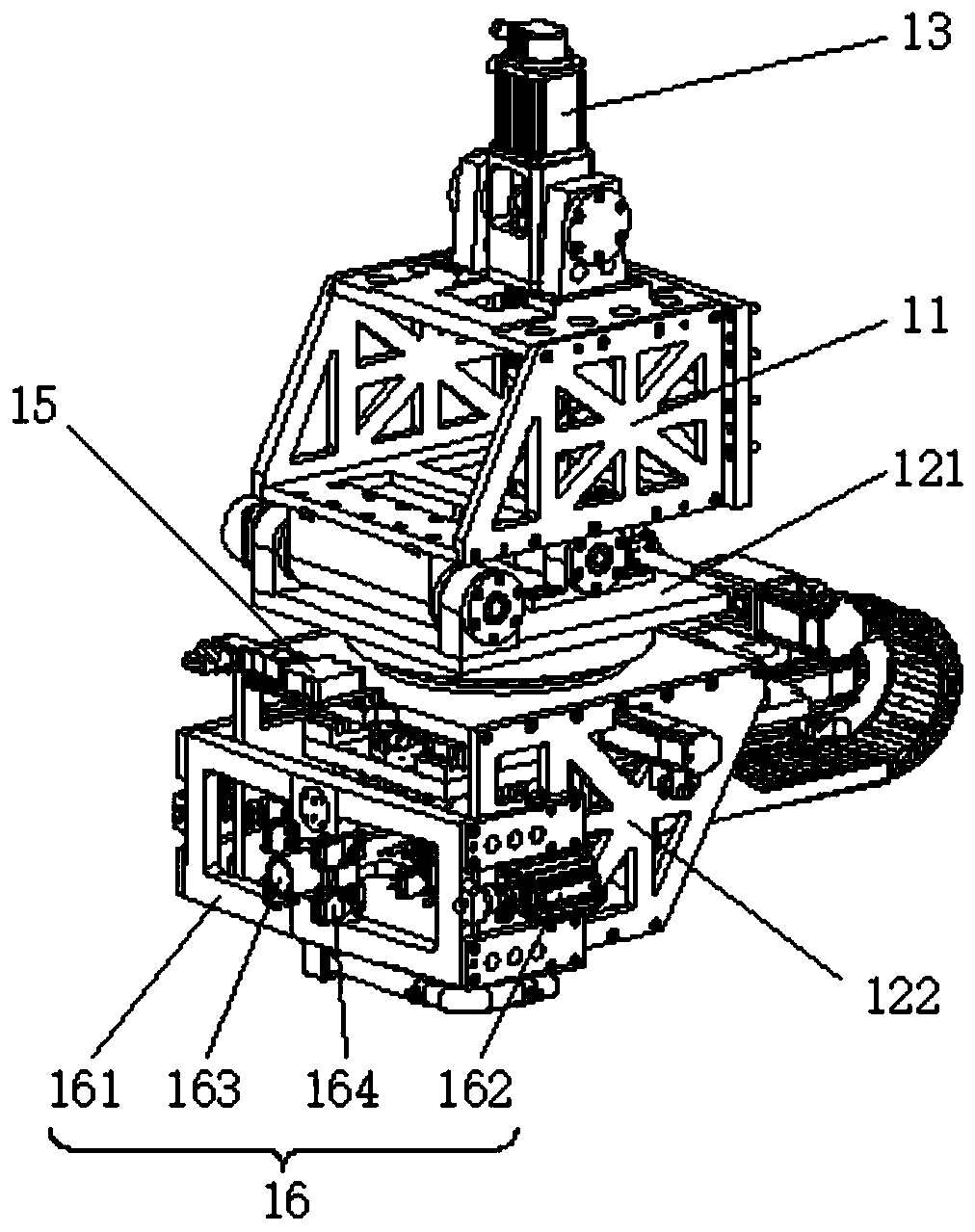

Riveting robot system

ActiveUS20210291256A1Effectively isolates interferenceImprove riveting precisionSpringsJointsIndustrial engineeringHydraulic pressure

The present invention discloses a riveting robot, comprising: a robot part provided on a chassis, and detachably coupled with a riveting tool part through a hydraulically quick change disk; a visual position identification part provided on a side of the hydraulically quick change disk and secured on the sixth axis of the front end of the robot part; an automatic rivet feeding part provided on a mounting baseplate which is secured on a chassis through a two-stage vibration damping structure; a riveter tailing material collection part used for collecting tailing materials produced during riveting; a riveting quality judgment part used for collecting riveting data, and processing and generating a riveting curve to realize judgment of the riveting quality.

Owner:MEISHAN CRRC FASTENING SYST CO LTD

Riveting machine

The invention provides a riveting machine which comprises a positioning assembly used for fixing a to-be-riveted workpiece, a riveting assembly and a limiting assembly, wherein the riveting assembly comprises a supporting component and a rivet head component arranged on the supporting component, and the supporting component and the rivet head component together move towards or away from the positioning assembly; the limiting assembly is arranged between the positioning assembly and the supporting component. Compared with the prior art, according to the riveting machine, the limiting assembly is arranged and accordingly a rivet head cannot damage the to-be-riveted workpiece in a pressed mode; the riveting accuracy of the riveting machine is improved, and the reject ratio of products riveted by the riveting machine is reduced.

Owner:SIP GOLDWAY TECH

Feeding, heating and auxiliary riveting method for riveting shafts

The invention discloses a feeding, heating and auxiliary riveting method for riveting shafts. The method comprises the steps as follows: a grabbing manipulator grabs a group of riveting shafts from a conveying belt, rotates and sends the riveting shafts to the position below a clamping and feeding device; a pushing driving device drives a pushing device to rise to push the group of riveting shafts into a group of shaft accommodating cavities; when the riveting shafts reach the set positions, a clamping driving device operates, and clamping devices clamp the riveting shafts; a telescoping driving device drives telescopic arms of heating devices to extend, and heating ends make contact with riveting parts of the riveting shafts for heating; a feeding driving device operates, the clamping and feeding device moves to the position below to-be-machined sheet metal at a riveting station; and the feeding driving device operates continuously, and the clamping and feeding device drives the group of riveting shafts to be embedded in corresponding riveting holes. The production efficiency and the automation degree of production are increased; fine adjustment of the perpendicularity is performed while the shafts are clamped, and the riveting precision is guaranteed; riveting is performed after heating, and thus the riveting precision and strength are enhanced.

Owner:太仓市华天冲压五金制品厂

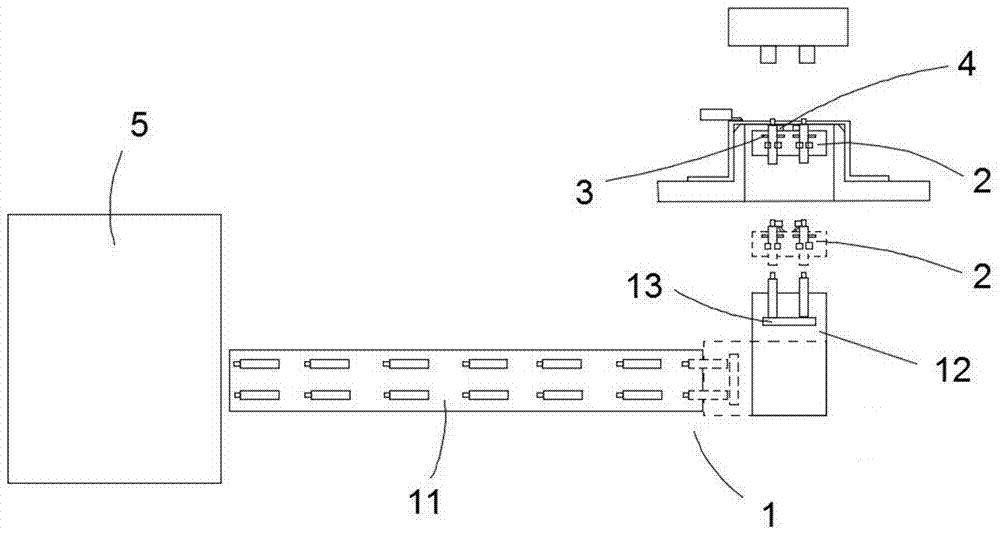

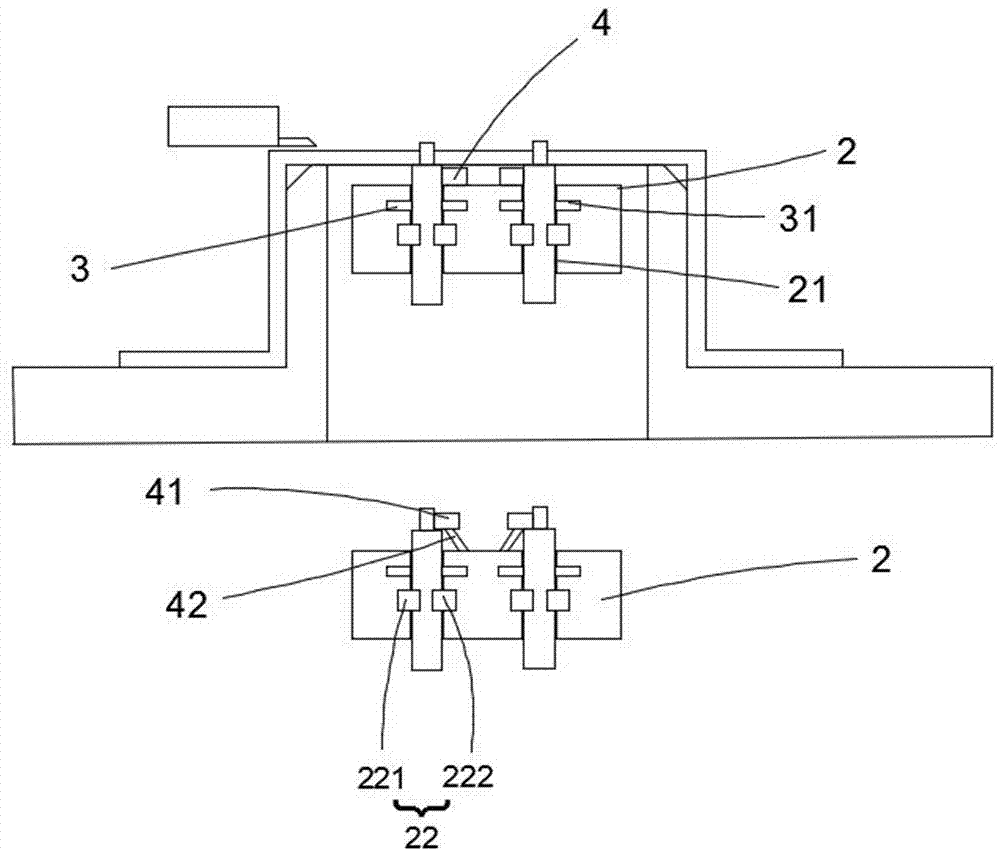

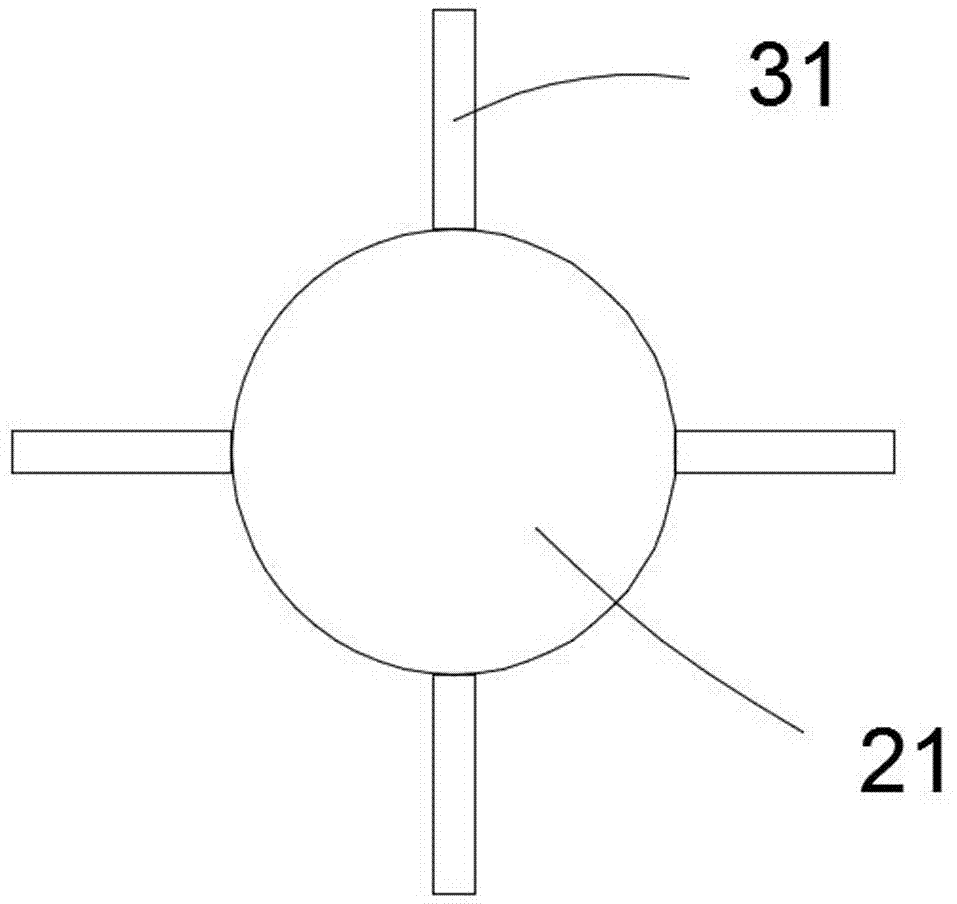

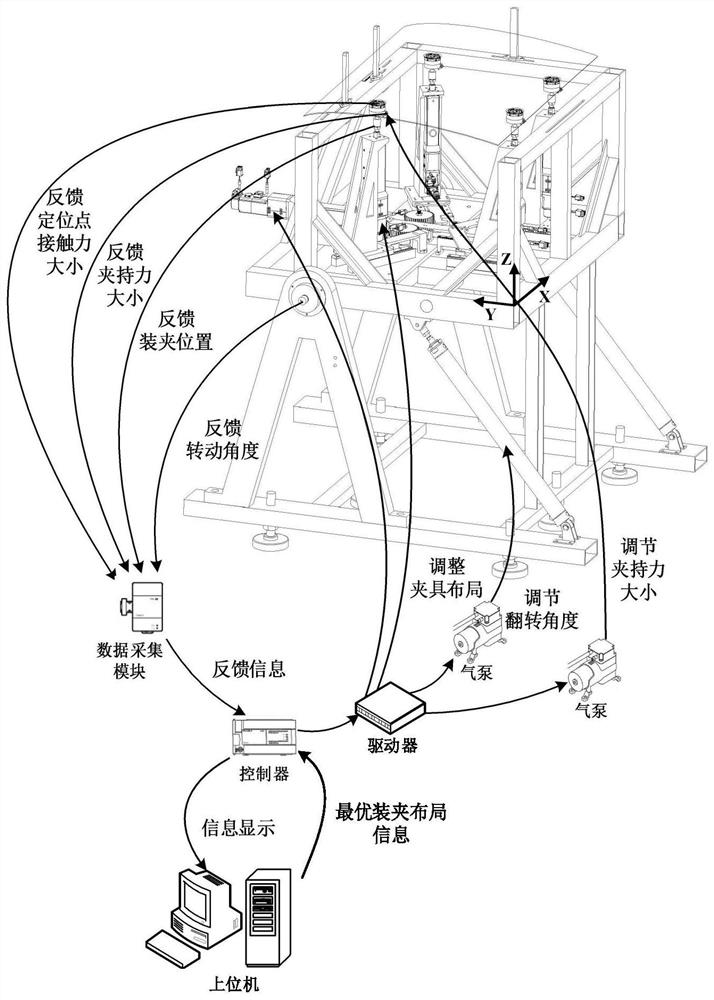

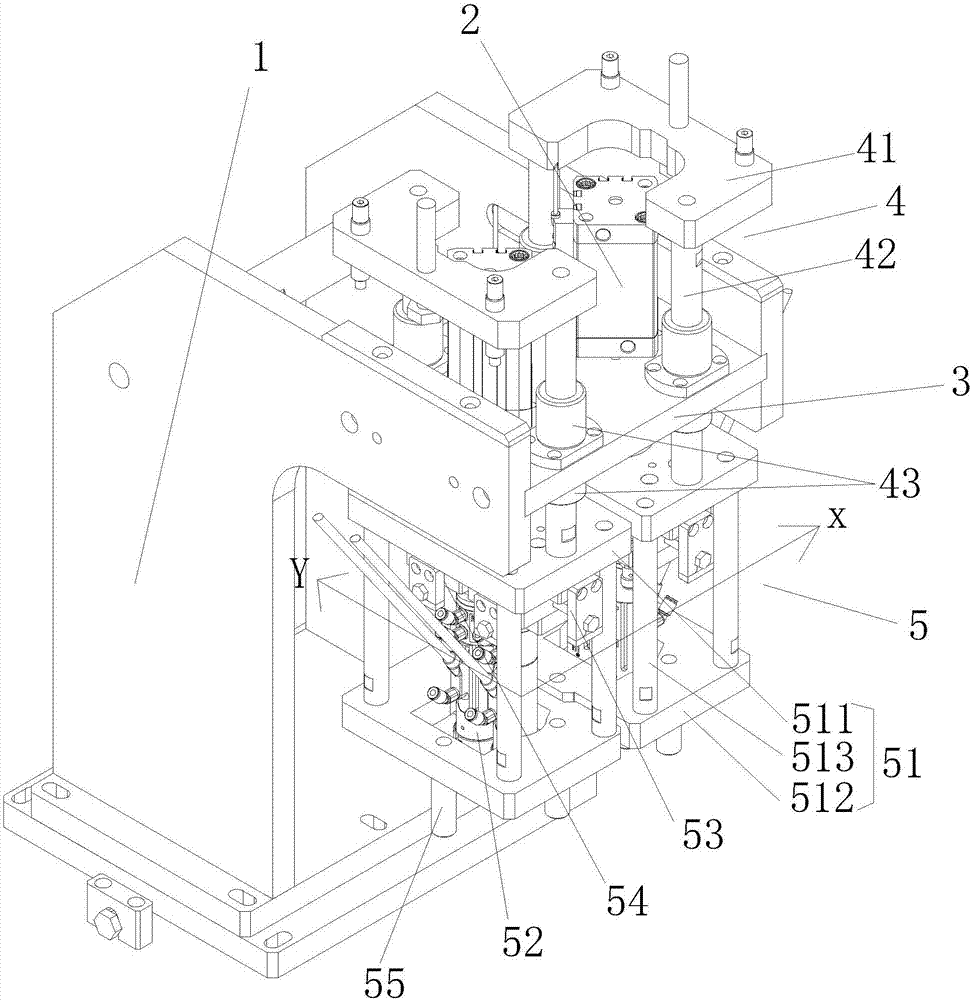

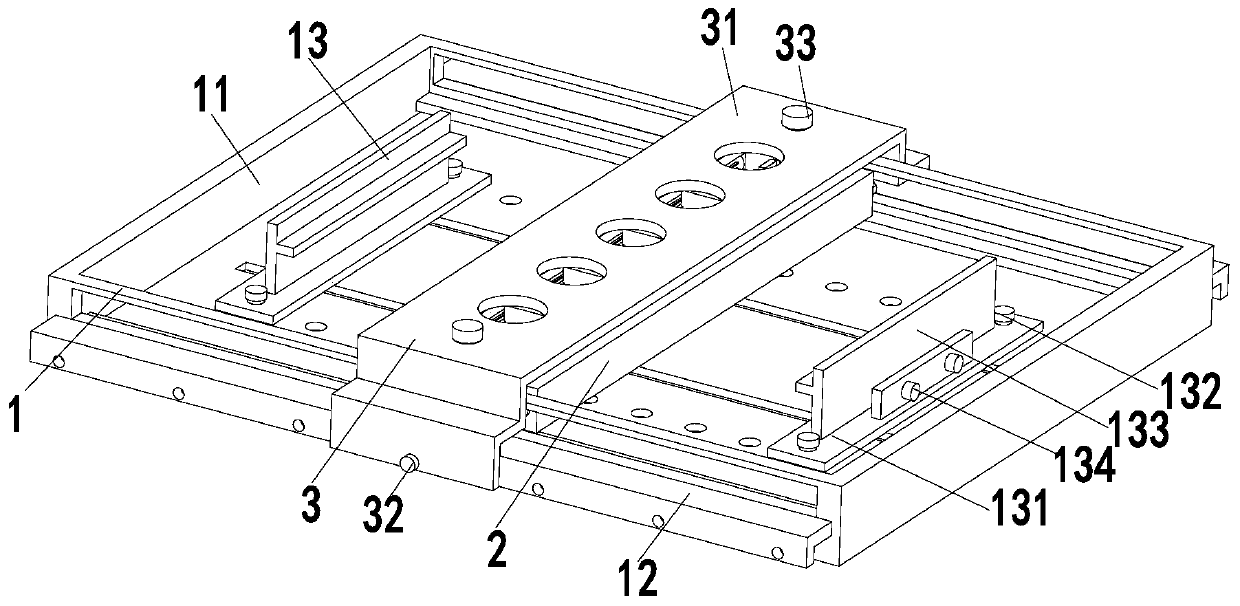

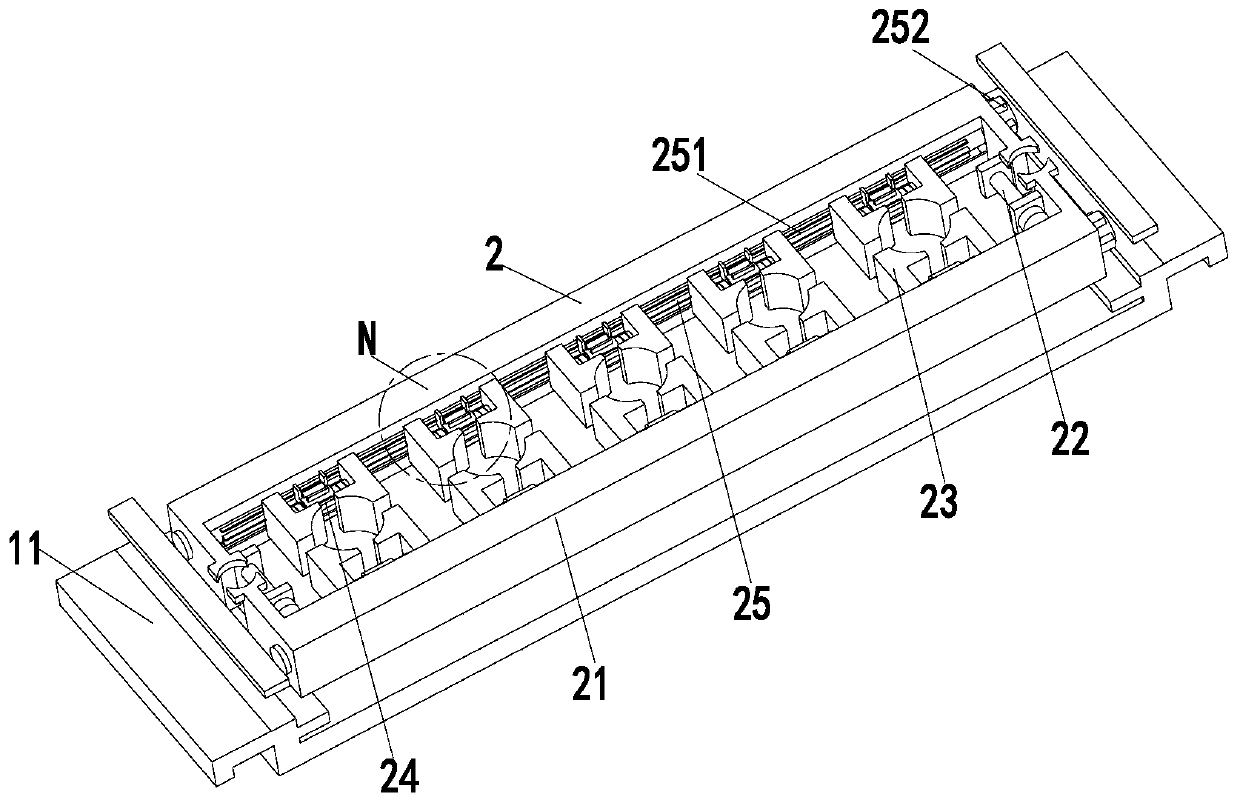

Turnover type intelligent reconfigurable riveting clamp for thin plate parts

ActiveCN112025310AMove preciselyHigh hole precisionWork holdersOther manufacturing equipments/toolsVacuum pressureControl engineering

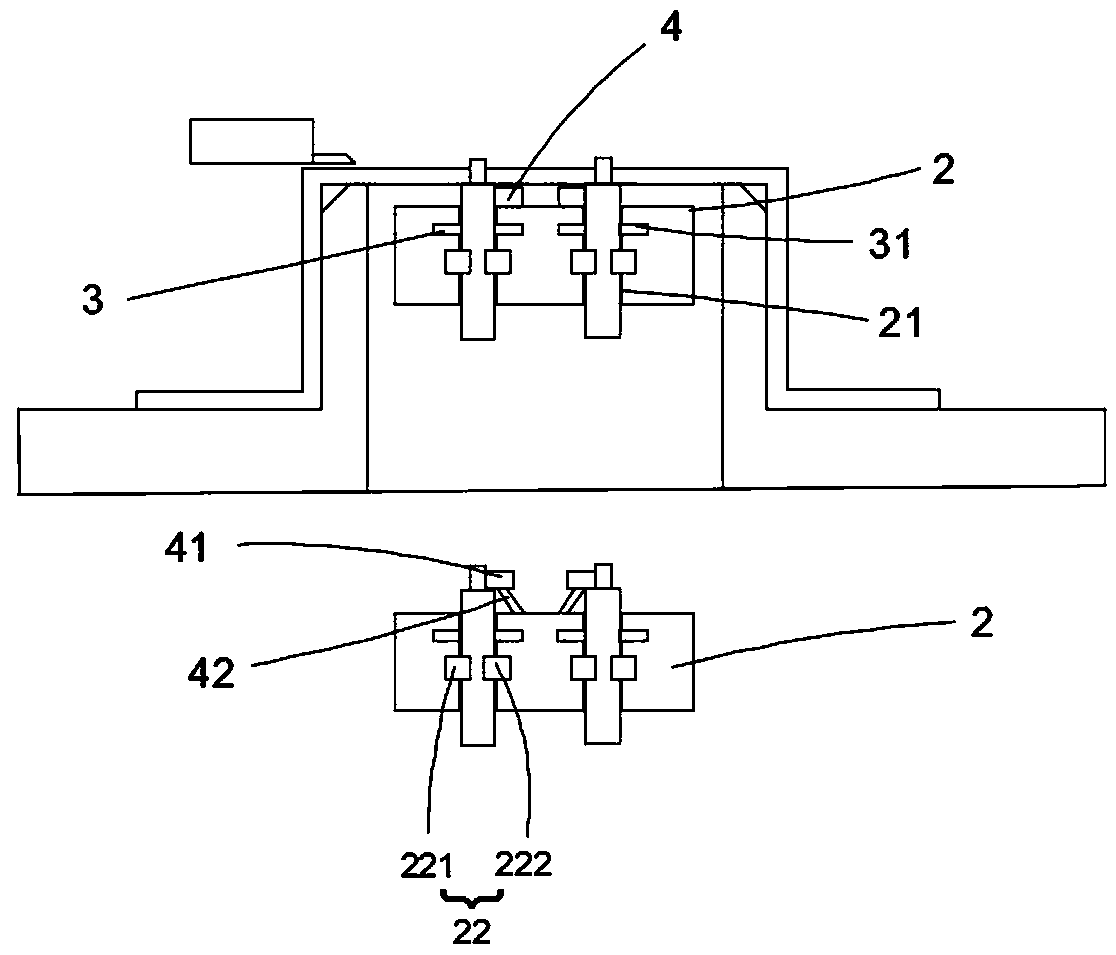

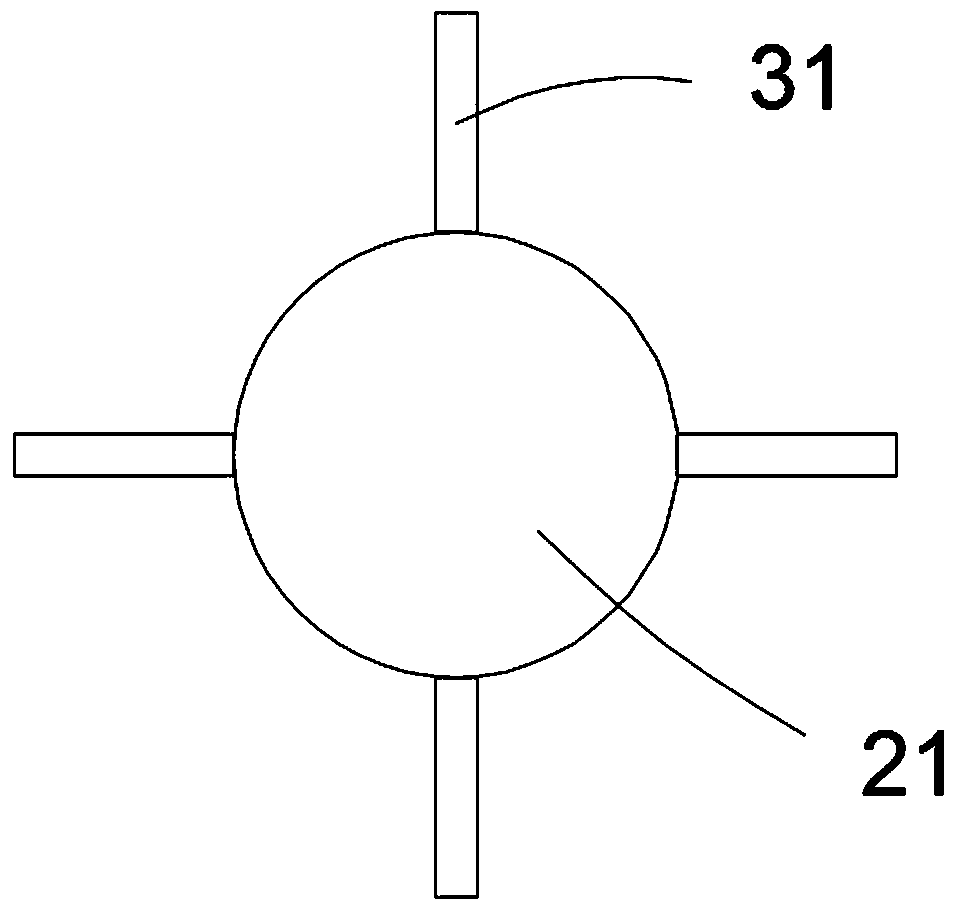

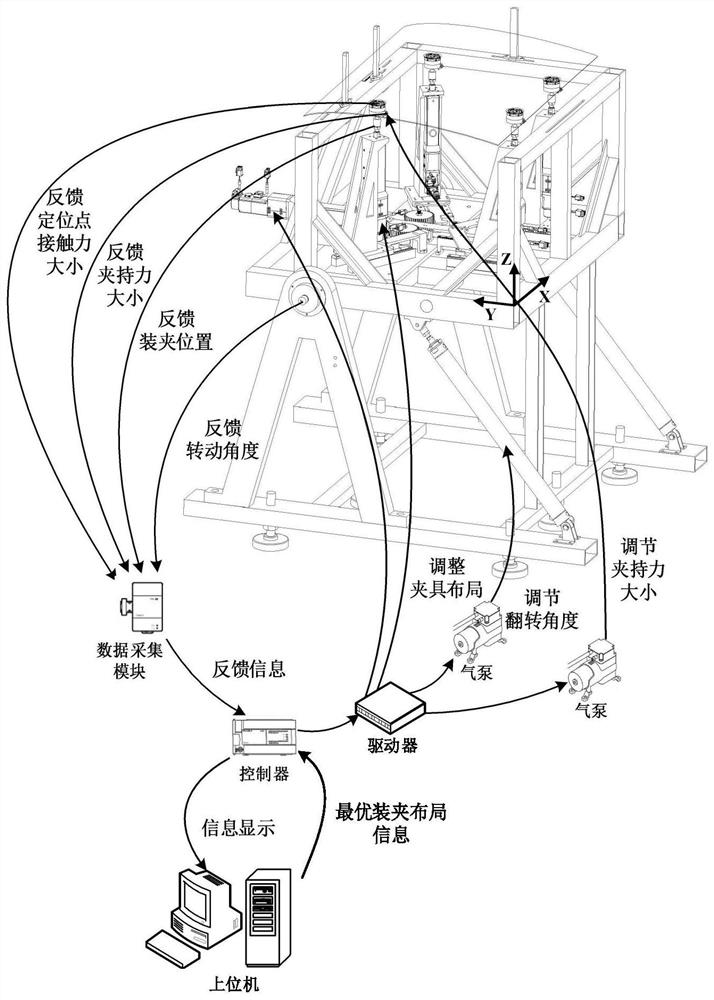

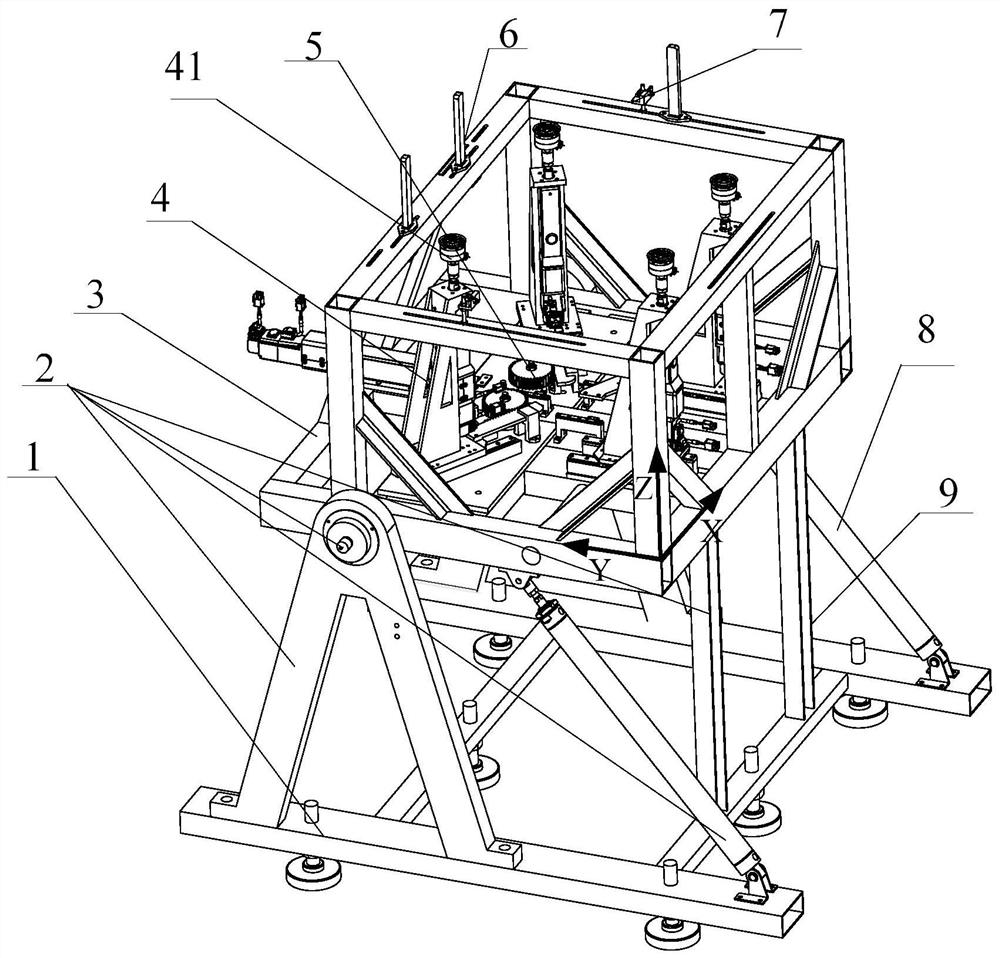

The invention discloses a turnover type intelligent reconfigurable riveting clamp for thin plate parts. The turnover type intelligent reconfigurable riveting clamp is mainly used for clamping the thinplate part for drilling and riveting operation. The turnover type intelligent reconfigurable riveting clamp mainly comprises a multi-point flexible turnover tool mechanical body, a sensing module anda control module, clamping is carried out on a skin mainly in an N-2-1 positioning mode, the actual position of a positioning ball head is fed back through a stay wire displacement sensor assembled on an electric cylinder, a force measuring sensor and a vacuum pressure sensor feed back actual positioning point contact force and clamping force, an angle sensor detects the actual overturning angleof an overturning workbench, a controller collects actual clamping layout information through the data collection module, the actual clamping layout information and optimal clamping layout data inputby an upper computer are analyzed and decided, instructions from the controller are executed by the electric cylinder and an air pump, and adjusting is carried out on the tool position and the clamping force. The turnover type intelligent reconfigurable riveting clamp is suitable for riveting thin plate parts with different sizes and curvatures, the clamping layout can be adjusted in the machininggap according to different hole forming and riveting positions, and the product quality is effectively guaranteed.

Owner:XIAN UNIV OF TECH

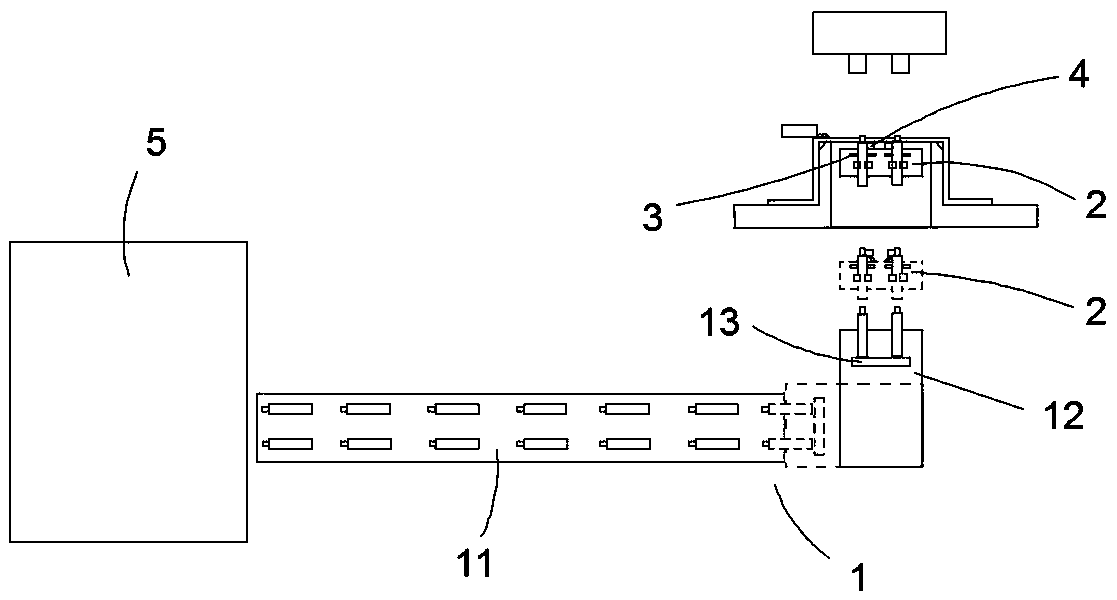

Machine for automatically combining and riveting gear shafts with gear plates in straight-line manner

A linear gear shaft and gear plate automatic combination riveting machine of the present invention includes a machine case, a machine table, a man-machine operation interface, a column gear feeding mechanism, a column gear stripping cylinder, a riveting combination mechanism, a piece gear feeding mechanism, and a finished product unloading mechanism. Feeding mechanism, pressure switch and pressure sensing display. The invention can realize a series of operations such as automatic feeding, automatic changing of the conveying direction of the workpiece, automatic positioning, automatic precise riveting, automatic material suction and unloading for the column gear and the plate gear. It not only has firm riveting, but also has high riveting efficiency. , high riveting precision and high production capacity, which also reduces the labor intensity and labor cost of workers, and ensures that the finished products riveted by it can reach a uniform standard. As a result, it has the problems of low riveting efficiency, poor riveting precision, inconsistent riveting pressure and difficulty in reaching uniform standards for riveted finished products.

Owner:罗飞龙

Infrared riveting mechanism

The invention discloses an infrared riveting mechanism, which comprises a frame, a driving device, a fixing plate and a riveting device, the fixing plate is arranged on the top of the frame, a driving device is arranged above the fixing plate, a riveting device is arranged under the fixing plate, and a fixed A through hole is opened on the board, and the driving device includes a movable end and a fixed end. The movable end of the driving device passes through the through hole and is connected to the top drive of the riveting device. The riveting device includes a fixed frame, an infrared riveting machine, an X-axis displacement adjustment mechanism and The Y-axis displacement adjustment mechanism, the X-axis displacement adjustment mechanism and the Y-axis displacement adjustment mechanism are respectively arranged on the inner top of the fixed frame, and the top of the infrared riveting machine is respectively connected with the X-axis displacement adjustment mechanism and the Y-axis displacement adjustment mechanism. Compared with the prior art, the invention not only can rivet parts in some narrow spaces, but also has high riveting precision.

Owner:儒拉玛特自动化技术(合肥)有限公司

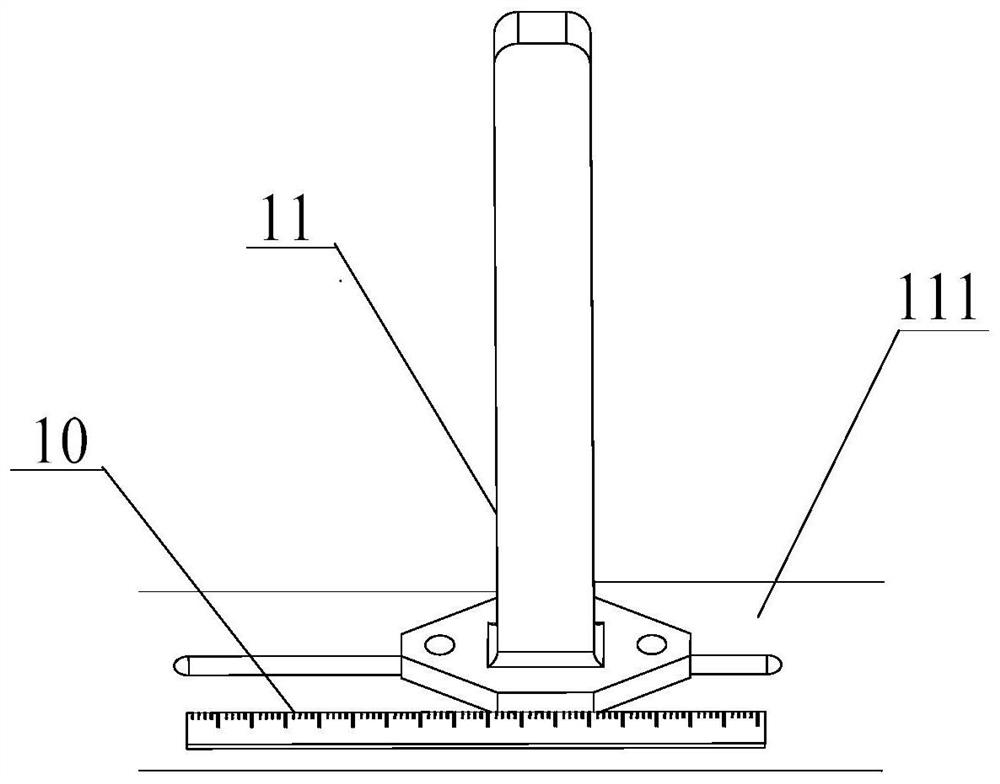

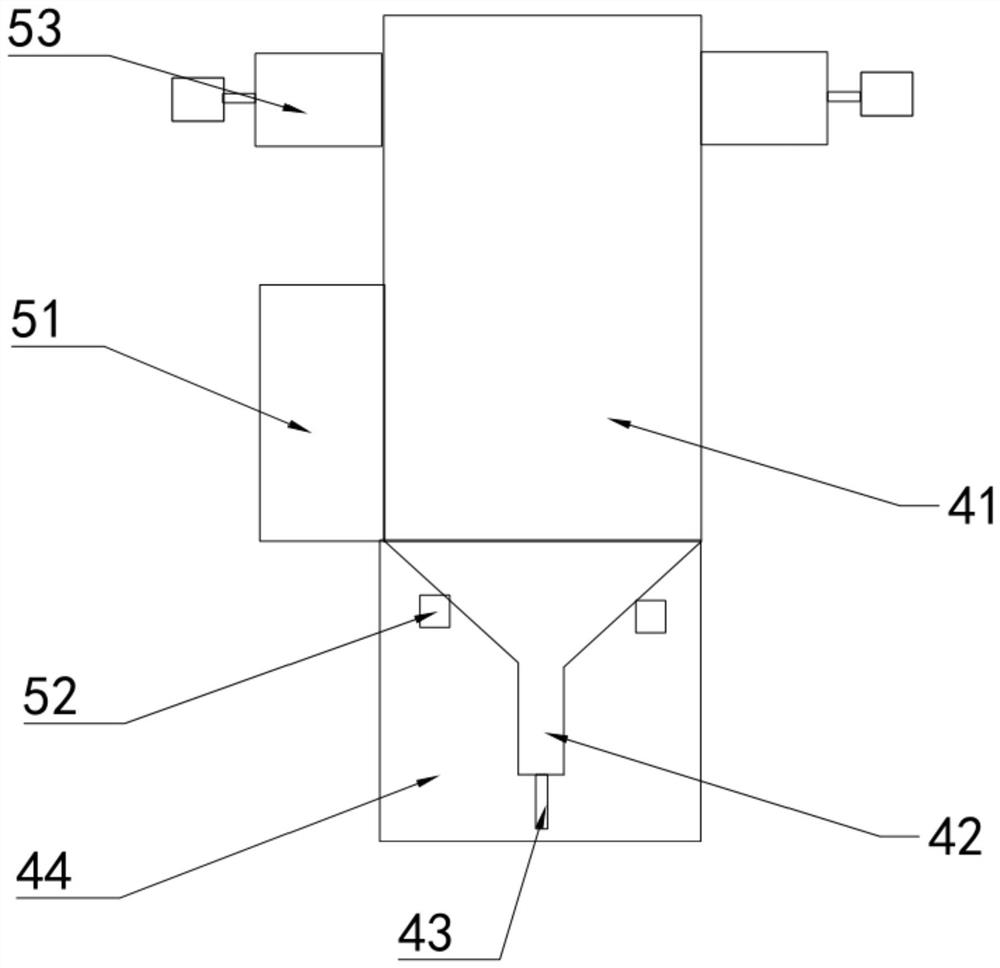

In-mold riveting automatic feeding mechanism

The invention discloses an automatic feeding mechanism for riveting in a die. The automatic feeding mechanism comprises a stamping upper die, a stamping lower die, a vibrating disc, a support plate, a vibrating disc drive device, a rivet retaining plate, a positioning pin and a positioning pin drive device, wherein the stamping upper die is positioned right above the stamping lower die in a longitudinal reciprocating manner, the positioning pin is disposed in the stamping lower die in a longitudinal liftable manner, the positioning pin drive device drives the positioning pin to longitudinally move up and down, the support plate is fixedly positioned on the outer side of the stamping lower die, the vibrating disc which can slide towards the internal directions of the stamping upper die and the stamping lower die in a reciprocating manner is positioned on the support plate, the rivet at the tail end of the discharge passage of the vibrating disc can coaxially directly face the positioning pin, the rivet retaining plate is positioned at the tail end of the discharge passage of the vibrating disc and can provide set resistance to the rivet at the tail end of the discharge passage of the vibrating disc, and the vibrating disc drive device drives the vibrating disc to move. The automatic feeding mechanism which is mechanically driven is simple in structure, energy saving, free of technical requirements on operators, less prone to failure, and high in production efficiency.

Owner:KUNSHAN HAO YUN PRECISION MOLD

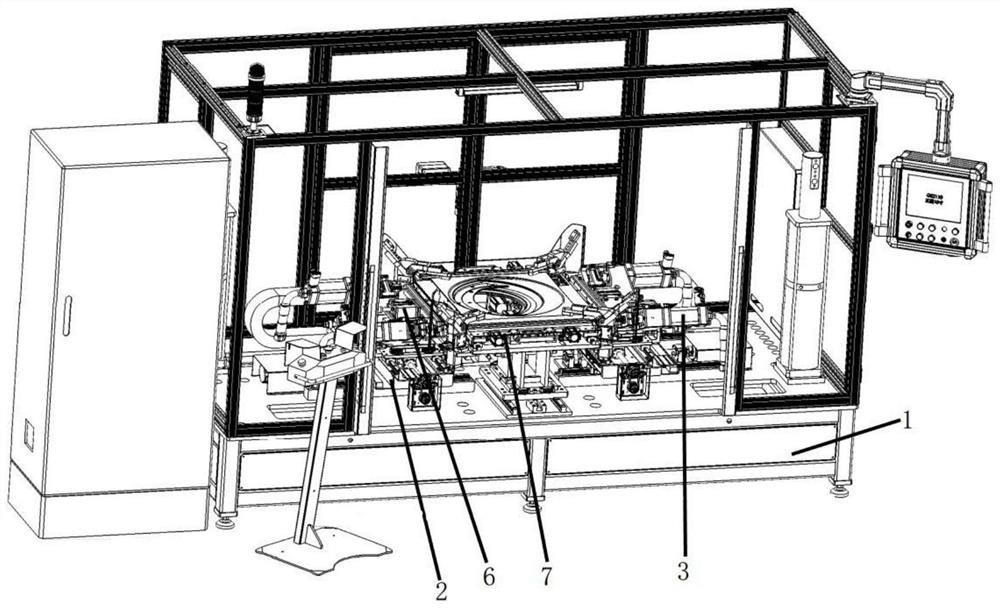

Full automatic three-dimensional multipoint hot riveting assembling process technique for die casting of magnesium alloy

The invention relates to a full automatic three-dimensional multipoint hot riveting assembling process technique for the die casting of magnesium alloy, which is provided with a full automatic three-dimensional multipoint cold riveting special device for the die cast of aluminum alloy, wherein the special device mainly comprises a vertical Z-direction servo linear sliding table, a rotary riveting power head system, a sliding table power mounting base, a horizontal Y-direction servo linear sliding table, a workpiece rotary riveting clamping apparatus, a horizontal X-direction servo linear sliding table, a working table panel and a frame, wherein the sliding table power mounting base and the working table panel are arranged on the frame respectively; the rotary riveting power head system is arranged on the vertical Z-direction servo linear sliding table; the vertical Z-direction servo linear sliding table is arranged on the sliding table power mounting base; the workpiece rotary riveting clamping apparatus is arranged on the horizontal Y-direction servo linear sliding table; the horizontal Y-direction servo linear sliding table is arranged on the horizontal X-direction servo linear sliding table; the horizontal X-direction servo linear sliding table is arranged on the working table panel; and the rotary riveting power head system is positioned above the workpiece rotary riveting clamping apparatus. Compared with the prior art, the riveting speed of the full automatic three-dimensional multipoint hot riveting assembling process technique is improved by 1.5 to 2 times, and the technique has the advantages of high riveting quality and connecting fastness, low fault rate, wide product specification adaptive range, high production efficiency, long riveting head service life, high riveting accuracy and the like.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

In-mold riveting continuous stamping die and using method thereof

The invention discloses an in-mold riveting continuous stamping die and a using method thereof. The in-mold riveting continuous stamping die comprises a first riveting stamping head, a second rivetingstamping head, a material belt, a feeding mechanism, a base plate, a first pushing and positioning mechanism, a second pushing and positioning mechanism and a second riveting plate. The first pushingand positioning mechanism, the second pushing and positioning mechanism and the second riveting plate are separately installed on the base plate. The first pushing and positioning mechanism and the second pushing and positioning mechanism separately comprises a first guide block and a first riveting plate. The feeding mechanism is connected with the first guide block, and a riveting piece passageis formed along the feeding mechanism, the first guide block and the first riveting plate. The material belt is positioned directly above the first riveting plate and the second riveting plate, and the first riveting stamping head and the second riveting stamping head are separately positioned above the material belt. The in-mold riveting continuous stamping die can realize full automation for in-mold continuous stamping riveting, and has high precision, high efficiency, high qualification rate and better safety.

Owner:广东天倬智能装备科技有限公司

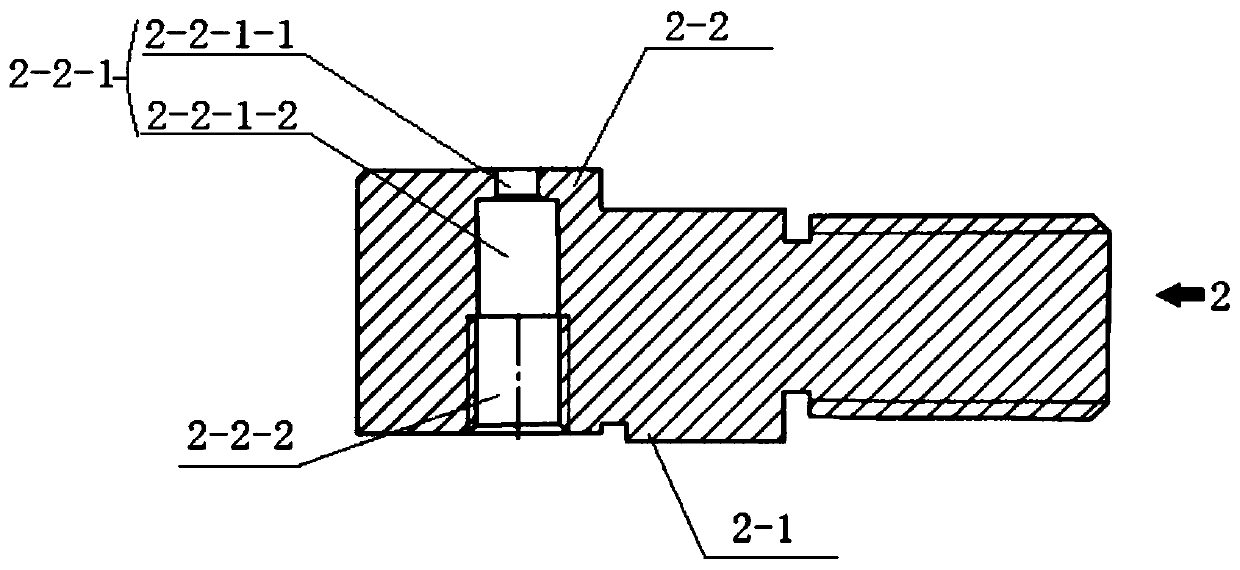

Electric connector ceramic ball riveting device and riveting method

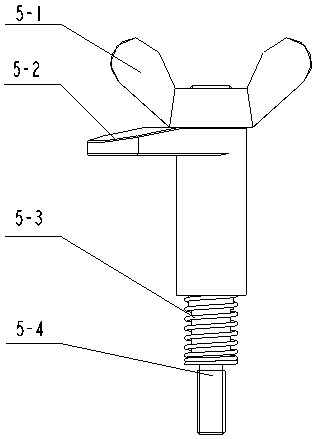

PendingCN110434588AHigh positioning accuracyAvoid positioning deviationMetal working apparatusSet screwElectricity

The invention provides an electric connector ceramic ball riveting device and a riveting method. The problems that according to an existing electric connector ceramic ball riveting method, the riveting quality cannot be guaranteed, the reject ratio is extremely high, the production efficiency of products is low, and the cost is high are solved. The riveting device comprises a positioning base, a shaft core, a hexagonal nut, a positioning pin, a spring, a set screw and a riveting pressure head. The invention further provides the riveting method of the riveting device. The riveting device and the riveting method have the advantages that the operation is simple, and after adjusting is completed, riveting can be completed even by a non-professional riveting person; the riveting precision is high, and the riveting requirements of multiple existing sockets can be completely met; the riveting qualification rate is high and is almost 100%; and the riveting efficiency is high, and compared withthe efficiency of the riveting technology at the current stage, the efficiency can be improved by 50% or more.

Owner:沈阳兴华航空电器有限责任公司

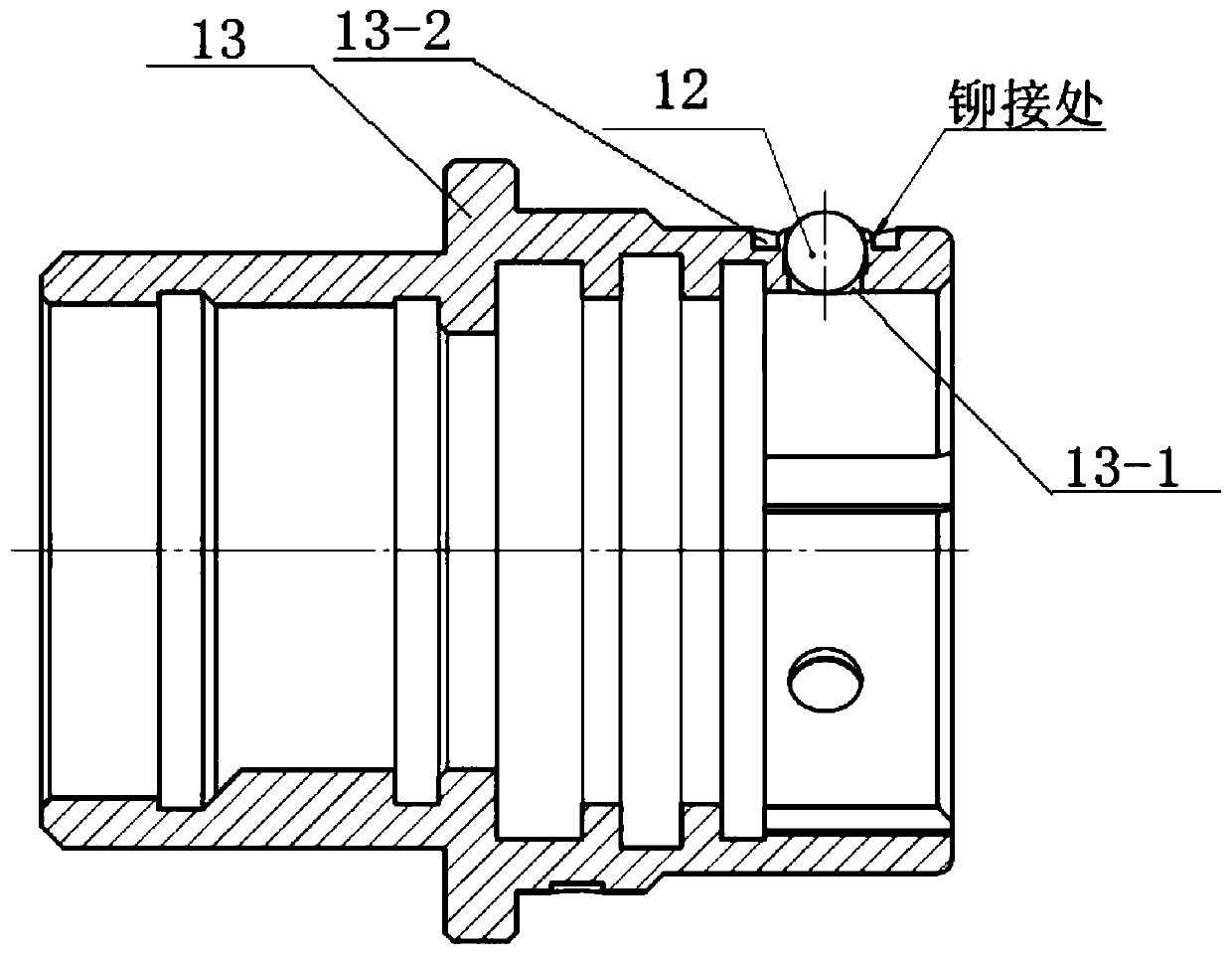

Drilling-riveting machine tool used for aircraft hull manufacturing

PendingCN110202381ARealize multi-axis linkageImprove riveting precisionMeasurement/indication equipmentsOther manufacturing equipments/toolsAirplaneEngineering

The invention relates to a drilling-riveting machine tool used for aircraft hull manufacturing. The drilling-riveting machine tool used for aircraft hull manufacturing is provided with a rack, whereinan end executer used for drilling-riveting is arranged on the rack; the rack comprises a portal frame, a ram, a slide table and a slide frame; the portal frame comprises two symmetrically-arranged vertical columns and a cross beam; the two ends of the cross beam are fixedly connected with the upper ends of the two vertical columns separately; the two ends of the ram are slidably arranged on the two vertical columns separately, and a first drive device capable of driving the ram to slide along Z axis is arranged on the ram; the slide table is slidably arranged on the ram, and a second drive device capable of driving the slide table to slide along Y axis is arranged on the slide table; the slide frame is slidably arranged on the slide table, and a third drive device capable of driving the slide frame to slide along X axis is arranged on the slide frame; and the end executer used for drilling-riveting is fixedly connected to one end of the slide frame. The drilling-riveting machine toolused for aircraft hull manufacturing is high in automation degree, and high in drilling-riveting efficiency and machining accuracy.

Owner:常州市三利精机有限公司

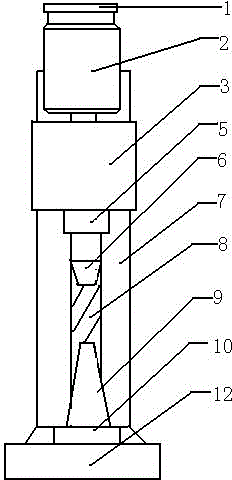

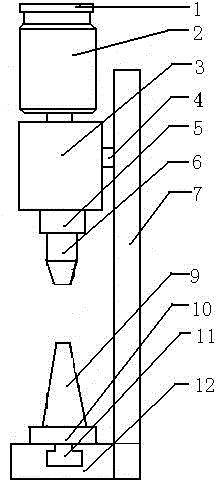

Novel high-precision riveting mechanical device

Provided is a novel high-precision riveting mechanical device. The novel high-precision riveting mechanical device is characterized in that the device comprises a piston rod, a hydraulic cylinder, a gearbox, a sliding block, an output shaft, an upper revolving-riveting die, a vertical post, a slide way, a lower revolving-riveting die, a base, an adjusting block and a workbench; the driver hydraulic cylinder is arranged at the top of the device; the upper end of the hydraulic cylinder is the telescopic piston rod; the gearbox is installed below the hydraulic cylinder and can slide on the vertical post provided with the slide way through the sliding block; the output shaft is installed below the gearbox, and the vertical post is fixedly welded to the workbench; the workbench is provided with a trapezoidal groove covering the adjusting block below the base; the lower revolving-riveting die is fixed to the base, and the upper revolving-riveting die is fixed to the output shaft. The novel high-precision riveting mechanical device has the advantages of being simple in structure, convenient to operation, short in working hour, high in riveting efficiency, riveting precision and flexibility, good in damping effect and long in service life.

Owner:严云成

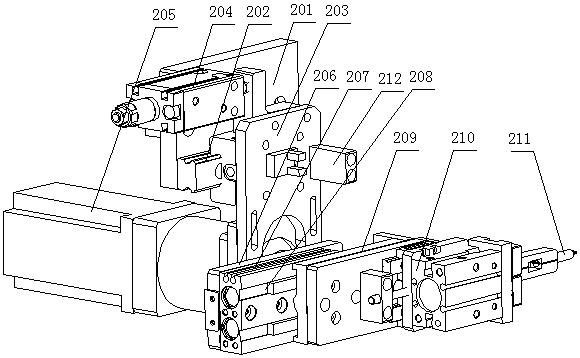

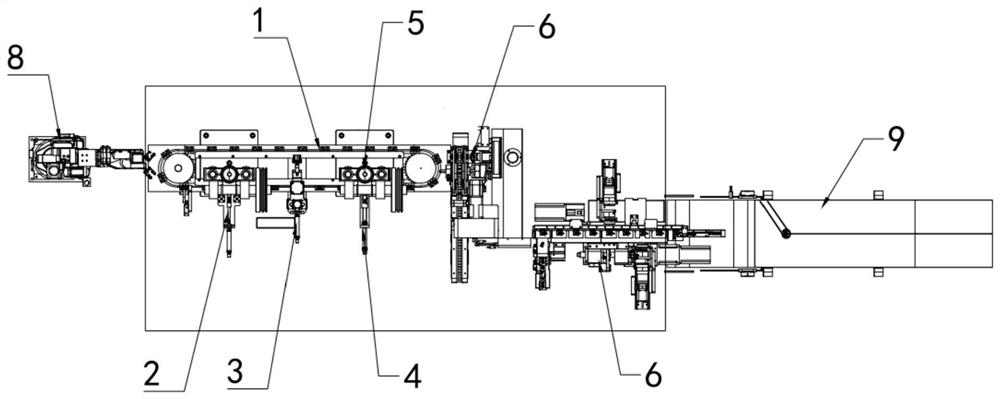

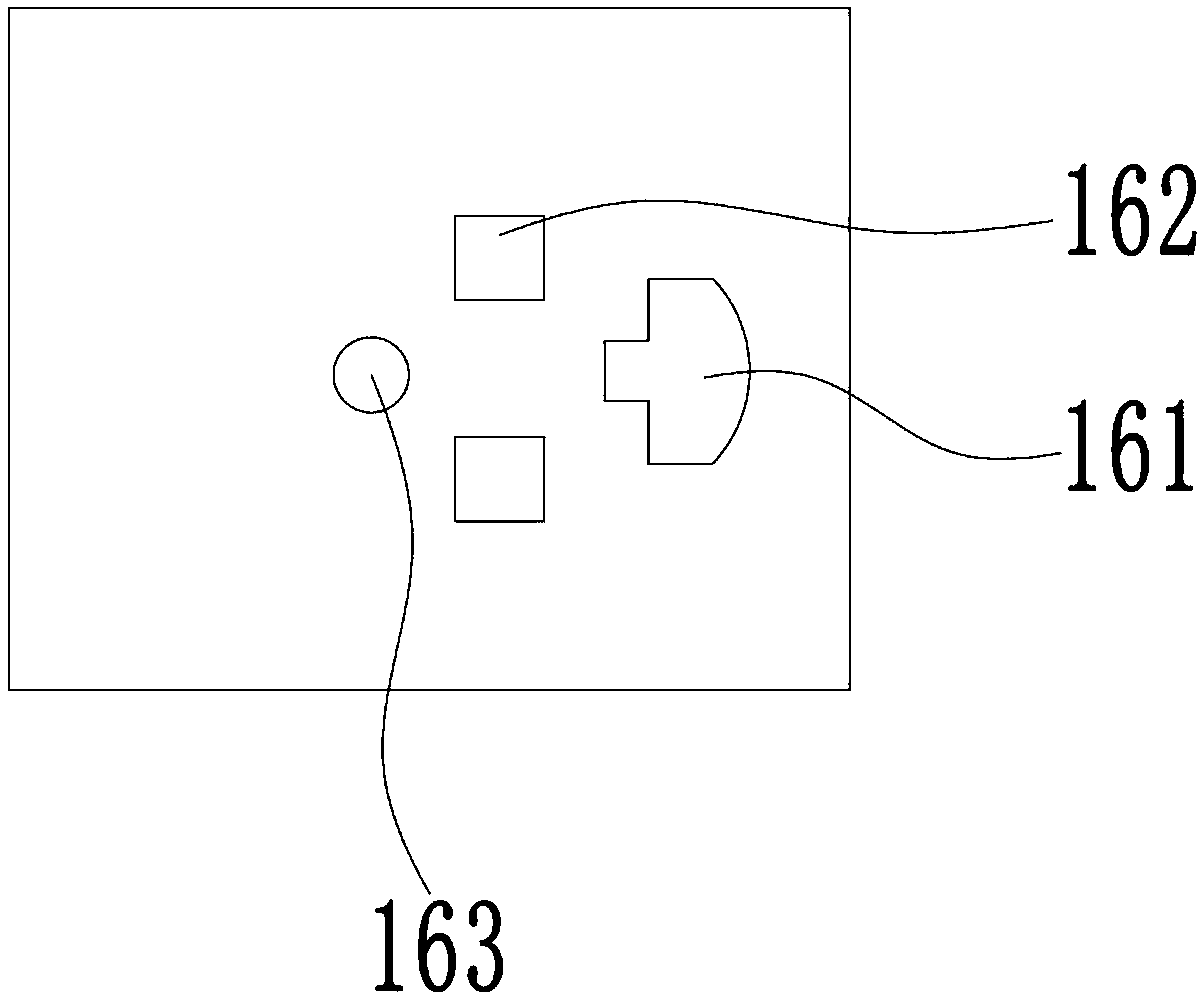

An electronic detonator chip foot wire riveting device

An electronic detonator chip leg riveting device, comprising a feeding module (1), a riveting module (4), a retrieving module (2) connected to the riveting module (4), a transfer module (5), and an empty box recovery module ( 3); the riveting module (4) includes the first linear slide rail (402), the riveting upper punching knife (403), the second linear slide rail (406), the riveting lower positioning knife (407), the link mechanism, and the second The cylinder (408); the transfer module (5) includes the third linear slide rail (502), the slide bracket (503), the longitudinal drive belt (504), the first servo motor (505), the fourth linear slide rail (506), The transfer plate (507), the transverse drive belt (508), the reclaiming module (2) includes the fifth linear slide rail (202), the rotating cylinder mounting seat (203), the third cylinder (204), the rotating cylinder (205), Cylinder mounting plate (206), the fourth cylinder (207), the sixth linear slide rail (208), finger cylinder mount (209), finger cylinder (210).

Owner:XIANGNAN EXPLOSION APPLIANCES HUNAN PROV

Clothes dryer control seat servo automatic riveting equipment

The invention discloses clothes dryer control seat servo automatic riveting equipment. The clothes dryer control seat servo automatic riveting equipment comprises a horizontally-arranged workbench, two first sliding seats symmetrically arranged on the workbench and a positioning mechanism, the first sliding seats are arranged on the workbench in a sliding mode through first guide rails, and the top end of each first sliding seat is provided with two pincer bodies which slide relatively; the pincer bodies are arranged on the first sliding seats in a sliding mode through second sliding seats, the second sliding seats are arranged on the first sliding seats in a sliding mode through second guide rails, the first guide rails are perpendicular to the second guide rails, the pincer bodies are arranged on the second sliding seats in a sliding mode through third sliding seats, and the third sliding seats are arranged on the second sliding seats in a sliding mode through third guide rails, third guide rails are perpendicular to the second guide rails, and the positioning mechanism comprises two first clamping devices fixed to the first sliding seat correspondingly and two second clamping devices arranged on the workbench in a sliding mode. The clothes dryer control seat servo automatic riveting equipment is compact in structure, the four pincer bodies conduct riveting at the same time,and the riveting efficiency is improved.

Owner:SUZHOU SIMITCH MASCH CO LTD

A positioning riveting device for wing shaft seat assembly

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Full-automatic intelligent riveting device of motor rotor balance piece

PendingCN109332505AImprove riveting efficiencyImprove riveting precisionMetal-working feeding devicesManufacturing dynamo-electric machinesEngineering

Owner:SHANGHAI UNIV OF ENG SCI

Automobile spare part rotary-riveting connecting device

The invention discloses an automobile spare part rotary-riveting connecting device which comprises a workbench. A mechanical arm control host is mounted on one side of a machine body. The output end of the mechanical arm control host is connected with a rotating shaft. A riveting head on a riveting head assembly can ascend and descend and rotate at a high speed through a motor and a first air cylinder, the position of the riveting head can be finely adjusted through a stroke fine adjustment nut, and therefore the riveting head is more accurate during riveting. The mechanical arm control host is arranged on one side of the rotary-riveting connecting device, the rotating shaft and a lifting support are mounted, a second air cylinder and a suction cup can achieve up-and-down and left-and-right transmission, suction force is generated by the second air cylinder, air in the suction cup can be drawn out, and therefore air pressure is generated to easily adsorb automobile parts; after the suction cup places the automobile parts on a base, air is injected into the suction cup through the second air cylinder, the inner air pressure and the outer air pressure are equal, and the automobile parts can be separated; and thus, the cost of manually replacing the automobile parts can be omitted, and meanwhile potential safety hazards are reduced.

Owner:施米特(武汉)自动化技术有限公司

Feeding heating and auxiliary riveting method for riveted shaft

The invention discloses a feeding, heating and auxiliary riveting method for riveting shafts. The method comprises the steps as follows: a grabbing manipulator grabs a group of riveting shafts from a conveying belt, rotates and sends the riveting shafts to the position below a clamping and feeding device; a pushing driving device drives a pushing device to rise to push the group of riveting shafts into a group of shaft accommodating cavities; when the riveting shafts reach the set positions, a clamping driving device operates, and clamping devices clamp the riveting shafts; a telescoping driving device drives telescopic arms of heating devices to extend, and heating ends make contact with riveting parts of the riveting shafts for heating; a feeding driving device operates, the clamping and feeding device moves to the position below to-be-machined sheet metal at a riveting station; and the feeding driving device operates continuously, and the clamping and feeding device drives the group of riveting shafts to be embedded in corresponding riveting holes. The production efficiency and the automation degree of production are increased; fine adjustment of the perpendicularity is performed while the shafts are clamped, and the riveting precision is guaranteed; riveting is performed after heating, and thus the riveting precision and strength are enhanced.

Owner:太仓市华天冲压五金制品厂

An Intelligent Reconfigurable Riveting Fixture for Turning Thin Plate Parts

ActiveCN112025310BHigh hole precisionImprove riveting precisionWork holdersOther manufacturing equipments/toolsVacuum pressureControl engineering

The invention discloses an intelligent and reconfigurable riveting fixture for flip-type thin plate parts, which is mainly used for clamping thin plate parts for drilling and riveting operations. This intelligent tooling mainly includes a multi-point flexible flip tooling mechanical body, a sensing module and a control module. The skin is clamped mainly through the N-2-1 positioning method, and the actual position of the ball head is positioned by the cable displacement sensor equipped with the electric cylinder. , the load cell and the vacuum pressure sensor feed back the actual positioning point contact force and clamping force, and the angle sensor detects the actual flip angle of the flip table; the controller collects the actual clamping layout information through the data acquisition module, and communicates with the upper computer input The optimal clamping layout data is analyzed and decided, and the instructions from the controller are executed by the electric cylinder and air pump to adjust the position of the tooling and the clamping force. This intelligent reconfigurable flip tool is suitable for riveting of thin plate parts of different sizes and curvatures, and can adjust the clamping layout in the processing gap for different hole making and riveting positions, effectively ensuring product quality.

Owner:XIAN UNIV OF TECH

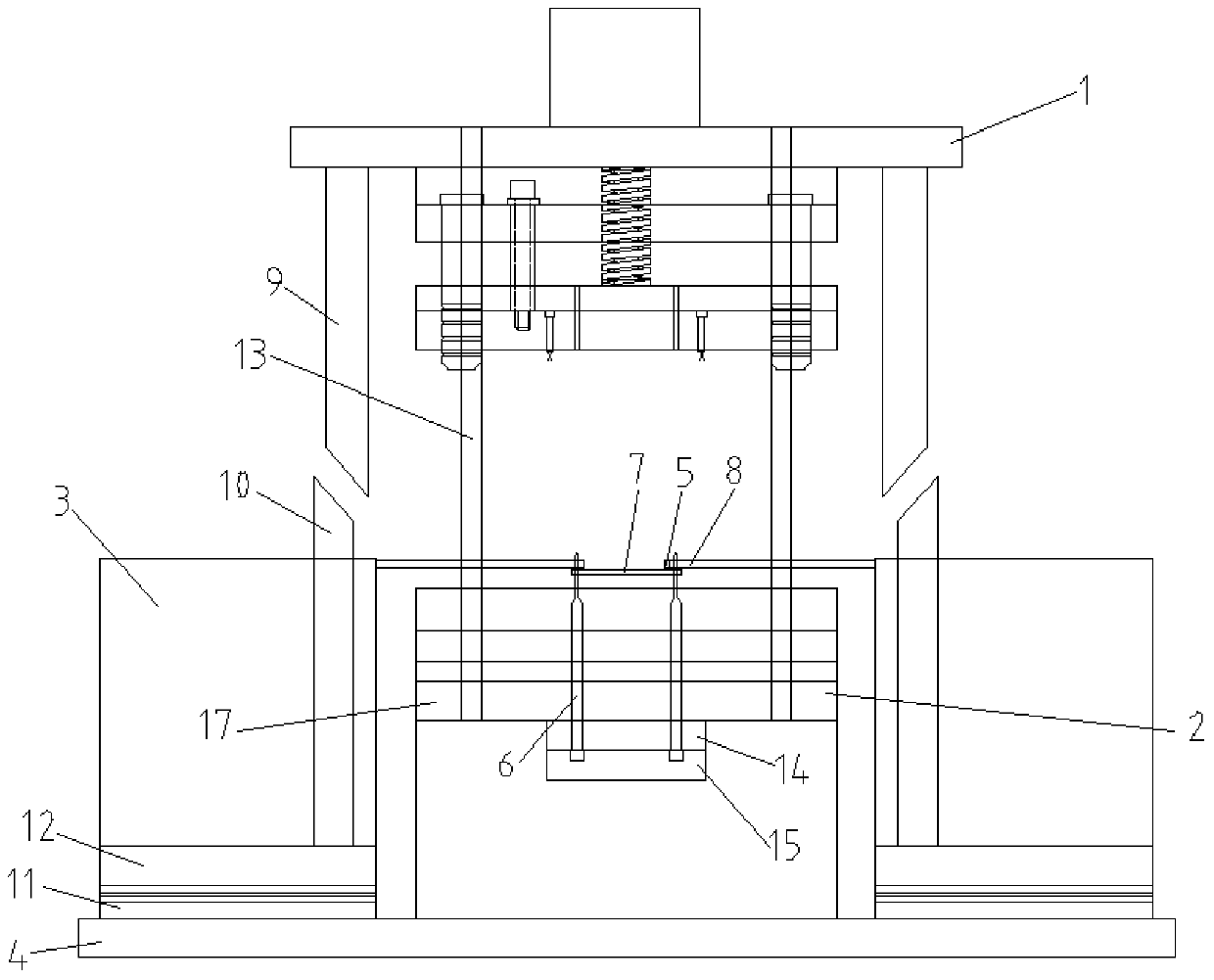

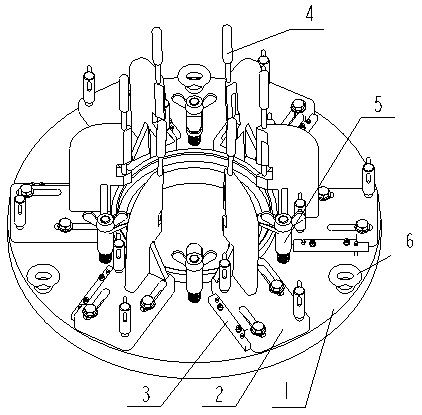

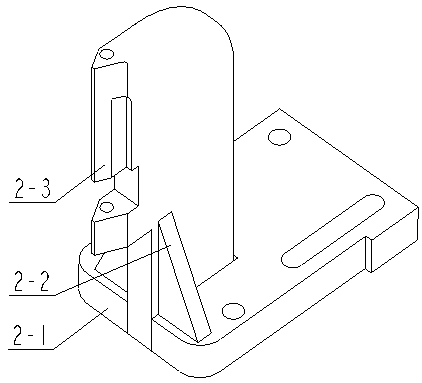

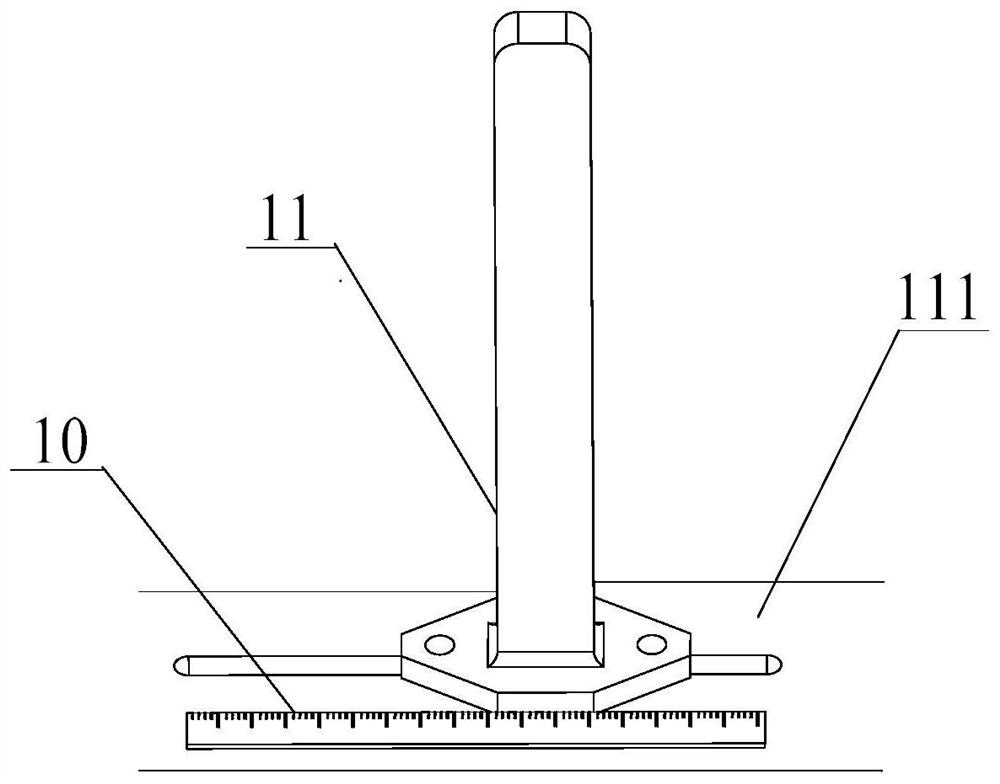

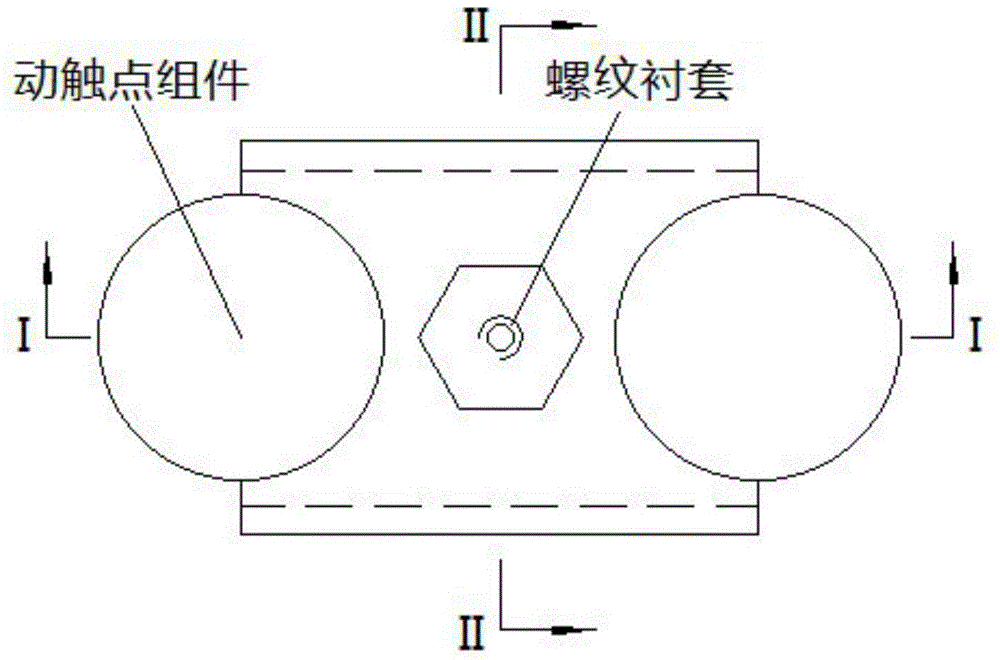

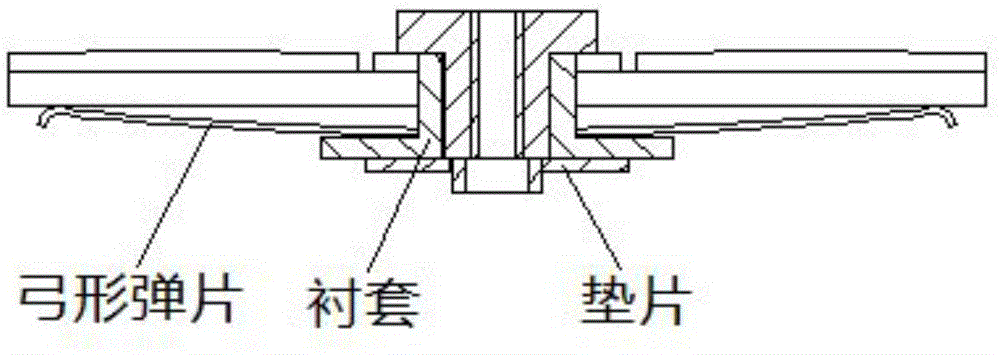

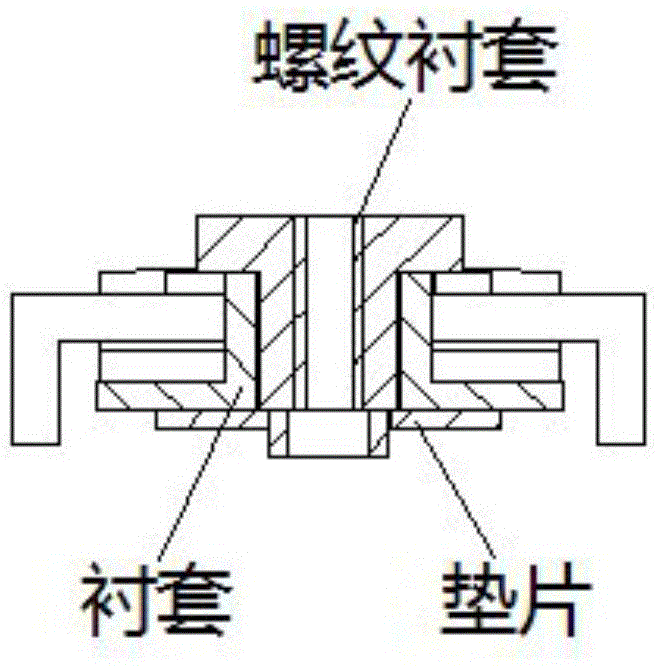

A riveting jig for a sealed contactor with an elastic reed moving contact piece assembly

ActiveCN104096770BReduce manual labor intensityReduce the threat of security risksMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a seal contactor riveting clamp for a moving contact chip component with an elastic reed. The seal contactor riveting clamp comprises a bottom plate, a pedestal fixedly connected above the bottom plate, and an upper punch matched with a lower punch, wherein a lower punch holder is installed above the pedestal through a connecting screw; the middle part of the lower punch holder is fixedly connected with the lower punch; the upper end of the upper punch is sheathed with a supporting arm; the top end of the upper punch is fixedly connected with a spherical nut; the lower end of the spherical nut is sheathed with return springs; a rubber block is fixedly connected onto the lower punch holder; a punching riveting pretightening mechanism is arranged between the rubber block and the upper punch. According to the seal contactor riveting clamp, as one punching riveting pretightening mechanism is arranged between the upper punch and the lower punch, the moving contact chip component with the elastic reed can be pretightened before punching riveting without the need of being manually pretightened; therefore the labor intensity of manpower can be decreased greatly; moreover, the riveting precision is effectively improved; meanwhile, the threat of potential safety hazards can also be lowered, so that the occupational accidents are reduced.

Owner:GUIZHOU TIANYI ELECTRICAL

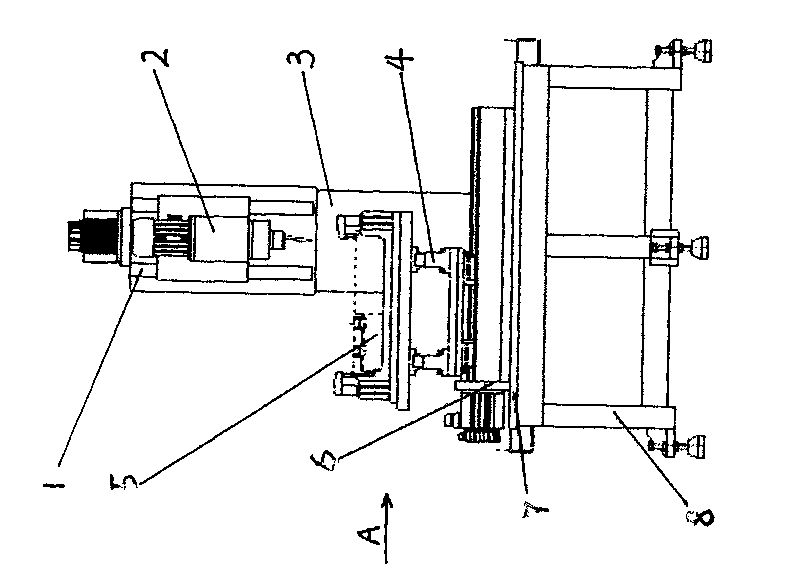

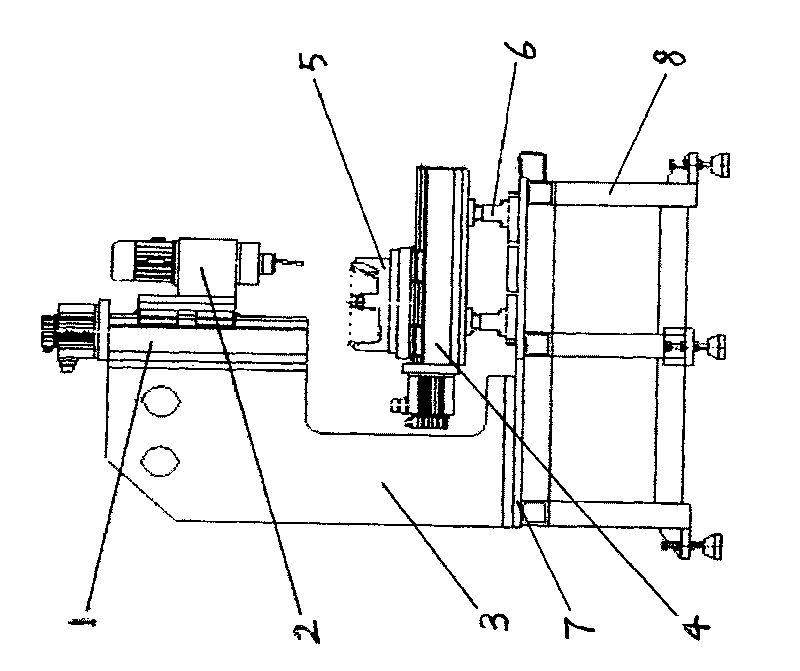

A heating and feeding device for shaft riveting

ActiveCN107378380BIncrease productivityHigh degree of production automationMetal working apparatusComputer moduleEngineering

The invention discloses a heating and feeding device for shaft riveting. The heating and feeding device comprises a conveying unit, a clamping and feeding unit, heating units and a control module. The clamping and feeding unit comprises a set of shaft storing cavities, clamping units and clamping and driving units. The heating units comprise heating ends, telescopic arms and telescopic driving units. The heating ends make contact with the riveting parts of shafts, the telescopic arms are connected with the telescopic driving units, the clamping units are connected with the clamping and driving units, and the clamping and feeding unit is connected with a feeding and driving unit. The set of shafts can be conveyed, grasped, clamped and transported to a mounting station simultaneously, the production efficiency is improved, and the production automation degree is increased; fine adjustment of the perpendicularity can be conducted while the shafts are clamped, so that the riveting precision is guaranteed; and heating is firstly conducted, then riveting is conducted, thus the riveting precision is improved, materials of the shafts can also be better jointed, and the riveting strength is enhanced.

Owner:太仓市华天冲压五金制品厂

A kind of assembly equipment of ignition tube assembly

ActiveCN111890014BRealize assembly and fixationImprove pass rateMetal working apparatusEngineeringMechanical engineering

The invention discloses an assembly device for an ignition tube assembly, which includes a riveting device and a detection device; the riveting device includes a first conveying mechanism, a first firmware mechanism, a second fastener mechanism and a riveting mechanism, and the riveting mechanism is provided with The position adjustment mechanism, the riveting mechanism includes a riveting bracket, a balancer, and a riveting gun. The riveting gun includes a gun body, a drive assembly, a pre-positioning part, and a punch. There is a magnetic connecting body, and an electromagnetic fixing piece is arranged at the rear of the magnetic connecting body corresponding to the center of the workpiece placement seat. According to the principle of electromagnetic riveting, the present invention uses a driving component to generate a strong impact force on the punch to realize the assembly and fixation of the component, and is provided with an electromagnetic fixing piece powered by a power supply, which absorbs the punch under the action of the magnetic connector. Fast and accurate positioning to ensure that the punch is on the same axis as the component to be riveted in the workpiece placement slot, improving riveting accuracy and effect.

Owner:东莞市旭高精密金属制品有限公司

Riveting and positioning device applied to T-shaped electric brake component

PendingCN108380808AImprove riveting precisionImprove machining accuracyPulp and paper industryEngineering

The invention provides a riveting and positioning device applied to a T-shaped electric brake component. The riveting and positioning device comprises a rack, wherein a base is arranged at the bottomof the rack, a mounting plate is fixedly arranged on the base, a chute is formed in the mounting plate, a first positioning plate is in sliding connection to the interior of the chute, a rotating shaft is installed on the first positioning plate, the rotating shaft is in driving connection with an eccentric shaft, a second positioning plate is connected to the rotating shaft, a positioning part isarranged on the surface of the second positioning plate, a movable plate which moves in a vertical direction is installed on the rack, the movable plate is connected with a driving cylinder, and a riveting punch part which corresponds to the position of the positioning part is installed at the bottom of the movable plate. Compared with the prior art, the riveting and positioning device has the advantage that the machining precision can be effectively increased.

Owner:昆山仁硕机械制造有限公司

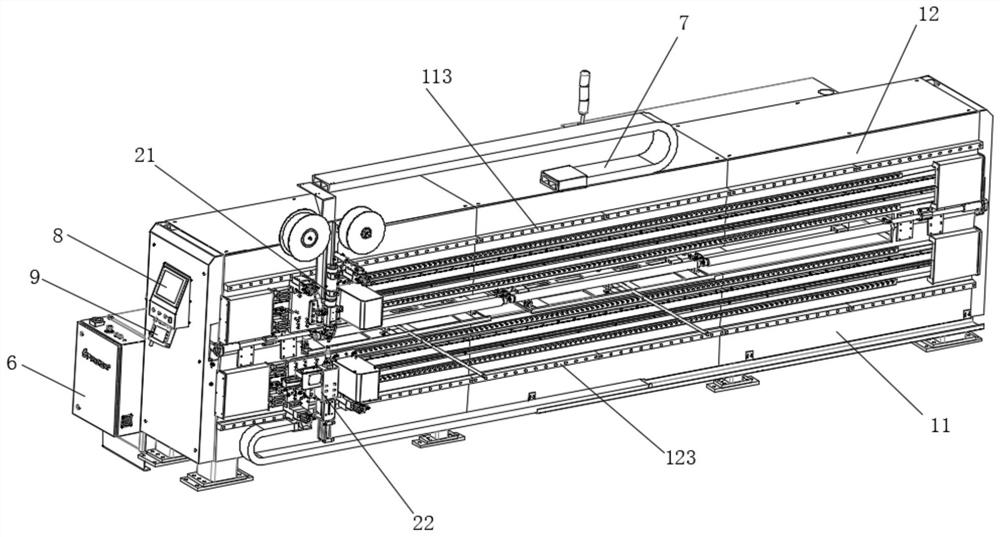

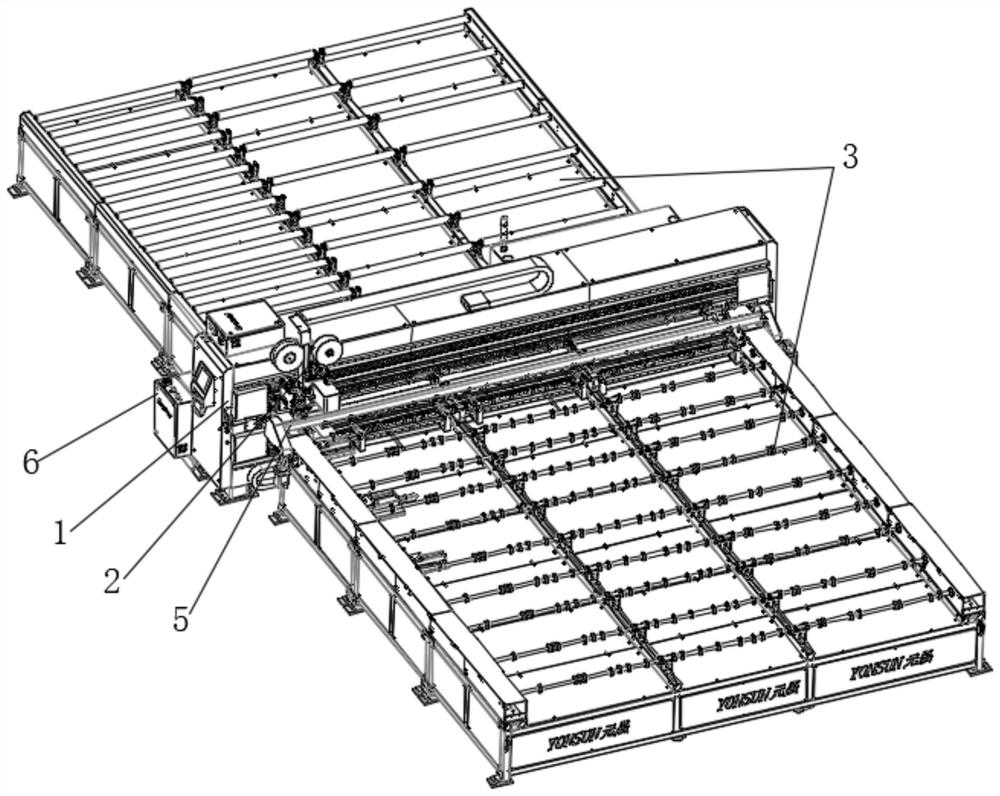

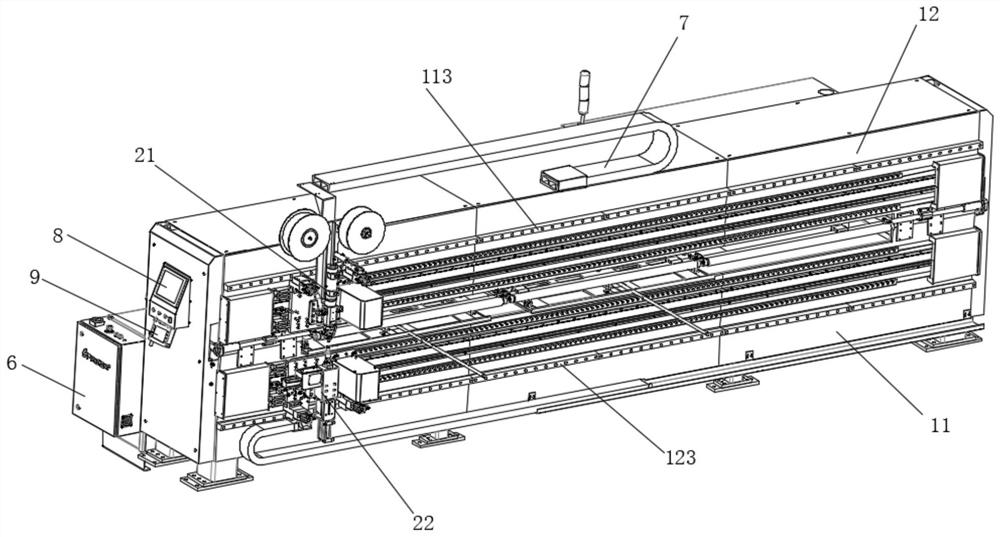

Automatic riveting module for traffic sign aluminum alloy bottom plate

InactiveCN111715834AOrderly and efficient riveting processHigh degree of automationStructural engineeringMechanical engineering

The invention discloses an automatic riveting module for a traffic sign aluminum alloy bottom plate. The automatic riveting module comprises a gantry support and a riveting mechanism. The gantry support comprises a first gantry and a second gantry. The second gantry is fixedly erected on the top face of the first gantry. The riveting mechanism comprises a self-propelled upper riveting module and aself-propelled lower riveting module. The self-propelled upper riveting module is movably mounted on the second gantry. The self-propelled lower riveting module is movably mounted on the first gantry. The self-propelled upper riveting module and the self-propelled lower riveting module synchronously move to carry out fixed-point riveting on a workpiece. The automatic riveting module is high in automation degree, high in production efficiency, capable of automatically riveting a traffic sign, high in riveting precision and good in riveting quality.

Owner:广州市公路实业发展有限公司 +1

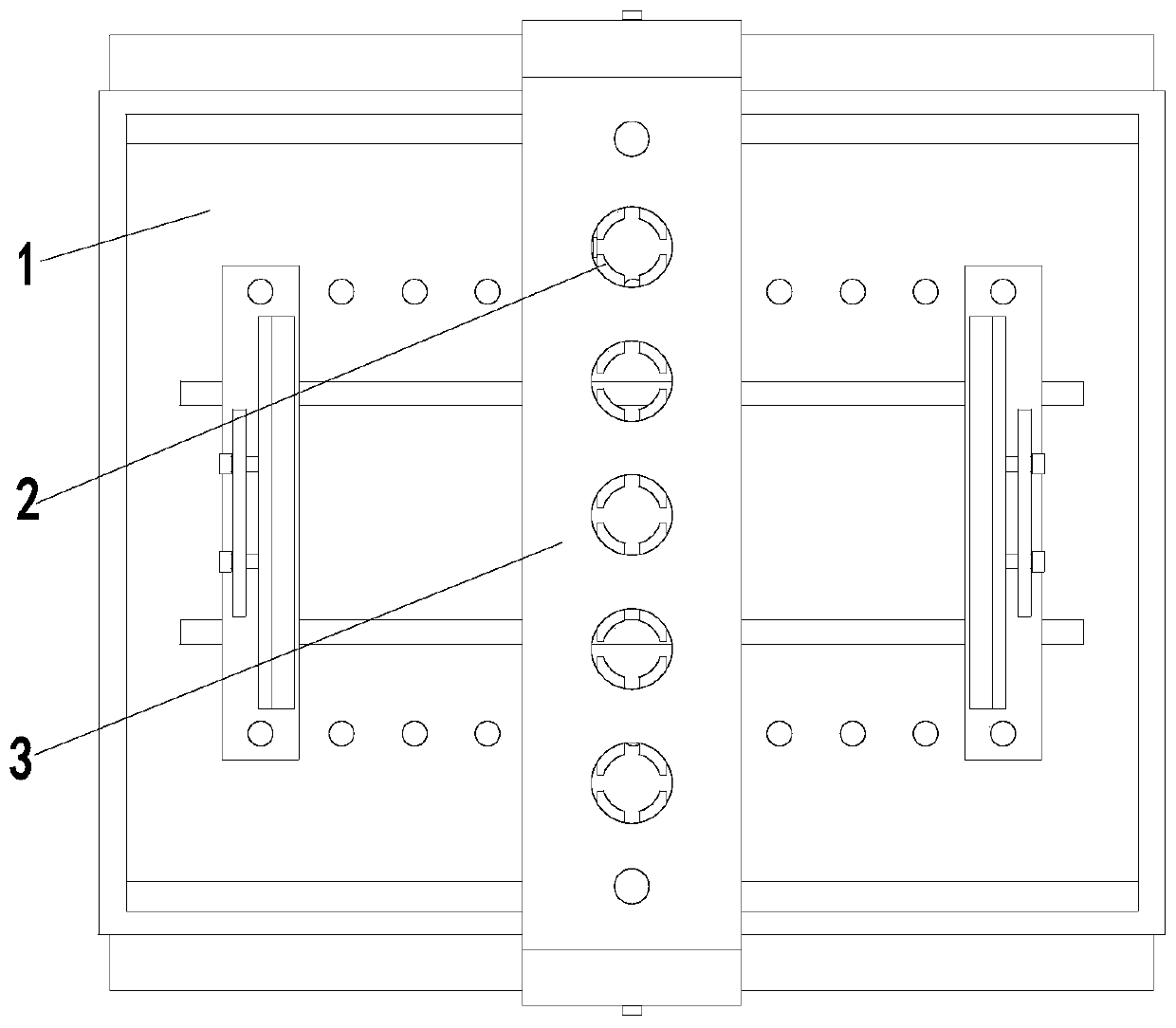

Riveting tooling mold for metal sheet metal parts

The invention relates to a metal sheet material sheet metal part riveting tooling mold. The metal sheet material sheet metal part riveting tooling mold comprises a fixed frame, bearing supporting molds and a position guide mold, wherein the fixed frame is internally provided with the bearing supporting molds, the upper ends of the bearing supporting molds are provided with the position guide mold, the position guide mold is installed on the outer wall of the fixed frame, the fixed frame comprises a frame body, positioning plates and clamping branch chains, the bearing supporting molds comprise a bearing supporting rack, adjusting bolts, adjusting blocks, adjusting rods and rotating rods, the position guide mold comprises a position guide rack, a positioning rod and a connection rod, and each clamping branch chain comprises a sliding rack, butt joint rods, a clamping plate and fastening bolts. According to the metal sheet material sheet metal part riveting tooling mold, by means of mutual coordination between the bearing supporting molds of adjustable gaps and the position guide mold capable of moving left and right, the riveting work of sheet metal parts is assisted, the purpose of improving the riveting accuracy is achieved, and the metal sheet material sheet metal part riveting tooling mold is suitable for rivets of different sizes and can meet the work requirements for single-row riveting and multi-row riveting.

Owner:江苏宝祥电力设备有限公司

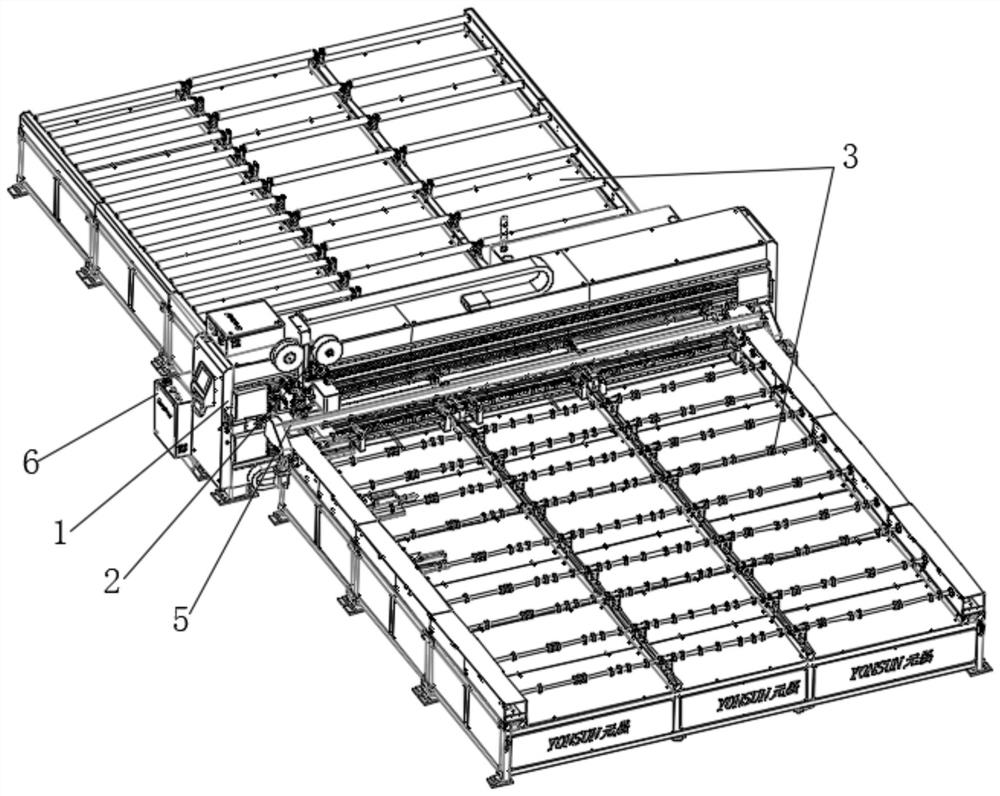

Traffic sign aluminum alloy bottom plate automatic riveting machine

InactiveCN111604459ARealize automatic deliveryRealize automatic positioning functionEngineeringPortal frame

The invention discloses a traffic sign aluminum alloy bottom plate automatic riveting machine. The traffic sign aluminum alloy bottom plate automatic riveting machine comprises a riveting mechanism, aconveying mechanism, a positioning mechanism and a pressing mechanism; the riveting mechanism comprises an upper self-propelled riveting module and a lower self-propelled riveting module; the upper self-propelled riveting module can be movably installed on a second portal frame, and the lower self-propelled riveting module can be movably installed on a first portal frame; the upper self-propelledriveting module and the lower self-propelled riveting module move synchronously and conduct fixed point riveting on a workpiece; the positioning mechanism comprises a workpiece front end positioningassembly and a workpiece side edge positioning assembly; and the workpiece front end positioning assembly is used for positioning the length of the front end of the workpiece, and the workpiece side edge positioning assembly is used for positioning the length of the side edge of the workpiece. The traffic sign aluminum alloy bottom plate automatic riveting machine is high in automation degree andproduction efficiency, can automatically rivet a traffic sign, and is high in riveting precision and good in riveting quality.

Owner:广州市公路实业发展有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com