Riveting tooling mold for metal sheet metal parts

A technology for riveting tooling and metal plates, applied in the field of plate processing, can solve the problems of reduced riveting precision, high work cost, large working space, etc., and achieve the effects of preventing the reduction of riveting precision, high adjustability and improving riveting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

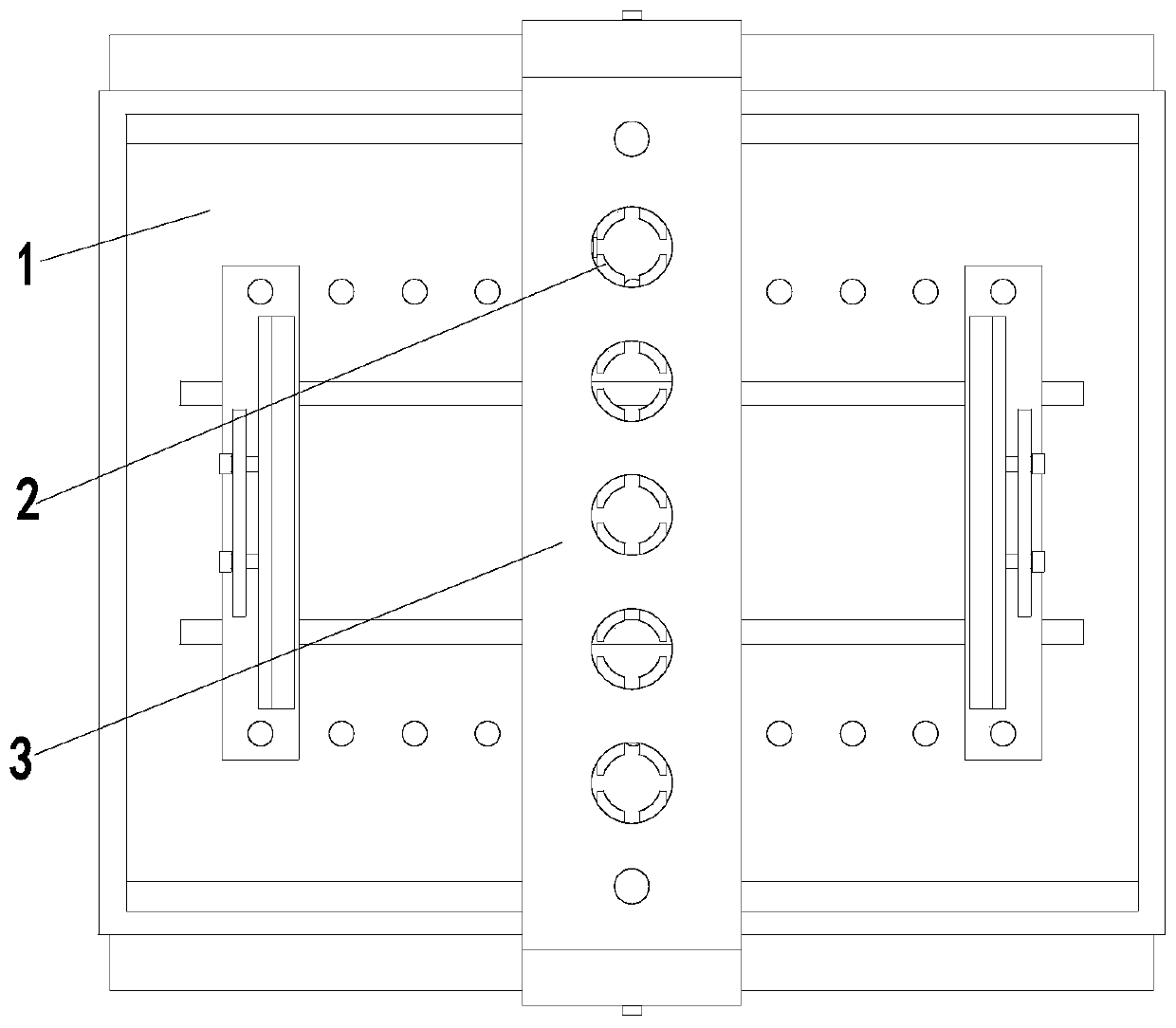

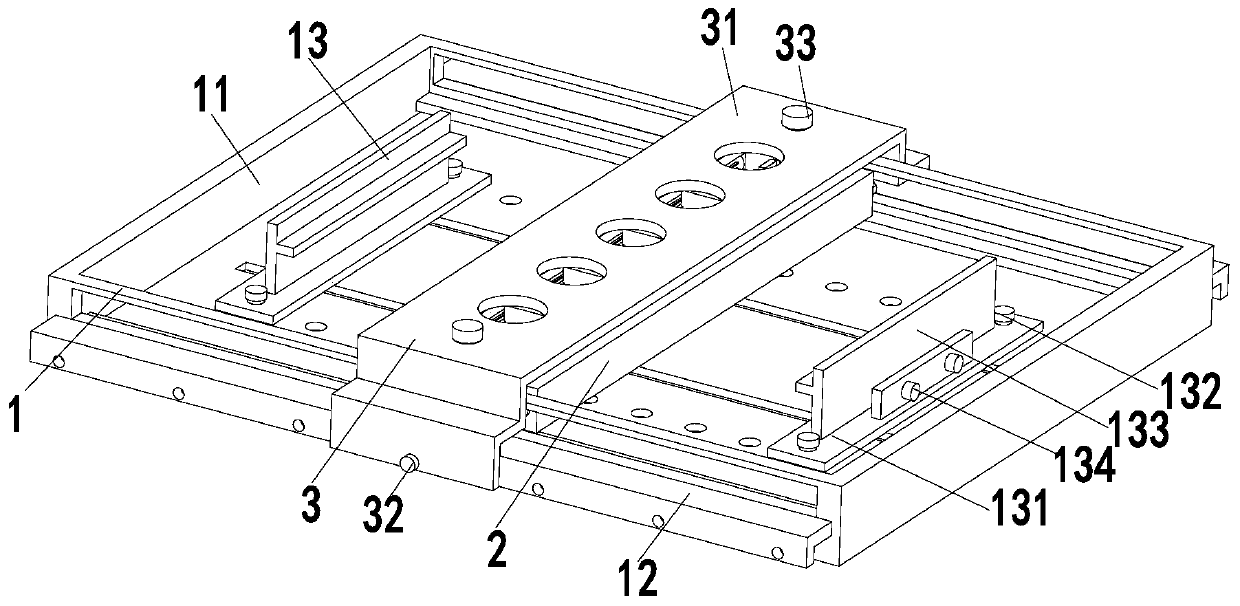

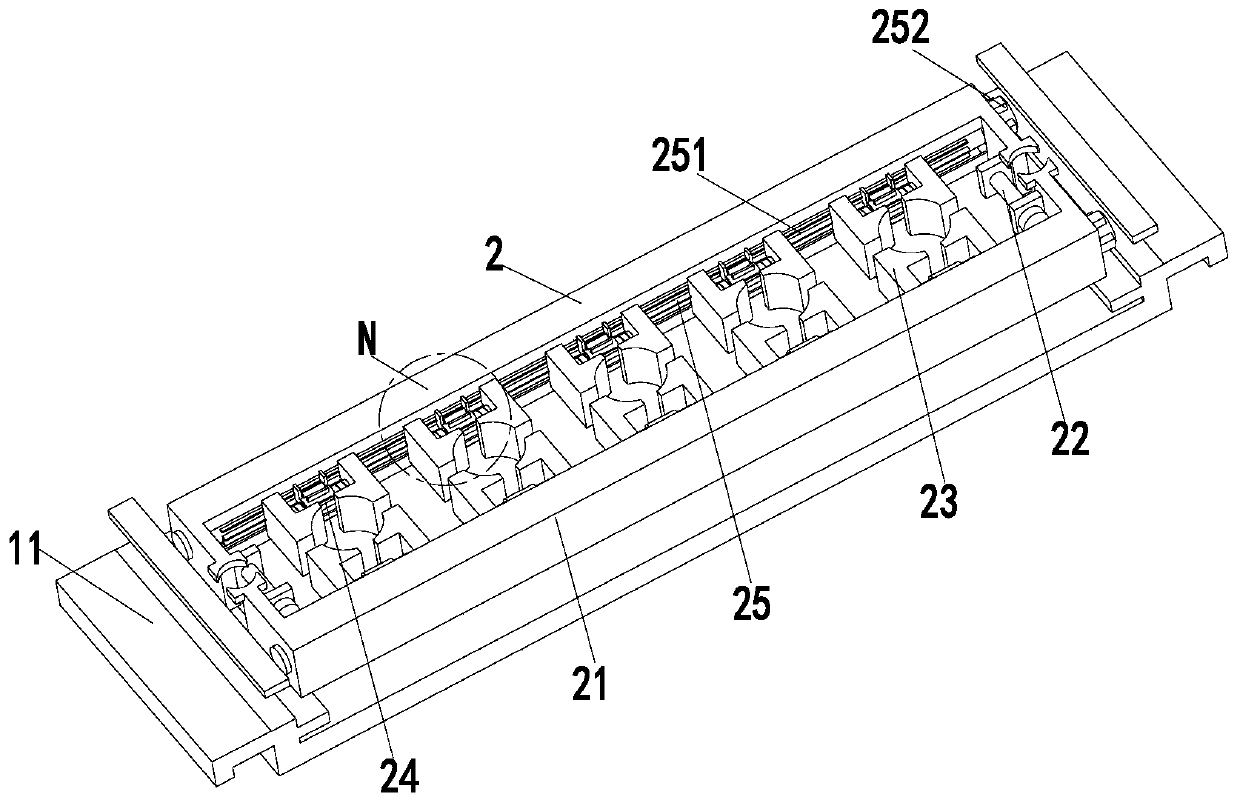

[0029] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 5 , to further elaborate the present invention.

[0030] A riveting tooling mold for metal sheet metal parts, including a fixed frame 1, a supporting mold 2 and a guiding mold 3, a supporting mold 2 is installed in the fixed frame 1, and a guiding mold is arranged on the upper end of the supporting mold 2 3. The guide mold 3 is installed on the outer wall of the fixed frame 1; where:

[0031] The fixed frame 1 includes a frame body 11, a positioning plate 12 and a clamping branch chain 13. The front and rear sides of the frame body 11 are symmetrically provided with strip grooves, and a positioning plate 12 is installed at the lower end of the strip groove. The positioning plate 12 is an inverted L shape. structure, positioning holes are evenly opened from left to right on the side wall of the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com