Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Good grabbing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

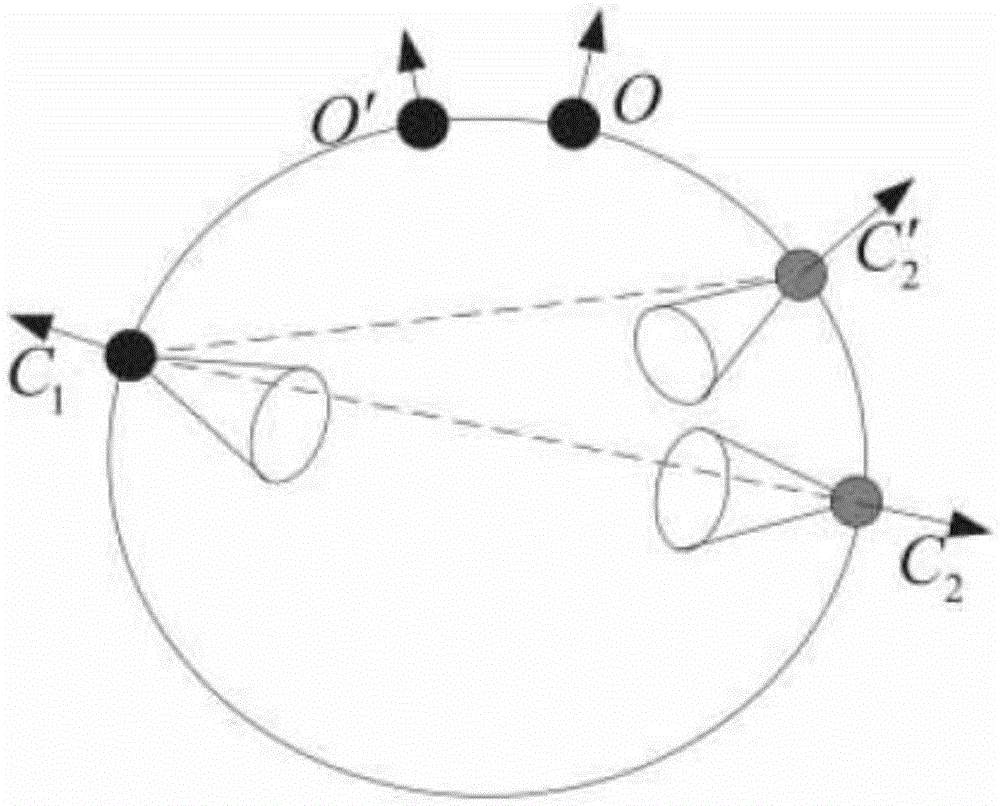

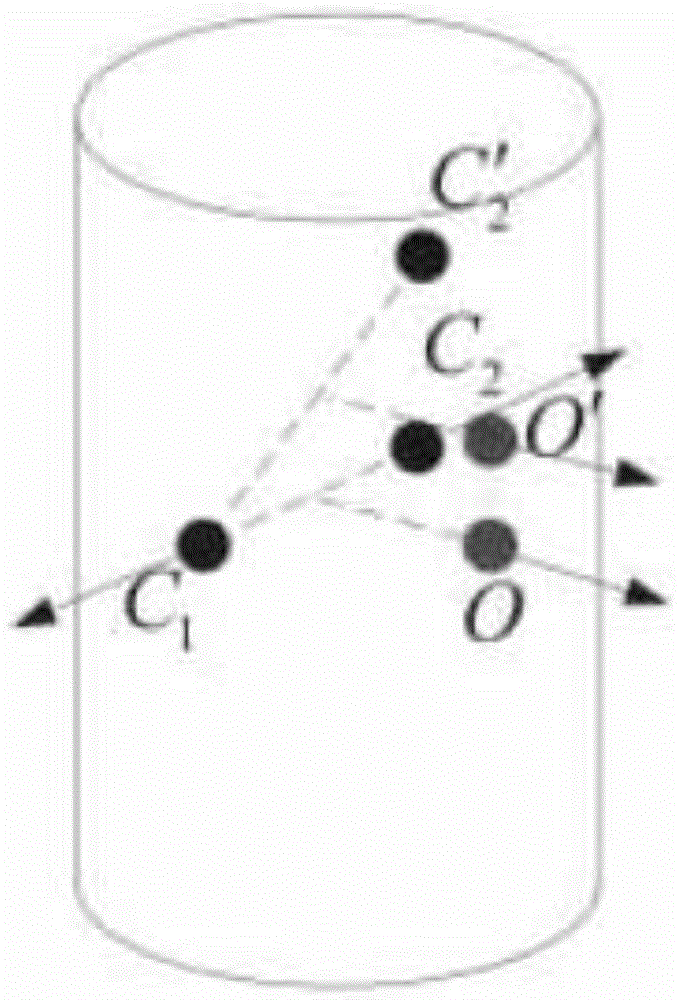

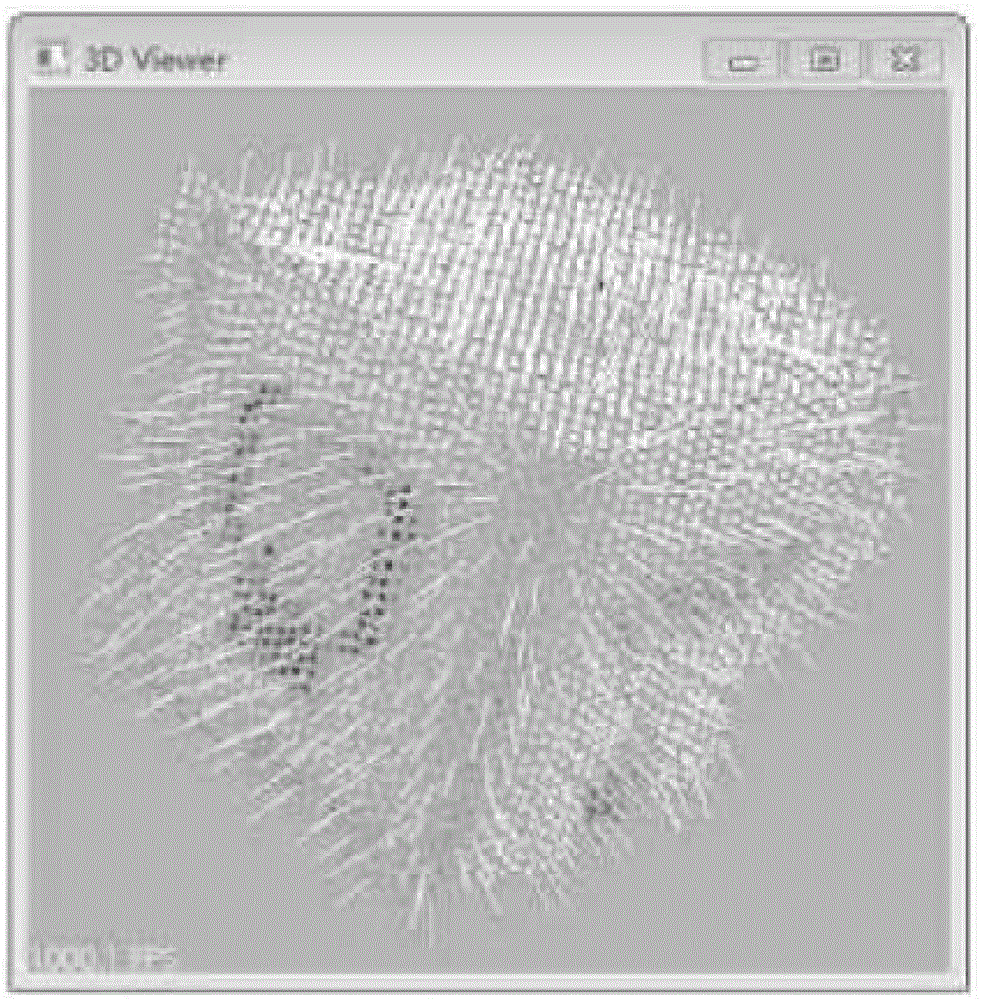

Robot under-actuated hand autonomous grasping method based on stereoscopic vision

ActiveCN105598965AEasy to operateGood application effectProgramme-controlled manipulatorImage analysisHand graspPoint cloud

The invention discloses a robot under-actuated hand autonomous grasping method based on stereoscopic vision, and relates to a robot autonomous grasping method. The problems that a grasping point can not be calculated through an existing robot grasping method until a three-dimensional model of an object is obtained in advance and the existing robot grasping method can only recognize a simple object and can not obtain a corresponding grasping point for a complicated object are solved. The method includes the steps of obtaining RGB-D point cloud of the object and the environment through a Kinect sensor and conducting filtering on the point cloud for a to-be-grasped object and the environment of the object; extracting normal vector included angle characteristics, coplanar characteristics, distance characteristics, grasping stability characteristics, collision detecting characteristics and corresponding constraint equations for the RGB-D point cloud; establishing a grasping planning scheme on the basis of Gaussian process classification; driving an under-actuated hand for grasping according to the grasping scheme, then judging whether the under-actuated hand has already grasped the object or not according to current detection till the under-actuated hand grasps the object, and releasing the object after completing the grasping task. The method is suitable for the field of robot grasping.

Owner:HARBIN INST OF TECH

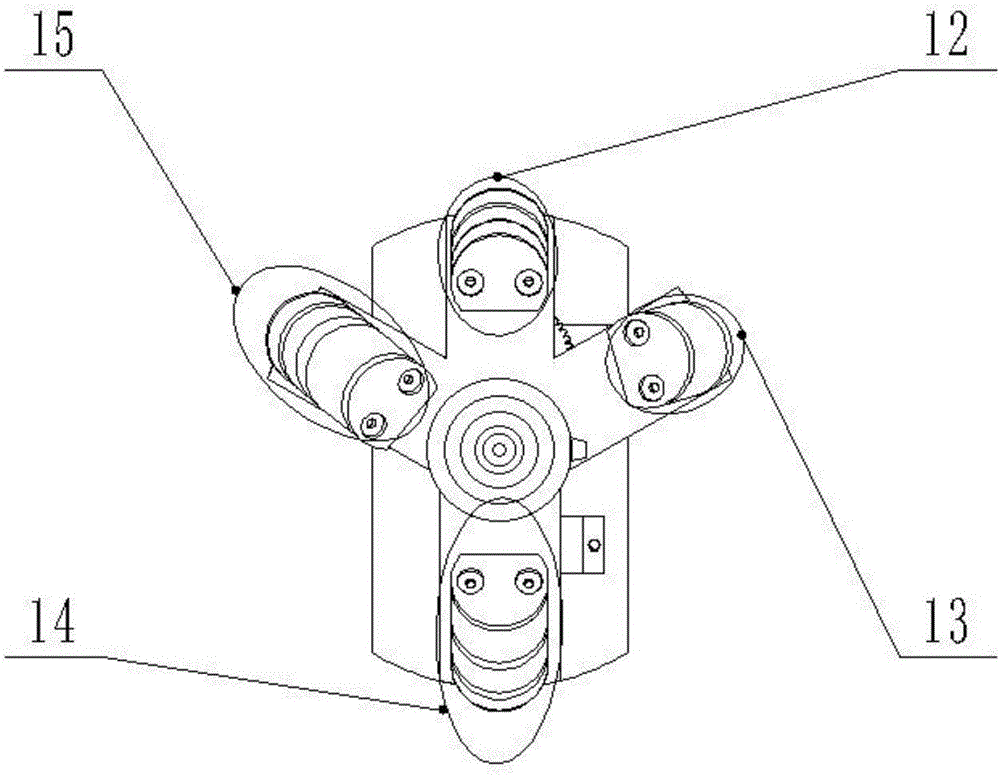

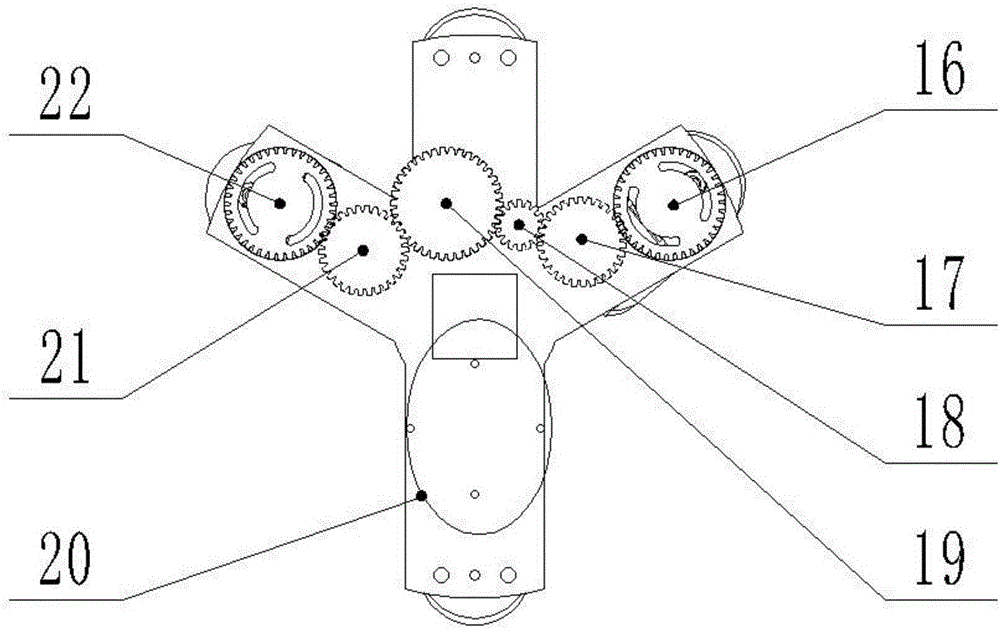

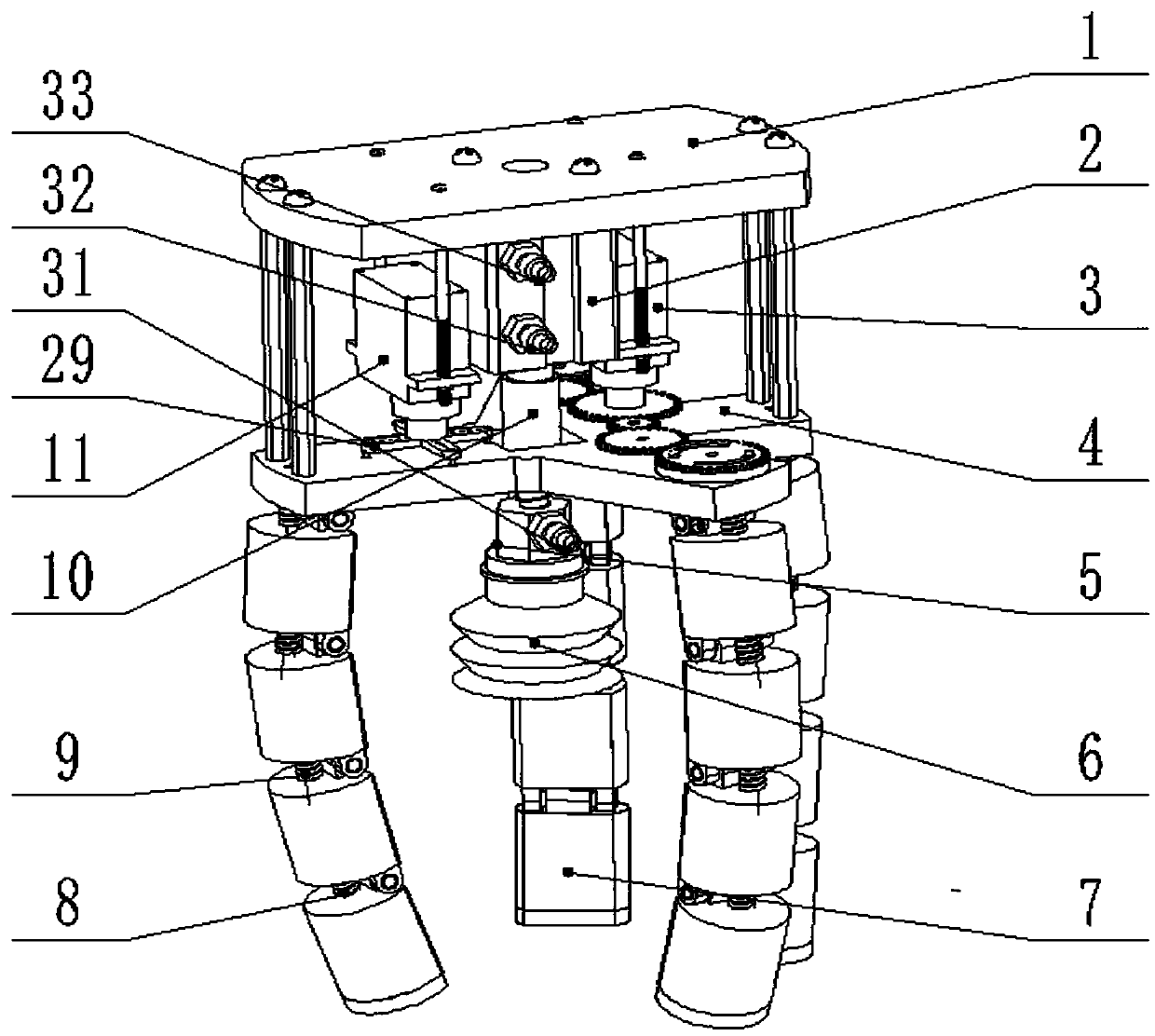

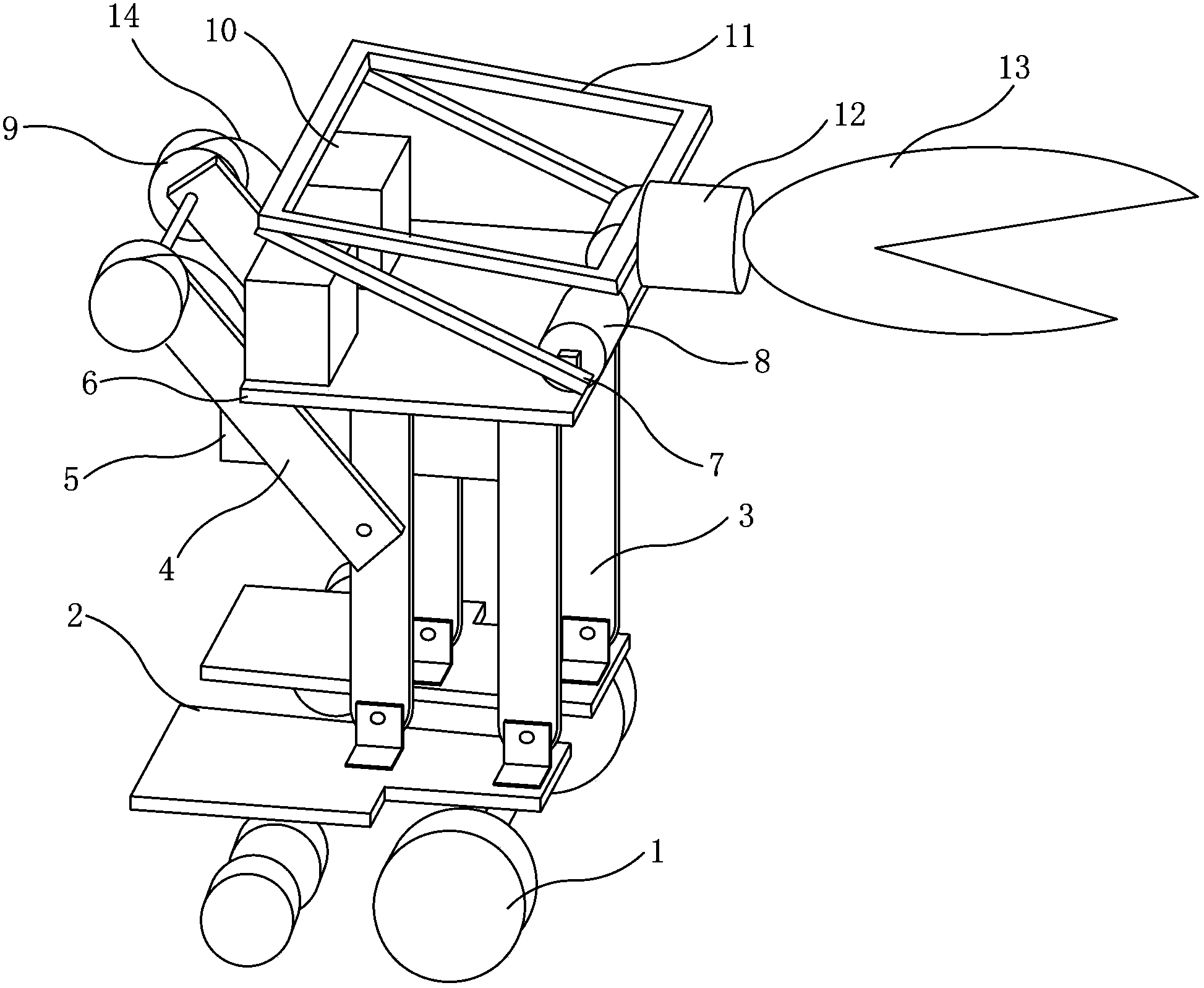

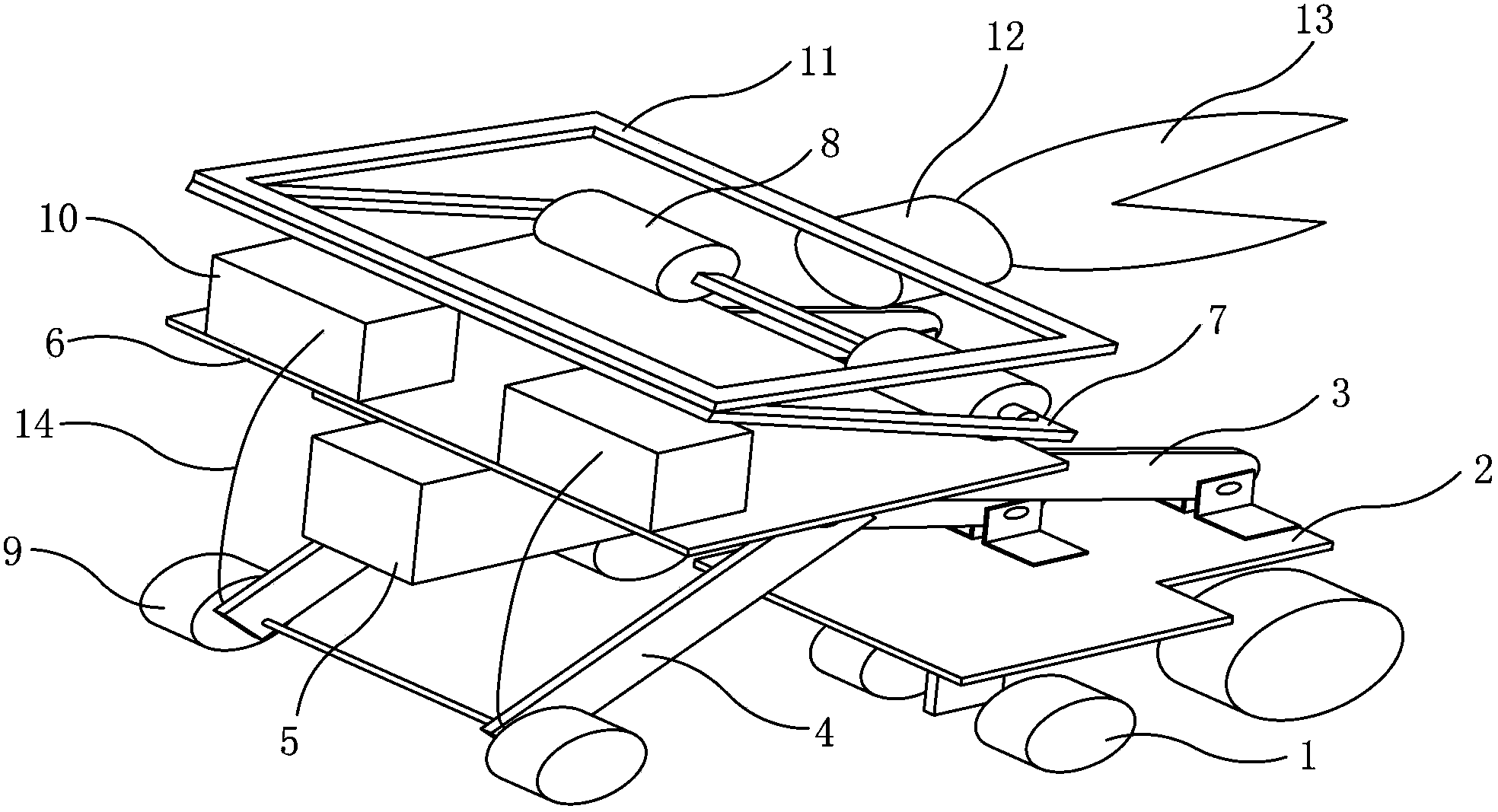

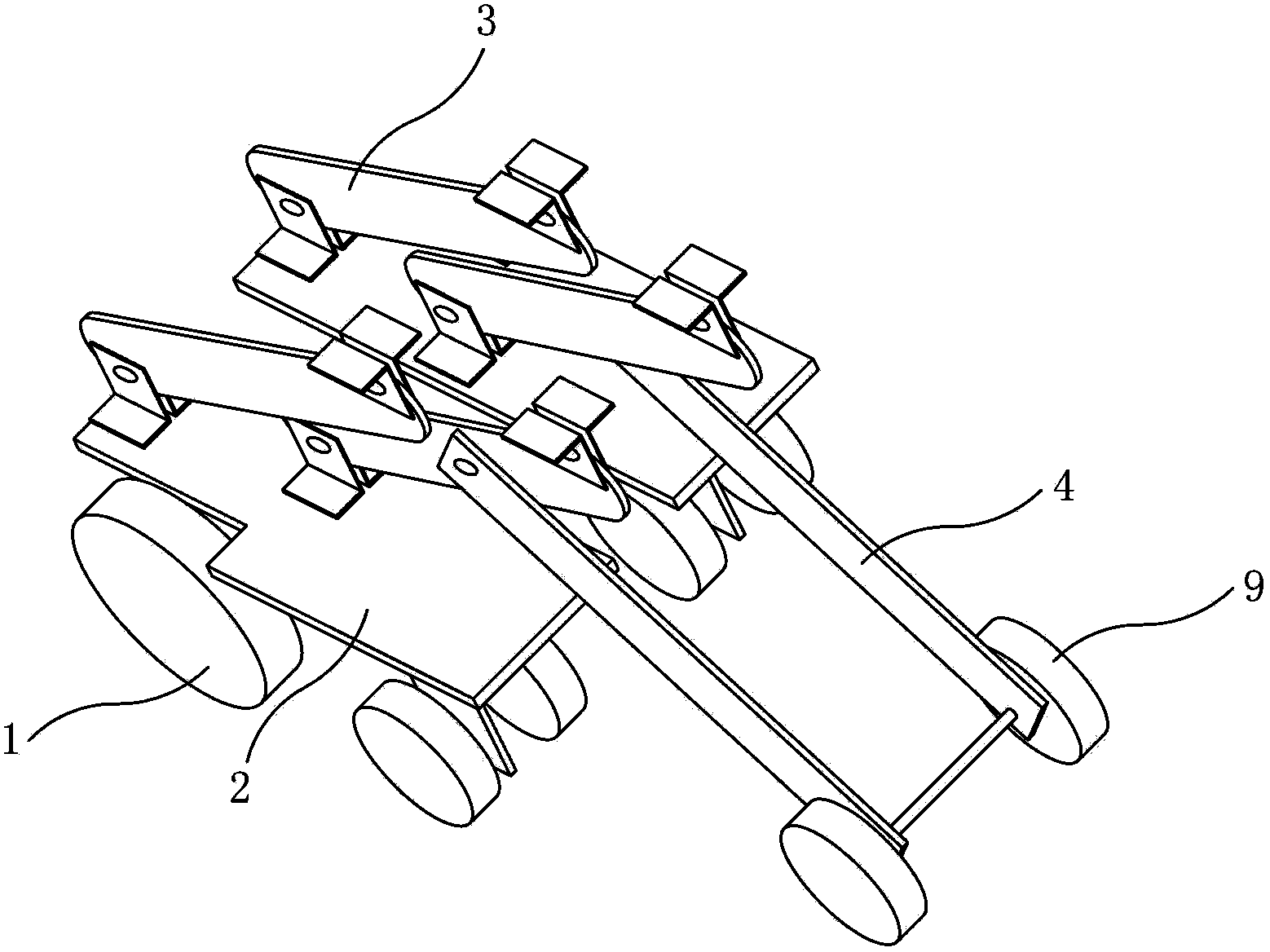

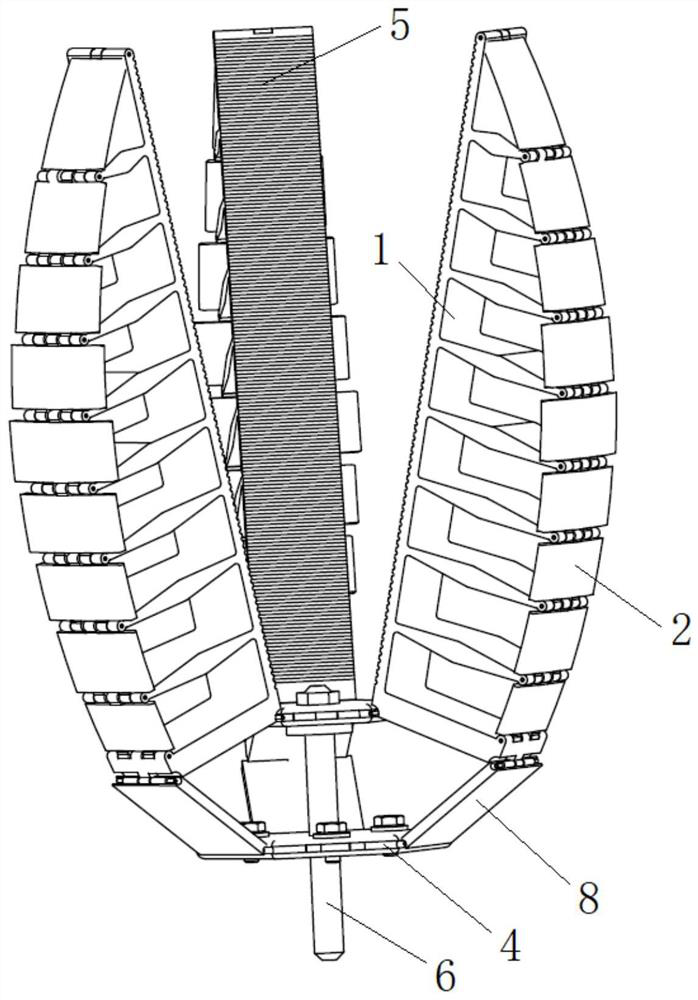

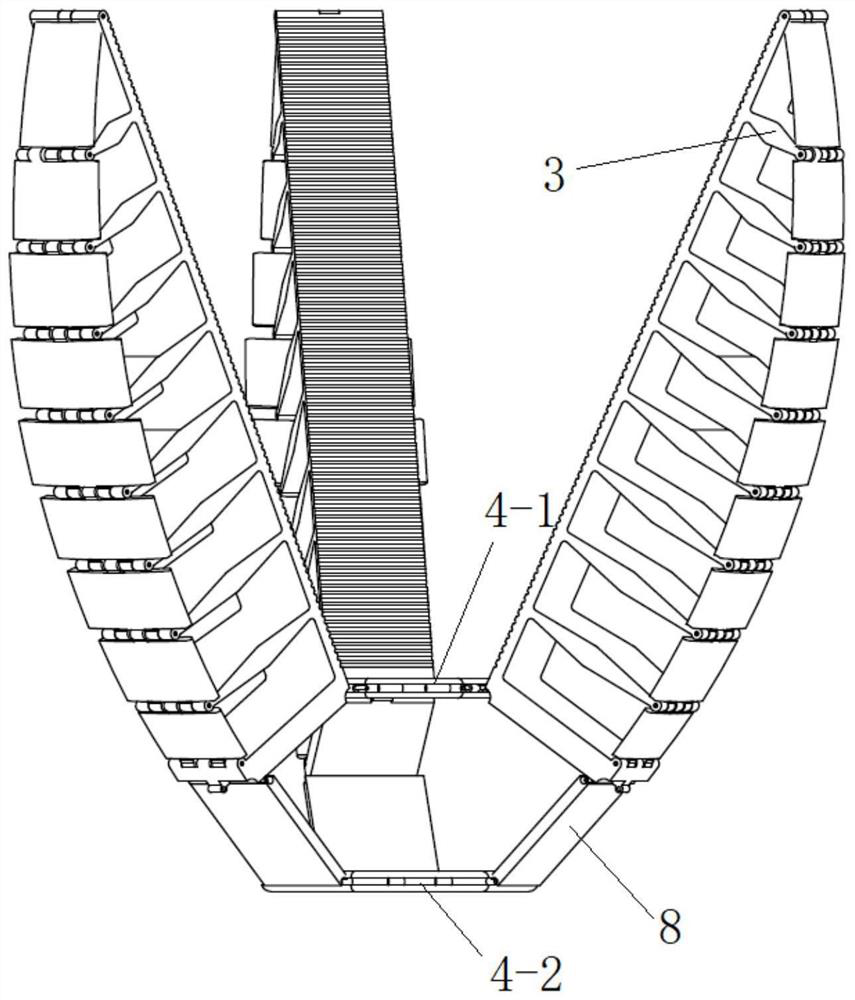

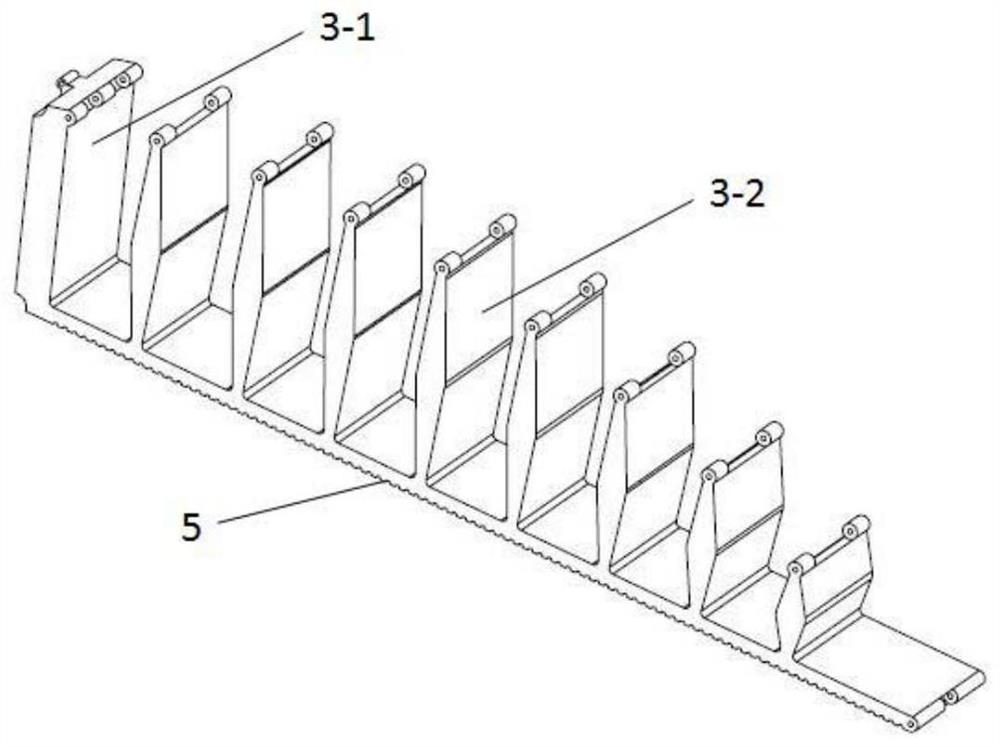

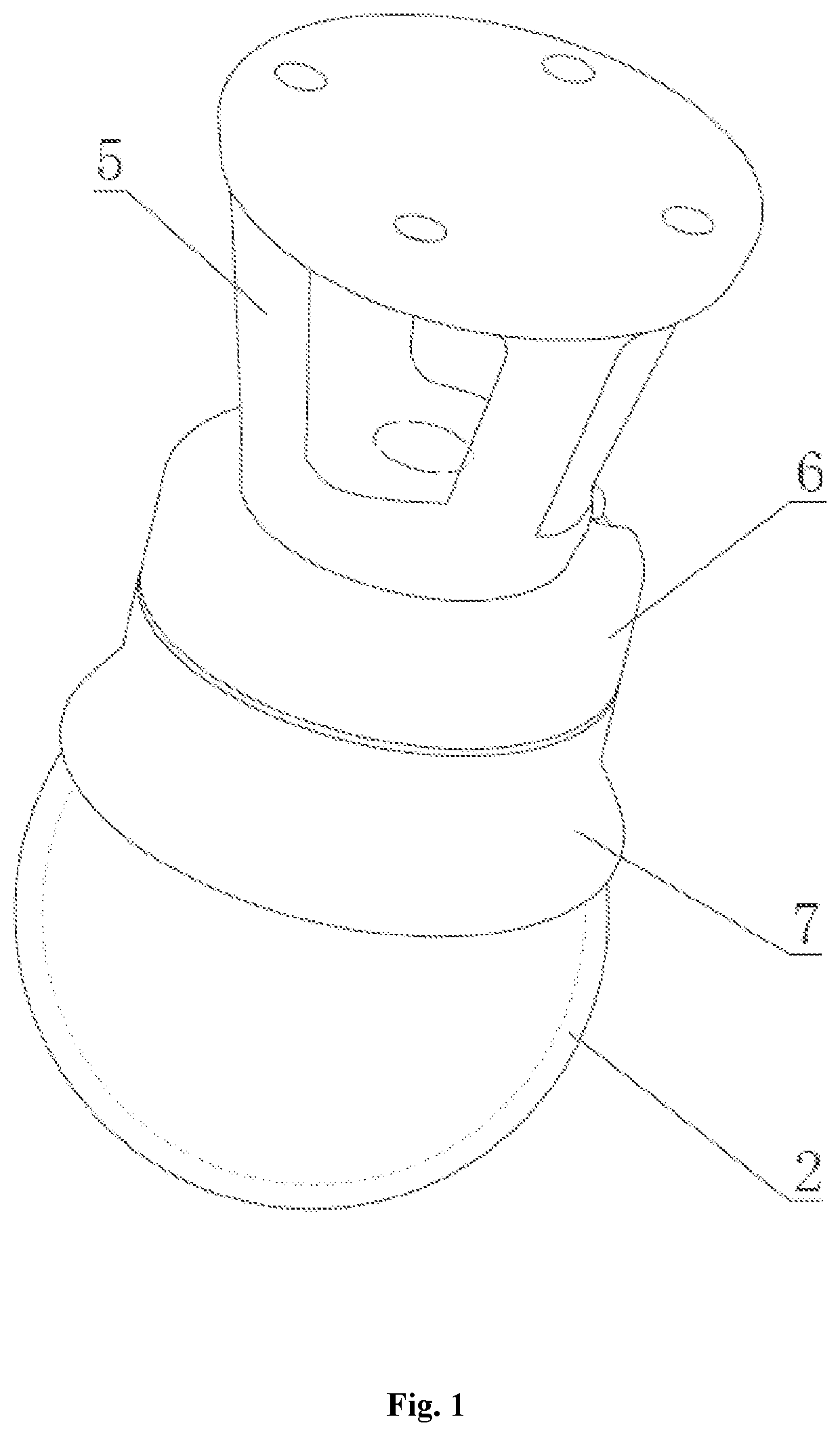

Under-actuated flexible terminal actuator aiming at special-shaped melons and fruits and simulating bird jaws

The invention relates to a bionic robot terminal actuator, in particular to a structural design of an under-actuated flexible terminal actuator simulating bird jaws, and is generally applied to the field of agricultural product picking robots and intelligent sorting and packing. The terminal actuator consists of a grabbing module, a sucking module, a power module and a fixed connecting module. When the terminal actuator performs a special-shaped melon and fruit grabbing task, the sucking module and the grabbing module are cooperated to finish the grabbing task. The terminal actuator has bionic characteristics, can realize flexible grabbing of the special-shaped melons and fruits, reduces damage of the melons and the fruits in the working process, and has the advantages of fast response speed and high working efficiency.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

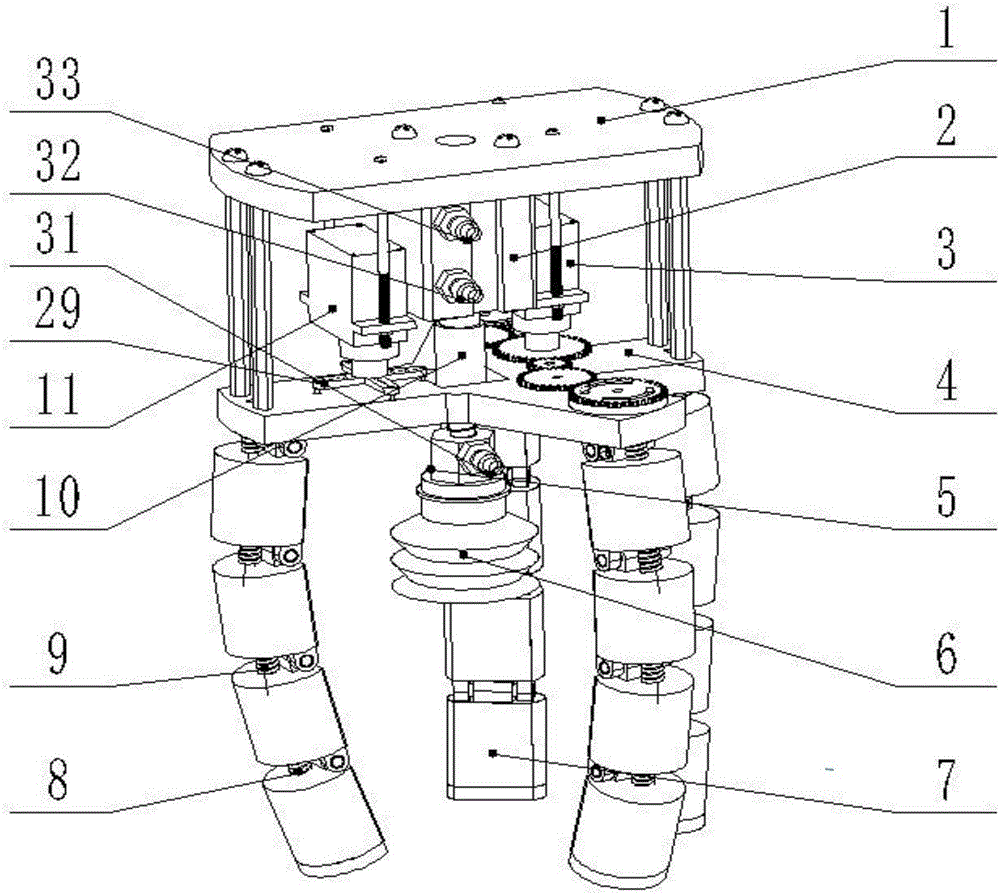

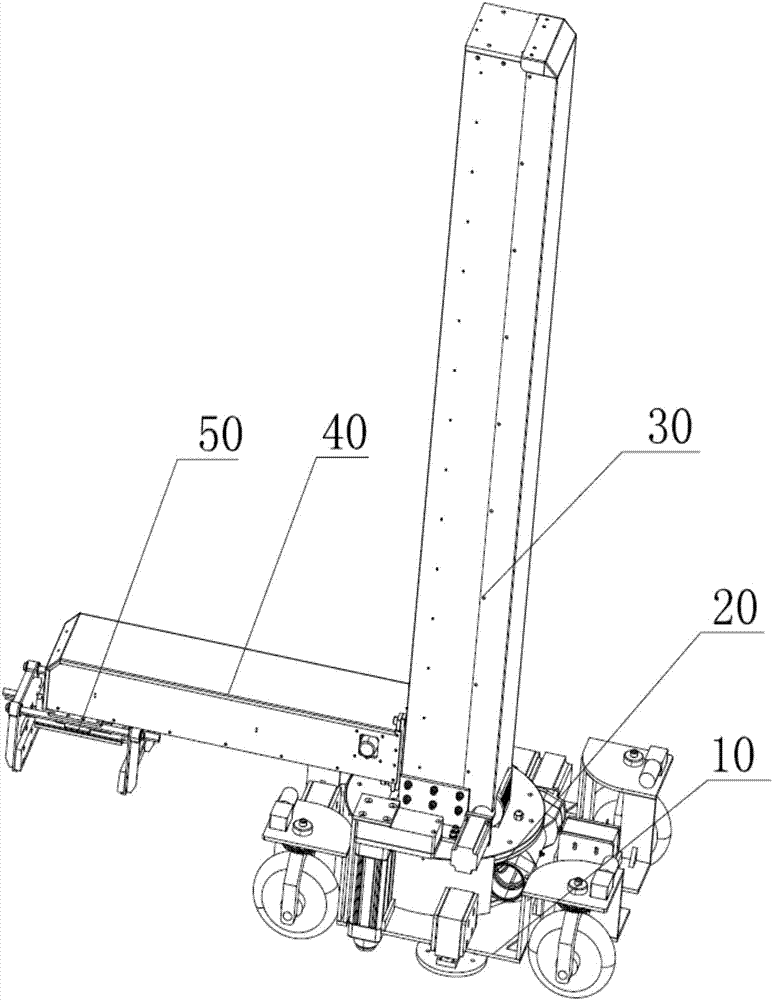

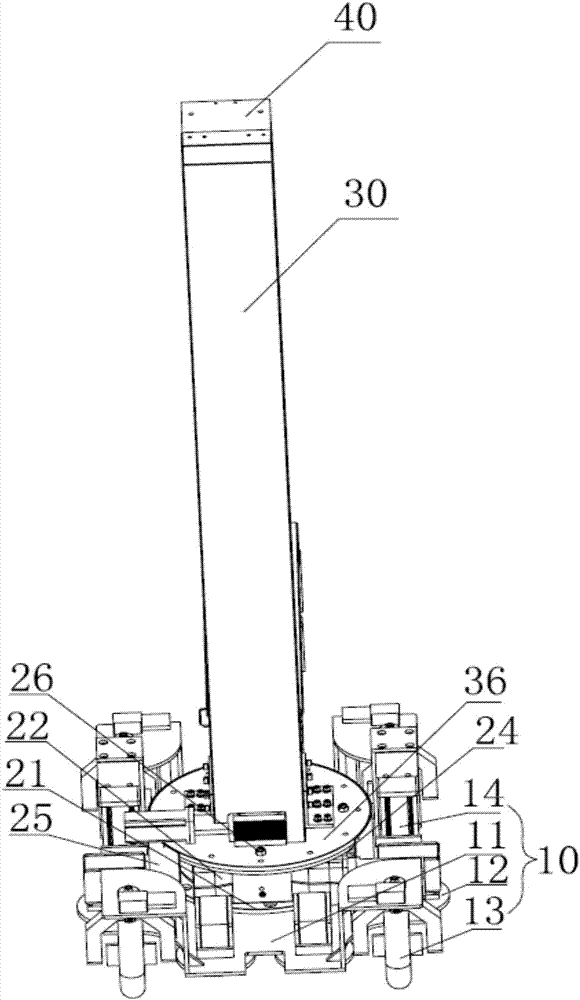

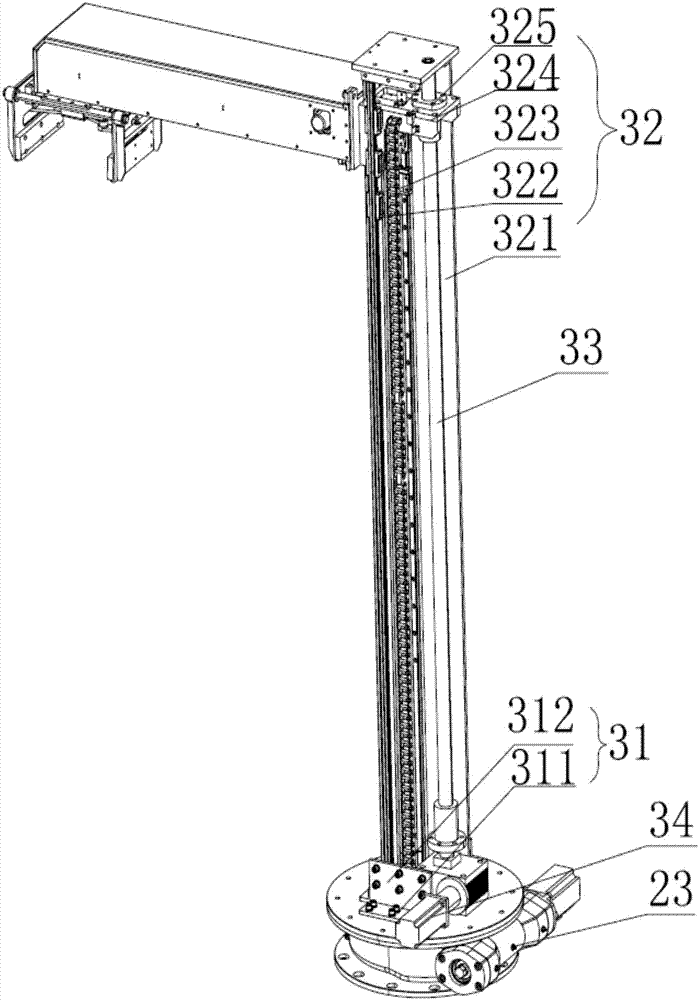

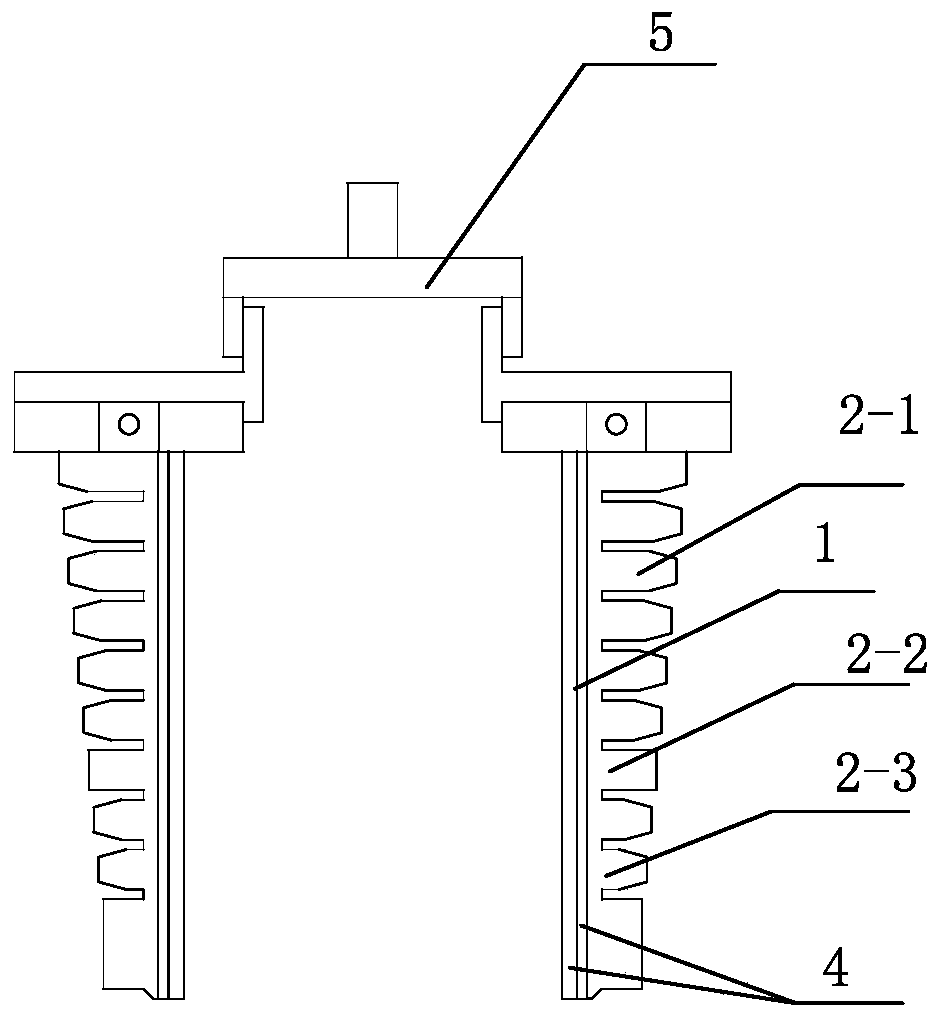

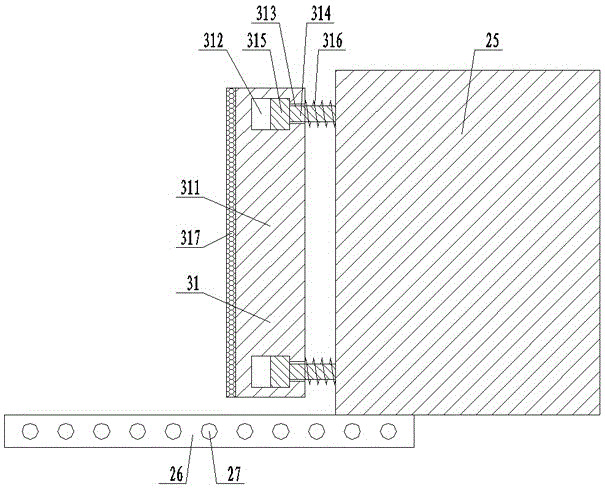

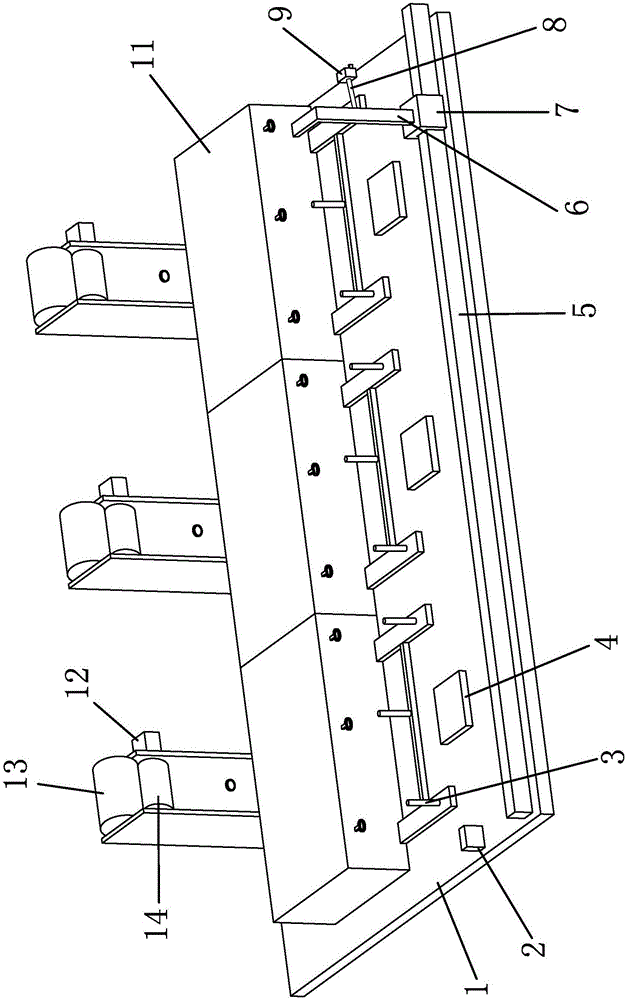

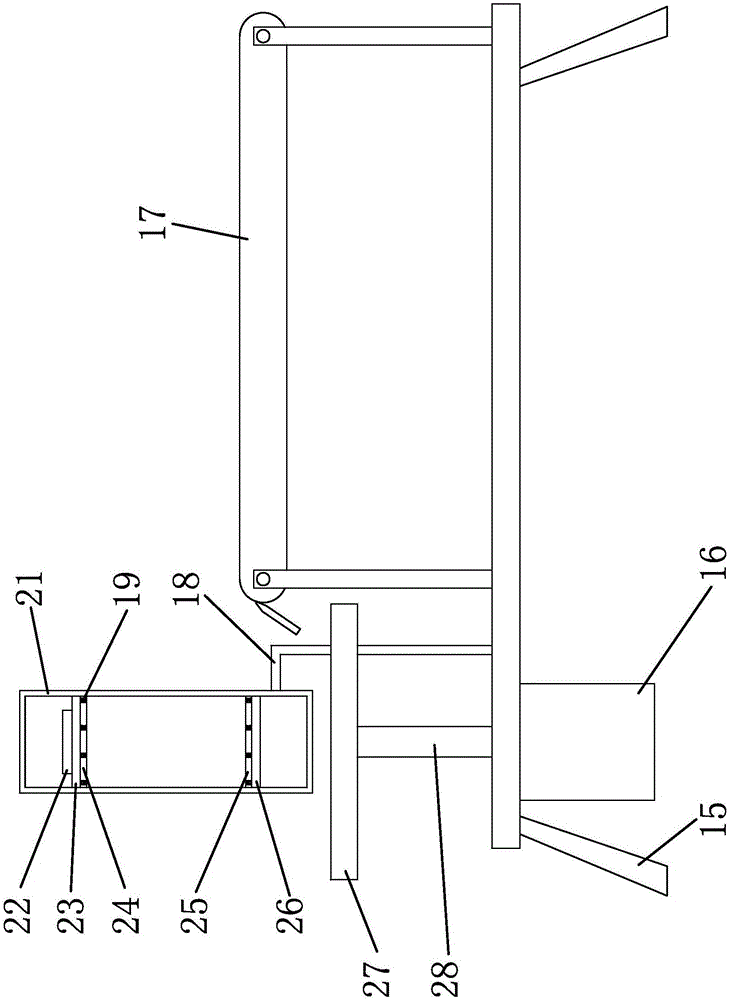

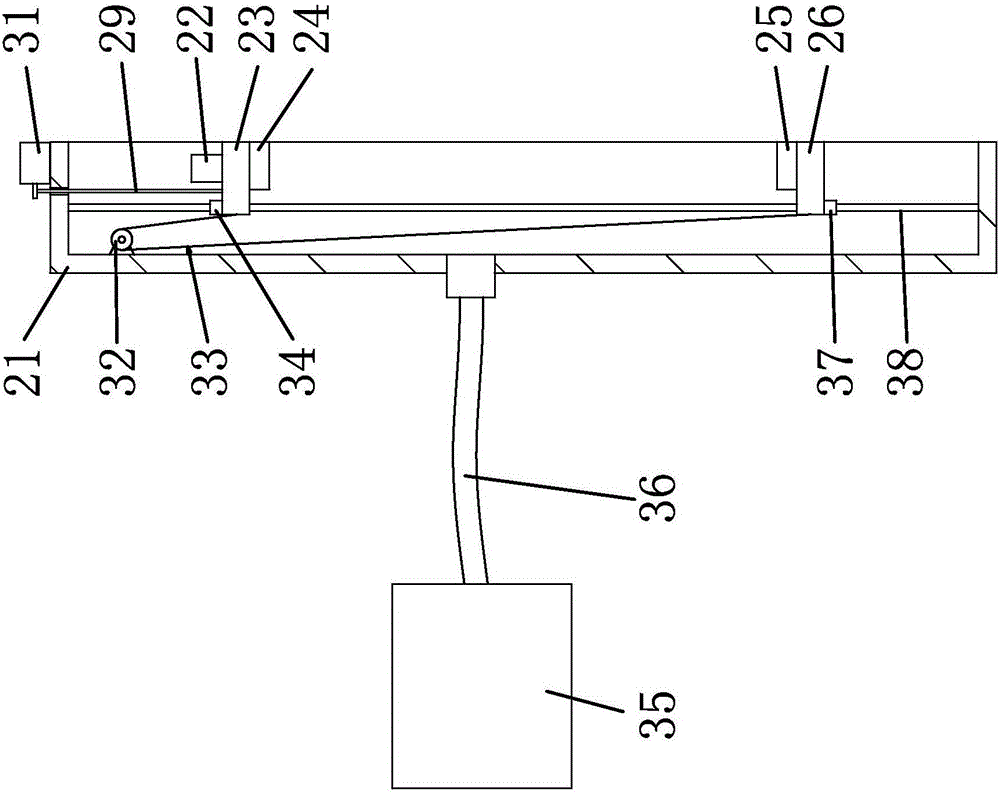

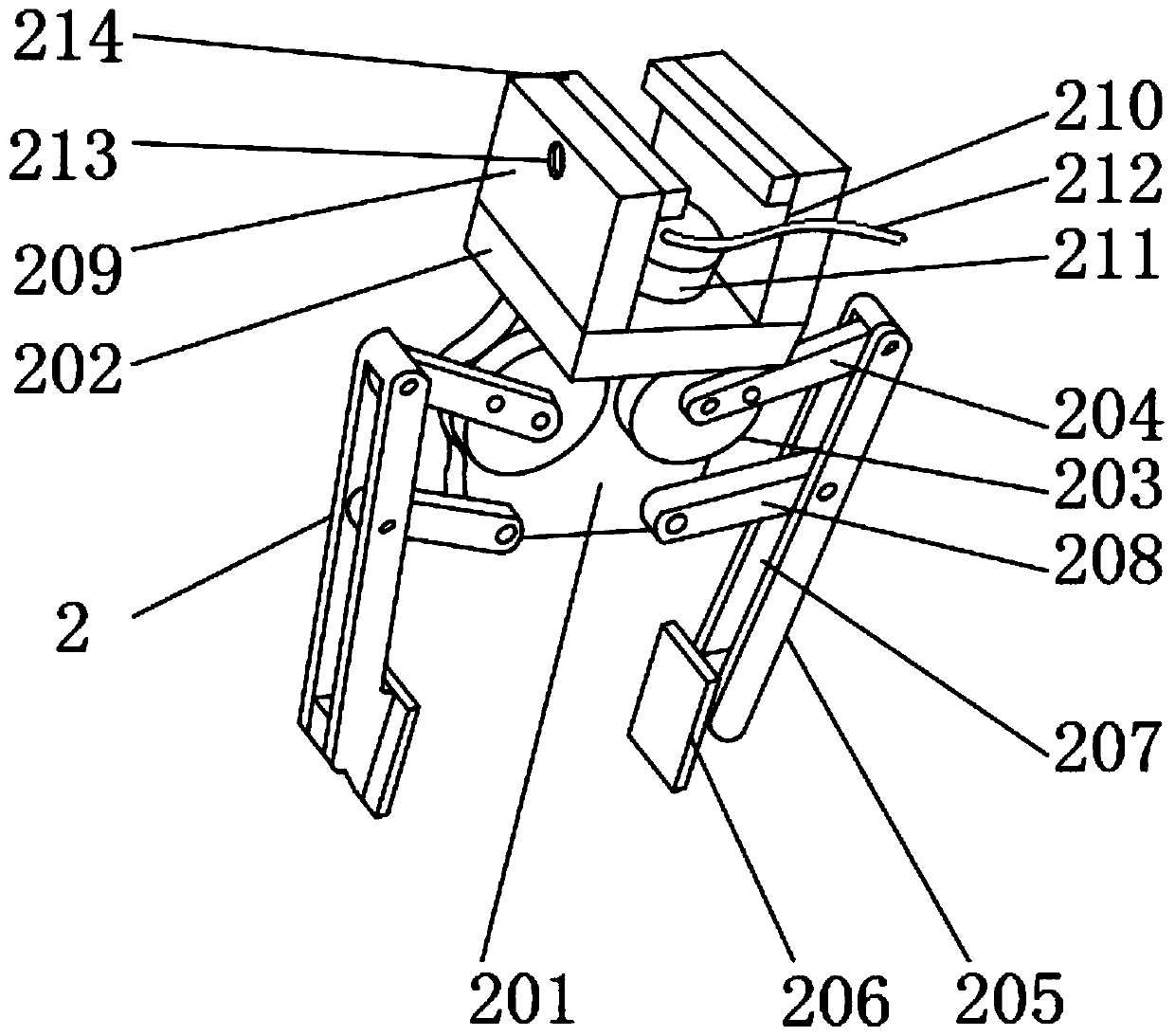

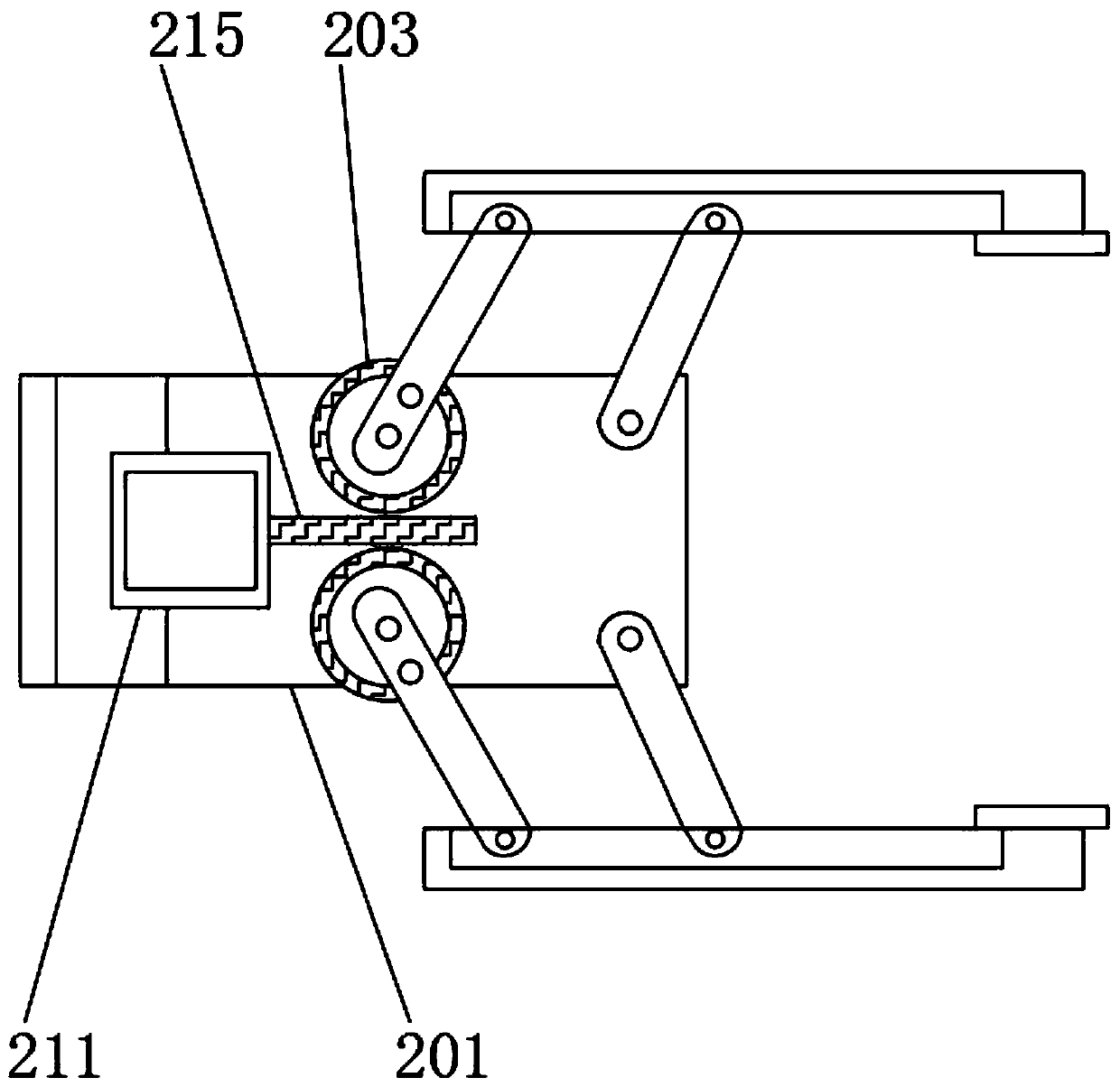

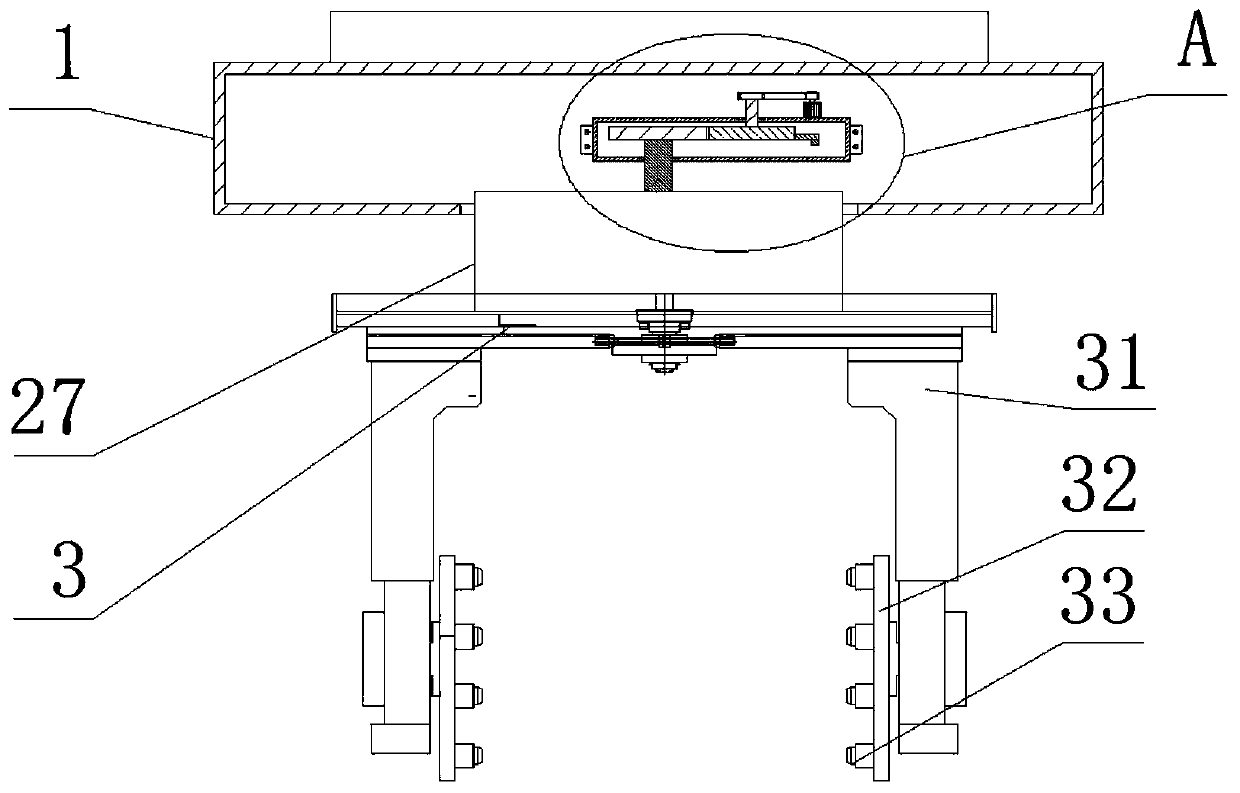

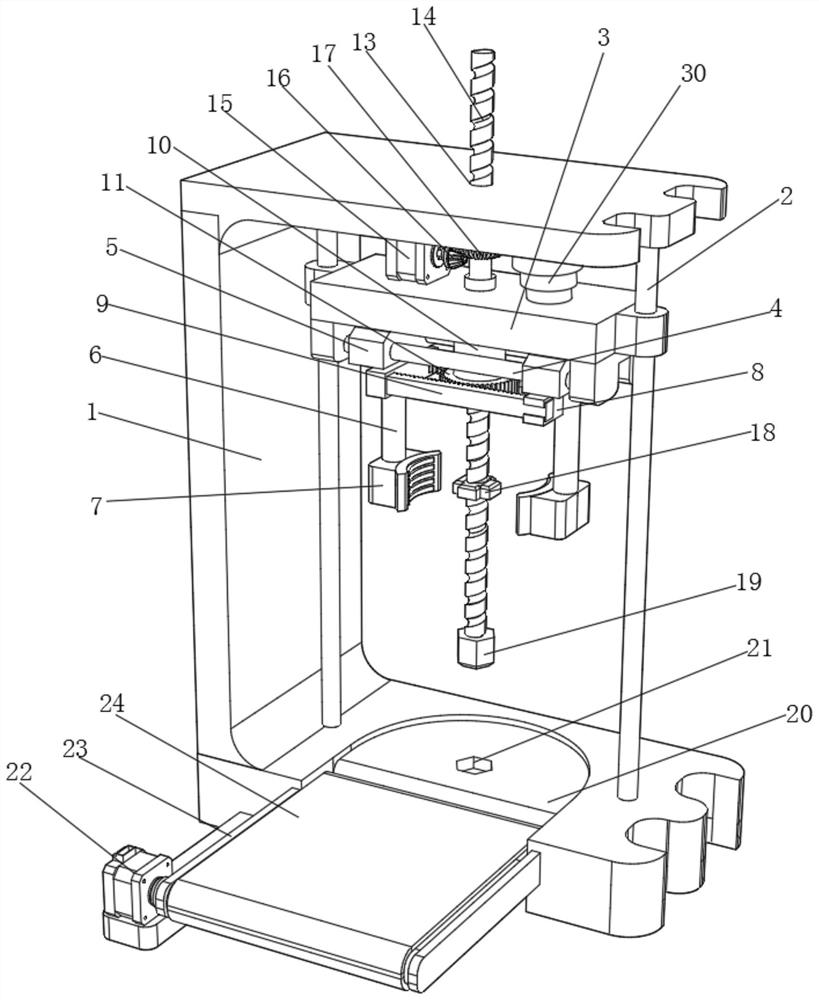

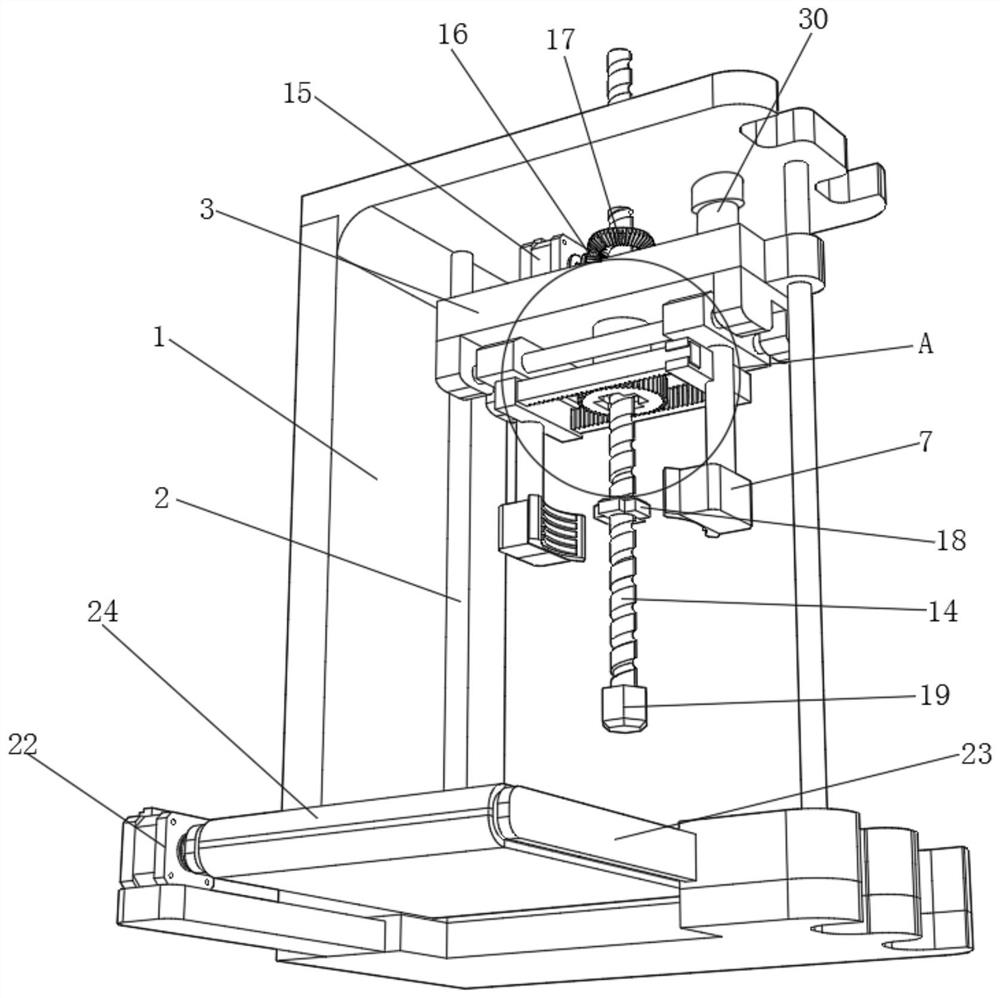

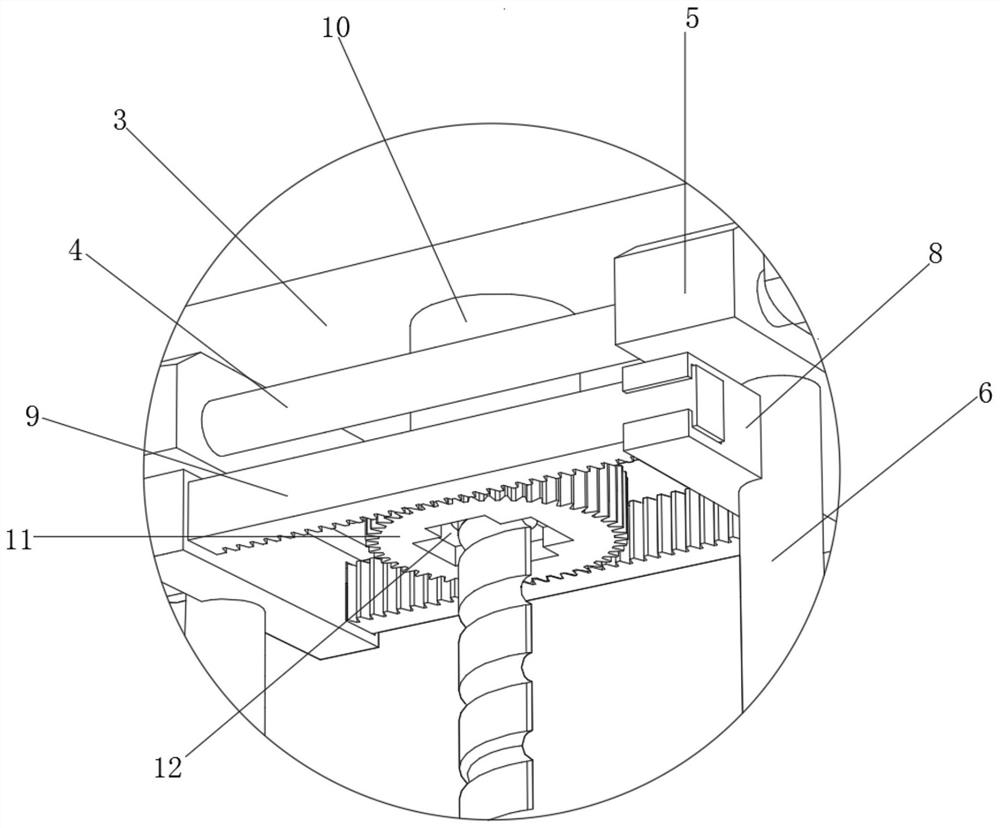

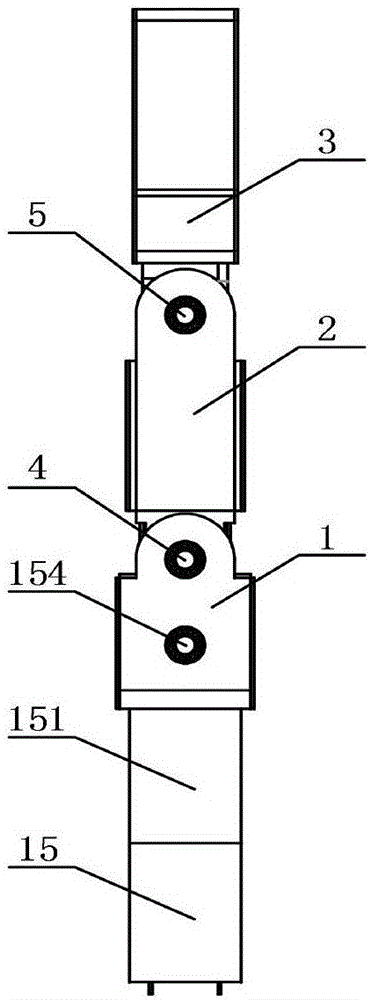

Portable bricklaying robot capable of being disassembled and assembled

ActiveCN107060355AAchieve fixationAchieve positioningBuilding material handlingManipulatorEngineeringSlide plate

The invention provides a portable bricklaying robot capable of being disassembled and assembled. The portable bricklaying robot comprises a lifting aerial ladder, a rotary pedestal, a liftable machine body and a top bricklaying module which are sequentially connected and capable of being singly disassembled and assembled. The rotary pedestal comprises a base, a first drive device, a gear set and a rotary supporting disc which are connected with one another. The liftable machine body comprises a second drive device, a first lead screw, a longitudinal guide rail structure and a plurality of first fixing plates. The top bricklaying module comprises a supporting plate and further comprises a plurality of second fixing plates, a second lead screw, a transverse guide rail mechanism, a third drive mechanism, a rotary grabbing device and a fourth drive device which are fixed to the supporting plate. The supporting plate is provided with a guide rail groove, a sliding plate fixing plate and a hole groove matched with the first lead screw. The portable bricklaying robot capable of being disassembled and assembled is simple in structure, easy to disassemble and assemble, liftable, low in weight, large in bricklaying weight and range which are capable of being achieved and good in grabbing effect.

Owner:HUAWAY IOT TECH

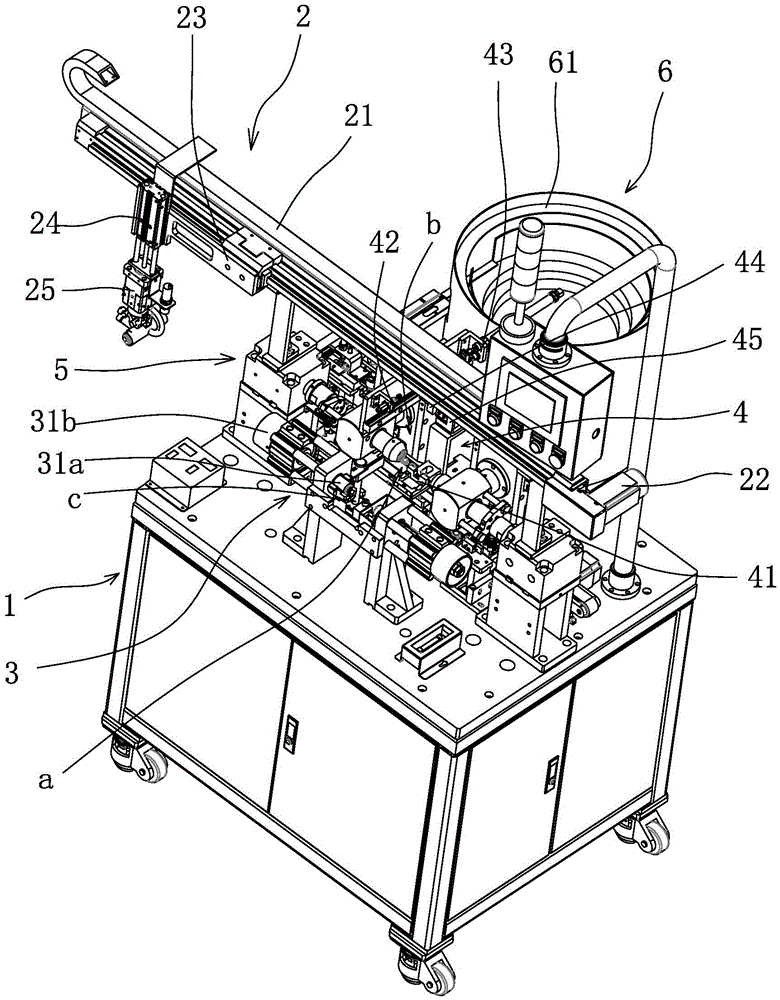

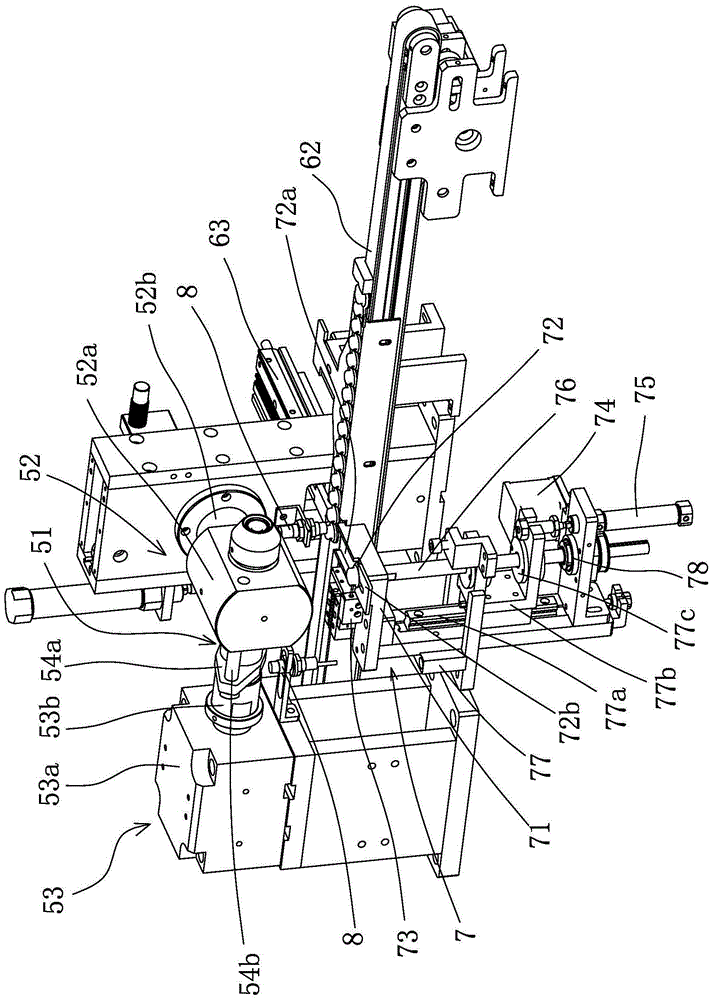

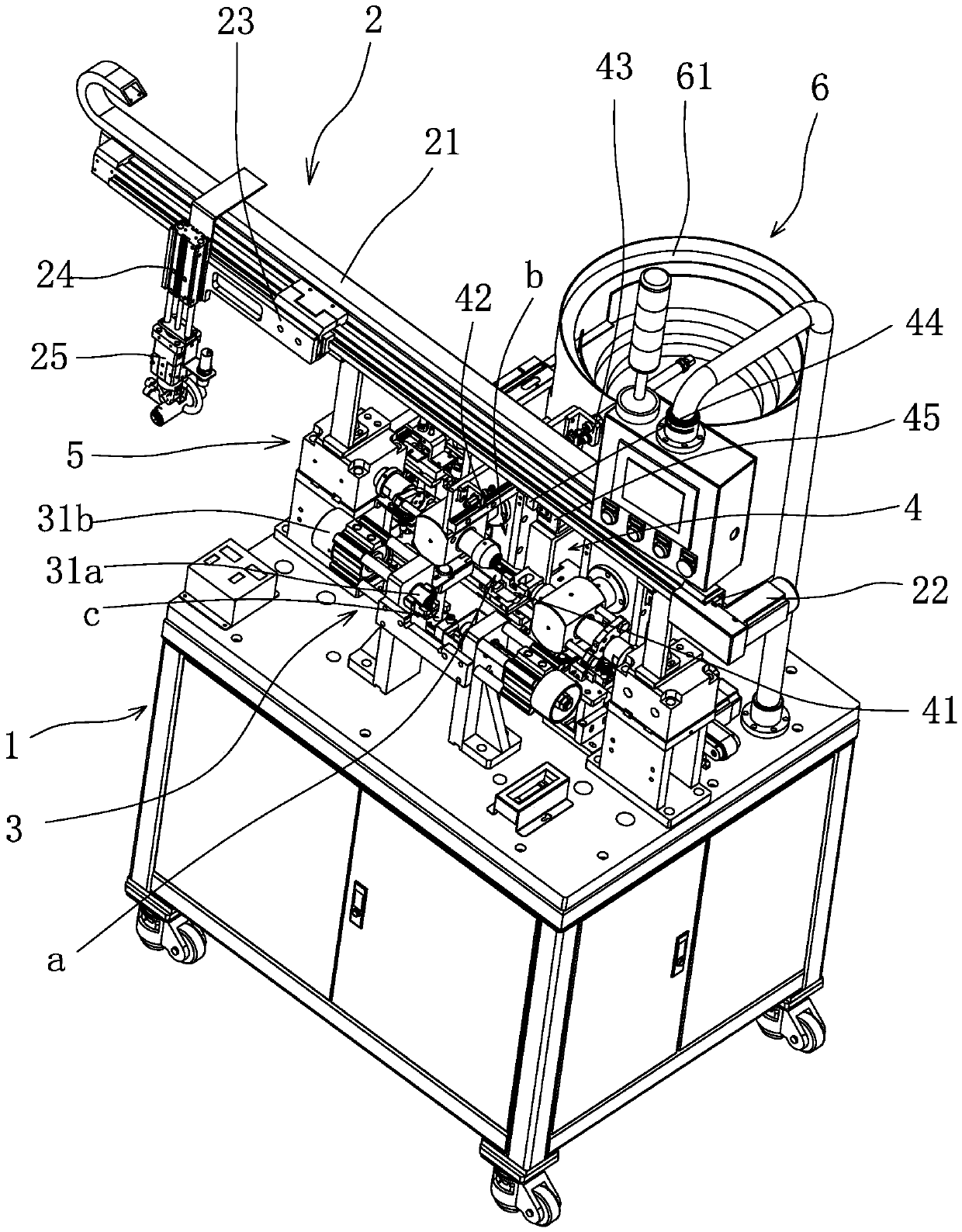

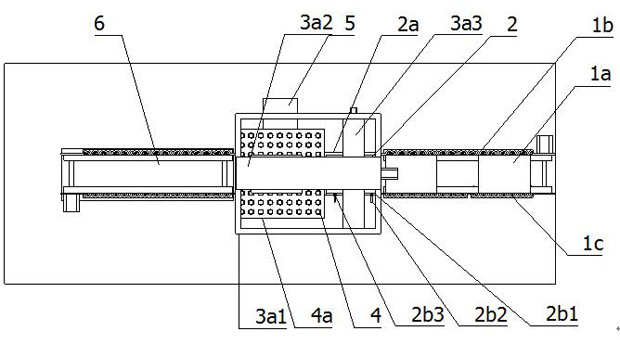

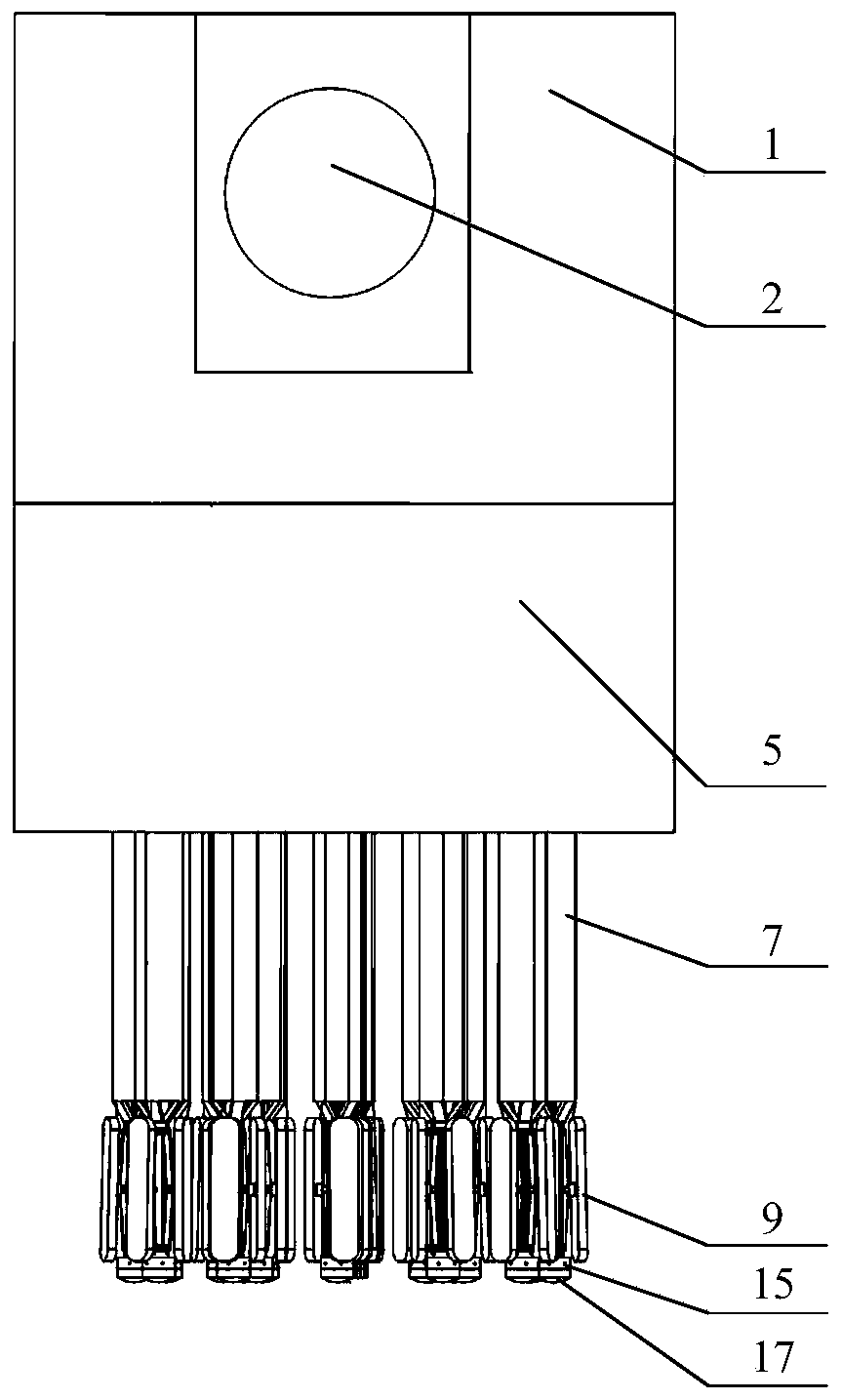

Riveting machine for end cap of four-way pipe

ActiveCN105619050AImprove work efficiencyImprove riveting precisionMetal working apparatusMechanical engineeringRiveting machines

The invention provides a riveting machine for an end cap of a four-way pipe. The riveting machine comprises a machine base and is characterized in that a first feed mechanism used for conveying the four-way pipe is arranged on the machine base; the first feed mechanism conveys the four-way pipe to a shaping mechanism for end opening shaping, and the four-way pipe subjected to end opening shaping is conveyed to a riveting station through a supporting mechanism; the riveting station is provided with a feed riveting mechanism; the feed riveting mechanism can suck up the end cap conveyed to a feed station through a second feed mechanism and rivet the end cap to the four-way pipe; and the feed station is provided with a detection device capable of adjusting the placing angle of the end cap. The riveting machine has the advantages of being high in production efficiency and riveting quality.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

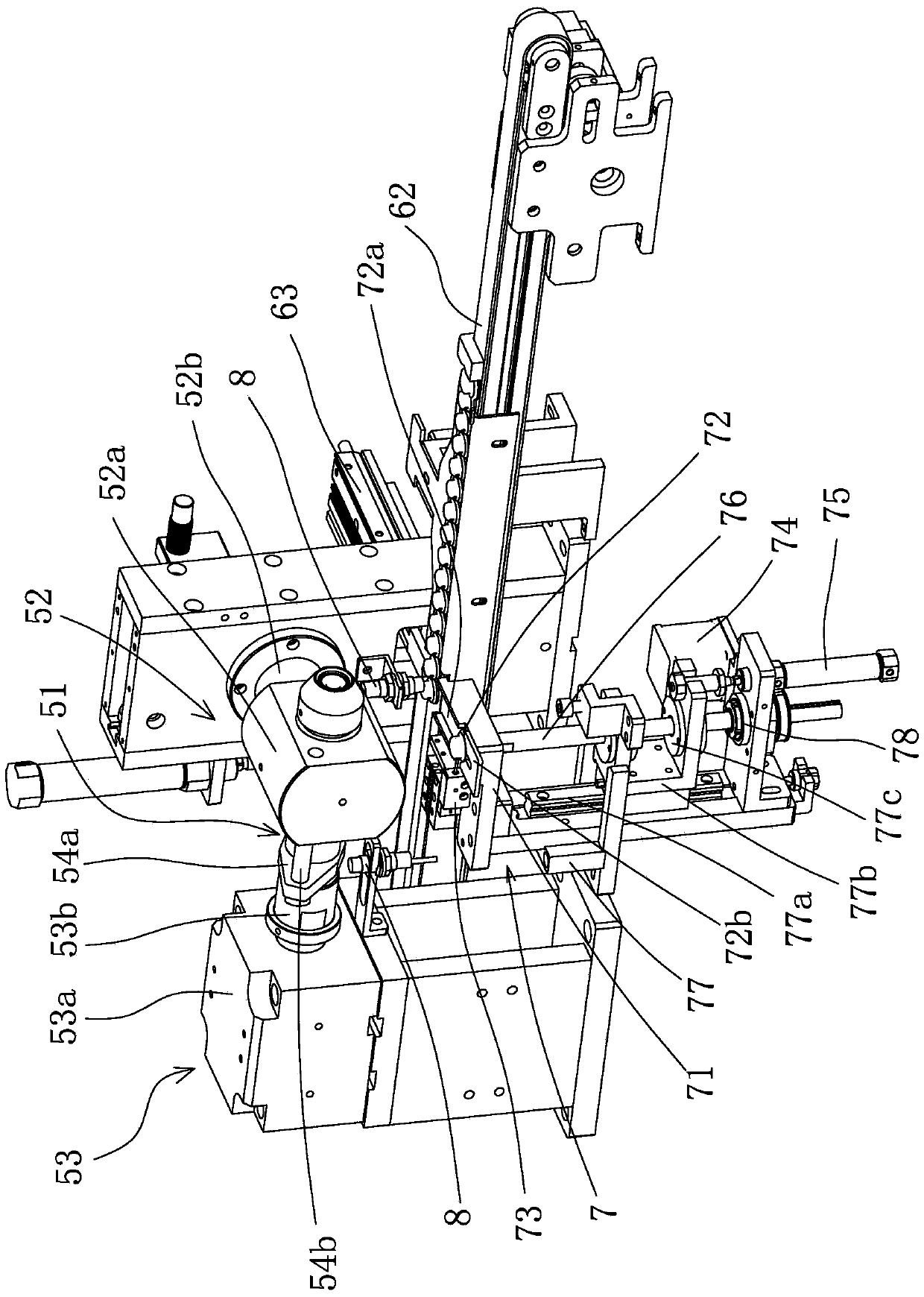

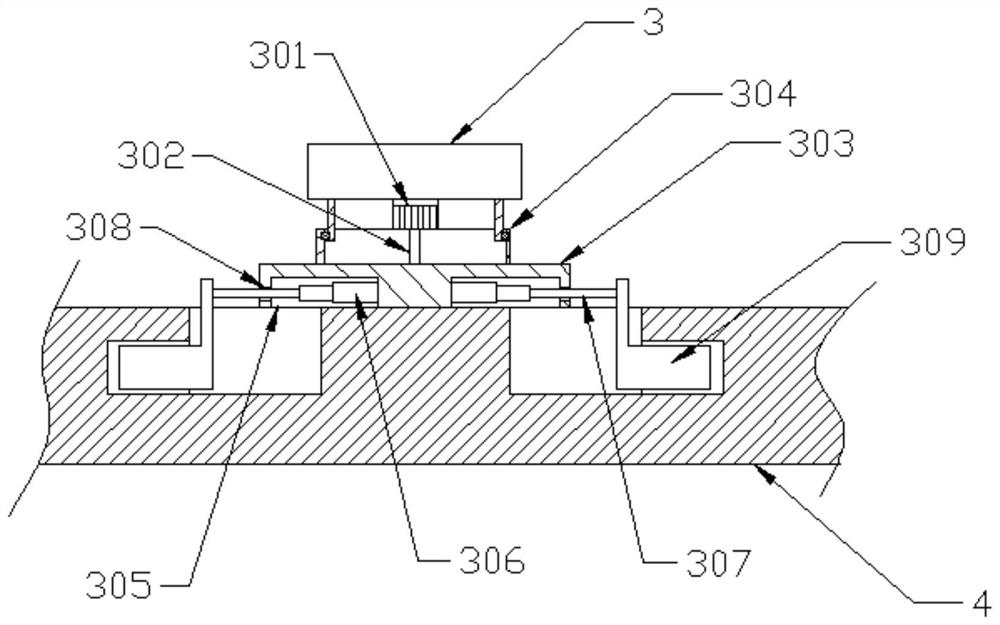

Charging and riveting mechanism for end caps of four-way pipe

PendingCN105537903AImprove work efficiencyImprove riveting precisionMetal working apparatusEngineeringPunching

The invention provides a charging and riveting mechanism for end caps of a four-way pipe. The charging and riveting mechanism comprises a stand, and is characterized in that the stand is provided with a detecting platform; the detecting platform is provided with a detecting seat body used for carrying the end covers; one side of the detecting seat body is provided with a sensor used for judging whether a setting angle of each end cap meets the requirement or not; the detecting seat body is provided with a first rotation driving mechanism capable of adjusting the setting angle of each end cap; a material sucking assembly capable of sucking the end caps is arranged above the detecting platform; the stand is provided with a drive assembly capable of driving the material sucking assembly to a punching work station; one side of the material sucking assembly is provided with a punching assembly capable of riveting the end caps at the punching work station. The charging and riveting mechanism disclosed by the invention has the advantages that production efficiency is high, and a riveting effect is good.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

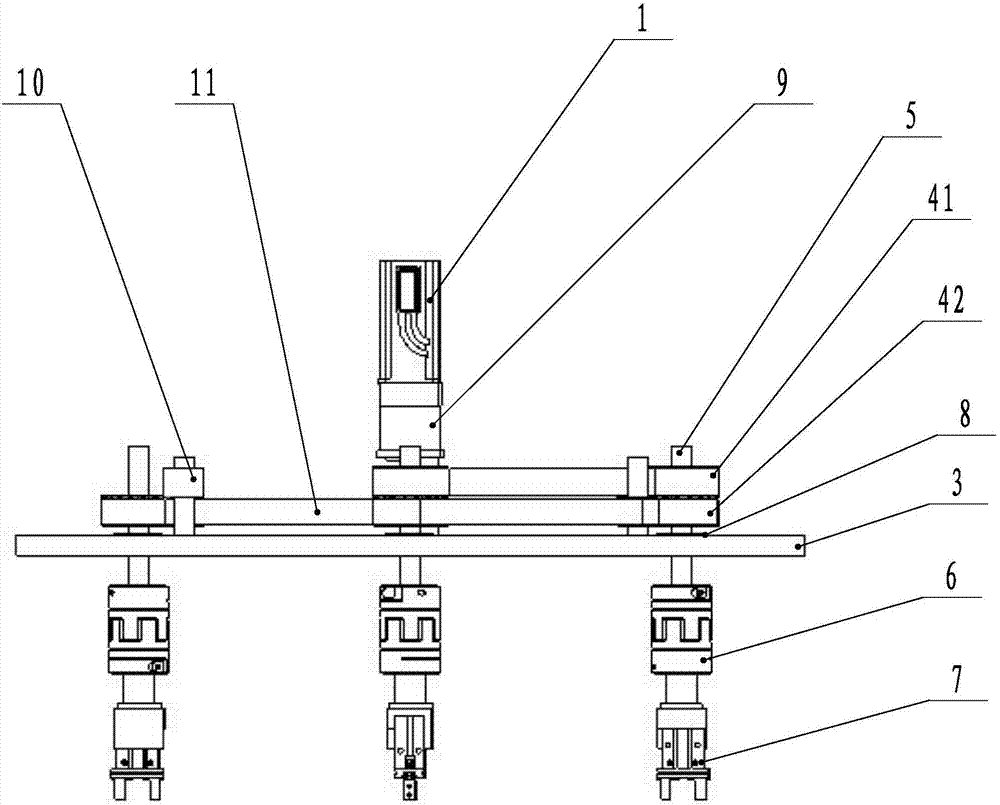

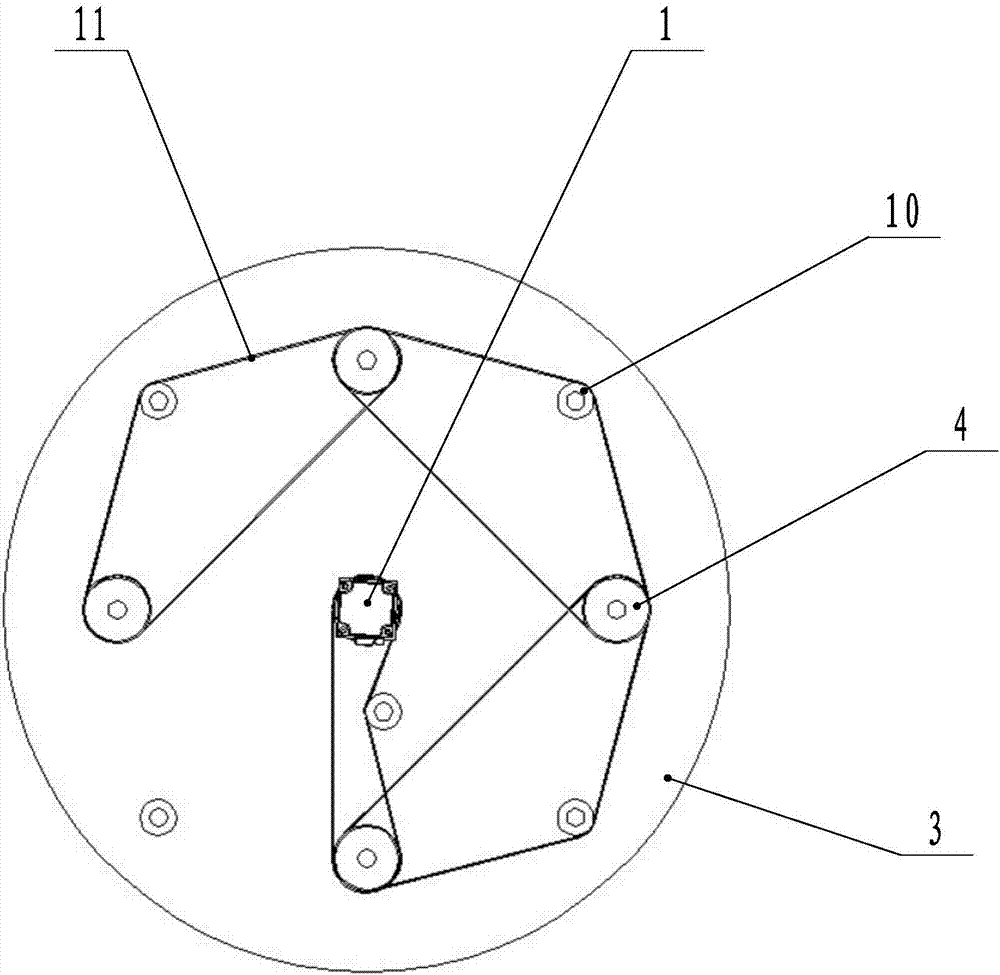

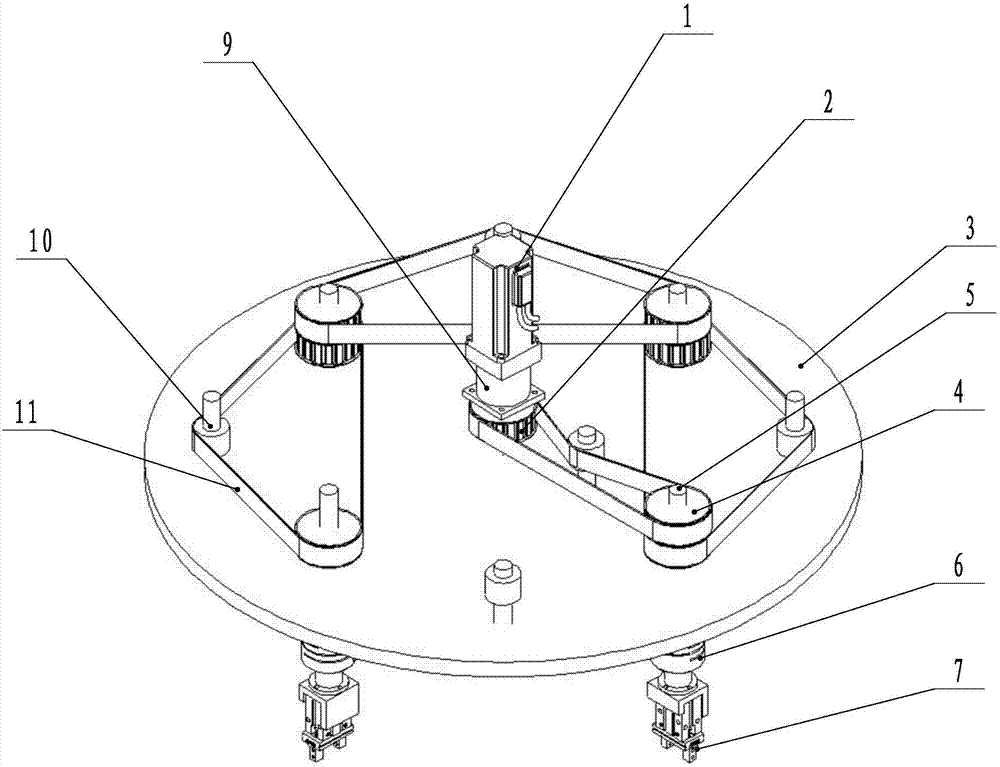

Single-motor-driven multi-gripper mechanism suitable for any gripper position

The invention discloses a single-motor-driven multi-gripper mechanism suitable for any gripper position. The mechanism is arranged on an XY plane movement mechanism and comprises a fixing frame and a plurality of gripper mechanisms; a driving motor which is provided with an encoder and can be used for teaching the rotating positions of the gripper mechanisms is arranged on the fixing frame; an output shaft of the driving motor is connected with a driving belt wheel in a driving mode; the driving belt wheel is connected with a driven belt wheel through a synchronous belt, the driven belt wheel can be connected to a driven belt wheel of the next stage through a synchronous belt, and each driven belt wheel is connected with a connecting shaft in a driving mode; and the connecting shafts are connected to the gripper mechanisms through connecting parts. According to the single-motor-driven multi-gripper mechanism, rotation of the multiple gripper mechanisms can be realized through one driving motor, and therefore the volume weight of the whole mechanism can be greatly reduced, the production cost can be reduced, the material grabbing performance of equipment can be improved, and in addition, the mechanism is driven by the synchronous belts, can be adapted to transmission connection between the gripper mechanisms at any distance and has the high practical value.

Owner:江门市蓬江区科技中心

Novel soft mechanical hand capable of realizing vertical plane grabbing

The invention discloses a novel soft mechanical hand capable of realizing vertical plane grabbing, and aims to provide the novel soft mechanical hand capable of realizing vertical plane grabbing and improving the grabbing stability, a soft body actuator which can adapt to the use requirements of irregular articles and a soft mechanical hand composed of the soft body actuator. The soft mechanical hand comprises a clamp and at least two soft body actuators symmetrically installed on the clamp, the soft actuator comprises a restraint layer and a base body positioned on one side of the restraint layer, wherein the base body comprises a pneumatic bending module and a grabbing module, one end of the pneumatic bending module is fixedly connected with the clamp, the tail end of the grabbing moduleis a free end, the grabbing module is of an air mesh type structure, and the grabbing module is driven by the pneumatic bending module to enable the grabbing module to realize the grabbing action ofthe vertical plane. The soft mechanical hand provided can be used for grabbing objects in a vertical plane, the contact area between the grabbing module and the grabbing object is large, the grabbingstability is high, and the mechanical hand can adapt to the shape of an object and is beneficial to grabbing of irregular objects.

Owner:TIANJIN UNIV

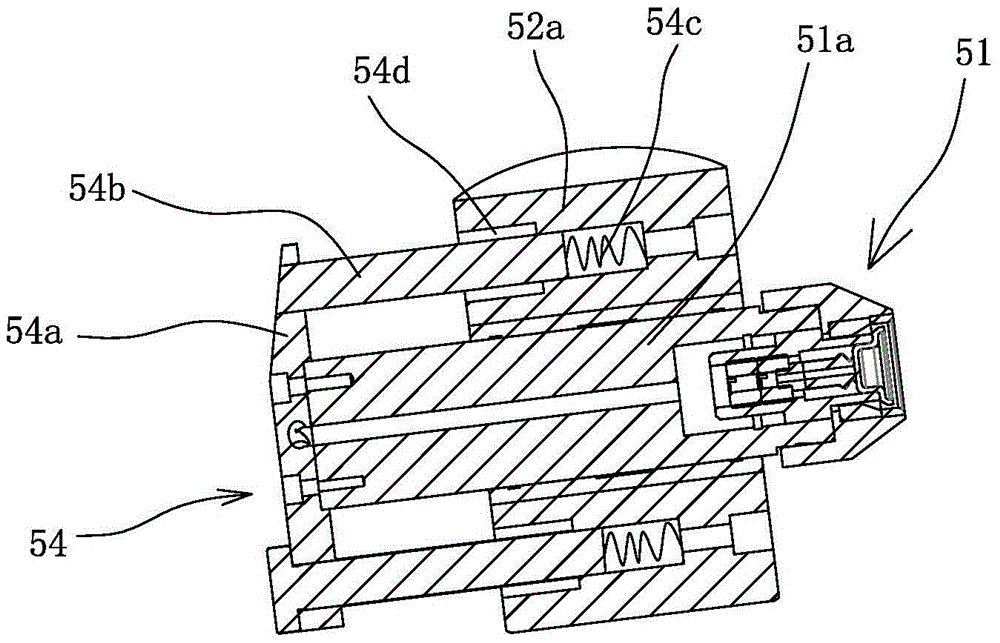

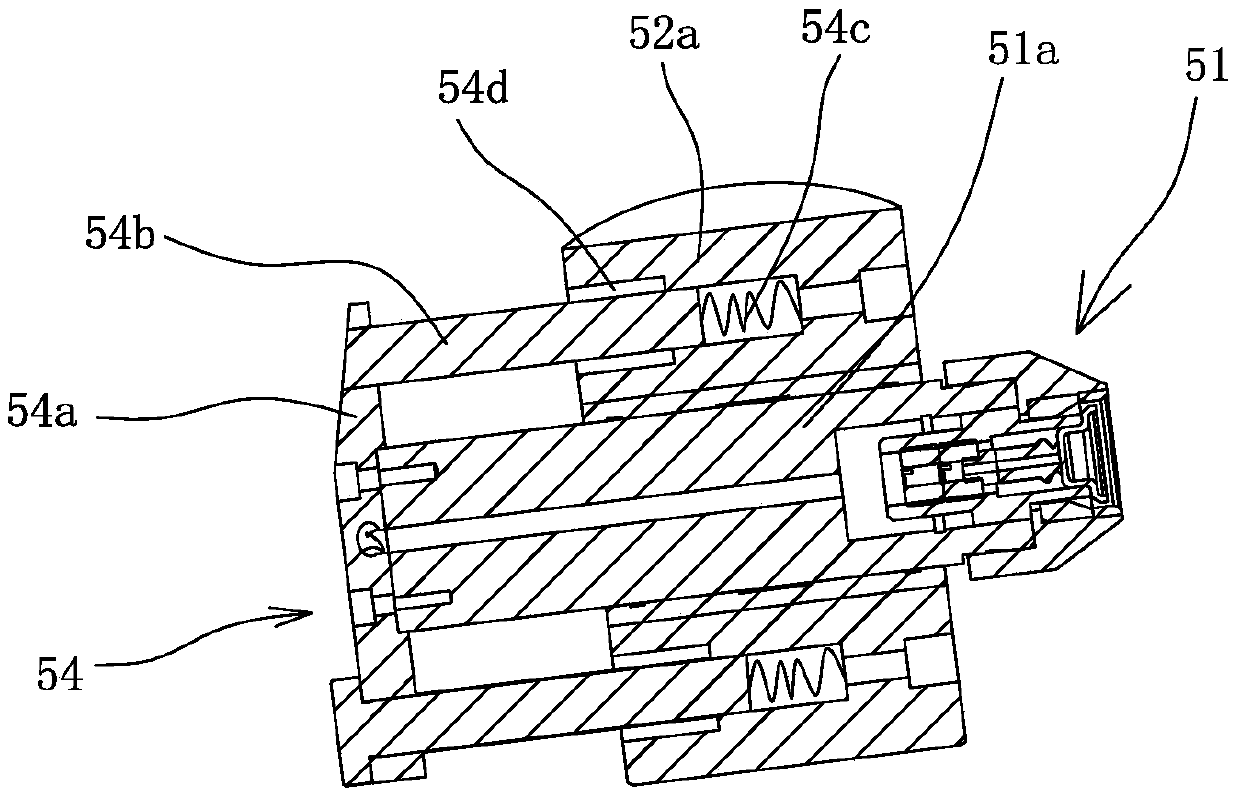

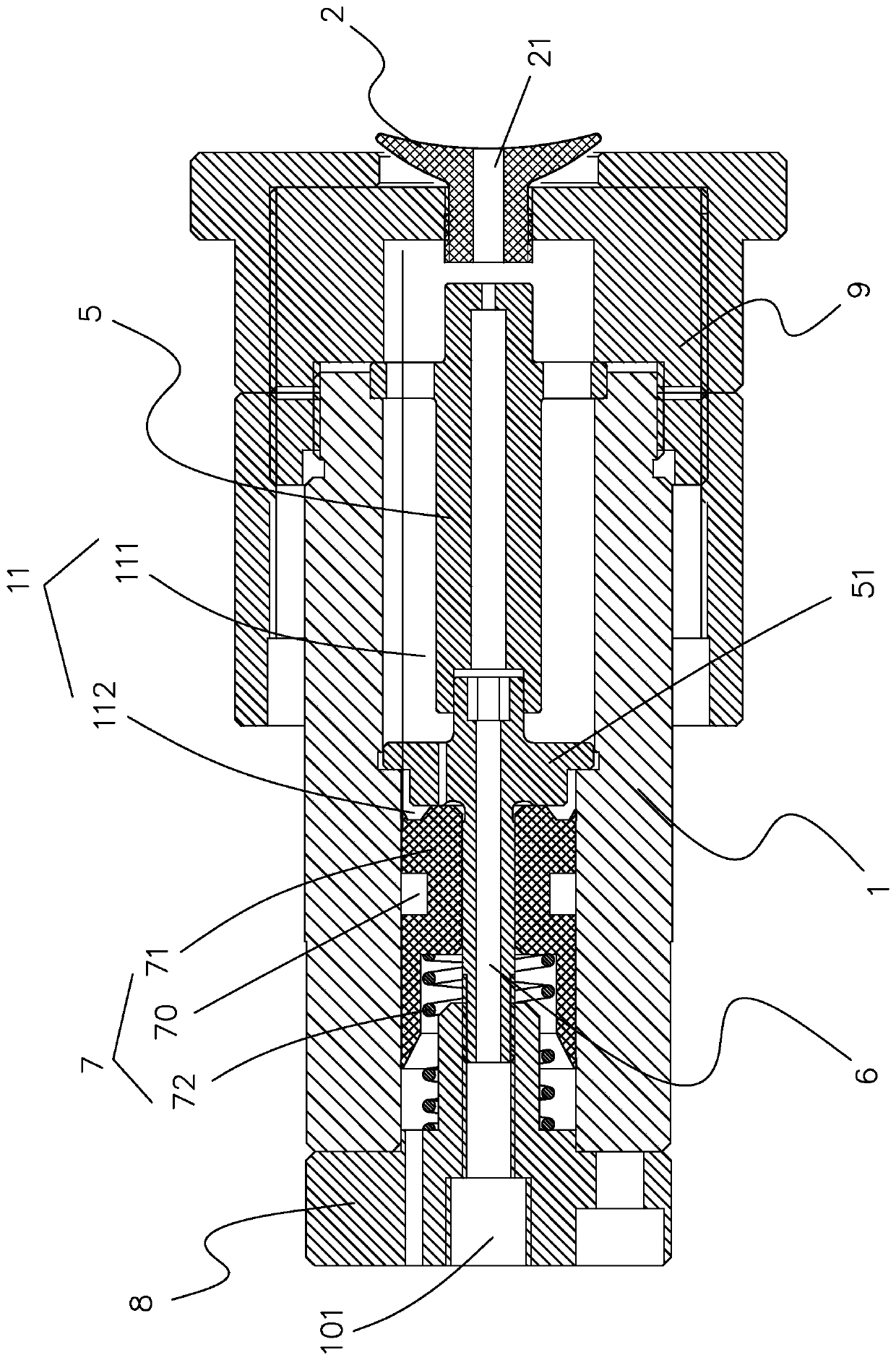

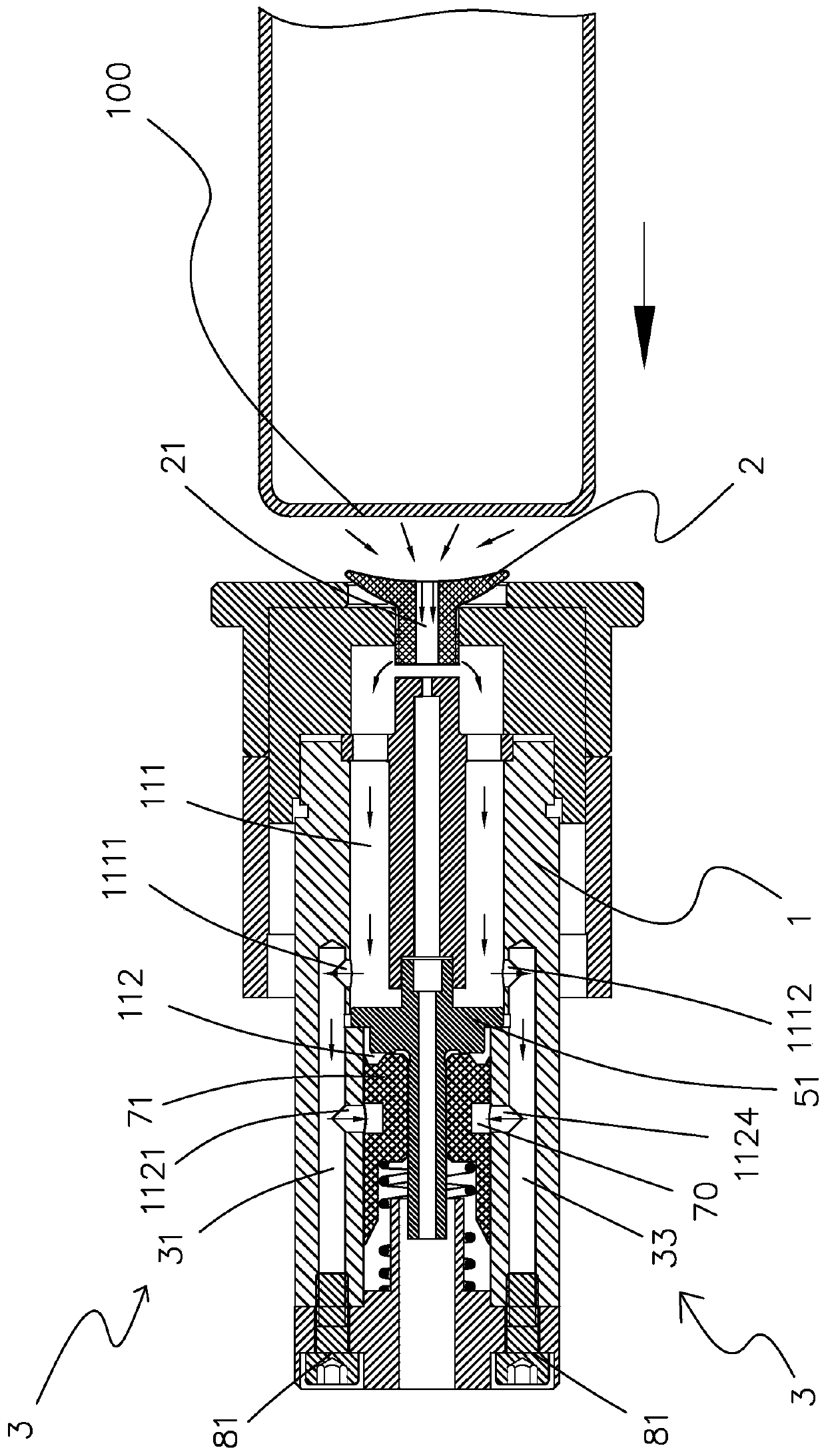

Bottle grabbing device and control method thereof

The invention provides a bottle grabbing device which is high in grabbing speed and stable in grabbing and a control method of the bottle grabbing device. The grabbing device comprises a seat body anda sucker arranged at the front end of the seat body. A ventilation hole is formed in the sucker, and a cavity communicating with the ventilation hole is formed in the seat body in the axial directionof the seat body. A negative-pressure channel and a positive-pressure channel communicating with the cavity are formed in the circumferential direction of the cavity. The negative-pressure channel communicates with the ventilation hole so that negative pressure can be formed by the ventilation hole, and the sucker can suck the bottom of a bottle so as to grab the bottle. A spindle is arranged inthe cavity in the axial direction of the cavity so as to block communication between the positive-pressure channel and the ventilation hole. The spindle is provided with an exhaust channel communicating with the ventilation hole so that the ventilation hole can recover the normal air pressure and the sucked bottle can be released. The spindle is sleeved with a piston assembly which can elasticallystretch and contract relative to the cavity when positive-pressure gas is led into the positive-pressure channel so as to block communication between the negative-pressure channel and the ventilationhole. The control method includes the negative-pressure forming step, the grabbing step and the releasing step.

Owner:GUANGDONG EURO ASIA PACKAGING

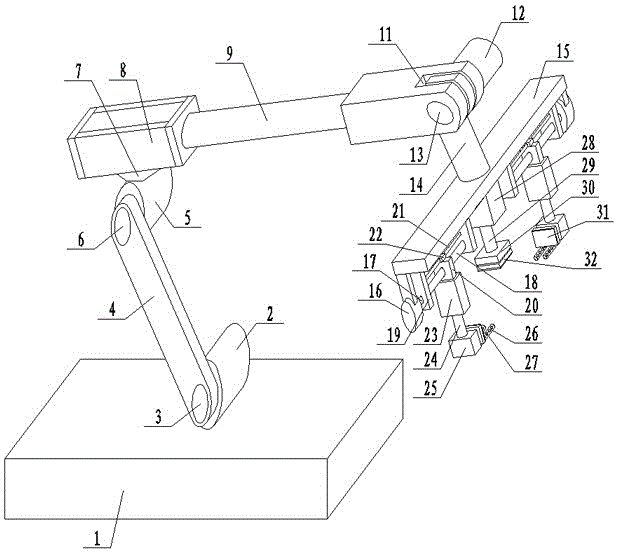

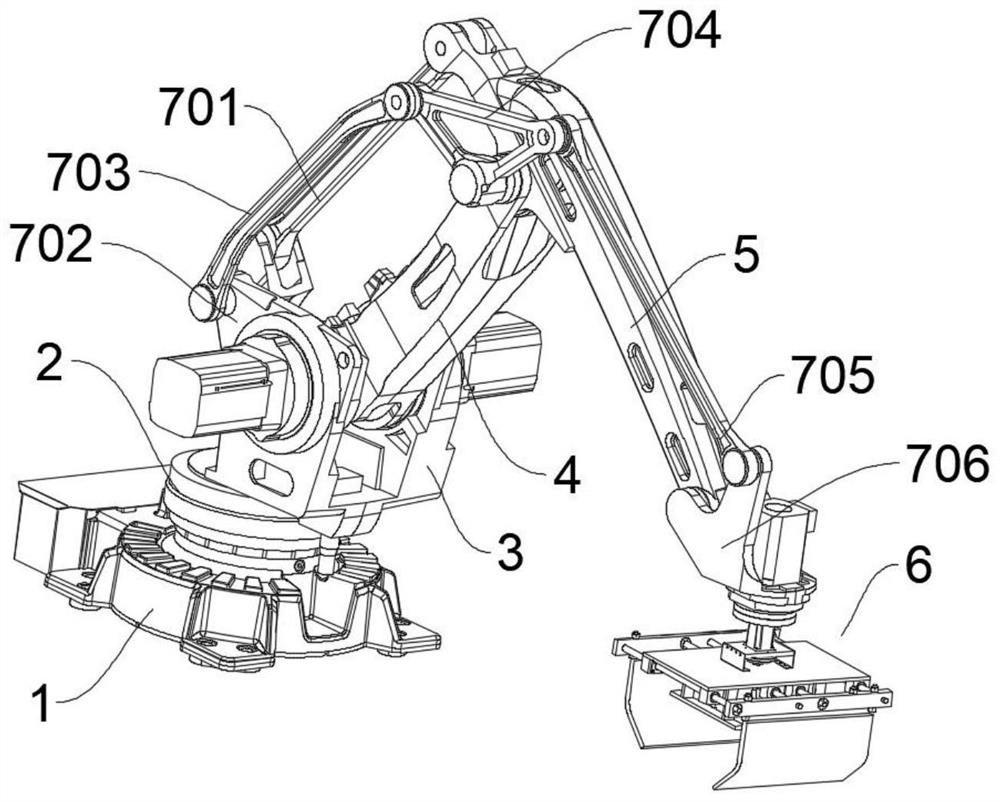

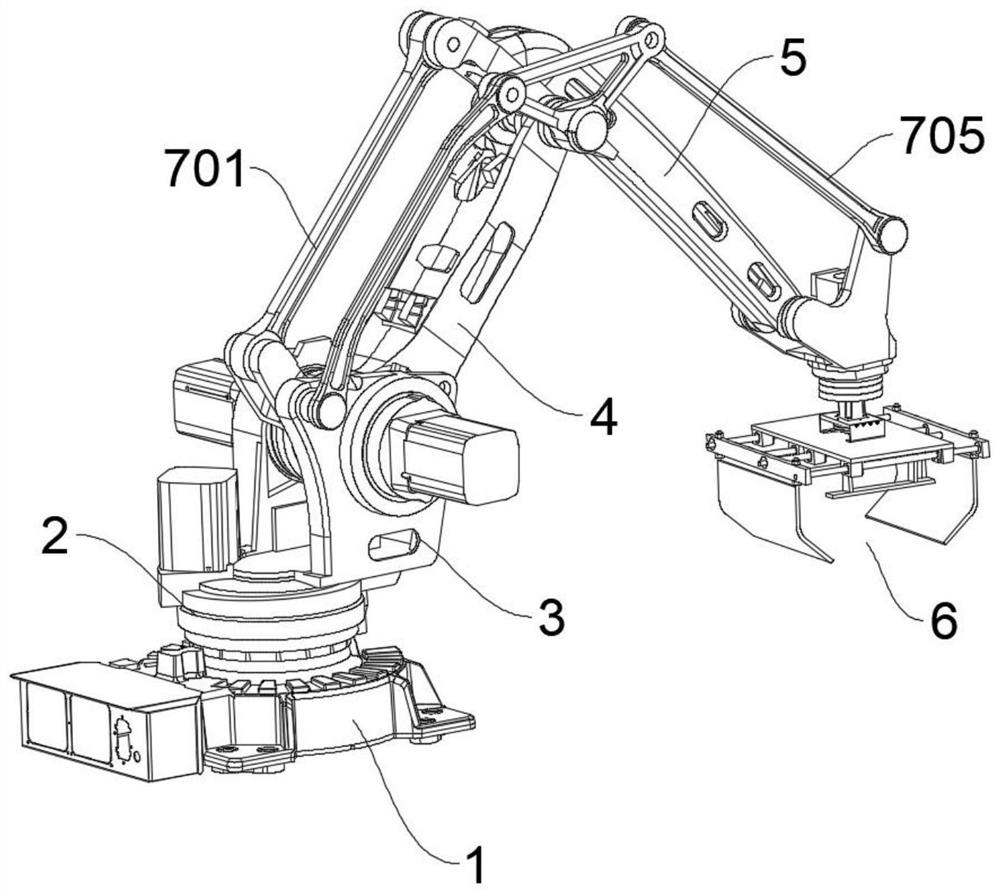

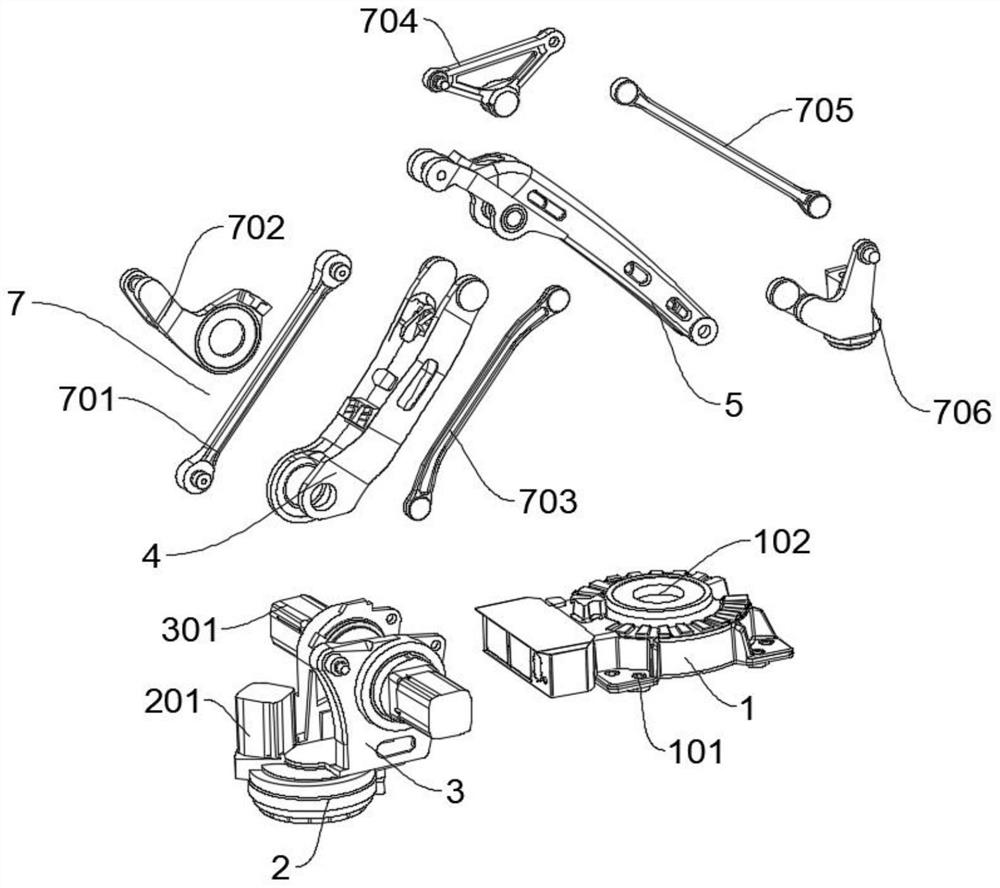

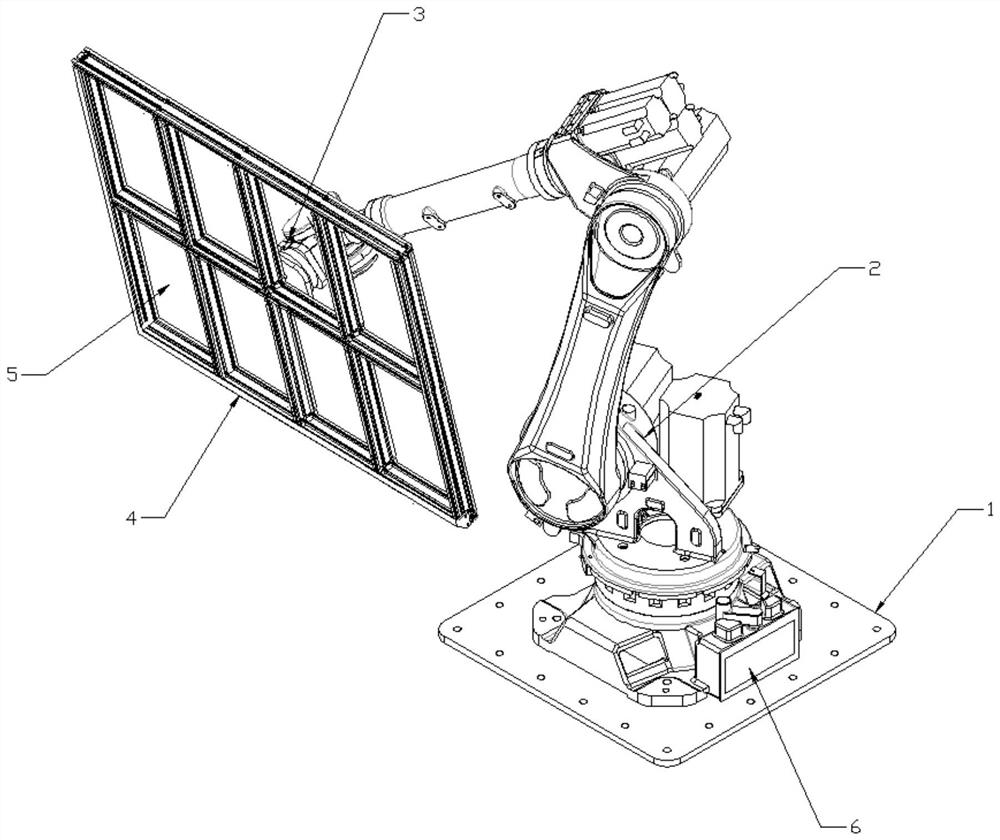

Robot structure for picking up car seat

InactiveCN106799729AWon't shakeAvoid deformationProgramme-controlled manipulatorGripping headsCar seatEngineering

The invention discloses a robot structure for picking up a car seat, comprising a pedestal and a first angle rotating motor fixedly arranged on the pedestal. The motor shaft of the first angle rotating motor is connected with the lower end of a first swing arm, the first swing arm is connected with the motor shaft of a second angle rotating motor, an air cylinder is arranged on the second angle rotating motor through a fixing seat, a mounting seat is arranged on the piston rod of the air cylinder, a mounting groove is arranged in the mounting seat, one side of the mounting seat is provided with a third angle rotating motor, the motor shaft of the third angle rotating motor stretches into the mounting groove and connected with the upper end of a second swing arm, the lower end of the second swing arm is provided with a cross beam, two sides of the lower end of the cross beam are symmetrically provided with servo gear motors, the motor shafts of the servo gear motors are respectively connected with threaded rods, and the thread directions of two threaded rods are opposite to each other.

Owner:YANCHENG GAOYUE MACHINERY

Processing method of high-elasticity light and thin composite yarns

ActiveCN106676698AWear-resistantBreathableFilament handlingWrapper twisting/gatheringWater basedAntistatic agent

The invention provides a processing method of high-elasticity light and thin composite yarns, and is used for solving the technical problems that the existing preparation method is unreasonable in components, the product quality is low and the like. The processing method of the high-elasticity light and thin composite yarn comprises the following steps: a, purchasing chinlon elater and viscose filament yarns as raw materials, and detecting whether the raw materials are in conformity with the national quality index of the textile industry; b, merging 3 to 5 chinlon elaters and 2 to 3 viscose filament yarns by virtue of a yarn merging apparatus, and then twisting to obtain a composite yarn; c, pouring 50 to 70 parts of organic silicon polyurethane water-base paint, 5 to 8 parts of antibacterial agent, 3 to 7 parts of antistatic agents, 2 to 3 parts of coupling agents, 0.8 to 1.2 parts of dispersing agents and 10 to 20 parts of water into a stirring machine to be mixed to obtain a coating solution, wherein the stirring time is 10 to 25 min; d, smearing the coating solution onto the surface of the composite yarn to obtain a high-elasticity light and thin composite yarn, and winding the high-elasticity light and thin composite yarn on a finished product reel; and e, packing the finished product reel by virtue of a packing apparatus. The processing method has the advantages of good product quality.

Owner:广东联合致尚技术有限公司

Multi-sensor feedback adaptive robot finger device and control method thereof

InactiveCN102303316BHigh dexterity freedomImprove reliabilityProgramme-controlled manipulatorGripping headsRobot handMotor drive

The invention discloses a multi-sensor feedback adaptive robot finger device and a control method thereof, and belongs to the technical field of robot hands. The device comprises two finger sections, a joint shaft, a motor, three sensors, a control module and a motor driving module. The device is a robot finger device for comprehensively implementing parameter adjustment and program control by using multiple sensors for feeding back signals, the motor driving module, the control module and an adaptive grabbing control algorithm; the device can realize adaptive grabbing of objects of differentshape and size, is easier to trigger the adaptive grabbing action, and is stable in grabbing, controllable in grabbing force and short in transmission chain; when the device is used for grabbing different objects, reprogramming is not needed; and the device is simple and convenient to use, meets requirement for grabbing of multiple objects, and can realize a robot hand with high flexibility and degree of freedom, high adaptability, low control difficulty and high reliability.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

Clamping mechanism for hoisting duct piece

Owner:HENAN WATER CONSERVANCY CONSTR ENG

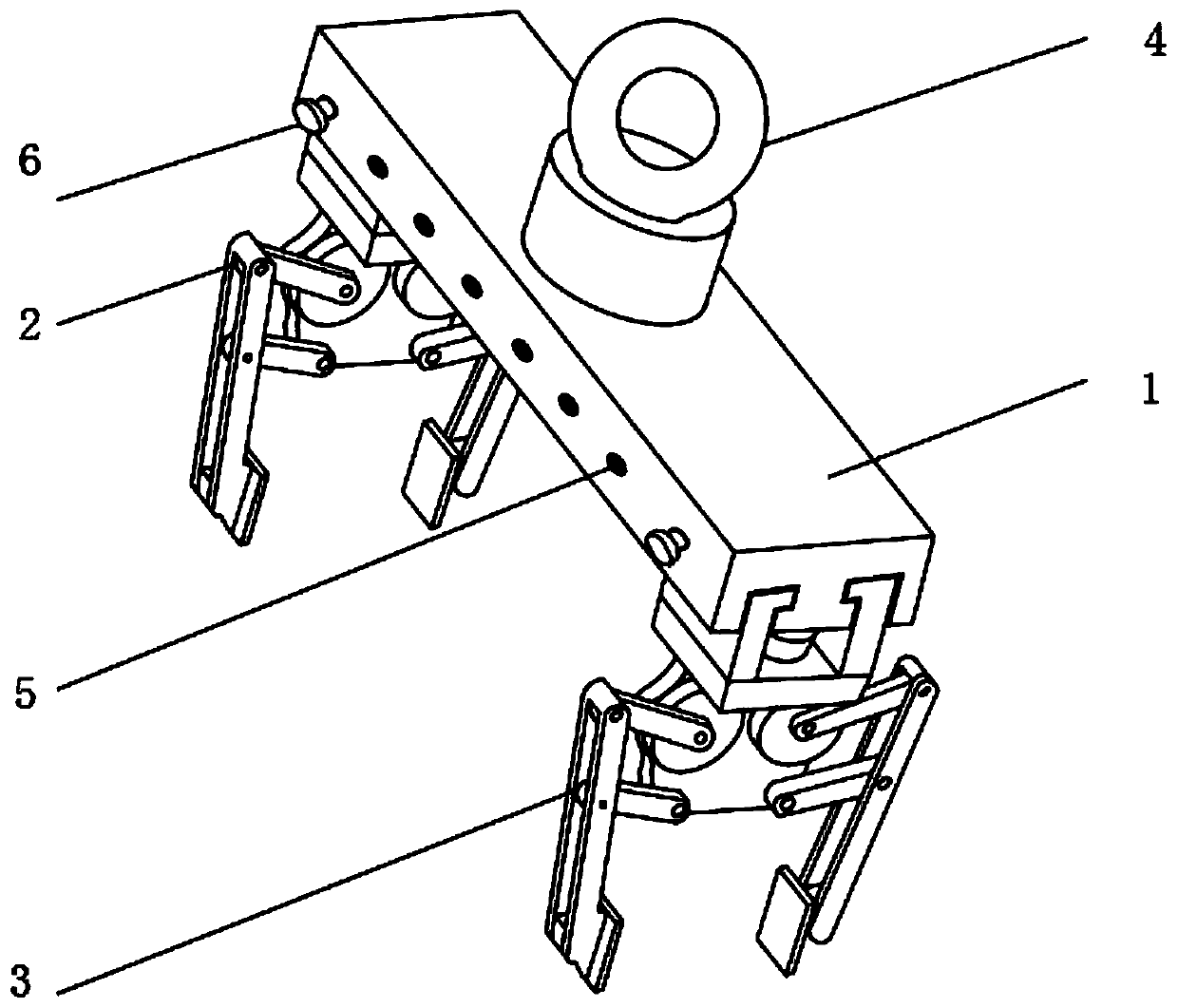

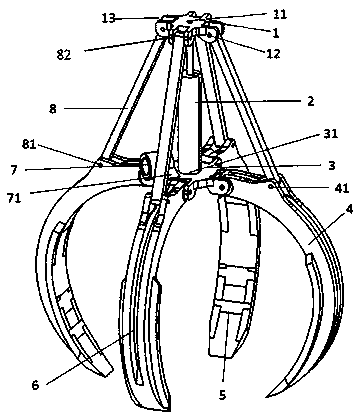

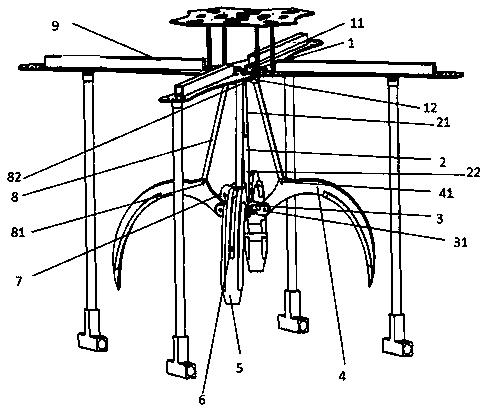

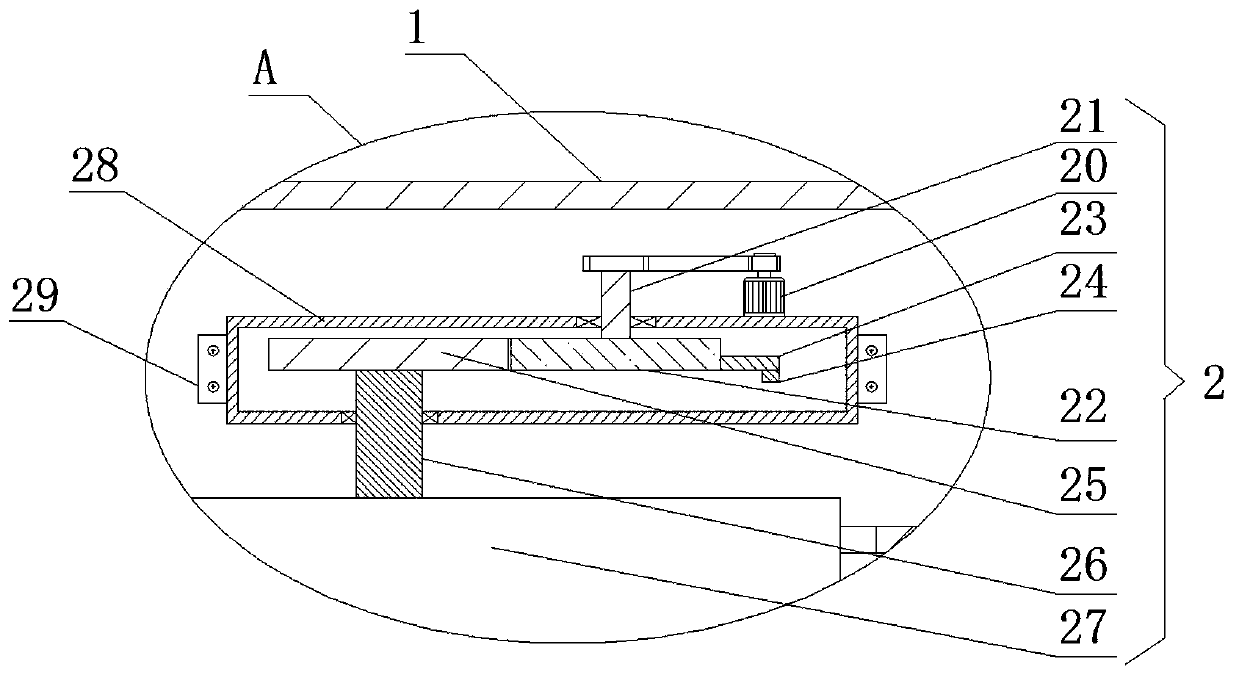

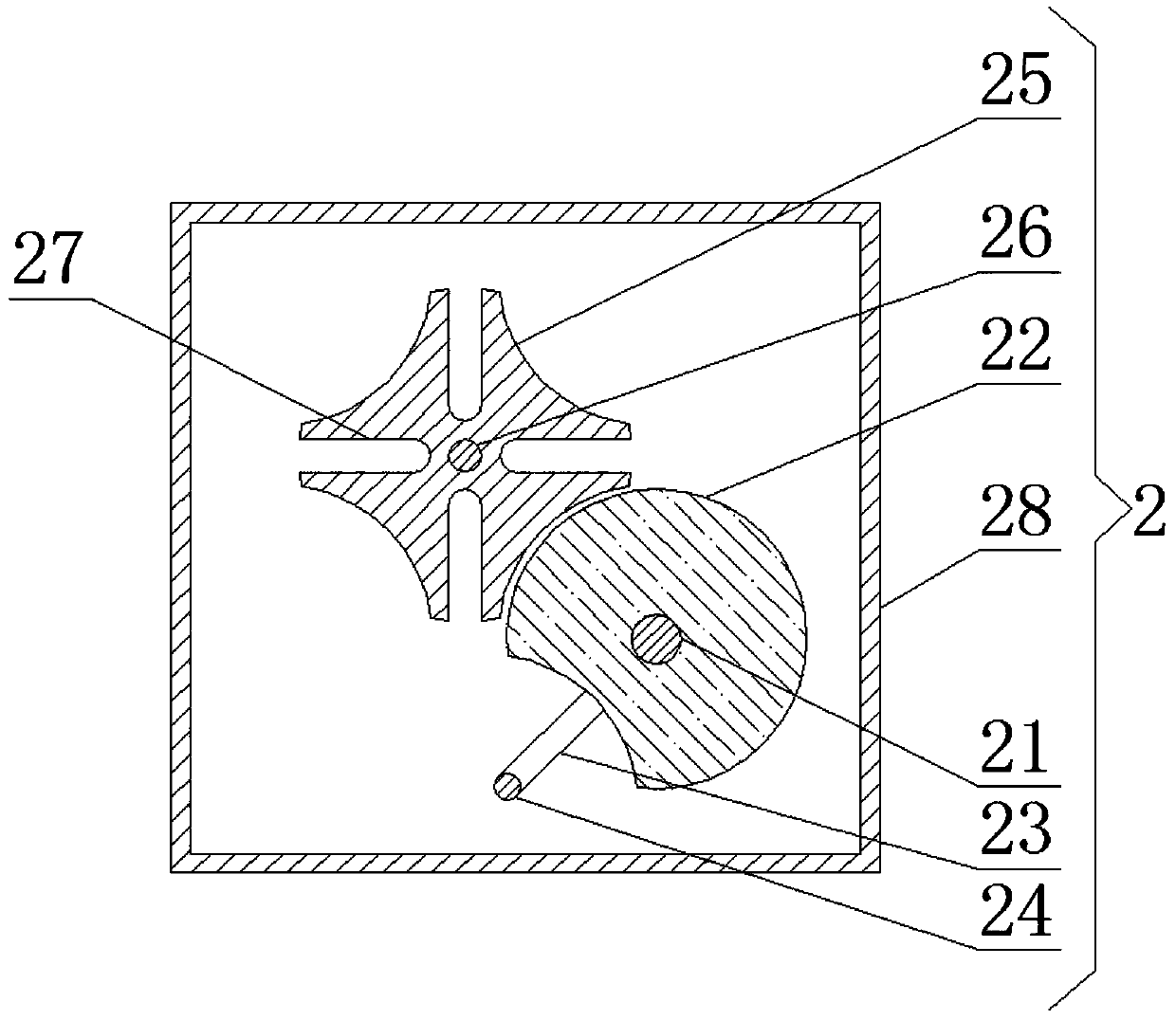

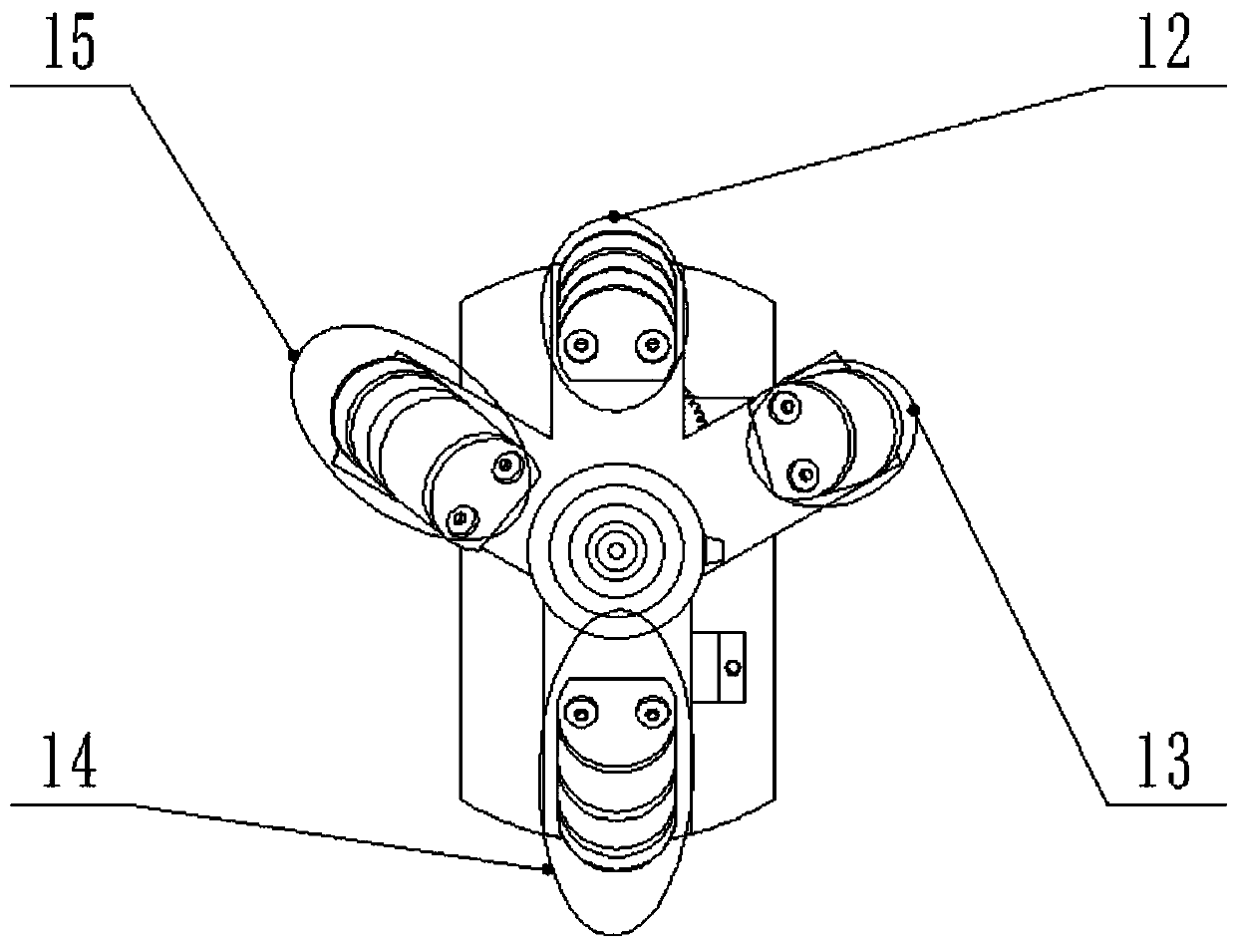

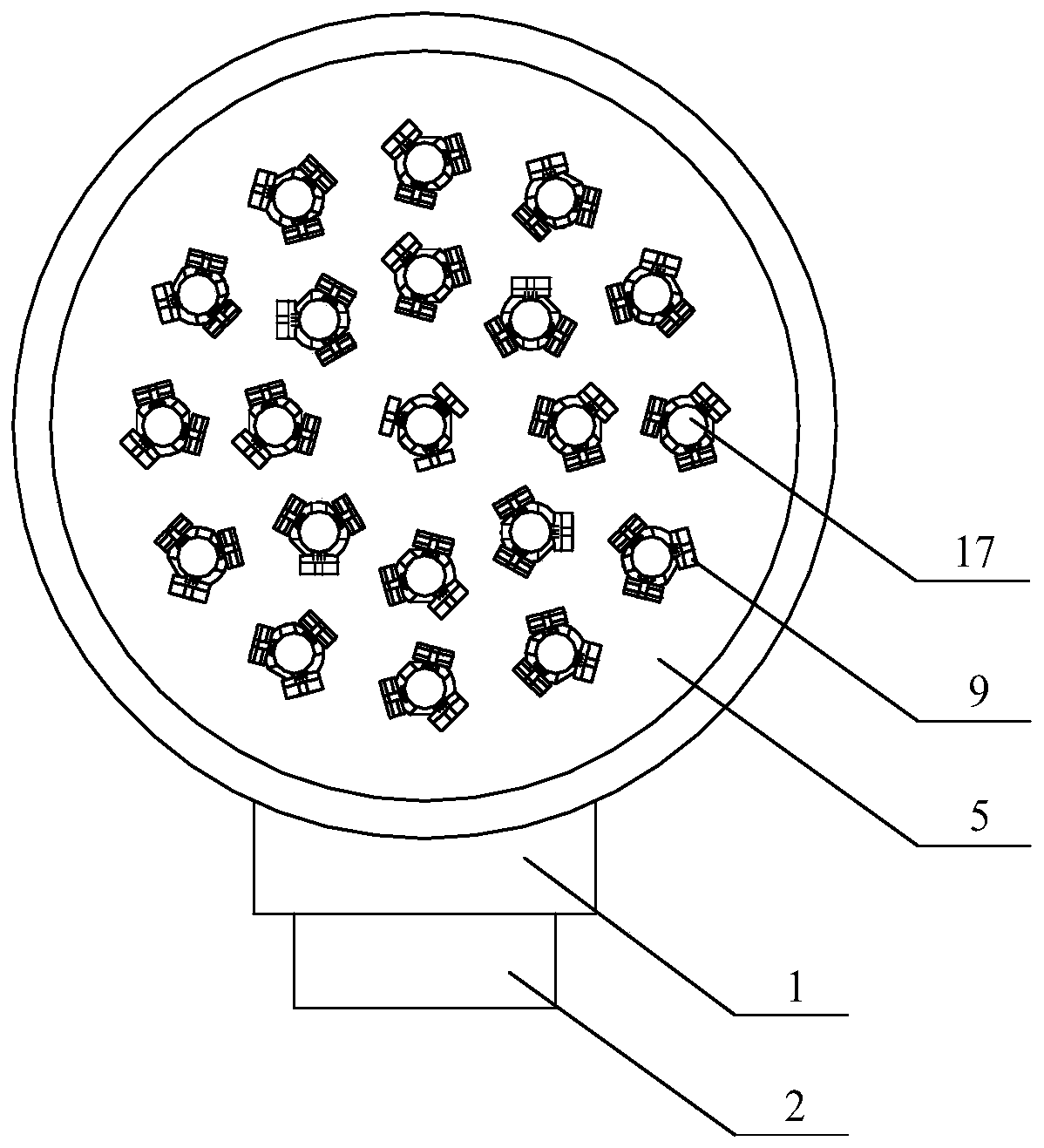

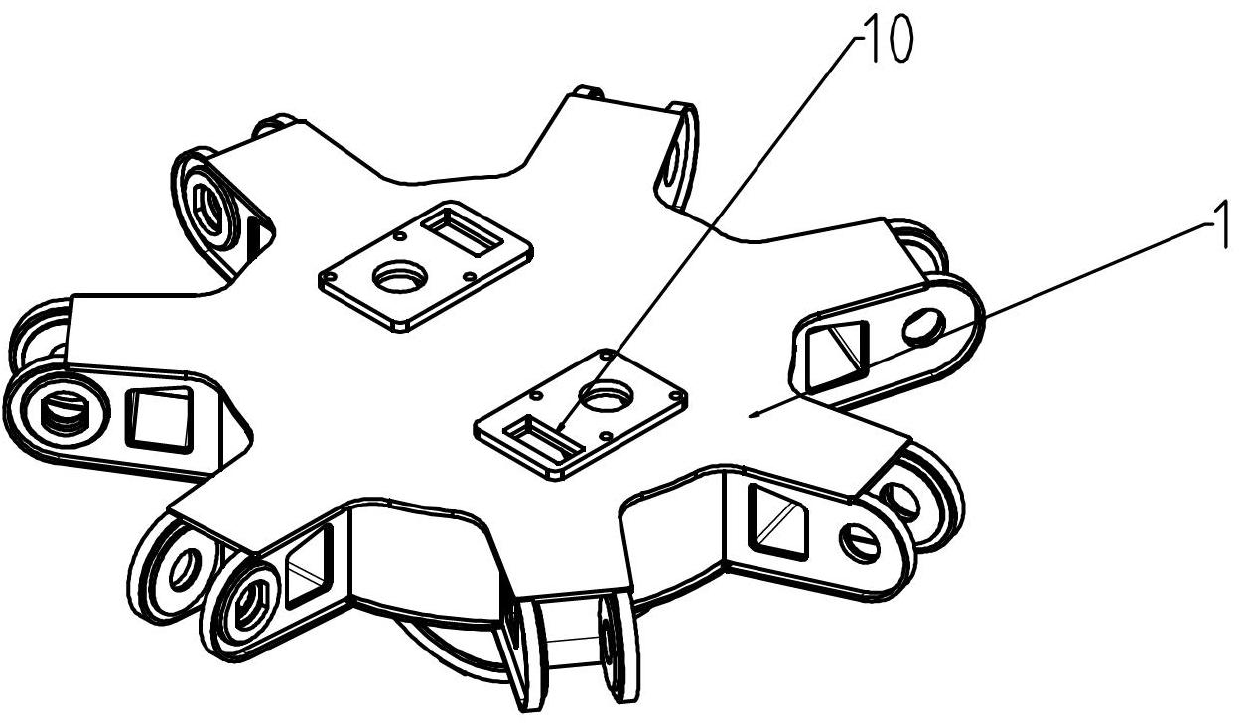

A small unmanned aerial vehicle adjustable bird claw type mechanical gripper device

PendingCN109250118ANot easy to fall offSimple structureGripping headsFreight handlingEngineeringControllability

An adjustable bird claw type mechanical gripper device for small unmanned aerial vehicles relates to a mount device for a small unmanned aerial vehicle. A connecting plate of the gripper (1) is a pie-shaped body of a positive cross type. A geometrical center of the pie-shaped body is provided with a threaded hole (11), to connect the power source structure (2), four U-shaped clamping grooves (13)are drawn out in four mutually perpendicular directions on the upper surface of the cake-like body, the spacing dimension of the two solid surfaces of the clamping grooves is consistent with the widthdimension of the head of the power lever, a special-shaped hole (12) is formed on the two solid surfaces of the clamping grooves, and the special-shaped hole (82) on the upper head of the power lever(8) is serially connected with an inner hexagon screw; a grasp center connecting plate (3) is different in shape from a grasp upper connecting plate (1) in that the grasp center connecting plate (3)is provided with a cylindrical center threaded hole (31). The device uses a telescopic rod to control the opening and closing of four grippers, which can control the position and force of gripping stably and accurately, and is more suitable for precise manipulation, and has strong stability and controllability, and obvious gripping effect.

Owner:SHENYANG UNIV

Special manipulator for sand and gravel crushing

PendingCN111618831AExcellent crawl rangeAchieve crawlingProgramme-controlled manipulatorJointsMechanical equipmentManipulator

The invention relates to the technical field of mechanical equipment, in particular to a special manipulator for crushing sand and gravel. The manipulator comprises a rotating assembly and a graspingassembly; the rotating assembly comprises a rotating part I and a rotating part II; the rotating part I comprises a mounting seat, a rotating seat and a wrist; the bottom of the rotating seat is mounted on the mounting seat; the wrist is fixedly mounted above the rotating seat; the wrist comprises a U-shaped part; the bottom of the U-shaped part is fixedly connected with the rotating seat; the U-shaped part is rotatably connected with the rotating part II; the rotating part II comprises a first arm part and a second arm part; the other end of the first arm part is rotatably connected with oneend of the second arm part; the other end of the second arm part is connected with the grasping assembly; the grasping assembly comprises a first clamping plate, a second clamping plate and a drivingmechanism; and the first clamping plate and the second clamping plate form a grasping space. The special manipulator for crushing the sand and gravel can rotate and pull out from multiple angles, canconveniently cooperate with sand and gravel collection and improve the efficiency of the sand and gravel collection.

Owner:南京航创特种机器人有限公司

Manipulator wrist positioning system and positioning method thereof

InactiveCN111347408AImprove practicalityImprove gripProgramme-controlled manipulatorGripping headsCircular discRobot hand

The invention discloses a manipulator wrist positioning system and a positioning method of the manipulator wrist positioning system, wherein the positioning system comprises an outer shell, a positioning structure, a servo motor, a first rotating shaft, a disc, an extension rod, a cylinder, a sheave, a second rotating shaft, a connecting plate, an inner shell, fixed plates, a manipulator steeringplatform, manipulator arm levers, rotating chucks and vacuum suction cups. The rotating chucks are driven by an air cylinder, so the rotating chucks can rotate in the vertical direction, and the practicability of a manipulator is improved; by installing the vacuum suction cups, the gripping effect of the manipulator can be improved, and uniform stress and stable clamping are achieved; through rotating fit of the disc, the sheave and the servo motor, rotating and positioning work of the manipulator in four directions can be realized, an external air cylinder is avoided from being used for positioning the manipulator, the cost is reduced, the positioning effect is excellent, and the stability is high. In conclusion, the movement speed of the manipulator can be controlled, the positioning effect is excellent, and the precision is accurate.

Owner:宁夏巨能机器人股份有限公司

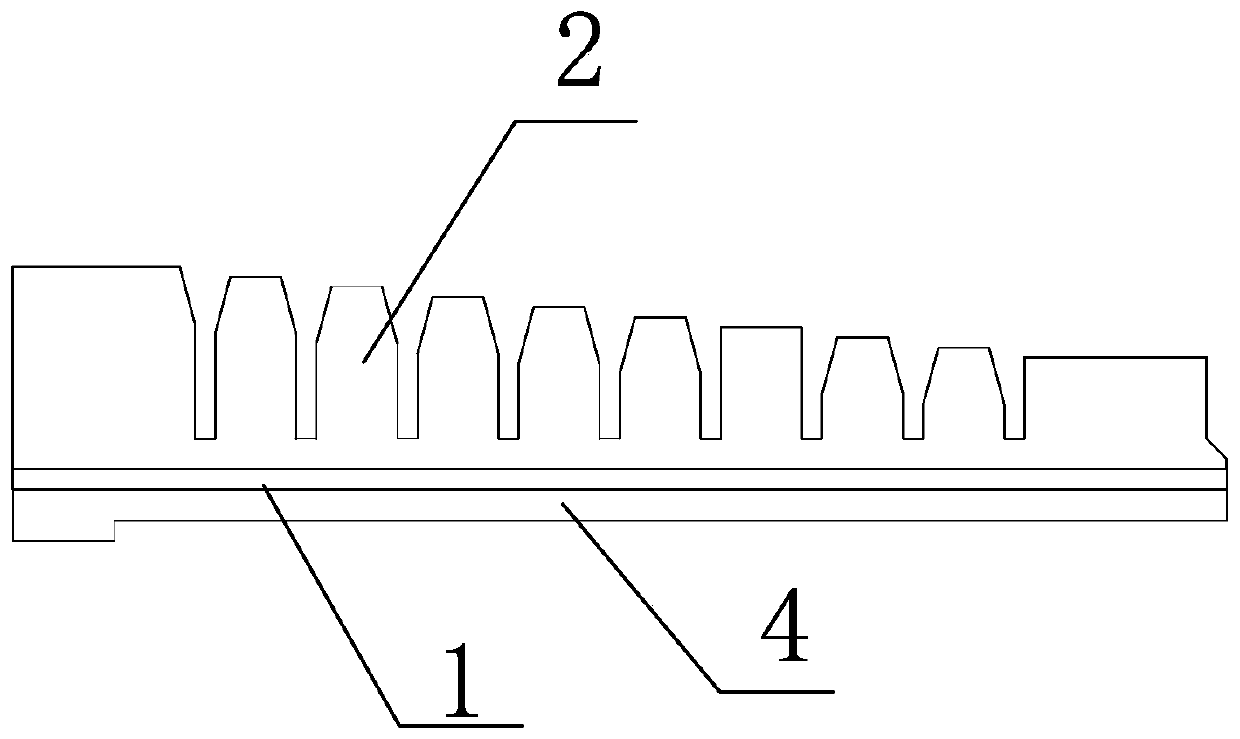

Two-direction perception adaptive robot finger device with closed-ring flexible piece and control method of two-direction perception adaptive robot finger device

InactiveCN106695851AImplement bi-directional crawlingGood grabbing effectGripping headsMotor drivePattern perception

The invention relates to a two-direction perception adaptive robot finger device with a closed-ring flexible piece and a control method of the two-direction perception adaptive robot finger device. The two-direction perception adaptive robot finger device comprises a base, two finger sections, two joint shafts, a driver, a flexible transmission piece, a sensor, a control module, a motor driving module and the like. The two-direction perception adaptive robot finger device realizes four grabbing modes: (1) a mode that the two-way perception adaptive robot finger device performs forward-direction parallel clamping and grabbing; (2) a mode that the two-way perception adaptive robot finger device firstly performs forward-direction parallel clamping and then performs adaptive grabbing; (3) a mode that the two-way perception adaptive robot finger device performs reverse-direction parallel clamping and grabbing; and (4) a mode that the two-way perception adaptive robot finger device firstly performs reverse-direction clamping and then performs adaptive grabbing; therefore, the unidirection adaptive grabbing effect of a conventional perception adaptive finger is achieved, and the two-direction adaptive grabbing effect and the two-direction parallel clamping and grabbing effect, which are not achieved by the conventional perception adaptive finger, are also achieved by the two-direction perception adaptive robot finger device; the grabbing range is large, the grabbing process is stable, the grabbing force is controllable, and a transmission chain is short; when the two-direction perception adaptive robot finger device is used for grabbing different objects, reprogramming is not needed, and the two-direction perception adaptive robot finger device is simple and convenient to use; and the two-direction perception adaptive robot finger device can realize high dexterity, high adaptability, high reliability, high stability and low control difficulty, and is suitable for a robot hand.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

New energy motor shell positioning gripper

ActiveCN111884451AHigh degree of automationGood grabbing effectManufacturing dynamo-electric machinesElectric machineNew energy

The invention relates to the technical field of new energy motor assembly, and discloses a new energy motor shell positioning gripper which comprises a supporting frame. Two guide rods are fixed in the supporting frame through bolts, the outer walls of the guide rods are slidably connected with a same mounting block, and two sliding shafts are fixed to the bottom of the mounting block through bolts. Two sliding blocks are slidably connected to one side of the outer wall of each sliding shaft, a connecting column is fixed to one side of the bottom of each sliding block through a bolt, a clamping block is fixed to the bottom of each connecting column through a bolt; two fixing blocks are fixed to one side of each connecting column through bolts, and a rack is fixed to one side of each fixingblock through a bolt; and a rotating column is rotatably connected to one side of the mounting block. According to the gripper, the positioning and grabbing automation degree is high, the grabbing effect is good, the positioning and grabbing precision can be better improved, motor shells of different sizes can be better and accurately grabbed, and therefore the grabbing efficiency can be better improved.

Owner:无锡泓阳电动科技有限公司

Automatic edging device with glass adsorption function

InactiveCN112692690AAvoid affecting workGuaranteed crawling effectBelt grinding machinesGrinding feedersPhysicsEngineering

The invention relates to the field of glass edging devices, in particular to an automatic edging device with a glass adsorption function. The automatic edging device with the glass adsorption function comprises a feeding conveyor belt which is used for directionally moving glass to be edged; a positioning table is fixedly mounted at the output end of the feeding conveyor belt and used for positioning the glass to be edged; a glass adsorption device is used for accurately adsorbing the glass on the positioning table and driving the glass to move, and provided with a horizontal moving assembly, a vertical moving assembly and a vacuum suction cup; universal wheels are arranged on the side, away from the feeding conveying belt, of the positioning table; an edging device body is fixedly mounted on one side of the universal wheels and used for automatically polishing edges of the glass; and a discharging conveyor belt is fixedly mounted at the ends, away from the positioning table, of the universal wheels. According to the automatic edging device with the glass adsorption function, the purposes that the structure is simple and the edging machining can be carried out on different pieces of glass are achieved, so that the technical problems that the maintenance is inconvenient when equipment goes wrong and the equipment can only machine single glass are solved.

Owner:陈炳德

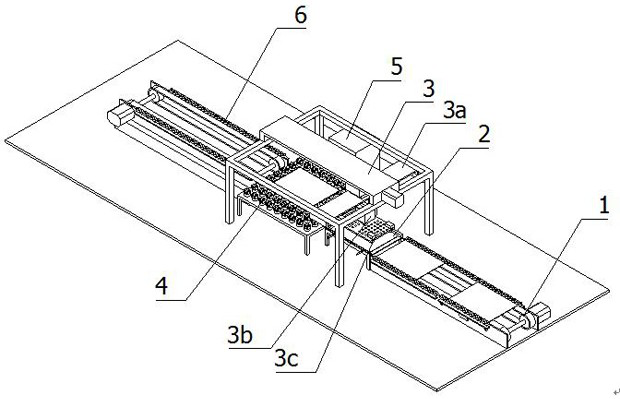

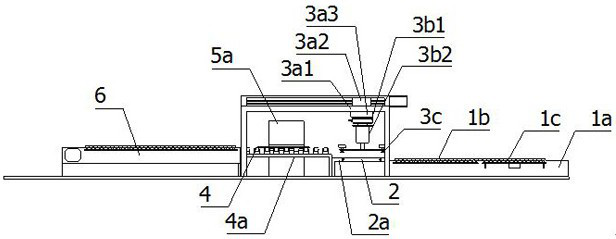

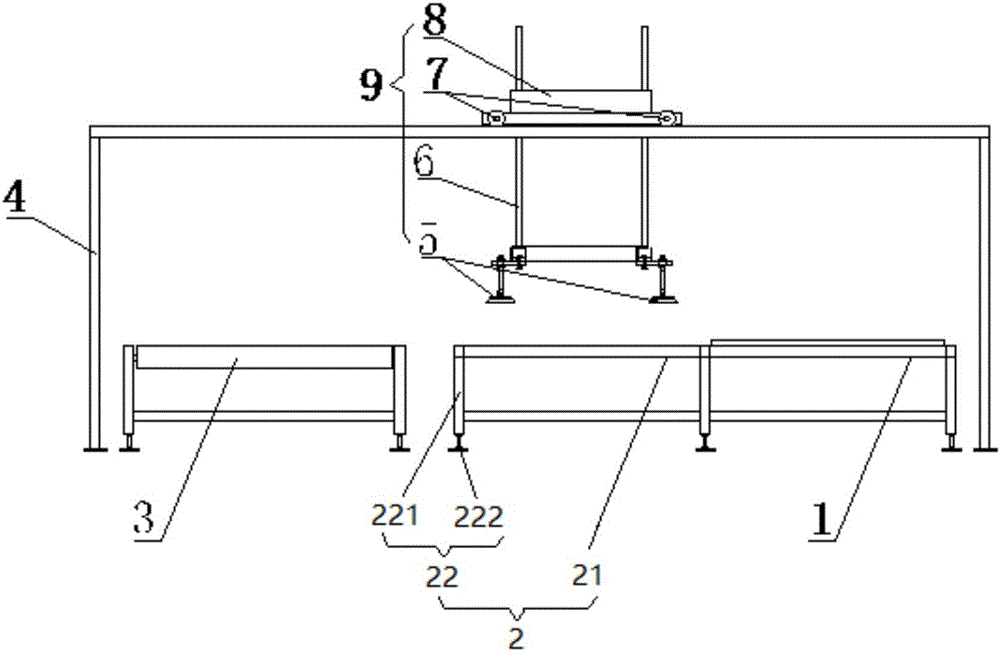

Wall synthesis production line and overline transferring device thereof

InactiveCN105836461AInhibit sheddingGood grabbing effectWork benchesConveyor partsProduction lineOverline

The invention discloses a wall synthesis production line and an overline transferring device thereof. The overline transferring device of the wall synthesis production line comprises a bracket and a transferring assembly. The bracket crosses over a material preparing area, an operation platform and a conveying line body which are arranged on the wall synthesis production line. The transferring assembly slides on the bracket, and the sliding stroke of the transferring assembly crosses over the operation platform and the conveying line body. The transferring assembly comprises a base, a gripping device bracket body and a gripping device, wherein the base is slidably arranged on a cross beam of the bracket, the gripping device bracket body is perpendicularly arranged on the base, and the gripping device is arranged on the gripping device bracket body. The gripping device bracket body is slidably arranged on the base. According to the wall synthesis production line and the overline transferring device thereof, the device is simple in structure and matched with production of the production line, and meanwhile the process that an assembled wall is conveyed to the designated conveying line body in an overline mode is achieved; and accordingly, overline operation in the production process is achieved, operation is convenient, and thus the production efficiency is improved.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

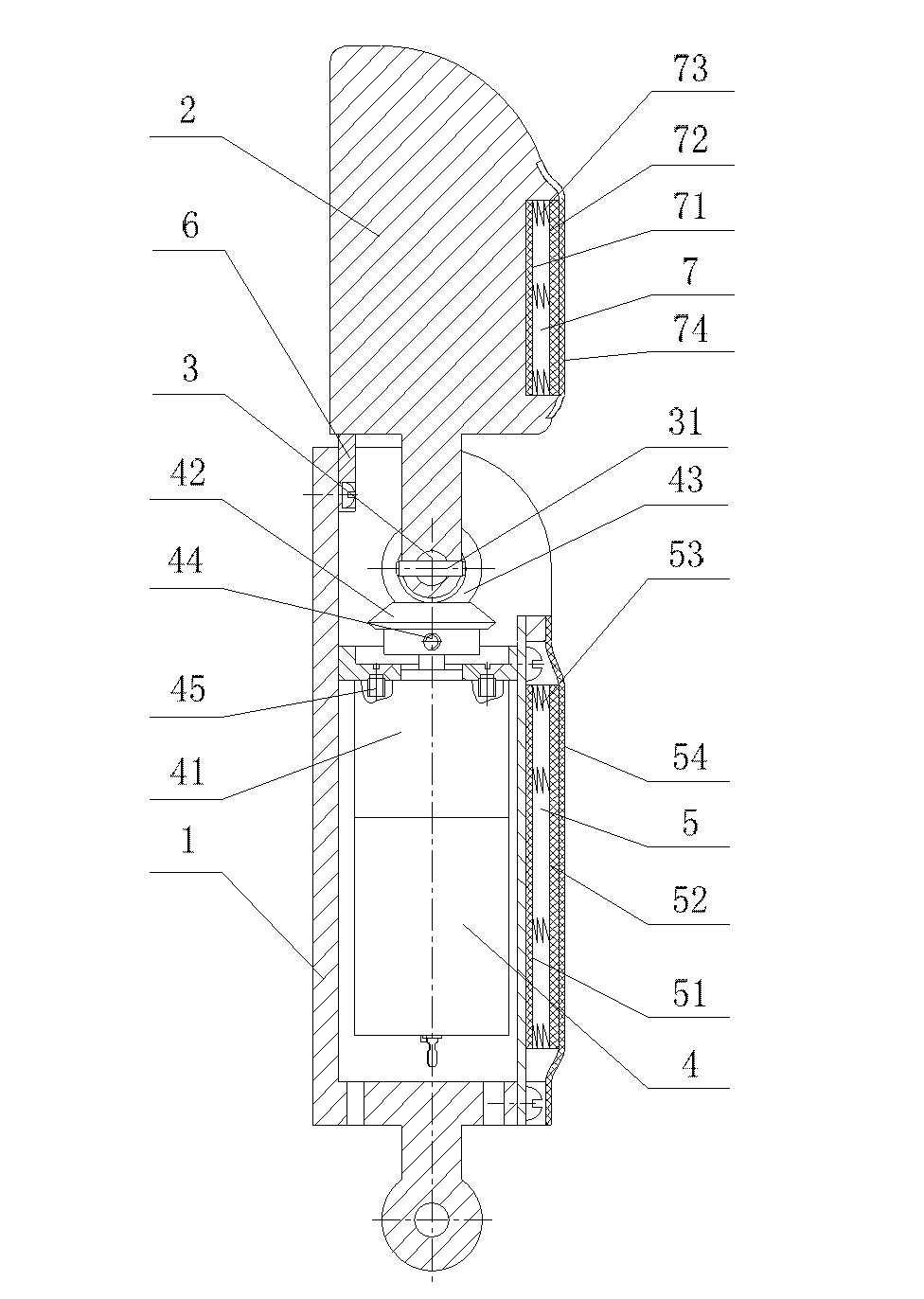

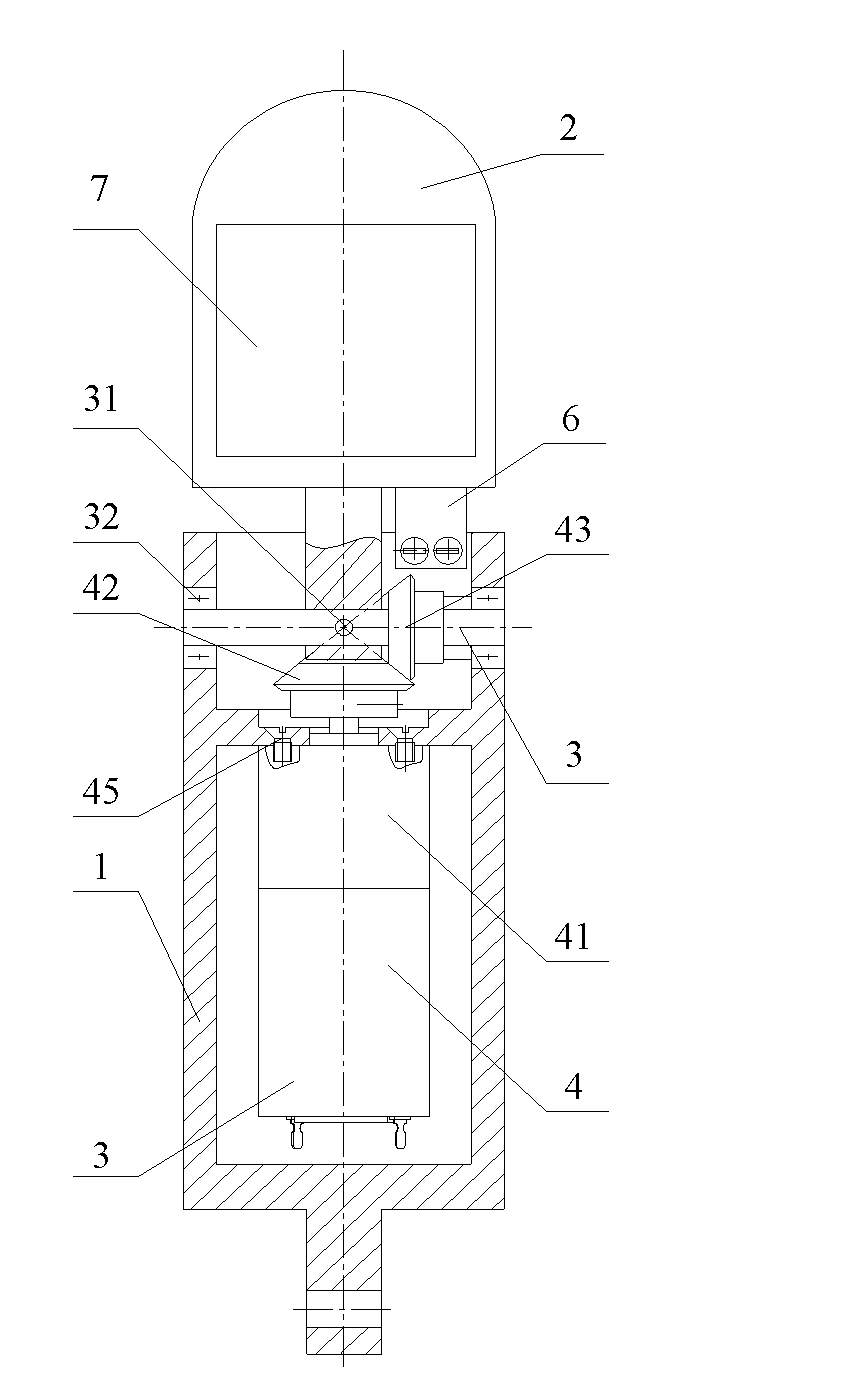

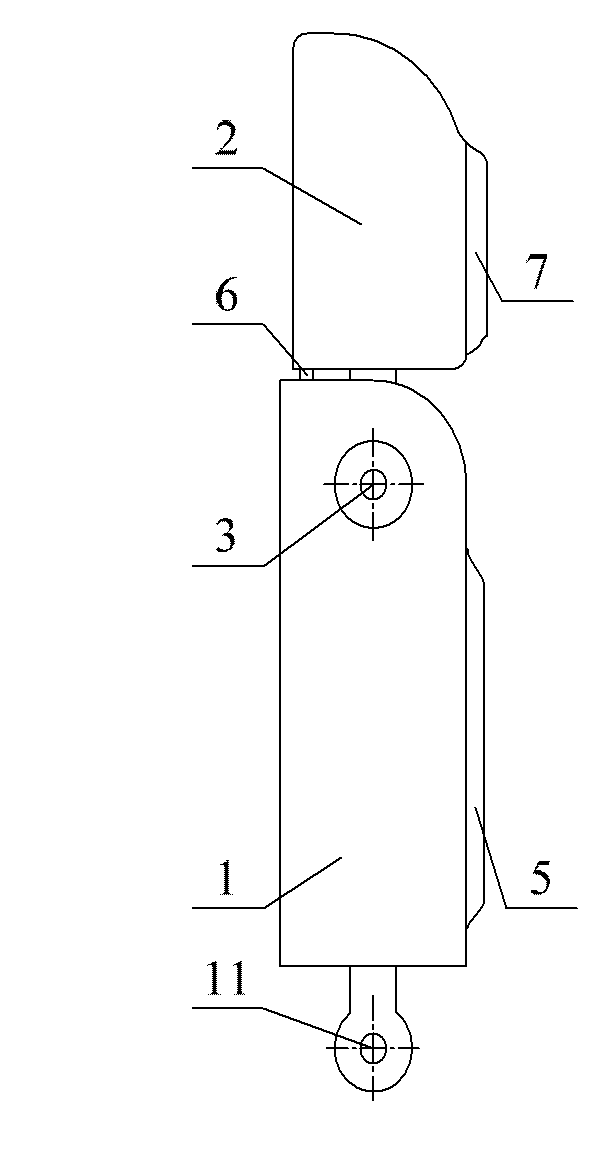

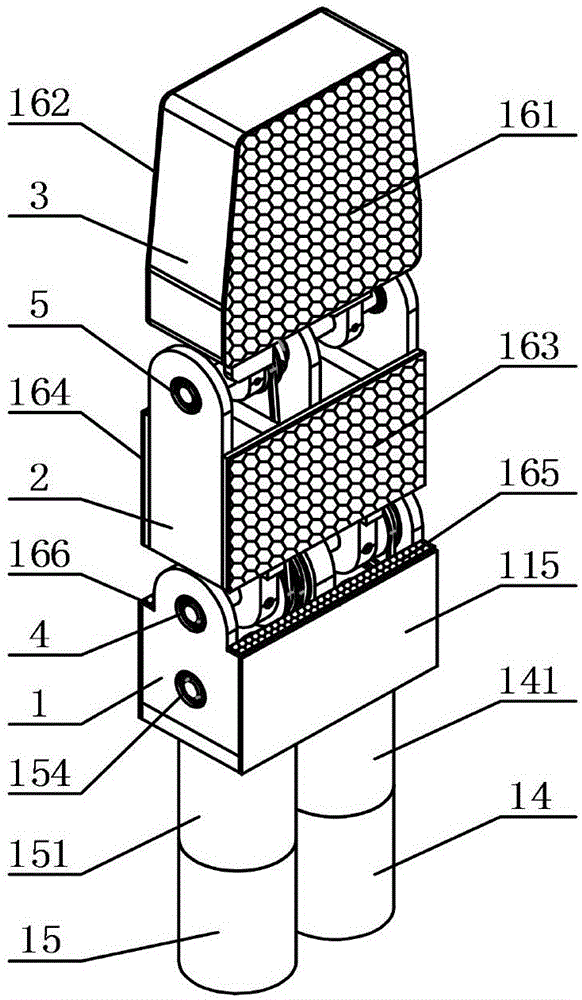

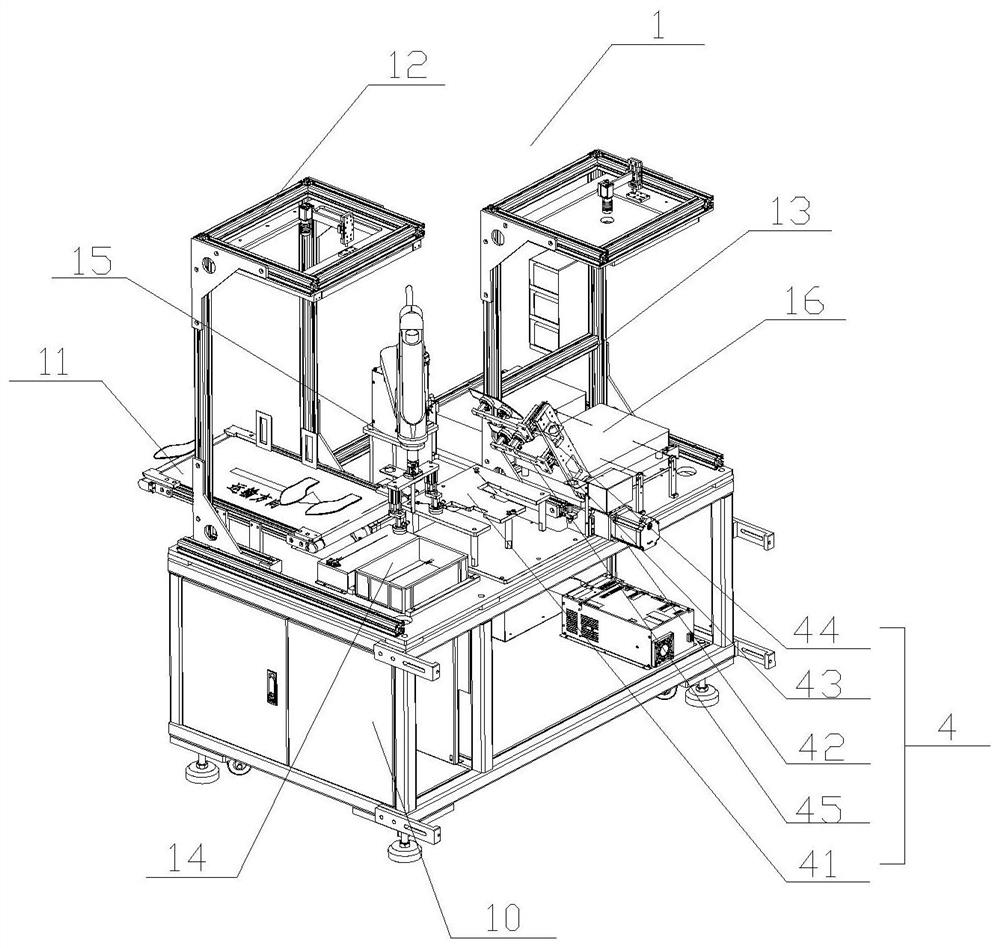

An underactuated flexible end effector for imitating bird claws of special-shaped melons and fruits

InactiveCN106625734BGuaranteed Adjustment CrawlGood grabbing effectGripping headsEngineeringRobot end effector

The invention relates to a bionic robot terminal actuator, in particular to a structural design of an under-actuated flexible terminal actuator simulating bird jaws, and is generally applied to the field of agricultural product picking robots and intelligent sorting and packing. The terminal actuator consists of a grabbing module, a sucking module, a power module and a fixed connecting module. When the terminal actuator performs a special-shaped melon and fruit grabbing task, the sucking module and the grabbing module are cooperated to finish the grabbing task. The terminal actuator has bionic characteristics, can realize flexible grabbing of the special-shaped melons and fruits, reduces damage of the melons and the fruits in the working process, and has the advantages of fast response speed and high working efficiency.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Simple robot

InactiveCN103406894AReasonable structural designIncrease productivityProgramme-controlled manipulatorEngineeringManipulator

The invention relates to a simple robot which is designed at the aim of solving the technical problems of similar products, such as inconvenience in goods carrying, and bad design of height regulation and good capturing. Base boards of the robot is provided with traveling wheels and peripheral sensors, wherein the traveling wheels are respectively provided with traveling wheel electric motors; the traveling wheel electric motors and the peripheral sensors are connected with a control box via a line; and the control box comprises a control circuit board and a storage battery; the simple robot is characterized in that a support frame is arranged on the base boards; the two ends of the support frame are respectively hinged to the base boards and the bottom surface of a top board; a manipulator is arranged on the table surface of the top board; a height sensor and a distance sensor are arranged on the manipulator; a supporting board lifting device is arranged on the support frame, and the supporting board lifting device drives the support frame to rise and fall, so as to achieve lifting and lowering. The simple robot has reasonable structural design, facilitates the improvement of the production efficiency, lowers manual labor, is convenient to use, capture and regulate the height, and is good in capture effect; in addition, the simple robot is suitable for goods carrying of workshops and factories and structure improvement of similar products.

Owner:吴亚平

Flexible mechanical claw and mechanical arm comprising same

ActiveCN112109109AGood grabbing effectAvoid breakingProgramme-controlled manipulatorJointsMechanical engineeringPhysics

The invention discloses a flexible mechanical claw and a mechanical arm comprising the same. The mechanical claw comprises a palm and two or more fingers pinned to the palm, wherein each finger comprises an inner claw and an outer claw; each inner claw comprises integrally formed base plate and cross beams; two or more cross beams are located on the outer side surface of each base plate, and the tops of the cross beams and the end B of the base plate are separately provided with pin joints for being connected with the corresponding outer claw; each outer claw is a cambered surface plate whichis composed of two or more connecting plates and is bent to a set radian; and each connecting plate is separately pinned between two adjacent cross beams or between the end B of the corresponding baseplate and the adjacent cross beam of the base plate. The inner claws and the outer claws of the mechanical claw are made of flexible materials with different hardness, and the mechanical structure design of the inner claws and the outer claws is combined, so that the mechanical claw can well wrap a target object, and meanwhile, the mechanical claw has a very strong grabbing characteristic.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

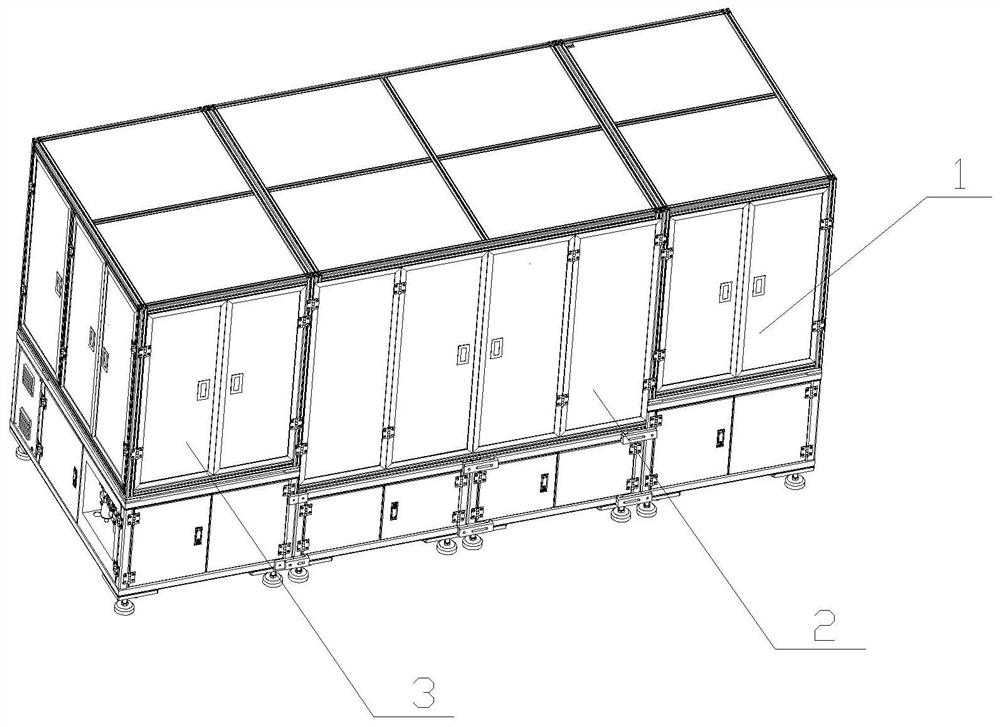

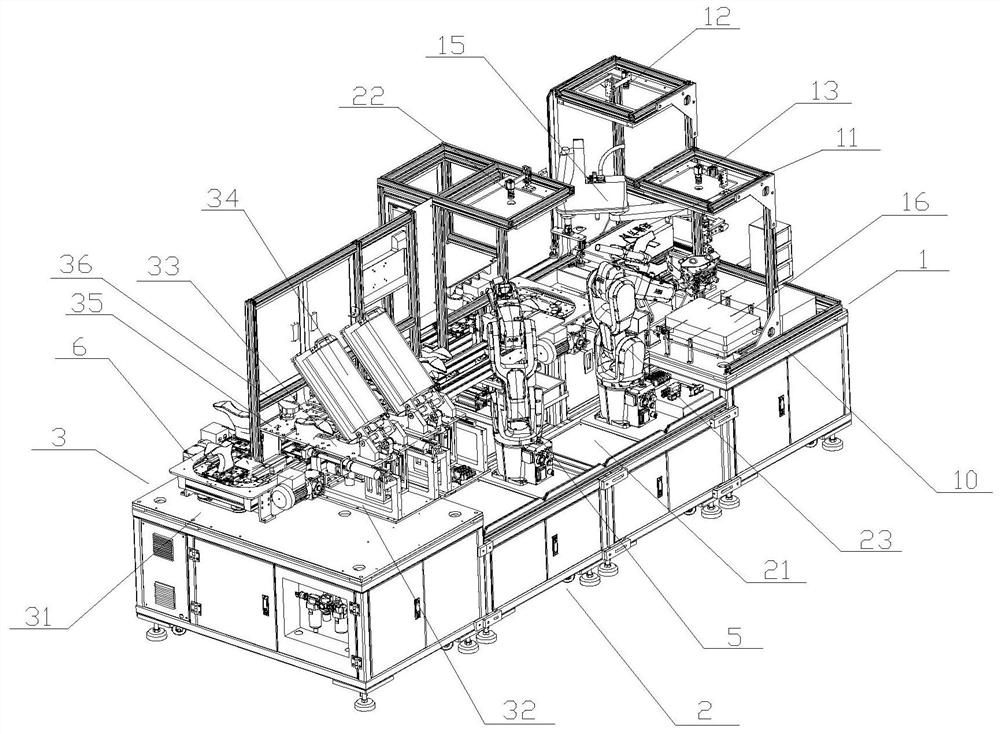

Novel intelligent sole pasting production line

ActiveCN113287838AAutomatically control the locking stateGood grabbing effectShoe gluingVisual recognitionTransfer mechanism

The invention discloses a novel intelligent sole pasting production line. The novel intelligent sole pasting production line comprises a sole transmission positioning module, a sole pasting module and a pressure maintaining module which are arranged in sequence, the sole positioning module comprises a conveying unit, a transferring mechanism, an overturning mechanism and a visual recognition mechanism, the conveying unit conveys a sole to a first position, and the transferring mechanism can transfer the sole to the overturning mechanism; the overturning mechanism is used for overturning the shoe sole and placing the shoe sole on the platform; the sole pasting module comprises a sole taking and placing mechanism, a shoe tree conveying mechanism and a rolling mechanism, the shoe tree conveying mechanism comprises a shoe tree conveying line, and a shoe tree carrying disc used for placing shoe trees is placed on the shoe tree conveying line; the shoe sole taking and placing mechanism takes a shoe sole on the platform and attaches the shoe sole to a shoe tree, the rolling mechanism rolls the shoe sole, the shoe tree conveying line conveys the shoe tree subjected to shoe sole attaching to the pressure maintaining module, and the pressure maintaining module maintains the pressure of the attaching portion of the shoe tree and the shoe sole. The novel intelligent sole pasting production line has the advantages of full-automatic sole pasting, suitability for sole pasting processing of various types of soles, accurate sole grabbing and pasting and the like.

Owner:知守科技(杭州)有限公司

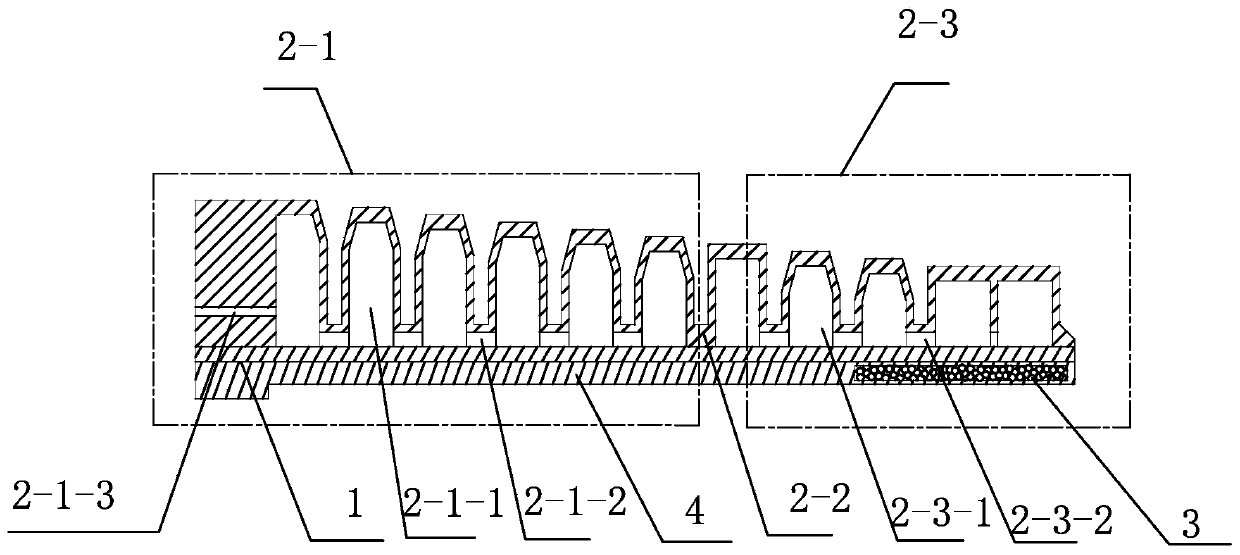

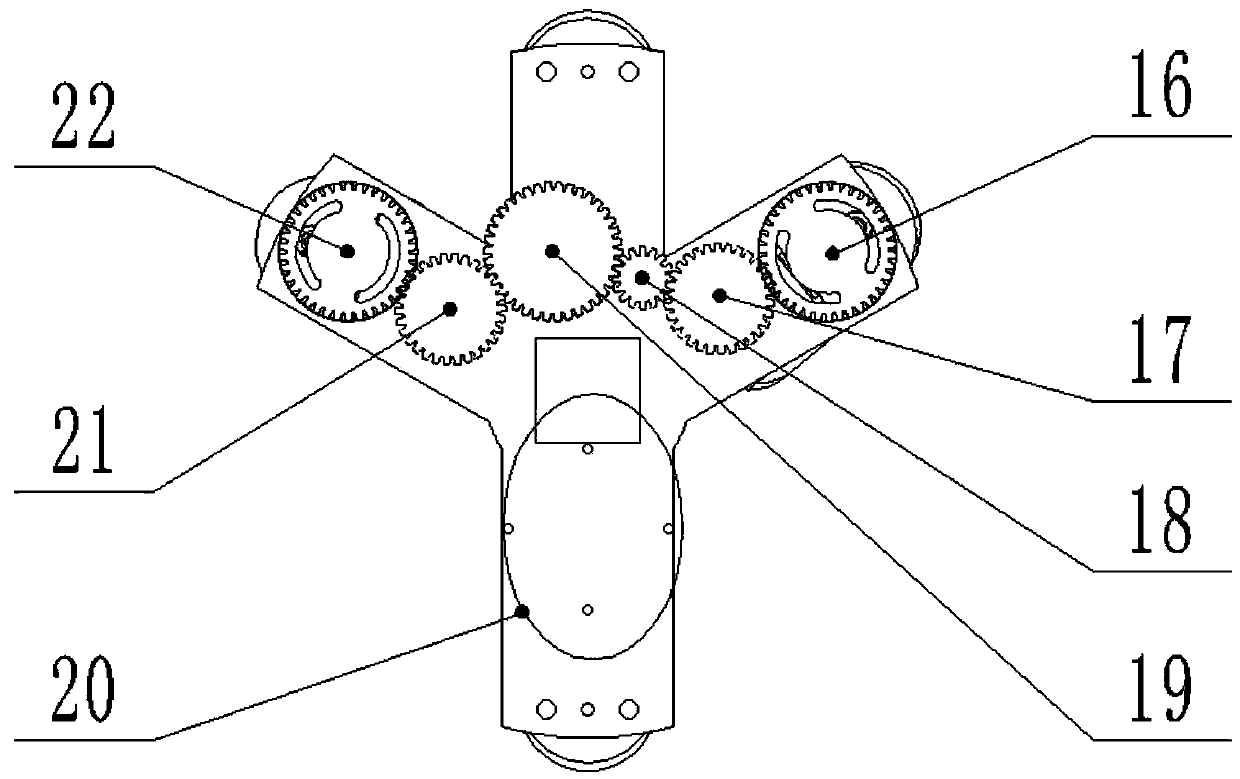

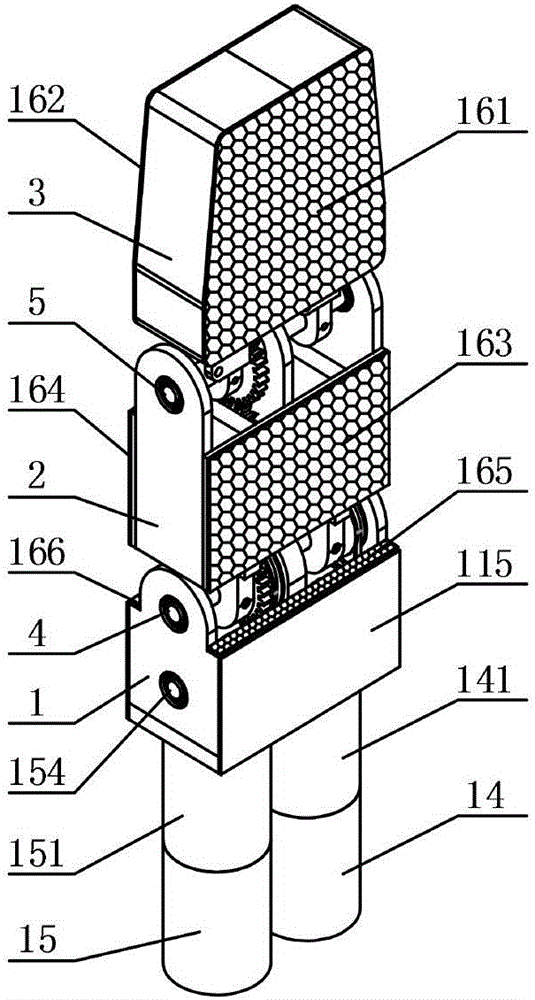

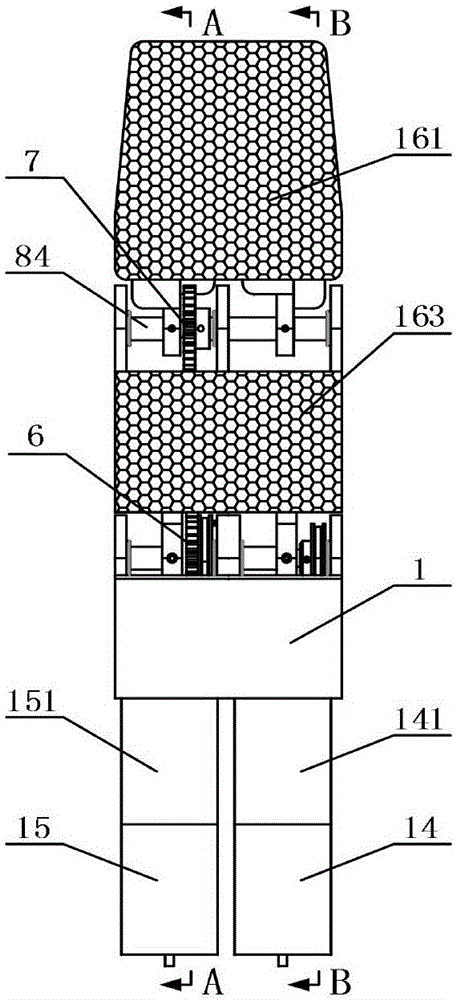

Gear-driven bidirectional parallel clamping perceiving self-adaptive robot finger device and control method

InactiveCN106737776AImplement bi-directional crawlingGood grabbing effectProgramme-controlled manipulatorJointsRobot handMotor drive

The invention discloses a gear-driven bidirectional parallel clamping perceiving self-adaptive robot finger device and a control method. The device comprises a base, two finger segments, two joint shafts, a driver, multiple gears, sensors, a control module, a motor driving module and the like. Four grasping modes including a forward parallel clamping and grasping mode, a forward parallel clamping and self-adaptive grasping mode, a reverse parallel clamping and grasping mode and a reverse parallel clamping and self-adaptive grasping mode are achieved. According to the device, not only can a unidirectional self-adaptive grasping effect of a traditional perceiving self-adaptive finger be achieved, but also a bidirectional self-adaptive grasping effect and a bidirectional parallel clamping and grasping effect which can not be achieved through the traditional perceiving self-adaptive finger are achieved; the grasping range is wide, the grasping process is stable, the grasping force is controllable, a driving chain is short, programming does not need to be conducted again when different objects are grasped, and use is easy and convenient; high flexibility, high self-adaptivity, high reliability, high stability and low control difficulty can be achieved, and the device is suitable for a robot hand.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

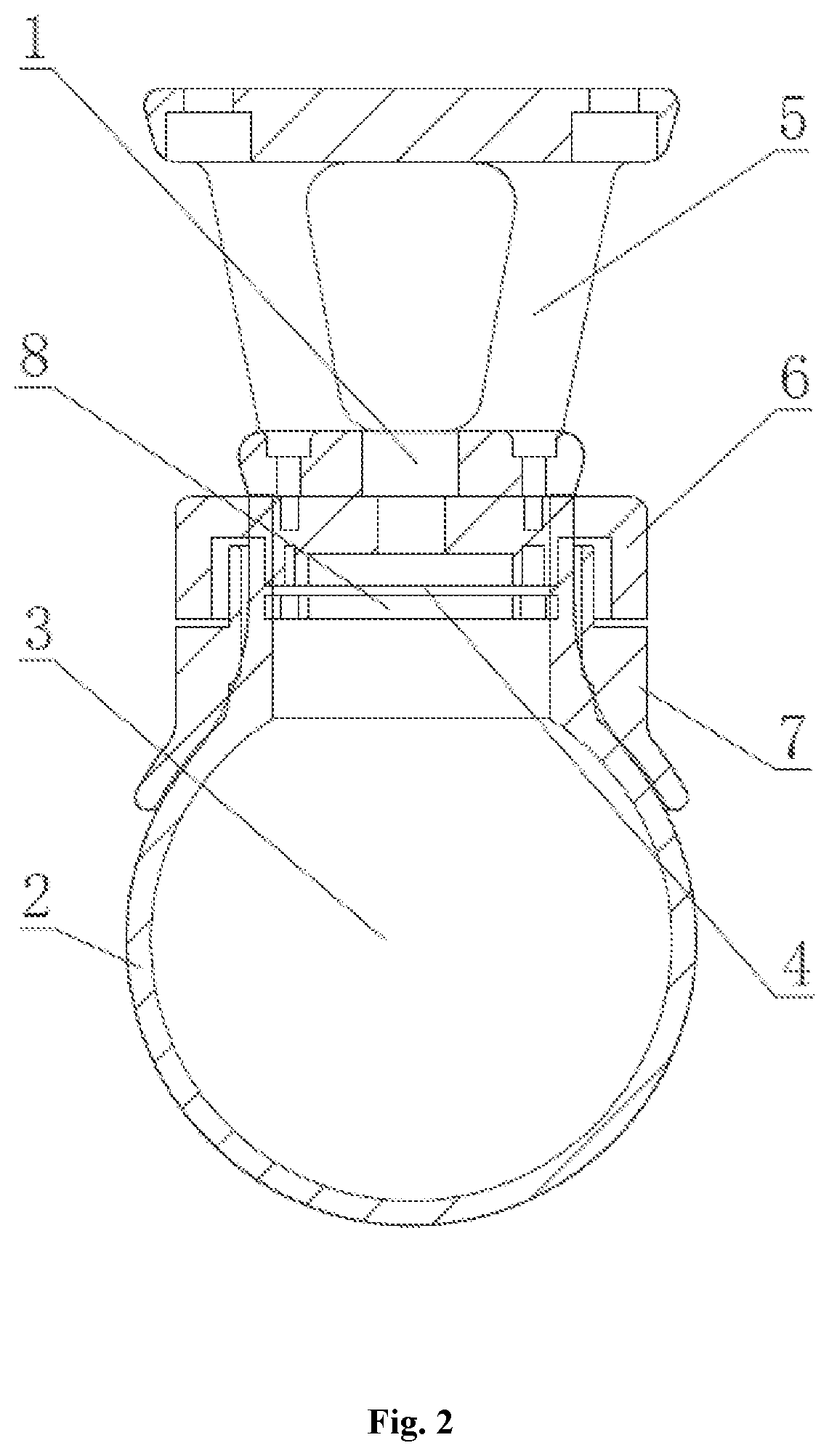

Grabbing Device

ActiveUS20210252719A1Improve gripGood grabbing effectGripping headsEngineeringMechanical engineering

A grabbing device, comprising a connection base, a gas pipeline provided in the connection base, a grabbing member having a hollow cavity and connected to the connection base, a filter layer provided between the hollow cavity and the gas pipeline, and particles filled in the hollow cavity. The gas pipeline is in communication with the hollow cavity by the filter layer for preventing the particles from entering the gas pipeline. The grabbing member is made of a flexible material, permitting the grabbing member to bulge when being inflated, and being recessed according to a shape of a surface of the object after the grabbing member contacts the object. The particles maintain the flexible state when the grabbing member is inflated, and the particles are pressed to the rigid state when withdrawing gas to deflate the grabbing member into a recessed position. The grabbing device can maintain a grip on objects having an irregular shape.

Owner:SUZHOU DITIAN ROBOT & AUTOMATION CO LTD

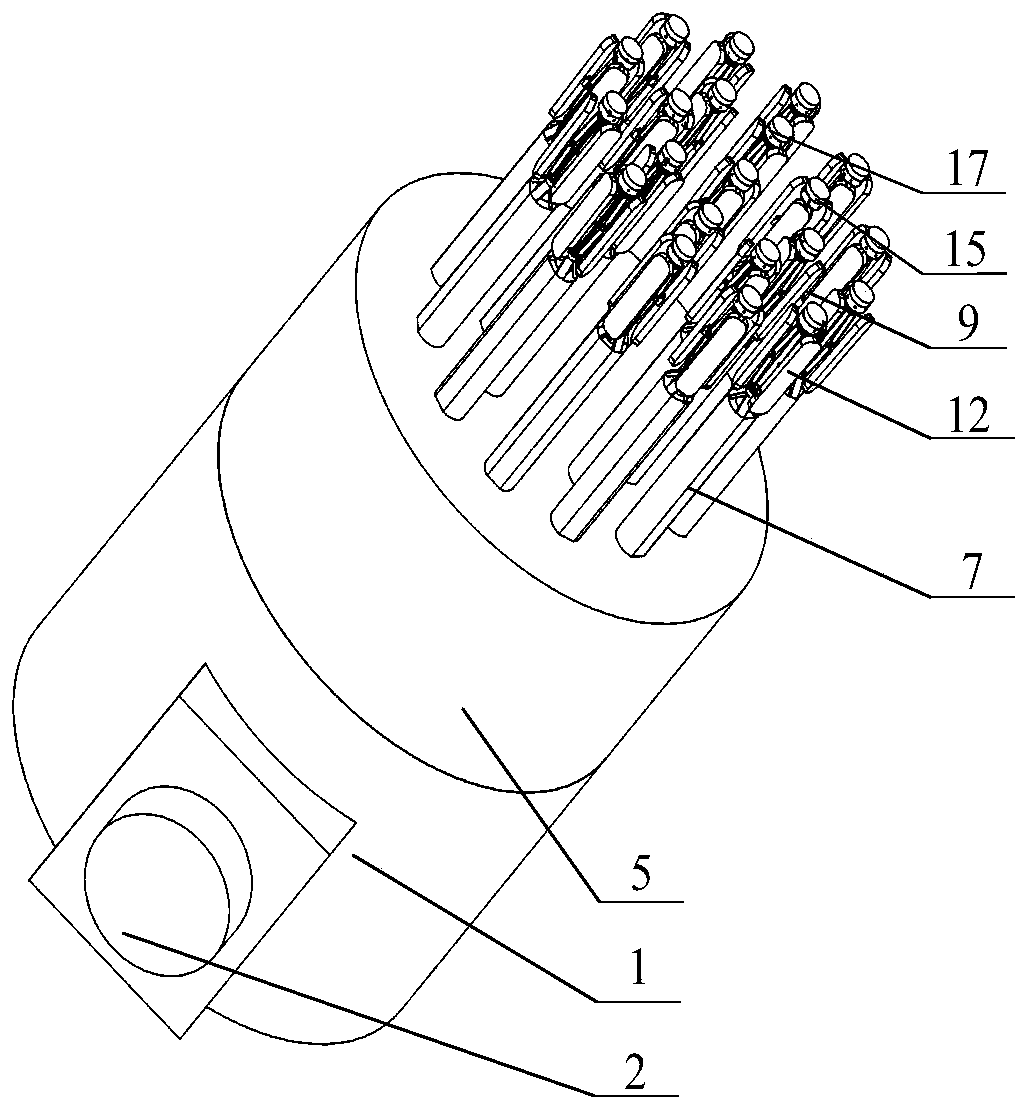

Tendon rope driven expansion grabbing sliding rod self-adaptive robot hand device

PendingCN111331587AImplement adaptive functionsEffective gripProgramme-controlled manipulatorGripping headsRobot handElectric machinery

The invention discloses a tendon rope driven expansion grabbing sliding rod self-adaptive robot hand device, and belongs to the technical field of robot hands. The tendon rope driven expansion grabbing sliding rod self-adaptive robot hand device comprises a base, a motor, a middle plate, a sliding groove plate, a transmission mechanism, tendon ropes, spring parts, sliding pushing rods, upper sliding rings, lower sliding rings, sliding parts, upper connecting rods, lower connecting rods, connecting elements, clamping plates, knuckle ends, elastic elements and connecting pins. The device is usedfor allowing a robot to grab an object, and a self-adaptive grabbing function is achieved. When the device makes contact with the object, the self-adaptive effect on the size and the shape of the object is achieved through the multiple sliding pushing rods; and then the motor works and draws the tendon ropes to be contracted, the clamping plates arranged at the lower ends of the sliding pushing rods expand and incline through shortening of the tendon ropes, the expanded clamping plates adapt to the side faces of the clamped object, object sliding can be prevented through inclination of the clamping plates, shape closed grabbing is generated, the multi-directional grabbing effect on the object is achieved, and stable grabbing on the object can be achieved. The device is good in reliability, low in energy consumption, long in service life and wide in application range.

Owner:TSINGHUA UNIV TIANJIN HIGH END EQUIP RES INST LUOYANG ADVANCED MFG IND RES & DEV BASE

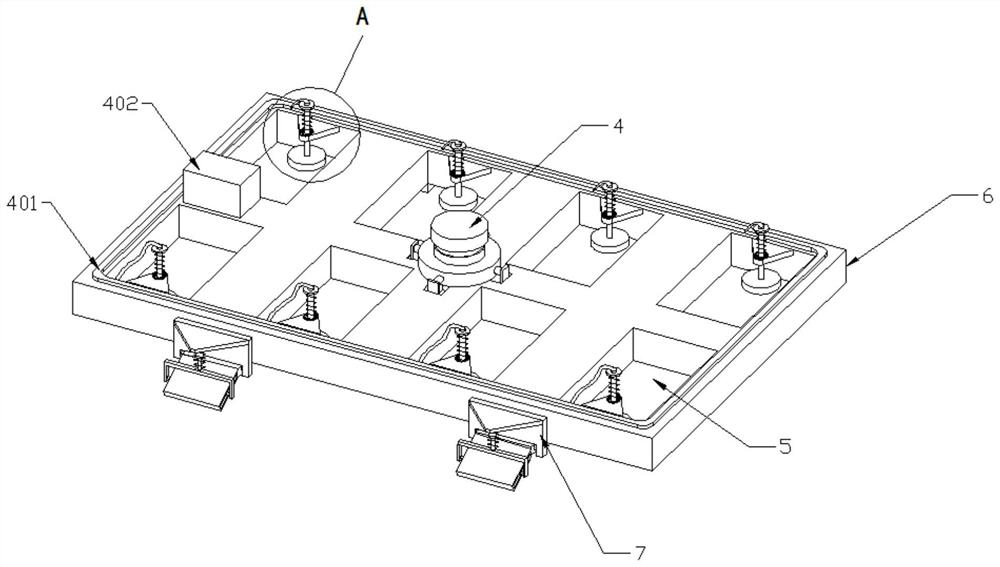

Grabbing device and grabbing method for glass multi-station manual splitting processing

ActiveCN113045192AReasonable structural designEasy loading and unloadingGlass severing apparatusGlass chipStructural engineering

The invention discloses a grabbing device for glass multi-station manual splitting processing. The grabbing device comprises a base, the top of the base is connected with a mechanical arm, the movable end of the mechanical arm is connected with an assembly table, the lower end of the assembly table is provided with a sectional material frame, a plurality of through grooves are formed in the sectional material frame, the plurality of sets of through grooves are distributed in a rectangular array shape, the top of the base is connected with a PLC, and the mechanical arm is electrically connected with the PLC. The grabbing device is reasonable in structural design, the glass grabbing angle can be conveniently adjusted during station transfer, the phenomenon that glass sheets accidentally fall off in the transfer process due to insufficient adsorption force can be prevented, a suction cup generates negative pressure adsorption on the glass sheets, and the good grabbing effect can be achieved; and the lower portion of a folded plate recovers to the vertical state after a sliding block moves upwards, and the glass sheets can be stably fed into a station, so that subsequent processing is facilitated.

Owner:芜湖镌诺自动化科技有限公司

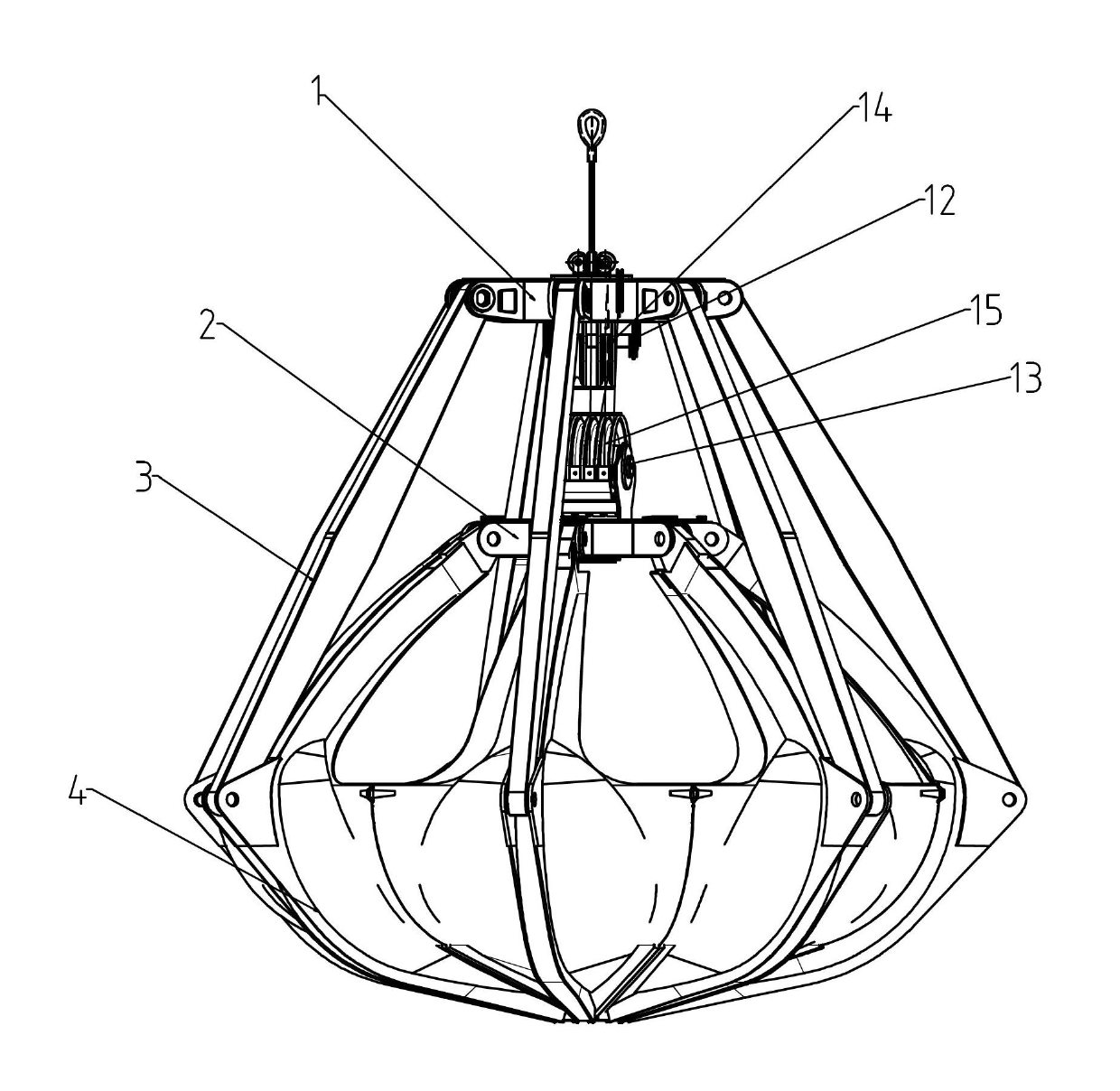

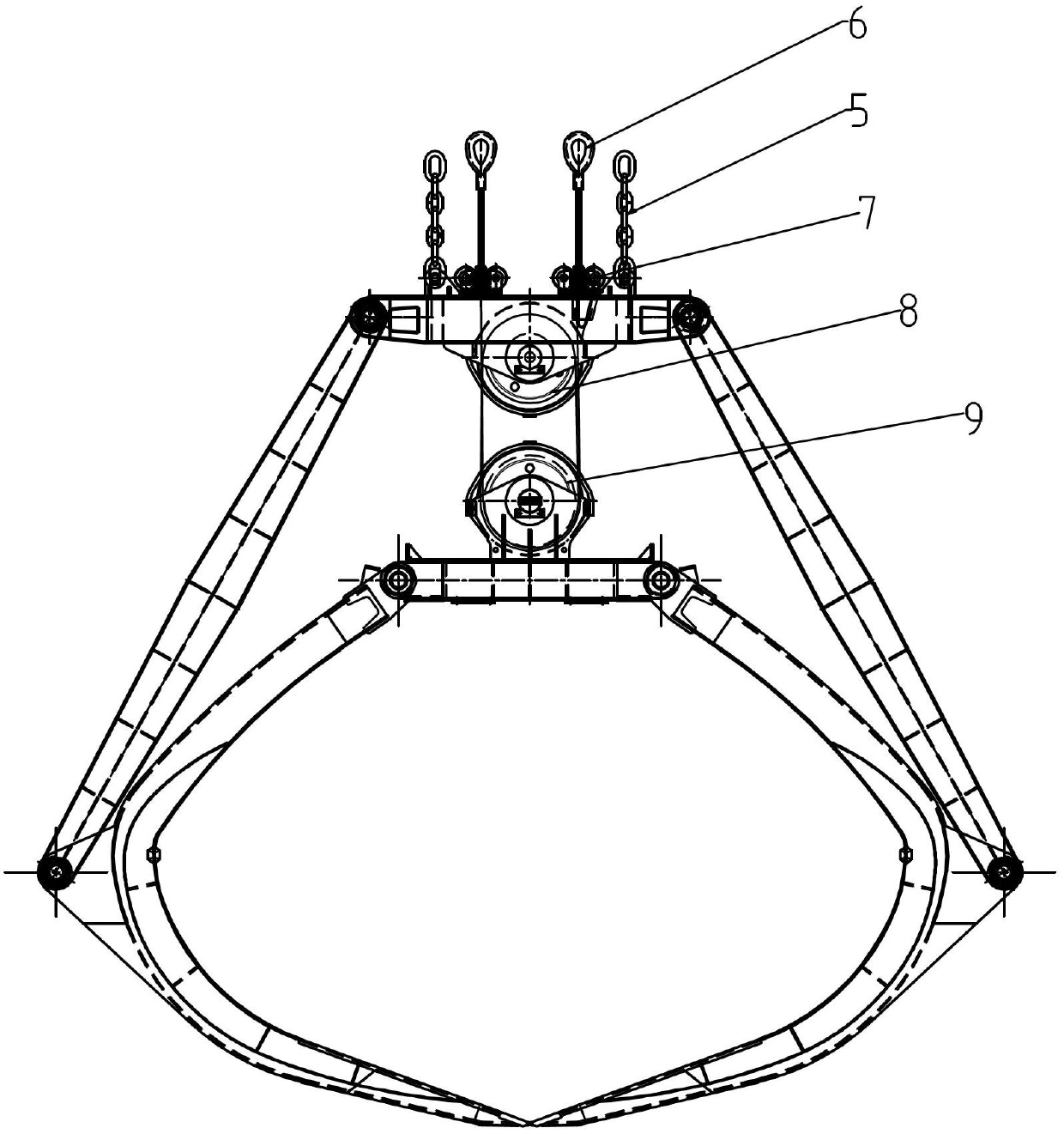

Universal mechanism for realizing triple or quadruple operation of grab bucket

ActiveCN102674150ASimple structureCompact structureLoad-engaging elementsBlock and tackleEngineering

The invention relates to a universal mechanism for realizing triple or quadruple operation of a grab bucket, which is particularly used for the triple or quadruple universal operation of the grab bucket and belongs to the technical field of crane equipment. The universal mechanism mainly comprises an upper support beam, a lower support beam, a support rod, a bucket body, an opening and closing rope, a guide wheel, an upper pulley block and a lower pulley block, wherein the upper support beam is hinged and connected with the upper end of the support rod, and the lower end of the support rod is hinged and connected with the side surface of the bucket body. The upper end of the bucket body is hinged and connected with the lower support beam. The universal mechanism has the advantages that the structure is simple, compact and reasonable, a better grabbing effect can be realized during the grabbing of different materials, the work efficiency of the grab bucket can also be improved, meanwhile, the triple or quadruple operation requirements can be met, the operation is convenient, and the cost of equipment is reduced.

Owner:无锡市新华起重工具有限公司

Billiard ball gripping device

The invention belongs to a billiard ball putting device, and particularly relates to a billiard ball gripping device for an automatic billiard ball machine. A polygonal inner frame body used for setting a billiard ball is arranged in an outer frame body, a back plate and the outer frame body are fixed, a plurality of thimble grooves are arranged on the outer frame body, the quantity of the thimble grooves is the same as that of sides of the inner frame body, a thimble base is arranged in each thimble groove, a plurality of thimbles used for billiard balls are arranged on the thimble base, holes are formed in the inner frame body, the thimbles can extend into the inner frame body, and the inner frame body can have two forms of a triangle and a diamond. The thimbles of different arrangement forms and sizes are designed for billiard balls with different putting methods and sizes, the whole set of billiard balls put in a plane can be stably gripped and fixed together with a good gripping effect, thus the billiard ball gripping device is simple to operate, can be widely applicable to various automatic billiard ball machines, and can also be manually operated so that the ball putting efficiency is increased.

Owner:BEIJING JIAOTONG UNIV

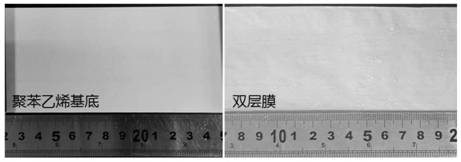

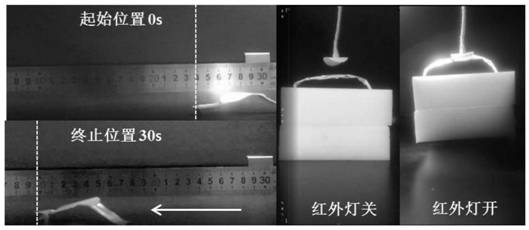

Double-layer film actuator and preparation method thereof

PendingCN112520685AIncrease humidityImprove stabilityDecorative surface effectsSolid-state devicesPhysicsThin membrane

The invention discloses a double-layer film actuator and a preparation method thereof, and belongs to the field of functional materials and soft robots. A layer of regularly arranged metal hydroxide directionally grows on a polymer film substrate through a solid-state alkali self-sacrificing method to form a double-layer structure comprising a polymer film and transition metal hydroxide. The preparation method is simple and low in cost, and large-scale preparation can be realized. Rapid, remarkable and stable deformation capacity is achieved under the conditions of humidity change, heating, infrared light and the like by means of the difference of humidity response of the double-layer thin film, and moving and object grabbing can be achieved through deformation control. Therefore, the method has important application value in the fields of flexible switches, artificial muscles, soft robots, environmental monitoring and the like.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com