Flexible mechanical claw and mechanical arm comprising same

A mechanical claw and flexible technology, applied in the field of intelligent robots, can solve problems such as joint joints with large load capacity, and achieve the effects of enhancing grasping stability, preventing finger eversion, and high spatial flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

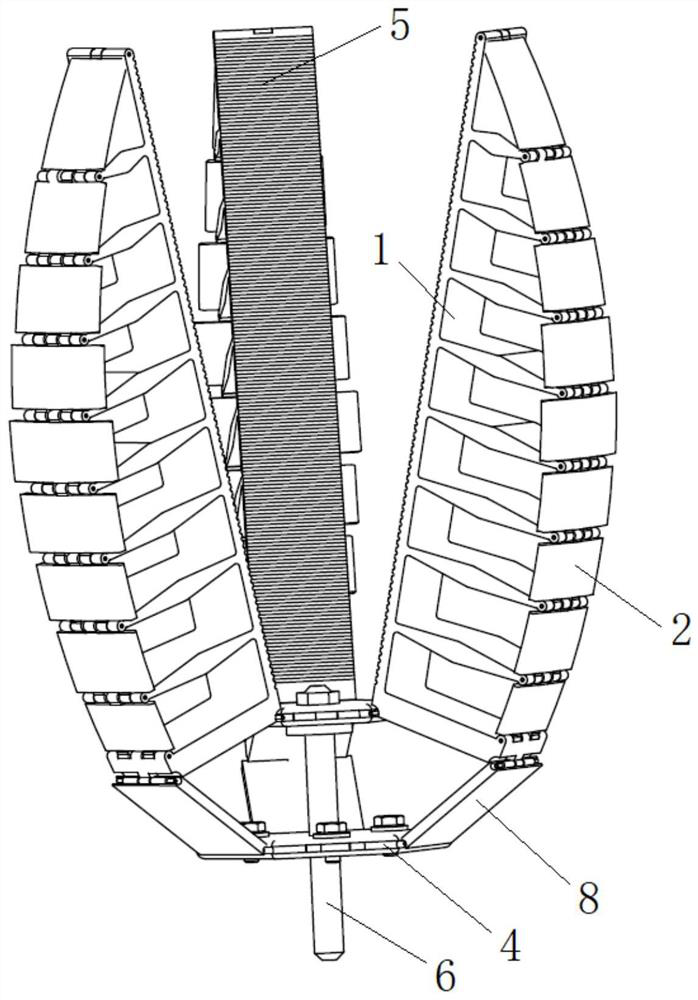

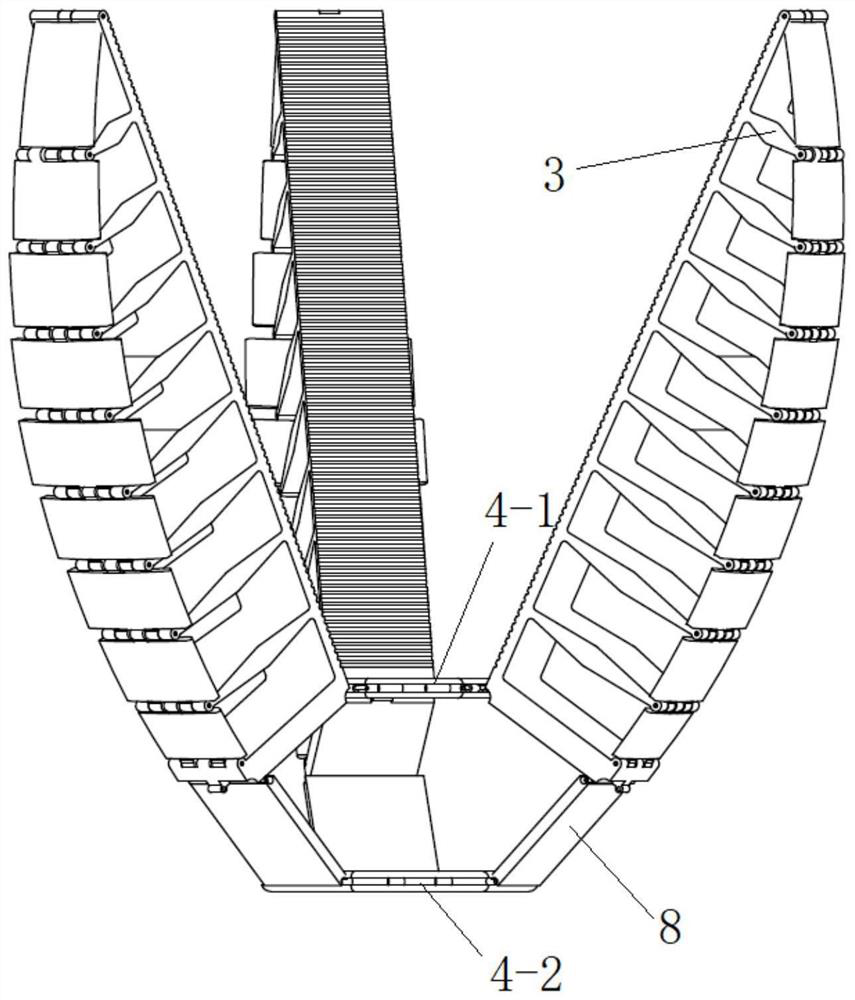

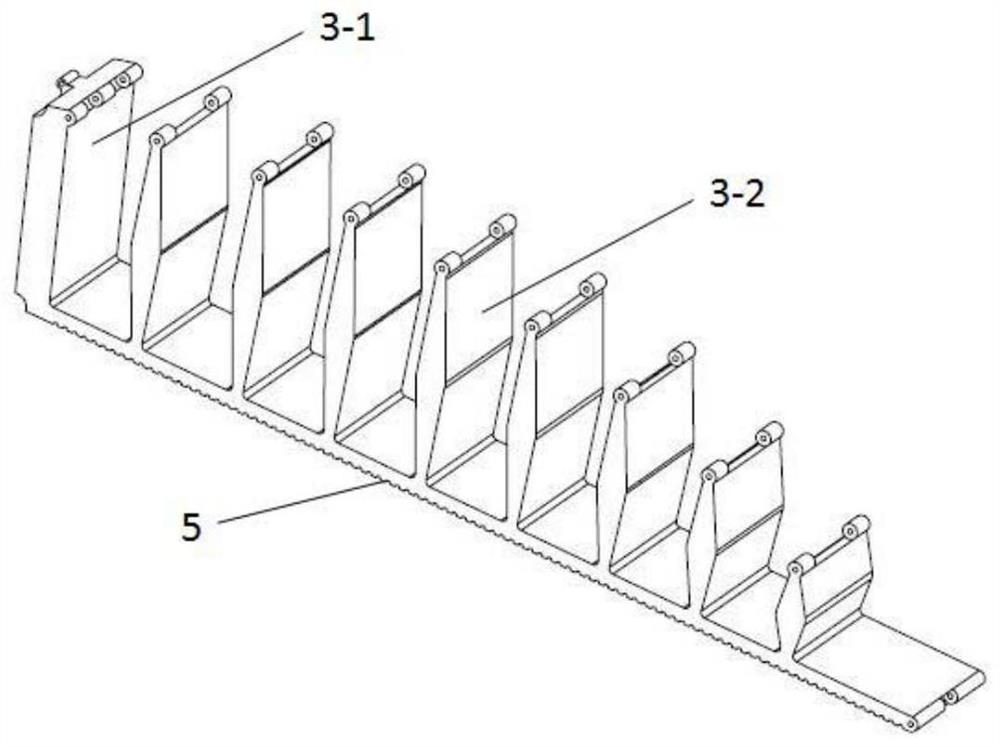

[0045] This embodiment provides a kind of flexible mechanical claw, refer to the attached Figure 1-2 , including: palm 4 and two or more fingers pinned to palm 4;

[0046] The palm 4 includes: a first plate 4-1, a second plate 4-2, a drive shaft 6 and a drive mechanism;

[0047] The first plate 4-1 and the second plate 4-2 are regular hexagonal plates, and the side length of the first plate 4-1 is smaller than the second plate 4-2, the first plate 4-1 and the second plate The materials of 4-2 are all made of metal materials;

[0048]The first plate 4-1 and the second plate 4-2 are arranged in parallel, and the six sides of the first plate 4-1 and the second plate 4-2 are parallel to each other; the drive shaft 6 passes through the Through the center of the first plate 4-1 and the second plate 4-2, and one end of the drive shaft 6 is fixedly connected with the first plate 4-1, and the other end of the drive shaft 6 is connected with the drive mechanism; when the drive mechan...

Embodiment 2

[0062] This embodiment provides a kind of flexible manipulator, refer to the attached Figure 5-7 , comprising: the mechanical claw and the arm body of Embodiment 1;

[0063] The arm body includes: wrist joint 9, forearm 10, upper arm 11, elbow joint 12 and shoulder joint 13;

[0064] The mechanical claw is installed on the front end of the forearm 10 through the wrist joint 9, the rear end of the forearm 10 is connected with the front end of the big arm 11 through the elbow joint 12, and the rear end of the big arm 11 is installed on the outside through the shoulder joint 13. On the supporting part; wherein, a supporting plate is fixed on the second plate 4-2 of the mechanical claw, and the supporting plate is installed on the wrist joint 9;

[0065] The wrist joint 9 has three degrees of freedom of rotation;

[0066] Both the elbow joint 12 and the shoulder joint 13 adopt double-slope bionic joints, which have two degrees of freedom of rotation;

[0067] Both the small ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com