Charging and riveting mechanism for end caps of four-way pipe

A riveting mechanism and pipe end technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low efficiency of riveting four-way valve, insufficient position accuracy of capillary socket, etc., to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

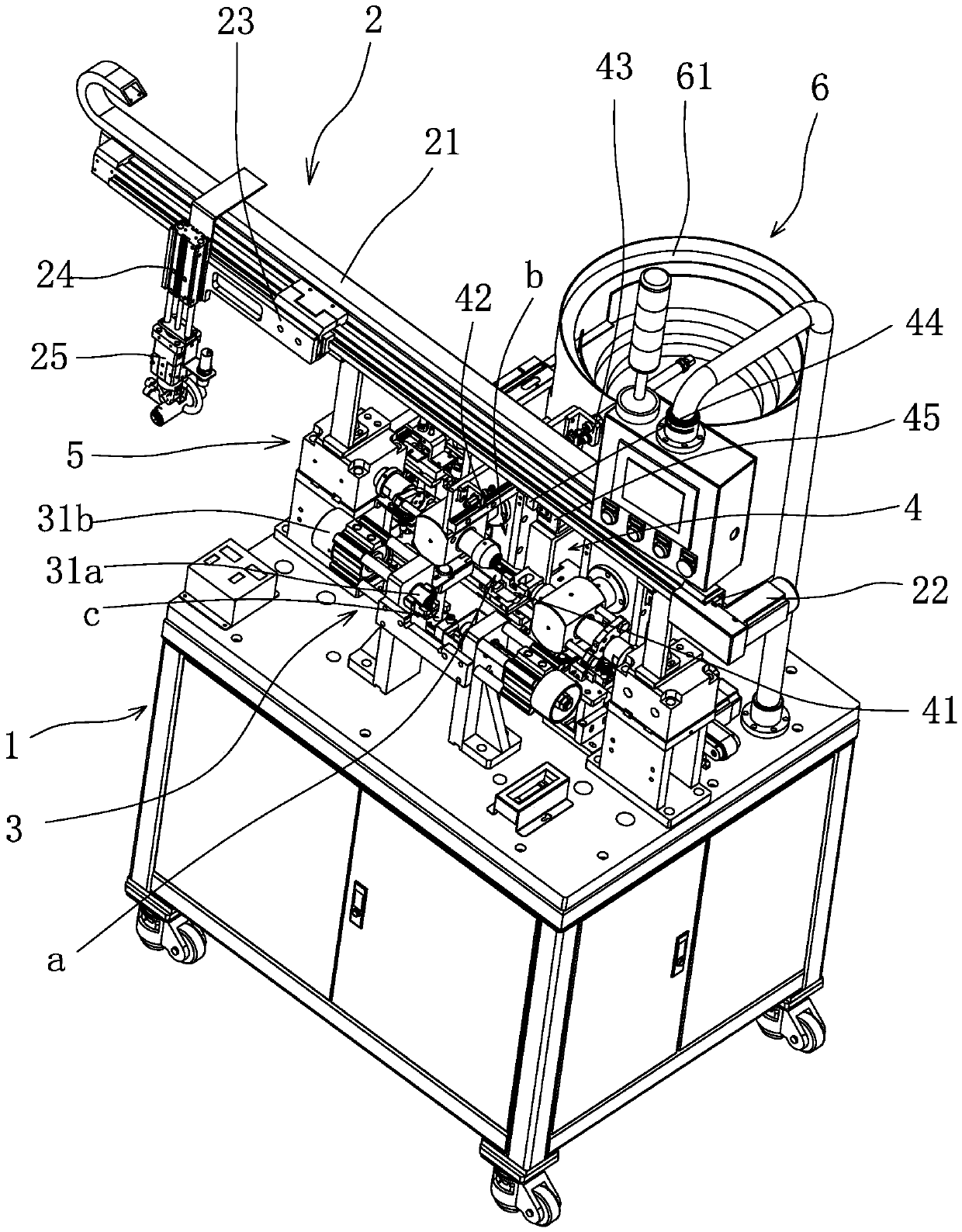

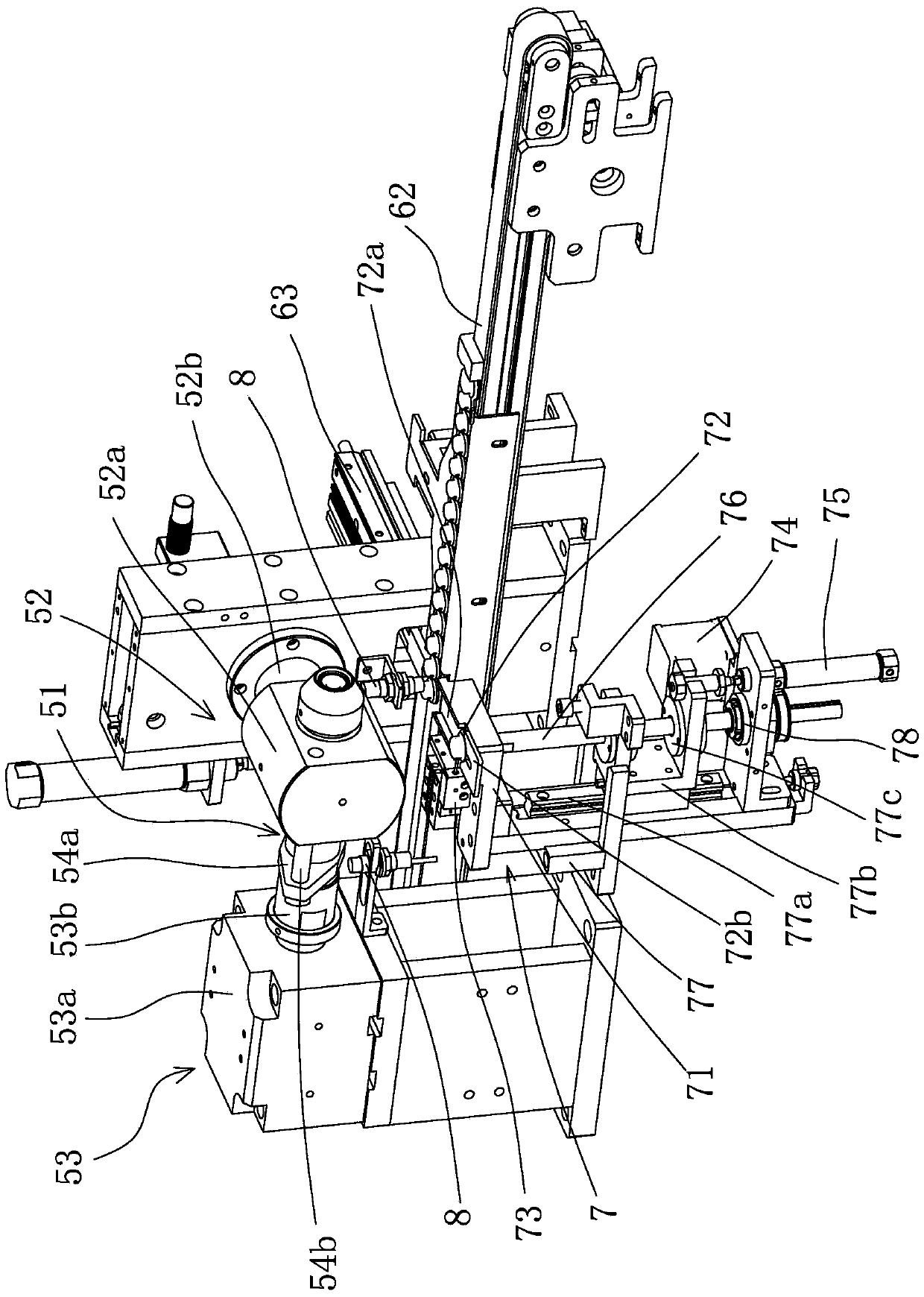

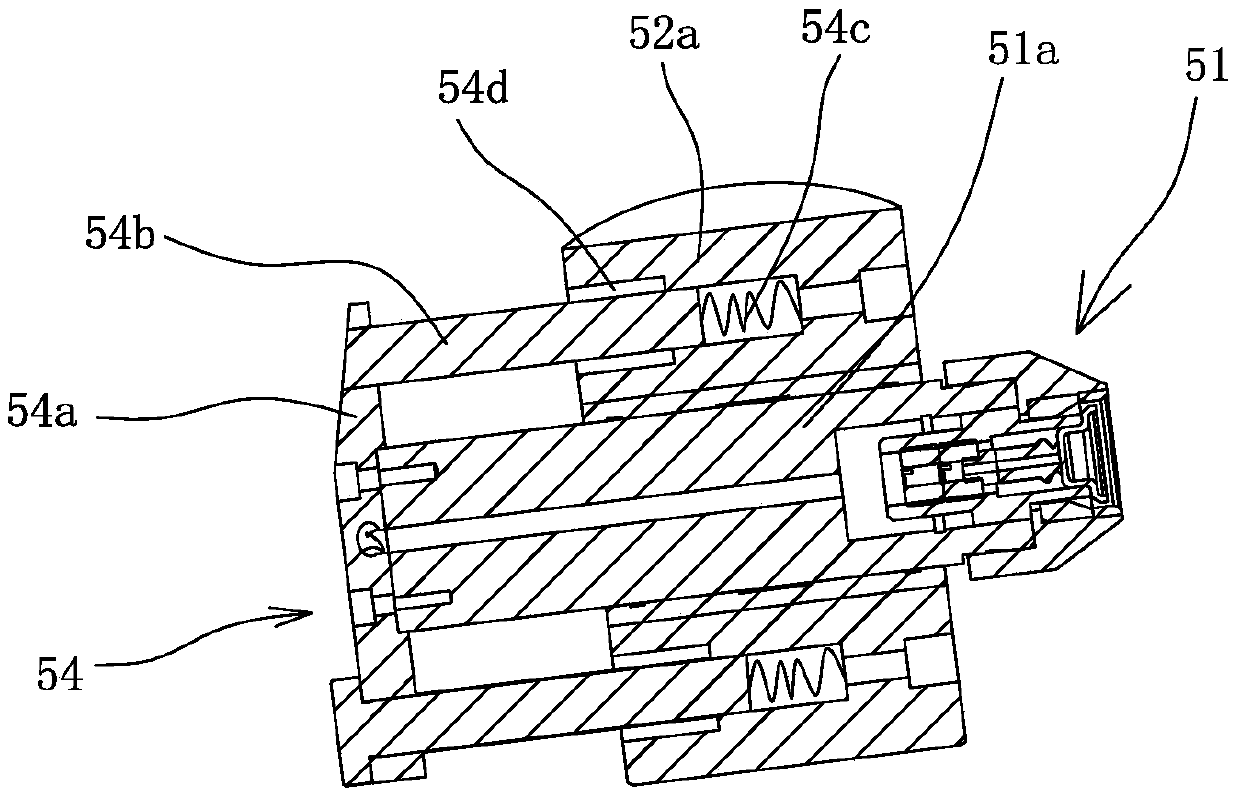

[0022] like figure 1 , figure 2 , image 3 , Figure 4 As shown, this scheme includes a machine base 1, and the machine base 1 is provided with a first feeding mechanism 2 for conveying a four-way pipe, and the first feeding mechanism 2 transports the four-way pipe to the shaping mechanism 3 for port shaping. After shaping The four-way pipe is transported to the riveting station a through the material holding mechanism 4, and the riveting station a is provided with a feeding riveting mechanism 5, and the feeding riveting mechanism 5 can absorb the second feeding mechanism 6 and transport it to the end cover of the feeding station The end cap is riveted to the cross pipe, and a detection device 7 capable of adjusting the placement angle of the end cap is provided on the feeding station.

[0023] Specifically, the detection device 7 includes a detection platform 71 on which a detection base 72 for placing the end caps is provided, and a sensor 73 for judging whether the plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com