Novel high-precision riveting mechanical device

A mechanical device and high-precision technology, applied in the field of new high-precision riveting mechanical devices, can solve the problems of inconsistent deformation, uneven deformation, and high labor intensity of personnel, and achieve high riveting accuracy, long practical life, and high riveting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

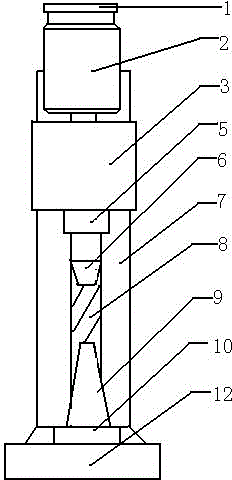

[0015] This embodiment provides a new high-precision riveting mechanical device, which is characterized in that: the new high-precision riveting mechanical device includes a piston rod (1), a hydraulic cylinder (2), a gearbox (3), a slider (4) ), output shaft (5), spin riveting upper mold (6), column (7), slideway (8), spin riveting lower mold (9), base (10), adjustment block (11), workbench (12) );

[0016] Among them: the top of the device is equipped with a drive hydraulic cylinder (2), the upper end of the hydraulic cylinder (2) is a telescopic piston rod (1), the hydraulic cylinder (2) is equipped with a gearbox (3), and the gearbox (3) can pass through the slider (4) Sliding on the column (7) with the slideway (8), the output shaft (5) is installed under the gearbox (3), and the column (7) is fixedly welded to the workbench (12), and the work The platform (12) is provided with a trapezoidal groove covering the adjusting block (11) below the base (10), the lower riveting di...

Embodiment 2

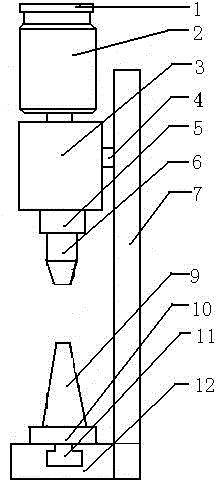

[0020] A new high-precision riveting mechanical device, characterized in that: the new high-precision riveting mechanical device includes a piston rod (1), a hydraulic cylinder (2), a gearbox (3), a slider (4), and an output shaft ( 5), spin riveting upper mold (6), column (7), slideway (8), spin riveting lower mold (9), base (10), adjustment block (11), worktable (12);

[0021] Among them: the top of the device is equipped with a drive hydraulic cylinder (2), the upper end of the hydraulic cylinder (2) is a telescopic piston rod (1), the hydraulic cylinder (2) is equipped with a gearbox (3), and the gearbox (3) can pass through the slider (4) Sliding on the column (7) with the slideway (8), the output shaft (5) is installed under the gearbox (3), and the column (7) is fixedly welded to the workbench (12), and the work The platform (12) is provided with a trapezoidal groove covering the adjusting block (11) below the base (10), the lower riveting die (9) is fixed on the base (10)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com