Riveting machine

A technology for riveting machines and riveting components, which is applied in the field of mechanical processing equipment, can solve the problems of crushing riveting machines and increasing the defective rate of products to be riveted, and achieve the effect of improving riveting precision and reducing defective rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

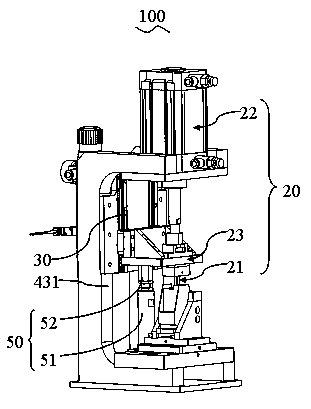

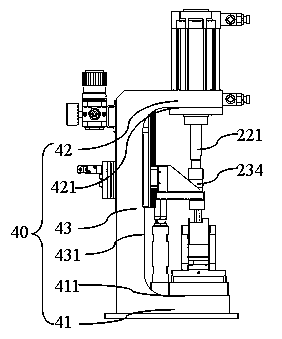

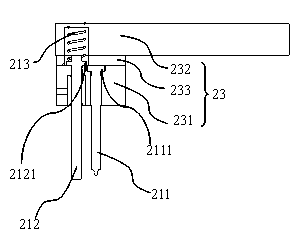

[0026] ginseng Figure 1 to Figure 5 As shown, the riveting machine 100 provided by the present invention includes:

[0027] The positioning assembly 10 is used to fix the workpiece to be riveted;

[0028] The riveting assembly 20 moves toward or away from the positioning assembly 10 to rivet the workpiece to be riveted;

[0029] The guide assembly 30 on which the riveting assembly 20 is disposed, and the guide assembly 30 limits the moving area of the riveting assembly 20 .

[0030] The riveting machine 100 defines the moving path of the riveting assembly 20 by setting the guide assembly 30 , so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com