In-mold riveting continuous stamping die and using method thereof

A stamping die and in-mold riveting technology, applied in the field of in-mold riveting continuous stamping die, can solve the problems of slow riveting speed, low production efficiency and high production input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in detail below.

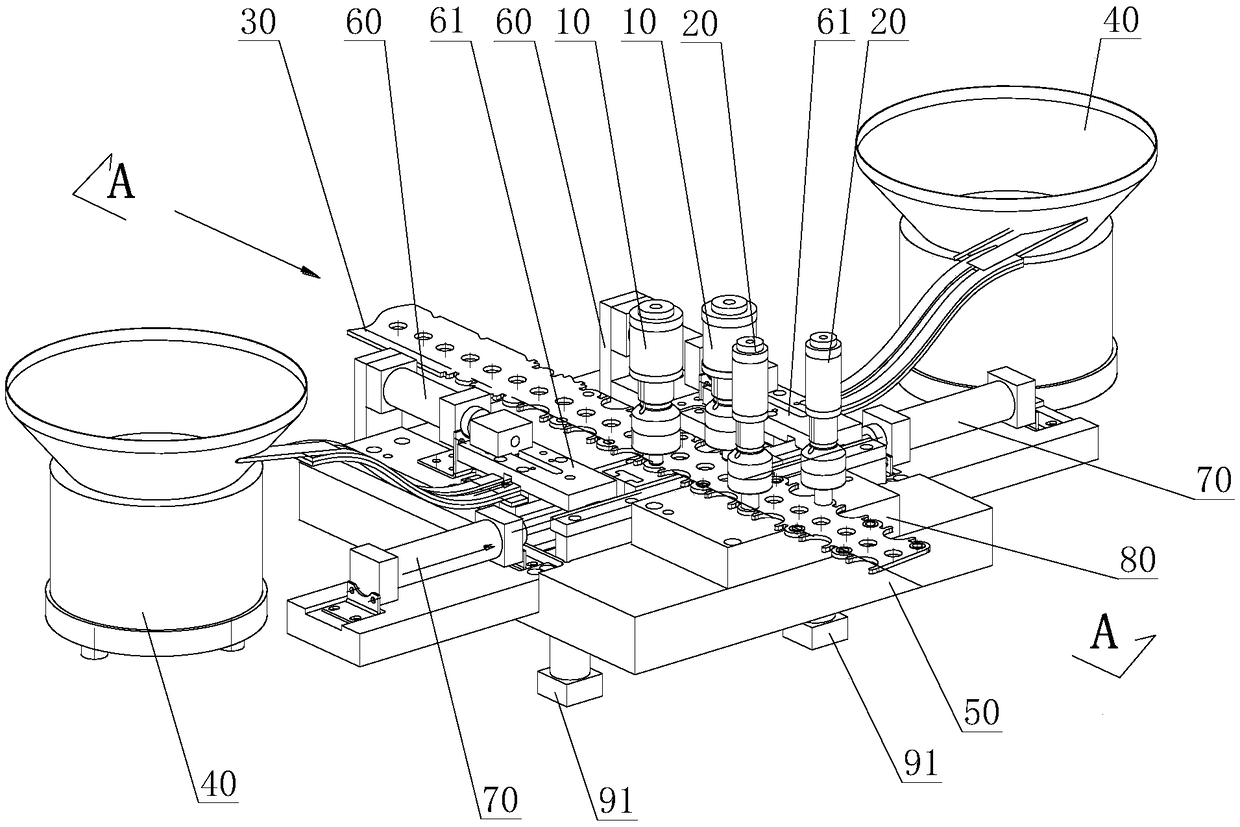

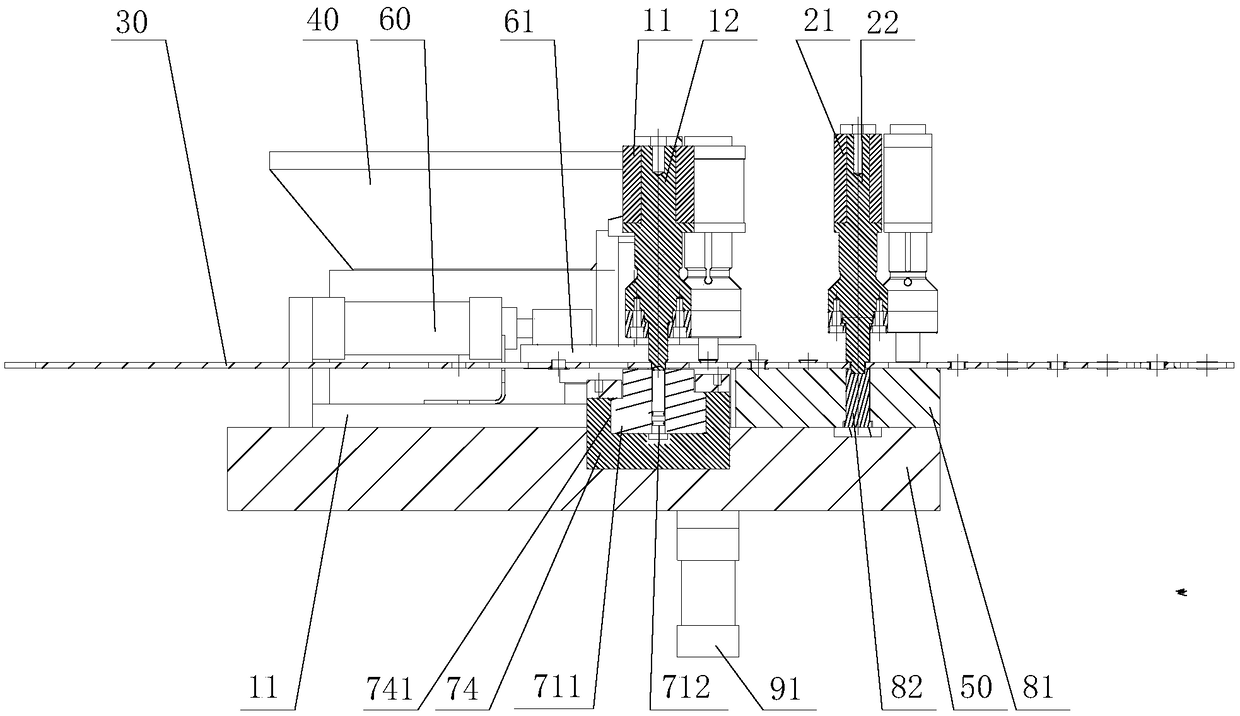

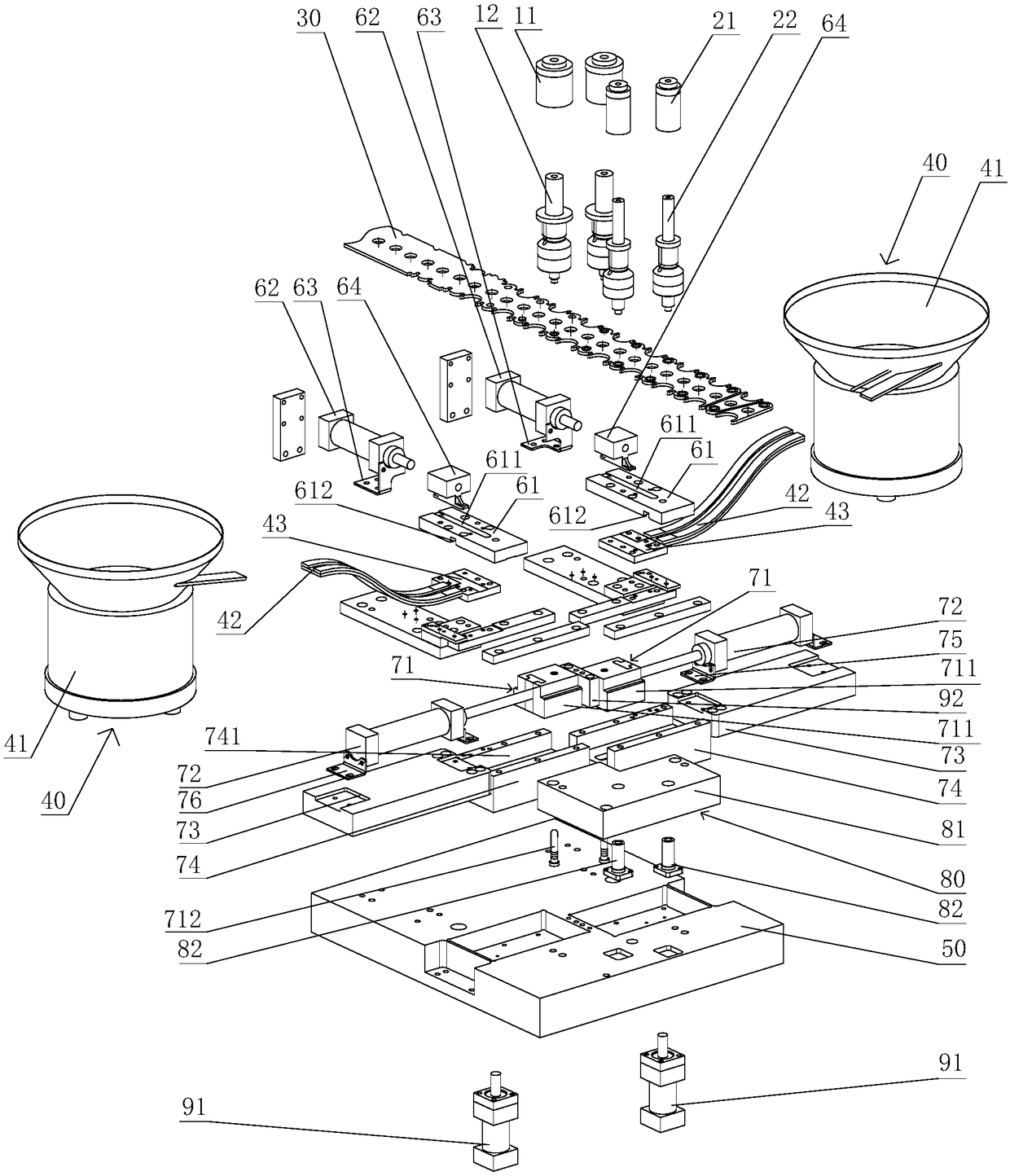

[0042] like Figure 1 to Figure 3As shown, the in-mold riveting continuous stamping die includes a first riveting punch head 10, a second riveting punch head 20, a material belt 30, a feeding mechanism 40, a substrate 50, a first push positioning mechanism 60, a second push positioning mechanism 70, The second riveting plate 80, the first pushing and positioning mechanism 60, the second pushing and positioning mechanism 70, and the second riveting plate 80 are installed on the base plate 50 respectively, and the first pushing and positioning mechanism 60 and the second pushing and positioning mechanism 70 respectively include a first guide block 61, the first riveting plate 71, the feeding mechanism 40 is connected with the first guide block 61, and the riveting passage is formed along the feeding mechanism 40, the first guiding block 61, and the first riveting plate 71; the strip 30 is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com